Cracking a skill-specific interview, like one for Proficiency in Sewing and Leatherworking Techniques, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Proficiency in Sewing and Leatherworking Techniques Interview

Q 1. What types of sewing machines are you proficient with?

My proficiency spans a range of sewing machines, from industrial models like the Juki DDL-8700 for heavy-duty leather work to domestic machines like the Singer 4423, ideal for lighter fabrics and detail work. I’m also comfortable using specialized machines like walking foot machines for even feed on multiple layers of leather and coverstitch machines for creating professional-looking seams. My experience encompasses both mechanical and computerized machines, allowing me to adapt to various project requirements and material thicknesses. For instance, the Juki’s robust build is essential when sewing thick saddle leather, while the Singer’s versatility is perfect for projects involving both leather and fabric.

Q 2. Describe your experience with different leather types and their properties.

My experience encompasses a wide spectrum of leathers, each with unique properties impacting the design and construction process. Full-grain leather, for example, boasts durability and a natural, beautiful grain, making it suitable for high-end goods. However, its thickness requires specialized needles and stitching techniques. Top-grain leather, while more affordable, is less durable and may require more careful handling. I’ve also worked extensively with suede, which has a softer, napped surface requiring different finishing techniques to prevent damage. Understanding these differences—their thickness, tensile strength, and grain – dictates needle selection, stitch length, and finishing methods. For example, I’d use a heavier-duty needle and a stronger thread for full-grain leather than for suede.

Q 3. Explain your process for creating a pattern from a design sketch.

Creating a pattern from a design sketch involves a multi-step process. First, I meticulously analyze the sketch, noting all dimensions and design details. I then translate these details onto paper, using accurate measurements and taking into account seam allowances. I often begin with a basic block pattern (a foundational pattern for the garment type) and then adjust it to match the specific design. This process might involve drafting new pattern pieces or modifying existing ones. Next, I test the pattern by creating a muslin toile (a test garment made from inexpensive fabric). This allows me to identify and correct any fit issues before working with the expensive leather. Finally, I refine the pattern based on the toile’s fit and make adjustments as needed, ensuring a perfect fit and a flawless final product. For example, creating a pattern for a leather jacket begins with a basic jacket block, adjusted for the specific design details like collar style, pocket placement, and sleeve shape.

Q 4. How do you ensure precision and accuracy in your sewing?

Precision and accuracy are paramount in leatherworking. I achieve this through careful planning and meticulous execution. Firstly, I use high-quality tools, including sharp needles, accurately calibrated sewing machines, and precise measuring instruments. Secondly, I pay close attention to detail throughout the process, ensuring accurate cutting, marking, and stitching. Thirdly, I utilize techniques like test stitching on scrap leather before applying stitches to the main project. Finally, I employ various strategies to maintain consistent stitch length and tension throughout the project. For instance, using a walking foot prevents slippage, particularly crucial with multiple layers of leather. This meticulous approach ensures consistent stitch quality and minimizes the risk of errors.

Q 5. What are your preferred leather finishing techniques?

My preferred leather finishing techniques depend largely on the project and the desired aesthetic. For a natural, rustic look, I might use a simple leather conditioner and a light buffing to enhance the leather’s natural beauty. For a more polished finish, I often employ various dyes and finishes, depending on the type of leather and the color desired. I’m proficient in applying edge paints and finishes, providing a clean, professional look to the leather edges. Techniques like hand-burnishing or tooling can add unique texture and detail. Choosing the correct finishing technique is critical – for example, applying a heavy-duty finish to delicate suede would damage its texture. I always conduct thorough research and testing to ensure I select the best method for each project.

Q 6. How do you troubleshoot common sewing machine problems?

Troubleshooting sewing machine issues is a vital skill. I systematically approach problems, starting with the simplest solutions. Common problems include skipped stitches, which often result from improper tension, a bent needle, or clogged bobbin case. I always check the needle for bends or damage first, then the bobbin area for lint or thread build-up. Jammed needles or broken threads can usually be traced to incorrect needle selection or improper thread tension. If the problem persists, I’ll check the machine’s manual for more specific troubleshooting advice and if necessary, consult a professional repair technician. A methodical approach, combined with a solid understanding of the machine’s mechanics, allows for swift and efficient problem resolution. For example, hearing a rhythmic clicking sound often indicates a timing issue requiring professional attention.

Q 7. Describe your experience with various stitching techniques (e.g., saddle stitch, blind stitch).

My expertise extends to a variety of stitching techniques, each suited to specific applications. The saddle stitch, a hand-stitching technique, offers incredible strength and durability, ideal for high-stress areas in leather goods. It’s a classic technique, offering both strength and visual appeal. The blind stitch, often used for attaching linings, minimizes stitch visibility. I also utilize machine stitching techniques, adjusting stitch length and type depending on the leather’s thickness and the project’s requirements. Understanding the strengths and limitations of each method allows for informed decisions, influencing both the aesthetic and structural integrity of the final product. For example, I might use a saddle stitch to construct a robust leather wallet, while employing a blind stitch to invisibly attach a lining to a leather bag.

Q 8. How do you select appropriate thread types for different fabrics and leathers?

Choosing the right thread is crucial for a durable and aesthetically pleasing finished product. The selection depends heavily on both the fabric and the leather’s weight, texture, and intended use. For delicate fabrics like silk or fine linen, I’d opt for a fine-gauge thread, such as a 100/3 cotton thread, known for its strength and smoothness. This prevents the thread from overpowering the fabric or creating visible holes. Heavier fabrics like canvas or denim might require a stronger thread like a heavier cotton or even a polyester thread for added durability, perhaps a 50/2 or even a 30/2.

With leather, the choice is equally important. For thinner leathers like kid or lambskin, a waxed linen thread, known for its strength and flexibility, would be a good choice. It’s strong enough to hold stitches without damaging the delicate leather. For thicker leathers, such as full-grain cowhide, a thicker, more robust thread like a polyester or nylon thread is often preferred to withstand the stress of heavy use. The color is another critical factor; I carefully select a thread color that complements or contrasts with the leather and fabric, enhancing the overall design. I might even use a contrasting color for a bold visual effect.

- Fine Fabrics (Silk, Linen): 100/3 Cotton Thread

- Heavy Fabrics (Canvas, Denim): 50/2 or 30/2 Cotton or Polyester Thread

- Thin Leather (Kid, Lambskin): Waxed Linen Thread

- Thick Leather (Cowhide): Polyester or Nylon Thread

Q 9. Explain your understanding of different leather dyeing methods.

Leather dyeing is an art form in itself, and various methods exist depending on the desired effect and type of leather. The most common methods include:

- Water-Based Dyes: These are easy to use and penetrate the leather well, offering a relatively even color distribution. However, they might not be as durable as other methods, particularly on areas exposed to significant wear and tear. I often use this for lighter colors and less durable items.

- Oil-Based Dyes (Fatliquors): These are often used to add richness and depth of color. They also act as a conditioner, softening and preserving the leather, adding flexibility and moisture. Oil dyes are commonly used to create unique antique effects.

- Acrylic Dyes: These are synthetic dyes that provide excellent color fastness and are commonly used when vibrancy and color-retention are crucial. I prefer acrylics for brighter, more resilient colors.

- Edge Dyeing: A specialized technique for coloring the edges of the leather, enhancing visual appeal and offering protection against wear. I often use this to neaten and professionally finish projects.

The choice of method depends heavily on the type of leather, the desired color, and the level of durability required. For instance, I wouldn’t use a water-based dye on a leather handbag destined for daily use; an acrylic or oil-based dye would be a better choice.

Q 10. How do you handle complex patterns or designs?

Handling complex patterns involves a methodical approach. I begin by carefully studying the pattern, breaking it down into smaller, manageable sections. I then create a detailed plan, outlining the order of assembly and identifying any potential challenges beforehand. This helps to prevent mistakes and maintain a smooth workflow. I might even create a small-scale prototype to test the pattern before committing to the final project.

For example, when constructing a complex leather garment with multiple panels and intricate stitching, I would start by pre-cutting all the pieces carefully and meticulously, making sure that all cuts are accurate. Next, I would assemble the sections one by one, checking the fit at each stage. This incremental approach ensures that any errors are easily corrected along the way, rather than waiting until the end. Careful marking and using a variety of stitching techniques depending on the stress points ensure the final product is durable and looks flawless.

Q 11. Describe your experience with various cutting tools for leather.

My experience encompasses a range of cutting tools, each with its own strengths and weaknesses. For precise cutting of leather, I rely heavily on:

- Sharp Rotary Cutters: These are indispensable for clean, consistent cuts, especially when working with large sheets of leather or intricate patterns. Regular sharpening is crucial to maintain their precision.

- Leather Shears: Heavy-duty shears are essential for thicker leathers, providing the power to make clean cuts without tearing the material. Proper maintenance, including regular lubrication, is essential to their longevity.

- Utility Knives with Replacement Blades: Excellent for detail work and intricate cuts, utility knives are useful for trimming seams and shaping smaller pieces. Regular blade changes are crucial to maintain sharpness and prevent uneven cuts.

- Clicker Dies (for mass production): These are specialized metal dies used in conjunction with a press to create identical cuts in high volume. These are crucial for efficiency in large scale leather production.

Selecting the right tool for the job is paramount. Using the wrong tool can lead to damaged materials and frustrating results. For instance, I wouldn’t use a rotary cutter on extremely thick leather; shears would be far more suitable.

Q 12. What are your strategies for managing time effectively on large projects?

Managing time effectively on large projects requires meticulous planning and a structured approach. I start by creating a detailed work breakdown structure (WBS), dividing the project into smaller, manageable tasks. This allows me to assign realistic timelines to each task and to track progress effectively. I use tools like Gantt charts to visualize the project’s schedule and identify potential bottlenecks.

Another key strategy is prioritizing tasks based on their criticality and dependencies. I focus on completing the most crucial tasks first to minimize delays and ensure that the project stays on track. Regular self-assessment of progress helps me identify areas where adjustments might be needed. For instance, if a task is taking longer than expected, I might re-evaluate my approach or seek assistance. Maintaining a clean and organized workspace further contributes to efficient time management.

Q 13. How do you maintain the quality and consistency of your work?

Maintaining quality and consistency requires a multifaceted approach. First and foremost, I prioritize using high-quality materials. The quality of the leather, thread, and other components directly impacts the final product. Secondly, I meticulously follow established techniques and procedures, ensuring consistency in each step of the process.

Regular quality checks are essential throughout the project, identifying and rectifying errors early. I also maintain detailed records of my work, including material specifications, techniques used, and any challenges encountered. This information is invaluable for identifying areas for improvement and for ensuring consistency across projects. Finally, continuous learning and refinement of my skills through practice and experimentation are key to delivering exceptional, consistently high-quality results.

Q 14. Describe your experience with hand-sewing techniques.

Hand-sewing is a fundamental skill in both sewing and leatherwork, offering a level of precision and control often unattainable with machines. I’m proficient in various hand-sewing techniques, including:

- Saddle Stitch: A durable and aesthetically pleasing stitch commonly used in leatherwork, creating a strong and even seam. It’s ideal for high-stress areas and adds a touch of elegance to the finished piece.

- Running Stitch: A basic stitch suitable for basting or for creating decorative seams. Its simplicity makes it quick and versatile.

- Backstitch: A strong and secure stitch ideal for seams requiring maximum strength and durability. It’s frequently used in areas subject to a lot of stress, such as seams on bags or straps.

- Blind Stitch: This stitch is virtually invisible, making it perfect for joining fabric or leather pieces without the seam being visible from the outside.

I select the appropriate technique based on the project’s requirements and the desired aesthetic. Hand-sewing allows for greater precision and control in areas where a machine would be too cumbersome or might damage the material. For example, I might use a saddle stitch for creating a sturdy leather belt, ensuring its longevity, and a blind stitch to neatly join two pieces of fabric without compromising the overall appearance.

Q 15. How do you handle challenging or irregular leather pieces?

Handling irregular leather pieces requires a combination of careful planning and adaptable techniques. Think of it like sculpting – you’re working with a material that has its own unique character.

First, I assess the piece. Is the irregularity a minor imperfection, or a significant variation in shape or size? Minor imperfections can often be incorporated into the design; a slight blemish might become a unique detail in a finished product. For larger irregularities, I might need to adjust my pattern. This often involves creating a template directly on the leather, carefully working around the imperfections, or piecing smaller, workable sections together.

For example, I once had a hide with a large scar. Instead of discarding it, I designed a bag where the scar became a focal point, adding a rustic, handcrafted charm. Sometimes, cleverly placing a decorative element, like stitching or a buckle, can also mask minor imperfections.

Tools like a swivel knife or rotary cutter allow for precise cutting around curves and irregular shapes, ensuring minimal waste and maximizing the usable area. Patience and precision are key – rushing can lead to errors and wasted material.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your experience with using different sewing machine feet.

My experience with different sewing machine feet is extensive, as the right foot is crucial for achieving a professional finish on various materials and projects. Think of them as specialized tools, each designed for a specific task.

- Walking foot: Essential for working with multiple layers of leather or thick fabrics, preventing slippage and ensuring even feeding. It’s like having two sets of feed dogs working together.

- Roller foot: Perfect for slippery or delicate materials like vinyl or very thin leather. The rollers help the fabric move smoothly under the needle, reducing friction and preventing puckering.

- Teflon foot: Ideal for materials that tend to stick to the needle plate, such as synthetics or coated fabrics. The non-stick surface ensures clean stitches.

- Zipper foot: Allows for precise stitching close to the zipper coil without catching or damaging the zipper teeth.

Choosing the wrong foot can lead to skipped stitches, puckering, or even damage to the machine or material. I always select the foot appropriate for the project, ensuring the final product is of the highest quality.

Q 17. What are some common mistakes in sewing and leatherwork, and how do you avoid them?

Common mistakes in sewing and leatherwork stem from a lack of preparation and attention to detail. It’s like baking a cake without following the recipe – the result might be disastrous.

- Poor Pattern Making: Inaccurate patterns lead to ill-fitting garments or products. I always double-check my measurements and create test pieces before cutting into the final material.

- Ignoring Grain Direction: Cutting leather against the grain can cause it to stretch or tear easily. Understanding grain direction is fundamental to achieving durability.

- Incorrect Stitching Tension: Uneven stitching tension results in puckering or loose stitches. I regularly check my machine’s tension settings and adjust them as needed, depending on the material’s thickness and type.

- Using Dull Needles or Blades: Dull tools cause skipped stitches and uneven cuts. Regularly sharpening tools is crucial for efficient and clean work.

Avoiding these mistakes requires careful planning, meticulous attention to detail, and regular maintenance of tools and equipment. It’s better to take the time to do things right the first time than to have to redo work later.

Q 18. How do you ensure the durability and longevity of your leather products?

Durability and longevity in leather products are achieved through a combination of material selection, construction techniques, and proper care. Think of it like building a sturdy house – the foundation and construction methods are crucial for its lifespan.

I prioritize using high-quality, full-grain leather known for its strength and resistance to wear and tear. Proper stitching techniques, such as saddle stitching, are employed to reinforce seams, ensuring strength and preventing unraveling. Reinforcing stress points with additional stitching or rivets further enhances durability. Finally, I often apply leather conditioners to maintain the leather’s suppleness and protect it from environmental damage.

For example, I use heavy-duty nylon thread for added strength in high-stress areas, particularly when constructing items that will receive significant use, such as bags or belts. These steps all contribute to a product’s longevity and ensure it stands the test of time.

Q 19. How do you deal with inconsistencies in fabric or leather materials?

Inconsistencies in materials require careful assessment and strategic problem-solving. It’s like working with a puzzle where some pieces don’t quite fit.

First, I inspect the material thoroughly to identify the nature and extent of the inconsistencies. Minor variations in color or texture can often be blended through careful placement and design. More significant variations might require piecing or adjusting the pattern to accommodate the inconsistencies. For instance, I might use the more consistent sections of leather for areas that are highly visible or that will experience significant wear and tear. Areas with imperfections can be strategically placed on the interior or underside of the project, where they are less noticeable.

Sometimes, creative problem-solving is needed. A slight variation in color can be incorporated into a design element, adding a touch of unique character to the final product. It is all about adapting the design to match the reality of the available materials, creating a beautiful finished product.

Q 20. Describe your experience with different types of zippers and fasteners.

My experience encompasses a wide range of zippers and fasteners, each with its own strengths and weaknesses. Choosing the right fastener is crucial for both functionality and aesthetics. It’s like selecting the right hardware for a piece of furniture – the wrong choice can compromise its strength and appeal.

- Metal zippers: Durable and robust, ideal for heavy-duty applications, but can be more challenging to sew.

- Nylon zippers: Lighter and more flexible, suitable for clothing and softer goods.

- Plastic zippers: Cost-effective but less durable than metal or nylon.

- Magnetic snaps: Convenient and easy to use, ideal for bags and wallets.

- Hook and loop fasteners (Velcro): Versatile and easy to sew, but less elegant than other fasteners.

- Buttons: Classic and versatile, but require buttonholes and careful placement.

I select the appropriate fastener based on the project’s requirements, considering factors like durability, aesthetics, and ease of use. Proper installation techniques are crucial to ensure a smooth, functional, and visually appealing finish.

Q 21. What safety precautions do you follow when working with sewing machines and leather tools?

Safety is paramount in sewing and leatherwork. It’s like working in a laboratory – proper safety precautions are essential to avoid injury.

- Sewing Machine Safety: Always keep my hands clear of moving parts, use the safety cover on the needle, and unplug the machine when changing needles or making adjustments. I always ensure the area around the machine is clear of obstructions.

- Leather Tool Safety: I use sharp tools with care, and always cut away from myself. Protective gear such as safety glasses and gloves are worn when working with cutting tools, especially rotary cutters and knives.

- Proper Workspace: My workspace is well-lit and organized, reducing the risk of accidents. I have a dedicated space for tools and materials, preventing clutter and ensuring a safer environment.

By following these safety guidelines, I significantly reduce the risk of accidents and maintain a safe working environment.

Q 22. How do you maintain and clean your sewing and leatherworking tools?

Maintaining sewing and leatherworking tools is crucial for their longevity and the quality of your work. It’s a bit like caring for your favorite chef’s knives – regular maintenance ensures they stay sharp and effective.

Sewing Machines: After each use, I brush away lint and dust from the bobbin case, feed dogs, and presser foot. I lubricate moving parts according to the manufacturer’s instructions, usually with a high-quality sewing machine oil. Regular cleaning prevents build-up that can cause jams or malfunctions. For example, I once had a machine that constantly jammed due to neglected lint, a simple cleaning solved the problem completely.

Needles: I inspect sewing machine needles before each project and replace them if they are bent, dull, or damaged. Leather needles, in particular, need regular replacement as they wear down quickly.

Leatherworking Tools: Leatherworking tools, like stitching chisels and mallets, benefit from regular cleaning with a stiff brush to remove leather scraps and debris. I oil my leatherworking tools periodically with a suitable leather oil to prevent rust and keep them functioning smoothly. This is especially important for tools made from carbon steel.

Storage: Proper storage is equally important. I store my tools in a clean, dry place, organized by type, to prevent damage and ensure easy access.

Q 23. Describe your experience with industrial sewing equipment.

My experience with industrial sewing equipment spans over 10 years, encompassing various machines like single-needle, double-needle, and even computerized sewing machines. I’m comfortable operating high-speed machines, understanding their nuances, including adjustments for stitch length, tension, and feed rate. I’ve worked extensively on machines from brands like Singer, Juki, and Brother. I’m proficient in troubleshooting common issues like skipped stitches, broken needles, and tension problems. For example, I once had to troubleshoot a malfunctioning double-needle machine during a large production run; by carefully checking the needle timing and tension, I quickly restored its functionality and prevented significant production delays.

Beyond operation, I understand the importance of maintenance for industrial equipment, including regular lubrication and cleaning to maintain optimal performance and extend the life of the machine. The experience has instilled in me a deep understanding of efficiency and precision required in high-volume sewing operations.

Q 24. What software programs are you familiar with for design or pattern making?

I’m proficient in several software programs for design and pattern making. These tools are essential for accurate pattern creation and efficient workflow.

Adobe Illustrator: I use Illustrator extensively for creating vector-based designs, which are crucial for clean, scalable patterns and precise artwork.

Adobe Photoshop: Photoshop is valuable for manipulating images, creating textures, and preparing artwork for print or digital output. For example, I recently used Photoshop to enhance a scanned sketch before creating the vector pattern in Illustrator.

Pattern Design Software (e.g., Pattern Design, OptiTex): I have experience using dedicated pattern-making software for generating and grading patterns, which is particularly helpful for complex garments or large production runs. The software allows for more efficient pattern adjustments and reduces manual labour.

Q 25. Explain your understanding of different leather tooling techniques.

Leather tooling involves shaping and decorating leather using various tools and techniques. It’s a process that allows for creating unique and personalized leather goods. Think of it as sculpting with leather.

Stamping: This involves using stamps to imprint designs onto the leather. Different stamps create different effects, ranging from simple geometric patterns to intricate floral designs.

Carving: Carving involves using specialized tools to cut and shape the leather, allowing for creation of raised or recessed designs. A skilled leatherworker can create complex three-dimensional designs through carving.

Embossing: Embossing creates a raised design by pressing the leather into a mold. It can be used to create subtle textures or highly detailed images.

Molding: This technique involves shaping the leather over forms to achieve specific curves or shapes, which is often used in making saddles or bags.

Edge Finishing: After tooling, the edges of the leather need finishing for durability and aesthetics. This involves processes like beveling, sanding, and polishing, which contribute to the overall quality of the finished product.

Q 26. How would you approach a project with a tight deadline?

Approaching a project with a tight deadline requires a methodical approach focused on efficiency and prioritization. I treat it like a race against the clock, meticulously planned.

Detailed Planning: I begin by breaking down the project into smaller, manageable tasks. This allows for better time management and easier tracking of progress. For example, if I am making a custom leather jacket, I’ll break down the task into pattern cutting, leather preparation, stitching, finishing and quality check.

Prioritization: I prioritize tasks based on their dependencies and urgency. Critical tasks are addressed first to ensure the project remains on track. In this context, stitching might take priority over the finer details of finishing touches.

Efficient Workflow: I optimize my workflow to minimize wasted time and effort. This includes efficient material handling and using tools that are appropriate for the task at hand. I might employ quicker stitching techniques if necessary.

Communication: Open communication with the client is essential. If there is a potential issue or delay, I proactively inform them and explore solutions together. Transparency builds trust and avoids misunderstandings.

Q 27. How do you stay up-to-date with new techniques and trends in sewing and leatherworking?

Staying current in sewing and leatherworking requires continuous learning. It’s an ever-evolving field with new techniques, materials, and tools appearing constantly.

Industry Publications: I subscribe to several industry magazines and online publications to stay abreast of new trends and techniques.

Workshops and Courses: I regularly attend workshops and courses to learn from experienced professionals and expand my skillset. This hands-on learning accelerates my development significantly.

Online Communities: I actively participate in online forums and communities to engage with other craftspeople, share ideas, and learn from their experiences. The collective knowledge available is immense.

Experimentation: I dedicate time to experimenting with new materials and techniques. This practical approach allows me to test and integrate new skills into my workflow.

Q 28. Describe your experience collaborating with designers or other craftspeople.

Collaboration is a cornerstone of successful projects in the design and crafts industry. I have a strong track record of working effectively with designers and other craftspeople.

Clear Communication: Effective communication is paramount. I ensure clear understanding of the project goals, deadlines, and expectations from the outset. This includes actively listening to input and openly discussing potential challenges or adjustments to the design.

Respect for Expertise: I value the expertise of designers and other craftspeople. I embrace their input and incorporate their suggestions into my work to generate a superior final product. For instance, in a recent collaborative project, the designer’s creative vision was enhanced by my technical expertise in leather tooling, resulting in a truly unique product.

Teamwork: I’m a team player, comfortable working collaboratively to achieve common goals. I’m adept at coordinating my work with others, ensuring seamless integration and timely completion of the project.

Problem-Solving: I actively participate in problem-solving discussions, offering creative solutions and contributing to finding the best path forward. Collaborating effectively allows us to resolve any challenges quickly and collaboratively.

Key Topics to Learn for Proficiency in Sewing and Leatherworking Techniques Interview

- Hand Sewing Techniques: Understanding various stitches (e.g., running stitch, backstitch, saddle stitch), their applications, and appropriate needle/thread selection for different materials. Consider the strengths and weaknesses of each stitch type for various projects.

- Machine Sewing Techniques: Familiarity with industrial and domestic sewing machines, including operation, maintenance, and troubleshooting common issues. Discuss experience with different machine settings and their impact on stitch quality and material handling.

- Leather Preparation and Finishing: Knowledge of leather types, conditioning, cleaning, and finishing techniques (e.g., edge finishing, dyeing, stamping). Be prepared to discuss the importance of proper leather preparation for optimal results.

- Pattern Making and Cutting: Explain your experience in creating patterns, transferring patterns to leather, and accurately cutting leather pieces, minimizing waste. Discuss different pattern-making methods and their suitability for different projects.

- Leatherworking Tools and Equipment: Demonstrate familiarity with various tools (e.g., awls, mallets, stitching groovers, punches) and their appropriate use in different leatherworking processes. Be ready to discuss safety precautions associated with using these tools.

- Project Planning and Execution: Describe your approach to planning and executing leatherwork projects, including material selection, time management, and problem-solving during the process. Showcase examples where you overcame challenges during a project.

- Quality Control and Inspection: Explain your methods for ensuring high-quality workmanship and identifying potential defects in your work. Describe your approach to correcting mistakes and maintaining consistent quality.

Next Steps

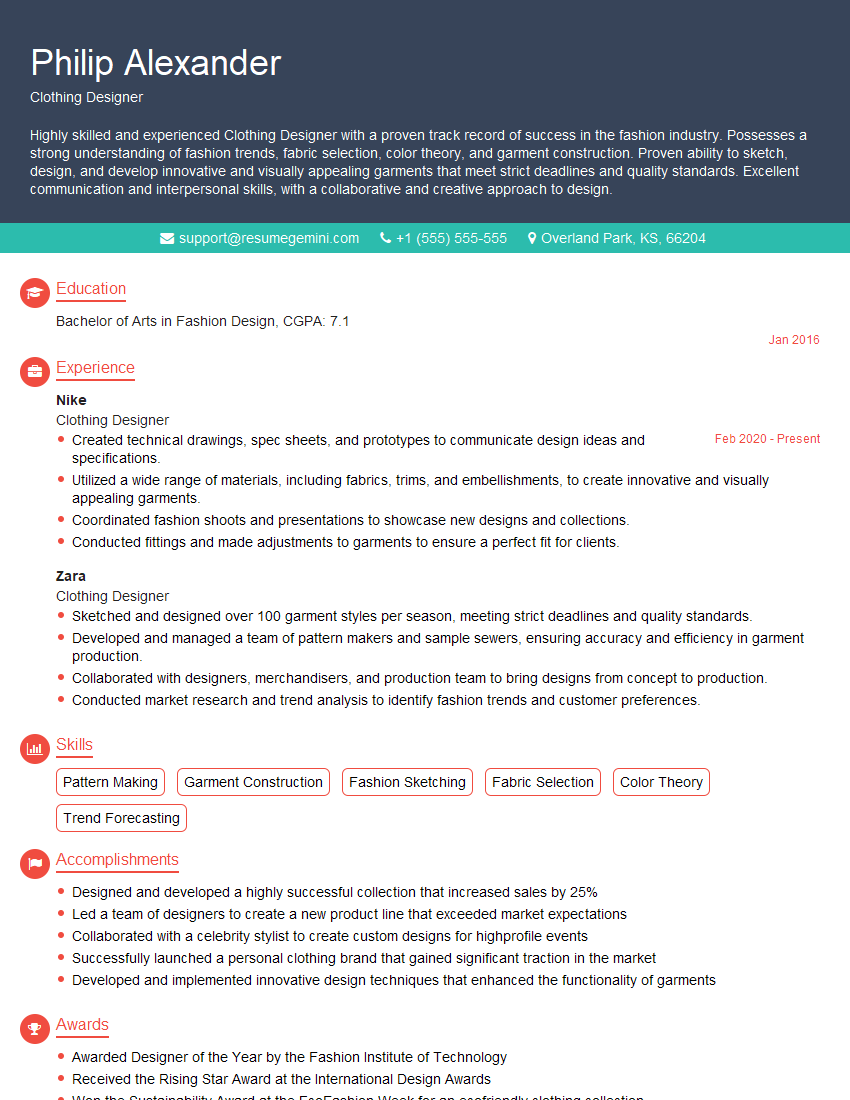

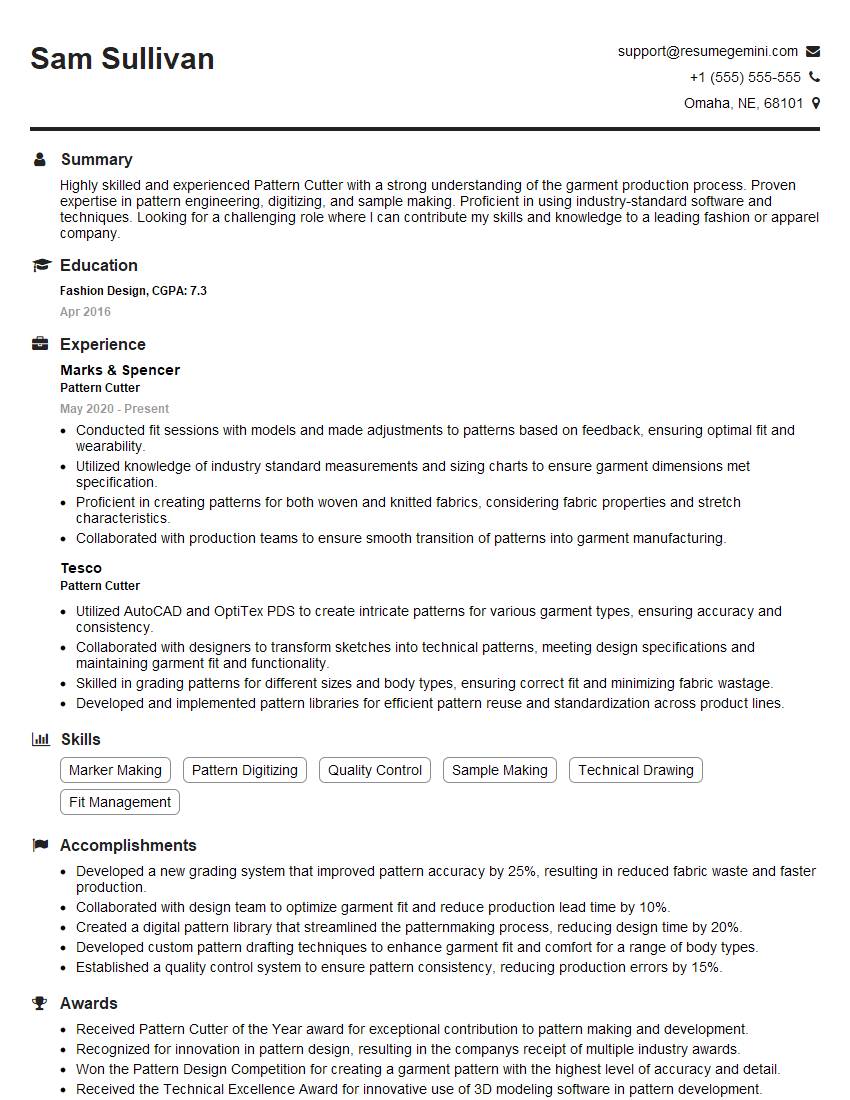

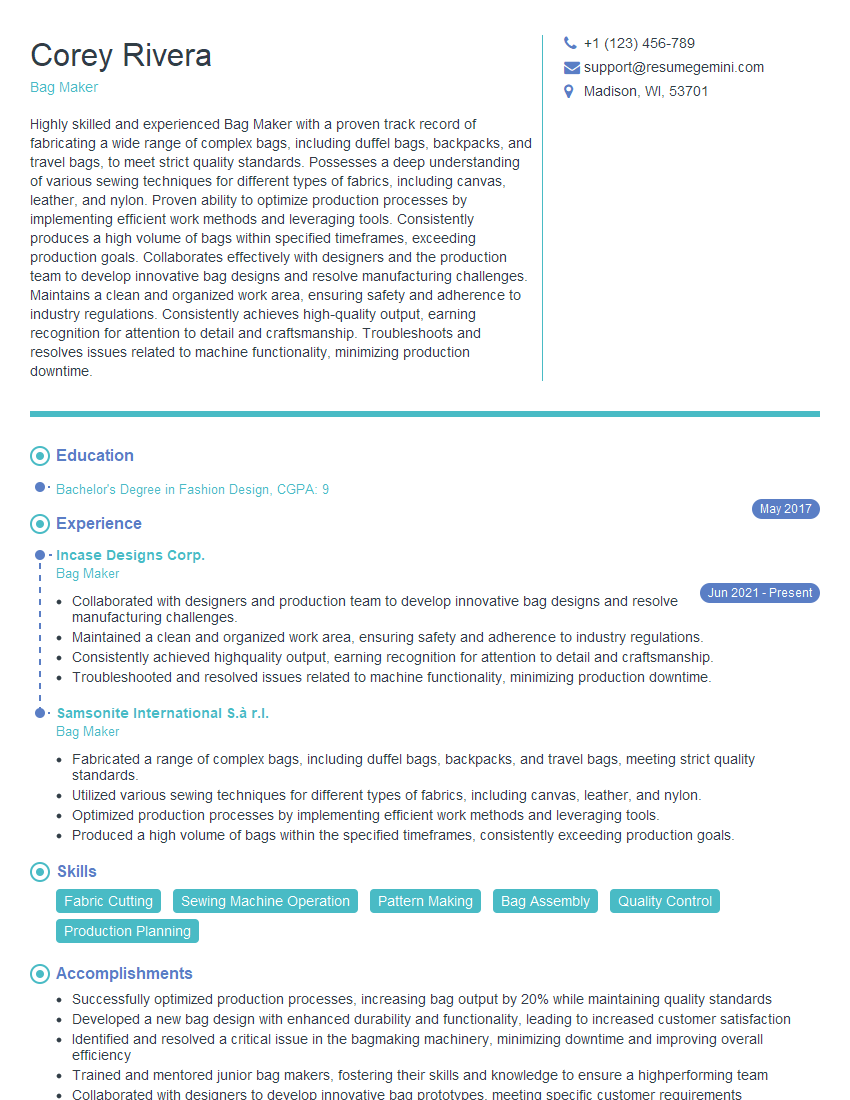

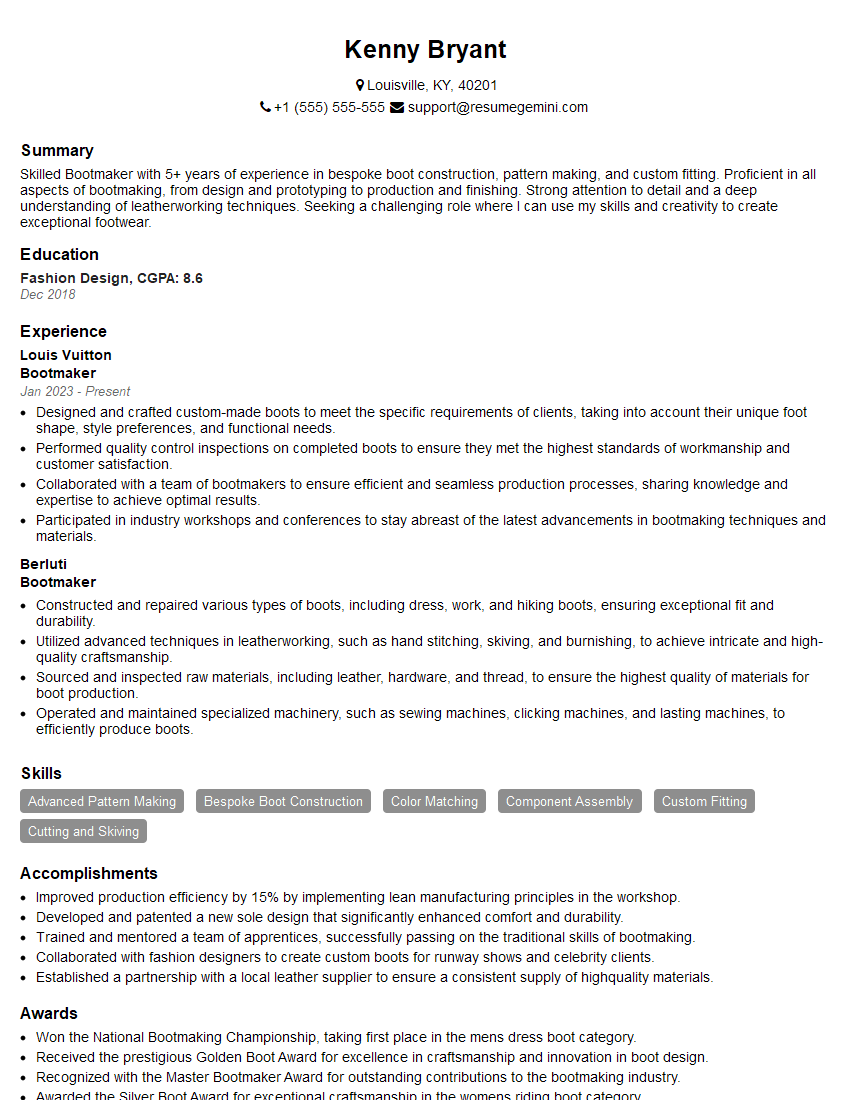

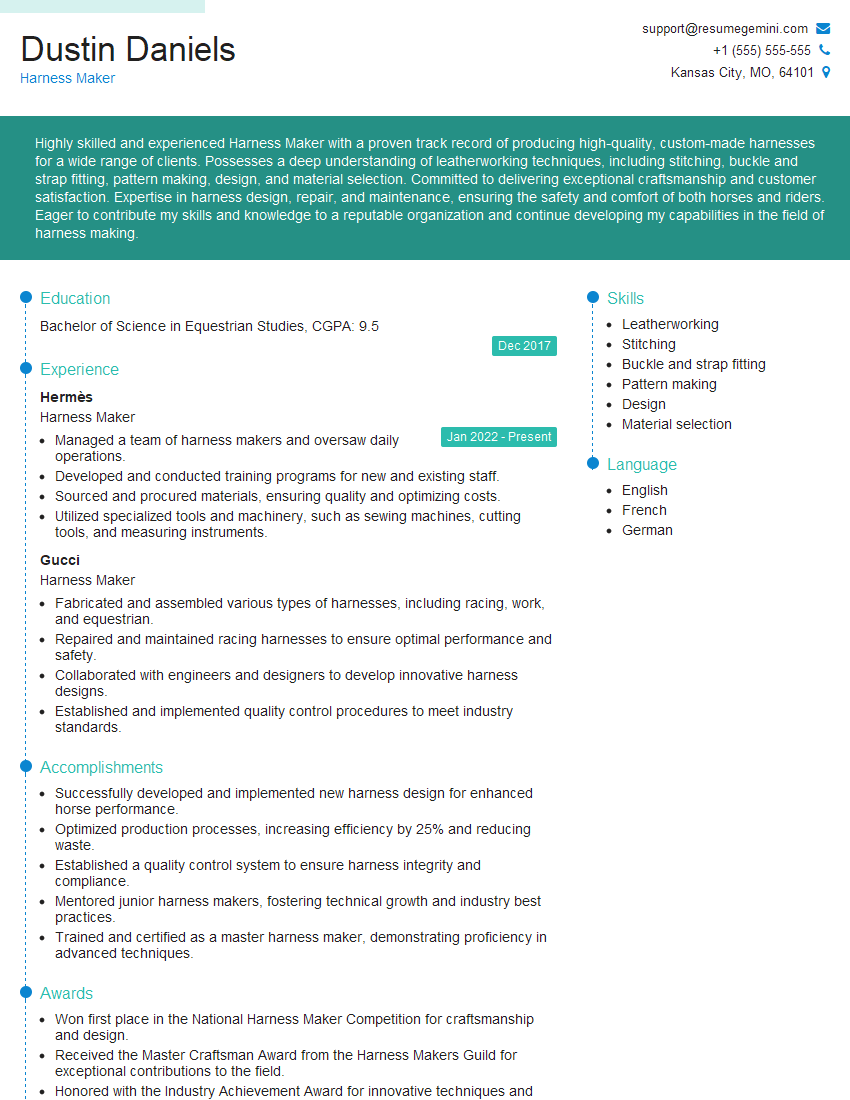

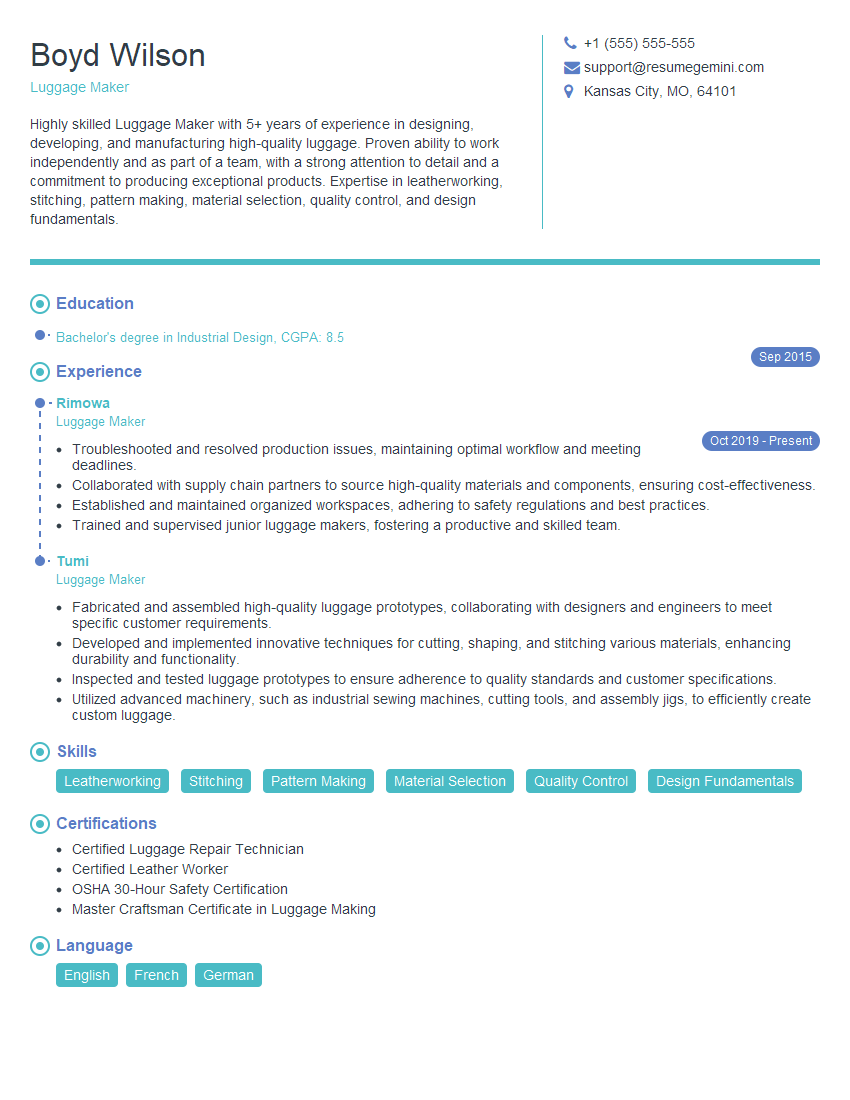

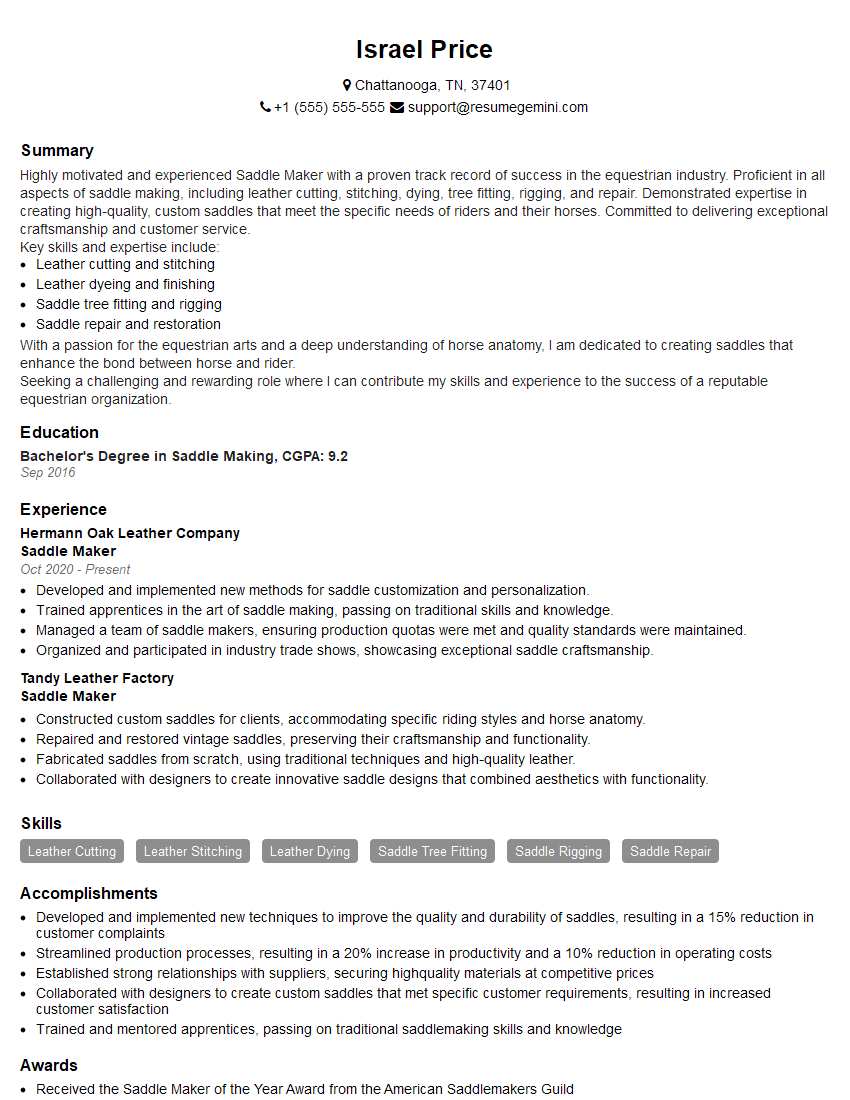

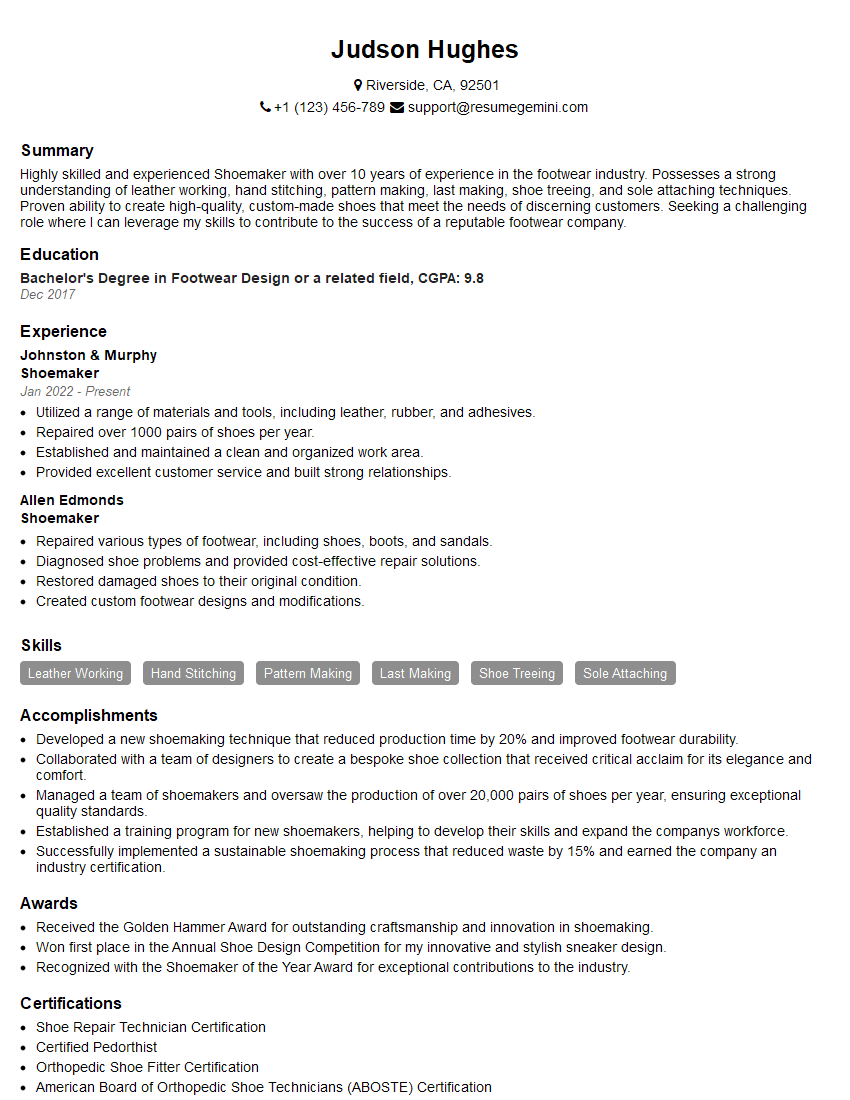

Mastering Proficiency in Sewing and Leatherworking Techniques opens doors to exciting career opportunities in fashion, design, upholstery, and more. To significantly boost your job prospects, creating a strong, ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to your skills and experience. Examples of resumes tailored to Proficiency in Sewing and Leatherworking Techniques are available to help you get started. Invest time in crafting a compelling resume—it’s your first impression on potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good