The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Knowledge of Mirror Polishing and Recoating Techniques interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Knowledge of Mirror Polishing and Recoating Techniques Interview

Q 1. Describe the different stages involved in mirror polishing.

Mirror polishing is a multi-stage process aiming to achieve an extremely smooth, reflective surface. Think of it like sculpting a mirror to perfection. It typically involves these stages:

- Rough Grinding: This initial stage removes significant material to shape the substrate to the desired form and remove any major defects. Coarse abrasives are used, and the goal is to achieve a relatively flat surface, not a polished one. Imagine starting with a rough block of stone and slowly shaping it with a chisel.

- Fine Grinding: Here, finer abrasives progressively reduce surface roughness and remove scratches left by the rough grinding stage. The grit size of the abrasive is gradually decreased, creating a smoother surface. It’s like sanding a piece of wood, starting with coarse sandpaper and moving to finer grits.

- Polishing: This crucial stage uses extremely fine abrasives and polishing compounds to achieve a mirror-like finish. The polishing process removes the remaining scratches and imperfections from the previous stages, resulting in a highly reflective surface. This is the equivalent of painstakingly buffing the wood to bring out its shine.

- Final Cleaning: After polishing, the mirror requires thorough cleaning to remove any residual polishing compounds. This is done using specialized cleaning solutions and techniques to avoid introducing new imperfections.

Q 2. What are the common materials used for mirror substrates and their polishing methods?

The choice of substrate material depends heavily on the application. Common materials include:

- Glass: The most common choice, offering good optical quality and relatively low cost. Polishing is typically achieved using cerium oxide polishing compounds.

- Silicon: Excellent for applications requiring high precision and thermal stability. Polishing can be done with diamond slurries or colloidal silica.

- Metal (e.g., Aluminum, Zerodur): Used for specific applications requiring high reflectivity in specific wavelengths. Polishing techniques vary based on the metal, often involving diamond-based methods or chemical-mechanical planarization (CMP).

The polishing method selected needs to match the substrate’s hardness and properties. For instance, softer materials like glass may be more easily polished using softer abrasives, while harder materials like silicon may require harder abrasives and more aggressive polishing techniques.

Q 3. Explain the concept of figure error and how it’s measured in mirror polishing.

Figure error refers to deviations from a perfect spherical or parabolic surface. Think of it as the imperfections in the shape of the mirror. These deviations cause distortions in the reflected image and affect the mirror’s optical performance. A perfect mirror would have zero figure error.

Figure error is measured using interferometry. An interferometer compares the wavefronts reflected from the mirror surface to a reference wavefront. The interference pattern produced reveals the deviations from the ideal surface shape. The results are typically quantified in terms of wavelengths (λ) or nanometers (nm), with smaller values indicating a better surface figure. For example, a mirror with a figure error of λ/10 means that the surface deviations are one-tenth of a wavelength of light.

Q 4. What are the various types of polishing compounds used, and when would you choose each?

Many polishing compounds are available, each with different properties:

- Cerium Oxide (CeO2): A common choice for glass polishing due to its effectiveness and relatively low cost. Excellent for achieving high-quality finishes.

- Colloidal Silica: Offers very fine particle sizes, making it ideal for achieving extremely smooth surfaces and sub-nanometer roughness. It’s frequently used in the later stages of polishing.

- Diamond Slurries: Used for polishing hard materials like silicon and metals. Diamond particles come in various sizes, allowing for control over the polishing aggressiveness.

- Pitch Polishers: Used for fine polishing, particularly with large optics. The pitch itself isn’t an abrasive; its action is primarily controlled by the polishing compound used with it.

The choice of polishing compound depends on the material being polished, the desired surface roughness, and the stage of the polishing process. For example, cerium oxide might be used in the initial polishing stages of glass, while colloidal silica would be employed in the final stages for ultra-smooth surfaces.

Q 5. Describe different techniques for achieving sub-nanometer surface roughness.

Achieving sub-nanometer surface roughness requires advanced techniques:

- Ion Beam Figuring (IBF): This method uses a beam of ions to precisely remove material from the mirror’s surface, achieving sub-nanometer accuracy. This is particularly useful for correcting figure errors.

- Chemical-Mechanical Planarization (CMP): A process that uses chemical etching and mechanical polishing to create extremely flat surfaces, often employed for silicon wafers and other hard materials. Can achieve sub-nanometer roughness when carefully controlled.

- Magneto-Rheological Finishing (MRF): Employs a magnetically controlled polishing tool to achieve very fine surface finishing. It offers excellent control over the polishing process and is capable of sub-nanometer roughness.

- Using very fine colloidal silica and optimized polishing parameters: This method involves utilizing extremely fine colloidal silica suspensions and carefully controlling parameters like pressure, speed, and polishing time to achieve ultra-smooth surfaces.

These techniques often require sophisticated equipment and precise control over various parameters.

Q 6. How do you assess the quality of a polished mirror surface?

Assessing the quality of a polished mirror involves multiple methods:

- Visual Inspection: While not quantitative, it can detect obvious defects like scratches or pits.

- Interferometry: Precisely measures the surface figure error, quantifying the deviation from an ideal surface.

- Scatterometry: Measures surface roughness and other micro-roughness features of the surface, providing a measure of the surface quality on a nanoscale.

- Atomic Force Microscopy (AFM): Provides a high-resolution three-dimensional image of the surface, revealing nanoscale surface features and roughness. It’s crucial for confirming the achievement of sub-nanometer roughness.

- Profilometry: Measures the surface topography and roughness in multiple dimensions providing more quantitative data on the surface imperfections.

The combination of these techniques provides a complete assessment of the mirror’s quality.

Q 7. What are the common defects encountered during mirror polishing, and how do you address them?

Common defects include:

- Scratches: Caused by abrasive particles or improper handling. Mitigation involves careful handling, using clean polishing pads and compounds, and employing appropriate cleaning procedures.

- Pits: Small indentations on the surface, often from hard particles embedded in polishing compounds. Careful filtering of polishing compounds and using clean environments can minimize this.

- Digs: Deeper imperfections, often caused by accidental contact with hard objects. They require more aggressive polishing or localized polishing with diamond pastes to correct.

- Roll-offs: Regions where the surface curvature changes abruptly. This might be corrected through re-polishing or advanced techniques like ion beam figuring.

Addressing these defects requires understanding their root cause. For example, scratches might necessitate repolishing with finer abrasives, while pits might necessitate localized polishing or even the removal and replacement of a portion of the mirror substrate if they are severe.

Q 8. Explain the process of optical coating deposition.

Optical coating deposition is the process of creating thin layers of material onto a substrate, typically a mirror, to modify its optical properties. Imagine painting a window with a special paint that controls how light passes through it – that’s essentially what optical coating does. The process involves several key steps:

- Substrate Preparation: The mirror surface undergoes meticulous cleaning and polishing to ensure a flawless base for the coating. Any imperfections can significantly affect the final quality.

- Coating Deposition: This is where the magic happens. Several techniques exist, including physical vapor deposition (PVD), chemical vapor deposition (CVD), and sol-gel methods. In PVD, materials are vaporized and then deposited onto the substrate under vacuum. CVD uses chemical reactions to deposit the coating. Sol-gel utilizes liquid precursors that are then converted into a solid coating through chemical reactions.

- Thickness Control: Precise control of the layer thickness is crucial because the optical properties depend on it. Monitoring techniques such as optical monitoring during deposition help achieve the desired thickness.

- Post-Deposition Processing: This may involve annealing (heating) the coated substrate to improve adhesion and stability. It can also help relieve stress built up during deposition.

For instance, in the manufacturing of high-quality telescope mirrors, extremely precise coating deposition is vital to achieve the desired reflectivity and minimize scattering of light.

Q 9. What are the different types of optical coatings, and their applications?

Optical coatings come in various types, each designed for specific applications:

- Anti-reflection (AR) coatings: Reduce reflection, maximizing light transmission. These are commonly found on eyeglasses and camera lenses. A classic example is a single-layer magnesium fluoride coating.

- High-reflection (HR) coatings: Maximize reflection at specific wavelengths, essential for mirrors in lasers and telescopes. These often involve multiple layers of different materials for enhanced reflectivity.

- Dichroic coatings: Reflect specific wavelengths while transmitting others. These are used in optical filters for separating different colors of light. Think of the colorful filters used in photography or theatrical lighting.

- Polarizing coatings: Selectively transmit light of a specific polarization. Polarizing sunglasses are a prime example, reducing glare by blocking horizontally polarized light.

- Metal coatings: Offer high reflectivity across a broad spectral range, often using aluminum or silver. These are used in mirrors for everyday applications.

The choice of coating depends heavily on the desired optical performance and the specific application. For example, a high-power laser mirror might need a highly durable high-reflection coating, while an inexpensive camera lens might use a simpler anti-reflection coating.

Q 10. Describe the principle of thin-film interference in optical coatings.

Thin-film interference is the fundamental principle behind many optical coatings. It relies on the constructive and destructive interference of light waves reflected from different layers of the coating. Imagine dropping two pebbles in a pond; the ripples interfere with each other, creating areas of higher and lower wave amplitude. Similarly, light waves reflected from the top and bottom surfaces of a thin film interfere.

If the optical path difference between these reflected waves is an integer multiple of the wavelength, constructive interference occurs, resulting in high reflectivity. Conversely, if the path difference is a half-integer multiple of the wavelength, destructive interference reduces reflectivity.

By carefully controlling the thickness and refractive indices of the individual layers, we can design coatings to maximize or minimize reflection at specific wavelengths. This precise control is achieved through sophisticated design software that calculates the necessary layer thicknesses to achieve the desired optical performance.

Q 11. What factors affect the durability and performance of optical coatings?

Several factors influence the durability and performance of optical coatings:

- Coating Material: The choice of materials significantly impacts the coating’s hardness, resistance to abrasion, and chemical stability. Some materials are more susceptible to environmental factors like humidity or UV radiation.

- Deposition Process: The deposition method affects the coating’s microstructure, density, and adhesion to the substrate. A poorly deposited coating will have inferior properties.

- Environmental Factors: Exposure to humidity, temperature variations, UV radiation, and other environmental factors can degrade the coating over time, affecting its reflectivity, transmission, or other optical properties. This is particularly crucial in harsh environments.

- Substrate Quality: The quality of the underlying substrate, including its surface finish and cleanliness, plays a critical role. Imperfections on the substrate can propagate into the coating, impacting its performance.

For example, coatings used in space telescopes must be exceptionally durable to withstand the harsh conditions of space, whereas coatings on eyeglasses might prioritize scratch resistance.

Q 12. How do you ensure the uniformity of an optical coating?

Ensuring coating uniformity is paramount for achieving consistent optical performance. Several techniques are employed:

- Substrate Rotation: Rotating the substrate during deposition ensures even coating distribution. Think of painting a wall – you wouldn’t paint only one section, right?

- Source-to-Substrate Distance: Maintaining a consistent distance between the coating source and the substrate is vital for uniform thickness.

- Precise Control of Deposition Parameters: Carefully controlling parameters like deposition rate, temperature, and pressure ensures uniform layer growth.

- In-situ Monitoring: Monitoring the coating thickness and uniformity during deposition using techniques like optical monitoring allows for real-time adjustments.

- Post-Deposition Inspection: After deposition, techniques such as profilometry and interferometry are used to assess the uniformity of the coating thickness and surface quality.

In practice, a combination of these methods is used to achieve the desired uniformity, often demanding precise control of the deposition process and sophisticated monitoring equipment.

Q 13. What are the common methods for recoating damaged mirrors?

Recoating damaged mirrors involves carefully removing the old coating and then depositing a new one. The process typically involves:

- Cleaning and Inspection: Thorough cleaning of the mirror surface is crucial to remove any contaminants or residual coating material. Careful inspection helps assess the extent of damage and plan the recoating strategy.

- Coating Removal: This step can be challenging, requiring specialized techniques depending on the type of coating. Methods include chemical etching, mechanical abrasion, or plasma cleaning. The goal is to remove the old coating without damaging the underlying mirror substrate.

- Substrate Repolishing (if necessary): If the substrate has been damaged, repolishing might be needed to restore its surface quality before recoating.

- Re-coating: This follows the same principles as initial coating deposition, using appropriate techniques for the desired coating type and optical properties. Precise control is crucial to ensure the new coating’s quality and uniformity.

For instance, a damaged telescope mirror might require recoating to restore its optical performance. The process would involve careful removal of the old coating, any needed repolishing, and then a precise redeposition of a high-reflectivity coating.

Q 14. Describe the challenges associated with recoating complex mirror shapes.

Recoating complex mirror shapes presents several challenges:

- Uniformity: Achieving uniform coating thickness on non-planar surfaces is difficult. The coating material might deposit unevenly due to shadowing effects or variations in the distance from the coating source.

- Accessibility: Accessing all areas of a complex mirror surface for cleaning and coating deposition can be challenging. Specialized fixtures and techniques might be required to ensure complete coverage.

- Coating Stress: Stress built up within the coating can be more significant on complex shapes, potentially leading to cracking or delamination. Careful control of deposition parameters is essential.

- Masking: If only parts of the mirror need recoating, precise masking is necessary to protect the undamaged areas. This adds complexity and necessitates meticulous planning.

For example, recoating a large, segmented telescope mirror requires precise control of each segment’s position and orientation during the coating process. Specialized robotic systems and advanced monitoring techniques are crucial for achieving uniform coverage and optimal optical performance.

Q 15. What are the quality control measures employed during the coating process?

Quality control in optical coating is paramount to ensuring the final product meets the required specifications. It’s a multi-stage process starting even before the coating begins. We meticulously inspect the substrate – the mirror itself – for any defects like scratches, pits, or irregularities that could compromise the final coating’s performance. This initial inspection often involves sophisticated interferometry to measure surface flatness to sub-nanometer accuracy.

During the coating process itself, we continuously monitor parameters like deposition rate, chamber pressure, and substrate temperature. Deviations from the set points are immediately flagged, and adjustments are made to maintain consistency. In-situ monitoring techniques, such as optical monitoring during deposition, provide real-time feedback on the thickness and uniformity of the coating layers.

Finally, post-coating inspection is crucial. We use techniques like spectrophotometry to measure the reflectance and transmittance of the coating across the relevant wavelength range, ensuring it meets the design specifications. We also employ surface profilometry and interferometry to assess the surface quality and uniformity of the finished coating, and look for defects like pinholes or particulate contamination. Any deviations lead to a thorough investigation and, if necessary, rejection of the coated component.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you measure the thickness and refractive index of an optical coating?

Measuring the thickness and refractive index of an optical coating is done using several well-established techniques. For thickness measurement, we frequently use optical methods. Ellipsometry, for example, is a powerful technique that measures the change in polarization state of light reflected from the coated surface. By analyzing this change, we can accurately determine the thickness of individual layers in a multilayer coating. Another method is spectrophotometry, where the reflectance or transmittance spectrum is measured and compared to a theoretical model to extract the layer thicknesses.

Determining the refractive index is often done simultaneously with thickness measurement using ellipsometry. The refractive index is a crucial parameter that determines how light interacts with the coating, and its accurate measurement is vital. Other techniques like prism coupling or spectroscopic reflectometry can also be used to determine the refractive index, depending on the coating material and its properties.

Think of it like this: imagine you’re layering different colored paints on a canvas. The ellipsometer helps determine how thick each layer is and how differently each layer bends the light, representing its refractive index, while the spectrophotometer tells you how much light is reflected or transmitted through the whole stack, providing a check on the overall results.

Q 17. Explain the role of environmental control in optical polishing and coating.

Environmental control plays a critical role in both optical polishing and coating. During polishing, dust particles can scratch the surface, rendering the mirror unusable. Therefore, a cleanroom environment with HEPA filtration is essential to minimize particulate contamination. Temperature and humidity also need to be controlled to prevent thermal expansion or contraction that can affect the accuracy of the polishing process. Even subtle variations can cause significant errors in polishing precision.

In the coating process, environmental control is even more stringent. The vacuum deposition process is extremely sensitive to contaminants, and even a small amount of airborne particles or moisture can lead to coating defects. Precise control of temperature and pressure is critical to ensure the proper deposition of the coating materials. The exact requirements vary depending on the coating materials and the required coating quality, but typically this means a class 100 or better cleanroom environment with highly controlled parameters. Imagine making a delicate cake – you wouldn’t want dust or fluctuating temperatures affecting its perfect texture.

Q 18. Describe the safety precautions necessary during mirror polishing and coating.

Safety is paramount in both mirror polishing and coating. Polishing involves abrasive materials and rotating machinery that pose potential hazards. Safety glasses and protective clothing are mandatory to protect against flying debris or chemical splashes. Proper machine guarding and lockout/tagout procedures are essential to prevent accidental start-ups during maintenance. Training on safe machine operation is crucial for all personnel involved.

Coating processes often involve vacuum chambers, high voltages, and potentially hazardous chemicals. Comprehensive safety training that covers specific hazards associated with the coating materials and equipment is required. Emergency procedures, including the handling of potential vacuum leaks or chemical spills, should be well-defined and regularly practiced. Personal protective equipment (PPE) including respirators, gloves, and safety glasses are essential. Regular safety inspections and maintenance of equipment are also vital to mitigate risks.

Q 19. What are the different types of polishing machines and their functionalities?

A variety of polishing machines exist, each designed for specific applications and levels of precision. For large mirrors, computer-controlled polishing machines with multiple actuators are used to achieve precise surface figures. These machines use a variety of polishing tools, such as pitch laps or polyurethane pads, and sophisticated control systems to precisely control the polishing process. Smaller mirrors can be polished using simpler machines, such as manual polishing machines or specialized tools.

For example, Magnetorheological Finishing (MRF) machines use a magnetic fluid to control the polishing process, allowing for high precision and adaptability. Ion Beam Figuring (IBF) employs a focused ion beam to etch the mirror surface, which is exceptionally precise for shaping intricate optical surfaces. The choice of machine depends on the size, shape, and desired accuracy of the mirror, as well as the material it’s made from.

- Computer-controlled polishing machines: Offer high precision and automation for large mirrors.

- Manual polishing machines: Simpler and more economical for smaller mirrors.

- Magnetorheological Finishing (MRF) machines: High precision for complex shapes.

- Ion Beam Figuring (IBF) machines: Extreme precision for intricate surfaces.

Q 20. How do you maintain and calibrate optical polishing equipment?

Maintaining and calibrating optical polishing equipment is critical for ensuring consistent performance and accurate results. Regular cleaning and lubrication of moving parts are essential. This includes checking and replacing worn components, such as polishing pads or bearings, to maintain optimal functionality. The polishing machine’s control system should be regularly checked and calibrated to guarantee accurate positioning and movement of the polishing head. This typically involves using precision measurement tools and alignment procedures.

Calibration of the machine often involves using reference standards, such as highly accurate flat mirrors or spheres, to verify the accuracy of the polishing process. Data from the calibration process is used to adjust and fine-tune the control system parameters. Regular maintenance logs should be kept to track the equipment’s condition and to schedule preventative maintenance tasks. Following the manufacturer’s recommendations for maintenance and calibration procedures is critical to ensure optimal performance and safety. It’s like servicing your car – regular maintenance ensures it operates efficiently and safely.

Q 21. What are the advantages and disadvantages of different polishing techniques (e.g., Ion Beam Figuring)?

Different polishing techniques offer various advantages and disadvantages. Traditional polishing techniques, using laps and abrasives, are relatively inexpensive but can be less precise and more time-consuming for complex shapes. Ion Beam Figuring (IBF), on the other hand, offers extremely high precision and the ability to create complex surface profiles, but it is significantly more expensive and slower for large areas.

Traditional Polishing (e.g., with laps and abrasives):

- Advantages: Relatively inexpensive, suitable for large areas.

- Disadvantages: Lower precision, time-consuming for complex shapes, can introduce subsurface damage.

Ion Beam Figuring (IBF):

- Advantages: Extremely high precision, capable of creating complex shapes, no subsurface damage.

- Disadvantages: Very expensive, slow for large areas, requires specialized equipment and expertise.

The choice of polishing technique depends on factors like the size and shape of the optic, required surface accuracy, budget constraints, and the desired turnaround time. It’s a balancing act between cost, precision, and efficiency.

Q 22. What is the importance of surface cleanliness in optical polishing?

Surface cleanliness is paramount in optical polishing because even microscopic particles can significantly degrade the final surface quality. Think of it like trying to paint a smooth wall with a dirty brush – the imperfections will show. Contaminants like dust, fingerprints, or polishing compound residue can cause scratches, pits, or other defects that scatter light, reducing the mirror’s reflectivity and overall performance. This is especially critical for high-precision optics used in telescopes, lasers, or lithography systems where even minor imperfections can compromise the entire system’s functionality.

For example, a single dust particle embedded during polishing can create a scattering site that reduces the image quality of a telescope mirror. Therefore, rigorous cleaning protocols using ultra-pure solvents, filtered air, and specialized cleaning tools are absolutely essential.

Q 23. Describe the process of cleaning and handling polished mirrors.

Cleaning and handling polished mirrors requires meticulous care to prevent damage. We typically use a cleanroom environment to minimize airborne contamination. The process usually involves several steps. First, we gently remove loose particles using a low-pressure, filtered air stream. Then, we use isopropyl alcohol (IPA) or other specialized cleaning solutions, applied with lint-free wipes or swabs, to remove any remaining residue. The cleaning process needs to be extremely gentle to avoid scratching the delicate surface. Finally, the mirror is meticulously rinsed with deionized water and allowed to dry in a clean environment. During handling, we always use clean gloves and avoid direct contact with the polished surface, often employing specialized mirror holders to minimize stress and prevent damage.

Imagine handling a freshly polished piece of jewelry; that level of care is required for high-quality optical mirrors.

Q 24. How does temperature affect the performance of optical coatings?

Temperature fluctuations can significantly impact the performance of optical coatings. Different materials expand and contract at different rates, a phenomenon known as thermal expansion mismatch. This can lead to stress within the coating layers, causing delamination (separation of layers), cracking, or changes in refractive index. These effects directly translate to performance degradation, including reduced reflectivity, increased scattering, and altered transmission characteristics. For instance, a mirror designed for use in a stable laboratory environment might fail dramatically if subjected to extreme temperature variations.

The design of the coating itself, including the selection of materials with similar thermal expansion coefficients, is crucial in mitigating temperature-related issues. In practice, we conduct thermal testing to evaluate coating stability and robustness under expected operating conditions.

Q 25. What is the role of substrate preparation in the quality of the final polished surface?

Substrate preparation is fundamentally important for achieving a high-quality polished surface. The initial condition of the substrate – be it glass, silicon, or another material – dictates the final surface quality achievable. Imperfections in the substrate, such as scratches, pits, or inhomogeneities, will propagate through the polishing process and limit the ultimate smoothness and flatness achievable. Therefore, careful cleaning, pre-polishing (if necessary), and surface figuring steps are critical before the final polishing begins. The goal is to create a substrate free of defects that could compromise the optical quality of the final mirror.

Think of building a house – a weak foundation will ultimately impact the entire structure. Similarly, poor substrate preparation will limit the quality of the final polished optical surface.

Q 26. How do you troubleshoot issues with poor adhesion in optical coatings?

Troubleshooting poor adhesion in optical coatings often involves a systematic approach. We first check the substrate cleaning process to ensure it was adequately prepared, ruling out contamination or residues as the cause. Then, we examine the coating deposition parameters, such as deposition rate, substrate temperature, and vacuum level. Deviations from the optimal parameters can drastically affect adhesion. Next, we analyze the coating composition and thickness, as incorrect stoichiometry or excessively thick layers can cause stress that leads to delamination. Finally, we might utilize advanced techniques like scanning electron microscopy (SEM) or X-ray photoelectron spectroscopy (XPS) for in-depth analysis of the coating-substrate interface.

Solving adhesion problems requires a blend of practical experience and analytical tools. Careful process control during the coating deposition is essential to prevent such issues.

Q 27. Describe your experience with different types of polishing laps and their usage.

My experience encompasses various polishing laps, each with its own advantages and disadvantages. For example, pitch laps are traditionally used for fine polishing, offering excellent conformity to the optic’s surface and generating exceptionally smooth finishes. However, pitch laps require careful preparation and maintenance. Alternatively, polyurethane laps offer greater durability and are easier to maintain, although they may not always achieve the same level of surface finish as pitch laps. For specialized applications like freeform optics, magnetorheological finishing (MRF) laps are often employed, providing high material removal rates and excellent control over the surface shape. The choice of lap material and its preparation are crucial factors determining the final surface quality.

Selecting the right lap is like choosing the right tool for a specific job. Each lap type is suited to particular applications, substrates, and desired surface qualities.

Q 28. Explain how you would determine the appropriate coating design for a specific application.

Determining the appropriate coating design for a specific application requires a thorough understanding of the intended use. Several factors must be considered, including the wavelength range of operation, desired reflectivity or transmissivity, durability requirements, and environmental conditions. For example, a solar telescope mirror might require a highly reflective coating optimized for visible light, with additional layers to suppress unwanted wavelengths. Conversely, a laser mirror might demand a highly reflective coating at a specific wavelength, with exceptional damage threshold. We often use optical design software to model and simulate different coating designs, comparing their performance characteristics to identify the optimal solution. Careful selection of coating materials and layer thicknesses is critical for achieving the desired optical properties.

It’s a bit like designing a custom suit – you need to know the occasion, the desired look, and the client’s requirements before beginning the design process.

Key Topics to Learn for Knowledge of Mirror Polishing and Recoating Techniques Interview

- Surface Preparation: Understanding different substrate materials, cleaning methods, and pre-polishing techniques to achieve optimal surface quality before polishing.

- Polishing Techniques: Mastering various polishing methods (e.g., pitch polishing, ion beam figuring) and their respective applications based on desired surface accuracy and material properties. Understanding the selection criteria for abrasives and polishing compounds.

- Coating Materials and Processes: Familiarity with different coating materials (e.g., aluminum, silver, dielectric coatings), their deposition methods (e.g., evaporation, sputtering), and the impact of process parameters on coating quality and performance.

- Metrology and Testing: Proficiency in using interferometry, profilometry, and other metrological techniques to assess surface quality, roughness, and coating uniformity. Understanding the interpretation of test results and their implications.

- Defect Identification and Correction: Ability to identify common defects during polishing and coating processes (e.g., scratches, pits, coating imperfections) and implement corrective actions to improve surface quality.

- Environmental Control: Understanding the impact of environmental factors (e.g., temperature, humidity, cleanliness) on the polishing and coating processes, and how to mitigate their influence.

- Safety Procedures and Handling of Materials: Knowledge of safety regulations and handling procedures for hazardous chemicals and equipment used in mirror polishing and recoating.

- Troubleshooting and Problem-Solving: Applying critical thinking skills to diagnose and resolve issues encountered during polishing and coating processes. Experience analyzing root causes and implementing preventative measures.

Next Steps

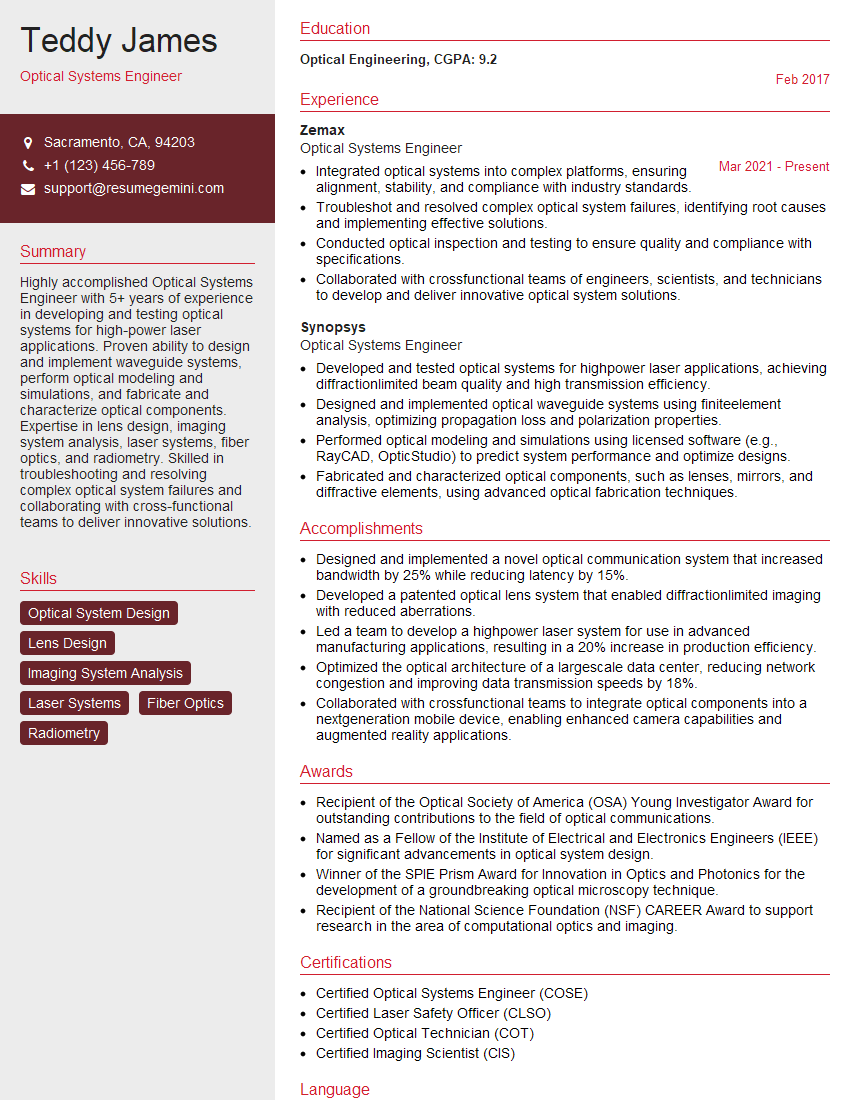

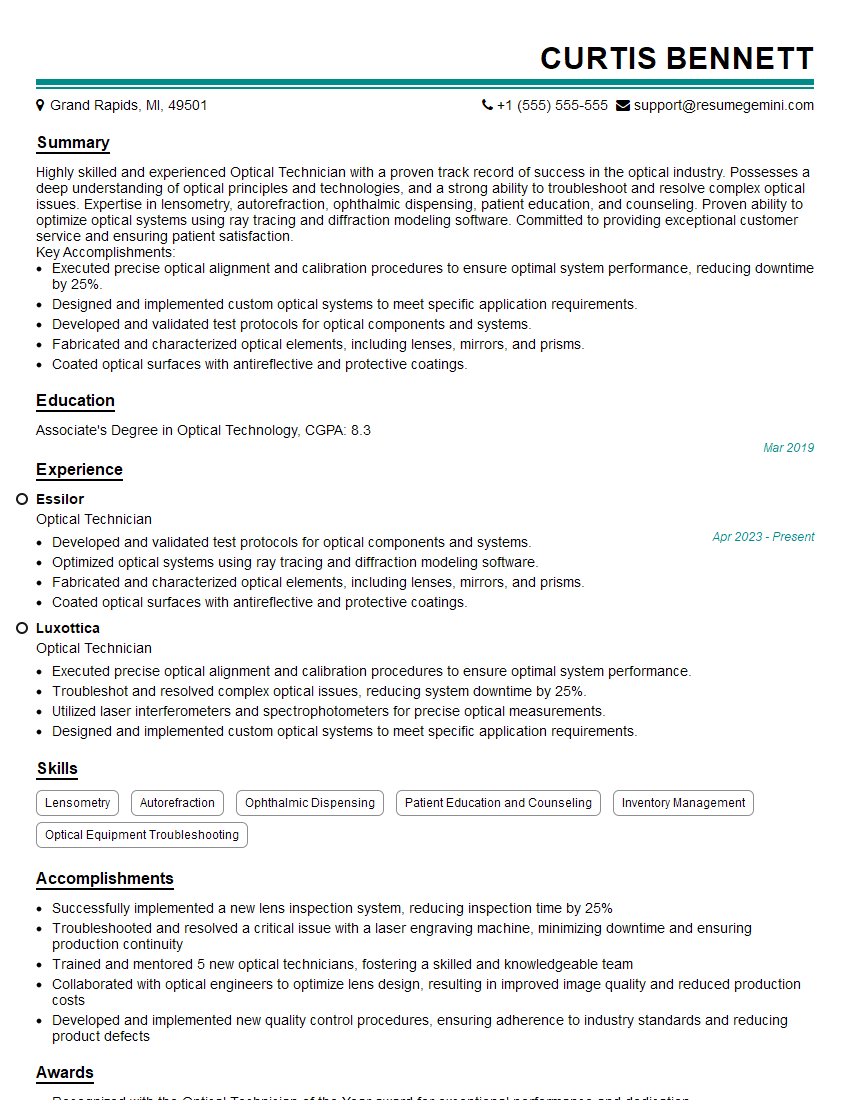

Mastering Knowledge of Mirror Polishing and Recoating Techniques is crucial for career advancement in optics, photonics, and related fields. A strong understanding of these techniques opens doors to specialized roles and higher responsibilities. To maximize your job prospects, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional and impactful resume. We provide examples of resumes tailored to Knowledge of Mirror Polishing and Recoating Techniques to guide you in showcasing your qualifications.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good