Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Mushroom Cultivation Knowledge interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Mushroom Cultivation Knowledge Interview

Q 1. Describe the different types of mushroom cultivation methods.

Mushroom cultivation methods vary based on scale and species. Broadly, they fall into two categories: extensive and intensive.

- Extensive Cultivation: This involves growing mushrooms in natural environments with minimal human intervention. Think wild mushroom foraging, but on a slightly larger scale. It’s less controlled and relies heavily on naturally occurring conditions. Yields are unpredictable and often low.

- Intensive Cultivation: This is the dominant method for commercial mushroom production. It involves precise control over environmental factors within a controlled environment, like a greenhouse or climate-controlled room. This allows for higher yields, consistent quality, and year-round production. Further sub-categories within intensive cultivation include methods like tray cultivation (using trays filled with substrate), bedding cultivation (growing mushrooms directly on a prepared substrate bed), and underground cultivation (for species that thrive in cooler, darker environments).

For example, oyster mushrooms can be successfully grown extensively on logs, whereas button mushrooms are almost exclusively cultivated intensively using a substrate like compost.

Q 2. Explain the life cycle of a commercially cultivated mushroom.

The life cycle of a commercially cultivated mushroom, such as the button mushroom (Agaricus bisporus), typically involves four stages:

- Spawn Production: This involves inoculating a grain substrate (like wheat or rye) with the mushroom’s mycelium (the vegetative part of the fungus). This creates the ‘spawn,’ which is then used to colonize the main growing substrate.

- Substrate Preparation and Spawning: This crucial step involves preparing a nutrient-rich substrate, often compost for button mushrooms, and then carefully mixing in the mushroom spawn. This allows the mycelium to spread and colonize the substrate.

- Incubation: The colonized substrate is then incubated under specific temperature and humidity conditions to promote mycelium growth. This phase focuses on creating a strong, healthy mycelium network throughout the substrate.

- Fruiting: Once the substrate is fully colonized, environmental conditions are adjusted to induce fruiting. This involves manipulating factors like temperature, humidity, light, and carbon dioxide levels to stimulate the formation and development of mushroom primordia (tiny mushroom buds), which will eventually grow into mature mushrooms.

Think of it like baking a cake: spawn production is preparing your ingredients, substrate preparation is mixing the batter, incubation is letting it rise, and fruiting is baking the cake!

Q 3. What are the key environmental factors influencing mushroom growth?

Mushroom growth is significantly influenced by several key environmental factors:

- Temperature: Different mushroom species have optimal temperature ranges for growth and fruiting. Maintaining consistent temperatures is critical.

- Humidity: High humidity (typically above 85%) is generally necessary for mushroom growth. However, excessively high humidity can lead to diseases.

- Light: While mushrooms don’t photosynthesize, light intensity and photoperiod (day length) can influence fruiting body development. Many species prefer low light conditions.

- Ventilation: Proper air exchange is vital to maintain optimal carbon dioxide levels and prevent the build-up of moisture or harmful gases. Too much carbon dioxide inhibits growth.

- pH: The substrate’s pH level influences nutrient availability and microbial activity. Most mushrooms prefer a slightly acidic environment.

Imagine a delicate ecosystem – even minor changes can significantly affect mushroom growth. Precise control is essential for high yields.

Q 4. How do you control temperature and humidity in a mushroom growing facility?

Controlling temperature and humidity in a mushroom growing facility requires a multi-pronged approach:

- Climate Control Systems: This involves using HVAC systems (heating, ventilation, and air conditioning) to maintain optimal temperature and humidity levels. Sensors monitor conditions, and the system automatically adjusts heating, cooling, and humidification accordingly.

- Evaporative Cooling: This technique uses water evaporation to cool the air, which is especially helpful in warmer climates. Misting systems are often employed.

- Humidifiers and Dehumidifiers: These devices are used to precisely adjust humidity levels, maintaining the required range.

- Insulation: Properly insulating the growing facility minimizes temperature fluctuations and reduces energy consumption.

- Monitoring and Control Systems: Sophisticated monitoring systems with alarms alert growers to any deviations from optimal conditions.

In essence, it’s like creating a microclimate perfectly suited for mushroom growth, irrespective of the outside conditions.

Q 5. What are the common pests and diseases affecting mushroom crops, and how do you manage them?

Mushroom crops are susceptible to various pests and diseases:

- Pests: Common pests include mites, sciarid flies, and fungal gnats. These insects feed on the mycelium or developing mushrooms, reducing yield and quality.

- Diseases: Bacterial and fungal diseases are significant threats. Common examples include bacterial blotch, wet bubble, and various molds. These diseases can rapidly spread, causing significant losses.

Management strategies include:

- Hygiene: Maintaining strict sanitation practices within the facility is crucial. Regular cleaning, disinfection, and pest control are essential.

- Biological Control: Introducing beneficial organisms, like predatory mites, to control pest populations.

- Chemical Control: Applying approved fungicides or insecticides as a last resort when other methods are insufficient. Always follow label instructions carefully.

- Resistant Cultivars: Selecting mushroom strains that exhibit natural resistance to common pests and diseases.

Think of it as protecting your crop like you would a garden – prevention is always better than cure.

Q 6. Explain the process of mushroom spawn production.

Mushroom spawn production involves inoculating a sterile grain substrate with mushroom mycelium to create a source of inoculum for growing mushrooms on a larger scale. This is a critical step that dictates the overall health and yield of your mushroom crop.

- Substrate Preparation: Sterile grain, often wheat or rye, is prepared. This usually involves cleaning, soaking, and sterilizing the grain to eliminate competing microorganisms.

- Mycelium Inoculation: A small amount of pure mushroom mycelium (obtained from a reputable supplier) is introduced into the sterile grain substrate under sterile conditions (often within a laminar flow hood).

- Incubation: The inoculated substrate is incubated under controlled environmental conditions (temperature and humidity) to allow the mycelium to grow and colonize the entire grain. This process typically takes several weeks.

- Quality Control: Throughout the process, quality control measures are implemented to prevent contamination by unwanted fungi or bacteria.

This process is very much like making a starter culture for sourdough bread – you are multiplying a pure culture of beneficial microorganisms.

Q 7. Describe the different types of mushroom substrates.

Mushroom substrates provide the nutrients required for mushroom growth. The type of substrate used depends on the mushroom species being cultivated.

- Compost: This is the most common substrate for button mushrooms (Agaricus bisporus). It’s a complex mixture of straw, horse manure, and other organic materials, carefully composted to provide the right balance of nutrients.

- Grain Substrates: These include wheat, rye, or other grains, often used for spawn production and for cultivating some species like oyster mushrooms.

- Sawdust: Mixed with other supplements, sawdust can be used as a substrate for certain mushroom species, especially shiitake mushrooms.

- Agricultural Residues: Materials like rice straw, corn stalks, and coffee grounds can be utilized, often requiring supplementation with nutrients.

- Synthetic Substrates: These are specifically designed mixtures of organic and inorganic materials that provide a consistent and optimized nutrient supply.

The choice of substrate directly impacts the yield and quality of the final product. A well-prepared substrate is fundamental to successful mushroom cultivation.

Q 8. How do you ensure the quality and safety of your mushroom harvest?

Ensuring the quality and safety of a mushroom harvest is paramount. It begins long before harvest, with meticulous attention to hygiene throughout the entire cultivation process. We start with clean substrates, preventing contamination from the outset. Regular monitoring for pests and diseases is crucial; early detection allows for prompt intervention, preventing widespread issues. During harvesting, we employ trained personnel who handle mushrooms gently to avoid bruising or damage. They also carefully examine each mushroom for defects and signs of contamination, discarding anything that doesn’t meet our strict quality standards. Post-harvest handling, as discussed later, further contributes to maintaining quality and safety.

For example, imagine a single contaminated mushroom contaminating an entire batch. This is why careful selection and disposal of substandard mushrooms are vital. This meticulous approach ensures that only the highest-quality, safest mushrooms reach consumers.

Q 9. What are the post-harvest handling techniques for mushrooms?

Post-harvest handling is crucial for maintaining mushroom quality and extending shelf life. It begins immediately after harvesting. Mushrooms are carefully cleaned using gentle methods to remove any adhering substrate or debris. Bruising must be avoided at all costs, as it accelerates deterioration. Cooling is the next critical step. Mushrooms are rapidly cooled to near-freezing temperatures (around 0-4°C) to slow down enzymatic activity and microbial growth. This can be achieved through hydrocooling or forced-air cooling. After cooling, mushrooms are carefully sorted and graded based on size, shape, and quality. Proper packaging, as discussed in the next answer, completes this process, maintaining optimal conditions for transit and storage.

Think of it like handling fresh fish – speed and low temperatures are essential to prevent spoilage. The same principles apply to mushrooms to maintain their freshness, flavor, and texture.

Q 10. What are the different methods for mushroom packaging and storage?

Mushroom packaging and storage methods vary depending on the type of mushroom, the intended market, and the desired shelf life. Packaging must allow for sufficient airflow to prevent moisture buildup and spoilage, while simultaneously protecting the mushrooms from physical damage and dehydration. Common packaging materials include perforated plastic bags, trays lined with absorbent paper, and breathable containers. Storage conditions are critical. Mushrooms should be stored in cool, dark, and humid environments to maintain their freshness and extend shelf life. Refrigeration at near-freezing temperatures (0-4°C) is the most common method. Modified atmosphere packaging (MAP), where the atmosphere within the package is modified to extend shelf life by reducing respiration rate and microbial growth, is also employed for longer-term storage.

For instance, delicate oyster mushrooms might require more cushioning and gentler handling than robust portobellos. Choosing the right packaging material and storage conditions is crucial to avoid spoilage and maintain quality.

Q 11. Explain the principles of mushroom composting.

Mushroom composting is a complex process of decomposing organic matter to create a suitable substrate for mushroom growth. It’s essentially controlled decomposition, mimicking natural processes. The process involves several stages. First, a mixture of raw materials, such as straw, horse manure, chicken litter, and other organic materials, is prepared. This mixture is then piled and allowed to undergo a period of composting. During this phase, microorganisms break down the complex organic matter, generating heat in the process. Temperature control is crucial, as excessively high temperatures can kill beneficial microorganisms, while temperatures that are too low can lead to slow decomposition and incomplete pasteurization. The composting process is usually monitored and managed by turning the pile periodically to ensure adequate aeration and even temperature distribution. This process essentially creates a nutrient-rich substrate ready to support mushroom mycelium growth. The final compost is usually pasteurized to eliminate competing organisms.

Think of it as making a rich, nourishing soil for your mushrooms. The better the compost, the healthier and more productive the mushroom crop.

Q 12. What are the nutritional requirements of mushrooms during different growth stages?

Mushroom nutritional requirements vary across different growth stages. During the spawn run (mycelial growth phase), the primary needs are carbon and nitrogen sources from the substrate, along with sufficient moisture. The substrate should provide adequate levels of essential macro and micronutrients, like phosphorus, potassium, and various trace elements. As the mushrooms begin to fruit (pinning and fruiting), the demand for water increases significantly. During this phase, maintaining proper humidity and substrate moisture is crucial for optimal fruit body development. Additionally, adequate levels of oxygen are essential for respiration and fruit body development. The specific nutritional needs vary depending on the species of mushroom being cultivated, so detailed knowledge is vital.

For instance, some mushroom species are more demanding than others in their nutrient requirements, and providing the right balance is key for success.

Q 13. How do you monitor and control the pH levels in a mushroom growing environment?

Monitoring and controlling pH is crucial for optimal mushroom growth. Mushrooms thrive within a specific pH range, usually slightly acidic. Deviations from this optimal range can negatively impact growth, yield, and even the quality of the final product. pH is measured regularly using a pH meter, taking samples from different locations within the growing environment to ensure uniformity. Adjustments are made as needed through the addition of acids (e.g., sulfuric acid) or bases (e.g., lime) to bring the pH back to the optimal range. The method of pH adjustment and the amount used should always be carefully considered based on the substrate and the mushroom species being cultivated. This is an iterative process with continual monitoring to maintain consistent pH conditions.

Think of it like maintaining the precise pH of an aquarium for optimal fish health. Similar precision is needed for optimal mushroom growth.

Q 14. Describe the role of aeration in mushroom cultivation.

Aeration plays a vital role in mushroom cultivation. Mushrooms, like all living organisms, require oxygen for respiration. Adequate aeration ensures sufficient oxygen supply for both mycelial growth and fruit body development. Insufficient aeration leads to reduced growth rates, poor fruit body development, and increased susceptibility to diseases. In indoor cultivation, aeration is achieved through various means, including ventilation systems, fans, and even simple airflow strategies. The frequency and intensity of aeration depend on factors such as the size of the growing area, the species of mushroom, and the growth stage. During the fruiting stage, adequate air circulation is particularly important to prevent moisture buildup and ensure optimal carbon dioxide levels.

Imagine trying to grow mushrooms in an airtight container; they wouldn’t survive due to lack of oxygen. Providing the right amount of airflow is essential for healthy mushroom development.

Q 15. What are the common challenges in mushroom cultivation, and how do you overcome them?

Mushroom cultivation, while rewarding, presents several challenges. These can be broadly categorized into environmental, biological, and operational issues.

- Environmental Challenges: Maintaining optimal temperature, humidity, and airflow is crucial. Fluctuations can lead to stunted growth, disease, or even crop failure. For example, a sudden drop in temperature during fruiting can cause mushrooms to abort their development.

- Biological Challenges: Mushroom crops are susceptible to various diseases and pests, such as bacterial infections, fungal contaminants (like Trichoderma), and insect infestations. These can decimate a crop if not managed proactively.

- Operational Challenges: Consistent substrate preparation, precise spawn inoculation, and skilled harvesting are crucial. Inconsistent substrate can lead to uneven growth and reduced yield. Contamination during any stage can severely impact the final product.

Overcoming these challenges involves a multi-pronged approach. This includes using climate-controlled growing environments, implementing rigorous sanitation protocols, selecting disease-resistant strains, and employing integrated pest management strategies. Regular monitoring, quick identification of issues, and prompt remedial actions are key to success. For instance, using pasteurization to sterilize the substrate greatly reduces the risk of contamination.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the importance of hygiene and sanitation in a mushroom farm.

Hygiene and sanitation are paramount in mushroom farming. They form the cornerstone of successful cultivation, directly impacting yield, quality, and profitability. Contamination by unwanted bacteria, fungi, or insects can quickly ruin an entire crop.

Maintaining a clean farm involves several practices:

- Facility sanitation: Regular cleaning and disinfection of growing rooms, equipment, and tools using appropriate fungicides and disinfectants.

- Substrate sterilization: Pasteurization or steam sterilization of the growing medium (substrate) eliminates competing microorganisms.

- Personal hygiene: Farm workers should wear clean protective clothing, gloves, and masks to prevent the introduction of contaminants.

- Pest control: Implementing an integrated pest management system to prevent and control insect infestations.

- Air filtration: Using HEPA filters to remove airborne contaminants.

Imagine a scenario where a single contaminated tool introduces Trichoderma into the growing area; this aggressive fungus can quickly overwhelm the mushroom crop, resulting in total loss. Strict adherence to sanitation protocols safeguards against such scenarios.

Q 17. What are the different types of mushrooms suitable for commercial cultivation?

Many mushroom species are suitable for commercial cultivation, each with its own specific requirements and market demands. Some popular choices include:

- Button mushrooms (Agaricus bisporus): The most widely cultivated species globally, known for its versatility and high demand.

- Oyster mushrooms (Pleurotus ostreatus): Easy to grow on various substrates, making them suitable for smaller-scale operations. They are popular for their delicate flavor and health benefits.

- Shiitake mushrooms (Lentinula edodes): Highly valued for their unique flavor and medicinal properties, requiring more specialized cultivation techniques.

- Portobello mushrooms (Agaricus bisporus): A larger, mature form of the button mushroom, preferred for its robust flavor and texture.

- Cremini mushrooms (Agaricus bisporus): A brown-capped variety of the button mushroom, offering a more earthy flavor.

The choice of species often depends on market demand, available resources, and the cultivator’s experience. Each species has its own growth characteristics and requires tailored management strategies.

Q 18. How do you determine the yield of a mushroom crop?

Determining mushroom yield involves careful measurement and calculation. It’s not just about the total weight but also considers the quality and marketability of the harvested mushrooms.

The process involves:

- Weighing the harvested mushrooms: This is the most straightforward method, usually done after each harvest. Weight is expressed in kilograms or pounds.

- Calculating yield per area: The total weight is then divided by the growing area (e.g., square meters or square feet) to get the yield per unit area. This provides a standardized measurement, allowing comparisons between different cultivation cycles or farms.

- Assessing the quality: The number and percentage of mushrooms that meet market standards (size, shape, appearance, absence of defects) are recorded. This ‘grade’ will affect the final yield calculation.

- Calculating biological efficiency: This measures the yield relative to the amount of substrate used. It is a key indicator of efficient resource utilization.

For example, a farm might harvest 100 kg of mushrooms from a 10 sq.m growing area. This gives a yield of 10 kg/sq.m. However, if 20% of the harvest is unmarketable, the effective yield would be adjusted accordingly.

Q 19. Describe the economic aspects of mushroom farming.

Mushroom farming presents a unique economic opportunity, with potential for both small-scale and large-scale operations. The economics depend on various factors.

- Start-up costs: These include establishing the facility, purchasing equipment, and preparing the substrate. Costs vary significantly based on the scale and technology involved.

- Operating costs: Ongoing expenses involve substrate preparation, labor, energy for climate control, and packaging. Efficient resource management is crucial to profitability.

- Market prices: The price of mushrooms fluctuates based on supply and demand. Diversifying the product range or securing contracts with buyers can stabilize income.

- Yield and efficiency: High yield and efficient production directly translate to higher profits. Improving cultivation practices and optimizing environmental conditions are critical here.

- Value-added products: Processing mushrooms into value-added products, such as dried mushrooms, mushroom powder, or extracts, can significantly improve profitability.

Success in mushroom farming requires careful financial planning, a good understanding of market dynamics, and efficient management practices. A well-designed business plan and market analysis are crucial before venturing into this industry.

Q 20. What are the sustainability practices in mushroom cultivation?

Sustainable mushroom cultivation emphasizes minimizing environmental impact and maximizing resource efficiency. Key practices include:

- Using sustainable substrates: Employing agricultural waste products like straw, coffee grounds, or wood chips as substrates reduces reliance on virgin resources and promotes waste recycling.

- Reducing water usage: Implementing water-efficient irrigation systems and recycling water where possible.

- Minimizing energy consumption: Using energy-efficient climate control systems and optimizing the growing environment to reduce energy needs.

- Reducing pesticide use: Implementing integrated pest management strategies that prioritize preventative measures and minimize or eliminate the use of chemical pesticides.

- Composting spent substrate: Spent substrate, after mushroom harvest, is a valuable compost that can be used to enrich soil or sold as a soil amendment.

For example, a farm could collaborate with local coffee shops to source spent coffee grounds as a substrate, reducing waste and creating a symbiotic relationship with another industry.

Q 21. How do you manage waste generated from mushroom cultivation?

Waste management in mushroom cultivation focuses on responsibly handling spent substrate and other byproducts to minimize environmental impact and potentially create value-added products.

Strategies include:

- Composting spent substrate: This is the most common method. Spent substrate is rich in nutrients and can be composted to create a valuable soil amendment for agriculture or horticulture. This also reduces landfill waste.

- Anaerobic digestion: In some cases, spent substrate can be processed through anaerobic digestion to generate biogas, a renewable energy source.

- Recycling packaging materials: Using recyclable or compostable packaging reduces environmental burden.

- Wastewater treatment: Any wastewater generated should be properly treated before disposal to prevent water pollution.

The choice of waste management method depends on factors like the scale of the operation, local regulations, and available infrastructure. Ideally, waste should be viewed as a resource, minimizing disposal and maximizing its potential for reuse or repurposing.

Q 22. Explain your experience with different mushroom varieties.

My experience spans a wide range of commercially cultivated mushrooms, from the ubiquitous button mushroom (Agaricus bisporus) – where I’ve honed expertise in optimizing growing conditions for both white and brown varieties – to gourmet species like oyster mushrooms (Pleurotus ostreatus) and shiitake (Lentinula edodes). I’ve also worked extensively with less common species, such as lion’s mane (Hericium erinaceus) and king oyster mushrooms (Pleurotus eryngii), each requiring a unique approach to substrate preparation, environmental control, and harvesting techniques. For example, with shiitake, mastering the process of log inoculation and outdoor cultivation was crucial, while oyster mushrooms require meticulous attention to humidity and airflow within the growing chamber. This diverse experience allows me to adapt to various mushroom species and cultivation challenges effectively.

- Button Mushrooms: Mastering different spawn runs, compost preparation, and casing layer techniques for optimal yield and size.

- Oyster Mushrooms: Expertise in various substrates, including straw, sawdust, and agricultural waste, and optimizing fruiting conditions for high yields.

- Shiitake Mushrooms: Experienced in both log cultivation and substrate bag techniques, including spawn inoculation and environmental control.

Q 23. Describe your knowledge of different mushroom substrate formulations.

Mushroom substrate formulation is a critical aspect of successful cultivation. The ideal substrate provides the necessary nutrients and moisture for optimal mycelial growth and fruiting. My knowledge encompasses both traditional and innovative substrate formulations. For example, with button mushrooms, I’m familiar with the complexities of preparing compost using horse manure, wheat straw, and other components, carefully monitoring temperature and moisture throughout the composting process. For gourmet mushrooms, I’ve worked with various substrates, including hardwood sawdust supplemented with wheat bran and other nutrients, straw-based substrates with added supplements, and even agricultural waste like coffee grounds. I understand the importance of pasteurization or sterilization to control contaminations, and the need for adjusting formulations based on the specific mushroom species and available resources. The key is finding the right balance of nutrients, water holding capacity, and aeration for the chosen species.

- Button Mushroom Compost: Expertise in phase composting, including the pre-composting, high-temperature pasteurization, and conditioning phases.

- Gourmet Mushroom Substrates: Formulating substrates using sawdust, straw, agricultural waste, and various nutrient supplements for optimal mycelial growth.

- Sterilization and Pasteurization: Deep understanding of different methods and their application to different substrate types.

Q 24. What is your experience with automated mushroom farming systems?

My experience with automated mushroom farming systems is substantial. I’ve been involved in the design, implementation, and optimization of several automated systems, integrating technologies like automated climate control, automated watering systems, and robotic harvesting units. One project involved designing a system for automated substrate loading, pasteurization, and inoculation, significantly reducing labor costs and improving consistency. Automating tasks like environmental monitoring (temperature, humidity, CO2 levels) allows for precise control and reduces the risk of human error. However, I also appreciate the limitations of complete automation and the continued need for skilled human intervention in areas such as quality control and troubleshooting. This includes managing the interplay between automated systems and manual processes for optimal efficiency and product quality.

For example, we implemented a system using sensors and control software to manage temperature and humidity levels within the growing rooms, significantly improving consistency and yield. This not only reduced labor costs but also minimized variations in mushroom quality.

Q 25. What are your skills in data analysis related to mushroom yield and quality?

My data analysis skills are crucial for optimizing mushroom production. I use statistical methods to analyze data from various sources, including environmental sensors, yield records, and quality assessments, to identify trends and patterns. This allows me to pinpoint factors influencing yield and quality, such as temperature fluctuations, substrate composition, or humidity levels. I’m proficient in using statistical software such as R and Python for data analysis and visualization. This involves creating models to predict yield based on various factors, optimizing growing parameters, and reducing waste. For example, I used regression analysis to model the relationship between temperature and humidity on the yield of oyster mushrooms, enabling us to fine-tune environmental controls for maximal productivity.

# Example R code snippet (simplified):model <- lm(yield ~ temperature + humidity, data = mushroom_data)summary(model)

Q 26. How do you maintain accurate records of mushroom production and sales?

Maintaining accurate records is essential for efficient farm management and regulatory compliance. I utilize a combination of digital and physical record-keeping systems. This includes detailed records of substrate preparation, spawn inoculation, environmental parameters (temperature, humidity, CO2, light), harvesting dates and yields, and sales data. This data is entered into a customized database, allowing for easy retrieval and analysis. Detailed inventory management tracks substrate use, spawn usage, and product sales to ensure smooth operations. We also use barcoding or RFID tagging for tracking individual batches, from substrate preparation to sale.

Regular reporting on key metrics such as yield, costs, and profitability allows for informed decision-making and continuous improvement. For example, we track the cost of each substrate batch to optimize the cost-effectiveness of our production.

Q 27. Explain your experience with implementing food safety protocols in a mushroom farm.

Implementing robust food safety protocols is paramount in mushroom farming. My experience includes designing and implementing systems that comply with relevant food safety regulations such as Good Agricultural Practices (GAP) and Good Manufacturing Practices (GMP). This involves implementing strict hygiene protocols throughout the entire production process, from substrate preparation to harvesting and packaging. We utilize regular sanitation procedures, employee training on food safety regulations, and pest control measures to prevent contamination. Traceability is a key component, and our record-keeping systems allow us to trace each batch of mushrooms throughout the entire production chain. Regular testing for microbial contamination and pesticide residue ensures that the final product meets stringent safety standards. We document all processes and compliance measures thoroughly, enabling easy audits.

Q 28. Describe your problem-solving skills related to mushroom cultivation challenges.

Problem-solving is an integral part of mushroom cultivation. I approach challenges systematically, using a combination of scientific knowledge, practical experience, and data analysis. For example, when faced with a sudden drop in yield, I systematically investigate potential causes, such as changes in environmental conditions, substrate quality, or the presence of contaminants. I'd analyze environmental data, inspect the substrate for microbial contamination, and review harvesting techniques. My troubleshooting strategies involve using data analysis tools to pinpoint the likely cause and developing targeted solutions. A systematic approach is critical, as is the ability to adapt quickly to changing circumstances and learn from past experiences. Documentation of problems and solutions helps to prevent future occurrences.

- Systematic Approach: Identifying the problem, analyzing potential causes, testing hypotheses, and implementing solutions.

- Data-Driven Decision Making: Utilizing data to inform decisions and track the effectiveness of implemented solutions.

- Continuous Learning: Learning from past mistakes and adapting strategies for improved results.

Key Topics to Learn for Your Mushroom Cultivation Knowledge Interview

- Substrate Preparation: Understanding different substrate types (e.g., straw, hardwood, grain), sterilization techniques, and the impact of substrate composition on yield and mushroom quality. Practical application: Troubleshooting substrate issues like contamination or insufficient colonization.

- Spawn Running and Inoculation: Mastering techniques for successful spawn run, including proper inoculation methods, environmental control (temperature, humidity), and recognizing signs of healthy mycelium growth. Practical application: Diagnosing and resolving problems with slow or uneven spawn colonization.

- Fruiting Body Development: Understanding the environmental factors influencing fruiting (light, humidity, ventilation, temperature), and the stages of mushroom development. Practical application: Optimizing fruiting conditions to maximize yield and quality of mushrooms.

- Pest and Disease Management: Identifying common pests and diseases affecting mushrooms, implementing preventative measures, and employing effective control strategies (biological, chemical, cultural). Practical application: Developing an integrated pest management plan for a mushroom farm.

- Post-Harvest Handling: Proper techniques for harvesting, cleaning, grading, and storing mushrooms to maintain quality and extend shelf life. Practical application: Implementing efficient post-harvest procedures to minimize losses and maximize profitability.

- Mushroom Species and Cultivars: Knowledge of different commercially grown mushroom species (e.g., oyster, shiitake, button) and their specific cultivation requirements. Practical application: Selecting appropriate cultivars based on market demands and environmental conditions.

- Farm Design and Management: Understanding the layout, infrastructure, and operational aspects of a mushroom farm, including climate control systems, waste management, and resource optimization. Practical application: Designing an efficient and sustainable mushroom farm operation.

Next Steps

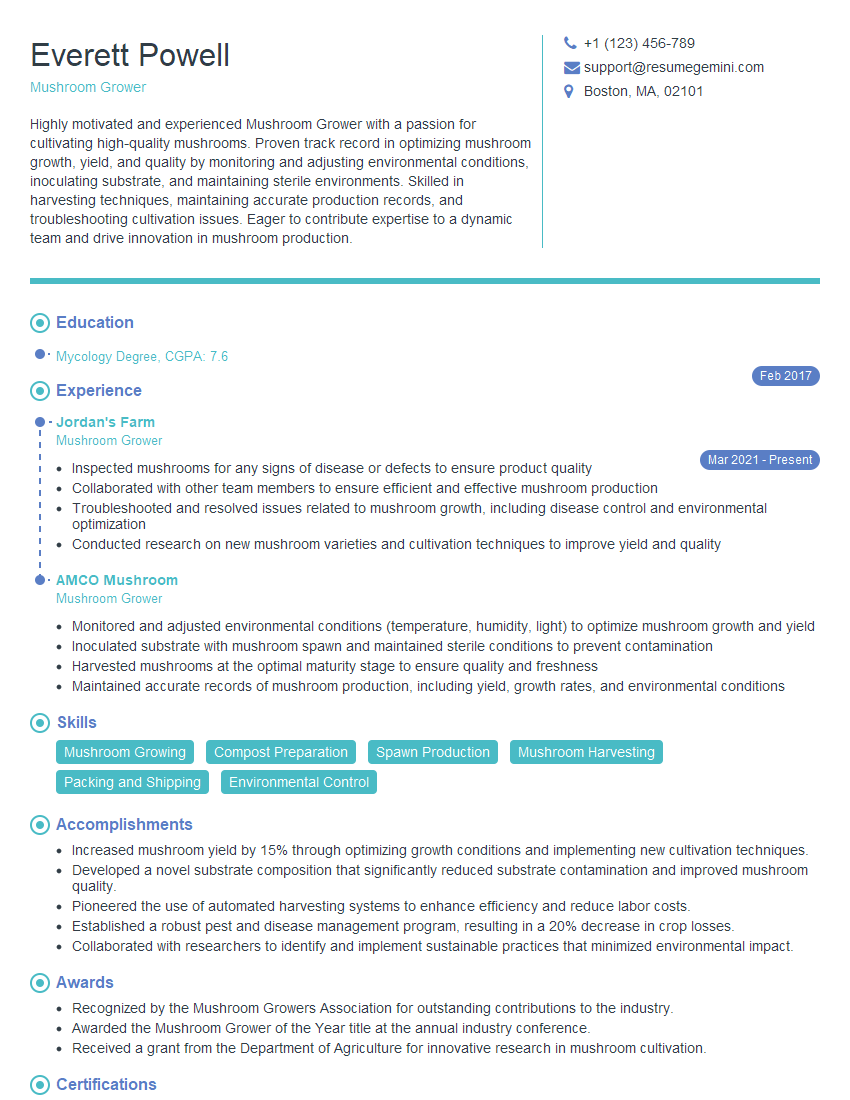

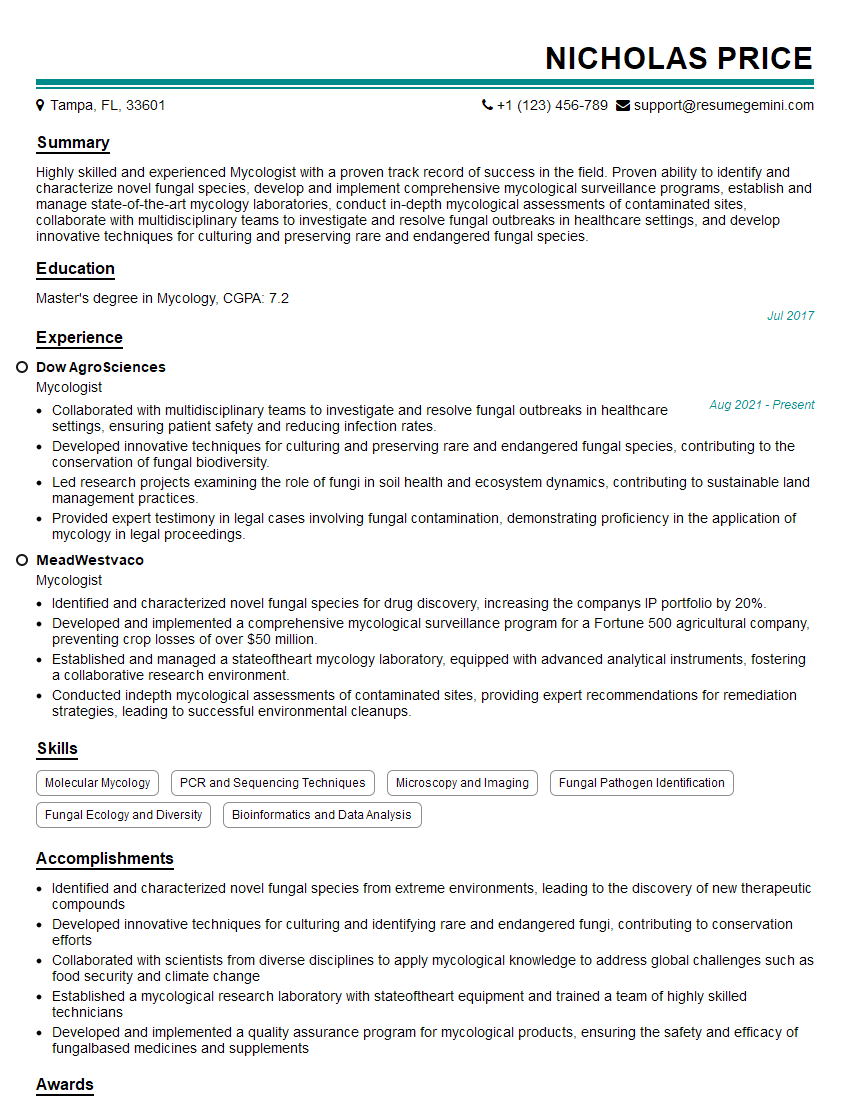

Mastering mushroom cultivation knowledge is crucial for a successful and rewarding career in this growing industry. Demonstrating your expertise through a strong resume is the first step. Building an ATS-friendly resume significantly increases your chances of getting noticed by potential employers. We highly recommend using ResumeGemini to craft a professional and effective resume. ResumeGemini provides you with the tools and resources to create a compelling document, and offers examples of resumes tailored to the specifics of Mushroom Cultivation Knowledge to help you get started. Let ResumeGemini help you showcase your skills and land your dream job!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good