Unlock your full potential by mastering the most common Reaction Chemistry interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Reaction Chemistry Interview

Q 1. Explain the difference between SN1 and SN2 reactions.

SN1 and SN2 reactions are both nucleophilic substitution reactions, meaning a nucleophile (an electron-rich species) replaces a leaving group (an atom or group that departs with a pair of electrons) on a carbon atom. However, they differ significantly in their mechanisms.

SN1 (Substitution Nucleophilic Unimolecular): This reaction proceeds in two steps. First, the leaving group departs, creating a carbocation intermediate. This step is the rate-determining step, meaning its speed governs the overall reaction rate. The second step involves the nucleophile attacking the carbocation to form the product. Because the rate depends only on the concentration of the substrate (the molecule undergoing substitution), it’s unimolecular. SN1 reactions are favored by tertiary substrates (those with three alkyl groups attached to the carbon bearing the leaving group) because they stabilize the carbocation intermediate. They typically occur in polar protic solvents (solvents that can form hydrogen bonds, like water or alcohols).

SN2 (Substitution Nucleophilic Bimolecular): This reaction proceeds in a single concerted step. The nucleophile attacks the carbon atom from the backside, simultaneously displacing the leaving group. This backside attack leads to inversion of stereochemistry at the carbon center. The reaction rate depends on the concentrations of both the substrate and the nucleophile, hence the term ‘bimolecular’. SN2 reactions are favored by primary substrates (those with one alkyl group attached to the carbon bearing the leaving group) and are best carried out in polar aprotic solvents (solvents that can dissolve polar compounds but cannot donate hydrogen bonds, like acetone or DMSO).

Example: The reaction of tert-butyl bromide with water is an SN1 reaction, while the reaction of methyl bromide with hydroxide ion is an SN2 reaction.

Q 2. Describe the factors influencing reaction rate.

Several factors influence the rate of a chemical reaction. Think of it like a recipe; you need the right ingredients and conditions for the dish to cook perfectly.

- Concentration of reactants: Higher concentrations mean more reactant molecules are available to collide and react, thus increasing the reaction rate. This is directly reflected in the rate law.

- Temperature: Increasing temperature provides reactants with more kinetic energy, leading to more frequent and energetic collisions, thus increasing the reaction rate. The Arrhenius equation quantifies this relationship.

- Surface area: For reactions involving solids, increasing surface area (e.g., by grinding a solid into a powder) exposes more reactant molecules to the other reactants, increasing the reaction rate.

- Presence of a catalyst: Catalysts provide an alternative reaction pathway with a lower activation energy, significantly increasing the reaction rate without being consumed in the process. Enzymes are biological catalysts.

- Nature of reactants: The inherent reactivity of the reactants plays a crucial role. Some molecules are inherently more reactive than others due to their electronic structure and bond strengths.

- Solvent effects: The solvent can influence the reaction rate by stabilizing or destabilizing intermediates or transition states. Polar solvents, for example, can stabilize charged intermediates.

Example: The combustion of wood is faster in pure oxygen than in air because the concentration of oxygen is higher in pure oxygen.

Q 3. What are the different types of chemical reactions?

Chemical reactions are classified into various types based on the changes they involve. Some key categories include:

- Combination reactions (Synthesis): Two or more substances combine to form a single, more complex substance.

A + B → AB - Decomposition reactions: A single compound breaks down into two or more simpler substances.

AB → A + B - Single displacement reactions: One element replaces another in a compound.

A + BC → AC + B - Double displacement reactions (Metathesis): Two compounds exchange ions or groups of atoms to form two new compounds.

AB + CD → AD + CB - Acid-base reactions (Neutralization): An acid reacts with a base to form a salt and water.

HA + BOH → BA + H₂O - Redox reactions (Oxidation-reduction): Involve the transfer of electrons between reactants. One substance is oxidized (loses electrons) while another is reduced (gains electrons).

- Combustion reactions: Rapid reaction with oxygen, usually producing heat and light. Often involves organic compounds.

Example: The rusting of iron (oxidation) is a redox reaction, while the burning of natural gas (methane) is a combustion reaction.

Q 4. Explain the concept of equilibrium constant.

The equilibrium constant (K) is a value that expresses the relationship between the concentrations of reactants and products in a reversible chemical reaction at equilibrium. At equilibrium, the rates of the forward and reverse reactions are equal, and the net change in concentrations is zero. A large K indicates that the equilibrium lies far to the right, favoring the products, while a small K indicates that the equilibrium lies far to the left, favoring the reactants.

For a general reversible reaction: aA + bB ⇌ cC + dD, the equilibrium constant expression is:

K = [C]c[D]d / [A]a[B]bwhere [A], [B], [C], and [D] represent the equilibrium concentrations of the respective species, and a, b, c, and d are their stoichiometric coefficients. The equilibrium constant is temperature-dependent; changing the temperature will alter the value of K.

Example: The equilibrium constant for the reaction N₂(g) + 3H₂(g) ⇌ 2NH₃(g) indicates the relative amounts of nitrogen, hydrogen, and ammonia present at equilibrium at a specific temperature.

Q 5. How do you determine the limiting reagent in a chemical reaction?

The limiting reagent is the reactant that is completely consumed first in a chemical reaction, thus limiting the amount of product that can be formed. To determine the limiting reagent, you need the balanced chemical equation and the amounts of each reactant.

Step-by-step procedure:

- Write the balanced chemical equation: This gives the stoichiometric ratios of reactants and products.

- Convert the given amounts of reactants to moles: Use molar masses to convert grams to moles.

- Use the stoichiometric ratios from the balanced equation to determine the moles of product that can be formed from each reactant: Divide the moles of each reactant by its stoichiometric coefficient. The reactant that produces the least amount of product is the limiting reagent.

Example: Consider the reaction 2H₂ + O₂ → 2H₂O. If you have 2 moles of H₂ and 1 mole of O₂, then according to the stoichiometry, 2 moles of H₂ can produce 2 moles of H₂O, and 1 mole of O₂ can produce 2 moles of H₂O. Both produce the same amount; neither is limiting. However, if you had 2 moles of H₂ and 0.5 moles of O₂, then 0.5 moles of O₂ would only produce 1 mole of H₂O, making O₂ the limiting reagent.

Q 6. Describe the concept of activation energy.

Activation energy (Ea) is the minimum amount of energy required for a chemical reaction to occur. Imagine pushing a boulder uphill; you need to apply enough energy to get it over the top before it can roll down the other side. The activation energy is like that ‘hill’ – the energy barrier that must be overcome for reactants to transform into products.

Reactant molecules need to collide with sufficient energy and proper orientation to break existing bonds and form new ones. Molecules with less than the activation energy will simply collide and bounce apart without reacting. The activation energy is related to the reaction rate; a lower activation energy means a faster reaction rate, as more molecules will possess the necessary energy to react.

Example: Catalysts work by lowering the activation energy of a reaction, making it proceed faster. For example, enzymes are biological catalysts that significantly reduce the activation energy of many biochemical reactions, allowing life processes to occur at reasonable rates.

Q 7. Explain Le Chatelier’s principle.

Le Chatelier’s principle states that if a change of condition is applied to a system in equilibrium, the system will shift in a direction that relieves the stress. This principle applies to reversible chemical reactions and describes how the system responds to changes in several factors.

- Change in concentration: Adding more reactant will shift the equilibrium to the right, favoring product formation. Removing product will also shift the equilibrium to the right. The opposite is true for removing reactant or adding product.

- Change in temperature: Increasing the temperature favors the endothermic reaction (the reaction that absorbs heat), while decreasing the temperature favors the exothermic reaction (the reaction that releases heat).

- Change in pressure: Changing the pressure affects the equilibrium only if the number of moles of gaseous reactants and products differs. Increasing pressure favors the side with fewer moles of gas, while decreasing pressure favors the side with more moles of gas.

Example: The Haber-Bosch process for ammonia synthesis (N₂(g) + 3H₂(g) ⇌ 2NH₃(g)) is exothermic. To favor ammonia production, high pressure and low temperature are used. However, very low temperatures slow the reaction rate, so a compromise must be reached.

Q 8. What are the different types of isomerism?

Isomerism refers to the existence of molecules with the same molecular formula but different arrangements of atoms. There are two main types: structural isomerism and stereoisomerism.

- Structural Isomerism: This involves isomers with different connectivity of atoms. There are several subtypes:

- Chain Isomerism: Different arrangements of the carbon skeleton (e.g., butane and isobutane).

- Position Isomerism: Different positions of a functional group on a carbon chain (e.g., 1-propanol and 2-propanol).

- Functional Group Isomerism: Same molecular formula but different functional groups (e.g., ethanol and dimethyl ether).

- Stereoisomerism: These isomers have the same connectivity but differ in the spatial arrangement of atoms. The key subtypes are:

- Geometric Isomerism (cis-trans isomerism): Occurs in alkenes and cyclic compounds due to restricted rotation around a double bond or ring. ‘Cis’ isomers have substituents on the same side, while ‘trans’ isomers have them on opposite sides.

- Optical Isomerism (Enantiomerism): Occurs when molecules are non-superimposable mirror images of each other (chiral molecules). They rotate plane-polarized light in opposite directions.

- Diastereomers: Stereoisomers that are not mirror images of each other. Examples include cis-trans isomers (if not also enantiomers) and different anomers of carbohydrates.

Understanding isomerism is crucial in drug design, as different isomers can have vastly different biological activities. For instance, one isomer of a drug might be effective, while another might be inactive or even toxic.

Q 9. Describe the mechanism of a Grignard reaction.

The Grignard reaction is an organometallic chemical reaction in which alkyl- or aryl-magnesium halides (Grignard reagents) add to a carbonyl group in aldehydes, ketones, esters or nitriles.

The mechanism begins with the formation of the Grignard reagent itself. This involves the reaction of an alkyl or aryl halide with magnesium metal in an anhydrous ether solvent (like diethyl ether or THF). This forms a highly reactive organomagnesium halide, which acts as a nucleophile.

R-X + Mg → R-MgX

The Grignard reagent then attacks the electrophilic carbon atom of the carbonyl group (aldehyde, ketone, ester, etc.). This forms an alkoxide intermediate.

R-MgX + R'2C=O → [R-C(OR')2-MgX]

Finally, an acidic workup (typically with dilute aqueous acid) protonates the alkoxide, yielding the alcohol product.

[R-C(OR')2-MgX] + H3O+ → R-C(OH)(R')2 + MgX(OH)

The reaction is highly sensitive to moisture because Grignard reagents react vigorously with water. Therefore, anhydrous conditions are absolutely essential.

Grignard reactions are essential in organic synthesis for forming carbon-carbon bonds and creating a wide range of functional groups, particularly alcohols.

Q 10. How do you perform a recrystallization?

Recrystallization is a purification technique used to isolate a solid compound from a solution. It relies on the difference in solubility of the desired compound at different temperatures.

- Dissolution: The impure solid is dissolved in a minimum amount of hot solvent. The choice of solvent is crucial; it should dissolve the compound well when hot and poorly when cold. The ideal solvent dissolves the impurities at all temperatures or doesn’t dissolve them at all.

- Hot Filtration (if necessary): If insoluble impurities are present, the hot solution is filtered to remove them while it’s still hot to prevent recrystallization in the filter.

- Cooling: The hot, clear solution is allowed to cool slowly, ideally at room temperature and then in an ice bath. Slow cooling allows for the formation of larger, purer crystals.

- Collection: The crystals are collected by vacuum filtration. The cold solvent remaining contains the soluble impurities. The crystals are then washed with small amounts of cold solvent to remove any remaining impurities on the crystal surface.

- Drying: The crystals are dried to remove residual solvent. This is typically done in a desiccator or under vacuum.

Imagine it like brewing tea. You dissolve tea leaves (impurities) and the tea compounds (desired product) in hot water. As the tea cools, the tea compounds are less soluble and crystallize (form the tea leaves at the bottom of your cup), leaving impurities behind in the water.

Q 11. Explain the use of chromatography in reaction chemistry.

Chromatography is a powerful separation technique used extensively in reaction chemistry to analyze reaction mixtures and purify compounds. It works by exploiting the differential affinities of compounds for a stationary phase and a mobile phase.

Different types of chromatography exist, each suited for different applications:

- Thin-Layer Chromatography (TLC): A simple, rapid technique using a thin layer of adsorbent (like silica gel) on a plate. The mobile phase moves up the plate by capillary action, separating compounds based on their polarity and interaction with the stationary phase. TLC is mainly used for qualitative analysis (identifying compounds and monitoring reaction progress).

- Column Chromatography: This technique uses a column packed with a stationary phase (e.g., silica gel, alumina). The mobile phase is passed through the column, separating compounds based on their affinity for the stationary and mobile phases. It can be used for both preparative (purifying large amounts of a compound) and analytical purposes.

- High-Performance Liquid Chromatography (HPLC): A more sophisticated form of column chromatography using high pressure to increase separation efficiency and speed. HPLC is a highly versatile technique with broad applications, including quantitative analysis and purification.

- Gas Chromatography (GC): Used to separate volatile compounds based on their different boiling points and interactions with a stationary phase inside a column. The separated compounds are detected using a detector. This technique is excellent for analyzing volatile reaction products.

Chromatography is indispensable in reaction chemistry for monitoring reaction progress, identifying reaction products, and purifying compounds for further analysis or use.

Q 12. What are the safety precautions associated with handling reactive chemicals?

Handling reactive chemicals requires strict adherence to safety protocols to prevent accidents and protect yourself and others.

- Personal Protective Equipment (PPE): Always wear appropriate PPE, including safety goggles, gloves (chemical-resistant, appropriate for the specific chemicals), lab coat, and closed-toe shoes.

- Fume Hoods: Perform reactions involving volatile or toxic chemicals inside a fume hood to prevent inhalation of hazardous vapors.

- Appropriate Handling Techniques: Use proper techniques for handling chemicals, avoiding direct contact and spills. Use appropriate glassware and equipment.

- Waste Disposal: Dispose of chemical waste properly according to established safety guidelines and institutional regulations. Never pour chemicals down the drain unless specifically permitted.

- Emergency Procedures: Be aware of emergency procedures, including the location of safety showers, eyewash stations, and fire extinguishers. Know how to respond to spills or other accidents.

- Chemical Compatibility: Always check for chemical compatibility before mixing chemicals. Some combinations can be extremely dangerous and lead to violent reactions.

- Safe Storage: Store chemicals properly according to their hazard classifications and compatibility. This typically involves segregated storage areas for different classes of chemicals.

- Risk Assessment: Before starting any experiment, conduct a thorough risk assessment to identify potential hazards and implement control measures.

Working with reactive chemicals is inherently risky, so meticulous attention to safety is paramount.

Q 13. How do you interpret NMR and IR spectra in reaction analysis?

NMR (Nuclear Magnetic Resonance) and IR (Infrared) spectroscopy are powerful tools for identifying and characterizing compounds formed in chemical reactions.

NMR Spectroscopy: Provides information about the carbon and hydrogen atoms in a molecule. The chemical shifts (δ) indicate the electronic environment of the atoms, and the integration reveals the relative number of atoms in each environment. Spin-spin coupling provides information about the connectivity of atoms. By analyzing the NMR spectrum, we can determine the structure of the product(s).

IR Spectroscopy: Detects functional groups in a molecule by observing the absorption of infrared light at specific frequencies. Each functional group has characteristic absorption bands, allowing identification of functional groups present in the product(s).

For example, if we’re expecting an alcohol product, the IR spectrum should show a broad absorption band around 3300 cm-1 (due to the O-H stretch), while the NMR spectrum should show a signal around 1-5 ppm, depending on the location of the -OH group. The integration of the signal will be one proton. The presence of these signals confirms the presence of the alcohol.

Both NMR and IR spectroscopy provide complementary information, enabling comprehensive structural elucidation of reaction products. Comparing the spectra of starting materials and products allows us to confirm whether the desired reaction occurred and to identify any by-products that might have formed.

Q 14. What is the significance of yield in a chemical reaction?

The yield of a chemical reaction represents the efficiency of the reaction in converting starting materials into the desired product. It’s expressed as the ratio of the actual amount of product obtained to the theoretical yield (the maximum amount of product that could be obtained if the reaction proceeded perfectly).

Yield (%) = (Actual yield / Theoretical yield) x 100

A high yield indicates a highly efficient reaction with minimal loss of starting material. A low yield implies that significant amounts of starting materials were either not converted to the product or were lost during the process. Factors contributing to low yields include incomplete reactions, side reactions, loss of product during purification, and experimental errors.

For example, if we start with 10 grams of a reactant and the theoretical yield is 15 grams of the product, but we only obtain 12 grams, the percentage yield is (12g / 15g) x 100% = 80%. This suggests a relatively efficient reaction, though there was some loss of product.

Yield is a crucial metric in reaction chemistry, providing insight into the efficiency of a reaction and helping to optimize reaction conditions to improve the efficiency and minimize waste.

Q 15. Explain different types of reaction kinetics.

Reaction kinetics studies the rates of chemical reactions and the factors that influence them. Different types are categorized based on the order of the reaction with respect to each reactant.

- Zero-order kinetics: The reaction rate is independent of the concentration of reactants. Think of a surface reaction where all active sites are occupied; increasing reactant concentration won’t speed it up further.

Rate = k - First-order kinetics: The reaction rate is directly proportional to the concentration of one reactant. Radioactive decay is a classic example.

Rate = k[A] - Second-order kinetics: The reaction rate is proportional to the square of the concentration of one reactant or the product of the concentrations of two reactants. Many bimolecular reactions fall into this category.

Rate = k[A]2orRate = k[A][B] - Higher-order kinetics: Reactions with orders greater than two are less common but can occur in complex systems.

- Pseudo-order kinetics: A reaction that appears to be of a certain order due to the overwhelming excess of one reactant. For instance, a reaction that’s actually second-order might appear first-order if one reactant’s concentration is much higher and remains virtually constant throughout.

Understanding reaction order is crucial for process optimization and scale-up, as it directly impacts reactor design and reaction time.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe the use of catalysts in chemical reactions.

Catalysts are substances that increase the rate of a chemical reaction without being consumed themselves. They achieve this by lowering the activation energy, the energy barrier that reactants must overcome to transform into products. Think of a catalyst as a matchmaker, facilitating the interaction between reactants without participating in the final product.

- Homogeneous catalysts: Exist in the same phase as the reactants (e.g., a liquid catalyst in a liquid reaction).

- Heterogeneous catalysts: Exist in a different phase than the reactants (e.g., a solid catalyst in a liquid reaction). These are often used in industrial processes due to their ease of separation from the product mixture.

Examples include enzymes (biological catalysts), platinum in catalytic converters (reducing harmful emissions), and zeolites (used in petroleum refining).

Catalyst design involves careful consideration of factors like active sites, surface area, and stability. Optimizing a catalyst can significantly improve reaction efficiency and reduce waste.

Q 17. How do you design and optimize a chemical reaction?

Designing and optimizing a chemical reaction is an iterative process involving multiple stages:

- Defining the reaction goal: What product do we want, and in what yield and purity? This sets the performance metrics for optimization.

- Choosing reaction conditions: This includes selecting solvents, temperature, pressure, and reactant concentrations. Thermodynamic and kinetic data are essential here.

- Reaction mechanism elucidation: Understanding the steps involved in the reaction helps identify rate-limiting steps and potential bottlenecks for optimization. Kinetic modeling can provide valuable insights.

- Experimental design: Systematic experiments are conducted to explore the reaction parameter space. Techniques like Design of Experiments (DOE) can efficiently determine the optimal conditions.

- Process optimization: Once promising conditions are identified, further refinement is done to maximize yield, selectivity, and reduce reaction time or energy consumption. This often involves adjustments to catalyst, reactor design, or reaction pathway.

- Scale-up: Transitioning from lab-scale reactions to industrial scale production requires careful consideration of heat and mass transfer, mixing efficiency, and reactor design.

For example, designing a reaction to synthesize a specific pharmaceutical might involve optimizing reaction temperature to maximize the desired isomer’s formation while minimizing the production of by-products. This could involve using a specific catalyst, choosing a suitable solvent, and precisely controlling temperature and pressure.

Q 18. Explain different reaction mechanisms (e.g., addition, substitution, elimination).

Reaction mechanisms describe the step-by-step process of a chemical reaction. Key types include:

- Addition reactions: Two or more molecules combine to form a larger one. The addition of bromine to an alkene is a classic example.

- Substitution reactions: An atom or group in a molecule is replaced by another atom or group. The SN1 and SN2 reactions in organic chemistry are prime examples. SN1 involves a carbocation intermediate, while SN2 is a concerted reaction.

- Elimination reactions: A molecule loses atoms or groups to form a double bond or a triple bond. Dehydration of alcohols to form alkenes is an example.

- Rearrangement reactions: Atoms within a molecule shift, leading to a structural isomer. The Claisen rearrangement is a good example of a [3,3]-sigmatropic rearrangement.

Understanding the reaction mechanism allows for the prediction and control of reaction outcomes. For instance, knowing whether a substitution reaction follows an SN1 or SN2 pathway helps predict the stereochemistry of the product.

Q 19. Describe different types of reactors used in industrial chemical processes.

Industrial chemical processes utilize various reactor types depending on the reaction’s characteristics and scale:

- Batch reactors: Reactants are added at the beginning, and the reaction proceeds until completion. Simple design but not suitable for large-scale continuous production.

- Continuous stirred-tank reactors (CSTR): Reactants are continuously fed, and products are continuously removed. Excellent mixing, but achieving high conversion might require multiple reactors in series.

- Plug flow reactors (PFR): Reactants flow through a tube with minimal back mixing. Allows for good control of residence time, beneficial for reactions that are sensitive to concentration changes.

- Fluidized-bed reactors: Solid catalysts are suspended in a gas or liquid stream. High surface area and excellent heat transfer are key advantages, often used in catalytic cracking in petroleum refineries.

The choice of reactor depends on factors like reaction kinetics, heat transfer requirements, and desired product quality. For instance, a highly exothermic reaction might necessitate a reactor with efficient cooling, such as a fluidized bed or a CSTR with external cooling.

Q 20. What are the challenges in scaling up a chemical reaction from lab to industrial scale?

Scaling up a chemical reaction presents several challenges:

- Heat and mass transfer: At larger scales, controlling temperature and ensuring efficient mixing becomes more difficult. Heat generated in a large-scale exothermic reaction can be difficult to remove, potentially leading to runaway reactions or decreased selectivity.

- Reactor design: Lab-scale reactors often lack the complexities of industrial-scale reactors. Efficient mixing, flow patterns, and heat transfer need careful design and modeling at a large scale.

- Reproducibility: Maintaining consistent reaction conditions at a large scale is crucial for product quality. Factors that are easily controlled in the lab, such as temperature homogeneity, become more challenging to maintain in a larger reactor.

- Safety: Handling larger quantities of reactants presents safety concerns that are less significant at a small scale. Safety protocols and emergency response systems need careful planning.

- Cost: Scale-up involves substantial capital investment in equipment, infrastructure, and personnel.

Careful process development, engineering design, and pilot plant studies are essential for successful scale-up. For example, a reaction that works perfectly in a small flask might suffer from poor heat transfer in a large-scale tank reactor.

Q 21. Explain the concept of selectivity and its importance.

Selectivity refers to the extent to which a reaction favors the formation of the desired product over other possible products (by-products). It is expressed as the ratio of the moles of the desired product to the total moles of all products formed.

Selectivity = (Moles of desired product) / (Total moles of all products)

High selectivity is crucial for efficient and cost-effective chemical processes. A low selectivity means more by-products are generated, requiring extensive separation and purification steps that add to the cost and complexity of the process. This wasted material can also pose environmental concerns.

For example, in the oxidation of an alkene, the desired product might be an epoxide, but other products like ketones or aldehydes could be formed. A highly selective catalyst or reaction conditions would favor the formation of the epoxide, minimizing the formation of unwanted products.

Q 22. How do you troubleshoot problems in a chemical reaction?

Troubleshooting a chemical reaction involves a systematic approach. Think of it like detective work – you need to gather clues to identify the culprit hindering your reaction. First, I’d meticulously review the experimental procedure, looking for any deviations from the established protocol. Did I use the correct reagents and solvents? Were the quantities accurate? Were the reaction conditions (temperature, pressure, time) precisely controlled?

Next, I’d analyze the reaction mixture. This often involves using analytical techniques (discussed in the next question) to determine the composition of the mixture. Low yield? That might point to incomplete conversion of reactants or the formation of side products. Impurities? They could be interfering with the desired reaction pathway. Unexpected products? This often indicates a problem with the reaction mechanism or conditions.

Then, I’d systematically investigate potential issues: impure starting materials, incorrect stoichiometry, inadequate mixing, or problems with the equipment (e.g., faulty thermometer, malfunctioning stirrer). I might also consider external factors like ambient temperature fluctuations or the quality of the reagents. Finally, I’d document all observations and adjustments made, treating each experiment as a learning opportunity to refine the reaction and improve future results.

For example, in a Grignard reaction (organometallic chemistry), a low yield could be due to insufficiently dry conditions, leading to the destruction of the Grignard reagent. By meticulously drying the glassware and reagents and using an inert atmosphere (like nitrogen), we could rectify the issue.

Q 23. Explain different analytical techniques used to monitor reaction progress.

Monitoring reaction progress is crucial for optimizing yield and selectivity. Several analytical techniques are employed, each offering a unique perspective. Think of it like having multiple detective tools – each reveals different aspects of the case.

- Nuclear Magnetic Resonance (NMR) Spectroscopy: Provides detailed structural information about the reactants, products, and intermediates. It’s like a fingerprint, uniquely identifying each molecule.

- Gas Chromatography (GC) and High-Performance Liquid Chromatography (HPLC): These separate components of a mixture, allowing for quantitative analysis of reactants and products. It’s like sorting through clues to count how much of each item is present.

- Infrared (IR) Spectroscopy: Identifies functional groups present in the molecules. This helps to determine if the desired functional groups have formed or if undesired side products are present.

- Mass Spectrometry (MS): Determines the mass-to-charge ratio of molecules, providing information about their molecular weight. This confirms the identity of the products.

- Titration: A quantitative method used to determine the concentration of a specific reactant or product. This is especially useful for monitoring reactions involving acids or bases.

The choice of technique depends on the specific reaction and the information needed. For example, in a polymerization reaction, GC or HPLC might be used to monitor the molecular weight distribution of the polymer over time.

Q 24. Describe the role of stoichiometry in chemical reactions.

Stoichiometry is the quantitative relationship between reactants and products in a chemical reaction. Imagine baking a cake: you need a precise ratio of flour, sugar, eggs, etc. to achieve the desired outcome. Similarly, in a chemical reaction, the stoichiometric ratios determine the amount of each reactant needed to produce a specific amount of product, and vice versa.

It’s governed by the balanced chemical equation. For instance, in the reaction 2H2 + O2 → 2H2O, the stoichiometric ratio of hydrogen to oxygen is 2:1. This means two moles of hydrogen react with one mole of oxygen to produce two moles of water. Deviation from these ratios can lead to incomplete reactions or the formation of unwanted byproducts. Understanding stoichiometry is fundamental to calculating reactant quantities, predicting product yields, and optimizing reaction conditions. In industrial settings, precise stoichiometric control is crucial for efficient and economical production of chemicals.

Q 25. Explain the difference between exothermic and endothermic reactions.

Exothermic and endothermic reactions are classified based on their heat exchange with the surroundings. Think of it as a system’s energy budget.

- Exothermic Reactions: These release heat to the surroundings. The energy of the products is lower than the energy of the reactants. Imagine burning wood – it releases heat, warming the surrounding environment. The enthalpy change (ΔH) is negative.

- Endothermic Reactions: These absorb heat from the surroundings. The energy of the products is higher than the energy of the reactants. Think of melting ice – it requires energy (heat) from the surroundings to change its phase. The enthalpy change (ΔH) is positive.

Many everyday processes involve exothermic or endothermic reactions. For example, combustion reactions (like burning fuel) are exothermic, while photosynthesis (plants converting sunlight to energy) is endothermic.

Q 26. Describe the importance of reaction conditions (temperature, pressure, solvent).

Reaction conditions, including temperature, pressure, and solvent, significantly impact reaction rate, yield, and selectivity. They act as catalysts, influencing the reaction pathway and outcome. Consider them as environmental factors influencing a delicate ecosystem of molecules.

- Temperature: Increasing temperature usually increases reaction rate, as molecules have more kinetic energy, leading to more frequent and energetic collisions. However, excessively high temperatures can lead to side reactions or decomposition of products.

- Pressure: Primarily affects reactions involving gases. Increasing pressure favors reactions that produce fewer gas molecules (Le Chatelier’s principle). For example, in the Haber-Bosch process for ammonia synthesis, high pressure is used to shift the equilibrium towards ammonia production.

- Solvent: The solvent influences reaction rate and selectivity by affecting reactant solubility, stability, and interactions. The choice of solvent is crucial for achieving desired results; a polar solvent may favor polar reactions, while a nonpolar solvent might be suitable for nonpolar reactions. In some cases, the solvent can even participate directly in the reaction mechanism.

Optimizing reaction conditions is a critical aspect of reaction design and achieving the desired product with maximum efficiency.

Q 27. How do you handle waste generated during a chemical reaction?

Waste handling in chemical reactions is crucial for environmental protection and safety. It’s not just about disposing of the waste; it’s about minimizing its generation in the first place.

My approach involves implementing the principles of Green Chemistry, which focuses on designing chemical processes that minimize waste and pollution. This includes selecting reagents and solvents that are less hazardous, using catalytic reactions to improve efficiency, and exploring alternative reaction pathways that produce less waste. Beyond this, proper waste segregation is crucial. I always follow established protocols and regulations for handling different types of chemical waste, categorizing them according to their hazard class (e.g., flammability, toxicity, reactivity). This involves proper labeling, containment, and disposal methods in accordance with local, regional, and national guidelines.

Waste neutralization, before disposal, is often necessary. For example, acidic waste might be neutralized with a base, and vice-versa. Some waste may also be recyclable, reducing waste volume and protecting the environment.

Q 28. Explain your experience with different types of chemical synthesis.

Throughout my career, I’ve been involved in various types of chemical synthesis, ranging from simple organic reactions to complex multi-step syntheses. I have extensive experience with:

- Organic synthesis: This includes the synthesis of various organic molecules, involving reactions like Grignard reactions, Wittig reactions, Diels-Alder reactions, and many more. I’m comfortable with protecting group strategies, and have experience with both solution-phase and solid-phase synthesis.

- Inorganic synthesis: I’ve synthesized various inorganic compounds, including metal complexes and coordination compounds, employing methods like precipitation, hydrothermal synthesis, and sol-gel methods. This often involves careful control of reaction conditions like pH, temperature, and concentration.

- Polymer synthesis: I’ve synthesized various polymers, including condensation polymers and addition polymers, using techniques like step-growth polymerization and chain-growth polymerization. The focus here is often on controlling the molecular weight and polydispersity of the resulting polymers.

Each synthesis type requires a unique understanding of reaction mechanisms, stoichiometry, and optimization of reaction conditions. My experience allows me to adapt and refine my techniques to meet the specific requirements of the project, always keeping safety and efficiency in mind.

Key Topics to Learn for Reaction Chemistry Interview

- Reaction Mechanisms: Understanding the step-by-step process of chemical reactions, including identifying intermediates and transition states. This is crucial for predicting reaction outcomes and designing synthetic pathways.

- Thermodynamics and Kinetics: Applying thermodynamic principles (Gibbs Free Energy, enthalpy, entropy) to predict reaction spontaneity and equilibrium. Understanding reaction rates and the factors influencing them (activation energy, temperature, concentration). Practical application: Optimizing reaction conditions for yield and speed.

- Reaction Stoichiometry and Calculations: Mastering mole calculations, limiting reagents, percent yield, and theoretical yield. This forms the foundation for quantitative analysis in chemistry.

- Catalysis: Understanding the role of catalysts in accelerating reaction rates and influencing selectivity. Practical application: Designing efficient catalytic systems for industrial processes.

- Spectroscopy and Analytical Techniques: Familiarize yourself with common techniques like NMR, IR, and Mass Spectrometry used to identify and characterize reaction products. Understanding how these techniques provide insights into reaction mechanisms.

- Organic Reaction Chemistry: A deep understanding of common organic reactions (SN1, SN2, E1, E2, additions, etc.) and their mechanisms. Practical application: Designing synthetic routes for target molecules.

- Inorganic Reaction Chemistry: Understanding the reactivity of inorganic compounds, focusing on oxidation states, redox reactions, and complex formation. Practical application: Developing new materials with specific properties.

- Problem-Solving and Data Analysis: Develop your ability to analyze experimental data, interpret results, and troubleshoot issues encountered during experiments. This is a highly sought-after skill in any chemistry role.

Next Steps

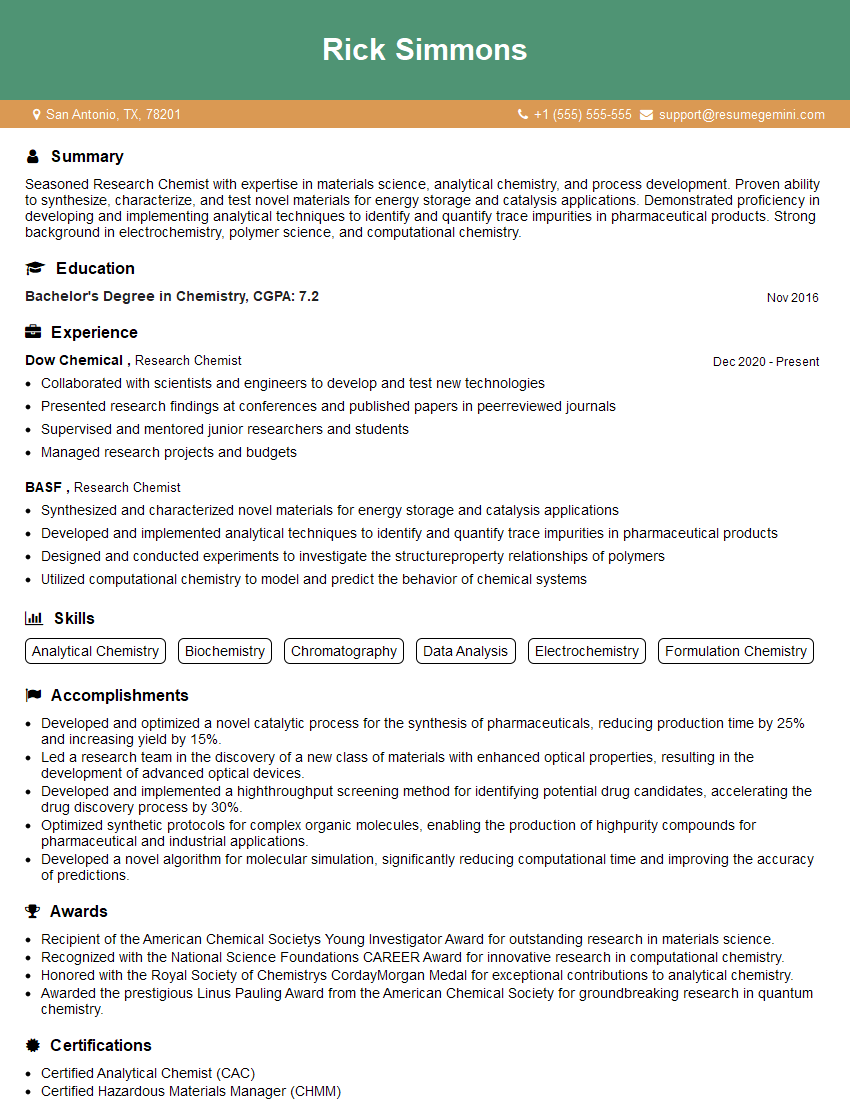

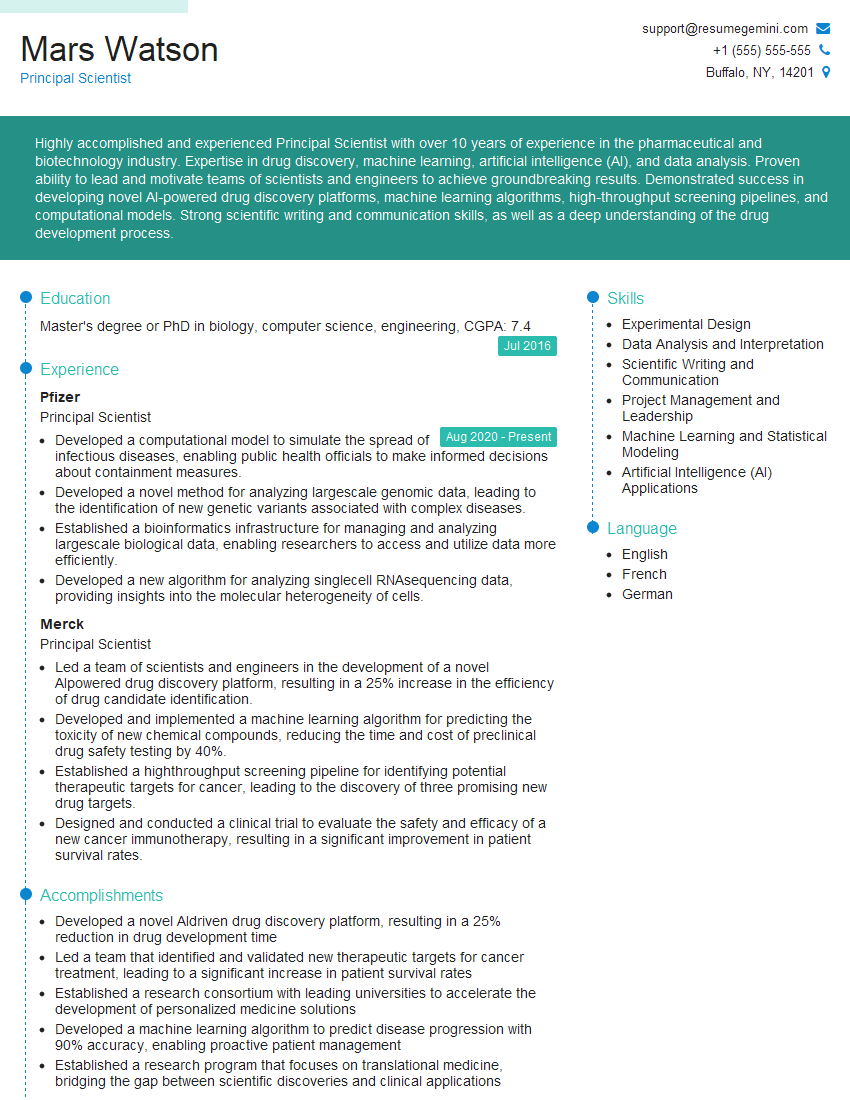

Mastering Reaction Chemistry is vital for career advancement in various fields, including pharmaceuticals, materials science, and environmental chemistry. A strong foundation in these concepts opens doors to exciting research and development opportunities. To enhance your job prospects, creating a well-structured, ATS-friendly resume is crucial. We highly recommend using ResumeGemini to build a professional and impactful resume that highlights your skills and experience effectively. ResumeGemini offers examples of resumes tailored specifically to Reaction Chemistry roles to help you craft the perfect application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good