Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Metalsmithing and Casting interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Metalsmithing and Casting Interview

Q 1. Explain the lost wax casting process in detail.

Lost wax casting, also known as investment casting, is a sophisticated method for creating intricate metal parts. Think of it like creating a metal sculpture using a mold made from wax. The process begins by creating a wax model of the desired part. This model is then invested, meaning it’s encased in a ceramic shell. The wax is melted out, leaving a cavity in the shell, which is then filled with molten metal. Once the metal solidifies, the ceramic shell is broken away, revealing the finished metal casting.

- Wax Model Creation: This can be done manually by carving or using techniques like 3D printing.

- Investment: The wax model is dipped repeatedly into a slurry of refractory material (ceramic) until a thick enough shell forms.

- Dewaxing: The wax is melted out, often using steam or hot water, leaving a void matching the wax pattern.

- Pouring: Molten metal is carefully poured into the cavity created by the dewaxing process.

- Solidification and Shell Removal: The metal solidifies within the mold, after which the ceramic shell is carefully broken away.

- Finishing: The casting is then cleaned and any necessary finishing processes are done, like grinding or polishing.

For example, lost wax casting is widely used in creating jewelry, dental appliances, and intricate turbine blades for jet engines. The precision and detail achievable make it ideal for complex geometries.

Q 2. Describe different types of casting processes (e.g., investment casting, sand casting, die casting).

Several casting methods exist, each with its own strengths and weaknesses. Let’s explore a few:

- Investment Casting (Lost Wax): As discussed earlier, this method excels in producing intricate, high-precision castings.

- Sand Casting: This is a more economical, large-scale method. A mold is created using sand packed around a pattern, then the pattern is removed leaving a cavity into which the metal is poured. It’s less precise than investment casting but handles larger volumes effectively. Think of automotive parts or large statues.

- Die Casting: Used for high-volume production of small to medium-sized parts, die casting employs a metal mold (die) that’s repeatedly filled with molten metal under high pressure. This results in high-quality, consistent castings. Examples include automotive components, housings for electronics, and various consumer goods. It produces excellent surface finishes but requires expensive tooling.

- Centrifugal Casting: This method uses centrifugal force to distribute molten metal evenly throughout a spinning mold, creating dense and uniform castings. It’s suitable for creating pipe sections and cylindrical parts.

The choice of casting method depends largely on factors like part complexity, production volume, dimensional accuracy requirements, surface finish needs, and budgetary considerations.

Q 3. What are the key differences between ferrous and non-ferrous metals in casting?

Ferrous and non-ferrous metals behave differently during casting, primarily due to their composition.

- Ferrous Metals (Iron-based): These metals, like steel and cast iron, typically have higher melting points and greater fluidity at their casting temperature. They are strong and durable but can be more prone to defects like shrinkage porosity due to their higher contraction rates upon cooling. Their higher melting points also necessitate more robust and energy-intensive furnaces.

- Non-ferrous Metals: These metals, such as aluminum, copper, zinc, and their alloys, generally have lower melting points and exhibit less fluidity compared to ferrous metals. They are often easier to cast and offer better corrosion resistance in many applications. However, some may have lower strength compared to steel.

For instance, aluminum’s low melting point and good castability makes it ideal for die casting applications. In contrast, cast iron’s higher strength and ability to absorb shock make it suitable for heavy-duty parts even with its greater casting challenges.

Q 4. How do you select the appropriate metal alloy for a specific casting application?

Selecting the right metal alloy is crucial for the success of a casting. The selection process depends on several factors:

- Mechanical Properties: Required strength, ductility, hardness, and fatigue resistance.

- Thermal Properties: Melting point, thermal expansion, and thermal conductivity.

- Corrosion Resistance: Ability to withstand exposure to various environments.

- Castability: How easily the metal flows and fills the mold cavity.

- Cost: Balancing performance needs with economic considerations.

- Machinability: How easily the casting can be further processed.

For example, if high strength and toughness are paramount, a high-strength steel alloy might be chosen. If corrosion resistance is critical, a stainless steel or a specific bronze alloy could be more appropriate. The application’s specific requirements will guide the alloy selection.

Q 5. Explain the importance of proper mold preparation in casting.

Proper mold preparation is paramount to achieving high-quality castings. Neglecting this step can lead to numerous defects. Key aspects include:

- Mold Material Selection: Choosing the correct sand type, ceramic material, or metal die based on the casting process and metal properties.

- Mold Making Techniques: Ensuring accurate pattern creation, proper compaction of the mold material (e.g., sand), and the creation of appropriate venting systems to allow for gas escape.

- Surface Treatment: Using coatings or mold releases to prevent sticking and ensure a clean surface finish on the casting.

- Drying/Baking: Removing moisture from the mold to prevent steam explosions during pouring.

- Preheating (where applicable): Preheating the mold can improve metal flow and reduce thermal shock.

Think of the mold as a vessel that must be meticulously prepared to handle the extreme temperatures and pressures involved in casting. A poorly prepared mold can lead to cracks, mis-shapes, or incomplete fillings.

Q 6. What are common defects encountered in casting, and how are they prevented?

Several common casting defects exist. Understanding their causes is essential for prevention:

- Shrinkage Porosity: Void formation due to metal contraction during cooling. This can be minimized by proper mold design, gating systems, and using alloys with lower shrinkage rates.

- Gas Porosity: Trapped gases in the casting during solidification. Good venting in the mold and degassing of the molten metal are crucial to prevent this.

- Cold Shut: Incomplete fusion of two molten metal streams, resulting in a seam or weakness in the casting. Proper pouring techniques and mold design can address this.

- Mold Shift: Movement of the mold halves during solidification, resulting in a misaligned or distorted casting. Secure mold clamping and proper cooling procedures are important.

- Sand Inclusion: Sand particles embedded in the casting surface. Careful mold preparation and proper mold release agents help prevent this.

Preventing defects involves meticulous attention to detail throughout the casting process. This includes careful selection of materials, optimized mold design, and precise control over pouring parameters.

Q 7. Describe your experience with different types of furnaces used in metal casting.

My experience encompasses various furnace types commonly used in metal casting, each with its own advantages and applications:

- Induction Furnaces: These furnaces use electromagnetic induction to heat the metal. They offer precise temperature control, rapid heating rates, and excellent stirring of the melt. I’ve extensively used them for non-ferrous metals like aluminum and copper alloys, as well as some ferrous applications requiring precise temperature control.

- Crucible Furnaces: These are versatile furnaces using various heating elements, including gas, electric resistance, or even fuel oil. They’re often used for smaller batches and are relatively simple to operate. I’ve utilized these extensively in laboratory and small-scale production settings.

- Electric Arc Furnaces: These furnaces use electric arcs to generate intense heat, typically for melting larger quantities of steel and other ferrous metals. Their high power density makes them suitable for high-throughput applications. My experience includes working with arc furnaces in industrial settings.

The choice of furnace depends on factors like the type of metal being melted, the desired production rate, the required level of temperature control, and budget. Each furnace type presents unique operational considerations and safety protocols that must be followed meticulously.

Q 8. How do you ensure the quality and dimensional accuracy of castings?

Ensuring the quality and dimensional accuracy of castings is paramount. It involves a multi-faceted approach starting from the design stage and continuing through to the final inspection. Think of it like baking a cake – you need the right recipe (design), the correct ingredients (materials), and precise baking time and temperature (casting process) to get the perfect result.

Pattern Accuracy: The pattern, a replica of the final casting, must be meticulously crafted to the exact dimensions specified in the engineering drawings. Any inaccuracies here will be directly reflected in the final casting. We often use precision machining and 3D printing to achieve this.

Mold Making: Careful mold preparation is critical. For sand casting, the sand must be properly compacted to avoid voids or shifting during pouring, leading to dimensional inconsistencies and surface defects. We use techniques like vibration and vacuum assisted molding for better compaction.

Pouring Technique: The molten metal must be poured smoothly and consistently to fill the mold completely, avoiding turbulence that could create air pockets or cold shuts. The temperature of the metal and the pouring rate are carefully controlled.

Cooling and Solidification: Controlling the cooling rate is crucial to minimize shrinkage and warping. Proper gating and risering systems help manage the flow of metal and ensure even cooling. These systems act like controlled pathways and reservoirs, guiding the molten metal and feeding it as it solidifies, preventing defects.

Inspection: Finally, rigorous inspection is essential. We use various methods, including visual inspection, dimensional measurement (using calipers, CMMs), and sometimes destructive testing like tensile testing, to verify the casting meets the required specifications.

Q 9. Explain the process of creating a pattern for sand casting.

Creating a pattern for sand casting is a crucial step that directly impacts the final casting’s quality. It’s like creating a mold for a cake – the better the mold, the better the cake.

Design: The process starts with the engineering drawing. The pattern maker interprets the drawing to determine the pattern’s overall shape, dimensions, and features like cores (for internal cavities).

Material Selection: The pattern material is chosen based on factors such as the casting metal, the number of castings required, and the desired surface finish. Common materials include wood (for simpler patterns), metal (for complex patterns and multiple castings), or polyurethane foam (for rapid prototyping).

Construction: The pattern is carefully constructed, ensuring accuracy in dimensions and details. This might involve woodworking techniques, machining, or 3D printing, depending on the chosen material and complexity of the design. We often add allowances for shrinkage during the metal’s solidification.

Finishing: Once constructed, the pattern is finished to ensure a smooth surface and to prevent any defects from transferring to the mold. This might involve sanding, smoothing, and applying parting agents (to prevent the mold from sticking to the pattern).

Example: For a simple cylindrical casting, a wooden pattern might suffice, while a complex engine block would require a more robust metal pattern, perhaps even constructed in multiple pieces to facilitate removal from the mold.

Q 10. What safety precautions are essential when working with molten metal?

Safety is paramount when working with molten metal, as it poses significant risks of burns, eye injuries, and inhalation of hazardous fumes. We treat molten metal with the utmost respect.

Personal Protective Equipment (PPE): This includes heat-resistant gloves, aprons, long sleeves, safety glasses with side shields, and closed-toe shoes. Full-face shields are often necessary for pouring operations.

Ventilation: Adequate ventilation is crucial to remove harmful fumes generated during melting and pouring. We ensure proper functioning of exhaust systems.

Proper Handling of Molten Metal: Molten metal should be handled with extreme caution, using appropriate tools such as ladles and tongs. Never pour directly into a mold; always use a suitable pouring system.

Emergency Procedures: We have established emergency procedures in place, including readily available fire extinguishers (appropriate type for the metal), first-aid kits, and emergency contact numbers. We conduct regular safety training for all personnel.

Spill Control: Having a plan in place for spills, including the use of specialized sand or materials to cool and contain spills is vital. Safety showers and eyewash stations should be nearby.

Q 11. How do you troubleshoot issues with metal flow during casting?

Troubleshooting metal flow issues requires a systematic approach, investigating various potential causes. Think of it like diagnosing a car problem – you need to systematically check various parts.

Insufficient Pouring Temperature: Molten metal that’s too cool will be viscous and flow poorly. We verify the metal temperature using thermocouples and adjust as needed.

Blocked Gating System: Air pockets or debris in the gating system can restrict metal flow. We inspect the gating system carefully to identify and remove any obstructions.

Mold Defects: A poorly made mold with insufficient venting or compaction can hinder metal flow. Careful mold making techniques are important.

Improper Mold Design: The mold’s design, including the location and size of gates and runners, directly impacts metal flow. This is addressed during design stage itself.

Pouring Technique: Incorrect pouring techniques, such as pouring too slowly or unevenly, can also cause problems. Training and careful execution is key.

By systematically checking these aspects, we can pinpoint and resolve issues, ensuring a smoother and more efficient casting process.

Q 12. What are your experiences with different finishing techniques for castings (e.g., polishing, tumbling)?

Finishing techniques significantly enhance the aesthetic appeal and functionality of castings. It’s like polishing a gem – it reveals its true beauty.

Polishing: This involves using abrasive materials of progressively finer grit to achieve a smooth, reflective surface. We utilize various techniques depending on the desired finish, including hand polishing for intricate details and automated polishing for larger castings.

Tumbling: This is a mass finishing technique that involves placing castings in a rotating drum filled with abrasive media (e.g., ceramic media, plastic media). It is effective for removing burrs and producing a consistent surface finish. We can vary the media and process parameters for different surface finishes.

Grinding: Grinding is used to remove excess material, smooth out imperfections, and prepare surfaces for further finishing. This could include bench grinding for smaller areas, and robotic grinding for larger surfaces.

Shot Blasting: This process uses small metal shot propelled at high velocity to remove surface defects, clean, and prepare surfaces for painting or coating. This results in a consistent surface texture.

Electroplating: For specific applications, electroplating can be used to add a protective layer, enhance corrosion resistance, or improve aesthetics. The specific metal to be electroplated depends on the use case.

The choice of finishing technique depends on the casting’s material, size, complexity, and the desired final aesthetic and functional requirements.

Q 13. Describe your experience with different types of welding techniques used in metalworking.

Welding is a crucial process in metalworking, allowing for joining different metal pieces. Each technique has its strengths and weaknesses, similar to choosing the right tool for a specific job.

Gas Metal Arc Welding (GMAW): This process, commonly known as MIG welding, uses a continuous wire electrode fed into a weld pool, protected by a shielding gas. It’s versatile and efficient for many applications.

Gas Tungsten Arc Welding (GTAW): This is also known as TIG welding. It uses a non-consumable tungsten electrode and a shielding gas to create high-quality welds. It’s ideal for precision work but is slower than GMAW.

Shielded Metal Arc Welding (SMAW): This is commonly known as stick welding. It uses a consumable electrode coated with flux. It’s portable and relatively inexpensive but produces less consistent welds than GMAW or GTAW.

Resistance Welding: This process uses electrical resistance to create a weld. It’s highly efficient for joining similar metals, often used in high-volume production. Spot welding and seam welding are common types.

My experience encompasses all these methods. The selection of the appropriate welding technique depends on the metals being joined, the desired weld quality, the production volume, and the available equipment.

Q 14. How do you interpret engineering drawings related to metal castings?

Interpreting engineering drawings for metal castings is fundamental. It’s like reading a recipe for a complex dish – each detail is important.

Dimensions and Tolerances: Understanding the precise dimensions and allowable tolerances is crucial for ensuring the casting meets specifications. We use tools like calipers and micrometers for verification.

Surface Finish Requirements: Drawings often specify surface finish requirements, indicating the desired roughness or smoothness. This determines the appropriate finishing processes to use.

Material Specifications: The drawings will specify the type of metal to be used for the casting, its properties and chemical composition. This choice is dictated by the final applications demands.

Section Views and Details: Detailed views provide information about the casting’s internal features, such as cavities, ribs, and cores. These drawings illustrate the internal structure of the cast piece.

Gating and Risering System: Drawings show the locations of gates, runners, and risers, which dictate how molten metal flows into the mold. A correctly designed system is essential for avoiding defects.

Proficiency in reading and interpreting these drawings is essential for ensuring that the pattern is accurately constructed and the casting process is executed correctly.

Q 15. Explain your experience with different types of metal forming processes.

My experience with metal forming encompasses a wide range of techniques, all crucial for shaping metal into desired forms. These processes can be broadly categorized into those that involve deformation (like hammering or rolling) and those that involve casting (pouring molten metal into a mold).

- Forging: This ancient technique involves shaping metal using repeated blows from a hammer. I’m proficient in both hand forging, perfect for intricate details, and power hammering, suitable for larger pieces or mass production. For example, I’ve used forging to create custom-designed drawer pulls and decorative elements for furniture.

- Rolling: This process reduces the thickness of metal by passing it through rollers. I’ve used rolling mills to create sheet metal for jewelry components and thinner gauge wires for intricate filigree work.

- Drawing: This technique pulls metal through a die to reduce its diameter, creating wire or tubing. I have experience with both cold drawing (at room temperature) and hot drawing (at elevated temperatures) techniques.

- Stamping: This method uses dies to create shapes in sheet metal through pressure. I utilize stamping for mass-producing standardized parts, such as bezels for gemstones.

- Spinning: This is a lathe-based process used to shape thin sheet metal over a rotating form. It is ideal for creating symmetrical, bowl-like shapes. I’ve employed spinning to craft unique pendant shapes.

- Casting: I’m extensively experienced in various casting methods, including investment casting (lost-wax), sand casting, and centrifugal casting, each with its own strengths and weaknesses depending on the desired outcome and scale of production. Investment casting allows for highly detailed work, perfect for intricate jewelry, while sand casting is more suitable for larger, less detailed pieces.

Understanding the nuances of each process, including material properties and tool selection, is essential to achieving the desired result. The choice of technique often depends on factors such as the metal’s properties, the design complexity, and the production volume.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe the process of creating a jewelry piece from start to finish.

Creating a jewelry piece is a multi-stage process that requires precision and artistic vision. Let’s take the example of a silver ring with a gemstone:

- Design: This begins with sketching ideas and refining the design. I often use CAD software (as discussed later) to create a 3D model allowing for precise measurements and adjustments before fabrication.

- Material Selection: I choose the appropriate metal (sterling silver in this case) and gemstone based on aesthetic preferences, durability requirements, and budget considerations. I source high-quality materials from reputable suppliers.

- Metal Preparation: This may involve sawing, filing, and shaping the silver sheet or wire to create the ring’s components – the band and the bezel for the gemstone.

- Gemstone Setting: The gemstone is securely set into the bezel using various techniques depending on its shape and setting style (e.g., prong setting, bezel setting, channel setting). I prioritize techniques that guarantee the gemstone’s security and enhance its brilliance.

- Assembly: If the ring has multiple components, they are carefully soldered or joined together using appropriate techniques. I pay meticulous attention to ensuring strong, seamless joints.

- Finishing: This is crucial for achieving the final polish and surface texture. The ring undergoes processes such as filing, sanding, polishing, and possibly texturing to achieve the desired look and feel.

- Quality Control: A final inspection checks for flaws, proper dimensions, and secure gemstone setting. I pay close attention to detail to guarantee customer satisfaction.

Throughout the entire process, I maintain a keen eye for detail and precision. Each step is crucial, and any flaw in one area can negatively impact the final product.

Q 17. How do you ensure the structural integrity of your metalwork?

Ensuring structural integrity is paramount in metalsmithing. It’s not just about aesthetics; it’s about creating a piece that will last. I achieve this through a combination of techniques:

- Proper Material Selection: Choosing the right metal alloy for the application is critical. For instance, sterling silver is suitable for jewelry, but it might not be strong enough for certain applications. I may opt for a stronger alloy if needed.

- Sound Construction Techniques: This involves employing the appropriate metal forming and joining techniques. Using the correct soldering or welding methods, ensuring proper overlap of joints, and avoiding thin sections vulnerable to stress are crucial.

- Careful Design: Designing pieces with strategically placed reinforcements or thicker sections in areas prone to stress enhances durability. I avoid sharp corners or abrupt changes in thickness, which could be stress points.

- Heat Treatment (where appropriate): Certain metals benefit from heat treatment processes that enhance their strength and hardness. This requires a thorough understanding of the metal’s properties and heat treatment schedules.

- Testing and Inspection: Regular quality control checks throughout the process, from raw material inspection to finished product examination, help detect potential weaknesses before the piece is completed.

For example, when making a large pendant, I’ll ensure the bail (the loop for hanging) is robust enough to support the weight of the pendant without bending or breaking. This often involves reinforcing the bail with thicker metal or using a more secure joining method.

Q 18. What are your experiences with different types of soldering and brazing techniques?

Soldering and brazing are crucial joining techniques in metalsmithing. The difference lies primarily in the melting point of the filler metal used. Soldering uses a filler metal with a lower melting point than the base metals, while brazing uses a filler metal with a higher melting point.

- Soft Soldering: This uses a low-temperature solder, typically lead-tin alloys or silver-based alloys with lower silver content. It’s suitable for joining smaller pieces or delicate work where high strength isn’t crucial. I often use soft soldering for attaching small components to jewelry.

- Hard Soldering (Silver Soldering): This uses silver-based alloys with higher silver content, resulting in stronger, higher-temperature joints. It’s ideal for joining thicker materials or when greater structural integrity is required. I often use hard soldering for structural components in larger pieces.

- Brazing: Brazing utilizes filler metals with even higher melting points, often brass or bronze, resulting in very strong joints suitable for heavier components or applications requiring high heat resistance. I use brazing for joining heavier gauge metals or when greater structural integrity is paramount.

My experience encompasses all these techniques, and my choice depends on the specific needs of the project. For instance, I’d use hard soldering to assemble a complex piece of jewelry, while soft soldering might be suitable for attaching a small clasp.

Q 19. Explain your experience with different types of metal alloys used in jewelry making.

My experience with metal alloys used in jewelry making is extensive. The choice of alloy depends on factors like desired color, durability, cost, and tarnish resistance.

- Sterling Silver (92.5% silver): This is a common choice for its affordability and attractive appearance. It does tarnish over time, requiring regular cleaning.

- Argentium Silver: This is a sterling silver alloy with added germanium, which significantly reduces tarnishing. It’s more expensive but offers increased longevity.

- Fine Silver (99.9% silver): This is very soft and malleable, requiring more care during handling and fabrication. It’s highly resistant to tarnishing but more costly than sterling silver.

- Gold Alloys (Karat Gold): The karat (e.g., 14k, 18k, 24k) indicates the percentage of gold in the alloy. Lower karat gold alloys contain other metals like copper, silver, and zinc, which affect color, hardness, and cost. 14k gold is a popular choice for jewelry due to its durability and affordability compared to higher karat gold.

- Platinum Alloys: Platinum is a highly durable and inert metal, ideal for high-end jewelry. It’s often alloyed with other metals to improve strength and workability.

- Brass and Bronze: These copper alloys are frequently used for decorative elements, due to their attractive colors and relative ease of casting.

I have experience working with all these alloys, selecting the appropriate one based on the project’s requirements and the client’s preferences.

Q 20. What software or CAD programs are you proficient in for designing metalwork?

Proficiency in CAD software is essential for modern metalsmithing. I am proficient in:

- Rhino 3D: This is a powerful 3D modeling software that I use for creating complex designs, generating precise blueprints, and producing renderings for client presentations. It allows me to simulate different manufacturing processes.

- SolidWorks: While less focused on organic forms, SolidWorks is invaluable for precise mechanical design and creating models for CNC machining (Computer Numerical Control) – a process I occasionally use for complex projects.

- Jewelry CAD Software (e.g., Matrix, Jewelcad): These specialized programs are designed for the nuances of jewelry design. They allow for creating highly detailed models of jewelry components, including gemstone settings, that can be directly used for 3D printing or CNC machining.

My CAD skills allow me to translate client visions into precise, manufacturable designs, minimizing errors and ensuring an efficient workflow.

Q 21. Describe your experience with quality control procedures in a metalsmithing environment.

Quality control is integral to my metalsmithing practice. It’s not just a final step; it’s integrated throughout the entire process.

- Material Inspection: I carefully inspect all raw materials upon arrival to ensure they meet the required specifications. This includes checking for flaws, accurate dimensions, and consistent composition.

- Process Monitoring: Throughout the fabrication process, I regularly check for dimensional accuracy, proper alignment of components, and structural integrity of the piece. This ensures that any potential issues are caught early and addressed promptly.

- Intermediate Inspections: After major stages of the process (e.g., after soldering, after polishing), I conduct detailed inspections to ensure the quality of the work and make necessary corrections.

- Final Inspection: The finished piece undergoes a thorough final inspection. This involves examining every detail, ensuring the structural integrity, confirming the gemstone (if applicable) is secure, and assessing the overall finish. This is a critical stage for identifying any minor imperfections.

- Documentation: I maintain thorough records of the entire process, from design to final inspection, which includes photographs and detailed notes. This helps identify any recurring issues and facilitates continuous improvement of my techniques.

My commitment to quality control ensures I deliver consistently high-quality metalwork that meets the expectations of my clients and lasts for years to come. I see it not merely as a check-off list, but as an integral part of my creative process.

Q 22. How do you manage your time and prioritize tasks in a fast-paced metalsmithing environment?

In the fast-paced world of metalsmithing, effective time management is crucial. I utilize a combination of techniques to prioritize tasks and ensure deadlines are met. My approach begins with meticulous project planning. This involves breaking down large projects into smaller, manageable steps, each with its own realistic timeline. I use a digital project management tool to track progress, set deadlines, and allocate time for each step. This allows me to easily visualize my workload and identify potential bottlenecks. For example, if I’m creating a complex silver necklace involving soldering, forging, and stone setting, I’ll meticulously schedule each stage, ensuring sufficient time for each process and accounting for potential delays. Furthermore, I prioritize urgent tasks using methods like the Eisenhower Matrix (urgent/important), allowing me to focus on high-impact activities first. Finally, I regularly review my schedule, adjusting as needed based on unforeseen challenges or opportunities. This iterative approach ensures flexibility and allows for efficient adaptation to changing circumstances.

Q 23. Describe your experience with working with different gauges of sheet metal.

My experience with sheet metal encompasses a wide range of gauges, from delicate 24-gauge materials used for intricate jewelry components to more substantial 18-gauge or even heavier gauges employed in larger sculptural pieces. Working with thinner gauges requires precision and finesse. Tools like fine-tipped punches, jeweler’s saws, and specialized hammers are necessary to avoid tearing or warping the metal. For instance, when creating a detailed filigree piece from 24-gauge silver, I must exercise extreme care to avoid damaging the thin material during forming or shaping. Conversely, thicker gauges allow for more aggressive shaping techniques, such as hammering or raising, creating stronger and more robust forms. For example, when working with 16-gauge copper for a larger bowl, I can use stronger hammers and more forceful techniques to shape the metal. The gauge selection is always dictated by the intended design and its functional requirements. Understanding the properties of various gauges is essential for creating successful and durable metalwork.

Q 24. Explain your experience with various metal finishing techniques for jewellery.

My experience with metal finishing techniques for jewelry is extensive and encompasses a variety of methods. I regularly use techniques such as polishing, buffing, and tumbling to achieve different levels of shine and smoothness. Polishing, using various grades of polishing compounds, removes scratches and imperfections to create a high luster. Buffing is employed for a more aggressive surface finish, often used to achieve a mirror-like shine on precious metals. Tumbling uses abrasive media in a rotating container to create a consistent and uniform finish on numerous pieces at once. Beyond these mechanical processes, I’m also proficient in chemical finishes. For example, I use various oxidizing solutions to darken silver, creating a more antique or aged look. I also apply protective coatings, like clear lacquers or epoxies, to shield jewelry from tarnishing and environmental damage. The choice of finishing technique depends on the desired aesthetic and the properties of the metal. For instance, a delicate gold pendant might require gentler polishing, while a more rustic silver ring might benefit from an oxidizing treatment to enhance its character.

Q 25. How do you handle unexpected issues or challenges during the manufacturing process?

Handling unexpected issues during the manufacturing process is a regular part of metalsmithing. My approach focuses on problem identification, creative solutions, and continuous learning. When facing a challenge, I first systematically analyze the situation, identifying the root cause. For example, if a solder joint fails, I assess the cleanliness of the metal surfaces, the type of solder used, and the temperature of the torch. This diagnostic approach helps pinpoint the issue. Once the root cause is identified, I explore several solutions. This might involve adjusting techniques, using different tools, or consulting relevant resources. If a casting comes out with a significant imperfection, I might re-evaluate the mold-making process, the metal pouring techniques, or consider alternative casting methods. I maintain a detailed record of my successes and failures, incorporating lessons learned into future projects. This continual improvement approach fosters adaptability and reduces the likelihood of similar issues arising in the future. It’s also important to have a network of experienced metalsmiths to consult for advice when I encounter truly intractable problems.

Q 26. Explain your understanding of different heat treatments for metals.

Heat treatment is a fundamental aspect of metalsmithing, influencing the strength, hardness, and ductility of the metal. Different metals require distinct heat treatments. Annealing, for instance, involves heating the metal to a specific temperature and then slowly cooling it. This process relieves internal stresses, making the metal softer and more pliable. It’s crucial for working with metals that have been work-hardened during shaping processes. Hardening involves heating the metal to a specific temperature and then rapidly cooling it, often in water or oil. This increases the hardness and strength of the metal but reduces its ductility. Tempering is a subsequent process to hardening, involving reheating to a lower temperature and then cooling, which reduces brittleness and increases toughness. This is vital for tools that require both strength and resilience. The specific temperature and cooling rates are crucial and vary greatly depending on the metal and desired outcome. A lack of proper control can easily ruin a workpiece. For example, overheating silver can cause it to become brittle and crack, while insufficient heating during annealing will not effectively relieve internal stresses. My experience encompasses heat treating a broad spectrum of metals including steel, silver, and copper, each demanding a precise and tailored approach.

Q 27. How do you maintain and care for your tools and equipment?

Maintaining tools and equipment is paramount to safety and productivity. I follow a meticulous cleaning and maintenance schedule. After each use, tools are thoroughly cleaned, removing any debris or residue. This prevents corrosion and damage. Abrasive tools are regularly sharpened and honed to maintain their efficiency and precision. For example, I use honing stones to keep my chasing tools in perfect working condition. Larger equipment, such as furnaces and casting equipment, requires regular inspections and maintenance according to manufacturer recommendations. This includes checking for wear and tear, replacing worn parts, and ensuring proper functionality. I keep a detailed log of maintenance procedures and any repairs needed, tracking any issues and their resolutions. Proper storage is also crucial. Tools are stored in organized racks, protecting them from damage and ensuring easy accessibility. This proactive approach minimizes downtime, prolongs the life of my tools, and ensures safety in the workshop.

Q 28. Describe your experience with working with precious metals (gold, silver, platinum).

Working with precious metals like gold, silver, and platinum requires specialized knowledge and techniques. These metals are considerably more valuable and often require different fabrication methods than base metals. I have extensive experience in all three, understanding their unique properties, including melting points, malleability, and workability. For example, gold’s high malleability requires gentle handling to prevent tearing. Silver’s tendency to tarnish necessitates careful storage and finishing techniques. Platinum’s high melting point requires specialized equipment for soldering and casting. I use appropriate safety measures when handling these metals, including proper ventilation and protective gear to prevent inhalation of fumes or exposure to hazardous chemicals used in refining and finishing. I meticulously weigh and account for all precious metal materials, adhering to strict industry standards and best practices to avoid losses. The fabrication of jewelry from precious metals often involves intricate designs demanding a high level of skill and precision, requiring the use of specialized tools and techniques.

Key Topics to Learn for Your Metalsmithing and Casting Interview

- Metal Properties and Selection: Understanding the characteristics of various metals (ferrous and non-ferrous) and their suitability for different casting and smithing techniques. Consider factors like melting point, strength, ductility, and machinability.

- Casting Processes: Gain a firm grasp of different casting methods such as sand casting, investment casting (lost-wax), die casting, and centrifugal casting. Be prepared to discuss the advantages and disadvantages of each, and their appropriate applications.

- Metalsmithing Techniques: Familiarize yourself with forging, hammering, annealing, quenching, and other heat-treating processes. Understand the impact of these techniques on metal structure and properties.

- Mold Making and Design: Explore the principles of mold design and construction, including considerations for gating, venting, and riser placement in casting. For smithing, discuss the importance of preparing the metal for shaping.

- Safety Procedures and Practices: Demonstrate a thorough understanding of safety protocols related to working with molten metal, high temperatures, and heavy machinery. This is crucial for any metalsmithing or casting role.

- Quality Control and Inspection: Learn about techniques for inspecting castings and smith-worked pieces for defects such as porosity, cracks, and dimensional inaccuracies. Be ready to discuss quality control measures and troubleshooting strategies.

- Design and Fabrication: Understand the process of translating a design into a functional piece, considering material limitations and production methods. This includes pattern making for casting and conceptualizing forms for smithing.

- Troubleshooting and Problem-Solving: Prepare examples showcasing your ability to identify and solve problems encountered during the casting or smithing process. Highlight your analytical skills and practical solutions.

Next Steps

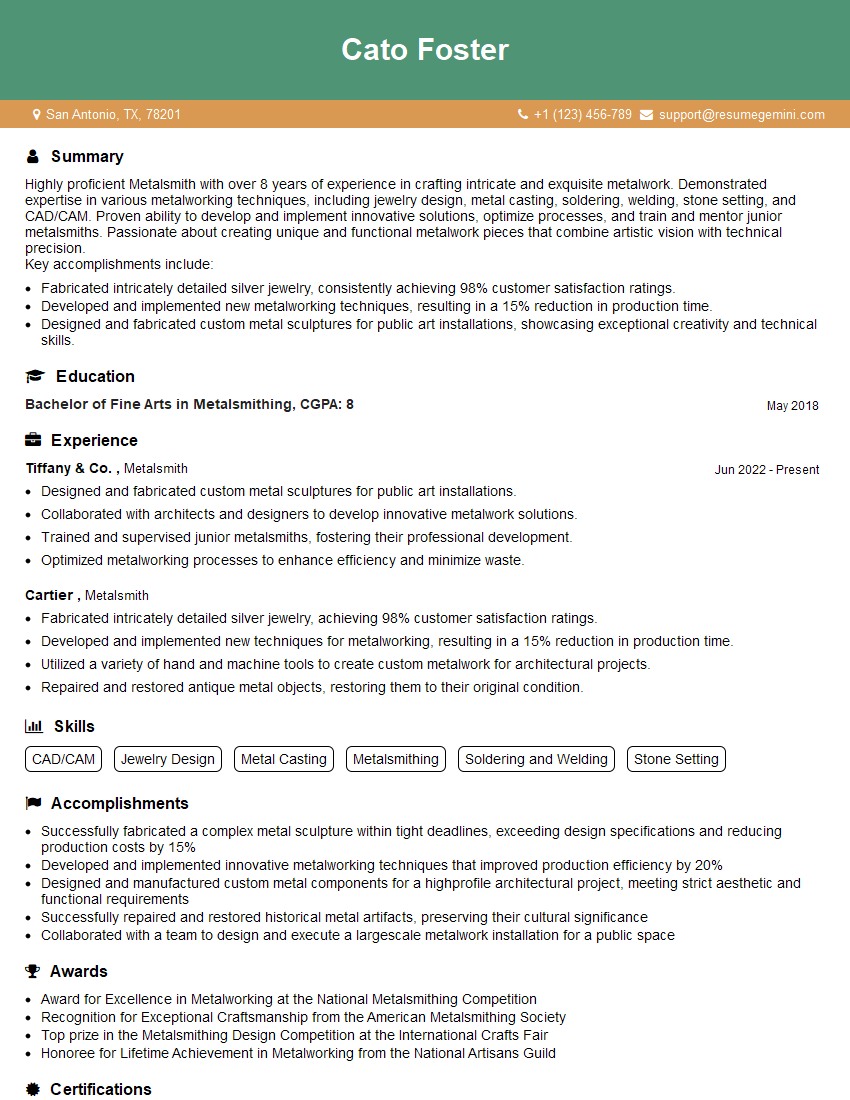

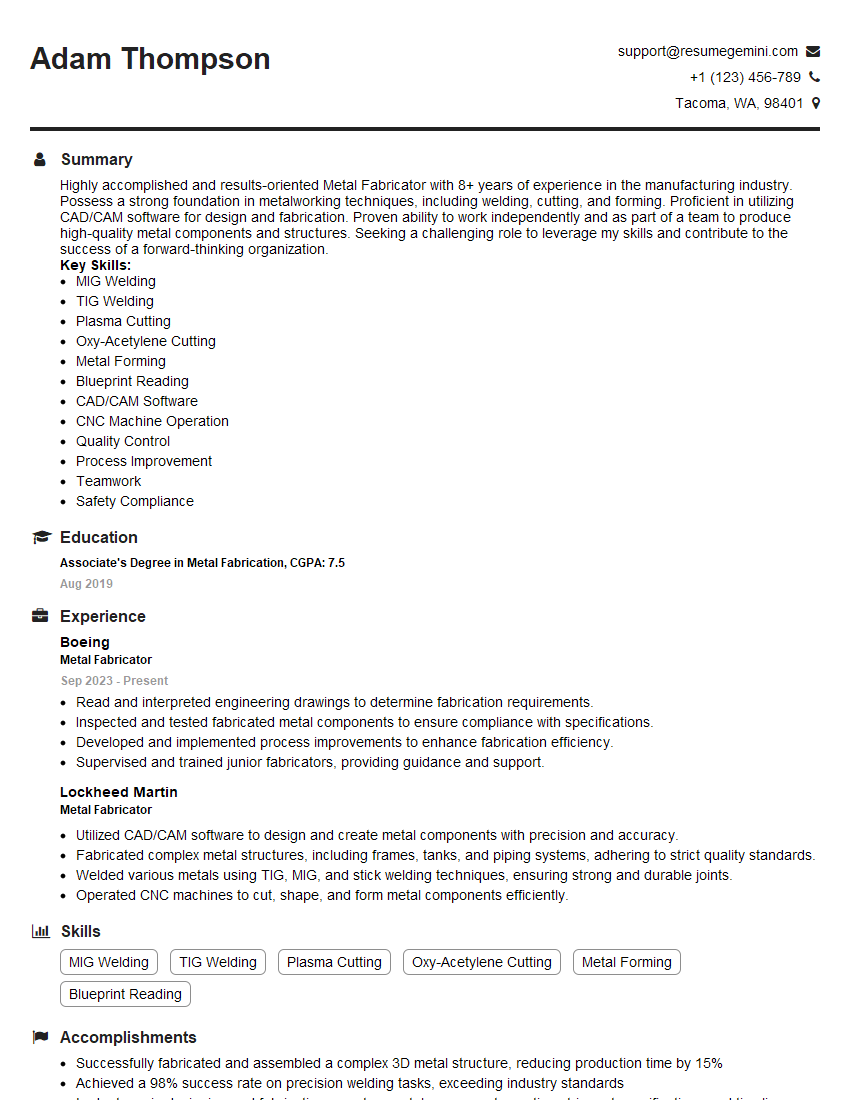

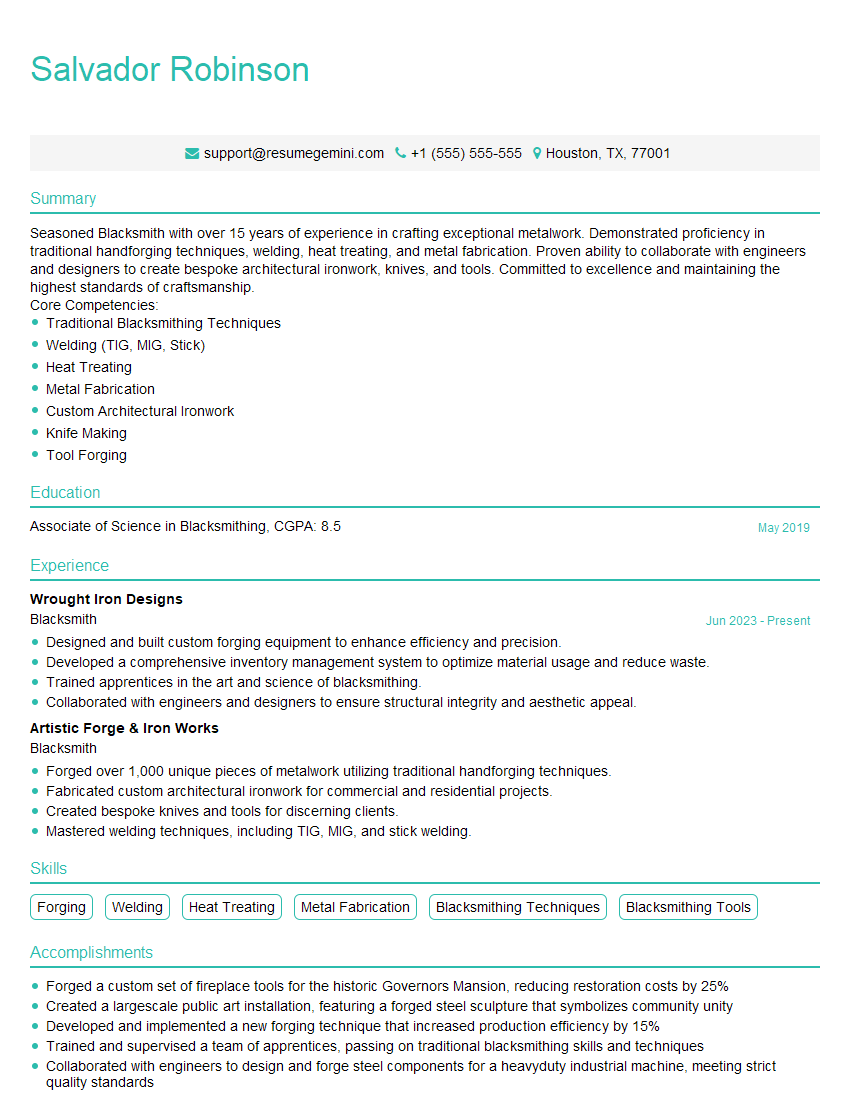

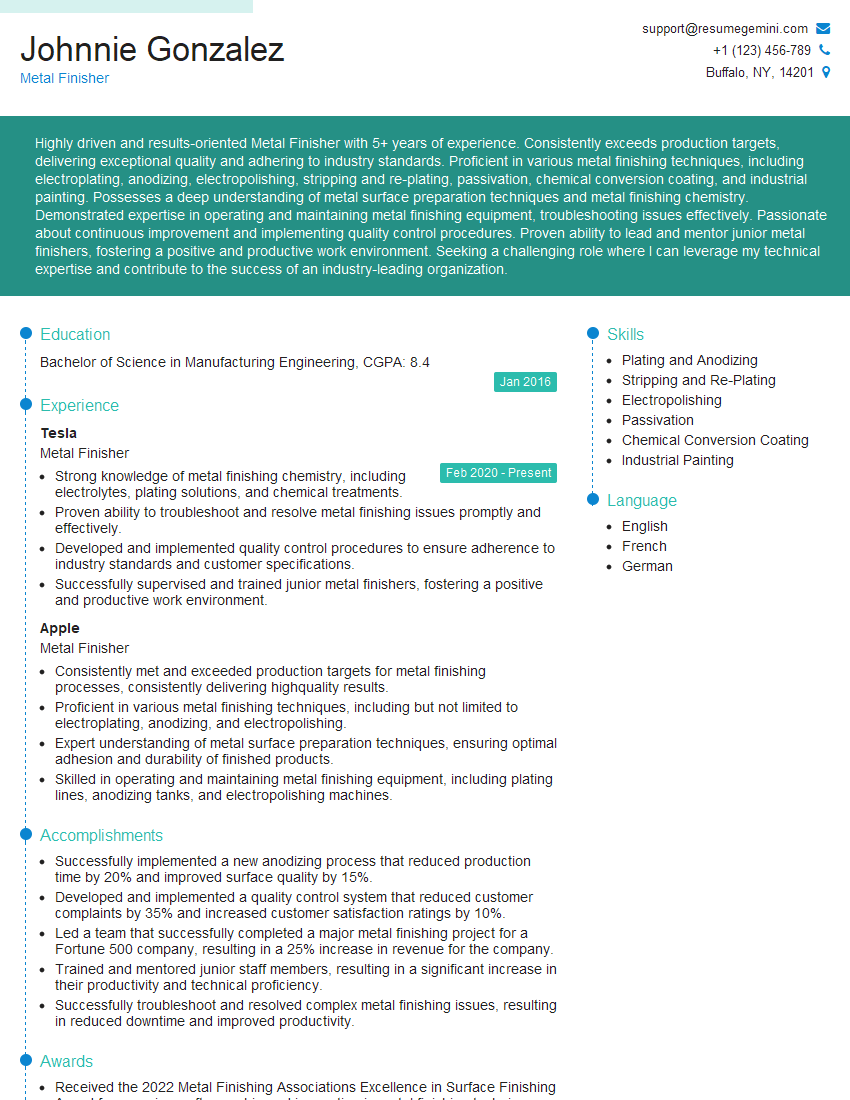

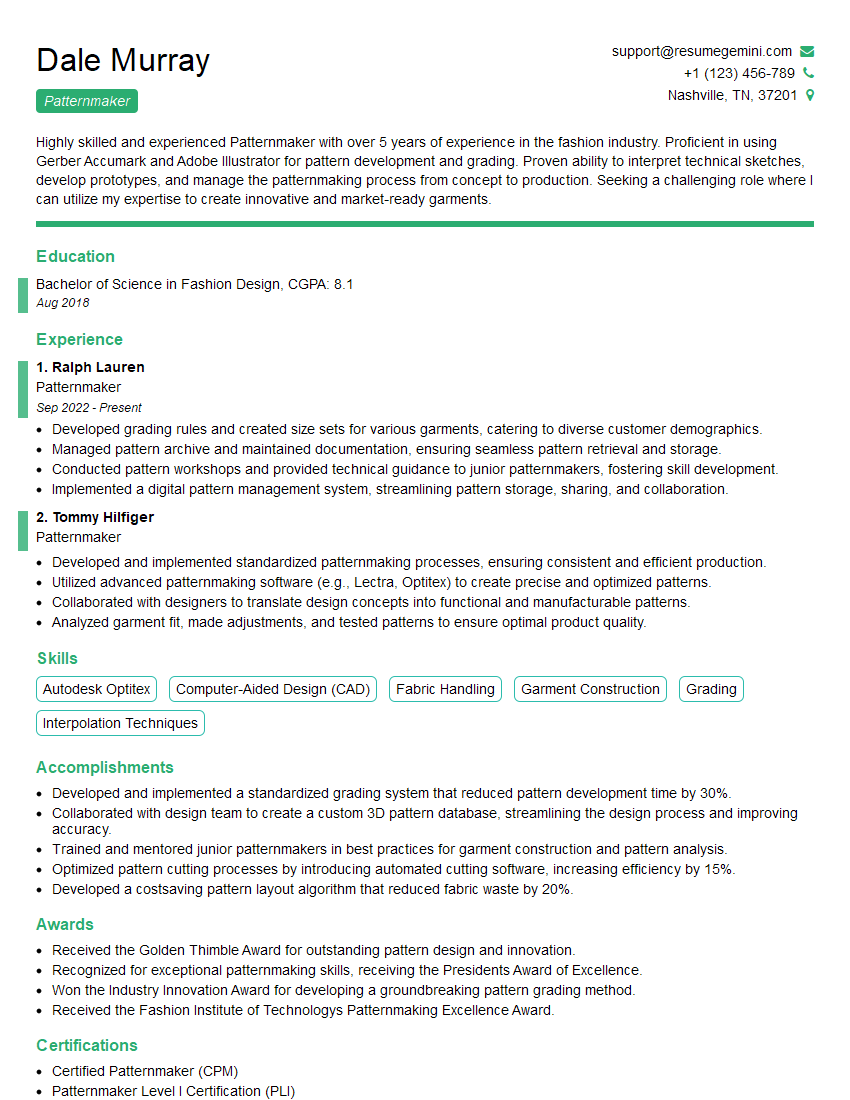

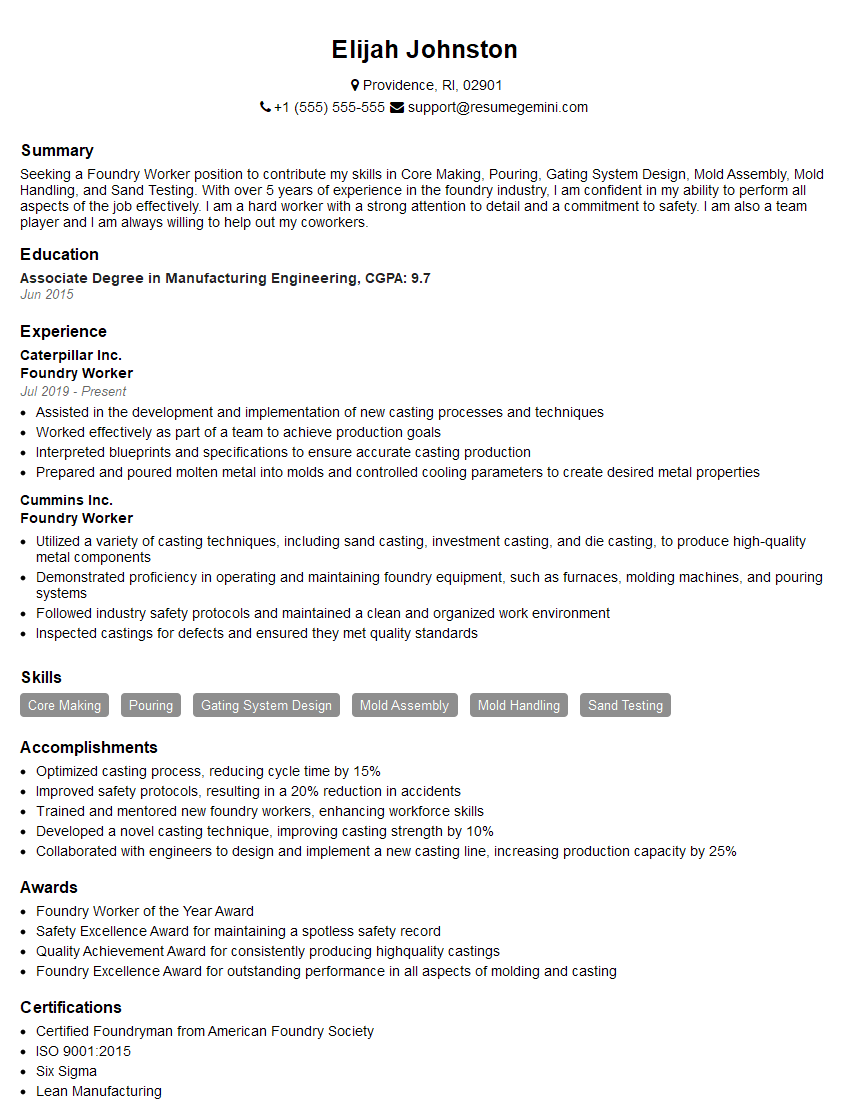

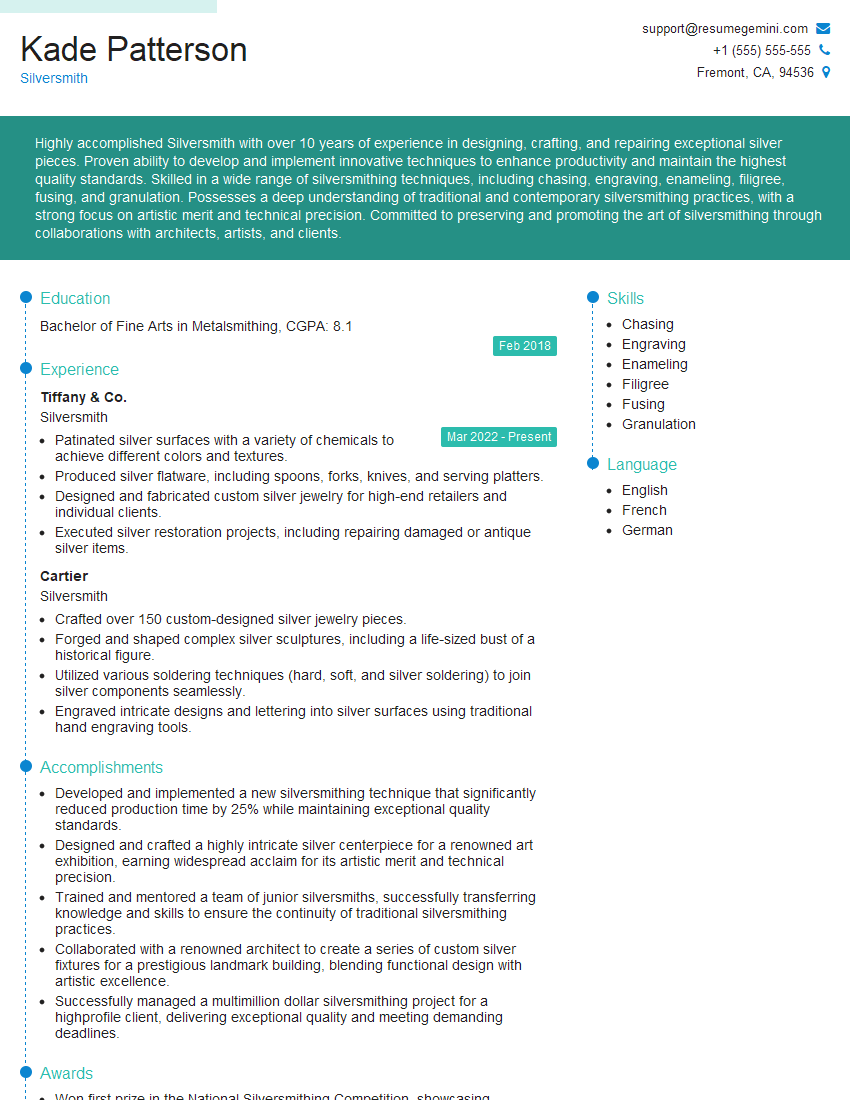

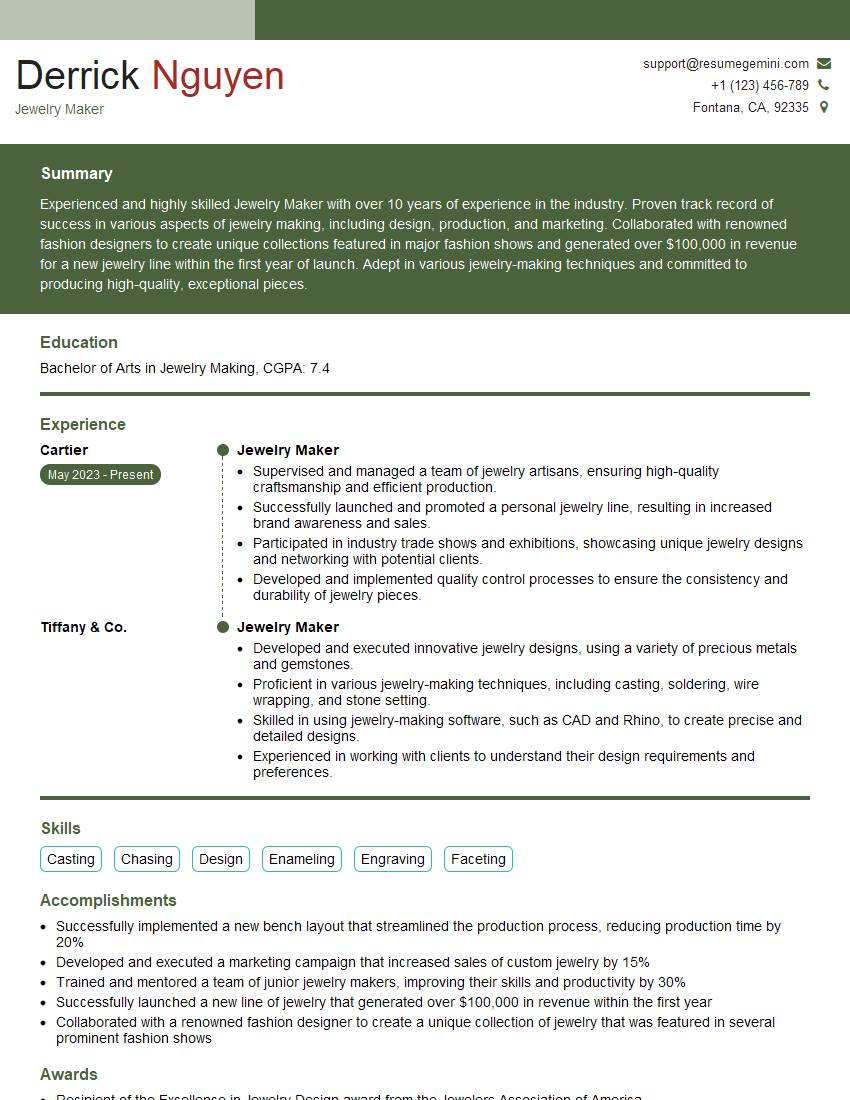

Mastering Metalsmithing and Casting opens doors to a rewarding career with diverse opportunities in manufacturing, art, and restoration. To stand out, a strong resume is vital. An ATS-friendly resume, optimized for applicant tracking systems, significantly increases your chances of getting noticed by recruiters. ResumeGemini is a trusted resource to help you craft a professional and impactful resume that showcases your skills and experience effectively. We provide examples of resumes tailored specifically to the Metalsmithing and Casting field to give you a head start.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good