Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Advanced techniques in fur cutting and styling interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Advanced techniques in fur cutting and styling Interview

Q 1. Describe your experience with various fur types (mink, fox, sable, etc.) and their unique cutting requirements.

My experience spans a wide range of fur types, each presenting unique challenges and opportunities. Mink, for instance, is known for its luxurious sheen and relatively even texture, making it ideal for sleek, fitted garments. Cutting mink requires precision to maintain the nap (the direction of the hair) for a consistent, elegant look. I often use sharp, fine-toothed shears to minimize damage to the delicate fibers. Fox fur, on the other hand, is much more textured and bulky. Its long guard hairs require careful consideration during pattern making and cutting to avoid unevenness. Techniques like grading (carefully adjusting seam allowances) are crucial to achieve a flattering silhouette. Sable, prized for its rich color and dense underfur, demands the utmost precision. Any damage is highly visible, so I utilize specialized techniques like using a rotary cutter with a very sharp blade to ensure clean, consistent cuts.

For example, when working with a full-length fox coat, I’d adapt the pattern to account for the fur’s volume, perhaps adding extra seam allowance for ease of movement and to accommodate the inherent bulkiness of the material. With sable, the focus is always on preserving the individual hairs’ integrity, so I might opt for simpler, more streamlined designs to minimize stress on the delicate fur.

Q 2. Explain your approach to pattern making for different fur garments.

My approach to pattern making for fur garments is fundamentally different from working with woven fabrics. The inherent qualities of fur – its thickness, nap direction, and potential for stretching – all necessitate adjustments. I always begin with a muslin mock-up, creating a precise pattern using traditional methods, adapted specifically for the fur’s unique characteristics. I meticulously consider the nap direction, ensuring that the pattern pieces are laid out to maximize the flow of the hair and avoid any disruptive breaks in the pattern. The pattern’s seam allowances need careful consideration, often being larger than in woven fabrics, to allow for ease of sewing and to accommodate the potential stretch and shifting of the fur during construction.

For example, when creating a fur vest, the pattern must be specifically designed to allow the fur to fall naturally, creating a drape that isn’t stiff or forced. This involves adding design elements and carefully considering the direction of the fur flow.

Q 3. How do you determine the optimal fur layout to minimize waste?

Minimizing waste in fur is paramount, both ethically and economically. I begin by carefully grading the fur skins, selecting those that are the most suitable for each pattern piece, based on their size, quality, and the direction of the fur. I use specialized software for computer-aided design (CAD) to create efficient layouts, but even with this technology, my experience plays a crucial role in making informed decisions. I prioritize matching the pattern pieces across multiple skins to ensure a consistent look and reduce waste. Skilled placement can minimize the use of otherwise unusable skin areas. This often involves thoughtful manipulation of the pattern pieces and careful assessment of the skin’s natural imperfections. The goal is always to find the optimal layout, a delicate balance between efficiency and aesthetics.

For instance, using a software to digitally map the fur skins allows me to virtually ‘place’ the pattern pieces on the skins prior to cutting, allowing for adjustments to reduce overall waste without affecting the final garment’s appearance. This is much more efficient than traditional cutting methods.

Q 4. What techniques do you use to achieve a seamless finish in fur garments?

Achieving a seamless finish is crucial in fur garments. I employ several techniques, beginning with precise cutting, using sharp tools to minimize fraying. Seams are carefully sewn using specialized fur sewing machines. The selection of the right stitch and thread is critical. When seaming, I prioritize invisible seams, techniques that minimize the visibility of stitches and maximize the garment’s elegance. This often involves using techniques like hand-sewing certain areas or using specialized blind stitching methods. Finishing involves careful cleaning and grooming of the fur, restoring the nap direction to ensure a polished appearance. Additional steps such as fur dressing and careful shaping also contribute to a truly seamless finish.

For example, a meticulously executed invisible seam on a mink stole will ensure that the finished garment appears as one continuous piece of fur, a testament to the mastery of the techniques.

Q 5. Describe your experience with different fur sewing techniques.

My experience encompasses a variety of fur sewing techniques, from traditional hand-sewing methods to utilizing specialized industrial sewing machines designed for fur. Hand-sewing is crucial for delicate repairs and finishing touches, while machine sewing is essential for efficiency on larger projects. I’m proficient in various stitch types, including the whip stitch, backstitch, and blindstitch – each chosen according to the specific fur type and the garment’s design. The choice of needle and thread is paramount; using the wrong tools can lead to damaged fur. I always select specialized needles designed to prevent snags and breakage and use threads that are strong and flexible enough to withstand the stress of sewing fur.

I frequently use a combination of hand and machine sewing. For example, I might use a machine to sew the main seams of a coat but then switch to hand-sewing for the intricate collar or cuffs, ensuring a truly high-end finish.

Q 6. How do you handle challenging fur textures or irregularities during cutting and styling?

Handling challenging fur textures or irregularities requires patience and skill. I assess the specific challenge, whether it’s a damaged area, a variation in fur density, or a significant color difference within a single skin. For minor irregularities, I might strategically place the pattern pieces to minimize their visibility, or use clever design elements to camouflage the imperfections. More significant issues might require careful patching or the use of supplemental pieces. The key is to maintain consistency and integrity across the garment, ensuring a visually pleasing result. The skillful application of specialized glues or careful stitching techniques can seamlessly integrate the repair, making it invisible to the naked eye.

For instance, if a skin has a noticeable bald spot, I might use a piece of similar fur from another skin to carefully fill in the gap. The process requires precision and attention to detail, and the resulting repair should be virtually undetectable.

Q 7. What are some common problems encountered during fur cutting and how do you resolve them?

Common problems during fur cutting include needle breaks, stitch inconsistencies, and unintended damage to the fur. Needle breaks often result from using inappropriate needles or excessive pressure. I address this by ensuring I use the correct needles for the fur type and by adjusting the machine’s settings to minimize stress on the needle. Stitch inconsistencies usually stem from incorrect tension settings or worn sewing machine parts, which are remedied by adjusting the machine and ensuring its proper maintenance. Damage to the fur can be minimized by using sharp, properly maintained shears and careful handling during the cutting process. Prevention is key; meticulous pre-cutting preparation and careful execution of each step dramatically reduce the likelihood of encountering these problems.

For example, if I notice a series of inconsistent stitches, I immediately check the tension settings of my sewing machine. Once the issue is identified and resolved, I will proceed with caution, re-examining my work to ensure a uniform quality throughout.

Q 8. Explain your knowledge of different fur dyeing and finishing techniques.

Fur dyeing and finishing are crucial for enhancing the aesthetic appeal and durability of fur garments. The process involves several techniques, each impacting the final look and feel.

- Dyeing: This can range from simple solid dyeing using vat dyes for even color saturation to more complex techniques like dip-dyeing for ombre effects or piece dyeing for unique patterns. The choice of dye depends on the fur type and desired outcome. For example, mink responds well to deep, rich colors, while fox fur can handle more vibrant hues.

- Finishing: This stage focuses on enhancing texture and sheen. Techniques include brushing, shearing, and glazing. Brushing fluffs the fur, creating volume. Shearing trims the fur for a smoother look, while glazing imparts a lustrous shine by applying a special solution.

- Special Effects: Advanced techniques may involve color blending, creating highlights, or using specialized finishes to mimic natural patterns. For instance, a tip-dyeing technique might create a striking two-tone effect, offering versatility in design.

Selecting the right combination of dyeing and finishing techniques is key to achieving the desired result. It’s a delicate balance, requiring expertise in understanding the properties of different furs and how they react to various treatments.

Q 9. How do you ensure the preservation and longevity of fur garments?

Preserving fur garments requires careful handling and storage. Proper care significantly extends their lifespan.

- Cleaning: Regular professional cleaning is essential. Amateur attempts can damage the fur fibers. Professional cleaners utilize specialized methods tailored to the type of fur.

- Storage: Fur should be stored in a cool, dry, and well-ventilated area, away from direct sunlight and moisture. Using breathable garment bags or specialized fur storage containers protects the fur from dust and insects. Cedar chips can help deter moths.

- Conditioning: Periodically, a professional conditioning treatment can help maintain the fur’s softness and suppleness. This helps prevent dryness and brittleness.

- Avoidance of Harsh Chemicals: Never use harsh chemicals, perfumes, or hairsprays near the fur, as these can damage the fibers.

Imagine treating a fur garment like a delicate antique – it demands respect and gentle care. Following these steps will ensure your fur garment remains beautiful for years to come.

Q 10. Describe your experience with fur repair and restoration.

Fur repair and restoration is a specialized area demanding precision and patience. I have extensive experience in various techniques, including:

- Patching: Repairing small tears or holes by carefully selecting a matching fur piece and seamlessly integrating it into the damaged area. This involves precise stitching techniques to ensure minimal visibility.

- Reshaping: Restoring the original shape of a garment by carefully manipulating the fur fibers and possibly adding padding or support structures.

- Color Correction: Addressing faded or discolored areas through careful dyeing or blending techniques.

- Cleaning and Deodorizing: Removing stains and unpleasant odors using specialized cleaning methods that preserve the fur’s quality.

One memorable restoration involved a vintage fox stole with significant damage. Through meticulous patching and reshaping, we were able to revitalize the piece, preserving its historical significance. My skills are built upon a deep understanding of fur’s structure and behavior, allowing me to approach every repair with the most appropriate method.

Q 11. What safety precautions do you take while working with fur cutting tools?

Safety is paramount when working with fur cutting tools. These tools are sharp and can cause serious injuries if not handled properly. My safety practices include:

- Sharp Tools Only: Using only sharp, well-maintained tools reduces the risk of slippage and accidental cuts. Dull tools require more force, increasing the likelihood of injury.

- Protective Gear: Always wearing protective gloves, safety glasses, and a dust mask. Gloves protect hands from cuts, while glasses and masks protect the eyes and lungs from flying fur and debris.

- Proper Tool Handling: Using each tool with its intended purpose and following manufacturer’s instructions. Never force a tool or use it in an inappropriate manner.

- Clean Workspace: Maintaining a clean and organized workspace minimizes the risk of accidental cuts or slips.

- First Aid Knowledge: Being aware of proper first aid procedures in case of an accident, including how to handle minor cuts and bleeding.

Safety isn’t just a set of rules; it’s a mindset that integrates itself into every aspect of my work. I believe a safe environment is crucial not only for the worker but also for the quality of the final product.

Q 12. How familiar are you with different fur grading and sorting methods?

Fur grading and sorting are critical steps in determining the quality and value of fur pelts. These methods involve assessing various factors to classify furs.

- Length and Density: Measuring the length and density of the fur fibers to determine the overall plushness and volume.

- Color and Lustre: Evaluating the color consistency, evenness, and the overall shine or lustre of the pelt.

- Texture and Handling: Assessing the softness, suppleness, and overall feel of the fur.

- Damage Assessment: Identifying any flaws, such as scars, missing fur, or imperfections.

- Grading Systems: Utilizing standardized grading systems to categorize pelts based on the evaluation of the above factors. These systems can vary depending on the type of fur and the market.

Imagine a skilled jeweler assessing the quality of a diamond. Fur grading requires a similar level of expertise and attention to detail. Accurate grading ensures fair pricing and appropriate use of furs in various applications.

Q 13. Explain your understanding of the ethical sourcing of fur.

Ethical sourcing of fur is of paramount importance. This goes beyond simply obtaining fur; it encompasses responsible practices throughout the entire supply chain.

- Sustainable Practices: Ensuring that fur comes from farms or trapping programs that prioritize animal welfare and sustainability. This includes appropriate animal husbandry, humane trapping methods, and minimal environmental impact.

- Traceability: Having full transparency in the origin of the fur, knowing exactly where it comes from and how it was obtained. This involves clear documentation and supply chain tracking.

- Compliance with Regulations: Adhering to all relevant national and international laws and regulations concerning fur trade and animal welfare.

- Supporting Responsible Suppliers: Partnering with suppliers who share a commitment to ethical sourcing and responsible practices.

Ethical sourcing is not just a trend; it’s a moral imperative. By prioritizing ethical practices, we ensure that the beauty of fur does not come at the expense of animal welfare or environmental sustainability.

Q 14. How do you maintain the quality and consistency of fur during production?

Maintaining fur quality and consistency during production requires a meticulous approach, starting from the initial selection of raw materials.

- Careful Selection: Choosing high-quality pelts with consistent characteristics. This involves rigorous inspection and sorting processes.

- Consistent Processing: Employing standardized processing methods for dyeing, finishing, and other treatments. This ensures uniformity across the entire production batch.

- Quality Control Checks: Regularly inspecting the fur at various stages of production to identify and address any inconsistencies or defects.

- Proper Handling: Handling the fur with care at all times to prevent damage or deterioration. This includes using appropriate tools and techniques.

- Environmental Controls: Maintaining consistent environmental conditions throughout the production process, such as temperature and humidity, to prevent damage to the fur.

Think of it as baking a cake; using the same recipe, measurements, and baking time every time will result in the same quality product. Consistency in fur production is about applying the same principles to ensure a superior end result.

Q 15. Describe your experience with computerized fur cutting systems.

My experience with computerized fur cutting systems spans over a decade. I’ve worked extensively with both 2D and 3D CAD/CAM systems specifically designed for the fur industry. These systems allow for incredibly precise pattern making, minimizing waste and maximizing the utilization of pelts. For instance, I’ve used systems that can automatically generate cutting paths based on the grain direction of the fur, ensuring a more consistent and aesthetically pleasing final product. This is crucial, especially with luxury furs where the natural beauty of the pelt is paramount. Beyond pattern generation, these systems often integrate with automated cutting machines, significantly increasing efficiency and reducing human error in the cutting process.

One particular project involved a complex mink coat design with intricate paneling. Using the computerized system, I was able to create a cutting pattern that minimized waste by 15% compared to traditional methods, a significant saving in material cost and environmental impact. The precision of the system also ensured a perfect fit between panels, leading to a flawless final garment.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What techniques do you use to create specific fur effects (e.g., volume, texture)?

Creating specific fur effects involves a multifaceted approach encompassing cutting techniques, styling, and finishing processes. To achieve volume, I employ techniques like shearing, which selectively removes fur fibers to create areas of varying density. For example, a fuller, more voluminous look around the collar of a coat might be achieved by leaving the fur longer and denser in that area. Conversely, I might shear the areas under the arms for better mobility and a slimmer silhouette. Textural variations are achieved through techniques such as plucking, which removes individual hairs, creating a more casual or distressed effect, or brushing, which can fluff the fur and add a softer texture.

Consider the effect of using a longer pile length, particularly on a fox fur collar. This instantly enhances volume and creates a luxurious feel. Conversely, a carefully executed shearing technique on the same collar could yield a sleek, low-profile look. The combination of these techniques allows for almost limitless creative possibilities.

Q 17. How do you adapt your techniques to different fur garment styles?

Adapting techniques to different fur garment styles requires a deep understanding of both the fur itself and the desired aesthetic. A full-length fur coat demands different techniques than a small fur stole. For instance, a coat might require more emphasis on consistent patterning and precise seaming to ensure a clean, polished look. The cutting angles will change according to the desired drape and shaping of the garment. However, a stole, often made from a single skin, might focus on showcasing the natural beauty of the fur with minimal manipulation, perhaps just careful trimming to enhance its natural shape.

The type of fur also influences the technique. Thick, luxurious furs like sable might require different handling and cutting strategies than thinner furs like mink. The cutting angle, pressure and even the sharpness of the tools all affect the final product. For example, a sharp blade is crucial for a clean cut in dense furs like fox, preventing damage to the fur.

Q 18. Explain your knowledge of different fur finishing processes (e.g., glazing, blocking).

Fur finishing processes are crucial for achieving the desired look and feel of a garment. Glazing involves carefully pressing and aligning the fur fibers to create a sleek, lustrous finish, often used for formal garments. This is usually done using specialized pressing machines at controlled temperatures and pressures to avoid damaging the fur. Blocking involves shaping the garment using forms and steam to create the desired drape and silhouette. This is especially important for coats and jackets, ensuring they hang correctly and maintain their shape over time.

Think of glazing like polishing a precious gemstone—it enhances the natural beauty and creates a refined sheen. Blocking, on the other hand, is akin to sculpting a piece of clay, molding the fur garment into its desired form. The combined use of glazing and blocking can elevate an ordinary fur garment into a masterpiece.

Q 19. How do you handle customer inquiries and complaints related to fur garments?

Handling customer inquiries and complaints requires a professional and empathetic approach. I begin by actively listening to the customer’s concerns, ensuring I fully understand the issue. This often involves examining the garment to identify the root cause of the problem, whether it be a manufacturing defect, damage during shipping, or simply a misunderstanding of how to care for the fur. Once I understand the situation, I explain the problem clearly and offer a solution, whether it be repair, replacement, or a refund, always aiming for a resolution that satisfies the customer.

A case in point involves a customer who complained about shedding in a new fox fur coat. After examining the coat, I determined that it was due to the natural shedding process, and I explained this to the customer, providing information on how to minimize shedding with proper care and storage. The key is to be transparent and honest, building trust with the customer.

Q 20. What is your experience with managing a team in a fur manufacturing environment?

My experience in managing a team in a fur manufacturing environment focuses on fostering a collaborative and efficient work environment. I believe in empowering team members, delegating responsibilities based on individual strengths, and providing regular feedback and training. Effective communication is key—I make sure all team members are aware of project goals, deadlines, and quality standards. I regularly hold team meetings to discuss progress, address challenges, and brainstorm solutions.

In one project, I managed a team of five skilled furriers in the production of a limited-edition collection. By establishing clear roles, responsibilities and timelines, and by proactively addressing potential bottlenecks, the team successfully delivered the collection on time and to the highest quality standards.

Q 21. Describe your experience with quality control procedures for fur garments.

Quality control procedures are paramount in the fur industry. My approach involves multiple checkpoints throughout the production process, from initial pelt selection to the final finishing stages. This includes meticulous inspection of pelts for any defects, careful monitoring of the cutting and sewing processes to ensure precision and accuracy, and rigorous checks of the finished garment for any imperfections. The use of specialized equipment, such as magnifying glasses and measuring tools, is crucial for detecting minute flaws.

We maintain detailed records of each garment, documenting the entire production process. This allows for tracing any potential issues back to their source and helps prevent similar problems in the future. Regular audits ensure that our quality control measures are consistently effective and efficient.

Q 22. How familiar are you with the latest advancements in fur technology?

My familiarity with advancements in fur technology is extensive. I stay abreast of the latest developments through industry publications, conferences, and collaborations with leading furriers. Recent advancements include improvements in tanning techniques resulting in more durable and supple furs, the development of innovative dyeing processes offering a wider range of colors and finishes with less environmental impact, and the creation of new tools and machinery that enhance precision and efficiency in cutting and sewing. For example, laser cutting technology allows for incredibly intricate designs and minimizes waste, while 3D modeling software enables detailed pre-visualization of complex garment construction before any cutting begins. This allows for better planning, reduced material costs, and improved accuracy in the final product.

Q 23. Describe your approach to designing and constructing complex fur garments.

Designing and constructing complex fur garments requires a multifaceted approach. It begins with a thorough understanding of the client’s vision and the properties of the chosen fur. I start by sketching multiple design options, considering the drape, texture, and overall aesthetic of the fur. Next, I create a detailed technical drawing which includes precise measurements and markings indicating the grain direction, nap, and placement of any additional materials. This stage incorporates considerations of pattern grading for different sizes and fitting adjustments. The actual construction involves meticulous cutting, paying close attention to the fur’s natural flow and minimizing waste. I prioritize precise stitching techniques that maintain the integrity of the fur and ensure a luxurious finish. Complex elements like intricate detailing, fur manipulation techniques like shearing and plucking, and the integration of other materials like leather or silk all require precise planning and execution. I use various specialized tools to ensure consistent results and superior quality.

Q 24. Explain your knowledge of fur anatomy and how it affects the cutting process.

A deep understanding of fur anatomy is crucial for successful cutting and styling. Different furs have unique characteristics including grain direction, nap (the direction the fur lies), and pelt size and shape. Understanding these variations is key to achieving the desired drape and appearance. For instance, cutting against the grain can result in a ruffled or uneven look, while cutting with the grain provides a smooth, consistent flow. The thickness and density of the fur also affect the cutting process, influencing the choice of tools and techniques. For example, thicker furs might require sharper blades and more careful manipulation to avoid damage. Furthermore, understanding how the fur grows on the animal dictates where you place patterns to avoid distortions or undesirable effects in the final garment.

Q 25. How do you incorporate sustainability practices into your fur work?

Sustainability is a paramount concern in my work. I prioritize sourcing furs from farms that adhere to high ethical and environmental standards. This involves choosing furs from animals raised humanely and ensuring responsible management of resources. Additionally, I minimize waste during the cutting process by employing efficient pattern design and utilizing innovative cutting techniques like laser cutting. Leftover fur scraps are carefully stored and repurposed whenever possible, for example, to create smaller items or add unique details to other projects. I also favor eco-friendly cleaning and preservation methods that minimize the environmental footprint of the fur garment’s lifecycle. Moreover, I advise clients on responsible care to extend the life of their fur garments.

Q 26. What is your experience with using various fur tools and equipment?

My experience with fur tools and equipment spans a wide range. I am proficient in using various types of shears, from classic hand shears to electric shears for bulk cutting and specialized shears for detailed work. I am also experienced with fur-specific knives, stitching tools, and pattern-making equipment. Additionally, I am adept at using laser cutters for precise, intricate cutting and 3D modeling software to create detailed patterns for complex garments. Maintaining these tools is crucial, ensuring sharpness and functionality for optimal performance and to avoid damaging the fur during the cutting and stitching process.

Q 27. Explain your experience with different fur preservation methods (e.g., cold storage).

Fur preservation is vital for maintaining the quality and longevity of the fur. I am well-versed in various methods, including cold storage, which is the most effective way to prevent deterioration, keeping furs in consistent, cool, and dry environments. I also understand the importance of proper cleaning and conditioning techniques to remove dirt and debris while maintaining the fur’s natural oils and luster. Improper preservation can lead to damage, including pest infestation, color fading, and structural weakening, rendering the fur unusable. My knowledge extends to the use of specialized chemicals and treatments designed to protect the fur from pests and environmental damage. Understanding the type of fur and its specific needs is key to selecting the best preservation method.

Q 28. Describe a challenging fur project you worked on and how you overcame the obstacles.

One particularly challenging project involved creating a full-length mink coat with an extremely intricate, almost lace-like pattern. The challenge lay in the delicate nature of the mink fur and the precision required to execute the design without causing damage. The initial pattern-making process was complex, requiring numerous iterations to ensure optimal fit and maintain the design’s integrity. The cutting itself was painstaking, demanding extreme precision to avoid fraying and ensure the delicate pattern held its shape. To overcome these obstacles, I utilized a combination of traditional hand-cutting techniques for intricate details and laser cutting for some of the larger sections. I also experimented with different stitching methods, selecting the most suitable approach to maintain the garment’s structural integrity while showcasing the delicacy of the fur pattern. The final result was a stunning garment that perfectly executed the client’s vision, demonstrating the power of meticulous planning and adaptable craftsmanship.

Key Topics to Learn for Advanced Techniques in Fur Cutting and Styling Interview

- Fur Grading and Selection: Understanding different fur types, qualities, and their suitability for specific designs. Practical application includes identifying imperfections and selecting appropriate furs for optimal results.

- Advanced Pattern Making: Adapting and creating complex patterns for various garment styles, considering fur’s unique drape and texture. This includes understanding how to account for fur’s nap and directional characteristics during pattern construction.

- Precision Cutting Techniques: Mastering specialized cutting methods for different fur types (e.g., sheared, long-haired, dyed) to achieve precise shaping and minimize waste. Problem-solving involves addressing challenges like uneven fur density and maintaining consistent cutting lines.

- Fur Sewing and Construction: Advanced stitching techniques for joining fur pieces, including techniques for minimizing visible seams and maintaining fur integrity. This also includes working with various lining materials and appropriate sewing machine settings.

- Finishing and Detailing: Expert techniques in cleaning, grooming, and finishing fur garments. This includes knowledge of specialized tools and methods for creating unique embellishments and detailing.

- Fur Repair and Restoration: Understanding common fur damage and implementing effective repair methods to restore and maintain the quality of fur garments.

- Sustainability and Ethical Sourcing: Familiarity with ethical sourcing practices and environmentally friendly techniques within the fur industry.

Next Steps

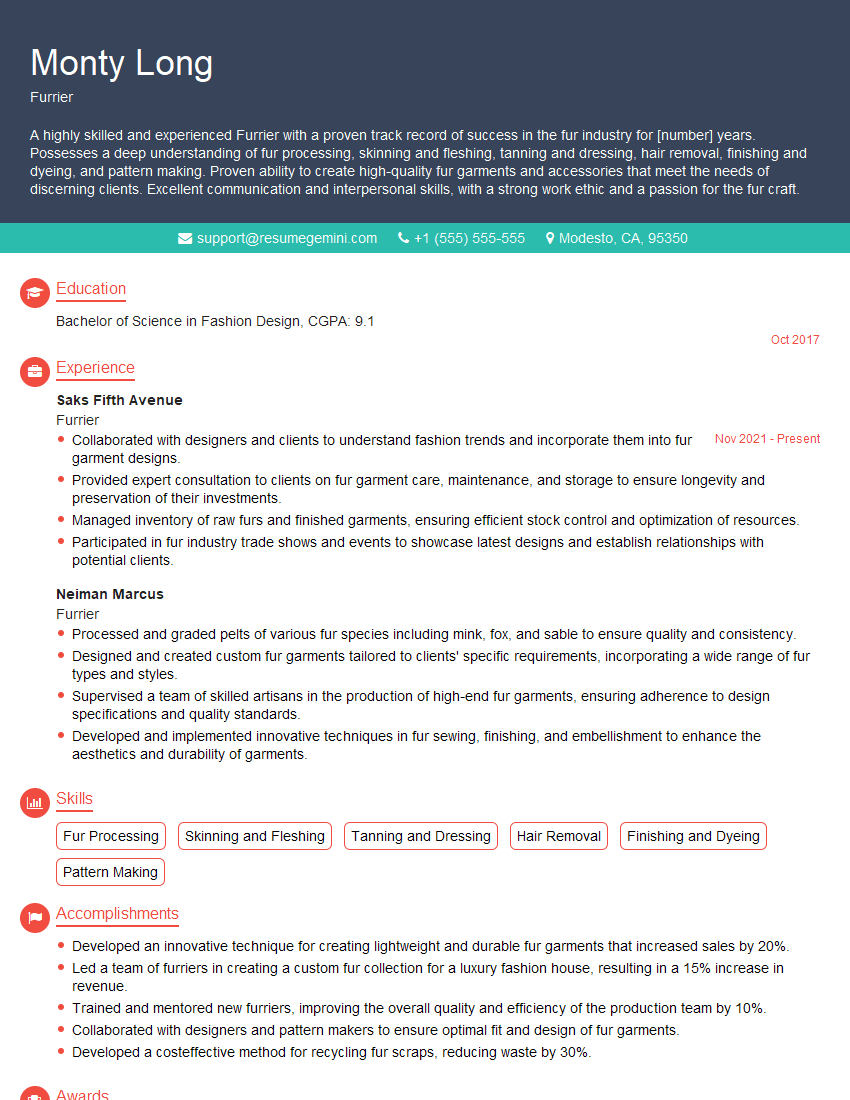

Mastering advanced techniques in fur cutting and styling opens doors to exciting career opportunities, allowing you to showcase your expertise in high-end fashion and luxury goods. A strong resume is crucial for securing your dream role. Creating an ATS-friendly resume that highlights your skills and experience is vital. ResumeGemini is a trusted resource that can help you craft a compelling and effective resume, ensuring your qualifications shine through. Examples of resumes tailored to Advanced Techniques in Fur Cutting and Styling are available to guide you. Take the next step in your career journey – build a resume that makes a statement with ResumeGemini.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good