Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Nailing Machine Operation interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Nailing Machine Operation Interview

Q 1. What types of nailing machines have you operated?

Throughout my career, I’ve operated a wide variety of nailing machines, ranging from pneumatic coil nailers commonly used in framing to heavier-duty framing nailers and specialized flooring nailers. I’ve also gained experience with smaller, more precise finish nailers for intricate woodwork. My experience includes both manual and automated systems. For example, I’ve worked extensively with Senco, Paslode, and Hitachi brands, each with their own unique operating characteristics and maintenance requirements. This diverse experience allows me to adapt quickly to different machinery and project needs.

Q 2. Describe your experience with different nail types and sizes.

My experience encompasses a broad spectrum of nail types and sizes. I’m proficient in using various nail sizes, from the small brads used in finish carpentry (e.g., 18-gauge brad nails) to the larger, heavier-duty nails used in framing (e.g., 16d common nails). I’m familiar with different nail materials, including steel, galvanized steel (for outdoor applications to resist rust), and even specialized nails like ring-shank nails for enhanced holding power. I understand how different nail types impact the overall strength and aesthetic quality of the finished product. For instance, choosing the wrong nail for a specific application could lead to splitting the wood or not achieving sufficient hold.

Q 3. How do you ensure consistent nail placement and depth?

Consistent nail placement and depth are crucial for both structural integrity and a professional finish. To achieve this, I focus on several key areas. First, I carefully adjust the nailer’s depth-of-drive setting according to the wood’s thickness and the nail length. Second, I maintain a firm grip on the nailer and ensure proper contact with the work surface before driving the nail. Third, I use a consistent, controlled trigger action to avoid inconsistencies in nail penetration. Finally, regular checks of the nailer’s performance throughout the day ensure consistent results. For example, if I notice even a slight change in nail placement, I immediately re-check and adjust the settings to maintain accuracy.

Q 4. Explain your process for troubleshooting malfunctioning nailing machines.

Troubleshooting nailing machine malfunctions involves a systematic approach. My first step is to identify the specific problem. Is the nailer jamming, misfiring, or not driving nails at all? Then I conduct visual inspections, checking for things like clogged air lines (for pneumatic nailers), bent or damaged nails in the magazine, or a faulty trigger mechanism. I also check the air pressure (for pneumatic nailers) to make sure it’s within the manufacturer’s specified range. If the problem persists, I might refer to the machine’s manual for more detailed troubleshooting steps, or consult with experienced colleagues. In one instance, I had a nailer that kept misfiring. After checking all the obvious things, I found a small piece of debris lodged in the firing mechanism. Removing this debris solved the issue immediately.

Q 5. What safety measures do you employ while operating a nailing machine?

Safety is my top priority when operating nailing machines. I always wear safety glasses to protect my eyes from flying debris. Hearing protection is also essential due to the noise generated by these machines. Furthermore, I ensure the work area is clear of obstructions and that I maintain a firm grip on the tool to prevent accidental discharge. I never point the nailer at myself or others. Before each use, I inspect the nailer for any signs of damage or wear, and I adhere strictly to the manufacturer’s safety guidelines. Regularly maintaining the equipment significantly reduces the likelihood of accidents.

Q 6. How do you maintain the optimal performance of your nailing machine?

Maintaining optimal nailer performance involves regular cleaning and lubrication. For pneumatic nailers, I regularly inspect and clean the air lines, ensuring there are no blockages. I lubricate moving parts as recommended by the manufacturer, using the appropriate lubricant. I also regularly inspect the nail magazine for jams or damage. Replacing worn parts promptly is critical. Neglecting maintenance can lead to decreased efficiency, increased risk of malfunctions, and ultimately, safety hazards. A well-maintained nailer is more efficient, accurate, and much safer to operate.

Q 7. What is your experience with preventative maintenance on nailing machines?

Preventative maintenance is crucial for extending the life and ensuring the safe operation of nailing machines. This includes regular inspections, cleaning, and lubrication as mentioned before, but also goes further. I check for wear and tear on critical components like the driving mechanism and the magazine. I also follow the manufacturer’s recommended maintenance schedule for things like replacing worn seals or belts. This proactive approach helps prevent unexpected breakdowns and costly repairs. For example, I once noticed a slight wear on the drive mechanism of a nailer during a routine inspection. Replacing it proactively prevented a costly and potentially dangerous malfunction down the line.

Q 8. Describe your experience with different types of wood and their impact on nailing.

Different wood types significantly impact nailing. Hardwoods like oak and maple are dense and require more force for nail penetration, potentially leading to nail bending or machine damage if not properly adjusted. Softwoods like pine and fir are easier to nail, but can also be prone to splitting if the nail is too large or driven too forcefully. The grain direction also plays a crucial role; nailing across the grain is more likely to cause splitting than nailing with the grain.

For example, when working with oak, I’d use a heavier-duty nailer and potentially a smaller nail size to avoid bending or splitting. Conversely, with pine, I could use a slightly larger nail and adjust the depth to prevent excessive penetration and potential surface damage.

- Hardwoods: Oak, Maple, Hickory – require higher driving force, smaller nails, risk of bending.

- Softwoods: Pine, Fir, Spruce – easier to nail, potential for splitting, larger nails possible.

- Grain Direction: Nailing with the grain minimizes splitting risk.

Q 9. How do you adjust nailing machine settings for different materials?

Adjusting nailing machine settings depends on the material and nail type. Key settings include pressure, depth, and sometimes even the angle of the drive. For harder woods, I increase the air pressure (for pneumatic nailers) or motor power (for electric nailers) to ensure proper nail penetration. The depth setting must also be adjusted to avoid driving the nail completely through the material or leaving it protruding. For softer woods, lower pressure and shallower depths are usually sufficient. The nail size itself is also a crucial factor: larger nails require more force.

Imagine nailing thin plywood versus a thick piece of hardwood. With plywood, you need a gentle setting to avoid going straight through; with hardwood, you’ll need significantly more power to embed the nail properly. I always test the settings on a scrap piece of the same material before starting the main project to fine-tune the process.

Q 10. What are the common causes of jams or malfunctions in nailing machines?

Jams and malfunctions in nailing machines stem from various causes. A common issue is the accumulation of dust and debris, especially in the nailing mechanism. This can clog the nail feed, preventing nails from advancing correctly. Another problem is worn or damaged parts like the driver blade or the air hose connection (for pneumatic nailers). Low air pressure or power supply issues can also lead to malfunctions. Improper nail loading or using nails of the wrong size or type can also frequently lead to jams and failures.

- Dust/Debris Buildup: Regular cleaning is crucial.

- Worn Parts: Requires timely replacement or maintenance.

- Low Air Pressure/Power: Check power sources and pressure gauges.

- Incorrect Nail Loading: Follow manufacturer instructions carefully.

- Incompatible Nail Size/Type: Use the nails specified for the machine.

Q 11. How do you handle production rate targets while maintaining quality?

Balancing production rate and quality demands a systematic approach. It’s not just about speed; consistency is key. I prioritize a consistent, high-quality output. I usually begin with a careful setup of the machine according to the material and work with a smaller batch to make sure the settings are accurate and the machine is working smoothly before ramping up. Throughout the process, I regularly inspect the finished product and the machine’s functionality to catch any potential issues. If there are even subtle signs of quality degradation, I immediately adjust the settings or investigate the cause of the problem rather than pushing for a higher rate of output. Effective communication with the team about any issues encountered and any necessary adjustments ensures that everyone remains aligned with the quality and production goals.

Think of it like baking a cake: you wouldn’t rush the process just to finish quicker, right? The same applies to nailing. Maintaining quality creates a better end product, reducing rework and waste in the long run. It can reduce project costs and increase the overall customer satisfaction.

Q 12. Describe your experience with pneumatic nailing machines.

I have extensive experience with pneumatic nailing machines. I’m proficient in operating various models, from lightweight finish nailers to heavy-duty framing nailers. My expertise includes understanding the air pressure requirements, lubrication procedures, and troubleshooting common pneumatic issues like air leaks. I understand the importance of regularly checking the air compressor, hoses, and fittings to ensure consistent and efficient operation. I’m also skilled in adjusting the air pressure to achieve optimal nailing performance for different materials and nail sizes. I’ve worked with various pneumatic systems ensuring proper maintenance and the safe handling of the equipment. One notable project involved using a high-volume framing nailer to complete a large-scale construction project, where the efficient operation of the pneumatic system was crucial for meeting tight deadlines.

Q 13. Explain your understanding of safety regulations related to nailing machine operation.

Safety is paramount when operating nailing machines. I adhere strictly to all safety regulations, including wearing appropriate personal protective equipment (PPE) like safety glasses and hearing protection. I ensure the work area is clear of obstructions and that the machine is properly grounded (if electric). Before starting any operation, I always check that the machine is in good working condition, with no obvious defects. I understand the importance of regular maintenance to prevent accidents, including inspecting hoses and checking for air leaks (on pneumatic models) and checking the electrical wiring (on electric models). Knowing the machine’s limitations is vital, and I never attempt to force the machine or use it beyond its capabilities. I familiarize myself with all relevant emergency procedures, including how to shut down the machine quickly in case of a malfunction and how to quickly respond in case of any injuries.

Q 14. How do you identify and report defects or malfunctions?

Defect identification is a crucial aspect of my work. I visually inspect each piece after nailing, checking for inconsistencies such as misaligned nails, protruding nails, or damaged wood. I use a systematic approach, paying close attention to details. If any defects are found, I immediately stop the process and report the issue through the appropriate channels. A detailed report including the nature of the defect, its location, the potential cause, and the number of affected pieces is crucial. I would often include photos or videos documenting the defect. This information is vital in addressing the root cause and preventing future occurrences. Sometimes, even subtle issues can indicate a larger problem with the machine or the process. I always prioritize proactive identification and reporting to ensure continuous quality control.

Q 15. What is your experience with coil nailers versus stick nailers?

Coil nailers and stick nailers are two fundamental types of nailing machines, each with its own strengths and weaknesses. Coil nailers use a long coil of nails, offering faster operation for high-volume jobs like framing. Think of it like a continuous roll of stamps – efficient and quick. Their speed comes at the cost of slightly less nail control. Stick nailers, on the other hand, require individual nail sticks to be loaded, making them better suited for precision work where nail placement is paramount, like furniture assembly or fine carpentry. This is akin to using individual stamps – slower, but allows for more control over placement. My experience encompasses extensive use of both; I’ve used coil nailers for large-scale construction projects, rapidly securing framing lumber, while I’ve relied on stick nailers for tasks requiring exact placement and less risk of mis-driving nails.

For instance, in one project framing a large house, the speed and efficiency of a coil nailer were essential to meet the project deadlines. However, for later interior trim work, where precision was key, I switched to a stick nailer to avoid damaging the finished surfaces.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure the quality and consistency of the finished product?

Ensuring quality and consistency in a finished product nailed with pneumatic tools hinges on several key aspects. First, proper machine maintenance is crucial. Regular lubrication, checking for air leaks, and ensuring the machine’s ability to drive nails consistently without jamming are paramount. Second, nail selection plays a vital role. The nail type must match the material being fastened; using the wrong size or type can lead to splitting or poor hold. Finally, consistent technique is essential. Maintaining proper stance, angle, and pressure prevents misfires or poorly driven nails. I always perform a test shot on scrap material before beginning any project to ensure the machine’s performance and avoid mistakes. A regular inspection of the finished work for protruding or improperly driven nails is also crucial.

In one instance, a slightly misaligned nail in the framing of a wall led to a significant amount of rework; hence my emphasis on maintaining consistent pressure and proper angle. By meticulously inspecting and correcting these small errors during the nailing process, I significantly reduce the likelihood of costly repairs or failures later on.

Q 17. Describe your experience with different types of nail guns.

My experience spans a wide range of nail guns, including framing nailers (both coil and stick), finish nailers, brad nailers, and roofing nailers. Framing nailers are workhorses designed for high-volume nailing into lumber, boasting high power. Finish nailers provide more precise placement of smaller nails, ideal for trim and cabinetry. Brad nailers utilize even smaller nails for finer applications. Roofing nailers are designed specifically for attaching roofing shingles and other roofing materials, requiring specialized features to penetrate tougher materials securely. Each tool has its unique applications and operating nuances; I’m adept at selecting the right tool for the specific task and material.

For example, I wouldn’t use a finish nailer to frame a wall; it lacks the power and the nails would be unsuitable for the task. Understanding the tool’s limitations and its suitable applications is key to efficiency and safety.

Q 18. What is your experience with using different types of nails?

My experience covers various nail types, each with specific applications. Common types include galvanized nails for outdoor use (resisting rust), coated nails for improved grip and driveability, and stainless steel nails for high-corrosion environments. The choice depends on the material being fastened and the project’s environmental exposure. I’ve used various lengths, gauges, and head styles, adapting to different needs. A thicker nail, for example, is better for hardwood, while a thinner nail might be suitable for softer wood to prevent splitting. The right choice significantly influences the final product’s strength and durability.

I once used the wrong type of nail in a deck project, which resulted in premature failure due to rust. Since then, I meticulously check the material properties and the appropriate nail type for every project.

Q 19. How do you address quality control issues related to nailing?

Addressing quality control issues in nailing involves a multi-pronged approach. First, regular visual inspections during and after nailing are crucial, checking for misdriven, protruding, or improperly placed nails. Second, if inconsistencies are found, identifying the root cause is critical. Is it a faulty nail gun needing repair or maintenance? Is the nail selection inappropriate? Is the nailing technique inconsistent? Third, corrective actions need to be immediately implemented. This could involve switching to a new tool, adjusting the pressure settings, or retraining the technique. Documenting these issues and their resolutions is also essential for preventing future occurrences. A proactive approach is far more effective than reacting to problems after they’ve caused significant damage.

In one instance, a consistent pattern of slightly bent nails led me to discover a problem with the air compressor’s pressure regulator; a simple repair prevented further damage and ensured consistently straight nails.

Q 20. Describe your experience working with different types of fasteners.

Beyond nails, my experience extends to other fasteners used in conjunction with nailing machines. This includes staples (for various applications, particularly upholstery and light framing) and screws (when increased holding power is needed). I understand the strengths and limitations of each fastener and choose appropriately. Staples offer speed and ease for certain applications where high holding strength isn’t critical. Screws provide superior holding power, especially in hardwoods or when dealing with high stress applications, often complementing or supplementing nailing in such instances. The choice is determined by the project requirements and the materials involved.

For example, I’ve used staples to secure roofing underlayment and screws to fasten deck boards onto joists for maximum strength and stability.

Q 21. What are the common problems you face when operating a nailing machine?

Common problems encountered during nailing machine operation include jams caused by bent nails, poor lubrication, or low air pressure. Misfires can result from incorrect depth settings or insufficient air pressure. Additionally, nail splitting occurs frequently when using the wrong nail size or type for the material. Safety issues, such as accidental nail discharge, are always a concern and necessitate proper training and adherence to safety guidelines. Regular maintenance, including cleaning, lubrication, and pressure checks, significantly reduces these issues. Proactive maintenance and attention to detail are essential for efficient and safe operation.

Once I experienced a series of misfires which turned out to be due to a clogged air hose. Addressing this simple issue quickly prevented further problems and safety hazards.

Q 22. How do you troubleshoot and resolve those problems?

Troubleshooting nailing machine problems requires a systematic approach. I begin by identifying the symptom – is it misfires, jams, slow operation, or something else? Then, I isolate the potential cause. This often involves checking the obvious first: Is the air compressor running properly and supplying sufficient pressure? Is the nail magazine full and properly loaded? Are the nails the correct size and type for the machine?

- Misfires: Often caused by low air pressure, a clogged air line, a faulty trigger mechanism, or a damaged firing mechanism. I’d check each systematically, starting with the air supply.

- Jams: Usually due to bent or damaged nails, a build-up of debris, or incorrect nail loading. Cleaning the machine and inspecting the nails is key here.

- Slow Operation: Could be due to low air pressure, a clogged air line, or a worn-out motor. Checking air pressure and inspecting the air lines is the first step.

Once the problem is identified, the solution often involves simple fixes like clearing a blockage, replacing a worn part, or adjusting air pressure. For more complex issues, I would consult the machine’s manual or seek assistance from a qualified technician.

Q 23. What is your experience with reading and interpreting schematics for nailing machines?

I’m proficient in reading and interpreting schematics for nailing machines. Schematics provide a visual representation of the machine’s components, their connections, and their functionality. Understanding these diagrams allows me to quickly diagnose problems, trace electrical circuits, and understand the machine’s overall working mechanism. I can identify individual components, follow the air pathways, and even understand the sequencing of the firing mechanism from the schematic.

For example, a schematic might show the path of compressed air from the compressor, through valves, and into the firing chamber. By following the lines on the schematic, I can easily pinpoint potential leaks or blockages. I can use the schematics effectively to trace wires, identify relays and solenoids, and comprehend the overall machine’s sequence of operation. This knowledge enables efficient troubleshooting and repair.

Q 24. How familiar are you with various nailing machine brands and models?

My experience encompasses a range of nailing machine brands and models, including Senco, Hitachi, Bostitch, and Paslode. I’ve worked extensively with both pneumatic and coil nailers, ranging from framing nailers to finish nailers. This broad exposure allows me to adapt quickly to different machine functionalities and troubleshooting procedures. I understand the nuances of each brand’s design and operational characteristics. For instance, I know that Senco machines might require a specific type of nail, while Paslode uses a different drive system. This understanding ensures efficient and effective operation and maintenance across diverse models.

Q 25. What is your process for cleaning and maintaining a nailing machine?

Cleaning and maintaining a nailing machine is crucial for its longevity and safe operation. My process involves several key steps:

- Regular Cleaning: After each use, I remove any debris, dust, or nails from the machine using compressed air and a brush. I pay particular attention to the nail guide, the firing mechanism, and the exhaust port.

- Lubrication: I regularly lubricate moving parts according to the manufacturer’s recommendations. This prevents wear and tear and ensures smooth operation.

- Inspection: I visually inspect the machine for any signs of damage, wear, or loose components. This includes checking the air hoses, connectors, and electrical wiring.

- Nail Magazine Check: I ensure that the nail magazine is functioning properly and there is no obstruction. The nails should feed smoothly into the machine.

- Air Line Maintenance: I periodically inspect the air line for leaks or damage and replace them as needed.

By following this regular maintenance schedule, I can prevent malfunctions, extend the machine’s life, and guarantee its safe and efficient operation.

Q 26. What is your experience with using different types of air compressors?

I have experience using various types of air compressors, from small portable units to larger stationary compressors. I understand the importance of matching the compressor’s capacity (measured in CFM – cubic feet per minute) and pressure (measured in PSI – pounds per square inch) to the requirements of the nailing machine. A compressor that’s too small will lead to inconsistent nailing and potentially damage the machine. Conversely, an excessively large compressor is unnecessary and can be wasteful.

I’m familiar with the different types of compressors – including reciprocating, rotary screw, and scroll compressors – and their respective advantages and disadvantages. I know how to troubleshoot issues like low pressure, leaks, and overheating in different compressor types. Understanding these aspects allows me to select the appropriate compressor for the job and to maintain it effectively to ensure sufficient and consistent air supply for the nailing machine.

Q 27. How do you ensure the safety of yourself and others while using a nailing machine?

Safety is paramount when operating a nailing machine. My safety procedures always include:

- Personal Protective Equipment (PPE): I always wear safety glasses, hearing protection, and work gloves. Depending on the job, I may also wear a dust mask and safety boots.

- Clear Workspace: Before starting, I ensure the work area is clear of obstructions and that I have a stable and secure footing.

- Machine Inspection: I always inspect the nailing machine before each use to make sure it’s in good working condition and that all safety features are functioning properly.

- Proper Technique: I use the nailing machine according to the manufacturer’s instructions, maintaining a firm grip and using appropriate pressure.

- Awareness of Surroundings: I maintain constant awareness of my surroundings, making sure there are no other people or obstacles in the vicinity of the nail gun’s range of operation.

- Proper Tool Storage: After use, I store the nailing machine and its associated components securely to prevent accidental injury.

By following these procedures, I ensure my safety and the safety of those around me.

Q 28. Describe a time you had to troubleshoot a complex nailing machine issue.

I once encountered a complex issue with a Paslode framing nailer. The machine was consistently misfiring, even with a fully charged battery and sufficient air pressure. I followed my usual troubleshooting steps: checked the air supply, inspected the nails, and cleaned the machine thoroughly. However, the problem persisted.

Consulting the machine’s schematic, I traced the air pathway and discovered a very small leak in a connector near the firing chamber. The leak was barely visible to the naked eye, but it was significantly affecting the machine’s ability to fire consistently. After replacing the connector, the machine operated flawlessly.

This experience highlighted the importance of thorough inspection, even of seemingly insignificant components, and the value of using schematics to understand the machine’s internal workings. It reinforced my commitment to systematic troubleshooting and the necessity of attention to detail in resolving complex issues.

Key Topics to Learn for Nailing Machine Operation Interview

- Machine Operation & Safety: Understanding the specific controls, functionalities, and safety protocols of various nailing machine models. This includes pre-operational checks, emergency shut-off procedures, and lockout/tagout protocols.

- Material Handling & Feeding: Proper techniques for loading and feeding materials (wood, nails, etc.) into the machine to ensure efficient and consistent operation, minimizing waste and jams.

- Troubleshooting & Maintenance: Identifying common malfunctions (e.g., jams, misfires, malfunctions in the nail feeding system), performing basic maintenance tasks, and understanding preventative maintenance schedules.

- Quality Control & Inspection: Inspecting finished products for quality, identifying defects, and understanding the impact of machine settings on the final product’s quality. This also includes understanding industry standards and quality control metrics.

- Production Optimization: Understanding techniques to maximize production efficiency, minimize downtime, and improve overall output. This includes knowledge of production targets and strategies to meet them.

- Understanding Nail Types and Applications: Knowledge of different nail types, sizes, and their suitability for various materials and applications.

Next Steps

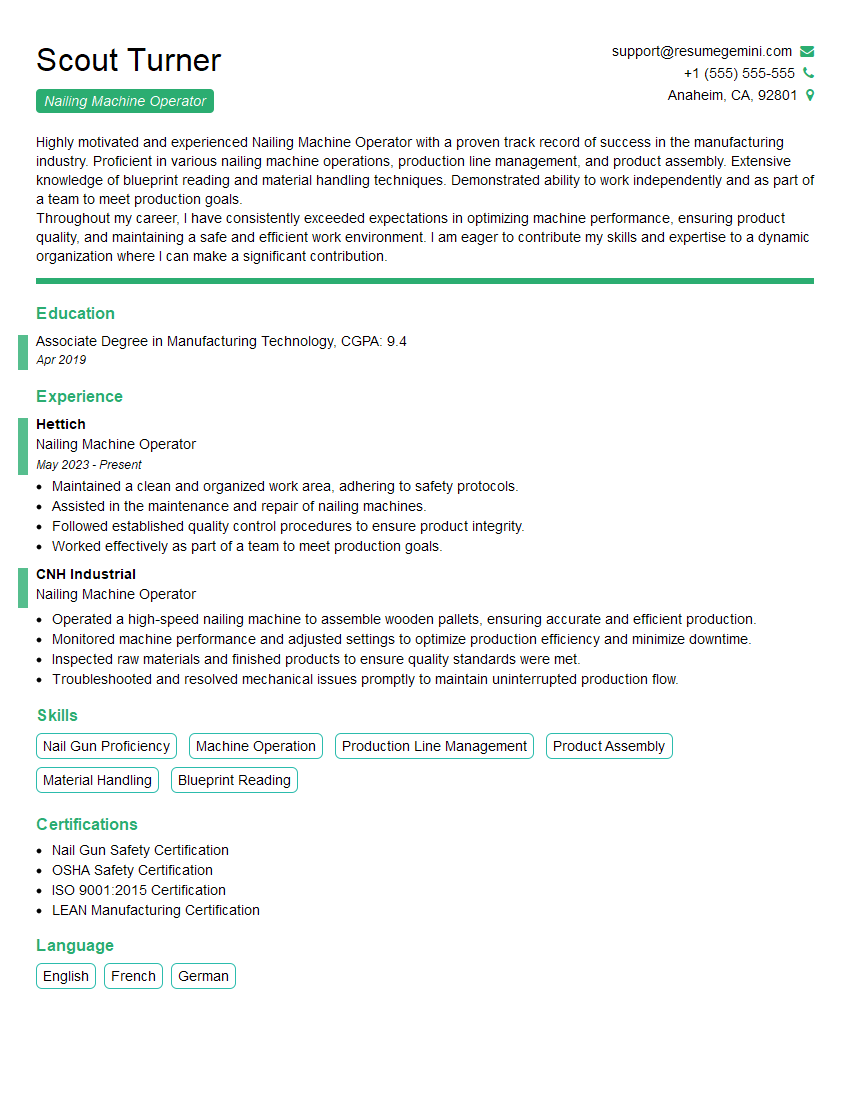

Mastering nailing machine operation opens doors to a rewarding career with opportunities for advancement and specialization within the manufacturing and construction industries. A strong understanding of these machines demonstrates valuable skills in precision, efficiency, and problem-solving, highly sought after by employers. To increase your job prospects, it’s crucial to create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional and impactful resume. Examples of resumes tailored to Nailing Machine Operation are available to help guide your resume creation process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi I am a troller at The aquatic interview center and I suddenly went so fast in Roblox and it was gone when I reset.

Hi,

Business owners spend hours every week worrying about their website—or avoiding it because it feels overwhelming.

We’d like to take that off your plate:

$69/month. Everything handled.

Our team will:

Design a custom website—or completely overhaul your current one

Take care of hosting as an option

Handle edits and improvements—up to 60 minutes of work included every month

No setup fees, no annual commitments. Just a site that makes a strong first impression.

Find out if it’s right for you:

https://websolutionsgenius.com/awardwinningwebsites

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good