Cracking a skill-specific interview, like one for Cotton Grading and Sorting, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Cotton Grading and Sorting Interview

Q 1. Explain the different grades of cotton and their characteristics.

Cotton grades are categorized based on fiber properties like length, strength, uniformity, micronaire, and color. Think of it like grading wine – different grapes and growing conditions yield different qualities. Higher grades command better prices due to superior spinning performance and fabric quality. Here’s a simplified breakdown:

- Extra-long Staple (ELS): Fibers exceeding 1 3/8 inches. These produce luxurious fabrics with exceptional strength and softness, used in high-end garments and linens. Examples include Pima and Egyptian cotton.

- Long Staple: Fibers ranging from 1 1/8 to 1 3/8 inches. Offers excellent strength and fineness, suitable for high-quality yarns and apparel.

- Medium Staple: Fibers between 7/8 and 1 1/8 inches. This is a widely used grade, versatile for a range of textiles including shirting, towels, and denim.

- Short Staple: Fibers shorter than 7/8 inches. Used in lower-quality yarns and blended fabrics, often for industrial applications like padding or lower-end clothing.

The specific grade also considers factors like strength, uniformity, and color, leading to further subdivisions within these main categories. A cotton bale might be graded as ‘Medium Staple, Grade 2’ indicating it meets the length criteria but has a slightly lower strength or color rating compared to a ‘Medium Staple, Grade 1’ bale.

Q 2. Describe the process of cotton fiber testing using the High Volume Instrument (HVI).

The High Volume Instrument (HVI) is the industry standard for automated testing of cotton fiber properties. It’s a complex machine that analyzes thousands of fibers in a matter of minutes, providing a comprehensive profile of the cotton sample’s quality. Imagine it as a sophisticated medical scanner for cotton.

The process involves feeding a prepared cotton sample into the HVI, where it’s subjected to a series of tests:

- Fiber Length: Measures the length distribution of the fibers, key for determining yarn strength and spinning performance.

- Fiber Strength: Determines the breaking strength of the fibers, crucial for fabric durability.

- Uniformity Index (UI): Measures the uniformity of fiber length, impacting the evenness of the yarn.

- Micronaire: Measures fiber fineness and maturity, influencing the softness and spinning behavior.

- Fiber Maturity: Assesses the degree of fiber wall development, related to strength and processing efficiency.

- Color: Evaluates the color grade using reflectance measurements, impacting the final fabric color.

The HVI generates a detailed report summarizing all these parameters, enabling accurate grading and quality control. These data points are critical in pricing the cotton and selecting it for specific textile applications. A high UI signifies better spinnability, while higher strength and length typically translate to premium pricing.

Q 3. How do you identify and classify cotton fiber imperfections?

Identifying cotton fiber imperfections requires a keen eye and experience. It’s like being a cotton detective, looking for clues that affect quality. Imperfections are generally categorized as:

- Seed Coat Fragments (SCFs): Small pieces of seed coat remaining attached to the fibers. They weaken the fibers and affect yarn quality. Think of them as tiny flaws disrupting the fiber’s integrity.

- Trash: Foreign materials like leaves, stems, and dirt mixed with the fibers. This lowers the overall grade and can damage machinery during processing.

- Short Fibers: Fibers significantly shorter than the average length, reducing strength and uniformity.

- Weak Fibers: Fibers that break easily due to various factors, impacting yarn strength.

- Color Variations: Differences in fiber color, impacting the uniformity of the final fabric.

- Damaged Fibers: Fibers that are physically damaged during harvesting or processing.

These imperfections are detected visually, often under magnification, and through laboratory tests. The level of imperfection affects the cotton’s grade; higher levels result in lower grades and reduced value. Experienced graders learn to visually assess these imperfections, aided by standardized reference samples and instruments.

Q 4. What are the key factors affecting cotton fiber strength and length?

Cotton fiber strength and length are significantly influenced by several factors:

- Genetics: The cotton variety plays a critical role. Some varieties are naturally stronger and longer than others. This is analogous to how different grape varietals produce wines with varying characteristics.

- Environmental Conditions: Factors like rainfall, temperature, and sunlight during the growing season significantly impact fiber development. Stressful conditions can lead to shorter, weaker fibers. Think of it as how a plant will thrive under ideal sunlight and water but struggle in harsh weather.

- Soil Fertility: Nutrient-rich soil provides the building blocks for strong, long fibers. Poor soil conditions result in weaker, shorter fibers.

- Pest and Disease Control: Infestations or diseases can damage the plant and fibers, resulting in compromised strength and length.

- Harvesting Practices: Proper harvesting methods are crucial to avoid fiber damage. Rough handling can lead to shorter, weaker fibers.

Optimizing these factors throughout the entire growing and harvesting process is key to producing high-quality cotton with superior strength and length.

Q 5. Explain the difference between micronaire and fiber maturity.

Micronaire and fiber maturity are closely related but distinct measures of cotton fiber properties. They both influence yarn quality and spinning performance, but in different ways.

Micronaire is a measure of fiber fineness and maturity, expressed as a dimensionless number. It essentially indicates the air permeability of a compressed cotton sample. A higher micronaire value often suggests coarser, less mature fibers, while a lower value indicates finer, more mature fibers. Think of it like the density of the fiber; a low micronaire means more tightly packed fibers.

Fiber maturity refers to the degree of fiber wall development. Mature fibers have thicker walls, resulting in greater strength and better spinning quality. Immature fibers have thinner walls, leading to weaker yarns and poorer spinning performance. This is the level of cell wall thickening; fully mature fibers have more robust cell walls.

While related, they aren’t interchangeable. A fiber can have a good micronaire but be immature, or vice versa. Both are important parameters in assessing overall cotton quality.

Q 6. How do you determine the color grade of cotton?

Cotton color grade is determined by comparing the cotton sample to standardized color scales. These scales use specific color targets that represent different levels of color, usually from white to yellow or stained. Imagine a paint color chart, but for cotton.

The most common method is using a spectrophotometer which measures the reflectance of light at different wavelengths. This data is then compared to the standard color scales to determine the color grade, often expressed as a numerical or alphabetical grade. The higher the grade, the whiter the cotton. The process eliminates subjectivity and ensures consistent grading.

Factors such as weather conditions during growth, soil conditions, and harvesting techniques can impact the final color of the cotton. Whiter cotton is usually preferred for higher-value applications, as it is easier to dye into bright colors without compromising the final outcome.

Q 7. Describe the role of moisture content in cotton grading.

Moisture content plays a critical role in cotton grading and processing. Cotton fibers are hygroscopic, meaning they absorb moisture from the surrounding environment. This affects the weight, strength, and other properties of the cotton, thus impacting grading accuracy and processing efficiency.

Before grading, the cotton sample needs to be conditioned to a standard moisture content, typically around 8%. This is done by exposing the sample to a controlled environment with specific temperature and humidity. If the moisture content is too high, the fibers appear stronger and longer than they actually are, leading to inaccurate grading. Conversely, if it’s too low, fibers become brittle and weaker leading to inaccuracies.

Therefore, precise moisture content control is crucial for fair and accurate grading. Any variation from the standard moisture content needs to be accounted for to ensure consistent and reliable results. Without it, two identically graded cotton samples could show different properties based on their individual moisture content.

Q 8. What are the common methods for determining cotton fiber fineness?

Determining cotton fiber fineness, a crucial aspect of quality assessment, involves measuring the diameter of individual fibers. This impacts the yarn’s strength, softness, and overall fabric properties. Several methods exist, each with its own strengths and weaknesses:

Micrometer Method: This traditional method involves manually measuring the diameter of fibers under a microscope. While precise for individual fibers, it’s time-consuming and subjective, making it less practical for large-scale assessments.

High Volume Instrument (HVI) System: This automated system is the industry standard. It uses an air-flow technique to determine fiber fineness, expressed as micronaire (a measure of fiber maturity and fineness). A micronaire reading of 3.5-4.5 is generally considered ideal for many applications.

AFIS (Advanced Fiber Information System): This sophisticated system provides a more detailed analysis of fiber properties, including length, strength, maturity, and fineness. AFIS uses image analysis to measure thousands of fibers, providing a statistically robust assessment, surpassing the HVI’s capacity for detailed fiber property analysis.

The choice of method depends on the required level of detail, available resources, and the scale of the assessment. For large-scale quality control, the HVI system is the most efficient, while AFIS offers more in-depth analysis for research and specialized applications.

Q 9. Explain the importance of cotton trash content in quality assessment.

Cotton trash content, encompassing all foreign materials present in the cotton bale (leaf, stem, seed coat fragments, sand, etc.), significantly impacts quality. High trash levels negatively affect several aspects of cotton processing and the final product:

Reduced Spinning Efficiency: Trash interferes with the smooth flow of cotton fibers during spinning, leading to machine breakages, production slowdowns, and yarn imperfections.

Weakening of Yarn & Fabric: Trash inclusions weaken the yarn and fabric, reducing their strength and durability. This is particularly relevant in applications requiring high tensile strength, such as industrial fabrics.

Deterioration of Fabric Appearance: Visible trash in the fabric compromises its aesthetic quality, affecting its marketability, especially in high-value products like clothing.

Increased Processing Costs: Cleaning and removing trash adds to processing costs, impacting the overall profitability of the cotton industry.

Therefore, assessing trash content is crucial for determining the grade and value of cotton. Standard methods involve visual inspection, automated trash analysis systems, and sometimes laboratory analysis of bale samples.

Q 10. How do you interpret HVI data to assess cotton quality?

The High Volume Instrument (HVI) system provides a wealth of data for assessing cotton quality. Understanding how to interpret this data is essential. The key parameters include:

Fiber Length (various measures, including length uniformity): Longer, more uniform fibers generally yield stronger, finer yarns.

Fiber Strength: This indicates the yarn’s tensile strength and overall fabric durability.

Micronaire: As mentioned earlier, this relates to fiber maturity and fineness, impacting yarn softness and handle.

Fiber Maturity: Mature fibers are stronger and less prone to damage during processing.

Fiber Uniformity: Uniform fibers result in better yarn quality and reduced spinning problems.

Trash Content: HVI systems can also provide estimates of trash content, though visual assessment remains crucial.

By analyzing these parameters, cotton professionals can determine the suitability of the cotton for specific end-uses. For instance, cotton with long, strong, and uniform fibers is ideal for high-quality apparel fabrics, while cotton with shorter fibers might be suitable for lower-grade applications.

Example: An HVI report showing high fiber length, strength, and uniformity, along with a desirable micronaire, would indicate high-quality cotton suitable for premium apparel manufacturing. Conversely, low fiber strength and high trash content would suggest lower quality and suitability for coarser fabrics or industrial applications.

Q 11. What are the limitations of the HVI system?

While the HVI system is a valuable tool, it does have limitations:

Sample Representativeness: The HVI analyzes a relatively small sample of cotton fibers. The sample may not perfectly represent the entire bale’s quality, potentially leading to slight variations.

Limited Information on Fiber Defects: HVI primarily provides bulk fiber properties. It doesn’t fully assess microscopic fiber defects that can significantly impact quality (e.g., immature fibers or structural flaws).

Dependence on Calibration and Maintenance: Accurate HVI results depend on proper calibration and regular maintenance of the instrument. Inaccurate calibration can lead to misleading data.

No Direct Assessment of Color or Trash: Color and trash assessment still relies on visual inspection, not automated HVI measurements.

Therefore, the HVI data should be viewed as one component of a comprehensive cotton quality assessment, supplemented by visual inspection and potentially other analytical techniques for a more holistic understanding.

Q 12. Describe the different types of cotton bale packaging and their impact on quality.

Cotton bales are packaged in various ways, impacting quality during storage and transport. Common methods include:

Standard Bale: The most prevalent method involves compressing cotton into a rectangular bale wrapped in burlap. This traditional method can be susceptible to moisture absorption, resulting in deterioration and potential microbial growth if not properly stored.

High-Density Bale: These bales are compressed more tightly, leading to increased fiber density and better protection against damage. However, improper compression can damage fibers.

Plastic-Wrapped Bales: Encasing the bale in plastic provides additional protection against moisture, pests, and contamination, leading to better preservation of fiber quality during transport and storage.

The choice of packaging affects factors such as:

Moisture Content: Proper packaging reduces moisture absorption, preventing microbial growth and fiber degradation.

Fiber Damage: Poor compression or harsh handling can damage fibers, reducing quality.

Pest Infestation: Plastic wrapping protects against pest infestation, maintaining quality.

Storage Efficiency: High-density bales save space in storage and transportation.

In summary, selecting the appropriate packaging method is vital to ensure cotton quality is maintained throughout the supply chain.

Q 13. How do you handle discrepancies in cotton grade assessments?

Discrepancies in cotton grade assessments can arise due to differences in grading standards, testing methodologies, or human error. Handling these discrepancies requires a systematic approach:

Review of Assessment Methods: Carefully review the procedures used by the different assessors to ensure consistency in sample selection, testing protocols, and data interpretation.

Calibration of Equipment: Verify that all testing equipment (e.g., HVI systems) is properly calibrated and functioning optimally.

Independent Testing: If discrepancies persist, an independent third-party testing laboratory can conduct a fresh assessment using standardized procedures. This serves as an objective verification.

Negotiation and Mediation: Open communication between the parties involved is crucial. If possible, attempt to resolve differences through negotiation and mediation to reach a mutually acceptable solution.

Dispute Resolution: If negotiations fail, a formal dispute resolution mechanism (e.g., arbitration) might be necessary to settle the matter impartially.

Clear documentation of each step in the process, including testing results and communication records, is crucial to support any subsequent dispute resolution.

Q 14. What are the ethical considerations in cotton grading and quality control?

Ethical considerations in cotton grading and quality control are paramount for ensuring fair trade practices and building trust within the industry. Key ethical aspects include:

Transparency and Accuracy: Maintaining transparency in assessment procedures and reporting results accurately is critical. Misrepresenting quality can severely damage trust and have legal repercussions.

Fairness and Impartiality: Assessors should maintain objectivity and avoid bias when evaluating cotton quality. Personal interests or relationships should not influence grading decisions.

Data Integrity: Ensuring data integrity is vital to avoid manipulation or falsification of results. Proper record-keeping and secure data management practices are necessary.

Environmental Sustainability: Promoting environmentally sustainable practices throughout the cotton supply chain, including responsible pest management and water usage, is ethically important.

Fair Labor Practices: Supporting fair wages, safe working conditions, and ethical labor practices within cotton production is crucial for ethical cotton grading and quality control.

Adherence to ethical principles ensures a sustainable and equitable cotton industry that benefits all stakeholders.

Q 15. Explain the impact of different agricultural practices on cotton fiber quality.

Agricultural practices significantly influence cotton fiber quality. Think of it like baking a cake – the ingredients and the process directly impact the final product. Factors such as irrigation, fertilization, pest and disease management, and harvesting techniques all play a crucial role.

Irrigation: Adequate and well-timed irrigation is vital for fiber development. Insufficient water leads to shorter, weaker fibers, while over-irrigation can result in weak, poorly developed bolls. For instance, drip irrigation often yields superior fiber quality compared to flood irrigation due to more precise water delivery.

Fertilization: The right balance of nutrients is essential. Nitrogen deficiency can lead to stunted growth and weak fibers, whereas excessive nitrogen can negatively affect fiber maturity and strength. Careful soil testing and balanced fertilization programs are key.

Pest and Disease Management: Pests and diseases can severely damage the bolls and reduce fiber quality. Effective pest and disease control through integrated pest management (IPM) strategies, including biological control and targeted pesticide application, are critical.

Harvesting Techniques: The method of harvesting significantly impacts fiber quality. Hand-picking, though labor-intensive, generally results in higher quality fiber because only mature bolls are selected. Mechanical harvesting, while efficient, can lead to increased amounts of trash and damage to the fibers if not properly managed.

In my experience, I’ve seen firsthand how farms employing sustainable practices like precision agriculture and crop rotation often produce cotton with superior fiber strength, length, and uniformity, leading to higher market prices.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe the role of standards (e.g., USDA standards) in cotton grading.

Standards like those set by the USDA (United States Department of Agriculture) are the cornerstone of fair and transparent cotton trading. They provide a common language and objective criteria for assessing fiber quality, enabling buyers and sellers to understand and compare different lots of cotton accurately. These standards define quality characteristics such as fiber length, strength, micronaire (fiber fineness), color, and trash content.

Imagine trying to buy apples without a standardized grading system – it would be chaotic! Similarly, USDA standards eliminate ambiguity and ensure that transactions are based on consistent, measurable quality parameters. For example, a USDA grade of ‘Middling’ conveys a specific range of fiber properties, allowing buyers to confidently anticipate the quality they’ll receive. These standards aren’t just for the US – many international markets use similar grading systems based on the USDA’s framework.

Discrepancies can arise from various factors, including variations in testing methodologies and equipment calibration. This is why strict adherence to the established protocols and regular equipment calibration are so important for maintaining accuracy in the grading process.

Q 17. How do you handle and resolve customer complaints related to cotton quality?

Handling customer complaints regarding cotton quality requires a systematic approach focusing on thorough investigation, clear communication, and fair resolution. My process involves the following steps:

Thorough Investigation: I begin by collecting all relevant information, including the customer’s specific complaint, the lot number of the cotton in question, and any supporting documentation such as test results. I then review our internal records to cross-reference the information provided.

Testing and Verification: We conduct independent testing of the disputed cotton sample using our calibrated equipment. This ensures objective evaluation and helps verify the original findings.

Communication and Feedback: Once the investigation is complete, I communicate the findings to the customer clearly and transparently, explaining the results of our tests and analysis. Open communication is vital in building trust and resolving conflicts.

Resolution and Follow-up: Depending on the findings, we determine the appropriate course of action, which might include offering a replacement shipment, a price adjustment, or a combination of solutions. We always follow up with the customer to ensure their satisfaction and address any remaining concerns.

For example, a past complaint involved a shipment where the customer claimed the micronaire was outside the agreed-upon range. Our testing confirmed a slight deviation, and we resolved the issue by offering a partial refund in line with the difference in value. Maintaining transparency and fairness throughout the process is paramount.

Q 18. What are the key factors influencing cotton price?

Cotton prices are influenced by a complex interplay of factors, making it a dynamic market. The key drivers include:

Supply and Demand: This is the most fundamental factor. A larger global cotton crop will generally lead to lower prices, while a smaller crop will push prices higher. Unforeseen events like droughts or extreme weather patterns can significantly impact supply.

Global Economic Conditions: The overall economic climate affects textile demand, which, in turn, influences cotton prices. Recessions or economic downturns tend to suppress cotton demand and prices.

Government Policies: Subsidies, tariffs, and quotas implemented by various governments can impact cotton production and trade flows. These policies can create significant price fluctuations.

Fiber Quality: Higher quality cotton, as defined by fiber length, strength, and uniformity, commands a premium price. The specific characteristics of the cotton influence its suitability for various textile applications, thus impacting pricing.

Currency Exchange Rates: Fluctuations in currency exchange rates can affect the cost of cotton for international buyers and sellers.

Speculation: Futures trading and speculative investment in the cotton market can drive price volatility, leading to short-term price swings independent of fundamental supply and demand factors.

Understanding these factors allows traders and producers to make better informed decisions.

Q 19. Describe your experience with different cotton varieties and their properties.

My experience encompasses a wide range of cotton varieties, each with unique properties influencing their suitability for different textile applications. Here are a few examples:

Pima Cotton (Gossypium barbadense): Known for its exceptionally long, fine, and strong fibers, Pima is prized for its luxurious feel and durability. It’s commonly used in high-end apparel and bedding.

Supima Cotton: A premium variety of Pima cotton grown in the US, Supima cotton undergoes stringent quality control measures. It has superior fiber properties resulting in exceptional softness and strength, perfect for apparel and other premium textiles.

Egyptian Cotton: Another long-staple cotton, Egyptian cotton is renowned for its softness and luster. It’s often used in fine linens and other luxury goods.

Upland Cotton (Gossypium hirsutum): This is the most widely grown cotton variety globally. While its fiber length is shorter than Pima or Egyptian cotton, Upland cotton is known for its versatility and relatively lower cost, making it suitable for a wide variety of textiles.

Each variety presents its challenges and rewards. For instance, Pima cotton demands more meticulous cultivation to achieve optimal quality, whereas Upland cotton is generally more adaptable to diverse growing conditions.

Q 20. Explain the process of cotton sampling and its importance.

Cotton sampling is a critical step in quality assessment, ensuring that a small representative portion accurately reflects the quality of the entire cotton bale or lot. This process uses various methods such as core sampling, where a sample is extracted from the center of the bale using a specialized tool. It’s essential for multiple reasons:

Accurate Quality Assessment: Sampling provides a manageable and representative sample for testing fiber properties like length, strength, micronaire, color, and trash content. Without proper sampling, it would be impossible to evaluate the quality of large bales effectively.

Fair Trading: Accurate sampling ensures fair and transparent transactions between buyers and sellers. Both parties can rely on the test results to determine the value of the cotton.

Quality Control: Sampling helps identify potential quality issues early in the process. This allows for corrective measures to be taken during the farming practices, ginning, or processing steps.

Dispute Resolution: In case of disputes, the samples provide objective evidence for verifying the cotton’s quality and resolving conflicts.

The method of sampling is carefully defined to ensure randomness and avoid biases. For example, we use a standardized number of cores per bale and always document the sampling process meticulously for traceability.

Q 21. How do you maintain the accuracy and reliability of testing equipment?

Maintaining the accuracy and reliability of testing equipment is paramount for ensuring consistent and dependable results. We implement a rigorous program that includes:

Regular Calibration and Maintenance: All testing instruments, including fiber length testers, strength testers, and colorimeters, undergo regular calibration using certified standards. We adhere to strict schedules and maintain detailed maintenance logs for each piece of equipment.

Operator Training: Our personnel receive comprehensive training on the proper use and maintenance of testing equipment. This ensures consistent operation and minimizes human error. Regular refresher courses help maintain a high level of proficiency.

Quality Control Checks: We employ quality control checks using reference samples to verify the accuracy of our testing procedures. This helps us identify and rectify any discrepancies in results.

Equipment Replacement: We have a policy for timely replacement of outdated or malfunctioning equipment to prevent unreliable data and ensure that we always have state-of-the-art instruments for precise measurements.

Our commitment to this program ensures that our testing results are reliable and provide a trustworthy basis for cotton quality assessment and grading.

Q 22. Describe your experience with different cotton testing instruments.

My experience with cotton testing instruments spans a wide range, encompassing both traditional methods and modern technologies. I’m proficient in using instruments that assess fiber properties like:

- Fiber Strength Tester (AFIS): This automated high-volume instrument measures fiber strength, length, uniformity, and maturity, providing crucial data for determining cotton quality and value. I’m adept at interpreting the resultant data and identifying potential issues in fiber development.

- HVI System (High Volume Instrument): Similar to AFIS, the HVI system offers a comprehensive analysis of fiber characteristics, but with a higher throughput. I’ve used this extensively to evaluate large batches of cotton quickly and efficiently, comparing results against industry standards.

- Microscope: While seemingly simple, a microscope is crucial for visualizing fiber morphology – identifying imperfections, maturity, and the presence of contaminants. I use this to supplement automated testing and ensure the accuracy of assessments, especially when dealing with unusual or problematic samples.

- Moisture Meter: Accurately measuring moisture content is crucial for consistent pricing and processing. I have experience with different types of moisture meters, understanding their limitations and selecting the appropriate instrument based on the context.

- Colorimeter: Determining cotton color is vital, particularly for high-value products. I’m experienced in using colorimeters to objectively measure color and ensure consistency, important for maintaining brand reputation.

My experience isn’t limited to using these instruments; I also understand their calibration, maintenance, and the importance of quality control to guarantee reliable results. I’ve regularly participated in instrument calibration checks and troubleshooting, ensuring data accuracy and minimizing errors.

Q 23. How do you ensure the traceability of cotton throughout the supply chain?

Traceability in the cotton supply chain is paramount for ensuring quality, ethical sourcing, and meeting increasing consumer demands for transparency. We achieve this through a multi-faceted approach:

- Unique Identification Numbers: Each bale of cotton receives a unique identification number (often a combination of producer, location, and harvest date) that follows it throughout the process. This number is scanned and recorded at every stage.

- Blockchain Technology: The use of blockchain provides a secure, immutable record of the cotton’s journey, from farm to final product. Each transaction is recorded, making it difficult to tamper with or erase information.

- GPS Tracking: In some instances, GPS tracking of cotton transport can be employed, providing real-time location information and further enhancing transparency.

- Digital Documentation: Detailed records, including grading reports, testing results, and processing information, are stored digitally. This allows for easy access and retrieval of information across the supply chain.

- Third-Party Audits: Regular audits by independent organizations verify the accuracy and integrity of the traceability system, building trust and confidence among stakeholders.

For example, in a recent project, we implemented a blockchain-based traceability system for a major textile company. This allowed their customers to trace their cotton purchases back to the specific farm and even view information on the farming practices used. This significantly enhanced their brand image and customer trust.

Q 24. What are the current challenges and trends in cotton grading and quality control?

The cotton grading and quality control industry faces several challenges and trends:

- Climate Change: Increased variability in weather patterns impacts cotton yield and quality, necessitating adaptive farming practices and robust quality control measures.

- Sustainability Concerns: Consumers are increasingly demanding sustainably produced cotton, pushing for reduced water usage, pesticide application, and improved worker welfare. This necessitates implementing and verifying sustainable practices throughout the supply chain.

- Technological Advancements: The industry is witnessing rapid technological advancements, including AI-powered grading systems and remote sensing technologies for monitoring crop health. Staying ahead of the curve requires continuous learning and adaptation.

- Supply Chain Disruptions: Global events and geopolitical instability can disrupt the supply chain, creating challenges for securing consistent and high-quality cotton supplies.

- Demand for Transparency and Traceability: As mentioned previously, consumer demand for transparency and traceability is driving the need for robust tracking systems and ethical sourcing practices.

One significant trend is the increasing use of data analytics and predictive modeling to improve cotton production, grading, and supply chain efficiency. We are leveraging big data to identify potential quality issues early, optimize resource allocation, and predict market trends.

Q 25. How do you stay updated with the latest developments in cotton technology and standards?

Staying updated in this dynamic field requires a multifaceted approach:

- Industry Publications and Journals: I regularly read publications such as the Cotton International magazine and scientific journals focusing on textile science and agricultural engineering. This keeps me abreast of the latest research and technological developments.

- Industry Conferences and Workshops: Attending conferences and workshops organized by organizations like the International Cotton Advisory Committee (ICAC) provides opportunities to network with experts, learn about new technologies, and stay informed about emerging trends.

- Online Resources and Databases: I utilize online resources and databases, such as those provided by the USDA, to access the latest market data, quality standards, and research findings.

- Professional Networks: Engaging with professional networks and online forums allows for the exchange of knowledge and experience with other professionals in the field.

- Continuous Learning Courses: I actively participate in professional development courses to enhance my expertise in cotton grading and quality control methodologies.

For example, I recently completed a course on the application of machine learning in cotton quality assessment, significantly enhancing my ability to analyze large datasets and improve the accuracy of our grading process.

Q 26. Describe a situation where you had to make a difficult decision regarding cotton quality.

In one instance, a large shipment of cotton arrived with inconsistent quality. Initial testing showed a significant portion falling below the agreed-upon standards for strength and uniformity. The decision to reject the shipment would have caused major disruptions to the production schedule of our client. However, accepting the shipment at the agreed-upon price would have resulted in significant financial losses for our company due to the need for extensive rework or the use of lower quality cotton.

My solution involved a detailed investigation, separating the cotton into different quality grades. I negotiated a tiered pricing system with the supplier, based on the identified quality variations. This allowed us to accept the shipment without significant financial loss, while also meeting the client’s production schedule requirements. This decision involved careful analysis of data, negotiation skills, and a strong understanding of the market dynamics. It highlighted the importance of flexibility and open communication in resolving complex quality issues.

Q 27. How do you contribute to a team environment in a cotton grading setting?

In a cotton grading setting, effective teamwork is crucial for accurate and efficient processing. I contribute to the team environment by:

- Sharing Expertise: I actively share my knowledge and experience with colleagues, mentoring junior staff and ensuring consistency in grading procedures.

- Collaborative Problem Solving: I participate actively in discussions to resolve quality issues, offering my insights and collaborating with colleagues to find the best solutions.

- Effective Communication: I maintain open and clear communication with colleagues, ensuring everyone is well-informed and understands the grading procedures and results.

- Supporting Team Goals: I support the team’s overall goals by being punctual, reliable, and contributing my share of the workload, promoting a positive and productive work environment.

- Respectful Interaction: I treat all colleagues with respect and foster a collaborative environment where everyone feels comfortable sharing their opinions and concerns.

For example, during a period of high workload, I volunteered to train new team members, ensuring they could quickly become productive and contribute to the overall efficiency of the team. This boosted morale and helped the team meet the demanding deadlines.

Q 28. Explain your experience in documenting and reporting cotton quality data.

Documenting and reporting cotton quality data is a critical aspect of my role, ensuring accurate record-keeping and traceability. My experience includes:

- Data Entry and Management: I am proficient in using software systems for entering, organizing, and managing large amounts of cotton quality data, from the initial testing results to final reports.

- Report Generation: I generate detailed reports, incorporating various quality parameters, statistical analysis, and visual representations such as charts and graphs. These reports are tailored to the specific needs of clients and internal stakeholders.

- Data Analysis and Interpretation: I analyze the collected data to identify trends, patterns, and potential quality issues, and use this information to improve our grading and quality control procedures.

- Quality Assurance: I ensure the accuracy and consistency of the documented data, implementing quality control measures to prevent errors and maintain data integrity.

- Compliance with Standards: All my documentation adheres to international and industry-specific standards, ensuring the quality and reliability of our data and reports.

For instance, I recently developed a new reporting system that automates the generation of quality reports, reducing manual effort and significantly improving the speed and efficiency of our reporting process. This improved system has significantly reduced the time spent on report generation and ensured greater data accuracy.

Key Topics to Learn for Your Cotton Grading and Sorting Interview

- Fiber Properties: Understanding staple length, strength, micronaire, color, and trash content – and how these impact cotton quality and value.

- Grading Standards: Familiarity with industry standards (e.g., USDA standards) and their practical application in assessing cotton quality.

- Sorting Techniques: Mastering manual and automated sorting methods, including the identification and separation of different fiber grades.

- Quality Control: Implementing effective quality control procedures throughout the grading and sorting process to ensure consistent product quality.

- Equipment Operation & Maintenance: Demonstrating knowledge of the machinery used in cotton grading and sorting, including troubleshooting and maintenance procedures.

- Data Analysis & Reporting: Understanding how to collect, analyze, and present data related to cotton quality and yield.

- Industry Best Practices: Staying up-to-date on current industry trends, technologies, and best practices in cotton grading and sorting.

- Problem-Solving & Decision-Making: Developing strategies to address challenges related to inconsistent cotton quality, equipment malfunctions, and other potential issues.

- Health & Safety: Understanding and adhering to relevant safety regulations and procedures within the cotton processing environment.

Next Steps

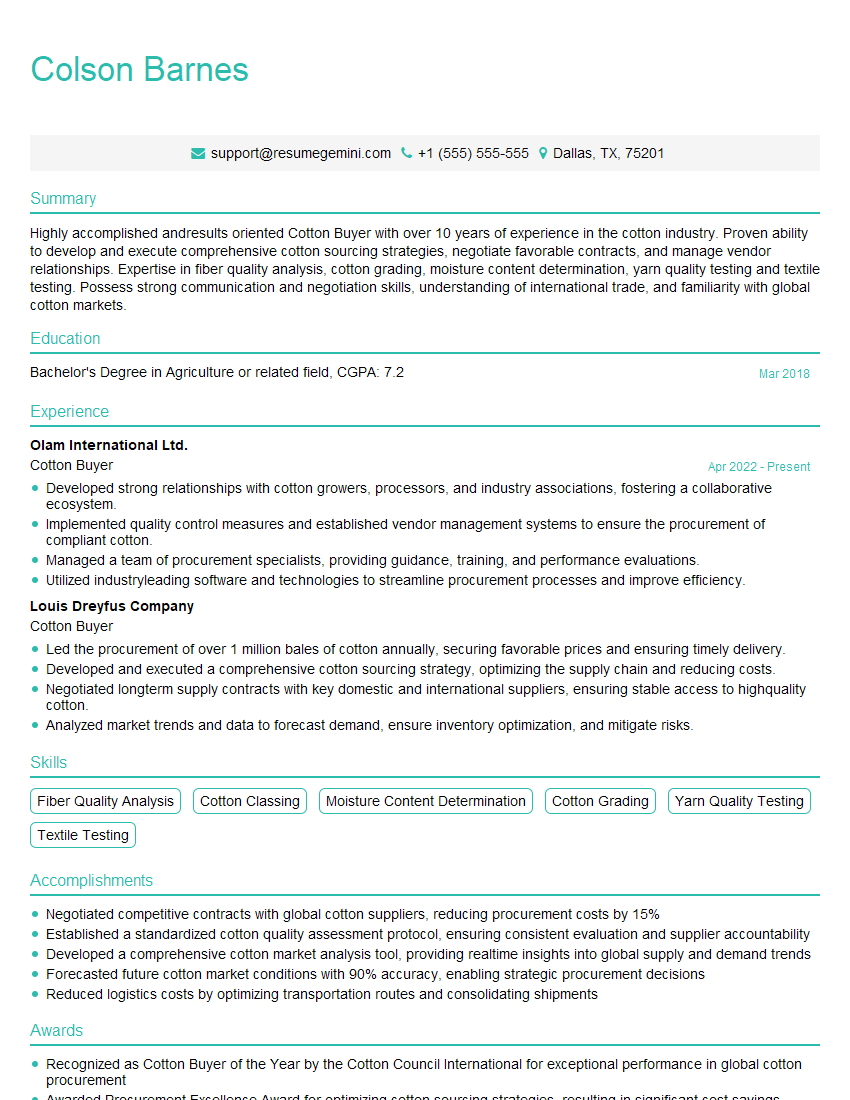

Mastering cotton grading and sorting opens doors to a rewarding career with excellent growth potential within the textile industry. Your expertise in assessing and classifying cotton will be highly valued by manufacturers and traders alike. To significantly increase your chances of landing your dream job, creating a strong, ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to the specific requirements of cotton grading and sorting roles. We provide examples of resumes tailored to this field to give you a head start. Invest time in crafting a compelling resume – it’s your first impression and a key element in securing an interview.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good