Preparation is the key to success in any interview. In this post, we’ll explore crucial Packaging Assembly interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Packaging Assembly Interview

Q 1. Describe your experience with different packaging materials (e.g., cardboard, plastic, etc.).

My experience spans a wide range of packaging materials, each with its own strengths and weaknesses. Cardboard, for instance, is versatile, cost-effective, and readily recyclable, making it ideal for many applications. However, it’s susceptible to moisture damage and offers limited barrier properties. I’ve extensively worked with various cardboard types, from single-wall to triple-wall, selecting the appropriate grade based on product fragility and shipping demands. Plastics, on the other hand, offer excellent barrier protection, preventing moisture, oxygen, and light from degrading the product. I’ve worked with various plastics like PET, HDPE, and PP, each suited to different applications and recycling streams. For example, PET is great for transparency and strength for bottled goods while HDPE is better for durable containers like milk jugs. Beyond these, I have experience with flexible films like polyethylene (PE) for pouches and wraps, and even more specialized materials like corrugated plastic for added protection and stiffness.

In one project, we transitioned from a less sustainable cardboard box to a reusable plastic container for a client’s product, significantly reducing waste and improving the customer experience. This involved careful consideration of material properties, cost implications, and recycling options.

Q 2. Explain your understanding of various packaging assembly techniques.

Packaging assembly techniques vary widely depending on the product and packaging type. Some common methods include:

- Manual Assembly: This involves hand-folding, gluing, and inserting products into packaging. It’s suitable for small-scale production or specialized packaging requiring precise handling. I’ve used this method extensively for delicate handcrafted items.

- Semi-automatic Assembly: This combines manual and automated steps. For example, a machine might form the box, but manual insertion of the product and sealing might still be required. This approach optimizes efficiency while maintaining control over specific steps.

- Fully Automated Assembly: High-volume production often utilizes fully automated lines. Machines handle all aspects, from forming the package to filling, sealing, and labeling. I’ve overseen and trouble-shot these systems for large-scale food and pharmaceutical packaging.

Understanding the capabilities and limitations of each technique is crucial for optimizing efficiency and maintaining product integrity. For example, a fully automated line is cost-effective for high volumes but requires substantial upfront investment. Manual assembly offers flexibility but is less efficient for large orders.

Q 3. What are your experiences with automated packaging machinery?

I possess extensive experience operating and maintaining various automated packaging machines, including carton erectors, case sealers, filling machines, and labeling systems. My expertise extends to both troubleshooting malfunctions and optimizing machine parameters for maximum efficiency and output. I’m proficient in operating and programming PLC (Programmable Logic Controllers) to control and monitor these automated systems. For example, I once optimized the settings of a case sealer on a production line, resulting in a 15% reduction in packaging material waste and a 10% increase in throughput. This involved analyzing the machine’s performance data, adjusting the pressure settings, and fine-tuning the sealing mechanism. I’m familiar with various brands and models of machinery and adept at swiftly identifying and resolving any operational issues.

Q 4. How do you ensure quality control during packaging assembly?

Quality control is paramount in packaging assembly. My approach involves a multi-layered strategy starting with:

- Incoming Material Inspection: Thoroughly checking the quality of raw materials like cardboard, plastic, and labels to ensure they meet specifications.

- In-process Monitoring: Regularly inspecting packages during the assembly process for defects like incorrect sealing, misaligned labels, or damaged products. This includes statistical process control (SPC) methods to identify trends and prevent defects.

- Final Product Inspection: A comprehensive check of finished packages to ensure they meet quality standards and regulatory requirements, including visual inspection, dimensional checks, and strength testing. Random sampling is used for efficiency.

- Documentation: Meticulously documenting all inspections, including any defects found and corrective actions taken. This ensures traceability and facilitates continuous improvement.

Beyond this, I implement preventative maintenance schedules on machinery to minimize malfunctions and ensure consistent output. This proactive approach significantly reduces the occurrence of packaging defects. A clear and well-defined quality control system is crucial for maintaining a consistent standard of quality and customer satisfaction.

Q 5. Describe your experience with troubleshooting packaging line issues.

Troubleshooting packaging line issues is a regular part of my work. My approach is systematic and involves:

- Identify the Problem: Pinpoint the exact nature of the issue – is it a machine malfunction, a material defect, or an operator error?

- Gather Data: Collect relevant information, such as error logs, production data, and witness statements.

- Analyze the Data: Identify patterns or root causes using techniques like fault tree analysis (FTA) or the 5 Whys.

- Develop Solutions: Based on the root cause analysis, formulate potential solutions, considering factors like time, cost, and safety.

- Implement and Test: Implement the chosen solution and thoroughly test to ensure it effectively resolves the issue and doesn’t create new ones.

- Document Findings: Record the problem, the solution, and the results to prevent recurrence and improve future troubleshooting.

For example, I once resolved a recurring jam in a high-speed carton erector by identifying a slight misalignment in the feed mechanism. A simple adjustment resolved the issue, improving throughput significantly. Careful analysis and a systematic approach are essential for effectively resolving packaging line problems.

Q 6. What is your experience with different types of packaging seals and closures?

My experience encompasses a wide variety of packaging seals and closures. These include:

- Adhesive Seals: Hot melt adhesives, pressure-sensitive adhesives, and water-based adhesives are used for various packaging types, offering different levels of strength and sealing capabilities. I’ve worked with various types of adhesives tailored to different substrates and environmental conditions.

- Mechanical Seals: These include crimping, heat sealing, induction sealing, and ultrasonic sealing. Each method has specific applications and advantages regarding speed, cost, and seal integrity. For instance, induction sealing provides an excellent barrier against tampering and moisture.

- Closures: This includes a wide range of options, such as screw caps, snap-on lids, twist-off caps, and zipper closures, each designed for specific product types and packaging formats. The choice depends on product properties, shelf life requirements, and ease of opening.

Understanding the properties of each sealing and closure method is crucial for selecting the best option for a particular product and ensuring product safety and integrity. In one case, I helped a client select a tamper-evident seal to enhance the security of their pharmaceutical product.

Q 7. How do you maintain a clean and organized workspace during packaging assembly?

Maintaining a clean and organized workspace is essential for efficient and safe packaging assembly. My approach includes:

- 5S Methodology: Implementing the 5S methodology (Sort, Set in Order, Shine, Standardize, Sustain) to organize the workspace and eliminate waste. This creates a safer, more efficient, and more productive environment.

- Regular Cleaning: Scheduling regular cleaning of the workspace to remove debris, spills, and discarded materials, reducing the risk of contamination and accidents.

- Proper Storage: Storing materials and tools in designated areas, organized and easily accessible, optimizing workflow and preventing clutter.

- Waste Management: Implementing a proper waste management system to dispose of packaging waste, recycling materials appropriately and reducing environmental impact.

- Training and Enforcement: Ensuring all team members are trained on proper housekeeping procedures and consistently follow established guidelines.

A clean and organized workspace directly contributes to improved efficiency, reduced errors, and enhanced safety, ultimately leading to higher quality packaging and increased productivity. This is a non-negotiable aspect of my professional standards.

Q 8. Explain your experience working with production targets and deadlines.

Meeting production targets and deadlines in packaging assembly requires meticulous planning and execution. I’ve consistently demonstrated the ability to manage multiple projects simultaneously, prioritizing tasks based on urgency and resource availability. My approach involves a three-step process:

- Planning & Forecasting: I begin by carefully analyzing the production schedule, considering factors like order volume, material availability, and equipment capacity. This often involves using software for capacity planning and production scheduling. I then create a detailed work plan, breaking down large tasks into smaller, manageable steps with assigned timelines.

- Real-time Monitoring & Adjustment: During the assembly process, I monitor progress against the plan, using key performance indicators (KPIs) like units per hour or defect rate. If delays occur, I promptly identify bottlenecks and implement corrective actions. This might involve adjusting the workflow, reallocating resources, or communicating any potential delays to stakeholders.

- Continuous Improvement: After completing a project, I conduct a thorough post-mortem analysis to identify areas for improvement. This involves reviewing the efficiency of the process, identifying waste, and brainstorming solutions to optimize future projects. I consistently document lessons learned to prevent repeating past mistakes.

For example, in my previous role at Acme Packaging, we faced a tight deadline for a large order of custom-designed boxes. By implementing a Kanban system to manage workflow and utilizing overtime strategically, we successfully met the deadline without compromising quality. This demonstrated my ability to effectively manage resources and deliver under pressure.

Q 9. Describe a time you had to solve a problem during a packaging assembly process.

During a high-volume packaging run for a new client’s fragile electronics, we experienced a significant increase in product damage. Initially, we suspected operator error, but a closer investigation revealed the packaging material itself was insufficient for protecting the product during transport. The existing bubble wrap wasn’t thick enough to absorb impacts effectively.

My solution involved a three-pronged approach:

- Immediate Action: I immediately stopped the assembly line and implemented a temporary solution by adding extra layers of bubble wrap to each package. This mitigated further damage until a permanent fix could be established.

- Root Cause Analysis: We contacted the packaging material supplier, reviewing the specifications to understand why the protective properties of the bubble wrap were inadequate. We discovered a batch defect in their recent production run.

- Long-Term Solution: We switched to a different, more robust protective packaging material from a reliable vendor, ensuring quality control measures were implemented to prevent similar occurrences. We also retrained operators on proper handling procedures for fragile items.

This experience highlighted the importance of not only reacting to problems but also proactively identifying and eliminating their root causes to prevent future disruptions.

Q 10. How familiar are you with safety regulations and procedures related to packaging assembly?

Safety is paramount in packaging assembly. I am thoroughly familiar with OSHA (Occupational Safety and Health Administration) guidelines and relevant industry-specific regulations. My knowledge encompasses:

- Personal Protective Equipment (PPE): Proper use of safety glasses, gloves, and hearing protection is essential. I ensure all team members understand and utilize appropriate PPE for their tasks.

- Machine Safety: I’m trained in the safe operation and maintenance of various packaging machinery, including proper lockout/tagout procedures to prevent accidental start-ups during maintenance or repairs.

- Ergonomics: I’m knowledgeable in ergonomic principles to minimize risks of repetitive strain injuries. I ensure workstations are properly set up and promote efficient and safe working postures.

- Hazard Communication: I understand the importance of properly labeling and handling hazardous materials, such as adhesives and cleaning solvents, adhering to all relevant safety data sheets (SDS).

I regularly conduct safety briefings and enforce safety protocols to create a safe and accident-free work environment. My proactive approach has consistently resulted in a low incident rate in my previous roles.

Q 11. What is your experience with using hand tools and machinery for packaging assembly?

I possess extensive experience using a wide range of hand tools and machinery commonly employed in packaging assembly. This includes:

- Hand Tools: Knives (box cutters, utility knives), tape dispensers, scissors, hand staplers, and various measuring tools (rulers, tape measures).

- Packaging Machinery: Automated box formers, taping machines, case sealers, shrink wrappers, and labeling machines. I am proficient in operating and troubleshooting these machines.

- Other Equipment: Pallet jacks, conveyor systems, and other material handling equipment. I’m capable of safely operating this equipment while adhering to safety regulations.

My expertise extends beyond simply operating these tools and machines; I also understand their maintenance and can perform basic troubleshooting tasks. This reduces downtime and increases productivity. I can confidently adapt to new machinery with minimal training, relying on my strong mechanical aptitude and problem-solving skills.

Q 12. How do you ensure the accuracy and efficiency of the packaging assembly process?

Ensuring accuracy and efficiency in packaging assembly requires a multifaceted approach. I focus on these key areas:

- Standardized Procedures: Implementing clear, documented Standard Operating Procedures (SOPs) for every task ensures consistency and reduces errors. These SOPs are regularly reviewed and updated.

- Quality Control Checks: I integrate quality checks at multiple stages of the assembly process, performing random sampling inspections to identify and correct any deviations from standards. This might involve visual inspection, dimensional checks, or functional testing.

- Data Analysis: I utilize data collected from production monitoring to track key performance indicators (KPIs) such as defect rates, throughput, and cycle times. Identifying trends and outliers allows for prompt interventions and continuous improvement.

- Continuous Improvement Initiatives: I actively seek ways to optimize the packaging assembly process through techniques like Lean Manufacturing (eliminating waste), Six Sigma (reducing variation), or Kaizen (continuous improvement). This includes streamlining workflows, improving material handling, and suggesting automation opportunities.

For instance, by implementing a 5S system (Sort, Set in Order, Shine, Standardize, Sustain) at a previous employer, we reduced waste and improved overall efficiency by 15%. This demonstrates my commitment to continuous improvement and its impact on accuracy and efficiency.

Q 13. Describe your experience with inventory management related to packaging materials.

Effective inventory management of packaging materials is crucial for maintaining a smooth and efficient packaging assembly process. My experience involves:

- Demand Forecasting: Accurate forecasting based on production schedules and sales projections helps prevent stockouts and reduces excess inventory.

- Inventory Tracking: Utilizing inventory management systems (either physical tracking or software) to maintain an accurate record of materials on hand, enabling better procurement planning.

- Vendor Management: Establishing strong relationships with packaging material suppliers to ensure timely delivery and quality control.

- Inventory Optimization: Implementing strategies like Just-in-Time (JIT) inventory management to minimize storage costs and reduce the risk of obsolescence.

In a previous role, I implemented a Kanban system for inventory management of our most frequently used packaging materials. This resulted in a 10% reduction in storage costs and a significant improvement in material availability, preventing production delays.

Q 14. How do you handle unexpected issues or delays during packaging assembly?

Handling unexpected issues or delays requires a calm, proactive, and systematic approach. My strategy typically involves:

- Immediate Assessment: Quickly identify the nature and scope of the problem. Is it a material shortage, equipment malfunction, or a quality issue?

- Communication: Promptly communicate the situation to relevant stakeholders, including supervisors, team members, and potentially clients. Transparency is key in mitigating potential fallout.

- Problem Solving: Employ problem-solving techniques, such as root cause analysis, to identify the underlying cause of the delay. This allows for a targeted solution, preventing recurrence.

- Contingency Planning: Having backup plans in place for foreseeable disruptions is crucial. This might involve having alternate suppliers, backup equipment, or alternative packaging solutions readily available.

- Documentation: Maintaining detailed records of the incident, including the cause, actions taken, and outcomes, allows for continuous improvement and better preparedness for future disruptions.

For example, when a critical piece of packaging equipment malfunctioned during a peak production period, I quickly assessed the situation, contacted the maintenance team, and simultaneously implemented a temporary workaround using manual processes. This minimized the production downtime and prevented significant delays.

Q 15. Explain your understanding of different packaging types (e.g., boxes, pouches, wraps).

Packaging types are incredibly diverse, each chosen based on product characteristics, shipping needs, and marketing goals. Think of it like choosing the right outfit – you wouldn’t wear a tuxedo to the beach!

- Boxes: These are workhorses, offering excellent protection and customization options. From simple corrugated cardboard for everyday items to sturdy double-walled boxes for fragile goods, they come in various sizes and materials. I’ve worked extensively with both standard and custom-designed boxes, including those with internal dividers for delicate products.

- Pouches: These flexible packages are ideal for products requiring airtight seals or a visually appealing presentation. Flexible films like polyethylene (PE), polypropylene (PP), and various laminates are commonly used. I’ve had experience with pouches using stand-up features, zippers, and spouts, particularly for food and beverage products.

- Wraps: This encompasses a wide range of materials used to enclose products, from simple shrink wrap for bundling to more sophisticated films that provide both protection and branding opportunities. I’ve used shrink wrap extensively in automated lines for increased efficiency, and I’m also familiar with flow wrap, which creates a continuous sealed package around individual items.

The selection process involves considering factors like product fragility, moisture sensitivity, required shelf life, and transportation conditions. For example, a delicate ceramic vase would need a robust box with cushioning, while a bar of soap could be safely packaged in a simple cardboard wrap.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are your experiences with different labeling techniques and machinery?

Labeling is crucial for conveying product information, branding, and regulatory compliance. My experience spans various techniques and machinery, each with its strengths and weaknesses.

- Techniques: I’m proficient in pressure-sensitive label application (using adhesive labels), thermal transfer printing (ideal for flexible packaging), and inkjet printing (allowing for variable data printing like batch numbers and expiration dates).

- Machinery: I’ve operated and maintained various label applicators, including rotary labelers (high-speed, suitable for large production runs) and inline labelers (integrated into the packaging line). I’ve also worked with thermal transfer printers and inkjet printers, understanding their setup, maintenance, and troubleshooting.

For instance, I once streamlined a labeling process by switching from manual label application to an automated rotary labeler, resulting in a significant increase in throughput and reduced labor costs. This involved careful consideration of label dimensions, adhesive type, and applicator settings.

Q 17. How familiar are you with lean manufacturing principles in packaging?

Lean manufacturing principles are vital for optimizing packaging assembly. They focus on eliminating waste and maximizing efficiency. Think of it as carefully choreographing a dance, ensuring every step is purposeful and contributes to the final product.

- Value Stream Mapping: I’ve participated in creating value stream maps to identify and eliminate non-value-added steps in the packaging process, reducing lead times and improving overall efficiency.

- 5S Methodology: I’m experienced in implementing 5S (Sort, Set in Order, Shine, Standardize, Sustain) to maintain a clean, organized, and efficient workspace, minimizing waste and improving safety.

- Kaizen Events: I’ve participated in Kaizen events (continuous improvement workshops) to brainstorm solutions and implement changes to improve operational efficiency. For example, one such event led to the redesign of our packaging line layout, reducing bottlenecks and increasing throughput by 15%.

In practice, this involves constantly looking for ways to reduce unnecessary movement, inventory, defects, and waiting time. The goal is to deliver high-quality packaged products with minimal resources and maximum speed.

Q 18. How do you prioritize tasks during a busy packaging assembly shift?

Prioritizing tasks during a busy shift requires a structured approach. My method combines urgency and importance, considering both production deadlines and potential bottlenecks.

- Urgent and Important: These are tasks that absolutely must be completed immediately, such as addressing a machine malfunction or fulfilling an urgent customer order. I tackle these first.

- Important but Not Urgent: These tasks, such as preventative maintenance or updating production records, are scheduled strategically to prevent them from becoming urgent.

- Urgent but Not Important: These tasks, often requests that don’t directly impact production deadlines, are delegated or deferred if possible.

- Neither Urgent nor Important: These tasks are reviewed regularly, and some may be eliminated altogether.

I use Kanban boards or similar visual management tools to track task progress and ensure nothing falls through the cracks. Clear communication with my team is critical to ensure everyone understands priorities and is working effectively together.

Q 19. What are your experience with using and maintaining packaging equipment?

I have extensive experience operating and maintaining a wide range of packaging equipment, from simple hand tools to sophisticated automated systems. Proactive maintenance is key to preventing downtime and ensuring consistent production.

- Equipment Types: I’m familiar with carton erectors, case sealers, labeling machines, shrink wrappers, and various types of conveyors. My experience includes both mechanical and electrical aspects of maintenance.

- Preventative Maintenance: I adhere to preventative maintenance schedules, performing regular inspections and cleaning to prevent malfunctions and extend equipment lifespan. This includes lubricating moving parts, checking for wear and tear, and replacing parts as needed.

- Troubleshooting: I can effectively troubleshoot equipment malfunctions, using diagnostic tools and my knowledge of mechanical and electrical systems to identify and resolve issues quickly.

For example, I once diagnosed a recurring jam in our case sealer by identifying a misaligned conveyor belt, a seemingly minor issue that caused significant downtime. Prompt identification and resolution saved the company considerable time and money.

Q 20. How do you ensure that all packaged products meet quality standards?

Quality control is paramount in packaging assembly. It’s not enough to just package products; they must meet stringent quality standards throughout the process.

- In-Process Checks: I conduct regular checks at various stages of the packaging process to identify and rectify any defects promptly. This might involve inspecting labels for accuracy, verifying seal integrity, or checking for damaged products.

- Statistical Process Control (SPC): I’m familiar with using SPC charts and techniques to monitor key process parameters and identify trends that may indicate quality issues before they escalate.

- Quality Audits: I actively participate in quality audits to ensure compliance with standards and identify areas for improvement. I’m familiar with ISO standards and other quality management systems.

For instance, I implemented a system of random sampling and inspection, leading to a reduction in customer complaints related to packaging defects. My proactive approach ensures that all products are accurately labeled, securely packaged, and meet customer expectations.

Q 21. Describe your experience with working in a team environment during packaging assembly.

Teamwork is fundamental in a fast-paced packaging assembly environment. Effective collaboration is essential for maintaining productivity, achieving quality goals, and resolving issues efficiently.

- Communication: I maintain clear and open communication with my team members, ensuring everyone is informed about tasks, priorities, and potential challenges.

- Collaboration: I actively collaborate with my colleagues, sharing knowledge, expertise, and workload to ensure efficiency and support each other during peak times.

- Problem-Solving: I contribute to a positive and collaborative problem-solving environment, where challenges are addressed through teamwork and creative solutions. We regularly brainstorm as a team to identify bottlenecks and improve processes.

I recall a time when a crucial piece of equipment malfunctioned during a high-demand period. Through quick teamwork and efficient communication, we managed to reroute the packaging process, minimizing disruption and fulfilling the order on time. That situation highlighted the value of a cohesive and well-communicating team.

Q 22. How do you communicate effectively with your colleagues during packaging operations?

Effective communication is crucial in a fast-paced packaging environment. I believe in a multi-pronged approach. Firstly, I utilize clear and concise verbal communication, ensuring everyone understands instructions and expectations. For example, before starting a new packaging run, I’ll verbally confirm the order details, packaging specifications, and any potential challenges with the team. Secondly, I leverage written communication through checklists, SOPs (Standard Operating Procedures), and daily reports to document processes, track progress, and address any issues that arise. Finally, I promote active listening and open dialogue to encourage feedback and address concerns promptly. If a problem occurs on the line, for example, a machine malfunction, I immediately communicate the issue to the supervisor and team, suggesting solutions collaboratively.

Q 23. What is your experience with different packaging design considerations?

My experience encompasses a wide range of packaging design considerations, from material selection to structural integrity and aesthetic appeal. I’ve worked with various materials including corrugated cardboard, plastic films, and rigid containers. I understand the importance of considering factors like product protection, cost-effectiveness, environmental impact, and shelf appeal. For instance, I once worked on a project where we needed to redesign packaging for a fragile product. We switched from a simple cardboard box to a custom-designed solution with foam inserts and reinforced corners, significantly reducing damage during shipping. Similarly, I’ve been involved in choosing sustainable materials like recycled cardboard to align with our company’s environmental goals.

I’m also familiar with designing for automation. This involves considering things like box dimensions and ease of robotic handling for increased efficiency. Finally, understanding and complying with regulations like FDA (Food and Drug Administration) guidelines for food packaging is a critical part of my design considerations.

Q 24. How do you adapt to changes in packaging assembly processes or procedures?

Adaptability is key in packaging assembly. I approach changes systematically. First, I carefully analyze the new process or procedure, understanding the reasons behind the change and its impact on the assembly line. Then, I actively participate in any training sessions to acquire the necessary skills. I also don’t hesitate to ask clarifying questions to ensure complete understanding. Finally, I embrace the change by actively contributing to the implementation, troubleshooting any emerging challenges, and suggesting improvements where possible. For instance, when our company implemented a new automated packaging machine, I actively participated in the training, quickly mastered the new system, and helped my colleagues adapt by sharing my knowledge and experience.

Q 25. Describe your experience with using a barcode scanner or other inventory tracking devices.

I have extensive experience using barcode scanners and other inventory tracking devices, including handheld scanners, RFID (Radio-Frequency Identification) readers, and inventory management software. I’m proficient in scanning barcodes to track product movement, verify inventory counts, and ensure accurate order fulfillment. For example, I’ve used barcode scanners to track individual units throughout the packaging process, identifying any discrepancies in real-time. This helps us maintain accurate inventory records and improve efficiency. I also understand the importance of data integrity and follow established procedures to ensure accurate data entry and reporting.

Q 26. How do you adhere to company policies and safety regulations in the packaging assembly line?

Adhering to company policies and safety regulations is paramount. I consistently follow all safety procedures, including wearing appropriate Personal Protective Equipment (PPE) like safety glasses, gloves, and steel-toed shoes. I’m familiar with and comply with all relevant safety protocols, including lockout/tagout procedures for machinery maintenance and proper handling of materials. I also actively participate in safety training and report any safety hazards or concerns immediately to my supervisor. I view safety not just as a regulation, but as a shared responsibility to ensure a safe and productive work environment for myself and my colleagues.

Q 27. What is your experience with training new employees in packaging assembly techniques?

I have significant experience training new employees. My approach focuses on hands-on learning and clear communication. I begin by explaining the overall packaging process and the importance of each step. I then demonstrate the techniques, focusing on proper procedures and safety precautions. I encourage questions throughout the training and provide constructive feedback to new employees, ensuring they understand the expectations. I also create checklists and use visual aids to reinforce learning. I use a mentoring approach, providing ongoing support and guidance until new employees demonstrate competence. For example, I’ve successfully trained numerous new hires, many of whom are now highly skilled members of our team.

Q 28. How familiar are you with statistical process control (SPC) in packaging?

I’m familiar with Statistical Process Control (SPC) in packaging. SPC uses statistical methods to monitor and control variations in processes, ensuring consistent quality and reducing defects. My understanding includes using control charts (like X-bar and R charts) to track key metrics, such as weight, dimensions, and seal integrity. I can identify patterns and trends that indicate potential process issues. For example, if I notice a trend of increasing variation in box weight on a control chart, I would investigate the cause, potentially addressing issues with the filling machine or material inconsistencies. This proactive approach helps prevent major quality problems and maintain consistent product quality.

Key Topics to Learn for Packaging Assembly Interview

- Understanding Packaging Materials: Familiarize yourself with various materials used in packaging (cardboard, plastic, film, etc.), their properties, and their suitability for different products. Consider the environmental impact of different materials.

- Assembly Line Processes: Learn about different assembly line configurations and methodologies, including automation and manual processes. Understand the importance of efficiency and quality control within these processes.

- Quality Control and Inspection: Master the techniques for identifying defects in packaging and assembled products. Understand the importance of adherence to quality standards and compliance regulations.

- Health and Safety Regulations: Familiarize yourself with relevant health and safety procedures and regulations within a packaging assembly environment, including proper use of equipment and personal protective equipment (PPE).

- Troubleshooting and Problem-Solving: Practice identifying and resolving common issues that arise during the assembly process, such as equipment malfunctions or material defects. Develop strategies for efficient troubleshooting.

- Inventory Management: Understand the importance of efficient inventory management in a packaging assembly setting, including tracking materials, minimizing waste, and ensuring timely supply.

- Lean Manufacturing Principles: Explore the application of lean manufacturing principles to optimize packaging assembly processes, such as reducing waste, improving flow, and enhancing overall efficiency.

Next Steps

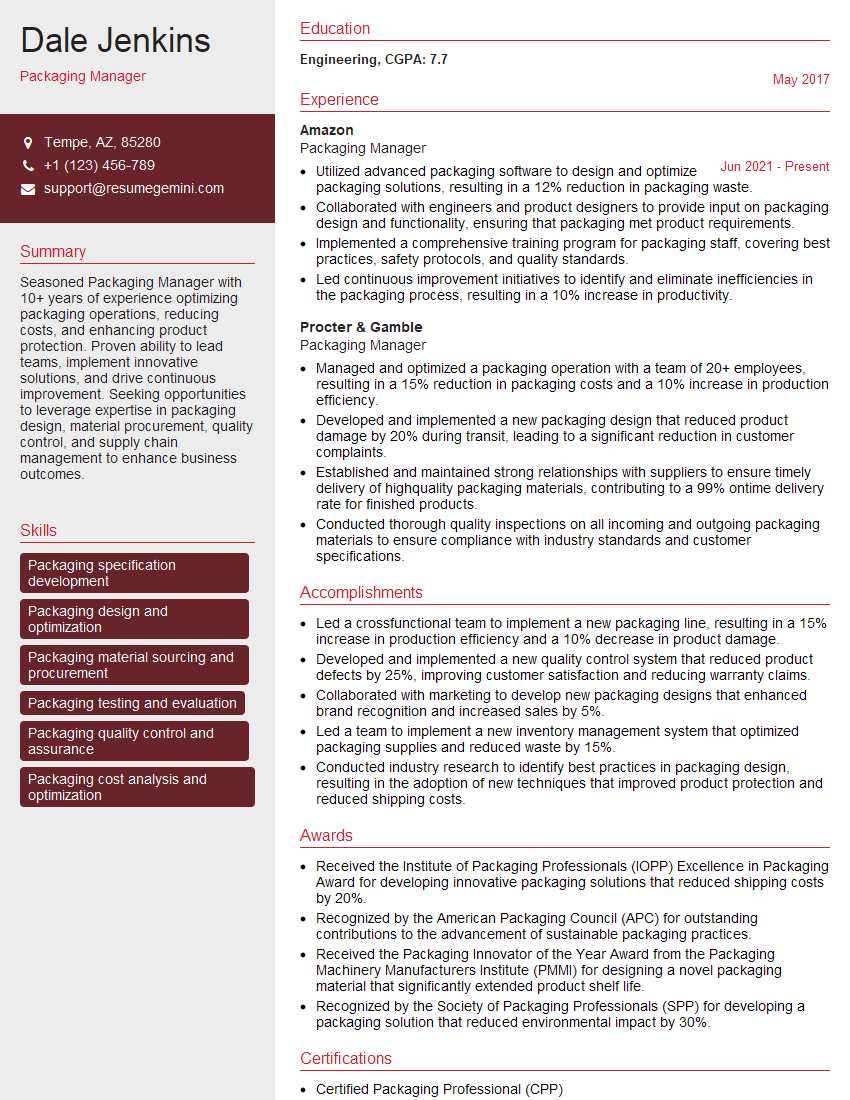

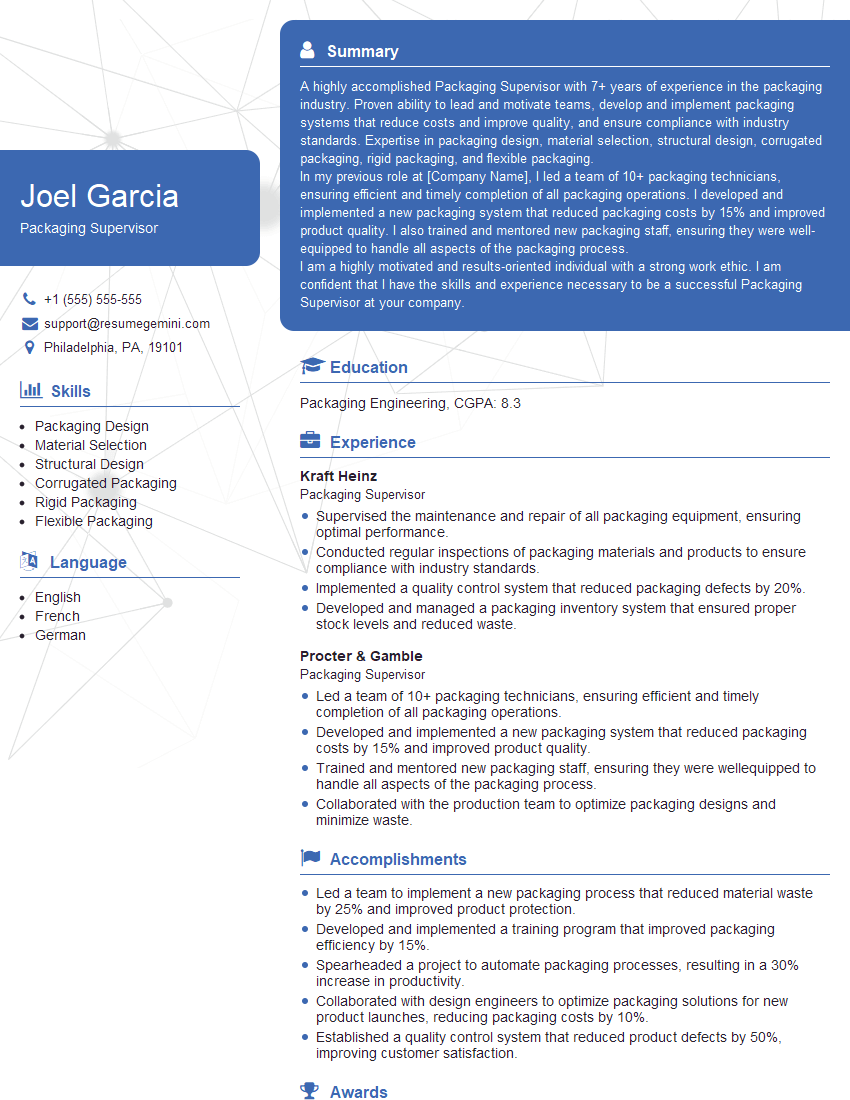

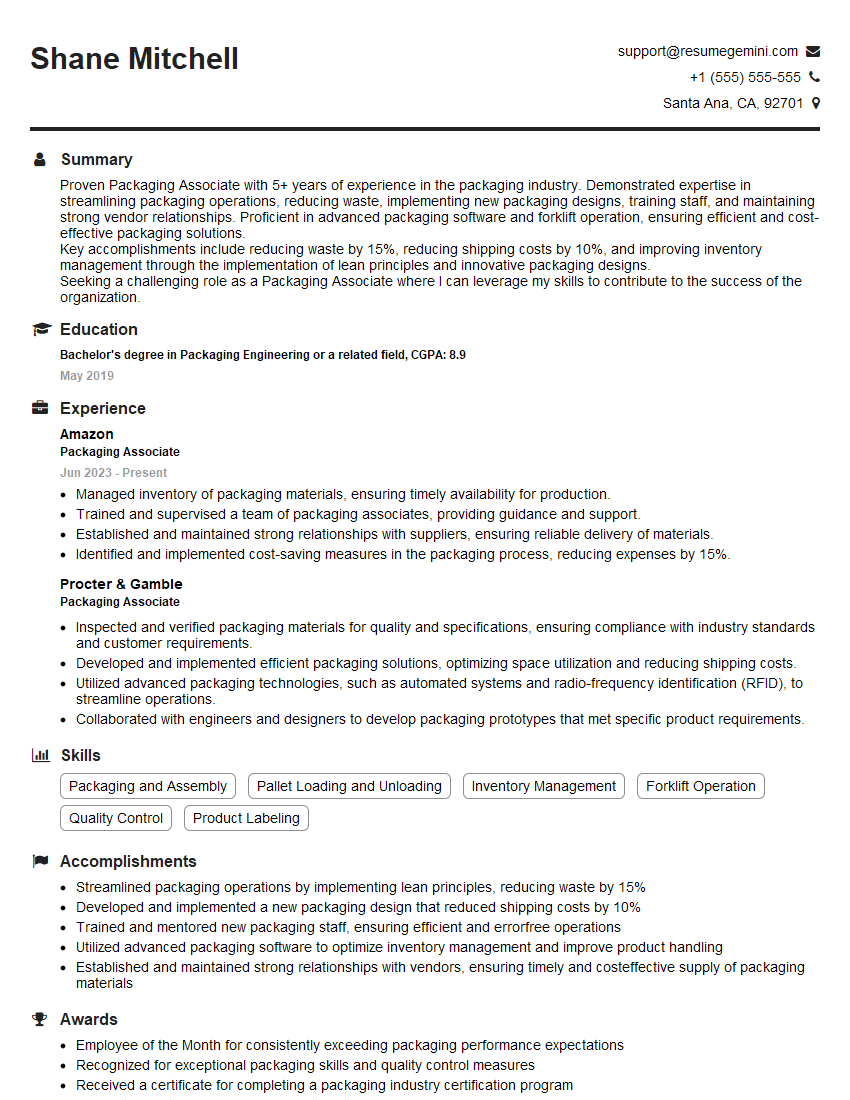

Mastering packaging assembly skills opens doors to a rewarding career with opportunities for advancement and specialization. A strong understanding of these processes is highly valued by employers. To increase your chances of landing your dream job, focus on creating a professional, ATS-friendly resume that highlights your skills and experience. ResumeGemini is a trusted resource that can help you build a compelling resume tailored to the packaging assembly industry. Examples of resumes tailored to Packaging Assembly are provided to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good