Preparation is the key to success in any interview. In this post, we’ll explore crucial Maintaining milking equipment and facilities interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Maintaining milking equipment and facilities Interview

Q 1. Describe your experience troubleshooting malfunctioning milking equipment.

Troubleshooting malfunctioning milking equipment requires a systematic approach. I begin by observing the problem – is the machine not pulsating correctly? Is there a vacuum leak? Is milk flow restricted? Once I’ve identified the symptom, I use a process of elimination to pinpoint the cause. For example, if the pulsator isn’t working, I’d first check the air supply, then the pulsator itself, inspecting for damaged components or air leaks. I often use a vacuum gauge to measure the vacuum level and a pressure gauge to check the air pressure. If the problem is a vacuum leak, I’d systematically check all the connections, looking for loose fittings or damaged tubing. I keep a detailed log of all issues, their causes, and solutions, building a knowledge base to prevent future issues. I find that diagrams and manuals are invaluable in this process. One time, a farmer was experiencing slow milk flow. Through systematic checking, I identified a blockage in the milk line; a simple cleaning resolved the issue, highlighting the importance of regular maintenance.

Q 2. What preventative maintenance procedures do you regularly perform on milking machines?

Preventative maintenance is crucial for maximizing milking machine efficiency, milk quality, and longevity. My routine includes:

- Daily checks: Inspecting all tubing and connections for leaks or damage, checking the pulsator for proper function, and ensuring the claw is clean and correctly assembled.

- Weekly cleaning: Thoroughly cleaning and sanitizing all milking components, including the cluster, milk line, and vacuum pump. This involves using appropriate detergents and sanitizers, following manufacturer guidelines meticulously.

- Monthly checks: Lubricating moving parts like the vacuum pump and pulsators, checking vacuum levels and air pressure using gauges. I also ensure that all the equipment operates within the correct parameters of speed and vacuum pressure, and perform necessary adjustments.

- Quarterly maintenance: More extensive checks include inspecting the vacuum pump for wear and tear, checking for corrosion, and replacing any worn parts. I also replace filters for the air supply and assess the overall condition of the milking system.

- Annual servicing: This involves a thorough professional inspection, service, and potentially replacement of parts as needed. This prevents major issues from arising.

This structured approach ensures the longevity and optimal function of the milking equipment and contributes to enhanced milk quality and herd health. Regular maintenance prevents costly repairs and downtime.

Q 3. How do you identify and address issues related to milk quality?

Milk quality issues can stem from various sources; hence, a multi-pronged approach is necessary. I would initially analyze the milk itself, looking at factors like somatic cell count (SCC), bacterial count, and presence of inhibitors. High SCC indicates mastitis (inflammation of the udder), often detected by visually examining the udder during milking or through routine testing. High bacterial counts suggest sanitation issues, which I would address by focusing on cleaning protocols. Inhibitors, substances affecting milk processing, might indicate issues with the cleaning process or contamination from the environment. I then trace it back to the equipment – are there any cracks or crevices in the milking equipment that are harboring bacteria? Are the milking clusters properly cleaned and sanitized? By systematically investigating the milk’s properties and the entire milking process, we can identify the root cause and implement corrective actions. For example, if I find high bacterial counts, I will focus on enhancing the sanitation procedures, including the use of correct temperature and concentration of detergents and sanitizers.

Q 4. Explain your understanding of different milking system types (e.g., robotic, parallel).

Milking systems vary significantly in their design and operation. Parallel milking systems involve several cows being milked simultaneously by a single operator. They are highly efficient for larger herds but require a substantial initial investment and considerable labor. Robotic milking systems are automated; cows enter a stall when ready and a robotic arm attaches and detaches the milking clusters. This system increases cow comfort and can result in higher milk yields, but they have a high initial cost and require specialized expertise for maintenance and troubleshooting. Other types include herringbone systems and rotary milking parlors, each with its own advantages and disadvantages in terms of efficiency, space requirements, and labor costs. My experience encompasses all these systems, allowing me to adapt my maintenance strategies to the specific needs of each type.

Q 5. What are the common causes of milking machine breakdowns and how do you resolve them?

Common milking machine breakdowns often stem from issues such as:

- Vacuum leaks: Loose connections, damaged tubing, or faulty vacuum pump. Resolution: Check all connections; replace damaged parts; service or replace the vacuum pump.

- Pulsator malfunctions: Damaged diaphragm, air leaks, or incorrect settings. Resolution: Repair or replace the pulsator; adjust settings as per manufacturer guidelines.

- Electrical failures: Faulty wiring, blown fuses, or motor problems. Resolution: Check wiring and fuses; repair or replace the motor.

Troubleshooting involves systematic checking, using diagnostic tools when necessary. I also proactively address potential issues by following a strict preventative maintenance schedule, preventing many problems before they occur. Proper documentation and accurate record keeping are essential for improving troubleshooting efficiency.

Q 6. How do you ensure the hygiene and sanitation of milking equipment and the milking parlor?

Maintaining hygiene and sanitation is paramount in preventing bacterial contamination of the milk and reducing the risk of mastitis. My approach involves a multi-step process:

- Pre-milking preparation: Cleaning and sanitizing the cow’s udder using approved products.

- Milking cluster sanitation: Thorough cleaning and sanitizing of all milking equipment using effective detergents and sanitizers, and following manufacturer recommendations.

- Post-milking cleaning: Immediate cleaning and sanitizing of all equipment with hot water, detergent, and sanitizer. This is crucial to prevent bacterial growth.

- Parlor sanitation: Regular cleaning and disinfection of the entire milking parlor, including floors, walls, and equipment. This helps maintain a clean and hygienic environment.

- Water quality: Using clean, chlorinated water for cleaning and sanitizing is vital.

I adhere strictly to established guidelines and best practices for milk hygiene to guarantee milk quality and safety. I also maintain detailed cleaning logs to monitor sanitation and identify any recurring issues.

Q 7. What safety protocols do you follow when maintaining milking equipment?

Safety is my top priority during milking equipment maintenance. I always follow these protocols:

- Lockout/Tagout procedures: Disconnecting power supplies before performing any maintenance or repair work to prevent electrical shocks.

- Personal Protective Equipment (PPE): Wearing appropriate PPE such as gloves, eye protection, and protective clothing to prevent injuries and exposure to chemicals.

- Safe handling of chemicals: Correctly handling and storing cleaning and sanitizing agents according to manufacturer instructions and safety data sheets.

- Vacuum safety: Exercising extreme caution when working with vacuum systems to prevent injuries from sudden pressure changes.

- Regular equipment inspections: Inspecting equipment for wear and tear, loose parts, and any potential hazards before commencing work.

By adhering to these safety protocols, I minimize the risk of accidents and ensure a safe working environment for myself and others. Regular training on safe work practices is essential for maintaining a safe and efficient operation.

Q 8. Describe your experience with the installation and commissioning of new milking systems.

My experience with installing and commissioning new milking systems spans over a decade. It’s a multi-stage process that begins with careful site assessment – ensuring adequate power, water supply, drainage, and space for the equipment and operator movement. Next comes the physical installation, which involves precise placement of the milking units, pipeline routing, and connection to the bulk tank. We then proceed to the commissioning phase, a critical step involving meticulous testing of every component. This includes checking the vacuum system for leaks, calibrating the milk meters, ensuring the automatic cluster removal functions properly, and confirming the correct functioning of the cleaning-in-place (CIP) system. I’ve worked on various systems, from herringbone parlors to rotary systems, and I always prioritize safety and hygiene throughout the entire process. For instance, on a recent project involving a new rotary parlor, we encountered a slight misalignment in the vacuum line which was identified during the commissioning phase and rectified before going live, preventing potential future problems.

We also incorporate rigorous testing of the control system, ensuring seamless data logging and integration with farm management software. Following commissioning, we provide comprehensive training to the farm staff on operation and maintenance procedures.

Q 9. How familiar are you with programmable logic controllers (PLCs) used in milking systems?

I’m highly proficient in working with PLCs (Programmable Logic Controllers) in milking systems. PLCs are the brains of the operation, controlling virtually every aspect, from vacuum regulation and milk flow to cluster removal and cleaning cycles. My expertise extends to troubleshooting PLC programming issues, modifying existing programs, and implementing new functionalities. I can read and interpret ladder logic diagrams, understand the input/output relationships, and diagnose faults using diagnostic tools. For example, I once resolved a production slowdown caused by a faulty sensor signal by identifying the incorrect programming in the PLC that misinterpreted the low-milk signal. This was achieved using a combination of the PLC’s diagnostic tools and my understanding of the system’s flow charts. I’m experienced with several PLC brands commonly used in dairy farming, such as Siemens and Allen-Bradley.

Q 10. How do you perform routine inspections of the milking parlor and associated infrastructure?

Routine inspections are crucial for maintaining optimal milking system performance and hygiene. My inspection process is methodical and follows a checklist. I start with a visual inspection of the entire milking parlor, checking for any signs of damage or leaks in the pipelines, vacuum lines, and milking clusters. I examine the condition of the floor and walls, checking for cleanliness and any signs of wear and tear. Next, I check the functionality of all equipment, including the vacuum pump, milk meter, and the CIP system. I meticulously inspect the milking clusters for proper functionality, checking for any blockages or damage. This is often followed by testing the functionality of the automatic cluster removal system. I then carefully inspect the bulk tank for cleanliness and proper temperature control. Finally, I review the data logs from the PLC for any irregularities or anomalies that might indicate a potential issue. Documenting every observation is critical, so I always maintain a detailed log for each inspection. This allows for proactive maintenance and early detection of potential problems. For example, a slight decrease in vacuum pressure consistently noted during inspections alerted us to a small leak in the vacuum line, which was then promptly repaired.

Q 11. Explain your experience with repairing vacuum pumps and pipelines in milking systems.

Repairing vacuum pumps and pipelines is a regular part of my work. I am familiar with diagnosing malfunctions in vacuum pumps, identifying issues such as worn bearings, damaged seals, or insufficient oil levels. I can perform routine maintenance, such as oil changes and filter replacements. With pipelines, I’m adept at locating and repairing leaks using appropriate welding techniques or replacing damaged sections. I am also experienced with different types of vacuum pump designs and understand the importance of maintaining the correct vacuum levels for efficient milking. For example, I once repaired a vacuum pump which was causing inconsistent vacuum, by replacing the worn-out vacuum pump diaphragm, resulting in restoring the desired vacuum level and efficiency of the milking system. Furthermore, I’m skilled in identifying the source of vacuum leaks using specialized leak detection tools. This ensures that the entire milking system operates at peak efficiency and minimizes the risk of contamination.

Q 12. What is your experience with troubleshooting electrical issues in milking equipment?

Troubleshooting electrical issues is a significant aspect of my role. I possess a strong understanding of electrical safety regulations and procedures. My troubleshooting approach involves systematically checking wiring, fuses, circuit breakers, and control panels. I use multimeters and other diagnostic tools to identify faulty components. I am also capable of tracing and repairing wiring issues, replacing faulty components, and restoring power to malfunctioning equipment. I understand the importance of proper grounding and earthing to prevent electrical shocks and equipment damage. A recent example involved a faulty motor in a milk pump. By using a multimeter, I was able to isolate the problem to a burnt-out winding in the motor, which was then promptly replaced. This involved safely disconnecting the power, verifying the correct voltage using a multimeter, and finally, installing and testing the new motor. Safety is always my top priority when dealing with electrical systems.

Q 13. How do you manage spare parts inventory for milking equipment maintenance?

Managing spare parts inventory is crucial for minimizing downtime. I employ a computerized inventory management system to track all parts, including their quantities, usage rates, and lead times for replenishment. This system allows me to forecast demand and maintain optimal stock levels, reducing the risk of delays due to unavailability of parts. The system also tracks the expiry dates for consumables such as cleaning chemicals and lubricants, ensuring that only fresh supplies are used. We classify parts into critical and non-critical categories. Critical parts, like vacuum pump seals, are kept in larger quantities, whereas non-critical parts are ordered on an as-needed basis. Regular audits ensure the system is functioning accurately, and allows for proactive identification of parts requiring replenishment. This efficient approach significantly reduces downtime and ensures the continued smooth operation of the milking system.

Q 14. What is your experience working with different types of milking equipment manufacturers?

I’ve worked with a wide range of milking equipment manufacturers, including DeLaval, GEA, Boumatic, and Fullwood Packo. Each manufacturer has its unique design features and technological specifications. This experience has allowed me to develop a comprehensive understanding of the commonalities and differences among various systems and components, making me a versatile and adaptable technician. I understand the specific needs and requirements of each manufacturer’s equipment, including the use of their proprietary software and tools. This adaptability allows me to quickly learn and effectively maintain any new system introduced on the farm, irrespective of the manufacturer. The ability to work with multiple systems is highly beneficial in a dynamic farm environment. My understanding of different manufacturers’ systems allows me to provide informed recommendations to clients, based on their specific needs and budgetary considerations.

Q 15. How familiar are you with relevant health and safety regulations related to dairy farming?

My familiarity with health and safety regulations in dairy farming is extensive. I’m thoroughly versed in OSHA (Occupational Safety and Health Administration) guidelines, as well as any state or local regulations specific to dairy operations. This includes understanding and adhering to standards for handling chemicals (like cleaning agents), operating machinery safely (milking machines, bulk tanks), and maintaining a hygienic environment to prevent contamination and the spread of disease. I’m particularly attentive to procedures regarding personal protective equipment (PPE), such as gloves, goggles, and boots, and the safe disposal of waste materials. For example, I always ensure that all cleaning agents are stored properly and handled according to the manufacturer’s instructions, preventing accidental exposure. Regular safety training is crucial, and I actively participate in updates to stay current with evolving best practices and legal requirements.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your experience with cleaning and sanitizing milking equipment using various cleaning agents.

Cleaning and sanitizing milking equipment is paramount for maintaining milk quality and preventing bacterial growth. My experience encompasses using a variety of cleaning agents, including alkaline detergents, acid cleaners, and sanitizers (like iodophors or chlorine-based solutions). The process typically involves a multi-step approach. First, the equipment is pre-rinsed with warm water to remove any visible milk residue. Then, a thorough wash with a hot, detergent solution follows, typically using a high-pressure washer to remove stubborn milk solids. After rinsing, a sanitizer is applied, ensuring proper contact time as indicated on the product label. This whole process is often automated in modern dairies, but I’m adept at both automated and manual cleaning procedures. For instance, I’ve worked with CIP (Clean-In-Place) systems, which automate the entire cleaning cycle, and I’m familiar with various types of detergent formulations for different equipment and levels of soiling. Regular monitoring and testing of the cleaning and sanitizing solutions are crucial to ensure their effectiveness. We often use ATP testing to verify the cleanliness of the equipment.

Q 17. How do you ensure the proper functioning of the milk cooling system?

Maintaining a properly functioning milk cooling system is critical to preserving milk quality and preventing spoilage. This involves regular checks of the refrigeration unit’s temperature, ensuring it consistently maintains the optimal temperature (typically below 40°F or 4°C). I routinely inspect the compressor, condenser, and evaporator for any signs of malfunction, such as unusual noises, leaks, or icing. Cleanliness is also vital; I ensure that the condenser coils are free from dust and debris, which can impede efficient heat transfer. Additionally, I monitor the milk flow through the cooling system and check the bulk tank’s temperature regularly using both the tank’s thermometer and independent verification equipment. I’m also experienced in troubleshooting common issues like refrigerant leaks, faulty sensors, or clogged lines, and I understand the importance of preventative maintenance, like changing filters and lubricating moving parts, to prolong the system’s lifespan and prevent costly repairs. For example, I once identified a failing compressor by detecting an unusual high-pitched whine, preventing a larger breakdown and potential milk spoilage.

Q 18. Describe your approach to diagnosing and repairing issues related to milk flow and measurement.

Diagnosing and repairing milk flow and measurement issues requires a systematic approach. I begin by carefully observing the entire milking system, checking for blockages, leaks, or any signs of malfunction in the milking units, vacuum lines, or milk transfer pipes. I’ll verify the proper functioning of pulsators, checking their rhythm and pressure. If there’s an issue with milk flow, I’ll investigate the vacuum pump, ensuring it’s producing the correct vacuum level. For measurement issues, I’ll check the milk meter’s calibration and look for any errors in the recording system. I’m familiar with various types of milk meters and their troubleshooting methods. I frequently use flow charts or diagnostic diagrams to help isolate the problem. For example, if the milk flow is consistently low, I might systematically check each section of the pipeline, starting from the milking cluster, to identify the point of restriction. Proper documentation of all troubleshooting steps and repairs is crucial for record-keeping and future maintenance.

Q 19. How do you document maintenance activities and generate reports?

I meticulously document all maintenance activities using both digital and paper-based systems. This includes detailed records of cleaning and sanitizing procedures, equipment inspections, repairs, and preventative maintenance schedules. I use computerized maintenance management systems (CMMS) to track equipment performance, identify recurring issues, and schedule future work. My reports include dates, times, work performed, parts used, and any observations about equipment conditions. I can generate various reports tailored to specific needs – for instance, a monthly report summarizing all maintenance activities, or a detailed report on a specific piece of equipment’s history. Clear and concise documentation is essential for compliance, auditing, and improving overall farm efficiency. I strive to make my reports readily accessible and easily understandable for others involved in farm operations.

Q 20. What is your experience with milk recording and data analysis related to milking efficiency?

My experience with milk recording and data analysis is significant. I’m proficient in using milk recording software to track individual cow milk production, helping identify high- and low-performing animals. This data, combined with other factors like somatic cell count (SCC) and breed information, is crucial for making informed management decisions. I can analyze milk yield trends to identify potential problems, such as health issues or nutritional deficiencies, that might impact milk production. I understand the importance of data accuracy and regularly verify the data’s reliability. This analysis contributes to improving milking efficiency by optimizing feeding strategies, implementing selective breeding programs, and ensuring timely intervention when problems arise. For example, by identifying cows with consistently lower milk yields, we can investigate possible health issues, optimize their diets, and improve their overall performance, impacting the farm’s overall profitability.

Q 21. Describe your experience working with different milk meters and monitoring systems.

I have extensive experience working with various milk meters and monitoring systems, including flow meters, weight sensors, and automated recording systems. I understand the principles of operation for each type and can troubleshoot common malfunctions. I can calibrate milk meters, ensuring accurate milk measurement and minimizing errors. My experience includes working with both in-line milk meters (integrated into the pipeline) and those used for individual cow measurements. I also understand the importance of integrating milk meter data with other farm management software for comprehensive record-keeping and analysis. For example, I’m familiar with systems that track individual cow milk production, identifying peak lactation periods, and helping detect any significant drops that might indicate health issues. Regular maintenance and calibration of these systems are essential for their accuracy and reliability, and I ensure that these tasks are carried out diligently and meticulously.

Q 22. What is your understanding of herd management and how it relates to milking equipment maintenance?

Herd management encompasses all aspects of caring for a dairy herd, from nutrition and breeding to health and milking. Effective herd management is intrinsically linked to milking equipment maintenance because the health and productivity of the cows are directly impacted by the hygiene and functionality of the milking system. For instance, a malfunctioning milking machine can lead to increased risk of mastitis (udder infection) due to improper vacuum levels or poor teat cup liner hygiene. This, in turn, reduces milk yield and overall herd profitability. Conversely, well-maintained equipment contributes to healthier cows, higher milk production, and reduced veterinary costs.

Specifically, regular maintenance schedules should be tailored to the herd size and milking system. For example, a larger herd with an automated milking system (AMS) will require more frequent checks and preventative maintenance compared to a smaller herd with a conventional parlor.

Q 23. How do you manage and prioritize maintenance tasks to minimize downtime?

Prioritizing maintenance tasks requires a proactive approach that combines preventative and corrective maintenance strategies. I use a computerized maintenance management system (CMMS) to schedule routine tasks such as lubrication, cleaning, and inspections of all milking equipment components. This system allows me to track maintenance history, predict potential failures, and manage spare parts inventory effectively. The CMMS also helps prioritize tasks based on criticality and potential downtime. For example, a faulty vacuum pump would be prioritized over a minor leak in a milk line. A visual inspection checklist is also vital, allowing for quick identification of problems before they escalate. We use a color-coded system – green for operational, yellow for needing attention soon, and red for immediate action – for easy identification of equipment status. This ensures efficient allocation of resources and minimizes disruption to milking operations.

In addition to scheduled maintenance, I conduct regular walk-through inspections to identify potential problems. This allows for quick interventions and prevents minor issues from becoming major breakdowns. This proactive approach is significantly more cost-effective than reacting to breakdowns.

Q 24. Describe your experience with the maintenance of refrigeration systems used in dairy facilities.

My experience with dairy refrigeration systems includes the maintenance of both plate and bulk tank chillers. This involves regular cleaning of condenser coils, monitoring refrigerant levels, and checking for leaks. I’m proficient in troubleshooting compressor issues, understanding the intricacies of the refrigeration cycle, and ensuring the system operates at peak efficiency. Regular monitoring of temperature and pressure readings is essential for detecting anomalies early on. Additionally, I have experience with preventative maintenance tasks such as oil changes and filter replacements. I understand the importance of maintaining optimal temperature for milk quality, preventing bacterial growth and ensuring safe storage. For example, in one instance, we detected a minor refrigerant leak causing a temperature fluctuation in the bulk tank. By addressing this promptly, we prevented potential milk spoilage and maintained compliance with food safety standards.

Q 25. How familiar are you with the principles of fluid mechanics as they apply to milking systems?

Understanding fluid mechanics is crucial for maintaining efficient milking systems. It governs the flow of milk through the milking machine, influencing vacuum levels, milk flow rate, and the potential for pulsation issues. I understand principles like Bernoulli’s principle, which explains the relationship between pressure and velocity of milk flow within the system. For example, an understanding of these principles allows me to troubleshoot issues relating to inadequate milk flow, such as blockages in the lines or incorrect vacuum settings. Similarly, I can diagnose issues related to pulsator function by analysing the pressure differentials and pulsation rates. Furthermore, knowledge of fluid dynamics helps in the proper sizing of pipes and selection of appropriate pumps to maintain optimal milk flow without causing damage to the udder.

Q 26. Explain your experience with the calibration and maintenance of milking machine components.

Calibration and maintenance of milking machine components is a key aspect of my role. This includes regular calibration of the vacuum pump, pulsator, and milk meter to ensure they operate within the manufacturer’s specifications. We utilize calibrated gauges and test equipment to ensure accuracy. Maintenance involves regular cleaning, lubrication, and replacement of worn parts such as pulsator diaphragms, claw components, and teat cup liners. Proper calibration prevents issues such as uneven milking, udder trauma from excessive vacuum, and inaccurate milk recording. For instance, inconsistent vacuum levels can lead to incomplete milk removal or injury to the cow’s teats. Regular calibration and maintenance ensure that the milking process is efficient, comfortable for the cows, and produces accurate milk yield data. We use a detailed logbook to record all calibration and maintenance activities, which is essential for traceability and compliance.

Q 27. How do you identify and address issues related to water quality in the milking parlor?

Water quality is paramount in maintaining hygienic milking practices. Poor water quality can lead to bacterial contamination of the milking system and result in mastitis. I regularly monitor water quality parameters, including chlorine levels, pH, and bacterial counts. We use water treatment systems, such as filters and UV sterilization, to ensure the water used for cleaning and sanitizing the milking equipment meets the required standards. Regular testing and monitoring are critical in preventing issues. A sudden increase in bacterial count, for example, would indicate a problem needing immediate attention. This could include cleaning the water system, replacing filters, or investigating a potential leak that is contaminating the supply. This proactive approach helps to minimize the risk of contamination and ensures the production of high-quality, safe milk.

Q 28. Describe your experience with the maintenance of various types of milking clusters and teat cups.

I have extensive experience maintaining various types of milking clusters and teat cups, from conventional to automated systems. This includes regular inspection, cleaning, and sanitization procedures. I’m familiar with different types of teat cup liners and their impact on milk yield and udder health. Regular inspection for wear and tear, including checking for cracks or damage in the teat cups, is critical to prevent udder irritation and infections. Proper liner replacement is essential to maintain optimal vacuum and milk flow. We use specific cleaning procedures according to the manufacturer’s recommendations and comply with all relevant food safety regulations. Regular maintenance ensures the longevity of these components and promotes udder health, thus contributing to higher milk production and a healthier herd. I understand the impact of different milking cluster designs on the milking process and ensure we select equipment appropriate for the size and type of our herd.

Key Topics to Learn for Maintaining Milking Equipment and Facilities Interview

- Milking Machine Operation and Maintenance: Understanding the various components of milking machines (e.g., pulsators, vacuum pumps, claw units), their functions, and routine maintenance procedures like cleaning, lubrication, and troubleshooting common malfunctions.

- Cleaning and Sanitization Protocols: Mastering effective cleaning and sanitization techniques to prevent bacterial contamination and maintain hygiene standards. This includes understanding different cleaning agents, their application, and proper rinsing procedures.

- Dairy Facility Hygiene and Biosecurity: Knowledge of maintaining a clean and safe dairy environment to minimize the risk of disease transmission. This involves understanding waste management, pest control, and implementing biosecurity measures.

- Troubleshooting and Repair: Developing problem-solving skills to identify and address malfunctions in milking equipment efficiently. This includes understanding diagnostic procedures and performing basic repairs or knowing when to call for professional assistance.

- Record Keeping and Preventative Maintenance: Implementing effective record-keeping systems to track maintenance activities, repairs, and cleaning schedules. Understanding the importance of preventative maintenance to minimize downtime and extend equipment lifespan.

- Safety Regulations and Procedures: Familiarity with relevant health and safety regulations concerning the operation and maintenance of milking equipment and facilities. This includes safe handling of chemicals and understanding personal protective equipment (PPE) requirements.

- Milk Quality and Handling: Understanding the impact of equipment maintenance on milk quality and the procedures for handling milk to ensure it meets industry standards.

Next Steps

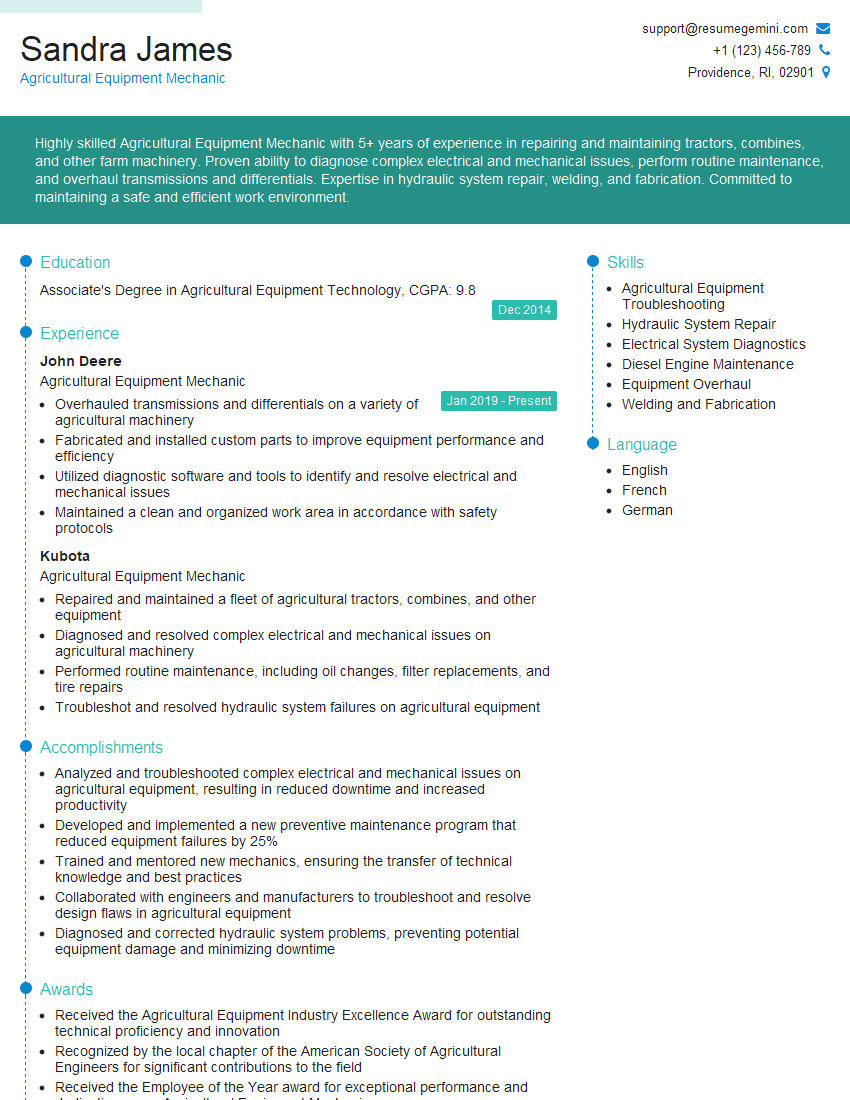

Mastering the maintenance of milking equipment and facilities is crucial for a successful and rewarding career in the dairy industry. It demonstrates your commitment to hygiene, efficiency, and animal welfare, making you a highly valuable asset to any dairy operation. To maximize your job prospects, creating a strong, ATS-friendly resume is vital. ResumeGemini can help you build a professional and impactful resume that highlights your skills and experience effectively. They provide examples of resumes tailored specifically to roles in Maintaining milking equipment and facilities, giving you a head start in crafting your application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good