Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Calibrate and Adjust Machines interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Calibrate and Adjust Machines Interview

Q 1. Describe your experience with various calibration methods.

My experience encompasses a wide range of calibration methods, tailored to the specific machine and its intended function. I’ve worked extensively with various techniques, including:

- Two-point calibration: This involves calibrating a machine using two known points, usually a minimum and maximum value. For instance, calibrating a pressure sensor using a known low and high pressure source. This is efficient for simpler machines with linear responses.

- Multi-point calibration: A more precise method using multiple known points across the machine’s operating range. This accounts for non-linearity and provides a better overall accuracy. I frequently use this for complex systems like spectrophotometers or analytical balances.

- Linearity calibration: This focuses on ensuring the machine’s output is proportional to its input across the entire range. Deviations from linearity are identified and corrected. I applied this extensively while calibrating robotic arms for precise movements.

- Offset and gain calibration: This method adjusts the machine’s zero point (offset) and the sensitivity (gain) to achieve accurate readings. I have used this commonly with signal processing equipment and various sensors.

The choice of method depends on several factors, including the machine’s complexity, required accuracy, and the available calibration standards.

Q 2. Explain the difference between calibration and adjustment.

While both calibration and adjustment involve fine-tuning a machine, they differ significantly in their purpose and approach.

- Calibration is the process of comparing a machine’s output to a known standard to determine its accuracy and systematic errors. It involves documenting the discrepancies and applying corrections. Think of it as verifying the machine’s ‘truthfulness’.

- Adjustment, on the other hand, is the process of modifying a machine’s internal settings or components to bring its output closer to the desired value. It addresses both systematic and random errors. Imagine it as ‘fine-tuning’ the machine.

For example, imagine a weight scale: Calibration would involve comparing its readings to known weights to determine if it’s consistently off by a certain amount. Adjustment would involve using internal mechanisms to rectify the systematic error, making the scale read accurately.

Q 3. How do you identify the root cause of machine inaccuracy?

Identifying the root cause of machine inaccuracy requires a systematic approach. I typically follow these steps:

- Gather data: Collect multiple readings under controlled conditions to identify patterns or trends.

- Analyze data: Use statistical methods to determine the magnitude and nature of the errors (random vs. systematic).

- Inspect the machine: Carefully examine the machine’s components, looking for wear, damage, or misalignment. This often involves checking connections, wiring, and mechanical parts.

- Test individual components: Isolate specific parts to determine if they are the source of error. This might involve using specialized test equipment.

- Review operational history: Consider the machine’s past usage, maintenance records, and environmental factors that might have contributed to the inaccuracy.

For instance, if a CNC machine is producing parts with inconsistent dimensions, the root cause could range from worn cutting tools to faulty motor controllers or even environmental factors such as temperature fluctuations.

Q 4. What are the common tools and equipment used in machine calibration?

The tools and equipment used depend heavily on the specific machine being calibrated. However, some common tools include:

- Precision measuring instruments: Micrometers, calipers, dial indicators, laser interferometers, etc., depending on the required accuracy and the type of measurement (length, angle, etc.).

- Calibration standards: Certified weights, pressure gauges, thermometers, voltage standards, etc., traceable to national or international standards.

- Test equipment: Oscilloscopes, multimeters, signal generators, power supplies, depending on the machine’s signal characteristics.

- Specialized software: For data acquisition, analysis, and report generation.

- Hand tools: Wrenches, screwdrivers, etc., for adjusting machine components.

I’m proficient in the safe and effective use of all these tools, ensuring adherence to safety protocols and best practices.

Q 5. Explain your proficiency with precision measuring instruments.

I possess extensive proficiency in using a wide array of precision measuring instruments. My skills encompass both the theoretical understanding of measurement uncertainty and the practical ability to operate these instruments effectively and accurately. This includes understanding their limitations, properly maintaining them, and interpreting the data they provide. I am highly skilled in using:

- Micrometers and Calipers: For precise linear measurements with high accuracy.

- Dial Indicators: For measuring small displacements and surface irregularities.

- Laser Interferometers: For highly accurate distance measurements over larger spans.

- Digital Multimeters: For measuring voltage, current, resistance, and other electrical parameters.

My experience also includes data analysis and error correction using statistical methods. I always meticulously document my measurements and include uncertainty analysis in my reports.

Q 6. Describe your experience with different types of calibration standards.

My experience includes working with various calibration standards, categorized by their traceability and accuracy. I’ve utilized:

- National standards: Standards traceable to national metrology institutes, offering the highest level of accuracy. These are essential for calibrating primary standards.

- International standards: Standards recognized globally and used for international comparisons of measurements.

- Secondary standards: These are calibrated against primary standards and used for calibrating instruments in the field. They provide a cost-effective way to maintain instrument accuracy.

- Working standards: Used in daily calibration checks to monitor instrument performance between formal calibrations.

The selection of the appropriate standard depends on the required accuracy and the type of measurement. Using appropriate standards is critical for maintaining traceability and ensuring measurement accuracy across the entire calibration chain.

Q 7. How do you ensure traceability in your calibration procedures?

Traceability in calibration is paramount to ensure the reliability of measurements. I maintain traceability through a robust system involving:

- Calibration certificates: Every standard and instrument I use has a valid calibration certificate from a recognized calibration laboratory, demonstrating its traceability to national or international standards.

- Documented procedures: I follow meticulously documented calibration procedures that detail the steps, equipment used, and expected results. This allows for consistent and repeatable calibration processes.

- Data management system: All calibration data are logged and managed in a secure database, facilitating easy retrieval and analysis. This includes instrument identification, calibration date, results, and uncertainties.

- Regular audits: The calibration procedures and data management system are subject to periodic audits to ensure their compliance with relevant standards and best practices.

This rigorous approach guarantees that all measurements are traceable back to fundamental standards, enabling the reliable comparison of results across different laboratories and time periods.

Q 8. What are the safety precautions you take during machine calibration?

Safety is paramount during machine calibration. Before I even touch a machine, I perform a thorough risk assessment, identifying potential hazards like moving parts, electrical components, and hazardous materials. This assessment informs my choice of personal protective equipment (PPE), which might include safety glasses, gloves, hearing protection, and even a full-body suit depending on the machine and its operating environment. I always ensure the machine is properly locked out and tagged out before commencing any work, following established lockout/tagout (LOTO) procedures to prevent accidental start-up. Throughout the calibration process, I maintain a cautious and methodical approach, carefully following the manufacturer’s instructions and adhering to all relevant safety regulations. For example, when working with high-voltage equipment, I utilize insulated tools and grounding straps to prevent electric shock. I am always attentive to my surroundings and will immediately stop work if I identify any unexpected issues or unsafe conditions.

Q 9. How do you document calibration results and maintain records?

Accurate and organized documentation is crucial for traceability and compliance. I use a standardized calibration report template that includes the machine’s identification number, date of calibration, calibration procedure followed, test equipment used (with its own calibration certificates), the measured values, and any adjustments made. The report also includes the technician’s signature and a space for approval. These reports are stored electronically in a secure database with version control to track revisions and ensure data integrity. Furthermore, I maintain a comprehensive calibration schedule, providing a clear overview of upcoming calibrations and ensuring all machines are calibrated within their specified frequency. This schedule is regularly reviewed and updated to reflect any changes in equipment or regulatory requirements. This system is not only essential for regulatory compliance but is also vital for identifying any trends or patterns that might suggest equipment is failing and needing attention.

Q 10. Explain your experience with statistical process control (SPC) in calibration.

Statistical Process Control (SPC) plays a vital role in ensuring the ongoing accuracy and reliability of calibration processes. I use control charts, like X-bar and R charts, to monitor the calibration data over time and identify any trends or shifts indicating potential problems. For instance, if the calibration readings consistently drift outside the control limits, it could indicate a problem with the machine, the calibration process, or the measuring equipment. This allows for proactive intervention, preventing costly downtime or inaccurate measurements. I also use capability analysis to assess the performance of our calibration processes and identify areas for improvement. This could mean reviewing calibration procedures, improving the quality of the measuring equipment, or retraining the calibration technicians. For example, I once identified a consistent bias in our pressure gauge calibrations using control charts. Upon further investigation, I discovered a slight miscalibration in the master pressure gauge we were using. Correcting this drastically improved the accuracy of our calibration process, saving a great deal of production time due to reduced rejects later on.

Q 11. How do you handle calibration discrepancies?

Calibration discrepancies require a systematic investigation. The first step is to verify the accuracy of the measuring instruments used during the calibration. This often involves checking the calibration certificates of the test equipment to ensure they are valid and within their specified tolerances. I then review the calibration procedure, checking for any errors or omissions. If the problem persists, I might conduct additional tests or use a different calibration method. If the discrepancy cannot be resolved through these steps, I isolate and analyze the machine to check for any faults. I document all steps in detail, including any corrective actions taken, and notify the relevant personnel. Depending on the severity of the discrepancy, the machine may be tagged out of service until the problem is resolved. For instance, I once encountered a significant discrepancy during a temperature calibration. My initial checks revealed nothing wrong. It turned out to be a loose thermocouple connector, an easily missed and easily fixed issue, yet it highlighted the importance of a thorough diagnostic process.

Q 12. Describe your troubleshooting experience with malfunctioning machines.

Troubleshooting malfunctioning machines requires a logical and systematic approach. I start by reviewing the machine’s operation manual and checking for any obvious signs of malfunction. I examine the machine’s error logs or diagnostic displays for any clues. If the problem is not immediately apparent, I use a step-by-step approach, isolating and testing individual components to narrow down the problem. I might use diagnostic tools, such as multimeters or oscilloscopes, to measure voltages, currents, and other signals. For example, I once resolved a malfunctioning robotic arm by tracing a faulty signal wire. If I’m unable to resolve the problem, I consult with colleagues, the machine manufacturer, or external experts. Good documentation throughout the troubleshooting process is critical for future reference and for escalating the problem to more senior personnel should the need arise.

Q 13. What are the key performance indicators (KPIs) for machine calibration?

Key Performance Indicators (KPIs) for machine calibration are critical for evaluating the effectiveness of the process. These KPIs often include the percentage of machines calibrated within the specified timeframe, the number of calibration discrepancies discovered, the average time taken for a calibration, and the overall cost of calibration. We also track the mean time between failures (MTBF) of machines after calibration, indicating the success of the calibrations in extending machine lifespan and reducing downtime. Another crucial KPI is the number of calibration-related production defects or quality issues, providing a direct measure of the calibration’s effectiveness in maintaining production quality. By closely monitoring these KPIs, we can identify areas for improvement and optimization in the calibration process.

Q 14. How do you ensure the accuracy and reliability of calibration results?

Accuracy and reliability in calibration are achieved through a combination of factors. First, using calibrated and traceable measuring instruments is fundamental. All our testing equipment undergoes regular calibration using instruments from a nationally accredited source. Following established calibration procedures meticulously also ensures consistency and minimizes human error. We regularly audit our calibration processes and implement continuous improvement measures. For instance, we regularly review the calibration data for trends and patterns, which aids in early identification of potential problems and ensures timely maintenance and repairs. The training and expertise of the calibration technicians also play a critical role in achieving accurate and reliable results. We provide regular training and refresher courses to keep our team up-to-date on the latest techniques and standards.

Q 15. Explain your experience with different types of machinery requiring calibration.

My experience encompasses a wide range of machinery requiring calibration, from simple analog instruments like pressure gauges and thermometers to highly complex CNC machines and automated testing equipment. I’ve worked with machines used in various industries, including manufacturing, pharmaceuticals, and aerospace. This broad experience has given me a solid understanding of the unique calibration needs of different machine types and the precision required in each case.

- Analog Instruments: I’m proficient in calibrating pressure gauges using deadweight testers and verifying thermometer accuracy against traceable standards. This often involves meticulous documentation and adherence to specific calibration procedures.

- CNC Machines: My experience includes calibrating CNC machines, focusing on ensuring precise axis movements, spindle speed accuracy, and tool offsets. This often requires understanding G-code programming and using specialized calibration tools provided by the machine manufacturer.

- Automated Testing Equipment: I’ve worked extensively with automated testing systems, calibrating various sensors, actuators, and data acquisition systems. This often involves using sophisticated calibration software and validating the accuracy of the system against known standards.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your experience with different calibration software?

Throughout my career, I’ve become proficient in using a variety of calibration software packages. My experience includes both general-purpose software for data acquisition and analysis, as well as specialized software provided by equipment manufacturers. Software proficiency is crucial for efficient and accurate calibration, enabling data logging, analysis, and report generation.

- General-Purpose Software: I’m adept at using software like LabVIEW and DASYLab for data acquisition, analysis, and report generation. These tools allow me to customize calibration procedures and generate comprehensive calibration certificates.

- Manufacturer-Specific Software: Many machines come with proprietary calibration software that’s crucial for efficient calibration and troubleshooting. I’ve gained expertise in using several of these packages, including those used for calibrating specific types of equipment like balances, spectrometers, and pressure transducers.

- Database Management: Effective calibration relies on meticulous record-keeping. I’m experienced with database systems for managing calibration data, ensuring traceability, and generating reports that meet regulatory requirements.

Q 17. Describe a time you had to calibrate a complex machine.

One challenging calibration involved a high-speed automated packaging machine used in the pharmaceutical industry. The machine was critical to production, and any downtime was extremely costly. The problem was inconsistent seal strength on the packaging. Initial troubleshooting revealed inconsistencies in the pneumatic system controlling the sealing pressure.

My approach was systematic:

- Thorough Assessment: I started with a comprehensive examination of the machine’s documentation and calibration history.

- Component-Level Calibration: I meticulously calibrated each pressure sensor, solenoid valve, and other pneumatic components, ensuring each component functioned within the manufacturer’s specifications.

- System-Level Calibration: After calibrating individual components, I tested the entire pneumatic system to ensure proper interaction between all components.

- Data Analysis: I used data acquisition software to monitor the pressure during the sealing process, identifying pressure fluctuations that were causing inconsistent seal strength.

- Corrective Action: Once the root cause was identified (a faulty air compressor), it was replaced, and the machine was recalibrated.

Successfully calibrating this complex machine required a deep understanding of the pneumatic system, proficiency in using calibration equipment, and a methodical approach to troubleshooting.

Q 18. How do you prioritize calibration tasks in a busy environment?

Prioritizing calibration tasks in a busy environment requires a structured approach. I utilize a combination of factors to determine the order of calibration:

- Criticality: Machines critical to production or safety are prioritized. This often involves a risk assessment to determine the potential consequences of malfunction.

- Calibration Due Dates: Calibration schedules are followed meticulously, ensuring timely calibration of instruments before their certification expires.

- Urgency: If a machine shows signs of malfunction or drift, its calibration is moved up the priority list.

- Regulatory Compliance: Machines subject to strict regulatory requirements (e.g., those used in pharmaceutical or medical device manufacturing) are given high priority to ensure compliance.

I use tools like a computerized maintenance management system (CMMS) to schedule and track calibration tasks effectively.

Q 19. How do you stay up-to-date with the latest calibration techniques and standards?

Staying current with calibration techniques and standards is vital in this field. I employ several strategies to maintain my expertise:

- Professional Development: I participate in relevant workshops, seminars, and training courses to update my skills on new calibration methods and technologies.

- Industry Publications: I subscribe to industry journals and publications to stay informed about the latest advancements in calibration technology and best practices.

- Manufacturer Updates: I regularly review updates and documentation provided by equipment manufacturers, ensuring I’m familiar with the latest calibration procedures and software releases.

- Networking: Participating in professional organizations and networking events allows me to share experiences and learn from other calibration professionals.

Q 20. What is your understanding of ISO 9001 and its relevance to calibration?

ISO 9001 is a globally recognized quality management system standard. Its principles are highly relevant to calibration because it emphasizes a systematic approach to managing processes and ensuring consistent product quality. Calibration plays a crucial role in maintaining the quality of products and services. A strong calibration program, aligned with ISO 9001, provides:

- Traceability: ISO 9001 requires traceability of calibration activities, ensuring that measurements can be linked back to national or international standards.

- Accuracy: By adhering to ISO 9001 guidelines, organizations can ensure the accuracy and reliability of their measurements, reducing errors and improving product quality.

- Compliance: Many industries require adherence to ISO 9001 as a prerequisite for business operations; a robust calibration program is essential to demonstrate compliance.

- Documentation: ISO 9001 stresses comprehensive documentation of calibration procedures and results, ensuring transparency and facilitating audits.

Q 21. Explain your experience with preventative maintenance related to calibration.

Preventative maintenance is crucial for ensuring the accuracy and longevity of calibration equipment. My approach involves a combination of:

- Regular Inspections: I conduct regular visual inspections of calibration equipment to identify any signs of wear and tear, damage, or potential malfunctions.

- Scheduled Maintenance: I follow manufacturers’ recommended maintenance schedules, ensuring that equipment is cleaned, lubricated, and serviced as needed.

- Calibration of Calibration Equipment: Even calibration equipment requires periodic calibration to ensure its own accuracy and reliability. This is a crucial step in maintaining traceability.

- Environmental Monitoring: Maintaining stable environmental conditions (temperature, humidity) is vital for the accurate operation of many calibration instruments. Regular monitoring helps ensure that these conditions are met.

By implementing a proactive preventative maintenance program, organizations can reduce downtime, extend the lifespan of their calibration equipment, and ensure the accuracy of their measurements.

Q 22. Describe your experience working with calibration certificates.

Calibration certificates are crucial documents that verify the accuracy and traceability of a machine’s calibration. They act as proof that a machine meets specified standards and is fit for its intended purpose. My experience involves meticulously reviewing these certificates, ensuring they include all necessary information: the equipment’s identification, calibration date, test methods used, results, uncertainties, and the signature of a qualified calibrator. I’ve worked with certificates from various manufacturers and accreditation bodies, understanding the nuances of different formats and ensuring they comply with relevant industry regulations and standards like ISO 17025. For instance, in one project involving a high-precision milling machine, a missing uncertainty value on the certificate nearly halted production until the discrepancy was resolved. This highlighted the critical importance of thorough certificate review and verification.

Q 23. How do you manage calibration schedules and deadlines?

Managing calibration schedules and deadlines requires a systematic approach. I typically use a combination of computerized maintenance management systems (CMMS) and spreadsheets to track calibration due dates. This allows for proactive scheduling, ensuring that calibrations are performed before equipment exceeds its acceptable tolerance limits. For example, I use a color-coded system within the CMMS: green indicates upcoming calibrations, yellow highlights those nearing their due date, and red flags overdue calibrations. This visual cue helps prioritize tasks and avoid costly production downtime. Furthermore, I regularly review the schedules, factoring in potential equipment usage spikes and planned maintenance activities to optimize the calibration process. This proactive planning ensures that calibration never disrupts critical workflows.

Q 24. What are the potential consequences of inaccurate machine calibration?

Inaccurate machine calibration can have severe consequences, ranging from minor inconsistencies in product quality to major safety hazards and significant financial losses. Inaccurate measurements can lead to rejected products, increased waste, and rework, directly impacting profitability. For example, an improperly calibrated weighing machine in a pharmaceutical manufacturing setting could result in incorrect dosages, with potentially life-threatening consequences. Similarly, a poorly calibrated CNC machine could produce parts outside of specifications, requiring costly scrapping or rework, causing production delays, and damaging reputation. In simpler terms, think of a poorly calibrated kitchen scale – your baking results will be inconsistent, and you might end up wasting ingredients. The same principle applies, but the consequences are far greater in industrial settings.

Q 25. How do you communicate calibration results to stakeholders?

Communicating calibration results to stakeholders is critical for transparency and accountability. I typically provide concise reports summarizing the calibration findings, including pass/fail status, measured values, uncertainties, and any necessary corrective actions. These reports are tailored to the audience; for technical staff, I provide detailed data and analysis, while for management, I offer a high-level summary focusing on key performance indicators and potential risks. I also utilize visual aids, such as charts and graphs, to effectively communicate complex data. For example, I might use a control chart to show the trend of a particular machine’s calibration over time, highlighting any deviations that require attention. Clear and timely communication ensures that stakeholders are informed and can take appropriate action.

Q 26. Explain your experience with different types of calibration errors.

Calibration errors can be broadly classified into systematic and random errors. Systematic errors are consistent and repeatable; they’re caused by inherent flaws in the measurement system, such as a bias in a measuring instrument. These errors can often be corrected through recalibration or adjustment. Random errors, on the other hand, are unpredictable and fluctuate during measurements. They are typically caused by environmental factors or operator inconsistencies. I’ve encountered both types in my work. For instance, a systematic error might arise from a consistently inaccurate temperature sensor in a testing environment, while random errors could be introduced by slight variations in operator technique when using a micrometer. Understanding the root cause of the error – whether systematic or random – is crucial for effectively implementing corrective actions and preventing future issues.

Q 27. How do you handle calibration equipment failure?

Calibration equipment failure can significantly disrupt operations. My response involves a multi-step process. First, I immediately assess the severity of the failure and its impact on ongoing calibration activities. If the failure is critical, I initiate a contingency plan, perhaps using a backup instrument or outsourcing the calibration to a trusted third-party service. While awaiting repair or replacement, I prioritize calibrating critical equipment first. Second, I meticulously document the failure, including the date, time, and nature of the malfunction, and any attempts at troubleshooting. This information is crucial for preventative maintenance and improving future calibration processes. Finally, once the equipment is repaired or replaced, I rigorously verify its functionality before resuming regular calibration activities.

Q 28. Describe a time you had to adapt your calibration methods to a specific situation.

During a project involving the calibration of a newly installed automated assembly line, I faced a unique challenge. The manufacturer’s recommended calibration procedure was overly time-consuming and disruptive to production. To address this, I devised a more streamlined approach using statistical process control (SPC) techniques. This involved monitoring key process parameters during the line’s normal operation and analyzing the data to identify and adjust any deviations from the desired specifications. This innovative approach significantly reduced calibration downtime while ensuring the line met quality standards. By adapting my methods, I improved efficiency and minimized disruptions to production, demonstrating flexibility and problem-solving capabilities.

Key Topics to Learn for Calibrate and Adjust Machines Interview

- Understanding Calibration Principles: Learn the fundamental concepts behind calibration, including accuracy, precision, and traceability. Explore different calibration methods and their applications.

- Machine Adjustment Techniques: Master various adjustment techniques for different machine types. Understand the impact of adjustments on machine performance and product quality. This includes both mechanical and electronic adjustments.

- Troubleshooting and Diagnostics: Develop your ability to identify and solve common machine malfunctions. Learn to use diagnostic tools and interpret error messages effectively. Practice systematic troubleshooting approaches.

- Safety Procedures and Regulations: Familiarize yourself with relevant safety protocols and regulations concerning machine operation, calibration, and adjustment. This is crucial for demonstrating responsibility and a commitment to safe working practices.

- Calibration Equipment and Instrumentation: Gain a comprehensive understanding of the various tools and instruments used in the calibration process, including their operation, maintenance, and limitations. Know how to select the appropriate equipment for specific tasks.

- Documentation and Record Keeping: Learn the importance of accurate and detailed documentation of calibration and adjustment procedures. Understand how to maintain proper records and comply with industry standards.

- Statistical Process Control (SPC): Familiarize yourself with basic SPC concepts and how they apply to machine calibration and adjustment. Understanding process variation and control charts is beneficial.

Next Steps

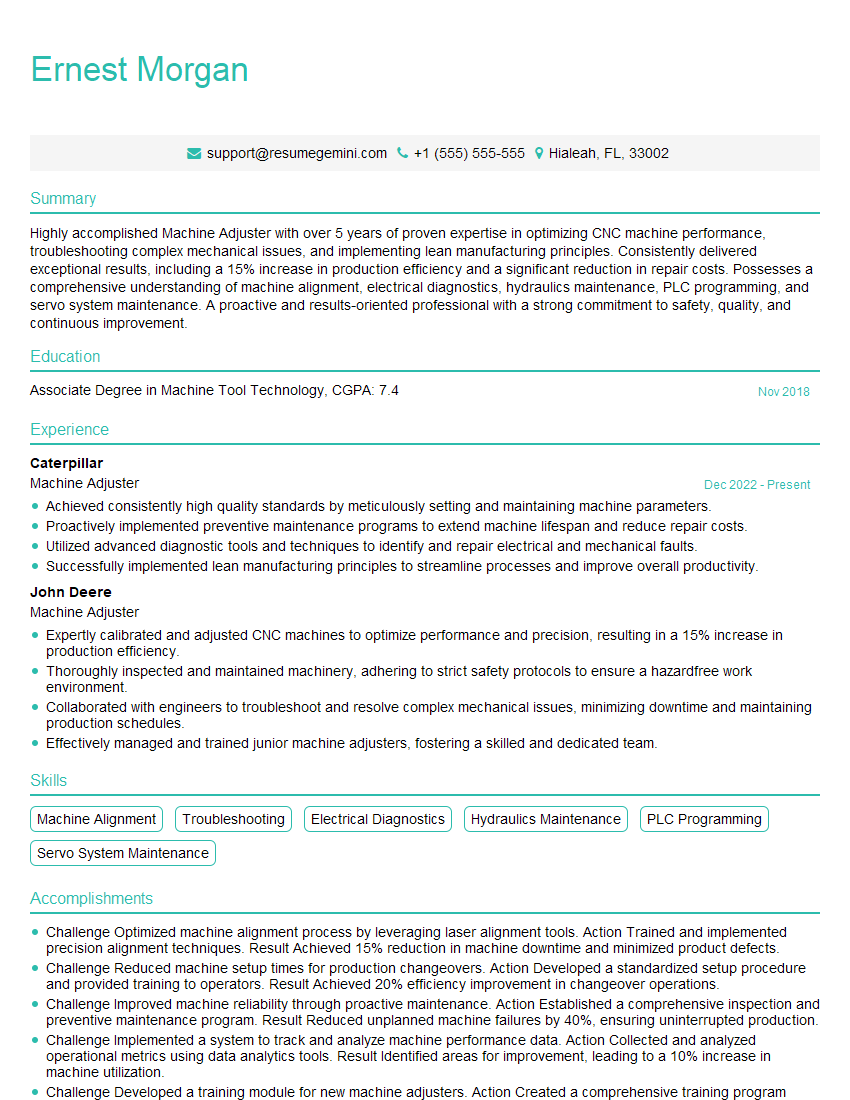

Mastering the skills of calibrating and adjusting machines is paramount for career advancement in many manufacturing and technical fields. It demonstrates a crucial blend of technical proficiency, problem-solving skills, and attention to detail. To significantly enhance your job prospects, it’s essential to create a resume that effectively showcases your expertise to Applicant Tracking Systems (ATS). ResumeGemini is a trusted resource that can help you build a professional and ATS-friendly resume. We provide examples of resumes tailored to Calibrate and Adjust Machines to help guide you in this process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good