Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Mycelium Inoculation interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Mycelium Inoculation Interview

Q 1. Explain the process of sterilizing substrates for mycelium inoculation.

Sterilizing substrates before mycelium inoculation is crucial to prevent unwanted microbial growth that can outcompete the desired fungus. Think of it like preparing a perfectly clean canvas for your artwork – any contamination will ruin the final piece. We achieve this through various methods, the most common being pressure cooking.

Pressure Cooking: This is the gold standard for most substrates. The high temperature and pressure (typically 15 PSI for 60-90 minutes) effectively kill bacteria, fungi, and spores. The pressure is essential, as it allows the steam to reach higher temperatures than simple boiling, ensuring complete sterilization. It’s important to ensure the substrate is evenly heated and that all air is expelled before sealing the pressure cooker.

Other Methods: While less common for larger-scale operations, other sterilization methods include using an autoclave (a more sophisticated pressure cooker) for more precise control, or, for smaller batches, dry heat sterilization in an oven at high temperatures for extended periods. However, both methods require careful monitoring and adherence to specific temperature and time protocols to achieve sterility.

Post-Sterilization: After sterilization, it’s vital to allow the substrate to cool completely to avoid thermal shock that could damage the mycelium upon inoculation. Maintaining sterility during the cooling process is also critical. This often involves cooling the sterilized substrate in a clean, sterile environment like a laminar flow hood.

Q 2. Describe different methods of mycelium inoculation (e.g., grain spawn, liquid culture).

Mycelium inoculation involves introducing the mycelium (the vegetative part of the fungus) to the sterilized substrate. Several methods exist, each with its advantages and disadvantages.

- Grain Spawn: This is a popular method where the mycelium is grown on a grain substrate (e.g., wheat berries, rye berries) before being used to inoculate larger substrates. The grain acts as a carrier, allowing for efficient distribution of the mycelium. Think of it as ‘planting seeds’ in a smaller, easier-to-manage area first.

- Liquid Culture (LC): This involves growing the mycelium in a liquid nutrient solution. This creates a highly concentrated source of mycelium that is then used to inoculate larger substrates. LC is efficient and allows for rapid multiplication of the mycelium, ideal for large-scale production.

- Agar Plate Cloning: Used primarily for maintaining pure cultures and creating mother cultures from which grain spawn or liquid culture is derived. This ensures genetic consistency of the mycelium.

- Tissue Culture: A more advanced technique focusing on isolation of specific mycelium from a tissue sample. It requires specialized equipment and training, and is often used in research and development.

The choice of method depends on factors like scale of operation, available resources, and the specific fungal species being cultivated.

Q 3. What are the common challenges encountered during mycelium inoculation, and how can they be addressed?

Mycelium inoculation is a delicate process, and various challenges can arise. Contamination is a major one, often stemming from unsanitized equipment or environments. Competition from other microbes can starve the desired mycelium of nutrients and overtake the substrate. Incorrect temperature and humidity can also stunt growth.

Addressing the Challenges:

- Contamination: Implementing strict aseptic techniques, thoroughly sterilizing equipment and workspaces, and using high-quality sterile substrates are key. A laminar flow hood is invaluable.

- Slow Growth: Ensuring the substrate is correctly prepared (pH, moisture content) and providing optimal environmental conditions (temperature and humidity) will promote growth. The choice of substrate and spawn also plays a significant role.

- Substrate Issues: Selecting an appropriate substrate, properly preparing it (sterilization and conditioning), and checking for proper moisture levels can prevent issues of substrate failure or collapse.

Careful observation, attention to detail, and a methodical approach are critical for overcoming these challenges. Maintaining accurate records is also essential for identifying trends and improving future inoculations.

Q 4. How do you ensure the sterility of your inoculation process?

Sterility is paramount. Think of it as a surgical procedure; any lapse can have disastrous consequences. We achieve this through a multi-pronged approach:

- Sterile Equipment and Supplies: All equipment (e.g., needles, syringes, inoculation loops) and supplies (substrates, containers) are properly sterilized before use (pressure cooking, autoclaving). Single-use items are preferred to minimize risks.

- Clean Work Environment: A clean room or laminar flow hood filters out airborne contaminants. The workspace is meticulously cleaned and disinfected before and after each inoculation session using appropriate disinfectants.

- Aseptic Technique: This involves meticulous practices during inoculation to minimize contamination risk. For example, working near a flame (Bunsen burner) to create an upward flow of air minimizes airborne contamination reaching the work area, wearing gloves, and minimizing exposure of sterilized materials to the environment.

- Regular Monitoring and Testing: Regularly examining inoculated cultures for signs of contamination is crucial for early detection and prompt action. Periodic sterility testing of the work area or equipment may also be implemented.

Strict adherence to these protocols is crucial for consistent success.

Q 5. What are the key factors influencing mycelium growth rate and yield?

Mycelium growth rate and yield are influenced by a number of interconnected factors:

- Substrate Quality and Composition: A nutrient-rich, properly sterilized substrate provides the building blocks for growth. Factors like pH, moisture content, and the type of substrate (grain, straw, wood) significantly affect growth.

- Environmental Conditions: Temperature and humidity are critical. Each fungal species has an optimal temperature and humidity range. Too much or too little of either can hinder growth. Air exchange is also important, preventing build-up of CO2 and other metabolic byproducts.

- Genetics of Mycelium: Different strains of the same fungus may display varying growth rates and yields. Selecting a vigorous strain is crucial.

- Inoculum Quality and Density: Using high-quality mycelium (obtained through methods like agar plates or liquid culture) and using a sufficient quantity of inoculum ensure robust colonization of the substrate.

- Contamination: Any contamination competes for resources, significantly impacting growth rate and yield.

Optimizing these factors through careful experimentation and precise control is critical for maximizing growth rate and yield.

Q 6. Explain the importance of substrate selection for successful mycelium inoculation.

Substrate selection is fundamental to successful mycelium inoculation. The substrate must provide the necessary nutrients for fungal growth. Think of it as selecting the right soil for planting specific crops.

Key Considerations:

- Nutrient Content: The substrate should be rich in carbohydrates, nitrogen, and other essential nutrients to support mycelium growth.

- Particle Size and Structure: The particle size and structure affect aeration and moisture retention. A balance is necessary, ensuring good airflow while retaining enough moisture for growth.

- pH: The substrate’s pH should be within the optimal range for the particular fungal species. This influences nutrient availability and fungal growth.

- Sterilizability: The chosen substrate should be easily and effectively sterilized without significant nutrient loss or degradation.

- Species-Specific Requirements: Different fungi have different substrate preferences. Some may thrive on straw, while others may prefer wood chips or grain.

Careful consideration of these aspects, complemented by knowledge of the chosen fungal species, is critical for selecting the optimal substrate to ensure vigorous and successful mycelium growth.

Q 7. Describe the signs of contamination in a mycelium culture, and how to mitigate it.

Early detection of contamination is crucial. Signs may include changes in color (unexpected hues or discoloration), texture (slimy, fuzzy patches), or odor (foul smells). Bacterial contamination often appears as bacterial colonies (sometimes sticky and slimy), while fungal contaminants might appear as different colored fuzzy growths.

Mitigating Contamination:

- Isolation and Disposal: If contamination is detected, it’s crucial to isolate the affected culture to prevent spread. Proper disposal methods should be followed, often involving autoclaving to destroy the contaminants.

- Review of Sterility Protocols: Analyze the inoculation process meticulously to pinpoint possible sources of contamination, such as weak sterilization procedures, poor aseptic techniques, or environmental factors.

- Improved Sanitation: Enhance cleaning and disinfection protocols for the workspace and equipment to minimize future occurrences.

- Source Tracing: Try to determine the source of contamination (substrate, inoculum, equipment) to prevent future problems. This is very useful in large scale industrial operations.

Preventing contamination is always easier and more efficient than dealing with it after the fact. Therefore, meticulous attention to detail and the adherence to sterile techniques are crucial from the start of the process.

Q 8. How do you monitor the growth and health of mycelium cultures?

Monitoring mycelium growth and health is crucial for successful cultivation. We use a multi-pronged approach. Visually, we look for healthy, robust growth – a fluffy, white mycelium that spreads evenly across the substrate. Signs of contamination, such as discoloration (green, black, or other unusual hues), unusual odors, or slowed growth are immediate red flags.

Beyond visual inspection, we can assess the mycelium’s health through microscopic examination. This allows us to identify any unwanted organisms or to assess the hyphal density (the number of fungal threads). For quantification, we can weigh the biomass at intervals to track growth rate. Finally, measuring the substrate’s moisture content ensures optimal conditions for growth. Think of it like tending a garden; regular observation, coupled with the right tools, ensures a thriving crop.

Q 9. What are the different types of mycelium used in various applications?

Mycelium types vary widely, depending on the desired application. For mushroom cultivation, we might use strains of Agaricus bisporus (button mushrooms), Pleurotus ostreatus (oyster mushrooms), or Lentinula edodes (shiitake mushrooms), each with its own growth characteristics and substrate preferences. In bioremediation, fungi like Phanerochaete chrysosporium are used for their ability to break down pollutants. In the production of biomaterials, mycelia from species like Trametes versicolor or various Ganoderma species are cultivated for their strength and versatility. Choosing the right type of mycelium is fundamental to the success of any project, just as selecting the right seed for a particular crop is critical in agriculture.

Q 10. Explain the concept of spawn running and its importance in mushroom cultivation.

Spawn running is the process of allowing mycelium to colonize a substrate before fruiting. Imagine it as the preparation phase before the actual mushroom harvest. We start with a pure mycelium culture (the ‘spawn’) and introduce it to a larger volume of substrate (like grain, straw, or wood). The mycelium then spreads through this substrate, consuming the nutrients and establishing itself. The importance lies in ensuring the substrate is fully colonized by the desired fungus *before* triggering fruiting conditions. This prevents unwanted competitors and maximizes the yield of mushrooms. A poorly colonized substrate risks contamination and lower yields; it’s like trying to build a house on a weak foundation – it’s unstable and prone to collapse.

Q 11. How do you scale up mycelium inoculation for large-scale production?

Scaling up mycelium inoculation for large-scale production requires a well-planned, phased approach. We start with a mother culture, which is carefully maintained and used to inoculate a larger quantity of spawn. This spawn, after sufficient colonization, is used to inoculate an even larger volume of substrate. This serial subculturing approach, carefully managed in a clean environment, is key. Automation plays a significant role; machines can handle large volumes of substrate, ensuring consistent inoculation density. For example, automated mixing and filling systems allow for precise and efficient distribution of the spawn within the growing substrate. The entire process needs to be rigorously monitored to maintain sterility and quality control. Think of it as an assembly line, where each step ensures the high-quality final product.

Q 12. Discuss the role of environmental factors (temperature, humidity, light) in mycelium growth.

Environmental factors heavily influence mycelium growth. Temperature is crucial; each species has an optimal temperature range. Too high, and the mycelium might die; too low, and growth will slow. Humidity is similarly important; the substrate needs to retain sufficient moisture for the mycelium to thrive. Excessive dryness leads to stunted growth, while excessive moisture fosters contamination. Light is generally less critical for most species of mycelium, though some prefer darkness for fruiting, and excessive light might damage hyphae. Think of it like the Goldilocks principle – we need to find the ‘just right’ conditions for healthy growth, which varies considerably between different species.

Q 13. Describe different types of substrates suitable for various types of mycelium.

Substrate selection depends largely on the type of mycelium being cultivated. Oyster mushrooms, for instance, can thrive on various agricultural wastes like straw or hardwood sawdust. Button mushrooms typically prefer a compost substrate, while shiitake mushrooms might use logs or sawdust blocks. Some mycelia, used in bioremediation, can even grow on polluted soil or industrial waste. The substrate should provide necessary nutrients and a suitable physical structure for the mycelium to colonize effectively. Selecting the right substrate is like choosing the right soil for a particular plant; it directly impacts the success of cultivation.

Q 14. How do you assess the quality of mycelium inoculum before use?

Assessing inoculum quality is paramount. We first visually inspect for purity; the mycelium should be white and free from contaminants. Microscopic examination confirms the absence of bacteria or other fungi. We also assess the vigor of the mycelium; healthy inoculum should exhibit rapid, consistent growth. We often test the inoculum’s viability by placing a small sample onto a fresh agar plate. Rapid growth on the plate indicates a healthy and viable inoculum. Using poor quality inoculum is akin to using poor quality seeds in agriculture – it will severely impact yield and potentially introduce diseases or contaminants.

Q 15. Explain the process of transferring mycelium from one substrate to another.

Transferring mycelium, also known as subculturing, is a crucial step in maintaining healthy and vigorous fungal cultures. It involves carefully moving a portion of actively growing mycelium from an existing substrate (like agar or grain) to a fresh substrate. This prevents nutrient depletion and maintains genetic consistency. The process is akin to propagating a plant by taking cuttings.

The steps typically involve:

- Preparing the new substrate: This might involve sterilizing grain, preparing agar plates, or readying other suitable media.

- Preparing the inoculum: A small, healthy section of mycelium from the source culture is carefully excised using a sterile scalpel or inoculating loop.

- Aseptic transfer: This is performed in a sterile environment (like a laminar flow hood) to prevent contamination. The mycelium is gently transferred to the new substrate, ensuring contact.

- Incubation: The new culture is then incubated under optimal conditions (temperature, humidity, light) to allow the mycelium to colonize the new substrate.

For example, transferring from an agar plate to grain involves placing small agar plugs containing mycelium onto the sterilized grain. The mycelium then grows throughout the grain, preparing it for use in further cultivation or fruiting.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are some common contaminants found in mycelium cultures?

Contamination in mycelium cultures is a significant concern. It can quickly overgrow the desired mycelium, ruining the culture. Common contaminants include various bacteria, yeasts, and molds. These unwelcome guests compete for nutrients and often produce metabolites that inhibit mycelium growth.

- Bacteria: Often appear as slimy or discolored areas on the substrate.

- Yeasts: Can create a film or powdery appearance.

- Molds: Exhibit fuzzy or hairy growths in various colors.

Identifying contaminants requires a keen eye and sometimes, microscopic examination. Preventing contamination is crucial and involves meticulous sterilization of all equipment and careful aseptic techniques during transfer.

Q 17. How do you troubleshoot issues related to slow or stalled mycelium growth?

Slow or stalled mycelium growth can be frustrating, but often diagnosable. Several factors can contribute to this:

- Contamination: As mentioned, this is a major culprit. Examine the culture carefully for signs of unwanted organisms.

- Improper incubation conditions: Incorrect temperature or humidity can significantly impact growth. Ensure optimal conditions for the specific fungus.

- Nutrient depletion: If the substrate is exhausted of nutrients, growth will slow. This often happens with older cultures.

- Substrate issues: Problems with the substrate’s pH, moisture content, or sterilization can affect growth.

- Genetic factors: Some strains are naturally slower growing than others.

Troubleshooting involves systematically investigating these possibilities. Microscopic examination, checking incubation parameters, and preparing a fresh subculture can help pinpoint the problem and get growth back on track. For instance, if a culture is slow due to nutrient depletion, transferring it to fresh substrate often solves the issue.

Q 18. Describe your experience with different types of sterilization equipment.

Sterilization is paramount in mycology. I’ve worked extensively with various equipment:

- Autoclaves: These are essential for sterilizing liquids and solid substrates using high-pressure steam. I’ve used both benchtop and larger industrial autoclaves, ensuring proper sterilization cycles based on the load and the material.

- Pressure cookers: A more affordable alternative for sterilizing smaller volumes, but require careful monitoring of pressure and time.

- UV sterilization cabinets: Useful for surface sterilization of equipment before entering a sterile work environment.

- Dry heat ovens: Employed for sterilizing glassware and other heat-resistant materials, though requiring longer cycles compared to autoclaving.

The choice of equipment depends on the scale of operations and the types of materials being sterilized. Understanding the principles of each method is vital for effective sterilization.

Q 19. What safety precautions do you take when working with mycelium cultures?

Safety is paramount when working with mycelium cultures. While most fungi are not inherently hazardous, maintaining sterile conditions is critical to prevent contamination, and potentially harmful reactions from accidental exposure to allergens or irritants. My safety procedures include:

- Working in a laminar flow hood: This provides a sterile workspace, minimizing the risk of airborne contamination.

- Wearing appropriate PPE: Gloves, masks, and lab coats are essential to prevent cross-contamination and protect against allergens.

- Proper disposal of waste: Contaminated materials are autoclaved before disposal.

- Sterile technique: Meticulous attention to detail to prevent introducing contaminants.

One specific incident highlighted the importance of safety. A colleague accidentally inhaled spores, resulting in a mild allergic reaction. This reinforced the need for rigorous mask usage, particularly when working with large-scale cultures or spore suspensions.

Q 20. How do you maintain accurate records of your mycelium inoculation procedures?

Maintaining accurate records is vital for reproducibility and tracking the progress of cultures. My record-keeping system involves:

- Detailed lab notebooks: Documenting every step of the inoculation process, including date, time, substrate type, strain identity, incubation conditions, and observations.

- Digital database: Storing images and data electronically, allowing easy retrieval and analysis. This is linked to a bar-coding system that tracks each culture through its lifecycle.

- Strain logs: Maintaining comprehensive information on the origin and characteristics of each fungal strain.

This detailed record-keeping helps in troubleshooting issues, identifying successful methods, and maintaining the integrity of the cultures over time. It’s akin to a meticulous gardener maintaining a detailed plant diary, recording everything from watering schedules to pest infestations.

Q 21. Explain your understanding of different types of mycelium-based products.

Mycelium has a wide range of applications, leading to diverse products:

- Mycoprotein: A sustainable protein source used as a meat substitute. It’s produced through cultivating fungi on a large scale.

- Mushroom cultivation: For food and medicinal purposes. This encompasses various species and cultivation techniques.

- Mycoremediation: Using fungi to degrade pollutants in soil or water. This is an environmentally friendly approach to bioremediation.

- Mycomaterials: Utilizing mycelium as a building material, creating sustainable alternatives to traditional materials such as bricks or packaging.

- Enzyme production: Fungi are a rich source of enzymes used in various industrial processes.

The versatility of mycelium makes it an exciting area of research and development, constantly revealing new potential applications. The ongoing research into mycelium-based materials, for instance, promises to revolutionize construction and packaging industries.

Q 22. What are the advantages and disadvantages of different inoculation methods?

Mycelium inoculation, the process of introducing fungal mycelium into a substrate, boasts several methods, each with its own strengths and weaknesses. Let’s explore some common techniques:

- Liquid Inoculation (using a liquid culture): This is highly efficient for large-scale operations, offering uniform distribution and faster colonization. However, it requires specialized equipment (like a bioreactor or large sterile containers) and carries a higher risk of contamination.

- Grain Spawn Inoculation: This is a popular method for home and small-scale growers. Sterilized grains (like rye or wheat) are inoculated with mycelium, allowing for easy handling and relatively low risk of contamination. The colonization process is slower though compared to liquid culture, and scalability is limited.

- Plug Spawn Inoculation: Small, pre-colonized wood plugs are inserted directly into the substrate. This is simple and effective for certain substrates, particularly logs. However, it is less efficient for large-scale production and can be labor-intensive.

- Tissue Culture Inoculation: This highly sterile method involves transferring small pieces of mycelium from a pure culture to a new sterile substrate. While producing the highest quality spawn, it is very time-consuming and requires expert knowledge in sterile techniques. It’s often used in research or for very high-value mushroom production.

The choice of method depends heavily on factors like the scale of production, the type of fungus, the available resources and the desired level of control over the process. For instance, large-scale oyster mushroom production would often favor liquid inoculation, while shiitake log cultivation would lean towards plug spawn.

Q 23. How do you adapt your inoculation techniques for different species of fungi?

Adapting inoculation techniques for different fungal species is crucial for success. Each species has unique requirements concerning substrate preference, temperature, humidity, and even the ideal method of inoculation. For example:

- Oyster Mushrooms: These are often cultivated using liquid inoculation on various substrates like straw or hardwood sawdust, due to their fast-growing nature and tolerance to higher moisture levels.

- Shiitake Mushrooms: Shiitake cultivation often utilizes plug spawn, introducing pre-colonized plugs into hardwood logs. This method mimics their natural growth pattern. The choice of wood species is also critical for optimal growth.

- Lion’s Mane Mushrooms: These are often grown using grain spawn on substrates like hardwood sawdust. The spawn needs careful preparation and inoculation to ensure uniform colonization of the substrate.

Beyond substrate choice, adjustments in incubation conditions (temperature and humidity) are necessary. Some fungi thrive in higher temperatures, while others prefer cooler environments. Careful observation and monitoring of the mycelium’s growth are critical to ensure successful colonization.

Q 24. Describe your experience with quality control procedures in mycelium cultivation.

Quality control is paramount in mycelium cultivation to prevent contamination and ensure consistent product quality. My experience involves a multi-pronged approach:

- Sterile Techniques: Employing rigorous sterile techniques throughout the entire process, from substrate preparation to inoculation, is fundamental. This includes using autoclaves for sterilization and working in laminar flow hoods.

- Microscopic Examination: Regular microscopic examination of the mycelium samples helps identify any contamination early on. This allows for timely intervention to prevent widespread issues.

- Environmental Monitoring: Monitoring the environmental parameters (temperature, humidity, CO2 levels) within the cultivation facility ensures optimal conditions for fungal growth and minimizes the chances of contamination.

- Spawn Testing: Before using any spawn, we test its purity and vigor. This involves visually inspecting for any signs of contamination and assessing the rate of mycelial growth.

- Documentation: Maintaining detailed records of all stages of the cultivation process, including inoculation dates, environmental parameters, and any observations, is essential for traceability and troubleshooting.

A robust quality control program minimizes losses due to contamination and maximizes the chances of obtaining high-quality mycelium.

Q 25. Explain the importance of proper hygiene and sanitation in a mycelium cultivation facility.

Hygiene and sanitation are non-negotiable in a mycelium cultivation facility. Fungi are highly susceptible to bacterial and fungal contamination, which can quickly wipe out an entire batch. Maintaining a clean and sterile environment is crucial for successful cultivation:

- Regular Cleaning and Disinfection: Surfaces should be regularly cleaned and disinfected using appropriate solutions, such as bleach solutions or other approved disinfectants.

- Air Filtration: High-efficiency particulate air (HEPA) filters help remove airborne contaminants, significantly reducing the risk of contamination.

- Personal Protective Equipment (PPE): Using appropriate PPE, including sterile gloves, masks, and lab coats, helps prevent the introduction of contaminants from personnel.

- Waste Management: Implementing a proper waste management system helps prevent the spread of pathogens and ensures the safe disposal of contaminated materials.

- Pest Control: Implementing effective pest control measures protects against insect infestations that can introduce contaminants.

Think of it like a surgical operating room; the higher the cleanliness standards, the lower the risk of contamination and the higher the yield of healthy mycelium.

Q 26. Describe your experience with automated inoculation systems.

My experience with automated inoculation systems has been overwhelmingly positive, especially for large-scale production. These systems offer several advantages:

- Increased Efficiency: Automated systems significantly speed up the inoculation process, reducing labor costs and increasing overall throughput.

- Improved Consistency: Automated systems ensure consistent inoculation density and distribution, leading to more uniform colonization.

- Reduced Contamination Risk: Automated systems often incorporate features that minimize the risk of contamination, such as closed systems and automated sterilization processes.

- Data Acquisition: Many systems incorporate data logging capabilities, providing valuable information about the inoculation process and helping optimize parameters.

For instance, we use a robotic system that precisely dispenses liquid inoculum into large bags of substrate. The system maintains strict sterility and provides detailed records of each inoculation batch. It’s a significant upgrade from manual inoculation, especially for the scale of our operation.

Q 27. How do you handle unexpected issues during the inoculation process?

Unexpected issues during inoculation are inevitable. My approach involves a systematic troubleshooting process:

- Identify the Problem: Carefully observe and document the nature of the issue. Is it slow colonization, contamination, or equipment malfunction?

- Isolate the Source: Try to pinpoint the source of the problem. Is it a problem with the inoculum, the substrate, the equipment, or the environmental conditions?

- Implement Corrective Actions: Based on the identified source, take appropriate corrective actions. This might involve adjusting environmental parameters, replacing contaminated materials, or repairing faulty equipment.

- Document and Analyze: Thoroughly document all steps taken and the outcomes. Analyze the incident to understand its cause and implement preventative measures to avoid recurrence.

For example, if I notice slow colonization, I might check the temperature and humidity levels, analyze the inoculum for viability, or inspect the substrate for any issues. If contamination is detected, immediate sterilization measures are employed and the contaminated material discarded. Data analysis then helps prevent future instances.

Q 28. Explain your understanding of the economic and environmental impact of Mycelium cultivation.

Mycelium cultivation has significant economic and environmental impacts. Economically, it offers diverse applications:

- Mushroom Production: A significant source of food and income globally.

- Biomaterials: Mycelium is increasingly used to create sustainable packaging, construction materials, and textiles, replacing petroleum-based products.

- Bioremediation: Mycelium can help clean up pollutants from the environment, offering a sustainable solution to environmental problems.

Environmentally, mycelium cultivation offers several benefits:

- Sustainability: It uses agricultural waste as a substrate, reducing waste and promoting circular economy principles.

- Reduced Carbon Footprint: Mycelium-based products have a lower carbon footprint compared to many traditional materials.

- Biodegradability: Mycelium-based products are biodegradable, reducing environmental pollution.

However, large-scale cultivation must be managed sustainably to avoid negative impacts on resources and ecosystems. Careful consideration of energy consumption, water usage, and waste management is crucial for responsible development of this burgeoning industry.

Key Topics to Learn for Mycelium Inoculation Interview

- Understanding Mycelium Growth & Development: Explore the factors influencing mycelial growth, including substrate composition, temperature, humidity, and aeration. Understand the different growth phases and their implications for inoculation success.

- Sterile Techniques & Aseptic Practices: Master the principles of sterile technique to prevent contamination during the inoculation process. This includes understanding the use of autoclaves, laminar flow hoods, and proper sterilization methods for equipment and materials.

- Inoculation Methods & Techniques: Learn various inoculation methods, including grain spawn, liquid culture, and tissue culture techniques. Understand the advantages and disadvantages of each method and their suitability for different applications.

- Substrate Preparation & Selection: Explore the importance of substrate selection based on the target fungal species and the desired outcome. Understand the process of substrate preparation, including sterilization and conditioning.

- Monitoring & Troubleshooting: Learn how to monitor the growth of mycelium after inoculation. Understand common problems encountered during the process, such as contamination, slow growth, and substrate issues, and develop strategies for troubleshooting.

- Quality Control & Assurance: Understand the importance of quality control measures to ensure the purity and viability of the mycelium. Learn about methods for detecting contamination and ensuring consistent results.

- Scale-Up & Production: Explore the principles and challenges of scaling up mycelium inoculation from laboratory to industrial settings. This includes understanding the importance of automation and optimization for large-scale production.

- Safety Considerations: Familiarize yourself with relevant safety protocols and procedures related to handling mycelia and working in laboratory or production environments.

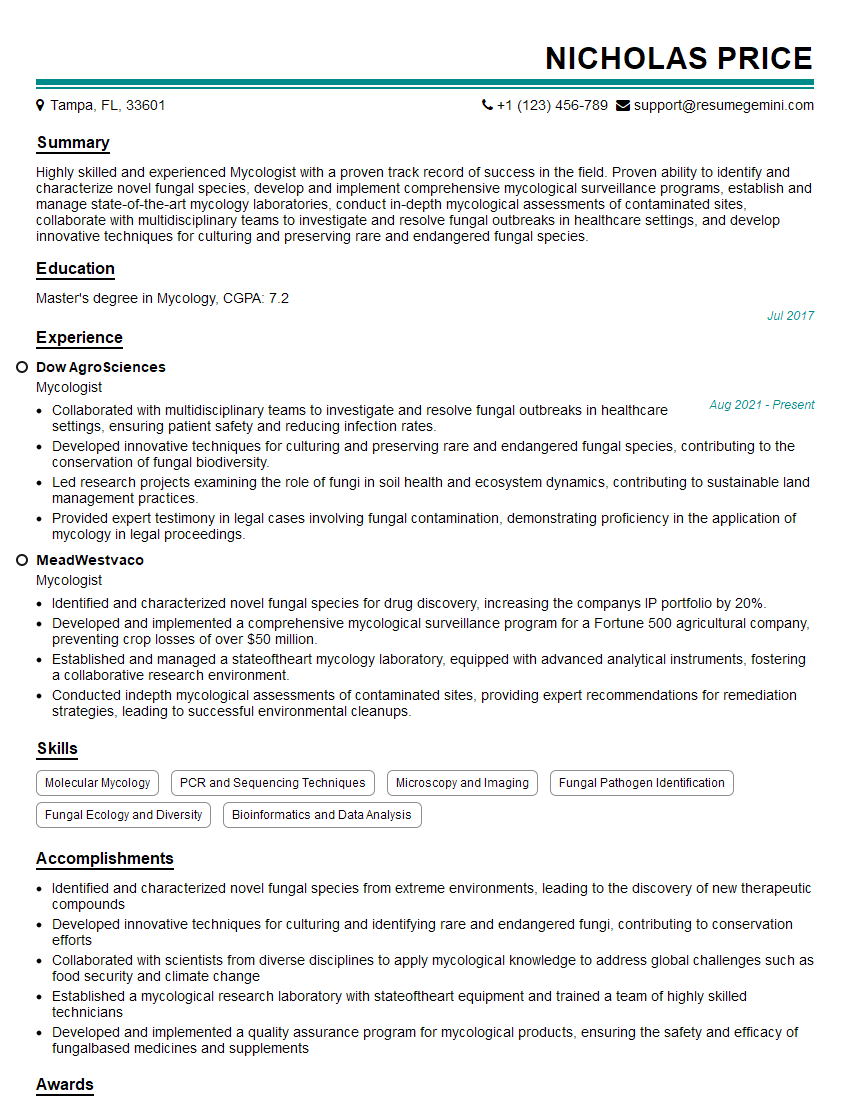

Next Steps

Mastering Mycelium Inoculation opens doors to exciting career opportunities in the burgeoning fields of mycology, bioremediation, and sustainable materials. A strong understanding of these techniques is highly sought after by employers. To significantly increase your chances of landing your dream role, focus on creating an ATS-friendly resume that effectively highlights your skills and experience. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to the specific demands of the Mycelium Inoculation field. Examples of resumes tailored to Mycelium Inoculation are available to guide you. Invest time in crafting a compelling resume – it’s your first impression and a crucial step in securing your next opportunity.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good