Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Operating and maintaining milking machines interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Operating and maintaining milking machines Interview

Q 1. Describe the different types of milking machines.

Milking machines broadly fall into two categories: bucket milking machines and pipeline milking machines. Bucket systems are simpler, typically used on smaller farms, and involve manually attaching and detaching units to individual cows, collecting milk into buckets. Pipeline systems, common on larger farms, are more automated. Milk is conveyed directly from the milking units through a pipeline system to a bulk tank.

Within these categories, there are variations in the type of milking unit, such as those using claw-type clusters versus individual teat cup systems. There are also differences in the vacuum systems employed, with some using claw-based vacuum regulators and others having more sophisticated electronic control systems.

- Bucket Milking Machines: Simpler, portable, suitable for smaller herds.

- Pipeline Milking Machines: More complex, automated, higher throughput, used on larger farms.

Q 2. Explain the principle of vacuum regulation in a milking machine.

Vacuum regulation in a milking machine is crucial for maintaining a consistent milking pressure that’s gentle on the cow’s udder yet effective in removing milk. It involves precisely controlling the level of vacuum within the milking system. The ideal vacuum level is typically between 12-15 inches of mercury (Hg). Too high a vacuum can cause udder trauma and damage, while too low a vacuum results in slow or incomplete milking.

This regulation usually involves a vacuum pump, a vacuum regulator (often a pressure-sensitive valve), and vacuum lines distributing the vacuum throughout the system. The regulator maintains the set vacuum level by opening and closing a valve, adjusting the air flow to compensate for fluctuations in vacuum demand. Think of it like a sophisticated pressure relief valve in your car’s cooling system—it maintains consistent pressure, preventing damage.

Q 3. How do you troubleshoot a milking machine with low vacuum?

Low vacuum is a common problem, and troubleshooting involves a systematic approach. First, check the vacuum gauge to confirm low pressure. Then, proceed with this checklist:

- Check the vacuum pump: Inspect for leaks in the pump itself, ensure the pump belt is tight and in good condition, and check the pump’s oil level (if applicable).

- Examine the vacuum lines: Carefully inspect all vacuum lines for cracks, holes, or loose connections. Leaks can significantly reduce vacuum. Use soapy water to identify potential leaks.

- Check the vacuum regulator: Verify that the regulator is functioning correctly and adjusting appropriately. If it’s faulty, it may need replacement.

- Check the vacuum receiver: Make sure the receiver isn’t excessively full of air and is properly sealed.

- Air Leaks in the Milking System: Check all connections between the pipeline and the milking units, ensuring tight seals and correct assembly.

If the problem persists after these checks, it may require professional assistance.

Q 4. What are the common causes of pulsator malfunctions?

Pulsator malfunctions often stem from wear and tear, incorrect settings, or blockages. Common causes include:

- Worn or damaged parts: The pulsator is a delicate mechanism with rubber components and moving parts. These can wear out over time, leading to irregular pulsation or failure to pulse altogether. Regular inspection is key.

- Air leaks: Leaks within the pulsator can affect the vacuum, resulting in uneven pulsation.

- Blockages: Dirt, milk residue, or other debris can clog the internal parts of the pulsator. This can impede its proper operation.

- Incorrect settings: The pulsator’s setting determines the frequency and ratio of vacuum and atmospheric pressure cycles. Incorrect settings can be detrimental to udder health and cause issues.

- Incorrect air pressure: If the air pressure supplied to the pulsator is too low or too high it can affect its function.

Regular lubrication and cleaning is critical to prevent many of these issues.

Q 5. How do you clean and sanitize a milking machine?

Cleaning and sanitizing a milking machine is paramount for maintaining hygiene, preventing bacterial contamination, and ensuring the quality of the milk. A thorough cleaning procedure involves:

- Pre-cleaning: Immediately after milking, rinse all components (teat cups, claw, tubing, etc.) thoroughly with cold water to remove milk residue. This prevents milk from drying and sticking to surfaces.

- Washing: Use a detergent solution appropriate for milking machine cleaning (follow the manufacturer’s instructions carefully). Scrub all components to remove remaining milk solids and grease. Automated cleaning systems are often used on larger farms.

- Rinsing: Thoroughly rinse all components with clean, potable water to remove all traces of detergent.

- Sanitizing: Apply an approved sanitizer according to the manufacturer’s instructions. Allow sufficient contact time before rinsing. Common sanitizers include chlorine solutions, iodophors, and acid anionic detergents.

- Drying: Allow the components to air dry or dry them with clean cloths.

Regular and correct cleaning is the most effective way to prevent mastitis and ensure the highest quality milk.

Q 6. Describe the proper procedure for attaching and detaching milking units.

Attaching and detaching milking units should be done gently and efficiently to minimize stress on the cow and prevent damage to the udder.

Attachment: Carefully wipe the teats with a clean cloth, ensuring the teats are clean and free of debris. Align the teat cups with the teats and gently press them onto the teats. Use an even pressure on each teat cup, and avoid twisting or pulling.

Detachment: Turn off the vacuum to the cluster before disconnecting. This helps prevent sudden changes in pressure that can damage the teats. Gently remove the teat cups while supporting the udder and ensuring no sudden jarring.

Proper training is essential to ensure that this process is done correctly every time and minimizes the risk of udder trauma.

Q 7. Explain the importance of maintaining proper milk flow rates.

Maintaining proper milk flow rates is critical for several reasons:

- Cow Comfort: A slow milk flow rate means the cow spends more time under the milking machine, increasing stress and discomfort.

- Milk Quality: Slow flow rates can lead to increased chances of bacterial contamination as the milk remains in the udder longer.

- Udder Health: Consistent, appropriate flow rates prevent excessive vacuum exposure, which can contribute to udder damage and mastitis.

- Milking Efficiency: Optimal flow rates ensure a quick and efficient milking process, maximizing output and reducing labor costs.

Factors affecting milk flow rates include vacuum level, pulsator settings, teat cup liner condition, and the cow’s individual milk production capabilities. Regular checks and adjustments can ensure optimal milk flow.

Q 8. What are the signs of a faulty claw?

A faulty claw is a critical issue in milking, impacting milk yield and cow health. Several signs indicate trouble. Look for leaks – milk dripping from the claw itself or around the connections to the teat cups is a major red flag. Uneven milk flow from different teat cups suggests a blockage or problem within the claw. Damaged parts, such as cracks or dents in the claw, compromise its integrity and should be immediately addressed. Finally, unusual noises during milking, like hissing or gurgling, can indicate air leaks within the claw assembly.

Imagine the claw as a central hub – if one spoke (a teat cup) is malfunctioning, the entire system is affected. Regular visual checks and listening for unusual sounds are crucial in early detection.

Q 9. How do you identify and resolve teat cup liner issues?

Teat cup liners are consumable items that directly interact with the cow’s udder, so their condition is paramount. Hardening or cracking of the liner is a major issue, leading to discomfort for the cow and potential for injury. Excessive wear, visible as thinning or stretching, reduces their effectiveness and can cause slippage. Milkstone buildup can also restrict milk flow and harbor bacteria.

Troubleshooting starts with a visual inspection. Regularly check for the above issues. Replace liners that show any signs of damage or excessive wear. Proper cleaning and sanitization (using a suitable detergent and sanitizer) are essential to prevent milkstone build-up. Regularly rotating liners between milkings can prolong their life.

Q 10. What are the safety precautions when operating a milking machine?

Safety is paramount when operating a milking machine. Always ensure the machine is properly grounded to prevent electrical shocks. Never operate the machine with wet hands or in a wet environment. Wear appropriate protective clothing, including gloves, to avoid injury from sharp components or contamination from milk. Be cautious of moving parts and ensure they are properly guarded. Regular maintenance checks to identify and fix potential hazards are also critical. Finally, always follow the manufacturer’s safety guidelines provided in the machine’s manual.

Think of it like driving a car – you wouldn’t operate it without proper safety measures. Similarly, responsible milking practices involve following all safety protocols to protect both you and the animal.

Q 11. How often should milking machine components be replaced?

Milking machine components have varying lifespans dependent on usage frequency, cleaning practices and maintenance routines. Teat cup liners should be replaced every 3-4 weeks as a minimum to prevent damage to the cow’s teats. Pulsators typically last for 2-3 years, depending on usage, while other components like vacuum pumps and claws might last for up to 5 or more years with careful maintenance. However, always consult your machine’s manual and maintenance schedule.

Regular replacement of these items is not merely a cost; it’s an investment in cow health, milk quality and overall efficiency. Preventative maintenance is significantly cheaper than dealing with breakdowns.

Q 12. Describe the process of preventative maintenance for a milking machine.

Preventative maintenance is crucial for optimal milking machine performance and longevity. It involves a combination of daily, weekly and monthly checks. Daily, inspect the equipment for leaks, damage, and cleanliness. Weekly, conduct thorough cleaning and sanitization of all components, especially the teat cup liners. Monthly, perform more in-depth checks of the vacuum pump, pulsator, and other critical components. This may involve lubrication of moving parts and checking for wear and tear. Consider using a maintenance log to track your activities and aid in early problem identification.

Think of it as regular servicing of your car – small, consistent attention prevents major breakdowns.

Q 13. What are the different types of milking machine pulsators and their functions?

Milking machines employ different pulsator types to mimic the natural suckling action of a calf. The most common types are the air-over-milk and the air-in-milk pulsators. Air-over-milk pulsators create pulsation by alternately directing air and vacuum into a chamber above the teat cup liner, whereas air-in-milk pulsators generate pulses by switching between air and vacuum within the liner itself. Each type has advantages and disadvantages relating to effectiveness, maintenance and cost. The choice depends on various factors including the milking system design and individual preferences.

Understanding the functionality of each type is vital for effective troubleshooting and maintenance.

Q 14. How do you troubleshoot a milking machine with inconsistent pulsation?

Inconsistent pulsation is a significant problem impacting both milk yield and cow comfort. Troubleshooting starts with identifying the cause. First, check the pulsator itself for damage or blockages. Next, inspect the airlines and vacuum lines for leaks or kinks, which might disrupt the airflow. A malfunctioning vacuum pump can also cause inconsistent pulsation. Finally, make sure the pulsator regulator is correctly set according to the manufacturer’s recommendations. Use a pulsation meter to measure the actual pulsation rate and compare it with the desired range.

Systematic troubleshooting, checking each component step-by-step, is crucial in isolating the problem.

Q 15. How do you maintain the air compressor for a milking machine?

Maintaining an air compressor for a milking machine is crucial for consistent vacuum performance. Think of it as the heart of the system – if it falters, the whole process suffers. Regular maintenance involves several key steps:

Regular Oil Checks and Changes: Check the oil level frequently, following the manufacturer’s recommendations. Dirty oil can damage the compressor’s internal components. Change the oil according to the schedule, usually every 6 months or as the hours of operation dictate.

Air Filter Cleaning/Replacement: A clogged air filter restricts airflow, forcing the compressor to work harder and potentially overheating. Clean or replace the filter as needed; a dirty filter will significantly reduce compressor lifespan. I once had a farmer who neglected this, resulting in a compressor failure during peak milking time – a costly and time-consuming repair.

Belt Tension and Condition: Check the drive belt for wear and tear and ensure it’s properly tensioned. A loose or worn belt can slip, reducing efficiency and potentially damaging the compressor. A visual inspection and a simple tension test are sufficient.

Pressure Switch and Safety Valve Checks: Verify the pressure switch is functioning correctly to maintain the correct vacuum level. Regularly check the safety valve to ensure it releases pressure if it gets too high, preventing damage to the compressor.

Regular Lubrication: Apply lubricant to moving parts as specified in the manufacturer’s manual, reducing friction and wear. This helps extend the compressor’s overall life.

Moisture Removal: Moisture in the air compressor can lead to rust and corrosion. Many compressors have a drain valve to remove accumulated moisture – this should be done regularly.

By adhering to this schedule, you’ll ensure your air compressor operates at peak efficiency and extends its service life significantly, minimizing downtime and costly repairs.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the signs of a vacuum leak in a milking machine?

Identifying a vacuum leak in a milking machine requires a keen eye and understanding of the system. Several signs can indicate a leak:

Low Vacuum Gauge Readings: The most obvious sign. If the vacuum gauge consistently reads lower than the recommended level, there’s a leak somewhere in the system.

Slow Milking Time: A leak will reduce the vacuum, making the milking process slower than usual. This is often the first clue that something is wrong.

Milk Leaking from the System: Look for milk dripping or leaking from any connections, claws, or tubing. This directly indicates a breach in the vacuum.

Unusual Noises: Hissing sounds during milking or from the vacuum pump often indicate air escaping from a leak.

Inconsistent Milk Flow: Intermittent or fluctuating milk flow is another symptom. This is indicative of an inconsistent vacuum level.

Remember, even a small leak can significantly affect the efficiency and hygiene of your milking operation. Prompt detection and repair are essential.

Q 17. How do you test the vacuum level of a milking machine?

Testing the vacuum level is straightforward. Most milking machines have a vacuum gauge, which directly indicates the vacuum level in inches of mercury (Hg) or kilopascals (kPa). To test the vacuum:

Ensure the System is Running: Start the milking machine and allow it to reach its normal operating state.

Check the Vacuum Gauge: Observe the reading on the vacuum gauge. The desired vacuum level varies depending on the machine and manufacturer’s specifications, but usually falls within the range of 12-15 inches of Hg (40-50 kPa).

Compare to Manufacturer’s Specifications: Consult your machine’s manual for the recommended vacuum range. Significant deviations indicate a problem.

Vacuum Gauge Calibration: Periodically have your vacuum gauge calibrated to ensure accurate readings. An inaccurate gauge can lead to incorrect diagnoses and troubleshooting.

If the vacuum level is consistently low, you might need to troubleshoot for leaks or other issues within the vacuum pump or system.

Q 18. Explain the importance of proper milk line cleaning.

Proper milk line cleaning is paramount to maintain hygiene and prevent bacterial contamination, which can affect milk quality and potentially lead to significant economic losses. It’s a critical step for maintaining food safety.

Preventing Bacterial Growth: Milk is a breeding ground for bacteria. Thorough cleaning removes milk residues and prevents bacterial growth, maintaining milk quality and extending shelf life.

Maintaining Equipment Longevity: Milk residue can cause build-up and corrosion within the milk lines, shortening the lifespan of your equipment and requiring more frequent and costly replacements. Regular cleaning helps prolong the life of the system.

Meeting Regulatory Standards: Food safety regulations demand rigorous cleaning protocols to ensure the safety and quality of the milk produced. Proper cleaning practices ensure compliance with these regulations and avoid potential penalties.

Preventing Mastitis: Improper cleaning can lead to bacteria entering the teat cups and udder, resulting in mastitis (udder infection) which is costly in terms of reduced milk yield and vet bills.

Think of it this way: every speck of milk left behind is a potential breeding ground for bacteria, threatening the entire production cycle. Cleaning isn’t just hygiene – it’s good business.

Q 19. Describe the different types of milk filters and their uses.

Milk filters play a critical role in removing impurities from the milk, preventing clogs and ensuring a high-quality product. Different types of filters exist, each serving a specific purpose:

Paper Filters: These are disposable filters used for in-line filtration, trapping larger particles like hair and debris. They’re inexpensive and easy to replace but require frequent changes.

Screen Filters: These consist of fine mesh screens that remove larger particles. They are reusable and can be cleaned and sterilized, providing a more cost-effective solution in the long run.

Disc Filters: These filters utilize disposable or reusable discs with varying pore sizes, allowing for more precise filtration and removal of smaller particles. They offer higher filtration efficiency than paper or screen filters but can be more expensive.

Bag Filters: Milk is passed through a disposable filter bag, effectively removing larger particles. These filters are convenient and easy to use, often employed for pre-filtration.

The choice of filter depends on factors like milk quality, budget constraints, and the desired level of filtration. A combination of different types can be utilized for optimal results.

Q 20. How do you diagnose and repair a faulty milk pump?

Diagnosing and repairing a faulty milk pump requires a systematic approach. First, pinpoint the problem:

Check Power Supply: Ensure the pump is receiving power and the circuit breaker isn’t tripped. A simple check that’s often overlooked.

Listen for Unusual Noises: Unusual noises (grinding, squealing, humming) often indicate mechanical problems within the pump.

Check for Leaks: Leaks in the pump seals can drastically reduce its efficiency. Look for any signs of leakage around the pump.

Inspect the Impeller: The impeller (rotating part) might be damaged or worn. Inspect it for any cracks or damage. This usually requires disassembling the pump.

Check Valves: If the pump isn’t creating sufficient vacuum or pressure, check for malfunctioning check valves. These are relatively easy to replace.

Motor Issues: If the motor isn’t running or is running weakly, it might need professional attention; it’s best to call a qualified technician.

Repairing a pump varies depending on the type of pump and the nature of the fault. Sometimes, it’s simply a case of replacing a seal or check valve. More severe problems, however, often require professional assistance. I’ve seen farmers attempt repairs themselves, only to cause further damage and increase the overall cost. Calling a qualified technician can save time and money in the long run.

Q 21. What are the common causes of milk line blockages?

Milk line blockages are a common issue, often caused by a combination of factors:

Milk Residue Buildup: Incomplete cleaning leaves milk residue, which hardens and restricts milk flow over time.

Fat Accumulation: High-fat milk can lead to fat globules sticking to the inner walls of the milk lines, gradually restricting flow.

Mineral Deposits: Hard water can lead to mineral deposits within the milk lines, restricting the flow of milk.

Foreign Objects: Hair, insects, or other debris can enter the system and cause blockages.

Incorrect Cleaning Procedures: Inadequate cleaning and sterilization lead to milk residue buildup and blockage.

Preventing blockages relies on a robust cleaning and sanitation regimen using appropriate cleaning agents and techniques. Regular inspections and preventative maintenance are also vital.

Q 22. How do you troubleshoot a milking machine with excessive milk leakage?

Excessive milk leakage in a milking machine points to a problem in the vacuum system or the liner/claw assembly. Think of it like a leaky faucet – you need to pinpoint where the water (milk) is escaping.

Troubleshooting Steps:

- Inspect the liners: Check for tears, holes, or wear and tear. Liners are the rubber cups that surround the cow’s teats. Damaged liners are a common cause of leakage. Replace any damaged liners immediately.

- Examine the claw: The claw is the component that collects milk from the liners. Look for cracks or loose seals within the claw. Milk leakage here can indicate a faulty seal or a cracked claw unit, requiring replacement.

- Check the vacuum lines: Inspect the entire vacuum line for leaks. A hissing sound can indicate a hole in the tubing or a loose connection. Use soapy water to identify leak points – bubbles will form where air is escaping.

- Verify vacuum pump function: Ensure the vacuum pump is operating correctly and maintaining the appropriate vacuum level. A malfunctioning pump will compromise the suction, leading to leakage.

- Assess the pulsator: The pulsator creates the rhythmic vacuum and release cycle. A faulty pulsator might not provide enough vacuum or may have irregular cycles, leading to milk leakage.

- Check the milk receiver: Ensure there are no cracks or loose connections in the milk receiver. Any crack here may allow milk to escape into the system and not into the collection point.

Example: On a farm I worked, excessive leakage traced back to a small crack in the claw we initially overlooked. Replacing the claw immediately solved the issue.

Q 23. What are the environmental factors that can affect milking machine performance?

Environmental factors significantly influence milking machine performance. Think of it as creating the right conditions for a successful milking operation.

- Temperature: Extreme heat can cause milk to become thinner and more prone to leakage. Cold temperatures can affect the flexibility of rubber components, potentially causing cracking or reducing the effectiveness of the vacuum.

- Humidity: High humidity can affect the vacuum system’s efficiency and potentially lead to corrosion of metal components. Low humidity can make rubber components brittle.

- Dust and debris: Dust and dirt can clog vacuum lines and affect the efficiency of the pulsator and other parts. Regular cleaning is crucial.

- Power supply fluctuations: Inconsistent power supply can disrupt the milking process. A sudden power drop will halt the system, while consistent low voltage might reduce pump efficiency.

Practical Application: In areas with significant temperature fluctuations, scheduling milking times to avoid peak heat or cold can be beneficial. Regular cleaning of the system will mitigate the impact of dust and debris.

Q 24. Describe the importance of regular lubrication of milking machine components.

Regular lubrication is crucial for maintaining the efficiency and longevity of a milking machine. Imagine a bicycle chain – without lubrication, it would quickly wear down and break. Similarly, moving parts in a milking machine require lubrication to minimize friction and wear.

- Reduced friction: Lubrication minimizes friction between moving parts, reducing wear and tear. This translates to a longer lifespan for the machine and fewer repairs.

- Improved efficiency: Smooth, well-lubricated parts operate more efficiently, ensuring the machine runs smoothly and effectively.

- Prevents corrosion: Lubricants often contain corrosion inhibitors, helping to protect metal components from rust and degradation, extending their life.

Specific examples: Pumps, pulsators, and other moving parts should be lubricated according to the manufacturer’s instructions, typically with food-grade lubricants. Failure to lubricate can lead to increased noise, reduced efficiency, and eventual component failure.

Q 25. How do you handle emergency situations, such as a power outage during milking?

A power outage during milking is a serious situation. Your priority is the cows’ well-being and preventing milk contamination.

- Immediately stop the milking unit: This prevents potential injury to the cows and damage to the equipment.

- Manually detach the milking clusters: Carefully remove the clusters from the cows’ teats to avoid injury.

- Ensure teats are clean and dry: Use a clean cloth or towel to gently wipe down the teats.

- If possible, use a backup power source: Some farms have backup generators that can temporarily power the system until the main power is restored. If applicable, switch over.

- Monitor cows closely: Observe the cows for any signs of discomfort or distress.

- If the power is unavailable for an extended period, manually milk the cows: In such cases, complete milking by hand to avoid mastitis risk.

Example: During a severe thunderstorm, we experienced a power outage. Our quick response, immediately detaching the clusters and using our backup generator, minimized any disruption to the milking routine.

Q 26. What is your experience with different brands of milking machines?

Throughout my career, I’ve worked with various milking machine brands, including DeLaval, BouMatic, and WestfaliaSurge. Each brand has its strengths and weaknesses. For example, DeLaval is known for its robust and reliable systems, while BouMatic is often praised for its innovative designs.

My experience encompasses installation, maintenance, troubleshooting, and repair of these brands, enabling me to identify and address issues specific to each system. I’m familiar with their respective parts, service manuals, and troubleshooting procedures. This broad experience makes me adept at working across different systems and solving problems effectively regardless of the brand.

Q 27. Explain your knowledge of automated milking systems.

Automated milking systems (AMS) represent a significant advancement in dairy farming. These systems allow cows to be milked at their own convenience, eliminating the need for scheduled milking sessions. This is a major shift from traditional systems.

My knowledge of AMS covers several aspects:

- System operation: I understand how the robotic arm identifies, attaches, and detaches milking units, how it measures milk yield, and how it detects potential problems like mastitis.

- Maintenance and cleaning: AMS require regular maintenance and automated cleaning cycles. I’m proficient in handling these tasks, including cleaning robots, sensors, and milking units.

- Troubleshooting: I’m familiar with common issues in AMS, such as robot malfunctions, sensor errors, and data interpretation challenges. I have experience identifying and rectifying these issues effectively.

- Data management: AMS generate significant amounts of data on milk yield, cow health, and milking patterns. I’m adept at interpreting this data to optimize farm operations and improve animal welfare.

Example: I once resolved a recurring issue with an AMS system where a sensor was miscalibrating. By analyzing the data logs, I was able to pinpoint the problem and replace the faulty sensor, preventing further disruptions.

Q 28. How do you ensure the welfare of the cows during milking?

Ensuring cow welfare during milking is paramount. It’s not just about efficient milk production; it’s about responsible animal husbandry.

- Proper cluster attachment: The milking clusters must be attached correctly to avoid discomfort or injury. Incorrect attachment can cause teat damage.

- Maintaining appropriate vacuum levels: Too much vacuum can cause pain and injury; too little vacuum reduces milking efficiency. Regular checks and adjustments ensure an optimal balance.

- Regular teat cleaning and disinfection: Clean and disinfected teats minimize the risk of mastitis and other infections.

- Monitoring for signs of discomfort: Observation is key. I always pay close attention to the cows during milking, looking for signs of restlessness, discomfort, or pain. Addressing any issues promptly prevents complications.

- Providing adequate rest and access to feed and water: Cows need to be comfortable and well-nourished before, during, and after milking.

Example: I noticed one cow consistently exhibiting signs of discomfort during milking. After careful observation, I identified a minor teat injury. By addressing the injury and modifying the cluster attachment, I restored the cow’s comfort and avoided more serious health issues.

Key Topics to Learn for Operating and Maintaining Milking Machines Interview

- Milking Machine Components and Functionality: Understanding the various parts of a milking machine (e.g., claw, pulsator, vacuum pump) and how they work together to efficiently and hygienically milk cows. This includes knowledge of different milking machine types and their variations.

- Hygiene and Sanitation Protocols: Mastering cleaning and sanitizing procedures to prevent mastitis and maintain milk quality. This includes understanding the use of detergents, sanitizers, and proper disinfection techniques, as well as relevant regulations and best practices.

- Troubleshooting and Maintenance: Identifying and resolving common milking machine malfunctions, performing preventative maintenance tasks (e.g., lubrication, filter changes), and understanding the importance of routine inspections. This involves practical problem-solving skills and the ability to diagnose issues efficiently.

- Milking Techniques and Animal Welfare: Understanding best practices for efficient and stress-free milking, recognizing signs of discomfort in cows, and implementing humane handling techniques. This shows your commitment to both productivity and animal well-being.

- Vacuum System Management: Understanding the role of the vacuum system in milking efficiency and milk quality, including troubleshooting vacuum leaks and maintaining optimal vacuum levels. This demonstrates a deep understanding of the technical aspects of milking machine operation.

- Record Keeping and Data Analysis: Maintaining accurate records of milking procedures, machine performance, and milk yields. This includes basic data analysis to identify trends and areas for improvement in efficiency and productivity.

Next Steps

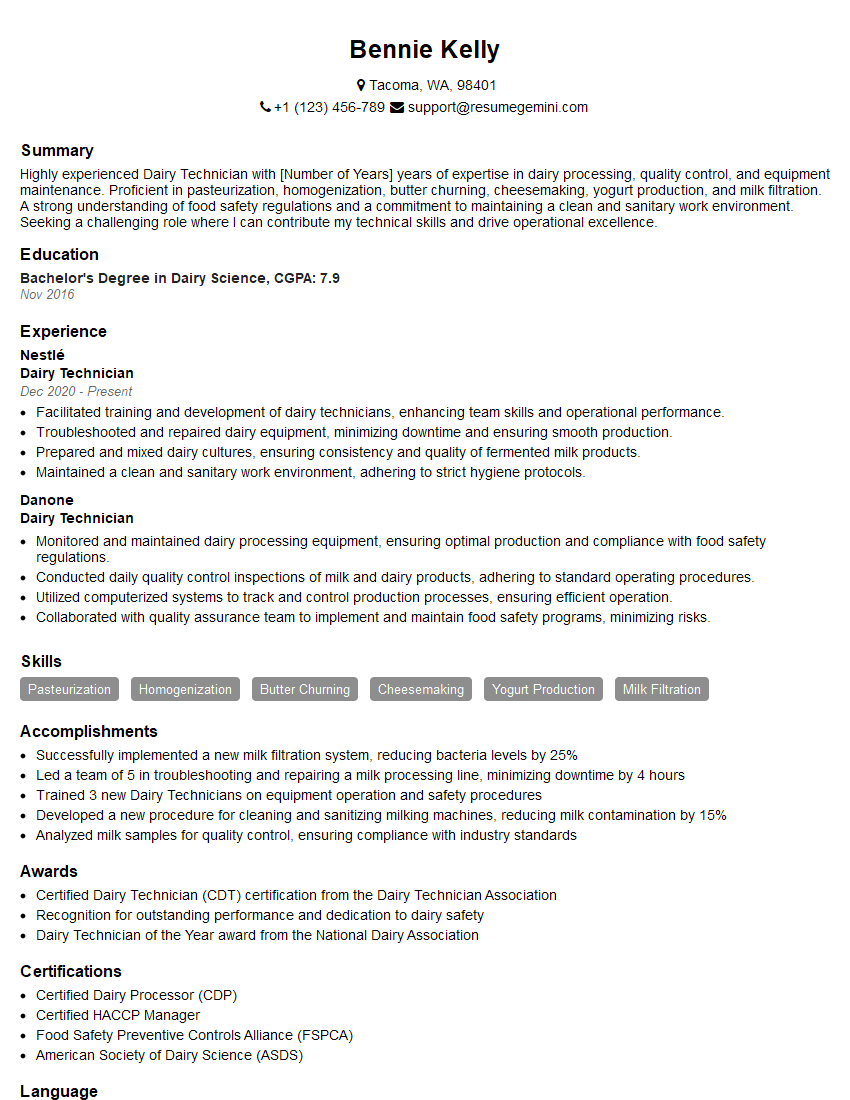

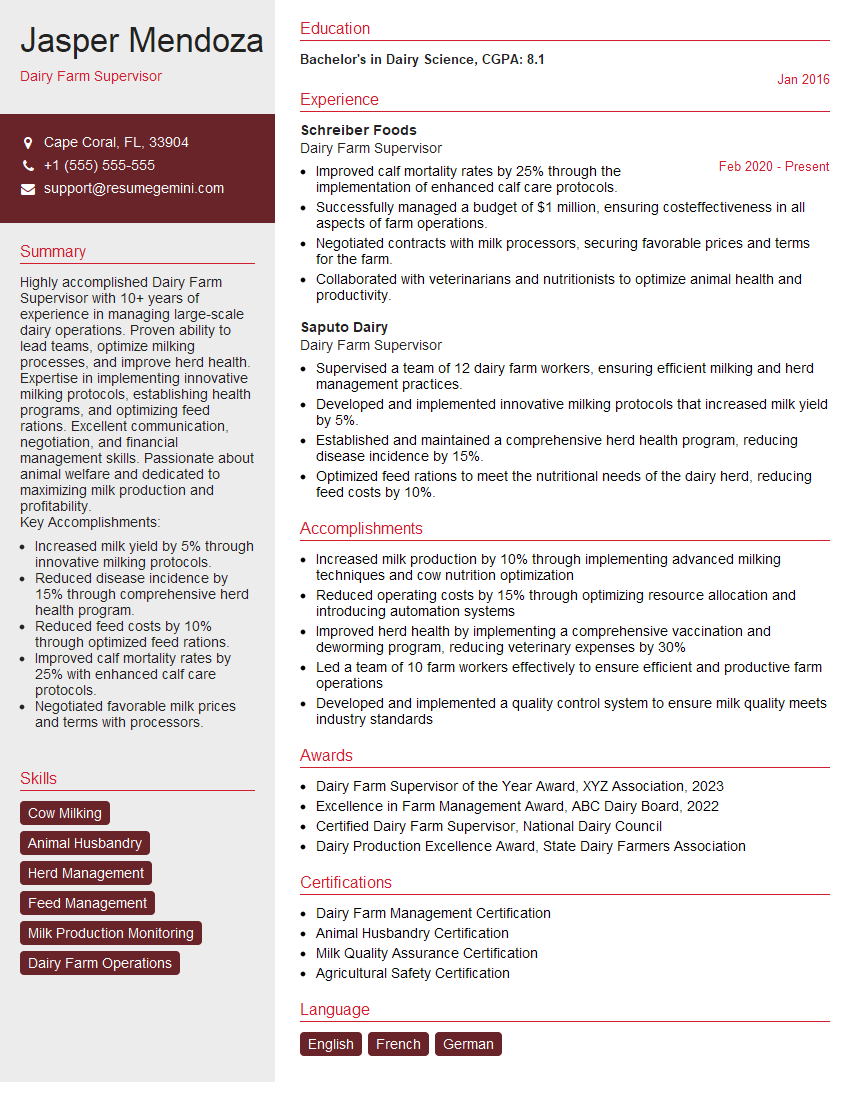

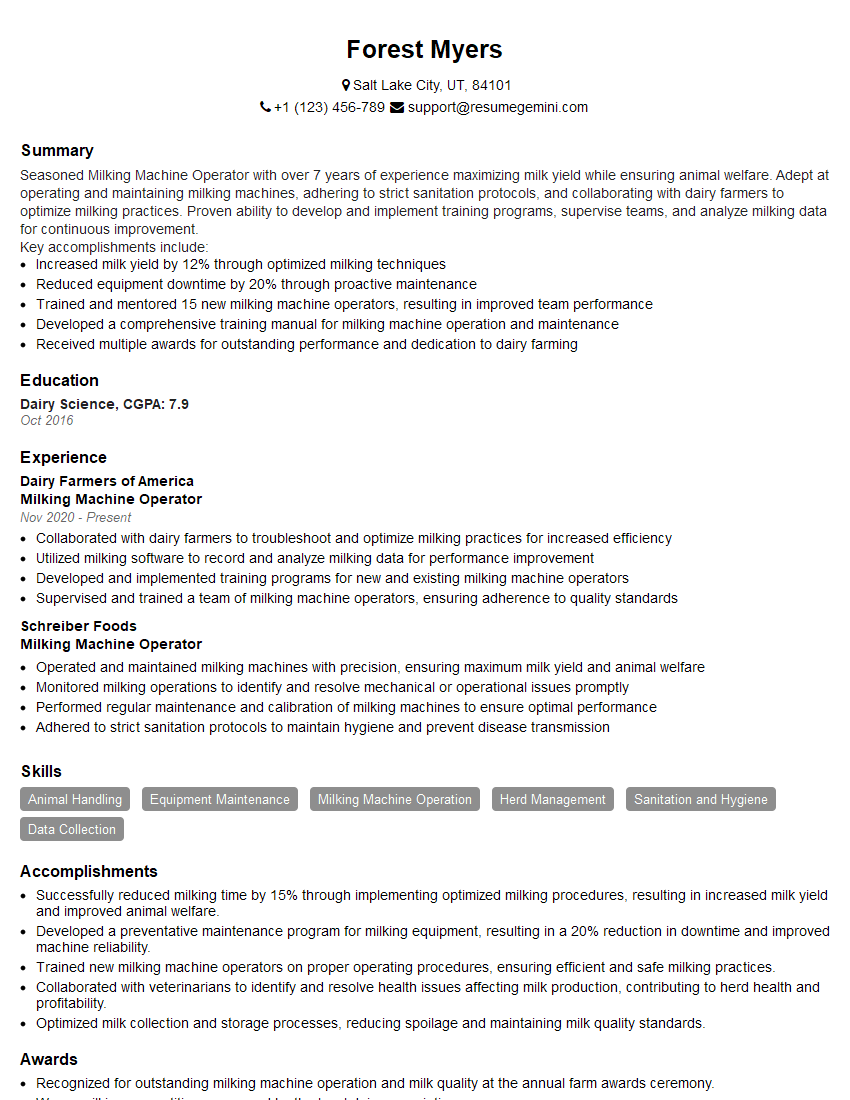

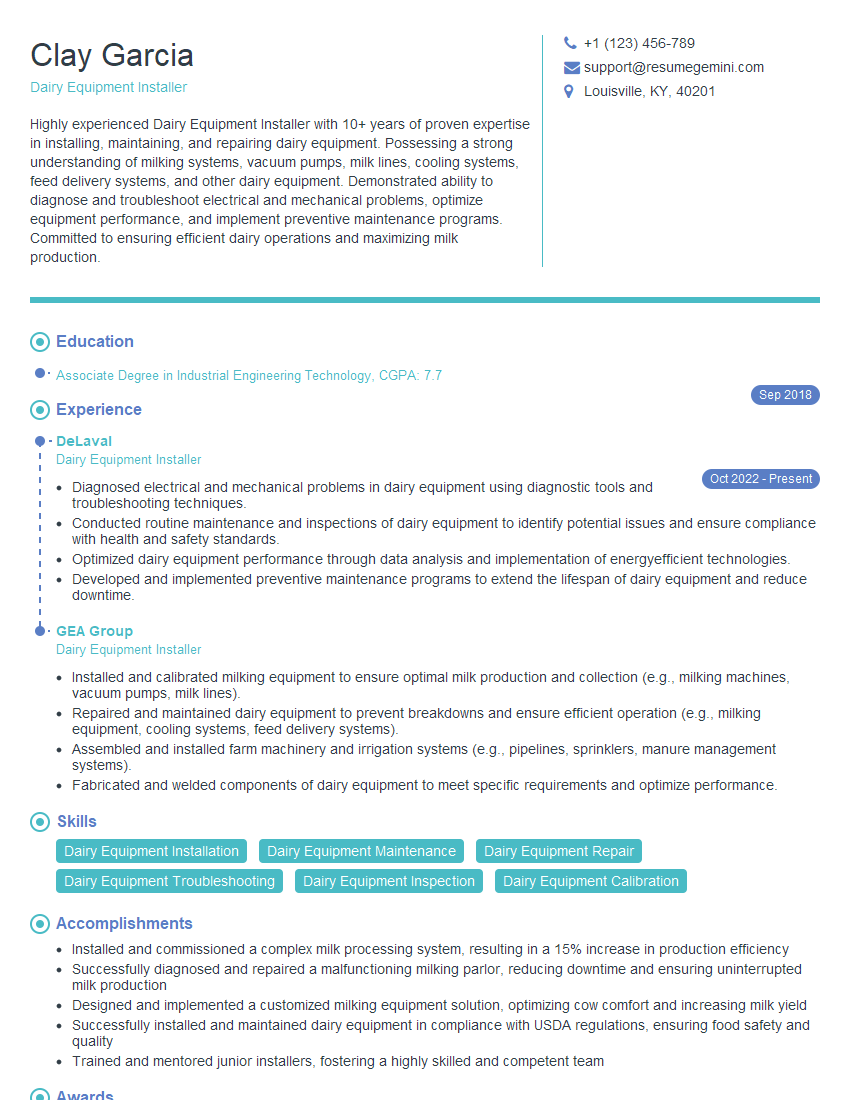

Mastering the operation and maintenance of milking machines is crucial for a successful and rewarding career in the dairy industry. Proficiency in this area opens doors to diverse roles with increasing responsibility and earning potential. To maximize your job prospects, crafting a strong, ATS-friendly resume is essential. ResumeGemini can help you create a professional and impactful resume that showcases your skills and experience effectively. Examples of resumes tailored to Operating and Maintaining Milking Machines are available to help guide you. Invest the time to build a compelling resume—it’s your first impression with potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good