Are you ready to stand out in your next interview? Understanding and preparing for Troubleshoot Mechanical Issues interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Troubleshoot Mechanical Issues Interview

Q 1. Describe your experience troubleshooting mechanical systems.

My experience in troubleshooting mechanical systems spans over 15 years, encompassing diverse industries like manufacturing, automotive, and heavy machinery. I’ve worked on everything from intricate robotic arms to large-scale conveyor systems. This experience has provided me with a broad understanding of various mechanical components, their functionalities, and common failure modes. I’m proficient in identifying root causes, not just treating symptoms. For example, I successfully diagnosed a recurring jam in a high-speed packaging machine, not by simply clearing the jam repeatedly, but by identifying a misaligned component that was causing the repeated jams. This required a deep understanding of the machine’s mechanics and the ability to systematically isolate the problem.

Q 2. Explain the process you follow when diagnosing a mechanical failure.

My diagnostic process follows a structured approach. It starts with a thorough visual inspection to identify any obvious damage or anomalies. This is followed by gathering information from the operator or maintenance logs, looking for clues about the circumstances of the failure. Then, I use a methodical approach to isolate the problem. This often involves systematically testing individual components, using relevant diagnostic tools like multimeters, pressure gauges, and specialized diagnostic software. I create a flowchart of my thought process to maintain focus on potential causes, which helps prevent jumping to conclusions. This flowchart helps rule out possibilities step by step, until the exact problem is found. Once the problem is identified, I create a detailed report which includes the findings, potential solutions, and cost estimates for repair or replacement.

Q 3. How do you prioritize repairs when multiple systems are malfunctioning?

Prioritizing repairs when multiple systems are malfunctioning requires a risk assessment. I prioritize based on factors like safety, operational impact, and cost. Systems posing immediate safety risks (e.g., a malfunctioning emergency stop) always come first. Next, I prioritize systems that cause the greatest disruption to production or critical operations. Finally, I address repairs based on their cost-effectiveness, opting for cheaper and faster fixes where possible unless a larger problem needs to be addressed first. For example, a small leak might be temporarily addressed with a band-aid solution while a larger, more critical issue causing significant operational downtime is fixed first.

Q 4. What tools and equipment are essential for effective mechanical troubleshooting?

Essential tools and equipment for effective troubleshooting vary depending on the system, but some common essentials include:

- Multimeters: For checking electrical continuity, voltage, and current.

- Pressure gauges: For measuring pressure in hydraulic or pneumatic systems.

- Thermometers: To detect overheating or abnormal temperature gradients.

- Torque wrenches: For ensuring proper tightening of fasteners.

- Micrometers and calipers: For precise measurements of components.

- Diagnostic software: System-specific software for reading error codes and sensor data.

- Basic hand tools: Wrenches, screwdrivers, pliers, etc.

- Lifting equipment (if needed): Jacks, hoists, or cranes for accessing and moving heavy components.

Beyond these tools, a well-stocked parts inventory and access to technical manuals or schematics are critical for efficient troubleshooting.

Q 5. Describe a time you had to troubleshoot a complex mechanical problem. What was your approach?

I once had to troubleshoot a complex issue with a large industrial press. The press would sporadically shut down, displaying a generic error code. My initial approach was systematic. I started with a thorough visual inspection, checked hydraulic fluid levels and pressure, and verified electrical connections. The error code pointed to a potential problem with the control system, but I suspected mechanical issues could be the root cause given the intermittent nature of the failure. Using a pressure gauge, I discovered a fluctuation in hydraulic pressure during the shutdown events. This led me to inspect the hydraulic pump and its associated components. I found a small crack in the pump’s housing that was causing internal leakage and pressure instability, leading to the intermittent shutdowns. The problem wasn’t evident at first glance, highlighting the importance of methodical investigation and the use of diagnostic tools to pinpoint hidden faults.

Q 6. How do you use diagnostic tools (e.g., multimeters, pressure gauges) to identify mechanical issues?

Diagnostic tools are crucial for accurate diagnosis. A multimeter helps detect electrical faults like shorts, open circuits, or incorrect voltage levels in motor controls or sensor circuits. For example, a low voltage reading on a motor could indicate a problem with the power supply or wiring. A pressure gauge is vital for identifying leaks or pressure drops in hydraulic or pneumatic systems. For instance, a consistently low pressure in a pneumatic cylinder might signify a leak in the system. Other tools, like specialized software, can access error codes within the system’s controller, pointing directly to the faulty component or subsystem. The effective use of these tools hinges on understanding the system’s operating principles and how these tools relate to expected measurements.

Q 7. How familiar are you with preventative maintenance schedules and their importance?

I’m very familiar with preventative maintenance schedules and their importance. They are crucial for extending the lifespan of equipment, reducing downtime, and preventing catastrophic failures. Preventative maintenance involves regular inspections, lubrication, cleaning, and component replacements according to a predetermined schedule. A well-defined schedule typically includes tasks like checking fluid levels, inspecting for wear and tear, and replacing parts at recommended intervals. This proactive approach reduces the likelihood of unexpected breakdowns, increases the safety of operations, and minimizes long-term maintenance costs. A clear understanding of a machine’s preventative maintenance requirements contributes to efficient operations and ensures that potential problems are addressed before they develop into significant issues.

Q 8. Explain your understanding of hydraulic and pneumatic systems.

Hydraulic and pneumatic systems are both fluid power systems used to transmit power, but they differ in the fluid they use. Hydraulic systems use incompressible liquids, typically oil, while pneumatic systems use compressible gases, most commonly air.

Hydraulic Systems: These systems utilize the pressure of a liquid to generate force and motion. Think of a car’s brake system – pushing the pedal creates pressure in the hydraulic fluid, which is then transferred to the brakes to stop the car. They are known for their high power density and precise control, often used in heavy machinery like excavators and bulldozers. However, they can be messy due to potential leaks and require careful maintenance to prevent contamination of the hydraulic fluid.

Pneumatic Systems: These systems leverage the pressure of a gas to achieve similar results. Examples include air-powered tools like drills and impact wrenches. Pneumatic systems are generally safer than hydraulic systems as the operating pressures are often lower and compressed air is less harmful than hydraulic fluid. They are also easier and less costly to maintain but often sacrifice power density for lighter applications. Think of a robotic arm in a factory, perhaps it is a pneumatic system for moving lighter parts.

Understanding the properties of each fluid (incompressible vs. compressible) is crucial to understanding their applications and limitations. The choice between a hydraulic or pneumatic system depends on the specific requirements of the application, considering factors like power needs, precision, safety, cost, and environmental concerns.

Q 9. How do you interpret mechanical drawings and schematics?

Interpreting mechanical drawings and schematics is fundamental to troubleshooting and repair. My approach involves a systematic review, starting with understanding the overall assembly and its purpose. I’m proficient in reading various types of drawings including orthographic projections (top, front, side views), isometric drawings (3D representation), and assembly drawings showing how components fit together.

I start by identifying key components and their relationships. I look for dimensions, tolerances, material specifications, and any special notes or annotations. Schematics, particularly for fluid power systems, show the flow of fluids and the components involved – valves, actuators, sensors, etc. I carefully trace the flow paths to understand the system’s operation under various conditions. I also often use software to generate 3D models from 2D drawings to further enhance my understanding of the system’s geometry and assembly.

For example, while troubleshooting a hydraulic system, I might refer to a schematic to trace the fluid path from the pump to an actuator. If there’s a problem with the actuator, the schematic helps isolate possible causes such as a faulty valve, clogged lines, or a leak in the system. This systematic approach ensures I effectively understand the design intent and can efficiently pinpoint malfunctioning components.

Q 10. Describe your experience with different types of bearings and their common failures.

I have extensive experience with various bearing types, including ball bearings, roller bearings (cylindrical, tapered, spherical), and journal bearings. Each type has its strengths and weaknesses, and understanding their characteristics is crucial for diagnosing failures.

- Ball Bearings: Excellent for high-speed applications and relatively low loads. Common failures include fatigue cracking due to high stress, wear from contamination (dust, debris), and improper lubrication.

- Roller Bearings: Suitable for heavy loads and moderate speeds. Failures can involve wear on rollers or races, cage damage, and fretting corrosion (localized wear at the interface of two surfaces).

- Journal Bearings: Often found in rotating shafts with heavy loads and low speeds. These bearings rely on a lubricating film to prevent direct contact between surfaces. Failure usually arises from insufficient lubrication, leading to scoring or seizing.

My approach to diagnosing bearing failures involves visual inspection (looking for signs of wear, damage, or unusual play), measurement of bearing clearances, and analysis of operating conditions. For example, in a rotating machinery failure investigation, I might find evidence of high-frequency vibrations indicating ball bearing fatigue. In that case, I’d need to carefully examine the raceways for pitting or spalling.

Q 11. What is your approach to documenting troubleshooting procedures and findings?

Thorough documentation is paramount in troubleshooting. My approach involves a multi-step process. Firstly, I create a detailed description of the problem, including all relevant symptoms and the system’s operational context. I then document the steps taken to diagnose the issue, including observations and measurements at each stage. This is often aided by photos and videos. Crucially, I document all corrective actions taken.

I use a structured format, often a combination of text and diagrams, to create clear and organized reports. This usually includes: initial symptoms, diagnostic tests performed, data collected (e.g., vibration measurements, pressure readings), potential root causes identified, actions taken, and final outcome. The report also includes recommendations for preventative maintenance to reduce the likelihood of recurrence.

Software like CMMS (Computerized Maintenance Management Systems) is used to store the documentation, and I ensure that the reports are easily accessible and searchable. This allows us to learn from past experiences and improve our troubleshooting efficiency and preventative maintenance strategies. A well-documented case history allows our team to see what has already been tried and avoids repetitive work.

Q 12. How do you identify root causes of recurring mechanical problems?

Identifying root causes of recurring problems requires a systematic and analytical approach. I employ techniques like the ‘5 Whys’ method, which involves repeatedly asking ‘why’ to uncover the underlying cause of a problem. This helps peel back layers of symptoms to reveal the root issue. I also utilize fault tree analysis, a top-down approach that graphically represents potential causes of a failure.

Data analysis plays a critical role. I use trend analysis to identify patterns in failures and correlate them to operating conditions, such as load, temperature, or environmental factors. Statistical process control charts help to monitor system performance and detect deviations from acceptable limits, providing early warnings of potential problems.

For example, if a pump fails repeatedly, the ‘5 Whys’ might reveal that it’s due to excessive vibration, caused by misalignment, which is due to improper installation. This then allows for a permanent solution focusing on proper installation techniques and alignment procedures. This approach emphasizes addressing the underlying problem rather than merely treating symptoms. It might reveal a problem with the materials selected, the process used, or even design flaws which can then be fed back into design and manufacturing process improvements.

Q 13. How do you communicate technical information clearly to non-technical personnel?

Effective communication with non-technical personnel is crucial. My approach involves avoiding technical jargon and using plain language. I use analogies and visual aids, such as diagrams or photos, to illustrate complex concepts. I focus on explaining the ‘what’ and the ‘why’ of the problem rather than getting bogged down in technical details.

I also tailor my communication to the audience’s level of understanding. For example, when explaining a mechanical issue to a manager, I might focus on the impact on production and cost, while when talking to a factory worker, I might focus on the practical implications and safety aspects. Using stories and real-world examples helps illustrate the problem and its solution in a way that is easy to grasp for anyone.

Active listening and feedback are essential. I make sure to check for understanding and address any questions or concerns. This ensures clear communication and prevents misunderstandings that can hinder problem resolution. A simple analogy of “imagine a bicycle chain that’s broken, it prevents the bike from moving” might be easier to visualize than discussing torque and rotational forces.

Q 14. Describe your experience with different types of pumps and their applications.

My experience encompasses a range of pumps, including centrifugal, positive displacement (reciprocating, rotary), and axial flow pumps. Each type is suited to different applications based on flow rate, pressure, fluid viscosity, and other factors.

- Centrifugal Pumps: These are widely used for moving large volumes of liquids at moderate pressures. They are relatively simple, efficient, and less expensive than positive displacement pumps. Examples include pumps used in water distribution systems and industrial processes.

- Positive Displacement Pumps: These pumps deliver a specific volume of fluid per revolution, making them suitable for high-pressure applications and fluids with high viscosity. Reciprocating pumps (like those in some oil wells) use a piston to move fluid, while rotary pumps use rotating elements to displace the liquid. Examples include pumps found in chemical processing and hydraulic systems.

- Axial Flow Pumps: These pumps move fluid parallel to the pump shaft, generating high flow rates with lower pressure rise. They’re often used in applications requiring large volumes of fluid such as irrigation systems.

Selecting the right pump depends on the specific requirements of the application. I consider factors like fluid properties, flow rate, pressure requirements, efficiency, and cost. Troubleshooting pump failures involves systematic checks for leaks, cavitation, wear of components (seals, impellers), and proper motor operation.

Q 15. How familiar are you with safety procedures related to mechanical equipment?

Safety is paramount in my work. My familiarity with safety procedures extends beyond simply knowing the rules; it’s ingrained in my approach to every task. This includes understanding and adhering to OSHA (or equivalent) regulations, lockout/tagout procedures (LOTO), using appropriate PPE (Personal Protective Equipment) like safety glasses, gloves, and hearing protection, and conducting thorough risk assessments before starting any work on mechanical equipment. For instance, before working on a conveyor belt, I wouldn’t just turn it off; I’d ensure it’s properly locked out and tagged out to prevent accidental start-up. I also prioritize regular safety training to remain updated on best practices and emerging hazards.

I always emphasize a proactive safety culture, where everyone on the team looks out for each other and reports potential hazards immediately. A near miss is just as important as an accident because it allows us to prevent future incidents.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your experience with PLC’s and their role in mechanical systems?

PLCs (Programmable Logic Controllers) are the brains of many modern mechanical systems. My experience encompasses programming, troubleshooting, and maintaining PLCs in various industrial settings. I’m proficient in several PLC programming languages, such as ladder logic, function block diagrams, and structured text. I understand how PLCs control actuators, sensors, and other components to automate mechanical processes. For example, I’ve worked on projects where PLCs controlled robotic arms in a manufacturing line, ensuring precise movements and efficient production. I’ve also used PLCs to monitor and control parameters like temperature, pressure, and flow rate in industrial processes, triggering alarms and safety shutdowns when necessary. Understanding PLC communication protocols like Ethernet/IP and Profibus is crucial for effective troubleshooting and integration with other systems.

Q 17. Describe your understanding of vibration analysis in troubleshooting.

Vibration analysis is a powerful diagnostic tool for identifying mechanical problems before they escalate into major failures. It involves measuring the vibrations produced by machinery to detect imbalances, misalignments, bearing wear, and other issues. I’m experienced in using vibration analyzers to collect data, analyzing frequency spectrums to pinpoint the source of the problem. For example, a high amplitude at a specific frequency might indicate a bearing defect, while a recurring pattern could point to imbalance. The analysis also incorporates amplitude and phase information to localize the problem within the machinery. My approach involves comparing the measured vibration signature with baseline data to identify anomalies and assess the severity of the problem.

Data acquisition techniques, both manual and automated, and signal processing methods are integral to this process. Knowing how to interpret the data accurately and effectively is as important as obtaining it.

Q 18. How do you use lubrication charts and guidelines for machinery maintenance?

Lubrication is critical for preventing premature wear and tear in machinery. I meticulously follow lubrication charts and guidelines, ensuring that the correct type and quantity of lubricant are used at the appropriate intervals. These charts typically specify the lubricant grade, frequency of lubrication, and the method of application (grease gun, oil bath, etc.). For example, a high-speed bearing will require a different type of grease than a slow-speed bearing. I also consider environmental factors, such as temperature and operating conditions, when selecting lubricants. Incorrect lubrication can lead to increased friction, heat generation, and ultimately, equipment failure. Regular monitoring of lubrication levels and condition is part of a preventative maintenance strategy to ensure optimal machine performance.

Q 19. How do you stay updated on new technologies and best practices in mechanical troubleshooting?

The field of mechanical troubleshooting is constantly evolving. To stay updated, I actively participate in professional organizations, attend industry conferences and webinars, and regularly read industry publications and journals. Online courses and manufacturer training programs provide valuable insights into new technologies and best practices. I also leverage online forums and communities to discuss challenges and share knowledge with other professionals. Continuous learning is vital to maintain my expertise and adapt to new developments in the field.

Q 20. Describe your experience with thermal imaging and its application in troubleshooting.

Thermal imaging is an invaluable troubleshooting technique that allows for non-contact temperature measurement. I utilize infrared cameras to detect temperature anomalies in mechanical equipment, which can indicate problems like overheating bearings, electrical shorts, or improper insulation. For example, an unusually hot motor winding might indicate an impending failure. By identifying these hot spots, I can pinpoint the source of the problem before it leads to catastrophic failure. Careful analysis of the thermal images, considering the operating parameters of the equipment, is key to successful troubleshooting.

Thermal imaging is particularly beneficial in situations where accessing internal components is difficult or dangerous. It allows for a quick and effective assessment of the overall thermal health of the system.

Q 21. How would you handle a situation where a critical piece of equipment fails unexpectedly?

Unexpected equipment failure requires a calm and systematic approach. My first step would be to ensure the safety of personnel and prevent further damage. This may involve immediately shutting down the system using emergency stop procedures and isolating the affected equipment. I’d then assess the situation to determine the extent of the damage and the impact on the overall process. For instance, if it’s a critical component in a production line, I’d assess the potential production losses and determine whether a temporary workaround is feasible.

Next, I’d gather information to diagnose the cause of the failure: examine the equipment for visible signs of damage, review maintenance logs, check sensor readings, and if necessary, involve other specialists (electrical, process control engineers, etc.). Once the cause is identified, I would then implement a solution, which may include temporary repairs, replacement of components, or a complete system overhaul. A thorough post-failure analysis would be critical to identify the root cause and prevent similar failures in the future. Documentation of the entire process, including the troubleshooting steps and corrective actions, would be meticulously maintained.

Q 22. What is your experience with different types of motors and their troubleshooting?

My experience encompasses a wide range of motor types, from simple DC motors to complex AC induction and servo motors. Troubleshooting involves a systematic approach. For example, with a malfunctioning DC motor, I’d first check for obvious issues like loose connections or a blown fuse. If the problem persists, I’d then move to more advanced diagnostics, measuring voltage and current to identify whether the problem lies in the motor itself, the power supply, or the control circuitry. With AC induction motors, I’d focus on things like bearing wear (indicated by unusual noise), stator winding faults (detected through resistance checks and insulation tests), and issues with the power capacitor (leading to reduced starting torque or overheating). For servo motors, the troubleshooting process often involves checking encoder signals, feedback loops, and the control algorithm itself, potentially requiring specialized diagnostic tools.

I’ve worked on motors in various applications, including robotics, industrial machinery, and automotive systems. One memorable case involved a robotic arm with a faulty servo motor that was causing intermittent movement. Through careful analysis of the motor’s control signals and a methodical process of elimination, I pinpointed a faulty encoder which was causing incorrect positional feedback, leading to the erratic behavior. Replacing the encoder resolved the issue.

Q 23. How familiar are you with different types of seals and gaskets?

My familiarity with seals and gaskets is extensive. I understand the different types, their applications, and their failure modes. For example, I know the difference between O-rings (simple, inexpensive, good for low-pressure applications), lip seals (effective at preventing leakage, good for rotating shafts), mechanical seals (designed for high pressure and demanding conditions), and various types of gaskets (e.g., rubber, metal, composite) which are chosen based on the application’s pressure, temperature, and chemical compatibility. I’ve worked with all of these in various industrial settings, including hydraulic systems, pumps, and engines.

Troubleshooting seal and gasket failures starts with identifying the leak. Once located, I analyze the cause – is it due to wear and tear, improper installation, chemical degradation, or excessive pressure? The solution then involves replacing the damaged seal or gasket, but equally importantly, addressing the root cause to prevent recurrence. For instance, if a seal fails due to excessive shaft runout, merely replacing the seal won’t solve the problem, addressing the shaft misalignment is crucial.

Q 24. Describe your experience with welding and fabrication techniques.

I possess significant experience in various welding and fabrication techniques, including MIG, TIG, and stick welding, as well as brazing and soldering. I’m proficient in selecting the appropriate welding process for a given material and application. My fabrication skills include working with various metals (steel, aluminum, stainless steel), cutting (plasma, oxy-fuel), and forming (bending, rolling). I’ve designed and fabricated custom jigs and fixtures to aid in the welding and assembly process, improving efficiency and ensuring accuracy.

For example, I once had to fabricate a custom mounting bracket for a piece of machinery. This involved selecting the appropriate material (stainless steel for corrosion resistance), cutting and shaping it using a plasma cutter and a bending press, then welding the various components together using TIG welding for a high-quality finish. The completed bracket fulfilled its role perfectly, demonstrating my capability to solve real-world problems through fabrication.

Q 25. What is your understanding of the principles of thermodynamics as applied to mechanical systems?

My understanding of thermodynamics is crucial to my work. I apply the principles of heat transfer, energy conversion, and entropy to analyze and troubleshoot mechanical systems. For instance, I understand how engine efficiency is affected by factors like compression ratio and heat loss, and how to diagnose issues related to inefficient combustion or inadequate cooling. I use this knowledge to optimize systems for performance and reliability.

In practical terms, understanding the Carnot cycle helps me understand the theoretical limits of engine efficiency. Troubleshooting overheating in a machine often involves considering heat transfer mechanisms—conduction, convection, and radiation—to identify the cause and implement effective solutions, such as improved cooling systems or insulation. The first law of thermodynamics (conservation of energy) is fundamental in understanding energy flows within a system.

Q 26. How would you troubleshoot a system with multiple possible points of failure?

Troubleshooting a system with multiple potential failure points requires a systematic and methodical approach. I often use a fault tree analysis or a similar structured method. This involves starting with the symptom and working backward, eliminating possibilities one by one. This is done by prioritizing potential points of failure based on their likelihood and impact.

For instance, I might start with the most likely causes first, checking the simplest and easiest components to access before moving to more complex ones. I also use diagnostic tools such as pressure gauges, temperature sensors, and multimeters to obtain quantitative data and correlate that data to known failure modes for the system’s components. I’ll often create a flowchart or checklist to ensure I cover all the potential issues and document my findings. If the problem persists, I consult any available schematics or manuals, or seek out help from experienced colleagues or online forums.

Q 27. What is your experience with preventative maintenance software?

I have experience using various preventative maintenance software packages. These tools allow for the scheduling of regular maintenance tasks, tracking of equipment history, and the generation of reports. This helps in optimizing maintenance schedules, reducing downtime, and improving overall equipment effectiveness (OEE).

For example, I’ve used software to schedule routine lubrication, inspection, and replacement of parts based on usage and manufacturer’s recommendations. The software also facilitates the tracking of spare parts inventory, helping to ensure that necessary parts are available when needed, reducing costly downtime.

Q 28. How do you manage your workload when facing multiple urgent mechanical issues?

Managing multiple urgent mechanical issues involves prioritization and efficient task management. I use a combination of techniques including urgency/impact matrix to rank issues, using techniques such as the Eisenhower Matrix (Urgent/Important). This helps me focus on the most critical issues first while ensuring that less urgent but still important tasks are not neglected. I also communicate clearly with stakeholders, setting expectations and providing updates on progress. In some situations, delegating tasks to other qualified personnel may be necessary to ensure timely resolution of all issues.

For example, if I’m facing a situation where one machine is completely shut down while others are experiencing minor issues, I’d prioritize the complete shutdown, bringing in additional resources if necessary. Simultaneously, I’d schedule the minor issues for repair during off-peak hours or assign them to other members of my team. Open communication and clear prioritization are key in such high-pressure situations.

Key Topics to Learn for Troubleshooting Mechanical Issues Interview

- Fundamentals of Mechanics: Understanding basic mechanical principles like forces, motion, energy, and stress/strain is crucial. This forms the foundation for diagnosing problems.

- Diagnostic Techniques: Learn about systematic troubleshooting methodologies, including visual inspection, listening for unusual sounds, and using diagnostic tools (e.g., multimeters, pressure gauges). Practical application involves describing how you’ve used these methods in past experiences.

- Hydraulic and Pneumatic Systems: Understanding the principles of fluid power and common components (pumps, valves, actuators) is essential for troubleshooting issues in systems utilizing these technologies. Be prepared to discuss real-world examples of troubleshooting in these systems.

- Mechanical Drawings and Schematics: Ability to interpret technical drawings and schematics is critical for identifying components and understanding system functionality. Practice reading and interpreting complex diagrams.

- Preventive Maintenance: Demonstrate understanding of preventative maintenance procedures and their role in minimizing mechanical failures. Highlight your experience in implementing or recommending preventative measures.

- Safety Procedures: Emphasize the importance of adhering to safety regulations and procedures during troubleshooting and repair. This showcases your responsible approach to the work.

- Root Cause Analysis: Mastering techniques for identifying the underlying cause of a mechanical issue, rather than just treating the symptoms. Be ready to explain your approach to root cause identification.

- Problem-Solving Strategies: Showcase your ability to approach complex mechanical problems systematically, using logical reasoning and critical thinking skills. Describe your problem-solving process in detail.

Next Steps

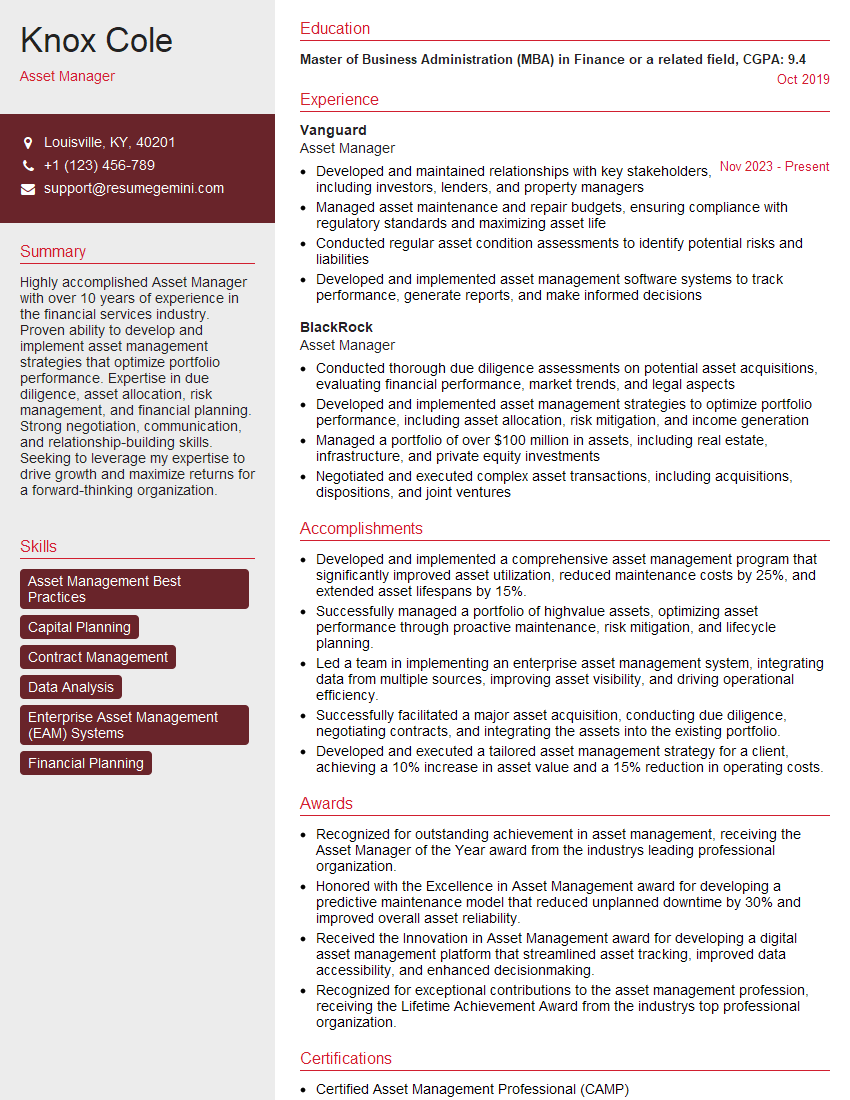

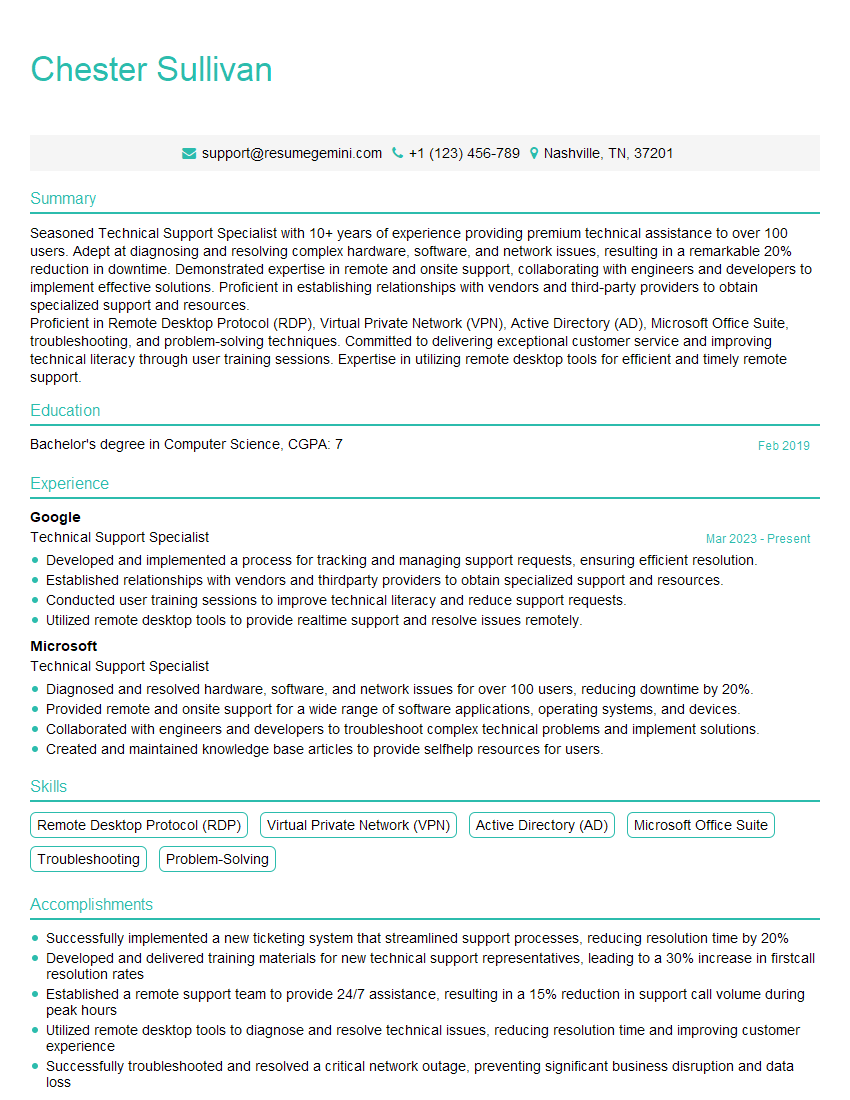

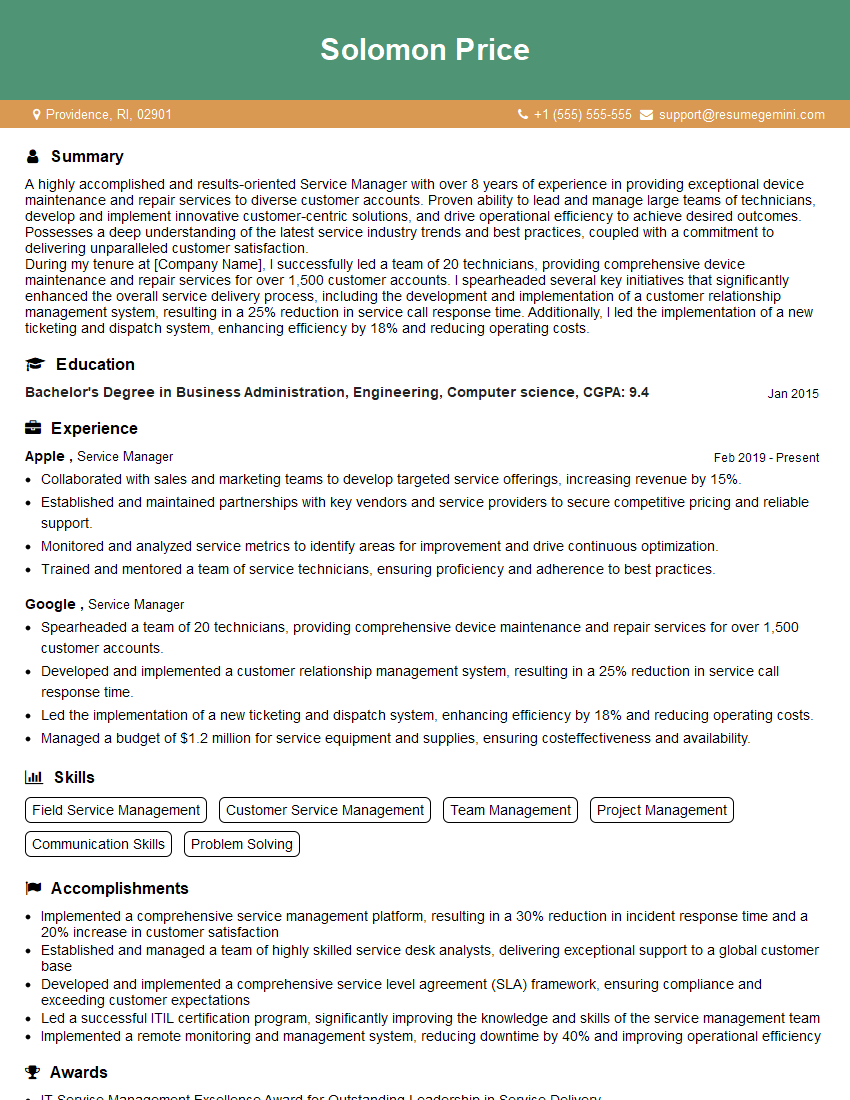

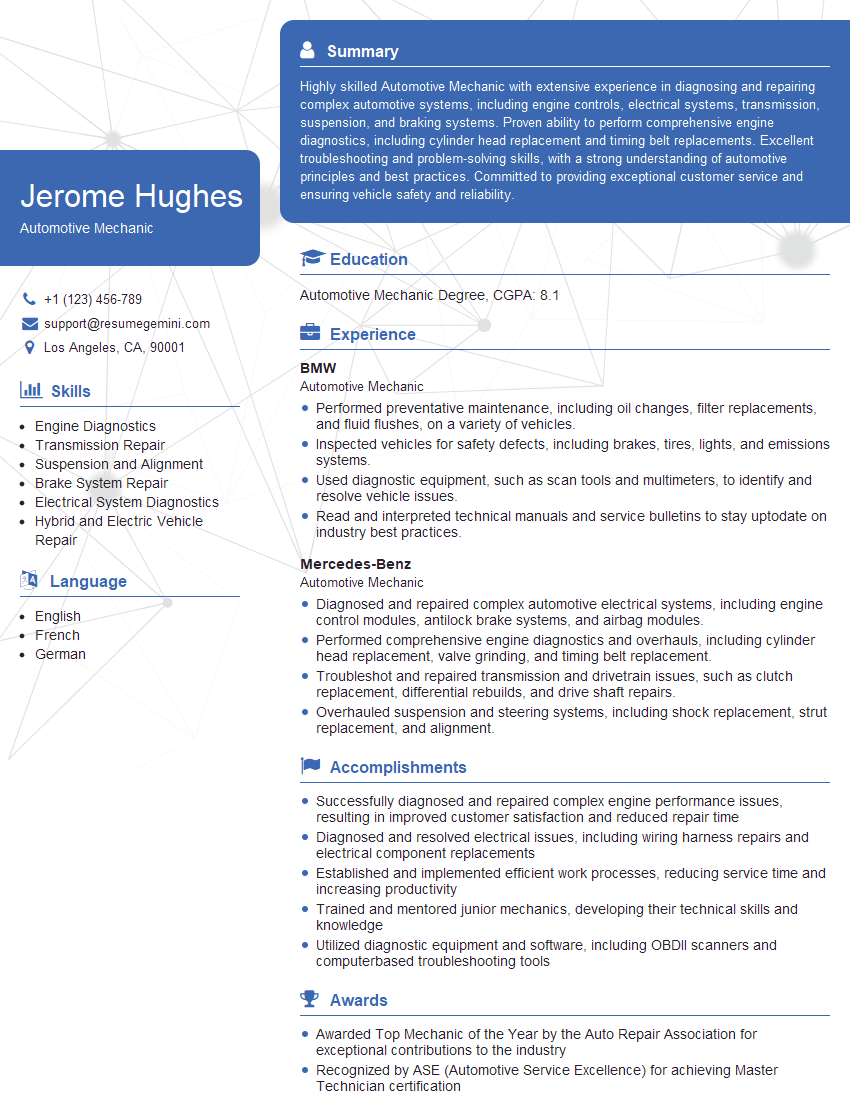

Mastering the art of troubleshooting mechanical issues significantly enhances your career prospects, opening doors to advanced roles and higher earning potential. A well-crafted, ATS-friendly resume is crucial for getting your foot in the door. To make your resume stand out and maximize your chances of landing your dream job, leverage the power of ResumeGemini. ResumeGemini provides a streamlined process for creating professional resumes, ensuring your skills and experience shine. Examples of resumes tailored to highlight expertise in troubleshooting mechanical issues are available for your reference, helping you craft a compelling application that showcases your abilities effectively.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good