The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Knowledge of Metallurgy and Nail Manufacturing interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Knowledge of Metallurgy and Nail Manufacturing Interview

Q 1. Explain the different types of steel used in nail manufacturing.

The type of steel used in nail manufacturing significantly impacts the final product’s quality and performance. Common choices are categorized by their carbon content and alloying elements, influencing strength, hardness, and ductility.

- Low Carbon Steel: This is the most common type, offering good ductility and formability, making it ideal for the wire drawing process. It’s relatively inexpensive but may lack the ultimate strength of higher carbon steels.

- Medium Carbon Steel: Provides a balance between strength and ductility. It’s stronger than low-carbon steel, making it suitable for larger or heavier-duty nails.

- High Carbon Steel: Offers superior strength and hardness but is less ductile, meaning it’s more difficult to work with. This is used for specialized nails needing exceptional strength and resistance to bending or breaking, such as concrete nails.

- Alloy Steels: These steels contain additional elements like manganese, chromium, or nickel to enhance specific properties like corrosion resistance or toughness. For example, stainless steel nails, often used in outdoor applications, leverage this approach.

The choice of steel depends on the intended application of the nail. A simple picture frame might use low-carbon steel, while a construction project might require higher-carbon or alloy steel for increased durability.

Q 2. Describe the process of wire drawing in nail production.

Wire drawing is a crucial step in nail manufacturing, transforming thick steel wire into thinner, uniform wire suitable for nail making. It involves pulling the wire through a series of progressively smaller dies (metal plates with precisely sized holes).

The process begins with a coil of relatively thick steel wire. This wire is heated to a specific temperature, depending on the steel type, to improve its ductility and reduce the risk of breakage during drawing. Then, it’s fed through the first die, reducing its diameter. The process is repeated through several dies, each reducing the diameter further, until the desired wire gauge is achieved.

Lubricants are crucial in this process to reduce friction, prevent the wire from breaking, and ensure a smooth surface finish. The final drawn wire is then carefully inspected for defects before proceeding to the next stage of nail production. Imagine squeezing clay through a progressively narrower tube – that’s similar to how wire drawing works, albeit at a much higher level of precision and using specialized equipment.

Q 3. What are the key metallurgical properties influencing nail strength and durability?

Several metallurgical properties influence nail strength and durability. Understanding these is critical for selecting the appropriate steel and manufacturing processes.

- Tensile Strength: This measures the nail’s resistance to being pulled apart. Higher tensile strength means a stronger nail, less prone to pulling out of the material it’s fastened into.

- Yield Strength: Indicates the stress at which the nail starts to deform permanently. A higher yield strength prevents the nail from bending or deforming under load.

- Hardness: Determines the nail’s resistance to indentation and wear. Harder nails are less likely to deform when hammered or driven into dense materials.

- Ductility: This refers to the nail’s ability to deform plastically without breaking. While too much ductility can lead to bending, a reasonable level of ductility allows for better penetration and less breakage during hammering.

- Toughness: Represents the nail’s ability to absorb energy before fracturing. Tougher nails are less susceptible to sudden failure under impact.

These properties are interconnected and are carefully balanced during steel selection and heat treatment to achieve the optimal nail performance for a given application.

Q 4. How does heat treatment affect the properties of nails?

Heat treatment significantly alters the metallurgical properties of nails, thus influencing their final performance. The most common heat treatment for nails is controlled cooling after heating the steel. This process manages the microstructure of the steel, impacting its strength, hardness, and toughness.

Annealing: This process involves heating the steel to a specific temperature, holding it there for a period, and then slowly cooling it. Annealing softens the steel, making it easier to work with during subsequent processes like wire drawing. It relieves internal stresses developed during prior manufacturing steps.

Tempering: After hardening, tempering reduces brittleness, improving toughness while retaining the desired level of hardness. This step is crucial in achieving a balance between strength and ductility.

The specific heat treatment parameters, such as temperature and cooling rate, depend on the type of steel and desired nail properties. Improper heat treatment can lead to weakened nails prone to breakage or bending.

Q 5. Explain the different types of nail coatings and their purposes.

Nail coatings enhance various aspects of nail performance and aesthetics. These coatings are applied after the nails are formed.

- Zinc Coating (Galvanizing): This provides excellent corrosion resistance, protecting the nail from rusting, especially in outdoor or damp environments. It’s achieved through a hot-dip process where the nails are submerged in molten zinc.

- Electroplating: Different metals, such as zinc, copper, or nickel, can be electroplated onto the nail surface, creating a thin, uniform coating that provides corrosion protection and often an improved appearance.

- Paint Coatings: These coatings offer primarily aesthetic benefits, providing a variety of colors and finishes. They also might offer limited corrosion resistance, depending on the paint type.

- Polymer Coatings: These coatings can provide enhanced corrosion protection and improve the nail’s grip, making them easier to drive and preventing them from slipping during hammering.

The choice of coating depends on the intended use of the nails. For outdoor applications, zinc coatings or specialized polymer coatings are preferred, while for interior use, aesthetic coatings may suffice.

Q 6. Describe the quality control measures implemented during nail manufacturing.

Rigorous quality control is essential in nail manufacturing to ensure consistent quality and performance. Measures are implemented at every stage of the process, from raw material inspection to final product testing.

- Raw Material Inspection: Incoming steel coils are inspected for chemical composition, dimensions, and surface quality to ensure they meet the specified requirements.

- Process Monitoring: Parameters such as wire drawing speeds, die dimensions, and heat treatment temperatures are carefully monitored and controlled to maintain consistency.

- Dimensional Checks: Nails are regularly checked for length, diameter, and head dimensions using automated measuring equipment. Variations outside the acceptable tolerance are rejected.

- Strength Testing: Samples of nails are subjected to tensile and bending tests to assess their strength and durability.

- Visual Inspection: Nails are visually inspected for surface defects, such as cracks, bends, or burrs.

- Statistical Process Control (SPC): SPC techniques are used to monitor the manufacturing process and identify any trends indicating potential problems.

Data from these checks are meticulously recorded and analyzed to identify and correct any deviations from the established standards, ensuring that only high-quality nails reach the market.

Q 7. What are common defects found in nails and their causes?

Several defects can occur during nail manufacturing, and understanding their causes is vital for improving the process.

- Bending: Can be caused by improper wire drawing, insufficient heat treatment, or damage during handling.

- Cracking: May result from flaws in the raw material, improper heat treatment (making the steel too brittle), or excessive stresses during forming.

- Head Defects: Poor head forming can lead to inconsistencies in head size, shape, or attachment to the shank, potentially affecting holding power.

- Surface Defects: Scratches, burrs, or other surface imperfections can arise from friction during processing or handling. These imperfections can reduce the nail’s aesthetic appeal and potentially its performance.

- Point Defects: A poorly formed or damaged point can make driving the nail difficult and reduce holding power.

Identifying the root cause of these defects often involves carefully examining the manufacturing process, inspecting equipment, and analyzing the characteristics of the raw material. Implementing corrective measures then focuses on adjusting process parameters, improving equipment, and better quality control of raw materials.

Q 8. How do you troubleshoot issues related to nail breakage or bending?

Troubleshooting nail breakage or bending involves systematically investigating the manufacturing process and material properties. Breakage often points to flaws in the material’s tensile strength or a problem during the forming process, such as improper heat treatment or cold working. Bending, on the other hand, might indicate insufficient hardness or a design flaw.

- Material Analysis: We’d start by checking the chemical composition of the wire used to make the nails. Variations from the specified composition can significantly impact strength and ductility. Microscopic examination can reveal internal flaws like cracks or inclusions.

- Manufacturing Process Review: We’d then scrutinize the entire manufacturing process – from wire drawing to heading and pointing. Issues could include:

- Insufficient heat treatment: Leads to brittle nails prone to breakage.

- Improper cold working: Can introduce internal stresses, weakening the nail.

- Defective machinery: Malfunctioning dies or improper calibration can lead to inconsistencies in the nail’s dimensions and strength.

- Testing: Tensile strength and hardness tests are crucial. We’d compare the results against established standards to pinpoint the root cause. Bend tests can also evaluate the nail’s flexibility and resistance to deformation.

- Example: If nails are bending too easily, we might find that the wire used has a lower carbon content than specified, resulting in reduced hardness. Alternatively, an improperly adjusted heading die could be producing nails with thinner shanks, making them susceptible to bending.

By systematically analyzing these factors, we can identify the cause of the problem and implement corrective actions.

Q 9. Explain the role of surface treatment in nail corrosion resistance.

Surface treatment is crucial for enhancing the corrosion resistance of nails, extending their lifespan, and preventing premature failure, especially in harsh environments. This involves applying coatings that protect the underlying metal from oxidation.

- Galvanization (Zinc Coating): This is a common method where nails are dipped in molten zinc. The zinc acts as a sacrificial anode, meaning it corrodes preferentially to the steel, protecting the nail. The thickness of the zinc coating directly affects the nail’s longevity.

- Electroplating: This technique uses an electrolytic cell to deposit a thin layer of a protective metal, like zinc, cadmium, or copper, onto the nail surface. Electroplating provides a uniform and consistent coating.

- Painting or Coating with Organic Polymers: This method offers a barrier between the nail and the environment, preventing moisture and oxygen from reaching the steel. However, these coatings can chip or peel off over time, reducing their effectiveness.

- Chromating: A chemical conversion coating that forms a thin, protective layer of chromium compounds on the steel surface. It enhances corrosion resistance and provides a good base for paints or other coatings.

The choice of surface treatment depends on factors like the application environment, cost considerations, and desired level of protection. For example, galvanized nails are widely used in outdoor applications, while electroplated nails might be preferred where a smoother finish is required.

Q 10. What are the environmental considerations in nail manufacturing?

Environmental considerations in nail manufacturing are significant, focusing on minimizing waste, reducing energy consumption, and controlling emissions to safeguard both human health and the environment.

- Waste Management: Proper disposal of waste materials like metal shavings, spent chemicals, and packaging is crucial. Recycling of scrap metal is essential for sustainable practices.

- Energy Efficiency: Optimizing energy consumption in furnaces, machinery, and other processes is vital. Investing in energy-efficient equipment can significantly reduce the environmental footprint.

- Air and Water Pollution: Controlling emissions of particulate matter, gases, and wastewater from the manufacturing process is paramount. Implementing appropriate pollution control technologies is necessary to comply with environmental regulations.

- Sustainable Sourcing: Utilizing recycled steel and sourcing raw materials responsibly contribute to a smaller environmental impact.

- Noise Pollution: Reducing noise levels from machinery through proper design and noise control measures is important for worker safety and the surrounding environment.

Adopting environmentally friendly practices not only reduces the negative impact on the environment but also enhances the company’s sustainability credentials and reputation.

Q 11. Describe the process of nail point formation.

Nail point formation is a crucial step in nail manufacturing that determines its penetration ability and ease of driving. It typically involves a specialized die and a high-pressure process.

The process generally involves the following steps:

- Cold Heading: The wire is initially cold-headed to form the nail head. The remaining portion is the shank.

- Pointing: The shank end is then fed into a pointing die. This die is shaped to create the desired nail point profile (e.g., diamond point, chisel point, or brad point).

- Forging or Extrusion: The die squeezes and shapes the metal, gradually forming the point. The process is done at room temperature, relying on the plasticity of the metal.

- Die Design: The die’s design determines the nail point’s geometry and sharpness, significantly influencing its driving characteristics.

Properly formed points are crucial for minimizing splitting of the wood when driving the nail. A sharp, well-formed point reduces the force required for penetration.

Q 12. What are the different types of nail heads and their applications?

Nail heads vary in shape and size, tailored for different applications. The head design influences the nail’s holding power, appearance, and ease of driving.

- Common Nail Heads:

- Round Head: The most common type, suitable for general carpentry and construction.

- Flat Head: Sits flush against the surface, ideal for finishing work where a smooth, even surface is desired.

- Oval Head: A compromise between round and flat heads, offering a balance between holding power and a relatively low profile.

- Brads: Small nails with very small heads, mainly used for trim work and fine carpentry.

- Finishing Nails: Small nails with a narrow head, designed for situations where a small, less visible head is needed.

- Specialty Nail Heads:

- Rose Head: Decorative nail head with a raised, ornamental design.

- Clout Nails: Large, heavy nails with large heads, often used for outdoor applications.

The selection of nail head depends on the application and the aesthetic requirements of the project. For instance, flat-head nails would be used for interior trim to ensure a smooth finish, while round-head nails are more appropriate for rougher work where holding power is paramount.

Q 13. How does the nail’s shank diameter influence its holding power?

The shank diameter, or thickness, of a nail directly impacts its holding power. A larger diameter shank provides a greater surface area in contact with the wood, increasing friction and resistance to withdrawal.

Think of it like this: a thicker nail is like a wider screw thread; it has more material to grip the wood fibers. This increased surface area results in:

- Increased Friction: The larger contact area increases the frictional resistance between the nail and the wood, making it harder to pull out.

- Greater Wood Fiber Engagement: A thicker shank engages more wood fibers, creating a stronger mechanical interlocking.

- Reduced Shear Stress: The larger cross-sectional area of the shank reduces the shear stress experienced by the nail when subjected to lateral forces.

However, using excessively thick nails might lead to wood splitting, so finding the right balance between holding power and minimizing wood damage is critical.

Q 14. Explain the concept of tensile strength in relation to nails.

Tensile strength is a crucial measure of a nail’s ability to withstand pulling forces. It represents the maximum stress a nail can endure before it breaks when being pulled apart. A higher tensile strength indicates a stronger, more reliable nail.

In the context of nail manufacturing, tensile strength is directly related to the:

- Material Composition: The type and amount of alloying elements in the steel, such as carbon, significantly affect its tensile strength.

- Manufacturing Process: Proper heat treatment and cold working during the manufacturing process are essential for achieving the desired tensile strength.

- Nail Design: The nail’s dimensions, especially the shank diameter, also influence its overall tensile strength.

Testing for tensile strength involves applying a controlled pulling force to a nail until it breaks. The force at which it breaks is then used to calculate the tensile strength. Nails with higher tensile strength are more resistant to being pulled out from the wood, increasing their overall performance and reliability.

Q 15. What are the safety considerations in nail manufacturing?

Safety in nail manufacturing is paramount, encompassing a multitude of hazards. The primary concerns revolve around the high-speed machinery involved, the sharp nature of the product itself, and the potential exposure to hazardous materials.

- Machinery Hazards: The manufacturing process involves heavy machinery with moving parts, posing risks of entanglement, crushing, and amputation. Strict adherence to lockout/tagout procedures is critical during maintenance and repair. Regular safety inspections and operator training are essential.

- Sharp Objects: Nails themselves are inherently sharp. Proper handling procedures, including the use of appropriate personal protective equipment (PPE) such as cut-resistant gloves and safety glasses, are mandatory to prevent punctures and injuries. Furthermore, the workplace should be kept clean and free of debris to minimize the risk of slips and falls on sharp objects.

- Hazardous Materials: Depending on the type of nail being produced (e.g., galvanized, coated), workers may be exposed to chemicals like zinc (in galvanizing) or coatings containing volatile organic compounds (VOCs). Proper ventilation, the use of respirators where appropriate, and adherence to relevant safety data sheets (SDS) are non-negotiable.

- Noise Pollution: The machinery used in nail manufacturing often generates significant noise. Hearing protection is essential for workers to prevent hearing loss over time. Regular hearing tests are recommended.

Effective safety management requires a proactive approach including regular safety audits, employee training, and the implementation of robust safety protocols to mitigate these hazards.

Career Expert Tips:

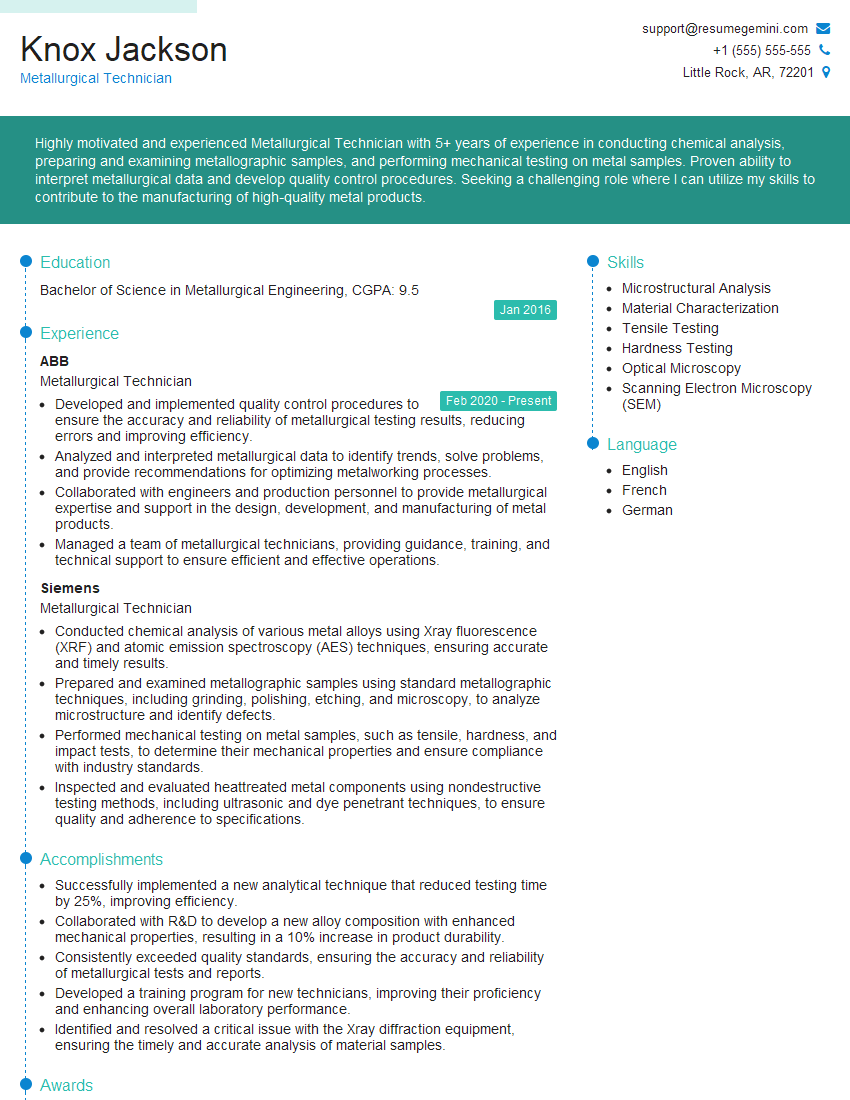

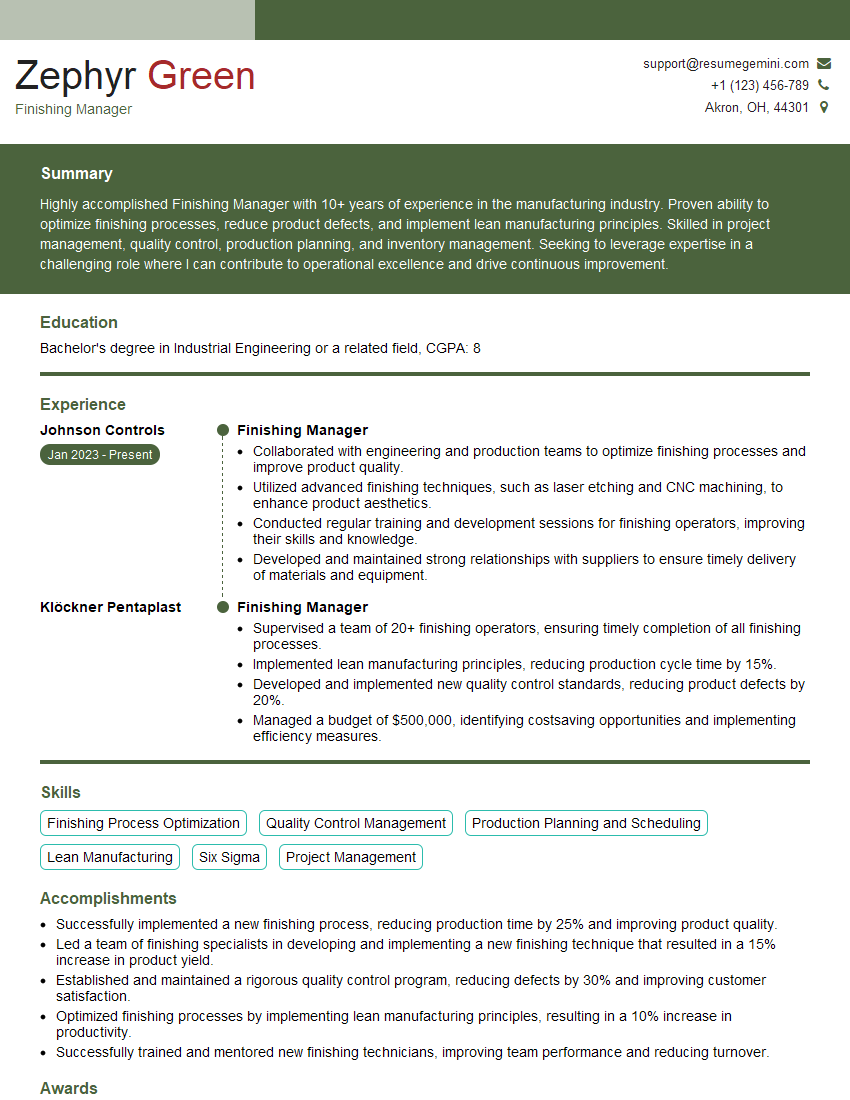

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure consistency in nail dimensions during production?

Maintaining consistent nail dimensions is crucial for quality control and functionality. This is achieved through a combination of precise machinery settings, rigorous quality control measures, and the use of advanced measuring tools.

- Precise Machine Calibration: The wire drawing and cutting machinery needs to be meticulously calibrated. This includes setting the wire feed rate, the cutting die dimensions, and the head’s punching pressure to consistently produce nails of the specified length, diameter, and head shape.

- Automated Quality Control: Modern nail manufacturing often incorporates automated inspection systems. These systems use sensors and image processing to detect deviations from the specified dimensions. Nails outside the acceptable tolerance range are automatically rejected.

- Regular Monitoring: Even with automation, human oversight is important. Regular checks using precision measuring tools (e.g., micrometers, calipers) are performed to ensure the continued accuracy of the machines and identify any potential drifts in dimensions.

- Material Consistency: Maintaining consistent input material is also vital. Fluctuations in wire diameter due to variations in the raw material can impact nail dimensions. Strict quality control of the incoming wire is therefore critical.

Imagine baking a cake: You’d use a precise recipe and carefully measure ingredients to ensure consistent results. Nail manufacturing employs similar principles for dimensional consistency.

Q 17. Describe the role of automation in nail manufacturing.

Automation has revolutionized nail manufacturing, increasing productivity, improving quality control, and enhancing worker safety. Various stages of the process have been automated, leading to significantly higher output and improved precision compared to manual methods.

- Wire Feeding and Cutting: Automated systems precisely feed wire into the cutting and heading machinery, ensuring a consistent flow of material and reducing the risk of human error.

- Heading and Pointing: The forming of the nail head and point is often automated, resulting in uniform shapes and sizes.

- Quality Control Inspection: As previously mentioned, automated inspection systems rapidly check dimensions, detect defects, and reject substandard nails.

- Packaging and Handling: Automated systems handle the sorting, counting, and packaging of nails, increasing efficiency and reducing manual labor.

Automation not only speeds up the process but also reduces human error, leading to a more consistent and higher-quality product. It also creates a safer working environment by minimizing human interaction with high-speed machinery.

Q 18. Explain different types of nail manufacturing machinery.

Nail manufacturing machinery can be broadly categorized into several types, each performing a specific function in the overall process.

- Wire Drawing Machines: These machines reduce the diameter of the raw wire to the required size for nail production.

- Straightening Machines: These machines straighten the wire to eliminate any kinks or bends before the cutting and forming process.

- Cutting Machines: These machines cut the straightened wire into the required lengths for individual nails. They are often integrated with the heading machine.

- Heading Machines: These machines form the heads of the nails by striking the cut wire with a die. They are usually highly automated and can produce thousands of nails per hour.

- Pointing Machines: These machines shape the points of the nails, often integrated with the heading machine.

- Galvanizing Machines (for galvanized nails): These machines apply a protective zinc coating to the nails to enhance their corrosion resistance. This typically involves a process of dipping the nails in a molten zinc bath.

- Coating Machines (for coated nails): These machines apply various coatings such as paint or polymers to improve aesthetics or performance.

- Packaging Machines: These automate the counting, sorting, and packaging of nails.

The complexity and automation level of these machines vary depending on the scale and sophistication of the manufacturing facility. Smaller operations might use simpler, manually operated machines, while larger facilities rely on highly automated, integrated systems.

Q 19. What are the advantages and disadvantages of using different nail materials?

Different nail materials offer various advantages and disadvantages in terms of cost, strength, corrosion resistance, and other properties.

- Steel Nails: These are the most common type, offering a good balance of strength and cost. However, they are susceptible to rust unless galvanized or coated.

- Galvanized Steel Nails: The zinc coating provides excellent corrosion resistance, making them suitable for outdoor use. The galvanizing process adds to the cost.

- Stainless Steel Nails: These nails offer superior corrosion resistance compared to galvanized steel, but are significantly more expensive.

- Aluminum Nails: These are lightweight and corrosion-resistant, often used in applications where weight is a concern, such as aluminum siding. However, they are generally less strong than steel nails.

- Brass Nails: These nails are corrosion-resistant and offer a decorative finish. Their use is often limited to specialized applications due to their relatively high cost.

The choice of material depends on the specific application. For example, galvanized steel nails are ideal for construction projects exposed to the elements, while stainless steel nails might be preferred for marine applications requiring exceptional corrosion resistance.

Q 20. How do you assess the hardness of nails?

The hardness of nails is typically assessed using standardized hardness testing methods. The most common is the Rockwell hardness test.

The Rockwell hardness test indents the nail’s surface with a precisely calibrated indenter under a specific load. The depth of indentation is measured, and this value is used to determine the hardness according to a pre-defined scale (e.g., Rockwell C scale for harder materials). The higher the Rockwell number, the harder the material.

Other methods such as the Brinell or Vickers hardness tests can also be used, although Rockwell is more common for nails due to its relative simplicity and speed. The hardness is crucial because it directly influences the nail’s strength and its ability to penetrate materials without bending or breaking.

Testing is usually performed on samples taken from the production run. This helps ensure that the hardness remains within acceptable limits and that the nails meet the required strength specifications.

Q 21. Describe the process of galvanizing nails.

Galvanizing nails is a crucial process for enhancing their corrosion resistance. It involves coating the nails with a layer of zinc through a process called hot-dip galvanizing.

- Cleaning: The nails are first cleaned to remove any dirt, grease, or mill scale that might prevent proper adhesion of the zinc coating.

- Fluxing: A flux (a chemical cleaning agent) is applied to the nails to further clean the surface and help the zinc to adhere better.

- Hot-Dip Galvanizing: The cleaned and fluxed nails are then immersed in a bath of molten zinc at a temperature typically around 840°F (450°C). The zinc melts and adheres to the surface of the nails, forming a protective coating.

- Cooling and Finishing: After the galvanizing process, the nails are cooled and then may undergo further processing, such as passivation (a treatment to improve corrosion resistance further).

The thickness of the zinc coating can be controlled by adjusting the time the nails spend in the molten zinc bath. This thickness determines the level of corrosion protection. Hot-dip galvanizing provides a durable, long-lasting coating that significantly extends the lifespan of the nails, especially in outdoor environments.

Q 22. How do you handle and resolve customer complaints related to nail quality?

Handling customer complaints about nail quality begins with a structured approach emphasizing empathy and thorough investigation. First, I acknowledge the customer’s frustration and assure them their concern is important. Then, I gather detailed information about the issue: the type of nail, the quantity affected, the specific defect (e.g., bending, breakage, surface flaws), and the application method. This helps pinpoint the root cause.

Next, I visually inspect the sample nails, paying attention to metallurgical aspects. Are there inconsistencies in the heat treatment leading to brittleness? Are there inclusions or imperfections in the raw material (wire)? Is there evidence of improper handling or storage leading to damage? I might even use a microscope for closer examination. Based on this analysis, I determine if the problem stems from raw material, the manufacturing process, or post-production handling.

Depending on the findings, I’ll initiate corrective actions. This might involve adjusting the heat treatment parameters, refining the wire drawing process, improving quality control checks, or retraining personnel. We document every step, from the initial complaint to the resolution, ensuring we learn from the experience and prevent similar issues in the future. If necessary, a full refund or replacement is provided. Maintaining a strong customer relationship is paramount, so I always follow up after the resolution to confirm their satisfaction and build trust.

Q 23. What is your experience with statistical process control (SPC) in a manufacturing environment?

Statistical Process Control (SPC) is fundamental to nail manufacturing. My experience involves implementing and maintaining SPC charts – specifically, control charts like X-bar and R charts – to monitor critical quality characteristics such as nail diameter, length, and tensile strength. These charts track the process’s central tendency and variability over time, allowing us to detect shifts in the process before they result in significant product defects.

For instance, we might monitor the diameter of nails produced on a specific machine. If data points fall outside the control limits of our X-bar and R charts, it signals a potential problem – perhaps a worn-out die, a change in raw material properties, or a machine malfunction. This early warning allows for timely intervention, preventing the production of a large batch of non-conforming nails. We’d investigate the root cause (as discussed below) and implement corrective actions. SPC isn’t just about reacting to problems; it’s also about identifying opportunities for process improvement and reducing variability, ultimately leading to higher quality and yield.

Q 24. Explain your experience with root cause analysis in a manufacturing setting.

Root cause analysis (RCA) is crucial for preventing recurring quality issues. I’m proficient in various RCA methodologies, including the 5 Whys, fishbone diagrams (Ishikawa diagrams), and fault tree analysis. Let’s illustrate with an example. Suppose we experience a higher-than-acceptable rate of nail breakage. We’d begin our RCA by asking ‘Why are the nails breaking?’

Using the 5 Whys, we might find:

- Why are the nails breaking? Because they lack sufficient tensile strength.

- Why is the tensile strength insufficient? Because the heat treatment process is inconsistent.

- Why is the heat treatment inconsistent? Because the furnace temperature control system is malfunctioning.

- Why is the temperature control system malfunctioning? Because of a faulty sensor.

- Why is the sensor faulty? Because it wasn’t properly calibrated during preventative maintenance.

This leads us to the root cause: inadequate preventative maintenance of the temperature control system. By addressing this root cause (replacing the sensor and improving calibration procedures), we resolve the problem and prevent future occurrences. Documenting the RCA process is critical for sharing knowledge and improving our preventative maintenance strategy.

Q 25. Describe your understanding of lean manufacturing principles.

Lean manufacturing principles aim to maximize customer value while minimizing waste. In a nail manufacturing context, this translates to eliminating activities that don’t add value to the final product. My understanding encompasses several lean concepts:

- Value Stream Mapping: Identifying and eliminating non-value-added steps in the nail production process, from raw material delivery to finished product shipment.

- 5S Methodology: Implementing a system for workplace organization (Sort, Set in Order, Shine, Standardize, Sustain) to improve efficiency and reduce waste.

- Kanban: Using a visual signaling system to manage inventory and workflow, preventing overproduction and reducing lead times.

- Kaizen (Continuous Improvement): Constantly seeking small, incremental improvements in all aspects of the manufacturing process. This includes worker involvement in identifying and resolving inefficiencies.

For example, implementing Kanban in our raw material supply chain ensures we only order the necessary amount of wire at any given time, reducing storage costs and minimizing waste. Regularly engaging in Kaizen events empowers employees to suggest and implement improvements, fostering a culture of continuous improvement and engagement.

Q 26. How do you manage production schedules and deadlines in a fast-paced manufacturing environment?

Managing production schedules and deadlines in a fast-paced environment requires careful planning, effective communication, and a proactive approach. I utilize project management tools and techniques, such as Gantt charts, to visually represent tasks, dependencies, and deadlines. This helps to clearly identify critical path activities and potential bottlenecks.

Regular meetings with production teams are vital to track progress, identify emerging issues, and make necessary adjustments. We use a combination of push and pull systems, responding to real-time demands while maintaining planned production targets. Real-time monitoring of key performance indicators (KPIs), such as production rate, defect rate, and machine uptime, enables prompt identification and resolution of potential delays.

Moreover, clear communication between different departments (e.g., purchasing, production, quality control, shipping) is crucial. This prevents unexpected delays due to missing materials or equipment failures. Proactive risk management, including contingency planning for potential disruptions (e.g., supply chain issues, equipment breakdowns), is also crucial in maintaining schedules and meeting deadlines.

Q 27. Describe a time you had to solve a complex problem in a manufacturing setting.

One challenge involved a sudden increase in customer returns due to nail bending. Initial investigations focused on the manufacturing process, but adjustments yielded little improvement. We employed a systematic root cause analysis, involving detailed metallurgical analysis of the returned nails and process parameter monitoring. It turned out that a recent change in the wire supplier had introduced subtle variations in the wire’s metallurgical composition, specifically in its carbon content.

The solution required collaborative efforts between our team, the wire supplier, and a metallurgical consultant. We analyzed the wire’s composition and its impact on the nail’s bending strength. This led to a revision in our heat treatment process to compensate for the slight differences in the wire’s properties. We also implemented more stringent incoming quality control checks on the wire to ensure consistent quality. The problem was eventually resolved, strengthening our relationships with suppliers and improving our overall quality control process. This experience highlighted the importance of a multi-disciplinary approach to problem-solving and the value of strong supplier relationships.

Q 28. What are your salary expectations?

My salary expectations are commensurate with my experience and skills in metallurgy, nail manufacturing, and lean management. Based on my research and understanding of the industry standards, I am targeting a salary range of [Insert Salary Range Here]. However, I’m open to discussing this further based on the specifics of the role and compensation package.

Key Topics to Learn for Your Knowledge of Metallurgy and Nail Manufacturing Interview

- Iron and Steel Metallurgy: Understanding the basics of iron and steel production, including the various processes like the Bessemer process, basic oxygen furnace, and electric arc furnace. Focus on the properties of different steel grades and their suitability for nail manufacturing.

- Material Properties and Testing: Familiarize yourself with tensile strength, yield strength, hardness, ductility, and impact resistance. Understand common testing methods used to determine these properties and their relevance to nail quality and performance.

- Heat Treatment: Learn about annealing, quenching, and tempering processes and how they affect the mechanical properties of steel wire used for nail production. Understand the importance of heat treatment in achieving desired nail characteristics like strength and flexibility.

- Wire Drawing and Nail Manufacturing Processes: Study the different stages involved in converting steel wire into nails, from wire drawing and heading to pointing and finishing. Understand the machinery involved and potential challenges in each step.

- Quality Control and Assurance: Explore the various quality control measures employed in nail manufacturing, including inspection techniques and methods to minimize defects. Understand industry standards and certifications related to nail quality.

- Defect Analysis and Troubleshooting: Develop your ability to identify common defects in nails and troubleshoot issues in the manufacturing process. This includes understanding the root causes of defects and implementing corrective actions.

- Cost Optimization and Production Efficiency: Explore strategies for optimizing production processes to minimize costs while maintaining high quality. This includes understanding energy efficiency and waste reduction techniques.

- Safety Regulations and Practices: Understand relevant safety regulations and best practices related to nail manufacturing, including machinery operation and handling of materials.

Next Steps

Mastering the knowledge of metallurgy and nail manufacturing significantly enhances your career prospects within this specialized industry. A strong understanding of these areas positions you for roles with greater responsibility and higher earning potential. To maximize your chances of securing your dream job, creating a compelling and ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional and impactful resume. We offer examples of resumes tailored to the Knowledge of Metallurgy and Nail Manufacturing field to guide you. Take the next step in your career journey – craft a resume that showcases your expertise and gets you noticed.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good