The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Primer Charger Operation interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Primer Charger Operation Interview

Q 1. Describe the different types of primer chargers used in ammunition manufacturing.

Primer chargers, crucial in ammunition manufacturing, come in various types, primarily categorized by their operational mechanism and output capacity. The most common are:

- Rotary Primer Feeders: These are high-speed, automated systems using a rotating disc to feed primers into the cartridge cases. They are ideal for mass production due to their efficiency. Think of it like a highly precise carousel, delivering primers one by one.

- Vibratory Feeders: These use vibrations to move primers along a channel, feeding them to the charging mechanism. While slower than rotary systems, they are often more cost-effective for smaller-scale operations or specific cartridge types.

- Gravity Feeders: These are simpler, often manual systems, where primers are dropped into the charging mechanism via gravity. They are best suited for very low-volume operations or specialized applications where precise control is paramount but speed is less critical.

- Inline Primer Feeders: These are integrated into larger assembly lines and directly feed primers to the cartridge case during the assembly process. They offer excellent integration and efficiency within a complete manufacturing line.

The choice of primer charger depends on factors such as production volume, cartridge type, required accuracy, and budget.

Q 2. Explain the process of setting up a primer charger for a specific cartridge type.

Setting up a primer charger for a specific cartridge type involves a meticulous process to ensure proper seating and prevent misfires or malfunctions. It typically includes these steps:

- Selecting the Correct Hopper and Feed Mechanism: The primer hopper and feeder must be compatible with the size and shape of the primers for the chosen cartridge.

- Adjusting the Primer Feed Rate: The feed rate is adjusted to match the speed of the case feeding mechanism, preventing jams and ensuring consistent primer placement. This often involves fine-tuning a screw or dial on the machine.

- Calibrating the Primer Seating Depth: The depth to which the primer is seated in the cartridge case is critical. Incorrect seating depth can lead to misfires or damage to the primer. This is adjusted using precisely calibrated tools and gauges.

- Checking for Proper Primer Orientation: The primer must be oriented correctly to ensure reliable ignition. The orientation mechanism is adjusted to ensure the primer cup faces the correct direction before seating.

- Testing and Adjustment: After the initial setup, a test run is conducted to verify the accuracy and consistency of the primer charging process. Adjustments are made as necessary until the desired parameters are achieved.

Visual inspection of the primers and cartridge cases throughout the process is crucial for identifying any issues early on.

Q 3. How do you ensure the accuracy and consistency of primer charging?

Ensuring accuracy and consistency in primer charging is paramount for ammunition reliability and safety. This is achieved through a combination of methods:

- Regular Calibration and Maintenance: Regular calibration of the primer seating depth and feed rate, along with routine maintenance, minimizes variations in the process.

- Quality Control Checks: Frequent sampling and inspection of charged cartridges ensures that primers are correctly seated and oriented. Statistical Process Control (SPC) charts help track performance over time.

- Use of Precision Components: High-quality components, precisely manufactured to tight tolerances, ensure consistent and reliable operation.

- Environmental Control: Maintaining a stable operating environment, with consistent temperature and humidity, prevents variations caused by external factors.

- Operator Training: Well-trained operators are crucial in maintaining consistent operation and identifying potential issues early on.

Imagine a baker making cakes – consistent ingredients, precise measurements, and a stable oven are all essential for a consistently good outcome. Primer charging is similar; consistency in all aspects leads to a reliable product.

Q 4. What safety precautions are essential when operating a primer charger?

Safety is paramount when operating primer chargers. Essential precautions include:

- Lockout/Tagout Procedures: Always follow lockout/tagout procedures before performing any maintenance or cleaning on the equipment to prevent accidental activation.

- Personal Protective Equipment (PPE): Wear appropriate PPE, including eye protection, hearing protection, and gloves, to minimize the risk of injury from moving parts or accidental primer explosions.

- Proper Grounding: Ensure the equipment is properly grounded to prevent static electricity buildup, which could cause primer ignition.

- Fire Suppression Systems: Have appropriate fire suppression systems in place to deal with any potential fires. Primers are explosive and require careful handling.

- Regular Inspections: Regular inspection of the equipment for any signs of wear or damage is crucial to prevent malfunctions and accidents.

- Training and Competence: Only trained and authorized personnel should operate the equipment.

Ignoring safety procedures can have catastrophic consequences, so adherence is non-negotiable.

Q 5. How do you identify and troubleshoot common malfunctions in a primer charger?

Troubleshooting primer charger malfunctions requires systematic investigation. Common problems and solutions include:

- Primer Jams: Caused by improper primer feed or orientation. Check the feed mechanism for obstructions, adjust the orientation mechanism, and ensure the primers are correctly positioned in the hopper.

- Inconsistent Primer Seating Depth: Check for wear on the seating mechanism, recalibrate the seating depth, and inspect the primers for any defects.

- Damaged Primers: Inspect the primers for cracks or other damage that could lead to misfires. Discard any damaged primers.

- Machine Malfunctions: Consult the equipment manual for troubleshooting guides or contact the manufacturer for support. This might involve checking electrical connections, replacing worn parts, or calling a qualified technician.

- No Primer Feed: Check for power supply issues, ensure the hopper is full, and verify that the feed mechanism is functioning correctly.

Systematic troubleshooting, starting with simple checks and progressing to more complex issues, is key to quickly identifying and resolving problems.

Q 6. What are the key performance indicators (KPIs) for a primer charger operator?

Key Performance Indicators (KPIs) for a primer charger operator focus on efficiency, accuracy, and safety. These include:

- Units Produced per Hour: Measures the output rate and overall efficiency of the operator and the machine.

- Primer Seating Depth Accuracy: Indicates the consistency and accuracy of the primer seating process. Measured using statistical process control (SPC).

- Primer Orientation Accuracy: Measures the percentage of primers correctly oriented during the charging process.

- Number of Jams or Stoppages per Hour: Indicates the reliability of the operation and the skill of the operator in preventing malfunctions.

- Safety Record: Tracks the number of accidents or near misses related to the operation of the primer charger.

Tracking these KPIs helps identify areas for improvement in both operator performance and machine efficiency.

Q 7. Explain the importance of regular maintenance and cleaning of primer charging equipment.

Regular maintenance and cleaning of primer charging equipment are crucial for ensuring consistent operation, preventing malfunctions, and maintaining safety. This involves:

- Daily Cleaning: Removing debris and spilled primers to prevent jams and contamination.

- Regular Lubrication: Lubricating moving parts to reduce wear and tear and ensure smooth operation.

- Periodic Inspections: Regularly inspecting for signs of wear, damage, or misalignment of parts.

- Calibration Checks: Regularly calibrating the primer seating depth and feed rate to maintain accuracy.

- Preventive Maintenance: Following a scheduled maintenance plan to replace worn parts and prevent major breakdowns.

Just as a car requires regular servicing, primer chargers need regular attention to maintain their efficiency and longevity. Ignoring maintenance can lead to costly repairs, production downtime, and potential safety hazards.

Q 8. How do you handle jams or misfeeds during the primer charging process?

Handling jams or misfeeds during primer charging requires a methodical approach, prioritizing safety. First, always ensure the machine is powered down and the charging mechanism is disengaged. Never attempt to force a primer through a jammed system. Then, carefully inspect the mechanism to identify the cause of the jam. Common causes include damaged primers, misaligned feeding components, or obstructions within the machine. If a damaged primer is the cause, gently remove it using appropriate tools, avoiding any sharp movements that could damage surrounding components. If the jam is due to a mechanical issue, you may need to consult the machine’s manual or contact a qualified technician.

Example: If a primer is stuck in the seating mechanism, use a soft-tipped tool, such as a plastic or wooden dowel, to gently dislodge it. Avoid using metal tools to prevent scratching or damaging the delicate components. Before restarting the machine, visually inspect all components for damage, ensuring smooth operation.

Q 9. Describe the quality control checks performed on primers after charging.

Quality control after primer charging is crucial for ammunition reliability and safety. This typically involves a multi-stage process. Visual inspection is the first step, checking for any obvious defects like bent or damaged primers, or inconsistent primer seating depth. A visual inspection can identify immediately obvious issues, such as a primer that is clearly damaged or improperly seated.

Next, we often use sampling and testing. A representative sample of charged cartridges is selected and checked using specialized gauging tools to ensure the primer is properly seated and within the correct depth tolerance. Incorrect seating depth can compromise ignition. Finally, in some cases, we may utilize automated inspection systems, which use optical sensors or other methods to detect defects at higher speeds than is possible with manual methods.

Q 10. What are the potential hazards associated with primer charging, and how are they mitigated?

Primer charging presents several hazards. Primers are explosive devices, so static electricity is a major concern. Static discharge can ignite primers, causing serious injury or death. We mitigate this risk through grounding equipment and personnel, using anti-static mats and clothing. Furthermore, loose clothing, jewelry, and long hair can get caught in moving parts, creating a potential hazard. We mitigate this by wearing appropriate Personal Protective Equipment (PPE), which includes safety glasses, gloves, and clothing that properly fits. Finally, the process involves dealing with small, potentially hazardous components, so maintaining a clean and organized workspace is essential to prevent accidental ingestion or injury from small parts. Regular maintenance and inspections of machinery are crucial to mitigate any mechanical malfunctions.

Q 11. How do you ensure the proper handling and storage of primers?

Proper handling and storage of primers are paramount to safety. Primers must be stored in their original containers, away from direct sunlight, heat, and moisture. These containers should be kept in a cool, dry, and well-ventilated location, securely locked away from unauthorized access. During handling, avoid dropping or impacting primers. Always use appropriate protective equipment, such as gloves, and always follow manufacturer instructions. Regularly inspect storage areas for any signs of damage or deterioration to the containers. Expired primers must be disposed of according to the relevant regulations. Think of it like handling any other explosive material – safety and care are paramount.

Q 12. Explain the different types of primers and their applications.

Primers are categorized by their composition and their application. Small Rifle Primers (SRP) are commonly used in handgun and rifle cartridges. Large Rifle Primers (LRP) are used in larger caliber rifles where a stronger ignition is needed. Small Pistol Primers (SPP) are used in most pistol cartridges and some small-caliber rifles. The choice of primer depends on the specific firearm and cartridge design. Besides the size, there are differences in their sensitivity and the power of the ignition that they provide. For example, some primers are designed for use in specific conditions or with specific types of propellant powder. Manufacturers provide detailed specifications for their products that are extremely important to consider when selecting a primer.

Q 13. What is the role of automation in modern primer charging systems?

Automation significantly improves efficiency and safety in modern primer charging systems. Automated systems offer increased speed and precision compared to manual methods, reducing the risk of human error. Automated systems can also monitor various parameters during the charging process, automatically detecting and signaling malfunctions or jams. This greatly reduces the chance of defective ammunition and improves overall quality. Examples of automation include robotic arms for handling primers, automated feeding mechanisms, and sophisticated vision systems for quality control. These systems improve throughput and greatly reduce the potential for injuries associated with manual handling.

Q 14. How do you interpret and respond to machine error messages?

Interpreting and responding to machine error messages requires careful attention. Each message indicates a specific problem. Begin by consulting the machine’s manual to understand the meaning of the error code. Common error codes may indicate jams, misfeeds, or sensor faults. Never ignore or override error messages; doing so may lead to further damage or create safety hazards. After identifying the issue using the manual, carry out the prescribed troubleshooting steps. If the problem persists, contact qualified maintenance personnel for further assistance. The safety of the operator and equipment is paramount, and understanding these procedures is a critical skill for anyone working with these machines.

Example: An error code indicating a ‘low primer level’ means the hopper is empty and needs refilling. However, an error code signaling ‘primer misalignment’ requires careful inspection and potential adjustment of the feeding mechanism.

Q 15. What are the environmental considerations in primer charging operations?

Environmental considerations in primer charging are paramount due to the hazardous nature of primer compounds. These compounds often contain heavy metals like lead and antimony, which pose significant risks to both workers and the environment. Key considerations include:

- Waste Management: Proper handling and disposal of primer waste, including spills and defective primers, is crucial. This often involves specialized waste contractors and adherence to strict regulatory guidelines. For example, we utilize sealed containers and specialized waste disposal services to ensure compliance.

- Air Quality: Dust and particulate matter generated during primer handling and charging operations can be a significant concern. Implementing effective ventilation systems, such as local exhaust ventilation at the charging machines, is critical to minimizing airborne exposure. Regular air quality monitoring is also essential.

- Water Pollution: Prevention of primer compounds from entering waterways is vital. This requires careful management of cleaning solutions and potential spills. We use containment systems and implement stringent cleaning protocols to prevent water contamination.

- Soil Contamination: Spills or leaks can contaminate the soil. Our procedures include immediate cleanup of any spills, and in case of significant contamination, soil remediation strategies are put in place.

Failure to address these environmental concerns can lead to significant fines, reputational damage, and environmental harm.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with different types of primer charging machines.

Throughout my career, I’ve worked with several types of primer charging machines, each with its unique strengths and weaknesses. These include:

- Gravimetric Feeders: These machines utilize precise weighing mechanisms to dispense the exact amount of primer compound into each primer cup. They provide excellent accuracy and consistency, minimizing variations in charge weight. I’ve had extensive experience with these, particularly with high-speed models used in large-scale production.

- Volumetric Feeders: These machines dispense a measured volume of primer compound. While simpler and less costly than gravimetric feeders, they are less accurate and more prone to variations in charge weight due to changes in powder density. I’ve used these in smaller-scale operations or for less demanding applications.

- Automatic Primer Charging Machines: These fully automated systems integrate primer cup feeding, charging, and crimping into a single process. They significantly increase production speed and efficiency but require higher initial investment and more specialized maintenance. My experience includes working with such a machine in a large-scale ammunition plant, which drastically improved our production output and consistency.

My experience spans various manufacturers and models, allowing me to troubleshoot and optimize performance across different systems. I’m adept at identifying and addressing issues related to calibration, component wear, and overall machine functionality.

Q 17. How do you maintain accurate records of production and quality control data?

Accurate record-keeping is vital for ensuring consistent product quality and complying with regulatory requirements. We maintain detailed production and quality control data using a combination of computerized systems and manual records. This includes:

- Production Logs: These logs meticulously track production parameters such as the number of primers charged, machine uptime, and any downtime due to maintenance or malfunctions. We record all relevant details such as date, time, operator, and machine ID.

- Quality Control Data: This includes the results of regular sample testing for charge weight, primer cup integrity, and overall primer performance. We employ statistical process control (SPC) techniques to monitor variations and identify potential issues early on. We use specialized software for data analysis and charting.

- Material Tracking: We meticulously document the lot numbers of all primer compounds and components, ensuring traceability throughout the production process. This facilitates investigation in case of quality issues.

- Database Management: All data is stored in a secure, centralized database, allowing for easy retrieval and analysis. Regular backups are performed to ensure data integrity.

This rigorous approach helps us identify trends, improve process efficiency, and maintain a high level of quality control.

Q 18. How do you ensure compliance with safety and regulatory standards?

Ensuring compliance with safety and regulatory standards is our top priority. This involves adherence to:

- OSHA Regulations: We strictly adhere to OSHA’s guidelines for hazardous materials handling, personal protective equipment (PPE), and workplace safety. Regular safety training is mandatory for all personnel. Examples include specific training on handling explosives and use of respirators.

- ATF Regulations: For ammunition manufacturing, we meticulously comply with Bureau of Alcohol, Tobacco, Firearms and Explosives regulations. This includes record-keeping requirements and strict controls over primer materials and production processes.

- Environmental Regulations: We comply with all applicable environmental regulations regarding waste disposal, air emissions, and water pollution. Environmental permits are maintained, and regular inspections are conducted to ensure compliance.

- Internal Safety Protocols: We have developed comprehensive internal safety protocols, including lockout/tagout procedures and emergency response plans. Regular safety audits are performed to identify and address potential hazards.

Safety is not just a procedure; it’s a culture within our organization.

Q 19. Describe your experience with preventative maintenance of primer charging equipment.

Preventative maintenance is crucial for maximizing equipment lifespan and minimizing production downtime. Our preventative maintenance program includes:

- Regular Inspections: Daily visual inspections of all primer charging equipment are performed to identify potential issues early on. This includes checking for wear and tear on components, loose parts, and any signs of malfunction.

- Scheduled Maintenance: We follow a strict schedule for more comprehensive maintenance tasks, including lubrication, cleaning, and replacement of worn parts. This schedule is based on manufacturer recommendations and our own operational experience.

- Calibration: Regular calibration of weighing mechanisms (for gravimetric feeders) and dispensing mechanisms (for volumetric feeders) is essential for maintaining accuracy and consistency in primer charge weights. We use certified calibration equipment and maintain meticulous calibration records.

- Component Replacement: We proactively replace worn components before they fail, reducing the risk of unexpected downtime and potential safety hazards. We maintain a robust inventory of spare parts.

Our preventative maintenance program is designed to minimize downtime, improve equipment longevity, and most importantly, enhance workplace safety.

Q 20. How do you identify and resolve discrepancies in primer charge weights?

Discrepancies in primer charge weights can have serious consequences, impacting the performance and safety of the ammunition. When such discrepancies are identified, we follow a systematic approach to resolve them:

- Identify the Source: We investigate the potential causes, including variations in powder density, machine malfunction, or incorrect calibration. This may involve reviewing production logs, quality control data, and conducting visual inspections of the equipment.

- Isolate the Problem: Once the source is identified, we isolate the affected primers or batches to prevent further issues. This may involve segregating batches and conducting more thorough quality control testing.

- Correct the Problem: Corrective actions are taken depending on the cause of the discrepancy. This may involve recalibrating the machine, adjusting powder feed settings, replacing worn parts, or even investigating a potential materials issue with the powder itself.

- Document the Resolution: A detailed record of the discrepancy, its cause, and the corrective actions taken is documented. This serves as a valuable learning experience and helps prevent similar issues from occurring in the future.

Our focus is on root cause analysis to ensure lasting solutions and maintain consistent quality.

Q 21. What is your experience with different types of primers (e.g., small rifle, large rifle)?

My experience encompasses a wide range of primers, including small rifle primers, large rifle primers, shotgun primers, and pistol primers. Each type presents unique handling and charging challenges:

- Small Rifle Primers: These are smaller and require more precise charging techniques to ensure consistency. The smaller size necessitates finer control over the powder dispensing mechanisms.

- Large Rifle Primers: These are larger and typically require a greater charge weight. While less sensitive to small variations, accuracy remains crucial for consistent performance.

- Shotgun Primers: These primers have unique design characteristics and require appropriate charging procedures to ensure reliability. They often require different handling equipment to prevent damage.

- Pistol Primers: These primers have specific size and charge weight requirements, different from rifle primers.

Understanding the specific characteristics of each primer type is crucial for safe and efficient charging operations. This knowledge allows me to adapt procedures and equipment settings to ensure optimal performance and consistent quality for all types of primers.

Q 22. How do you handle defective primers during the charging process?

Defective primers are a serious concern in the primer charging process, as they can lead to misfires, hangfires, or even catastrophic failures. My approach involves a multi-layered system of detection and handling.

- Visual Inspection: A crucial first step is a thorough visual inspection of primers before they enter the charging machine. We look for dents, cracks, or any signs of damage that might affect their functionality. Any suspect primers are immediately removed. Think of it like quality control for a crucial ingredient in a complex recipe.

- Automatic Detection Systems: Modern primer charging machines often incorporate automated sensors that can detect defective primers based on size, weight, or other physical characteristics. These systems reject primers that fall outside pre-defined parameters. This is analogous to an automated assembly line rejecting faulty parts.

- Regular Maintenance: Consistent maintenance of the charging equipment is vital to prevent the introduction of defects. Regular cleaning and lubrication of the mechanisms ensure the smooth and accurate handling of primers. Imagine this as keeping your kitchen appliances clean and well-maintained.

- Data Logging and Analysis: We meticulously record the number of defective primers identified and analyzed at each stage. This data allows us to identify trends and potential root causes of defects, further optimizing our quality control processes. This is like tracking your recipe’s successes and failures to improve the final product.

By implementing these layers of quality control, we minimize the risk of defective primers reaching the final product and ensure the highest level of safety and reliability.

Q 23. Explain your understanding of the relationship between primer weight and firearm function.

The relationship between primer weight and firearm function is critical. The primer’s function is to ignite the propellant, and the weight directly impacts the energy of this ignition. Too little weight might result in a weak ignition, leading to a misfire or a slow burn. Too much weight could generate excessive pressure, potentially damaging the firearm.

Think of it like a spark plug in a car engine: it needs the right amount of energy to ignite the fuel-air mixture. Too little energy, and the engine won’t start. Too much, and you risk damaging the engine.

Primer manufacturers carefully control the weight to ensure consistent performance. Variations outside a tightly controlled range can cause significant problems. This is meticulously documented and monitored in our operation.

Q 24. Describe your experience with troubleshooting electrical or mechanical issues in primer charging equipment.

My experience with troubleshooting electrical and mechanical issues in primer charging equipment is extensive. My approach involves a systematic process:

- Safety First: The first step is always to ensure the equipment is completely powered down and locked out before any troubleshooting begins. Safety is paramount.

- Visual Inspection: A careful visual inspection often reveals obvious issues such as loose connections, damaged wires, or mechanical obstructions.

- Systematic Testing: Using multimeters and other diagnostic tools, I systematically test individual components to isolate the fault. This might involve checking voltages, currents, and resistances. I might also check for continuity in circuits and pressure in pneumatic systems.

- Component Replacement: Once the faulty component is identified, it’s replaced with a verified good part. It’s vital to use only approved parts to ensure compatibility and safety.

- Documentation: All troubleshooting steps, findings, and repairs are meticulously documented to aid future maintenance and problem-solving.

For example, I once resolved a recurring issue where a primer feeder consistently jammed. By carefully examining the feeder mechanism and using precision measuring tools, I identified a slight misalignment causing the primers to bind. A simple adjustment restored the feeder’s proper operation. This highlights the importance of both methodical analysis and hands-on dexterity in troubleshooting.

Q 25. How do you contribute to a safe and productive work environment?

Contributing to a safe and productive work environment is a priority. I actively participate in safety meetings, follow all safety protocols, and promptly report any potential hazards. I believe in leading by example and promoting a culture of safety awareness.

Furthermore, I am always looking for ways to improve efficiency and productivity. This includes suggesting process improvements, helping train new employees, and assisting colleagues with their tasks. A collaborative and supportive environment yields better results and fosters a sense of teamwork, boosting productivity and overall morale.

Q 26. What is your experience with lean manufacturing principles in the context of primer charging?

My experience with lean manufacturing principles in primer charging focuses on waste reduction and efficiency optimization. We use several lean techniques, including:

- 5S Methodology: We maintain a clean, organized, and efficient workspace using the 5S principles (Sort, Set in Order, Shine, Standardize, Sustain). This ensures a safe and productive working environment.

- Value Stream Mapping: We analyze the entire primer charging process to identify and eliminate bottlenecks and non-value-added activities. For instance, we mapped out our entire primer handling procedure, pinpointing areas where unnecessary steps were causing delays and improving the overall flow.

- Kaizen Events: We regularly conduct Kaizen events to identify small, incremental improvements that can significantly enhance productivity and efficiency. For example, one Kaizen event led to a redesigned primer feeding mechanism, reducing jams and increasing throughput.

- Just-in-Time (JIT) Inventory: We maintain just enough primer inventory to meet immediate production needs, minimizing storage costs and reducing waste. This avoids unnecessary storage space and reduces the risk of primer degradation.

By consistently applying these lean manufacturing principles, we have been able to significantly reduce production time, improve product quality, and enhance overall efficiency.

Q 27. How would you train a new employee on proper primer charger operation procedures?

Training a new employee on primer charger operation involves a structured, multi-stage approach emphasizing safety and competency.

- Classroom Training: The training begins with classroom instruction covering safety procedures, equipment operation, quality control standards, and troubleshooting techniques. This ensures a comprehensive understanding of the theoretical aspects of the process.

- Hands-on Training: Next, the new employee observes experienced operators performing the tasks, followed by guided practice under close supervision. This practical experience is essential for skill development.

- Simulations: We use simulations to replicate real-world scenarios, such as dealing with equipment malfunctions or defective primers. This allows the trainee to practice problem-solving in a safe and controlled environment.

- Performance Evaluation: Regular performance evaluations ensure the trainee has achieved the required competency level before working independently. This includes both theoretical and practical assessments.

- Mentorship: An experienced operator mentors the new employee, providing ongoing support and guidance. This continuous feedback is vital for skill refinement.

The entire training process emphasizes safety protocols and adherence to quality control standards, fostering a culture of safety and precision.

Q 28. Describe a situation where you had to solve a complex problem related to primer charger operation.

One time, we experienced a significant increase in misfires despite no changes to the primer supply or charging process. This presented a complex problem.

We initiated a systematic investigation using a data-driven approach. We analyzed production data, focusing on the specific batches of ammunition showing high misfire rates. We examined the environmental conditions during the manufacturing process, scrutinized the equipment maintenance logs, and conducted thorough quality checks on all components of the primer charging system. The problem turned out to be a subtle issue: humidity changes in the manufacturing environment had altered the static electricity within the charging machine. This static electricity was affecting the reliable detonation of the primers.

The solution involved implementing improved humidity control in the production area and incorporating anti-static measures within the charging machine itself. This required careful calibration and testing. By addressing the root cause using meticulous data analysis and detailed system checks, we successfully resolved the high misfire rate and restored production efficiency.

Key Topics to Learn for Primer Charger Operation Interview

- Primer Charger Mechanics: Understanding the fundamental principles of primer charging, including the different types of primer chargers and their mechanisms. This includes exploring the various components and their functions.

- Safety Procedures and Regulations: Mastering the critical safety protocols and industry regulations surrounding primer charger operation. This involves understanding risk assessments, hazard identification, and safe operating procedures.

- Troubleshooting and Maintenance: Developing proficiency in identifying and resolving common malfunctions, performing routine maintenance, and understanding preventative maintenance schedules. This includes familiarity with diagnostic tools and techniques.

- Quality Control and Assurance: Grasping the importance of quality control in primer charging and the methods used to ensure consistent and accurate primer placement. This includes understanding the impact of variations in the process.

- Process Optimization and Efficiency: Exploring strategies for optimizing the primer charging process to increase efficiency and reduce downtime. This might include analyzing workflow, identifying bottlenecks, and suggesting improvements.

- Data Analysis and Reporting: Understanding the importance of data collection and analysis in optimizing primer charging performance. This includes familiarity with relevant metrics and reporting methods.

Next Steps

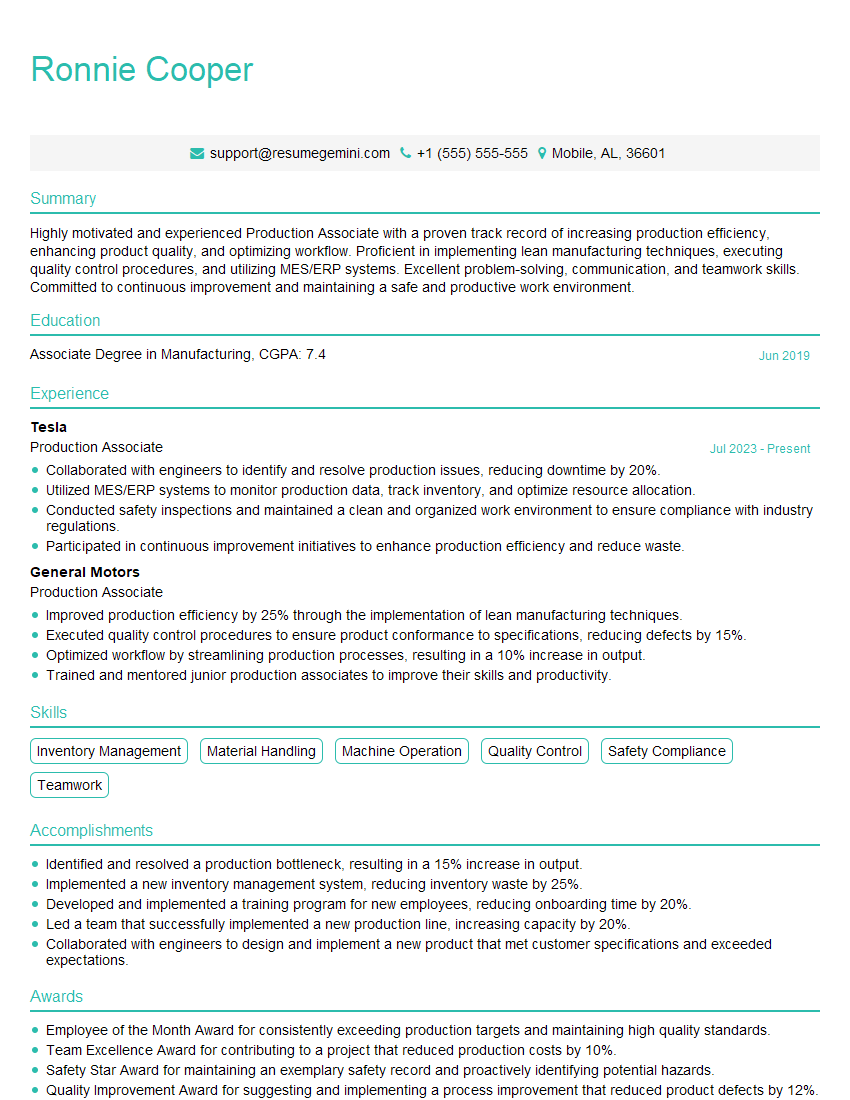

Mastering Primer Charger Operation opens doors to rewarding careers in manufacturing and production, offering opportunities for advancement and specialization. A strong understanding of this crucial process significantly enhances your value to potential employers. To stand out, focus on crafting an ATS-friendly resume that effectively highlights your skills and experience. ResumeGemini can help you build a professional and impactful resume that gets noticed. We provide examples of resumes tailored to Primer Charger Operation to guide you through the process, ensuring your application makes a lasting impression.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good