Unlock your full potential by mastering the most common Design and development of fur products interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Design and development of fur products Interview

Q 1. Explain the different types of fur used in garment manufacturing.

The world of fur offers a diverse range of options for garment manufacturing, each with unique properties and aesthetic qualities. Understanding these differences is crucial for selecting the right fur for a specific design and desired outcome.

- Mink: Known for its luxurious sheen, softness, and durability. It comes in various colors and grades, from darker, more richly colored Saga mink to lighter, more subtle variations. It’s a popular choice for coats, jackets, and stoles.

- Fox: Characterized by its long, full hairs and distinctive coloration patterns, often featuring a blend of colors like red, silver, or white. Fox fur is commonly used for trims, cuffs, and full-length garments, offering a dramatic, statement look.

- Sable: Highly prized for its deep, lustrous brown color and exceptional softness. Sable fur is incredibly dense and warm, making it ideal for luxurious coats and hats. Its value is directly tied to its density and the quality of the underfur.

- Chinchilla: Recognized for its exceptionally soft, dense, and incredibly fine underfur. Its luxurious feel and unique silver-grey color make it a highly sought-after material, often used for collars, cuffs, and smaller garments due to its delicate nature.

- Rabbit: A more affordable option, rabbit fur offers a range of textures and colors. It’s often used in more casual garments or as a lining due to its relatively less durable nature compared to others. Various processing techniques can dramatically alter the look and feel of rabbit fur.

- Shearling: This is sheepskin with the wool left on, offering a unique combination of warmth and softness. Shearling is often used for coats, jackets, and linings, particularly in colder climates.

This is just a small selection; many other furs like raccoon, lynx, and beaver are also used, each with its own distinct characteristics.

Q 2. Describe the process of fur grading and its importance.

Fur grading is a critical process that involves evaluating the quality of the pelts based on several key factors. It’s essential for determining the price and suitability of the fur for specific applications. A skilled grader assesses various aspects such as:

- Length and Density of Guard Hairs: The length and density of the longer, protective hairs influence the fur’s overall appearance and durability.

- Softness and Density of Underfur: A dense, soft underfur contributes significantly to the warmth and luxurious feel of the fur.

- Color and Lustre: Consistent color and a rich, lustrous sheen are highly desirable qualities.

- Condition of Pelt: This considers any imperfections like scars, damage, or missing areas. The condition directly impacts the grade and value of the pelt.

- Size and Shape: The size and shape of the pelt influence its usability and the efficiency of pattern cutting.

The grading process ensures that only the highest-quality pelts are selected for high-end garments, while pelts with imperfections may be used for other purposes or in garments where imperfections are less noticeable. This ensures price points reflect quality and creates consistent results in the final product.

Q 3. How do you select appropriate fur for a specific garment design?

Selecting the right fur for a garment design is a complex process that involves considering several factors. It’s not simply about aesthetics; practicality, durability, and the overall design concept play major roles.

- Design Style: A classic, tailored coat might call for a high-quality, luxurious fur like sable or mink, while a more casual, fun jacket might utilize a more affordable and easily managed fur like rabbit.

- Desired Look and Feel: Do you need a sleek and modern look, or something more rustic and textured? Different furs offer vastly different textures and aesthetics.

- Budget: The cost of fur varies dramatically depending on the animal, the quality of the pelt, and the processing techniques used.

- Seasonality: A heavy, thick fur like fox might be ideal for winter, while a lighter, more airy fur like chinchilla might be more appropriate for milder seasons.

- Garment Construction: Certain furs are better suited for certain garment styles. For example, delicate furs like chinchilla might be better suited for smaller garments or trims, whereas more durable furs like mink can be used for full-length coats.

For example, designing a sleek evening coat requires a fur with a high luster and smooth texture, like mink. In contrast, designing a rugged winter parka might use a more durable fur like coyote, which provides both warmth and a more textured appearance.

Q 4. What are the key considerations for pattern making in fur?

Pattern making for fur is significantly different from pattern making for woven fabrics due to the unique characteristics of fur pelts. Key considerations include:

- Fur Grain and Nap: The direction of the fur’s natural growth (nap) must be carefully considered to ensure a consistent and appealing look. Patterns need to be designed to follow the nap, often requiring more complex shaping and cutting techniques.

- Pelt Size and Shape: Fur pelts are naturally irregular in size and shape, unlike fabric rolls. Pattern pieces must be carefully placed and adapted to maximize material use and minimize waste.

- Stretch and Drape: The stretch and drape of fur vary greatly depending on the type and processing. Patterns need to account for this to achieve the desired fit and drape of the garment.

- Seams and Grainlines: Seams must be carefully placed to avoid disrupting the nap. This often necessitates adjusting traditional seam allowances and grading techniques.

- Pattern Adjustments for Fur Thickness: Thicker furs might require adjustments to pattern pieces to ensure a proper fit.

Imagine trying to cut a pattern on a puzzle with irregular pieces – that’s the essence of fur pattern making. It requires experience, precision, and a strong understanding of the material’s properties.

Q 5. Explain the challenges of cutting and sewing fur compared to other fabrics.

Cutting and sewing fur presents unique challenges compared to working with woven or knit fabrics. The key differences lie in the material’s structure and properties.

- Material Sensitivity: Fur is a delicate and sensitive material prone to damage from sharp tools or excessive pressure. Specialized tools and techniques are needed to avoid tearing or damaging the pelts.

- Cutting Techniques: Sharp, specialized shears are needed for precise cuts. Cutting must follow the fur’s nap direction to maintain its look and feel. Often, special cutting tables with specialized surfaces help prevent slipping or damage.

- Seams and Stitching: Stitching must be carefully executed to prevent pulling or damaging the fur fibers. Specialized needles and thread are often required. Overlapping seams rather than simple edge-to-edge seams are often used to achieve clean, secure joins that avoid damaging the pile.

- Handling Challenges: Fur pelts are bulky and can be difficult to manipulate, requiring a good understanding of material management.

- Slippage: Fur can be slippery, requiring extra care to secure material during cutting and sewing.

Consider sewing delicate lace compared to sturdy canvas. Fur falls somewhere in between – requiring both delicacy and a firm hand.

Q 6. Describe the different fur finishing techniques.

Fur finishing techniques are crucial for enhancing the appearance, feel, and durability of a fur garment. These techniques can significantly influence the final product’s quality and value.

- Shearing: Trimming the fur to create a consistent length and texture. This helps achieve a uniform look and feel.

- Plucking: Removing individual hairs to create a lighter, more airy texture. Often used to lighten up thicker furs.

- Dyeing: Changing the fur’s natural color. This allows for a wider range of color options and design possibilities.

- Glazing: A finishing technique that adds a glossy sheen to the fur, enhancing its luster.

- Finishing Touches: This encompasses various techniques used to enhance the garment’s aesthetic appeal, such as adding decorative elements or trims. These can add texture and interest, such as contrasting fur trims.

- Cleaning and Maintenance: Professional cleaning and care are essential for maintaining the quality and extending the life of fur garments. Using appropriate detergents and storage methods are key.

Just like a painter uses various brushes and techniques to finish a painting, furriers use multiple techniques to achieve the desired look and feel for the final fur garment.

Q 7. How do you ensure the quality and durability of a fur garment?

Ensuring the quality and durability of a fur garment requires attention to detail throughout the entire process, from selection of raw materials to finishing.

- Sourcing High-Quality Pelts: Starting with high-quality pelts is crucial. Careful grading and selection are essential to ensure consistent quality and reduce the likelihood of imperfections.

- Proper Pattern Making and Cutting: Accurate pattern making and careful cutting techniques minimize waste and reduce the risk of damage to the pelts.

- Skilled Seamanship: Careful stitching and seaming techniques ensure the garment’s durability and structural integrity. Using suitable needles and thread is crucial.

- Appropriate Finishing Techniques: The application of suitable finishing techniques enhances the fur’s appearance and durability while protecting the investment.

- Quality Control: Regular quality checks throughout the manufacturing process help identify and rectify any potential issues early on.

- Proper Storage and Care: Correct storage and care instructions are provided to the customer to ensure the longevity of their investment and maintain its condition. Professional cleaning is often recommended.

Think of it like building a house: Using high-quality materials, precise construction, and regular maintenance are all vital to ensure a long-lasting, beautiful structure. The same principle applies to fur garments.

Q 8. What are the ethical considerations in the fur industry?

Ethical considerations in the fur industry are multifaceted and highly debated. The primary concern revolves around animal welfare. The methods used to harvest fur, particularly in the case of farmed animals, often raise questions about humane treatment and the animals’ living conditions. Issues such as overcrowding, inadequate veterinary care, and the methods of killing can lead to significant suffering.

Beyond animal welfare, there are environmental concerns. Fur farming can have significant ecological impacts, including pollution from waste and the potential spread of disease. The use of certain trapping methods in wild fur harvesting can also negatively impact other wildlife populations. Finally, there are ethical questions regarding the consumer demand for fur, and the potential for supporting practices deemed inhumane by many. Transparency in sourcing and a commitment to ethical and sustainable practices are critical for addressing these concerns.

Q 9. Explain the role of CAD software in fur design and development.

CAD (Computer-Aided Design) software plays a crucial role in modern fur design and development, streamlining the entire process from initial concept to final product. It allows designers to create 2D and 3D patterns, simulate draping on virtual models, and experiment with different designs without the need for expensive physical prototypes.

For instance, software can accurately account for the natural variations in fur pelts – their size, shape, and direction of hair. This precision minimizes waste and maximizes the use of valuable materials. We can also use CAD to create complex 3D models of garments, even incorporating details like stitching and seaming. This allows for a highly realistic visualization of the final product before any physical production begins. Moreover, CAD facilitates communication and collaboration across design teams and manufacturers, improving efficiency and reducing errors.

Q 10. How do you manage fur sourcing and supply chain?

Managing fur sourcing and the supply chain requires a multi-pronged approach emphasizing traceability, ethical considerations, and quality control. We begin by carefully vetting our suppliers, ensuring they adhere to strict ethical standards regarding animal welfare and environmental sustainability. This often includes on-site visits to farms or auction houses to assess their practices firsthand.

Maintaining detailed records of each pelt’s origin, including farm identification and date of harvest, is crucial for traceability. This allows us to track the entire journey of the fur from origin to finished garment, ensuring transparency and accountability. Regular quality checks are performed at each stage of the supply chain, from raw pelts to the finished product, to identify and address any defects or issues. This ensures that only high-quality materials are used and that the final product meets our stringent quality standards.

Q 11. Describe your experience with different fur dyeing techniques.

My experience encompasses a wide range of fur dyeing techniques, each chosen based on the type of fur, the desired color, and the desired finish. Traditional methods like drum dyeing, where pelts are tumbled in large drums with dye solutions, are still widely used. This method is excellent for achieving even color saturation.

However, more advanced techniques, like spray dyeing, offer greater precision and allow for more complex color effects like ombre or highlights. We also employ techniques to create unique finishes. For example, we might use a process that retains the natural luster of the fur or one that gives it a more matte or velvety finish. Choosing the right technique is crucial, as it directly impacts the final look, feel, and durability of the garment.

Q 12. What are the common defects found in fur garments, and how are they addressed?

Common defects in fur garments can range from minor imperfections to significant flaws. These include inconsistencies in color, shedding, damaged or broken guard hairs, uneven stitching, and imperfections in the leather membrane.

Addressing these defects requires careful inspection at each stage of the production process. Minor issues, such as slight color variations, might be acceptable, whereas significant defects, like excessive shedding or large holes in the pelt, will necessitate repairs or the replacement of affected areas. Techniques for repair might include patching with similar fur, carefully re-stitching damaged seams, or using specialized treatments to address shedding. Quality control measures are crucial to minimizing defects and ensuring that the final product meets our standards.

Q 13. How do you handle customer complaints regarding fur quality?

Handling customer complaints about fur quality starts with empathetic listening and a thorough investigation. We carefully examine the garment, paying close attention to the specific issues raised by the customer.

Our process involves taking detailed photographs and notes documenting the defects. Depending on the nature of the complaint, the solution might range from offering a cleaning and repair service to offering a full or partial refund, or even a replacement garment. The goal is always to resolve the customer’s concerns fairly and efficiently, maintaining a positive relationship and upholding our reputation for quality.

Q 14. Describe your experience with fur trimming and shaping techniques.

Fur trimming and shaping techniques are essential for achieving the desired silhouette and aesthetic appeal of a garment. These techniques require a high degree of skill and precision.

We employ various methods, from hand-trimming with specialized shears to using more advanced techniques such as laser cutting for intricate designs. The choice of technique depends on the type of fur, the garment design, and the desired level of detail. Careful trimming helps to refine the overall shape, create clean lines, and highlight the natural beauty of the fur. Proper shaping ensures that the garment drapes correctly and fits well. Precision is key to preventing damage to the pelts and achieving a high-quality finished product.

Q 15. Explain the importance of understanding fur anatomy in design.

Understanding fur anatomy is paramount in fur design because it dictates drape, texture, and the overall aesthetic of the final garment. Just as a tailor understands the grain of fabric, a fur designer needs to know the direction of the hair, the density of the underfur, and the properties of the leather. This knowledge informs crucial decisions about pattern cutting, sewing techniques, and even the selection of the fur itself.

For example, understanding that the hair lies in a particular direction on a fox pelt will determine how the pattern pieces are arranged to achieve a smooth, even flow. Ignoring this could result in a garment with patchy or unnaturally matted areas. Similarly, knowing the thickness of the underfur helps predict how warm the garment will be and dictates the type of lining or interfacing needed. We might choose a thinner lining for a mink coat, which already has a dense underfur, and a thicker lining for a less dense fur like rabbit.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you create realistic fur textures in 3D design software?

Creating realistic fur textures in 3D software involves a multi-step process. We start by selecting the appropriate fur shader and adjusting its parameters. These parameters often include fur length, density, clumping, and even individual strand variations in color and curl. Many software packages provide tools to simulate the subtle variations seen in real fur. These tools, often found under the “Material” or “Shader” settings, can be quite powerful.

Beyond shader settings, realistic results are achievable by using high-resolution maps, such as normal maps and displacement maps, to add depth and detail to the surface. Normal maps particularly impact the illusion of fur; they alter the direction of reflected light to create the illusion of individual hairs, making the fur appear more voluminous. The displacement map also adds depth and enhances the realism, but often takes more computational power to render.

Finally, techniques like hair simulation, though computationally intensive, provide the highest level of realism, generating individual hairs that respond realistically to physics and lighting. I typically use a combination of these approaches, leveraging the efficiency of shaders and maps for large-scale projects and the fidelity of hair simulation for close-up renders or critical areas.

Q 17. What are the latest trends in fur fashion design?

Current trends in fur fashion are marked by a strong emphasis on sustainability, ethical sourcing, and innovative design techniques. We’re seeing a move away from traditional, overly-full looks. Instead, there is an increasing interest in more minimalist designs, utilizing natural colors and textures. Faux fur, crafted to mimic the look and feel of real fur, is becoming increasingly sophisticated and popular, fueled by ethical considerations.

Another trend is the integration of fur into unexpected designs. This might involve incorporating fur into apparel as accents or using it in accessories like hats, bags, and scarves. There is also exploration of unique textures and color treatments—think dyed or patterned furs that provide greater visual interest. This diversification is crucial for broadening the appeal of fur products.

Furthermore, upcycling and repurposing of vintage furs are gaining traction, reflecting the growing awareness of sustainable practices. Designing with a focus on longevity and creating versatile garments that can be worn for years is also a significant trend.

Q 18. Describe your experience with sustainable fur practices.

Sustainability is a core principle in my design practice. I actively source furs from ranches that adhere to strict animal welfare standards and prioritize traceability. I work with suppliers who can provide clear documentation of their sourcing processes, ensuring the furs are ethically sourced. I also frequently explore the use of reclaimed furs from vintage garments, giving these materials a new life and reducing waste.

Beyond sourcing, I incorporate sustainable practices into the design and manufacturing process itself. Minimizing waste during pattern cutting and using eco-friendly dyes and finishes are key elements. When designing a garment, I consider the potential for future upcycling or repurposing. This means creating designs that are timeless and versatile, maximizing their lifespan. I believe it’s essential to consider the full lifecycle of a fur product, from the animal’s welfare to the garment’s eventual disposal or recycling.

Q 19. How do you incorporate client feedback into fur garment design?

Incorporating client feedback is a crucial aspect of the design process. I use a variety of methods to ensure client satisfaction. This starts with thorough initial consultations to understand their preferences, budget, and lifestyle. I then create sketches and renderings to visualize the design, allowing clients to provide feedback early in the process. This iterative approach avoids costly rework later in the project. Client feedback is treated as an integral part of the creative process itself, informing decisions regarding fit, style, and other design elements.

I encourage open communication throughout the design process. I might use digital tools like mood boards, 3D modeling software, and virtual try-ons to help clients visualize the garment. Feedback is documented and reviewed, ensuring that all changes are integrated seamlessly into the design. My goal is to build a collaborative relationship with my clients, ensuring that the final product reflects their vision and expectations.

Q 20. What software and tools are you proficient in for fur design?

My proficiency spans several software packages vital for fur design and development. I am highly skilled in 3D modeling software such as CLO 3D, Marvelous Designer, and Blender, using them to create realistic digital prototypes and explore various design options. These tools allow for intricate detailing and virtual fitting to avoid costly alterations in the physical manufacturing phase. For rendering and visualization, I utilize programs like Keyshot and V-Ray, which give me fine-tuned control over lighting, textures, and overall presentation. For pattern making and grading, I’m proficient in industry-standard software such as Gerber Accumark, ensuring precise and efficient pattern creation.

Beyond software, I am adept at using a range of physical tools, including cutting and sewing equipment that are essential for handling fur’s unique properties, from specialized shears to different stitching methods for each kind of fur. This combination of digital and physical skills allows me to effectively and efficiently design and produce high-quality fur products.

Q 21. How do you manage a team in a fur manufacturing environment?

Managing a team in a fur manufacturing environment requires strong leadership, communication, and organizational skills. I foster a collaborative environment by clearly outlining project goals and expectations, assigning roles and responsibilities based on individual expertise, and creating open channels for communication and feedback. Regular team meetings are critical, allowing us to track progress, address challenges, and celebrate successes.

I emphasize the importance of meticulous quality control at every stage of the manufacturing process. This includes thorough inspections of the raw materials, meticulous craftsmanship during the cutting and sewing phases, and rigorous quality checks before the final product leaves the workshop. I believe in empowering my team members by providing them with opportunities for professional development and training. A well-trained and motivated team is crucial for producing high-quality fur products and maintaining our commitment to ethical and sustainable practices. Ultimately, my leadership style focuses on creating a positive and productive work environment that promotes both individual growth and collective success.

Q 22. Describe your experience with different fur pelt preparation methods.

Fur pelt preparation is crucial for creating high-quality garments. It involves several key steps, and the specific methods employed can significantly impact the final product’s texture, drape, and durability. My experience encompasses a range of techniques, including:

- Fleshing: Removing excess fat and tissue from the hide. This is often done using specialized machines, but can also be a manual process for smaller pelts or delicate furs. I’ve worked with both drum fleshers and hand fleshing tools, choosing the method based on the fur type and the desired outcome. For instance, delicate mink pelts require meticulous hand fleshing to prevent damage.

- Cleaning: Thoroughly washing the pelt to remove any remaining dirt, blood, or other impurities. Different cleaning agents are used depending on the fur type and its sensitivity. I’ve had experience with both wet and dry cleaning methods. For example, certain sensitive furs like fox require a gentler, more controlled wet cleaning process.

- Tanning: Converting the pelt from a perishable hide to a durable, stable leather. I’m proficient in various tanning techniques, including chrome tanning (commonly used for its speed and affordability), vegetable tanning (yielding a softer, more environmentally friendly result, though slower), and alum tanning (suitable for certain delicate furs). The choice of tanning method is critical; for instance, a chrome tan might be ideal for a mass-produced coat, while vegetable tanning might be preferred for a bespoke item.

- Stretching and Drying: Shaping and drying the pelt to achieve the desired dimensions and prevent shrinkage. This involves careful stretching on specialized frames or boards, ensuring even tension to avoid distortions. I’ve used both traditional wooden stretching frames and more modern, adjustable systems.

- Finishing: This final step includes processes such as combing, brushing, and glazing to enhance the fur’s luster and texture. This step is crucial for achieving the desired look and feel of the final garment, often requiring specialized tools and techniques depending on the fur type.

Understanding the nuances of each stage and adapting the process to different fur types is crucial for successful pelt preparation. I have personally developed a proficiency in adapting these methods based on the desired outcome, whether it is a soft, plush feel or a more structured, robust garment.

Q 23. What are the regulatory requirements for fur products in your region?

Regulatory requirements for fur products vary significantly by region. In my region [Specify your region, e.g., the European Union], compliance is paramount. Key regulations include:

- Species protection laws: Strict rules govern the sourcing of fur, prohibiting the use of endangered or protected species. Traders must possess accurate documentation proving the legal origin of the pelts, often involving CITES (Convention on International Trade in Endangered Species) permits.

- Animal welfare standards: Regulations often address the humane treatment of animals throughout their lives, from farming practices to slaughter methods. This includes stipulations regarding farm conditions, feeding, and veterinary care. Audits and inspections are commonly conducted to ensure adherence to these standards.

- Labeling requirements: Accurate labeling of fur products is mandatory, specifying the fur type (e.g., mink, fox, rabbit), origin (country of origin), and often the method of production (e.g., farmed or wild-caught). False or misleading labeling carries significant penalties.

- Chemical regulations: Strict rules exist on the use of certain chemicals in tanning and finishing processes, to minimize environmental impact and protect workers’ health. Manufacturers must use approved chemicals and adhere to waste disposal regulations.

Staying updated on these regulations is critical, as they can change. Non-compliance can result in severe legal and financial repercussions, including fines and product seizures. I actively monitor these regulations and ensure all my work adheres to the current legal framework.

Q 24. How do you calculate the material costs for a fur garment?

Calculating material costs for a fur garment is a multi-faceted process. It’s not just about the cost of the pelts; it also includes preparatory and finishing processes. I typically break it down as follows:

- Raw pelt cost: This is determined by the type of fur, its quality (grade), the size and condition of the pelts. High-quality pelts from certain species (e.g., sable) command significantly higher prices. I consider factors such as the density, luster, and uniformity of the fur.

- Preparation costs: This includes the costs of fleshing, cleaning, tanning, stretching, and other processes required to prepare the pelts for sewing. These costs are influenced by the time, labor, and materials (chemicals, etc.) involved. I track these costs meticulously, often using spreadsheets to maintain accurate records of expenses for each pelt.

- Trimming and waste: Not all of the pelt will be usable. I account for expected waste during the cutting and sewing process and adjust the material cost accordingly. This varies depending on the design and cutting efficiency.

- Linings and interlinings: These added materials contribute to the overall cost. The choice of lining fabric (silk, satin, etc.) also impacts the final price.

- Overhead: This covers storage, insurance, and other associated costs.

By carefully tracking all these expenses, I can accurately estimate the material cost per garment and factor it into the overall pricing strategy. I often use spreadsheets and software for cost tracking and analysis. It’s important to note that this calculation is iterative; experience and detailed records enable a more precise estimate over time.

Q 25. How do you manage production timelines and deadlines in fur manufacturing?

Managing production timelines and deadlines in fur manufacturing requires meticulous planning and effective communication. My approach involves:

- Detailed project planning: I start with a comprehensive project plan, breaking down the process into manageable stages with clearly defined timelines for each. This includes sourcing materials, pelt preparation, cutting, sewing, finishing, and quality control.

- Resource allocation: Efficient allocation of skilled labor and appropriate equipment is vital. I carefully assign tasks to team members based on their skills and experience. I ensure all necessary tools and materials are readily available.

- Regular monitoring and progress reports: I maintain close monitoring throughout the production process, using regular progress meetings to identify and address potential delays. I maintain detailed records, enabling timely adjustments to the schedule if needed.

- Contingency planning: Unforeseen challenges (e.g., material delays, equipment malfunction) are inevitable. I build in contingency time into the schedule to account for potential setbacks. I also have alternative suppliers or solutions in place to mitigate risks.

- Communication: Open communication with clients and team members is critical. Regular updates on progress, potential challenges, and any necessary adjustments to the timeline ensure everyone is informed and on the same page.

By using project management tools and strategies, I strive for efficiency and timely delivery, ensuring client satisfaction and maintaining a positive reputation.

Q 26. Explain your understanding of different fur stretching techniques.

Fur stretching techniques are crucial for achieving the desired shape and size of a pelt, preventing shrinkage, and ensuring consistent quality in the final garment. My experience includes:

- Board stretching: This traditional method uses wooden boards of varying sizes to stretch and shape the pelt. It’s particularly effective for smaller pelts and requires a great deal of skill and patience to achieve even stretching and prevent damage.

- Frame stretching: This method employs adjustable metal frames, allowing for precise control over the stretching process. It’s particularly suitable for larger pelts and mass production. I am experienced with various frame designs and techniques to optimize for different fur types.

- Mechanical stretching: Modern techniques employ automated or semi-automated stretching machines for increased efficiency and consistency. These machines provide precise control and significantly reduce labor time. I’ve worked with such equipment, gaining proficiency in operating and maintaining them.

The selection of the appropriate stretching technique depends on factors such as the size and type of the pelt, the desired final shape, and the production scale. Careful attention to detail is essential to avoid damaging the fur and to achieve a consistent, high-quality result. I’ve developed my expertise by experimenting with different methods and always adapting based on the specifics of the pelt and design.

Q 27. How do you handle challenges related to fur preservation and storage?

Fur preservation and storage are crucial to maintain the quality and longevity of pelts and finished garments. Improper storage can lead to damage from pests, mold, or degradation. My approach focuses on:

- Cleanliness: Pelts should be thoroughly cleaned and dried before storage. Any residual dirt or moisture can attract pests and promote mold growth. I ensure all pelts are properly cleaned and processed before storage.

- Pest control: Mothballs or cedar chips are traditional methods, but modern solutions often involve pheromone traps or professional pest control services. I employ a combination of methods, selecting based on the volume and types of furs being stored.

- Climate control: Consistent temperature and humidity levels are essential. Fluctuations can damage the fur and promote mold growth. I utilize climate-controlled storage facilities to maintain optimal conditions.

- Proper packaging: Individual pelts or garments should be properly wrapped in breathable material (e.g., acid-free tissue paper or muslin) to protect them from dust and moisture. I select packaging materials that will prevent damage while allowing for adequate air circulation.

- Regular inspection: Periodic inspection of stored pelts is essential to detect any signs of damage or pest infestation early on. I maintain detailed logs of storage locations, allowing for efficient monitoring.

Investing in proper storage practices is crucial to avoid significant losses from damage or degradation. I consider the long-term preservation of the materials a significant part of responsible fur handling.

Q 28. Describe your experience with different fur sewing machine types and their applications.

Sewing machines play a pivotal role in fur garment construction. My experience includes using a variety of machines, each suited to specific applications:

- Walking foot sewing machines: These machines are ideal for sewing multiple layers of fur, ensuring even feeding and preventing slippage. They are essential for constructing robust and durable garments.

- Overlock machines: Used for finishing seams, preventing fraying, and creating a professional finish. These are vital for providing a clean and durable edge on fur seams, which are often sensitive.

- Blind stitch machines: Essential for attaching linings and other interior components, creating invisible seams for a neat finish. These are critical for maintaining a clean, professional look in the finished garment.

- Specialized fur sewing machines: Some machines are specifically designed for fur, incorporating features like specialized needles and feed dogs to handle the delicate nature of fur pelts. These machines are designed to mitigate the risk of snagging or tearing the fur.

Selecting the right machine for each stage of garment construction is crucial for achieving optimal results. Proper machine maintenance and regular servicing are vital to ensure consistent performance and prevent costly repairs or delays. My familiarity with different machine types allows me to select and utilize the best tools for each specific need, improving efficiency and quality.

Key Topics to Learn for Design and Development of Fur Products Interview

- Fur Selection and Sourcing: Understanding different fur types (e.g., mink, fox, rabbit), their properties, ethical sourcing practices, and sustainability considerations. Practical application: Evaluating fur quality, identifying potential defects, and selecting appropriate furs for specific designs.

- Pattern Making and Grading: Mastering techniques for creating accurate patterns, adapting patterns for different fur types and sizes, and understanding grading principles for consistent sizing. Practical application: Developing patterns for garments, accessories, or other fur products, and ensuring a proper fit.

- Fur Handling and Preparation: Learning proper techniques for handling, stretching, and preparing fur for sewing and construction. Practical application: Minimizing damage to fur pelts during processing, ensuring consistent quality throughout the production process.

- Sewing Techniques: Mastering specialized sewing techniques appropriate for fur, including stitching methods, seam finishing, and techniques for handling delicate materials. Practical application: Constructing durable and aesthetically pleasing fur garments and accessories.

- Design Aesthetics and Trends: Staying current with design trends in the fur industry, understanding color palettes, and applying design principles to create innovative and marketable fur products. Practical application: Creating unique designs that meet market demands and reflect current fashion trends.

- Production Processes and Techniques: Understanding the complete production cycle, from initial design to final product, including cutting, sewing, finishing, and quality control. Practical application: Optimizing production workflows, identifying potential bottlenecks, and ensuring high-quality output.

- Quality Control and Inspection: Developing a keen eye for detail and understanding industry standards for quality control in fur products. Practical application: Identifying and addressing flaws in fur garments, ensuring compliance with quality standards.

Next Steps

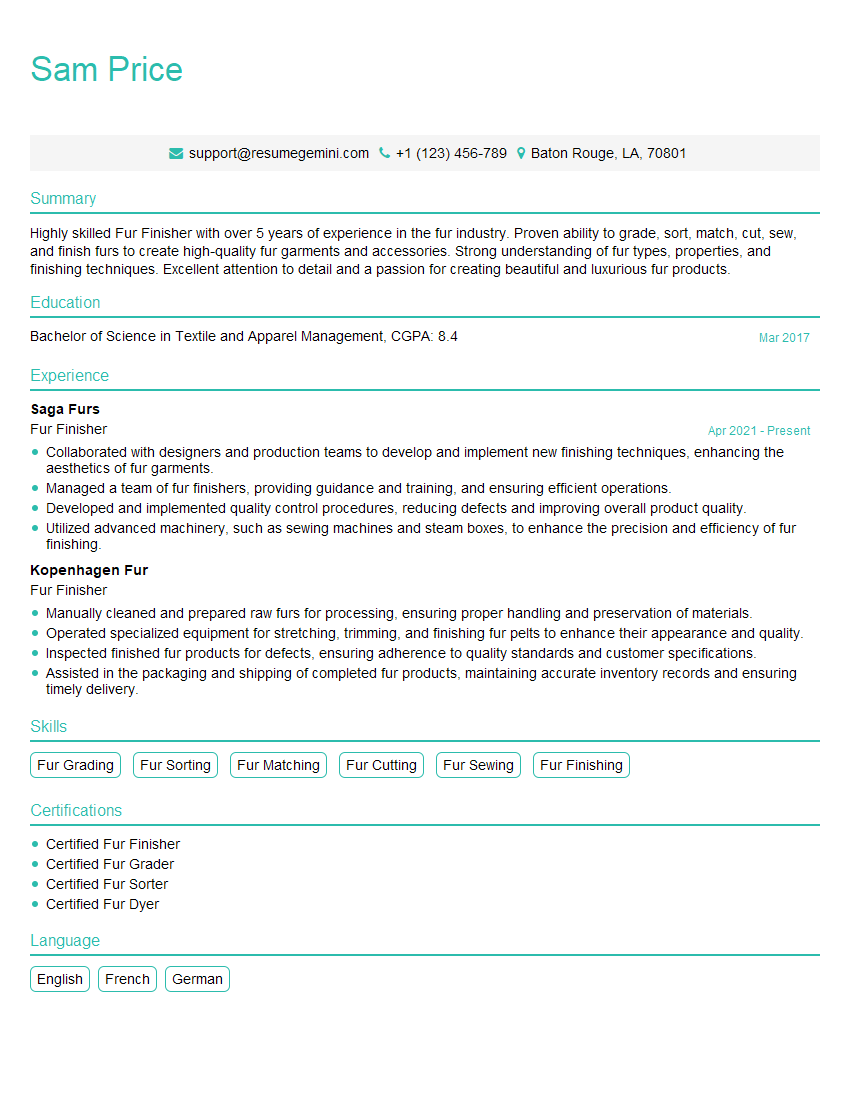

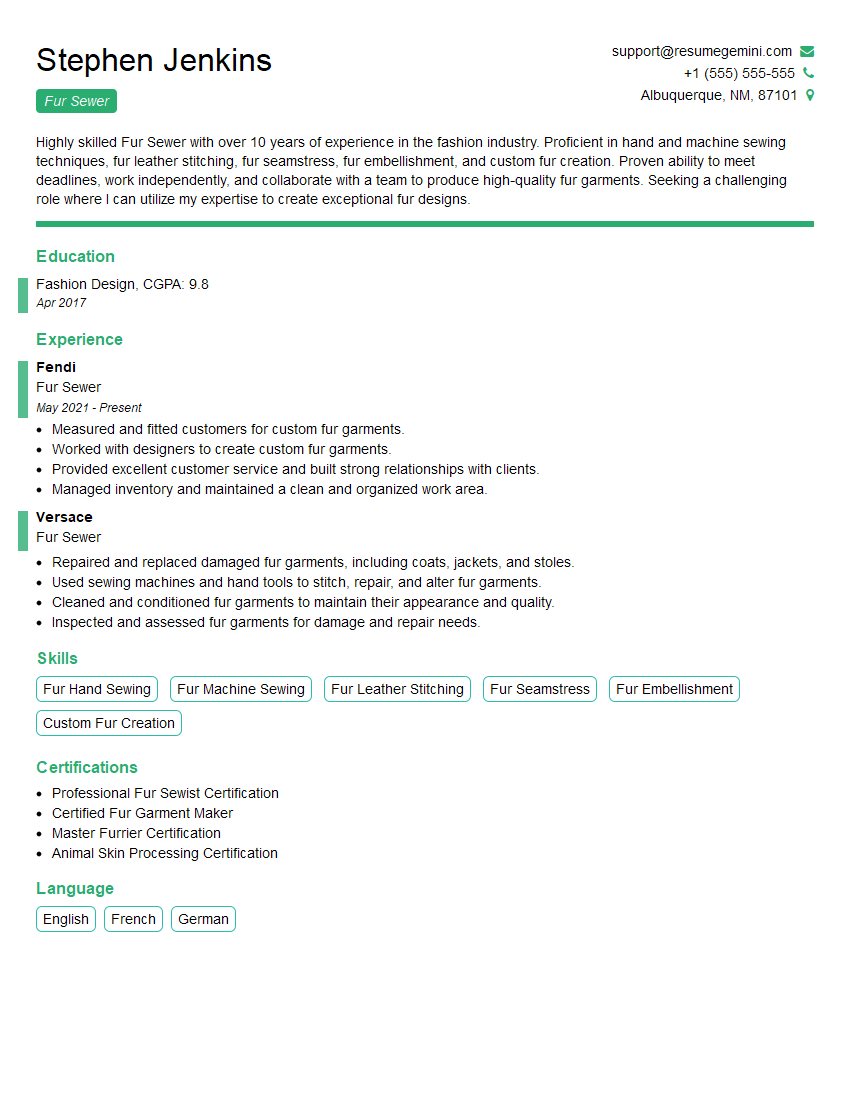

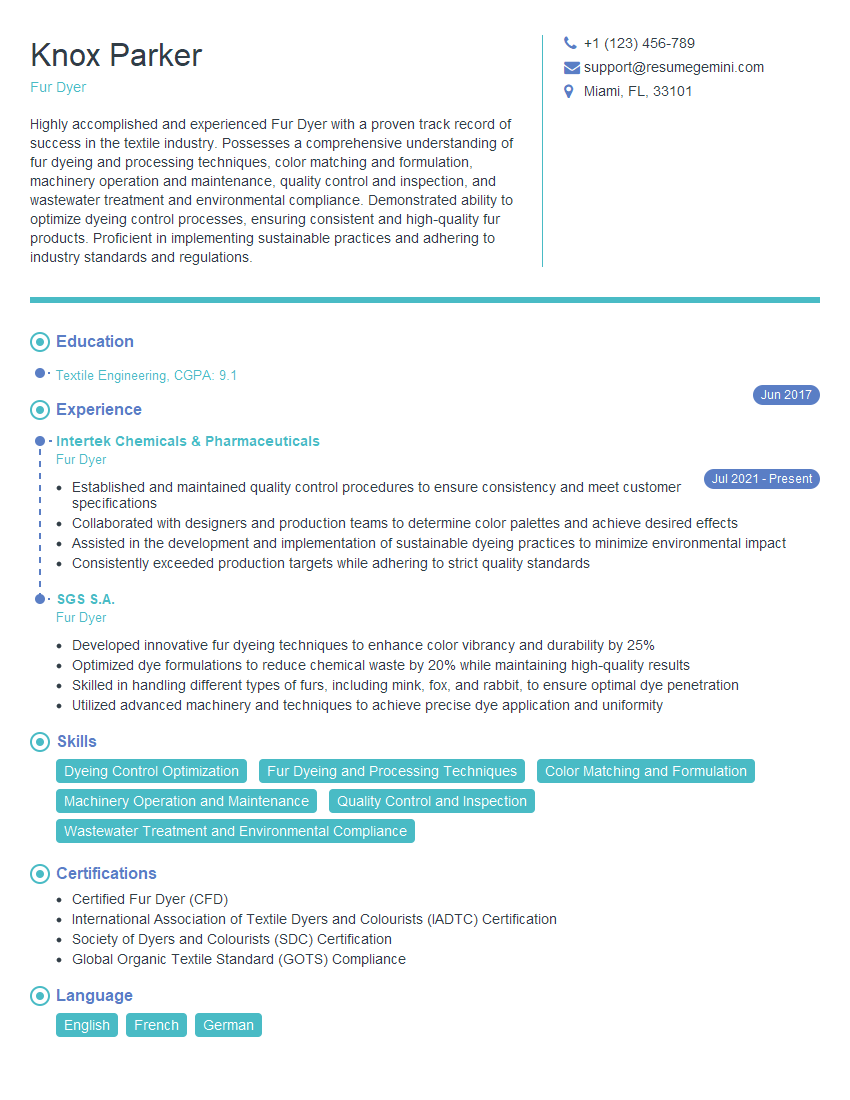

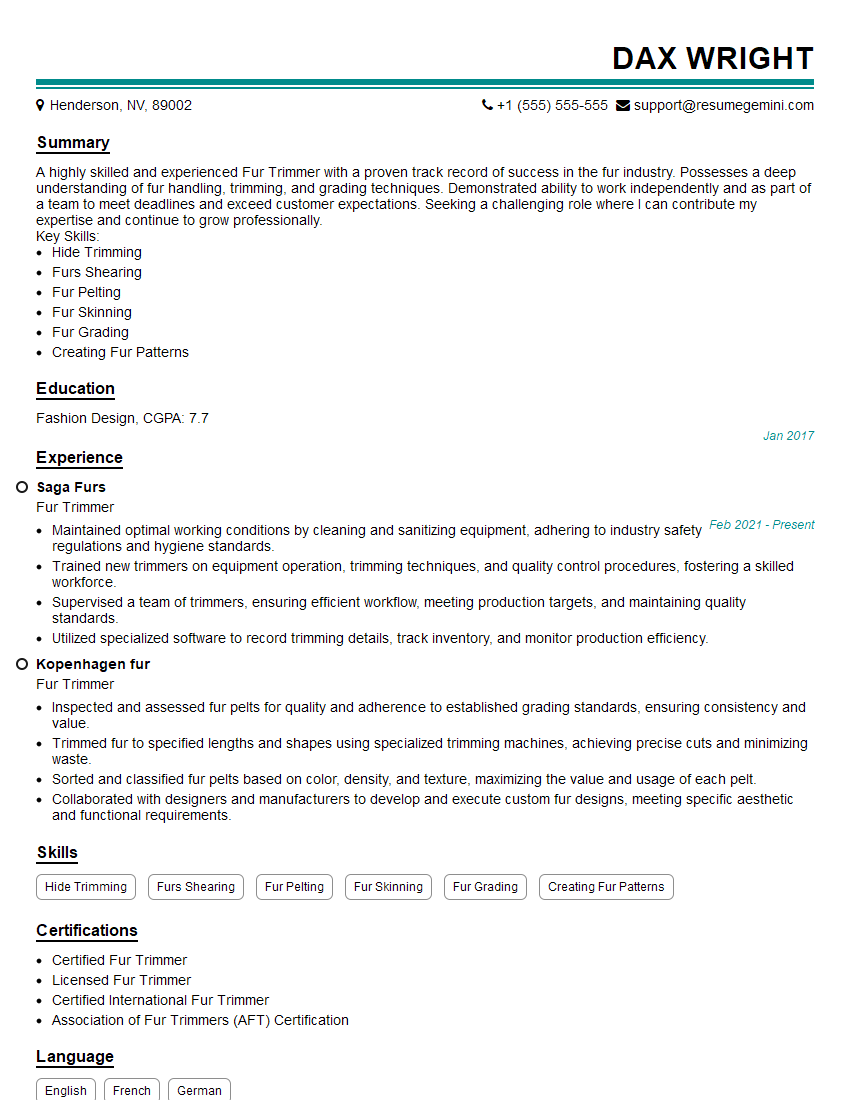

Mastering the design and development of fur products opens doors to exciting career opportunities in a specialized and creative field. To maximize your job prospects, focus on building a strong, ATS-friendly resume that highlights your skills and experience. ResumeGemini is a trusted resource that can help you create a professional and impactful resume tailored to the fur industry. Examples of resumes tailored to Design and development of fur products are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good