The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Measuring Equipment Calibration interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Measuring Equipment Calibration Interview

Q 1. Explain the importance of traceability in equipment calibration.

Traceability in equipment calibration is paramount because it ensures that the measurements you’re making are reliable and comparable to internationally recognized standards. Think of it like a chain linking your measurement back to a fundamental, universally accepted value. It establishes a clear and unbroken chain of custody, demonstrating how your calibration standards were themselves calibrated, and so on, ultimately leading back to a national or international metrology institute.

For example, if you’re calibrating a thermometer, traceability confirms that the equipment used to calibrate *that* thermometer was itself calibrated against a known standard, which was calibrated against another, and so on, ultimately leading back to a highly accurate reference standard maintained by a national standards organization. Without traceability, your measurements are essentially isolated and their accuracy cannot be reliably verified.

The absence of traceability can lead to significant problems in industries where precision is crucial, such as pharmaceuticals, aerospace, and manufacturing. Incorrect measurements can result in faulty products, safety hazards, and significant financial losses.

Q 2. Describe the different types of calibration uncertainties and their sources.

Calibration uncertainties represent the range within which the true value of a measurement lies. Several types exist, each originating from different sources:

- Random Uncertainty: This arises from unpredictable variations in measurements. Think of it as the natural ‘noise’ in the system. It’s often due to factors like temperature fluctuations or minute variations in the equipment’s operation. Statistical analysis helps to quantify and account for this type of uncertainty.

- Systematic Uncertainty: This is a consistent, repeatable error that affects all measurements in a specific direction (e.g., always reading slightly high). Sources include instrument biases, calibration standards’ inaccuracies, or environmental factors. Careful calibration procedures and rigorous testing help to minimize and identify systematic uncertainties.

- Standard Uncertainty: This represents the uncertainty associated with the calibration standard itself. High-quality calibration standards have lower standard uncertainties, contributing to greater overall measurement accuracy.

It is crucial to analyze and quantify all sources of uncertainty during a calibration to provide a complete picture of the measurement quality. This is often expressed as an expanded uncertainty, typically using a coverage factor of 2 (95% confidence interval). Imagine shooting arrows at a target – random uncertainties would spread the arrows around the bullseye, while systematic uncertainty might consistently pull all the arrows to one side.

Q 3. What are the key elements of a calibration procedure?

A comprehensive calibration procedure comprises several key elements:

- Preparation: This involves reviewing the instrument’s specifications, gathering necessary equipment (including calibration standards, tools, and documentation), and ensuring the environment meets the required conditions (e.g., temperature, humidity).

- Measurement: This entails systematically measuring the instrument’s performance against the calibration standard, following the manufacturer’s instructions and established best practices. Multiple measurements are typically taken to improve the accuracy and reduce the influence of random errors.

- Analysis: This involves comparing the measurements to the accepted values from the calibration standard. This stage includes calculating the deviation, uncertainties, and determining if the instrument is within acceptable tolerance limits.

- Documentation: Thorough documentation is crucial. A calibration certificate or report should include all relevant information: date, equipment details, calibration standards used, measurement results, uncertainties, and the conclusion of whether the equipment passed or failed the calibration.

- Corrective Action (if needed): If the instrument fails to meet the specified tolerances, corrective actions must be taken, such as adjustments, repairs, or even replacement. These actions must be fully documented.

A well-defined procedure ensures consistency, traceability, and compliance with standards like ISO/IEC 17025, which is important for many industries.

Q 4. How do you select the appropriate calibration standards?

Selecting appropriate calibration standards is critical for achieving accurate results. The primary considerations are:

- Accuracy: The standard’s accuracy should be significantly better than the instrument being calibrated (at least 10 times better). A less accurate standard will limit the overall accuracy that can be achieved.

- Range and Resolution: The standard’s range and resolution must be appropriate for the instrument’s operating range. Using a standard with a narrow range will not be effective for calibration across the entire instrument’s range.

- Traceability: The standard must be traceable to a national or international standard, ensuring the entire calibration chain is validated.

- Type: The calibration standard should match the type of instrument being calibrated (e.g., a precision resistor for calibrating a multimeter).

For instance, calibrating a high-precision digital multimeter might require a standard with an uncertainty significantly lower than the multimeter’s specifications. You wouldn’t use a low-cost standard for this; the resulting calibration would be unreliable.

Q 5. Explain the concept of calibration intervals and their determination.

Calibration intervals define how often an instrument needs to be recalibrated. Determining these intervals depends on several factors:

- Instrument Type and Usage: Instruments used frequently or in harsh conditions might require more frequent calibration than those used less often in controlled environments.

- Criticality of Measurement: Instruments used for critical measurements requiring high accuracy (e.g., medical devices) have shorter intervals.

- Instrument Stability: Instruments known to drift significantly over time need more frequent calibration.

- Past Calibration History: Consistent drift or out-of-tolerance readings in past calibrations might indicate a shorter interval.

- Manufacturer Recommendations: Manufacturers often provide guidelines or recommended calibration intervals in the instrument’s documentation.

Often, a risk assessment is performed to justify calibration intervals. If the consequence of inaccurate measurements is high, the calibration interval should be shorter. Establishing calibration intervals is a balance between ensuring accuracy and maintaining efficiency.

Q 6. Describe your experience with various calibration equipment (e.g., multimeters, oscilloscopes).

Throughout my career, I’ve extensively worked with various calibration equipment. I have experience calibrating multimeters using precision resistors and voltage standards, ensuring accurate measurements of voltage, current, and resistance. With oscilloscopes, I’ve utilized time-base and amplitude calibration standards, verifying the accuracy of time measurements and signal amplitude. This involves using signal generators and precision voltage sources to generate test signals with known characteristics. In addition, I’ve worked with other equipment including pressure gauges, thermometers, and balances, always ensuring adherence to the relevant calibration procedures and documentation.

One memorable instance involved troubleshooting a high-precision oscilloscope exhibiting a non-linear time-base error. Through meticulous investigation, including environmental checks and detailed analysis of the calibration data, we identified a faulty component, successfully resolving the issue and restoring the instrument’s accuracy.

Q 7. How do you handle discrepancies found during calibration?

Discrepancies found during calibration require a systematic approach. The first step involves verifying the calibration process itself – was it conducted correctly? Were the standards accurate? Were environmental factors controlled? If the process is confirmed as sound, the next step is to investigate the instrument. This may involve:

- Re-calibration: Repeat the calibration procedure to eliminate random errors. Multiple measurements help identify whether the discrepancy is truly significant or a result of random variation.

- Troubleshooting: If the discrepancy persists, troubleshooting the instrument is necessary. This might involve checking for obvious issues, such as loose connections, damaged components, or incorrect settings.

- Repair or Adjustment: If a fault is identified, the instrument might require repair or adjustment by a qualified technician. This should always be done in accordance with the manufacturer’s instructions.

- Replacement: In some cases, particularly if the instrument is significantly out of tolerance or the repair is cost-prohibitive, replacement may be the most economical and reliable solution.

Throughout this process, meticulous documentation is critical. All findings, actions, and decisions should be recorded in the calibration report. It’s essential to maintain a clear audit trail to ensure traceability and allow for future analysis.

Q 8. What are the different methods used for calibration (e.g., comparison, substitution)?

Calibration methods broadly fall into two categories: direct comparison and substitution. Direct comparison involves comparing the measurement device under test (MUT) to a known standard of higher accuracy. Think of it like comparing your watch to an atomic clock – you’re directly seeing the difference. Substitution, on the other hand, involves using the MUT to measure a known standard, then comparing the result to the standard’s known value. Imagine using your scale to weigh a 1kg weight – the difference between the reading and 1kg reveals the scale’s error.

- Direct Comparison: This is ideal for simple measurements where a direct visual or electronic comparison can be made. For example, comparing a calibrated thermometer to a reference thermometer immersed in the same temperature bath.

- Substitution: This method is often better for more complex instruments or when measuring multiple points. For example, calibrating a pressure gauge involves using a known pressure source and applying it to the MUT and then using a higher accuracy pressure standard.

- Other methods include: interpolation (using a series of known points to estimate values between them), and calculation using formulas derived from multiple measurements.

The choice of method depends on factors like the instrument type, the required accuracy, and the available equipment.

Q 9. Explain the concept of measurement error and its impact on calibration.

Measurement error refers to the difference between the measured value and the true value of a quantity. It’s essentially the uncertainty in our measurement. This error impacts calibration because it directly influences the accuracy of the instrument being calibrated. A large measurement error in our calibration process will lead to an inaccurate calibration, meaning the instrument’s readings won’t be reliable. This can have significant consequences in various fields, from manufacturing where inaccurate measurements can lead to faulty products, to medicine where incorrect measurements can impact patient care.

Sources of measurement errors include systematic errors (consistent biases, e.g., an improperly zeroed scale), random errors (unpredictable variations due to environmental factors or human error), and gross errors (blunders like misreading a scale). A well-designed calibration process aims to minimize all these error sources, often through repeated measurements, use of appropriate standards, and statistical analysis.

Q 10. How do you ensure the integrity of calibration data and records?

Ensuring data integrity is paramount. We use a multi-pronged approach. First, we employ a robust calibration management system, often software-based, that maintains a complete audit trail of all calibration activities. This includes details such as the date and time, the instrument tested, the standard used, the results, and the technician’s signature (electronic or physical). Secondly, we meticulously document the entire process, adhering to ISO/IEC 17025 standards (or industry-specific standards) for traceability and accuracy. Thirdly, regular internal audits are conducted to verify the system’s effectiveness and identify any weaknesses in our procedures. Lastly, we use secured database systems with access control to prevent unauthorized modification or deletion of data. This ensures that any discrepancies can be traced and corrected, maintaining the reliability and validity of our calibration records.

Q 11. What are the key regulatory requirements for equipment calibration in your industry?

Regulatory requirements vary depending on the industry and the type of equipment. However, some common standards include ISO/IEC 17025 (for calibration laboratories), ISO 9001 (quality management systems), and industry-specific regulations like those from the FDA (pharmaceutical industry) or aerospace standards (aerospace industry). These standards typically mandate regular calibration intervals, proper documentation, traceability to national standards, and the use of qualified personnel. Non-compliance can result in hefty fines, legal repercussions, and damage to reputation. A company’s inability to provide accurate calibration records can be a significant obstacle to business operations and compliance.

Q 12. Describe your experience with calibration software and databases.

I have extensive experience with various calibration software and databases, including [mention specific software or databases you’ve used, e.g., Fluke Calibration software, LIMS systems]. My expertise ranges from data entry and management to generating reports and analyzing trends. I’m proficient in using these systems to manage calibration schedules, track instrument performance, and generate certificates of calibration. I also have experience with integrating calibration databases with other enterprise resource planning (ERP) systems for streamlined data flow and reporting. One project where I found this beneficial was the implementation of a new LIMS system that improved data accuracy, reduced manual data entry, and ensured compliance with regulatory requirements.

Q 13. How do you manage and maintain calibration equipment?

Maintaining calibration equipment is crucial for ensuring its accuracy and longevity. This involves regular cleaning and maintenance according to the manufacturer’s recommendations. We also perform environmental monitoring to maintain stable conditions for sensitive equipment, such as temperature and humidity control. Regular preventative maintenance checks are scheduled and performed to identify and address potential issues before they affect calibration accuracy. We also maintain a detailed inventory of our calibration equipment, including its calibration history and any repair records. A key strategy is to designate a responsible individual or team to oversee the maintenance program, ensuring that all necessary actions are taken in a timely manner and all records are properly documented.

Q 14. Explain your understanding of statistical process control (SPC) in calibration.

Statistical Process Control (SPC) is a powerful tool used in calibration to monitor the stability and capability of the calibration process itself. It uses statistical methods, such as control charts, to identify trends, patterns, and variations in measurement data. For instance, we might use a control chart to monitor the measurements obtained from a specific standard. If the measurements fall consistently outside of predetermined control limits, this signals potential problems with either the standard itself or the calibration process, prompting an investigation and correction. By implementing SPC, we can improve the efficiency and reliability of our calibration processes, reducing errors and ensuring the accuracy of our calibrations. It helps to proactively identify and resolve issues before they impact the instruments we calibrate.

Q 15. How do you troubleshoot calibration equipment malfunctions?

Troubleshooting calibration equipment malfunctions involves a systematic approach. Think of it like diagnosing a car problem – you wouldn’t just randomly replace parts! First, I’d carefully examine the equipment for any visible damage, loose connections, or error messages. Then, I’d consult the equipment’s operational manual for troubleshooting guides and potential error codes.

For example, if a digital multimeter is giving erratic readings, I’d first check the battery, then the leads for damage or loose connections. I’d also test it against a known good standard to isolate whether the problem is with the meter itself or the test setup. If the problem persists, a deeper dive might involve checking internal components (if I’m qualified and it’s safe to do so) or contacting the manufacturer for repair or support.

My approach is always to start with the simplest checks and progressively move towards more complex diagnostics, documenting each step to ensure traceability. This systematic approach minimizes downtime and prevents unnecessary repairs.

Career Expert Tips:

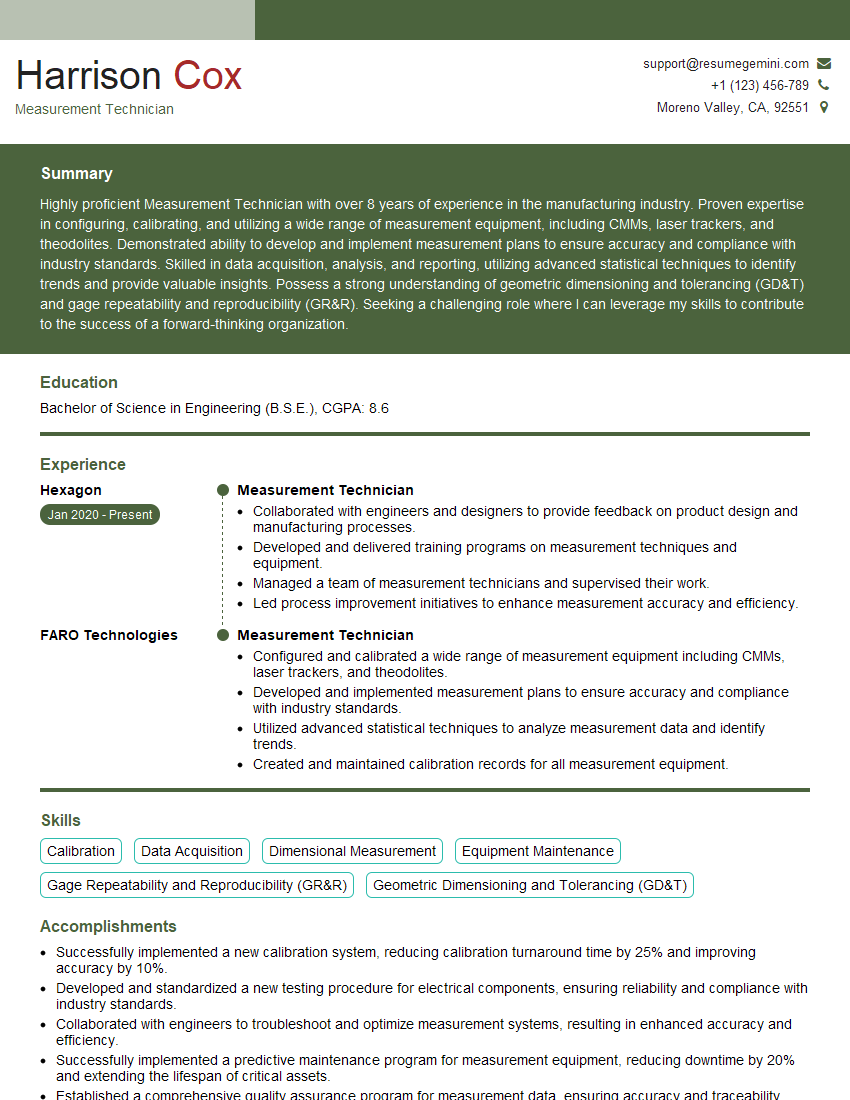

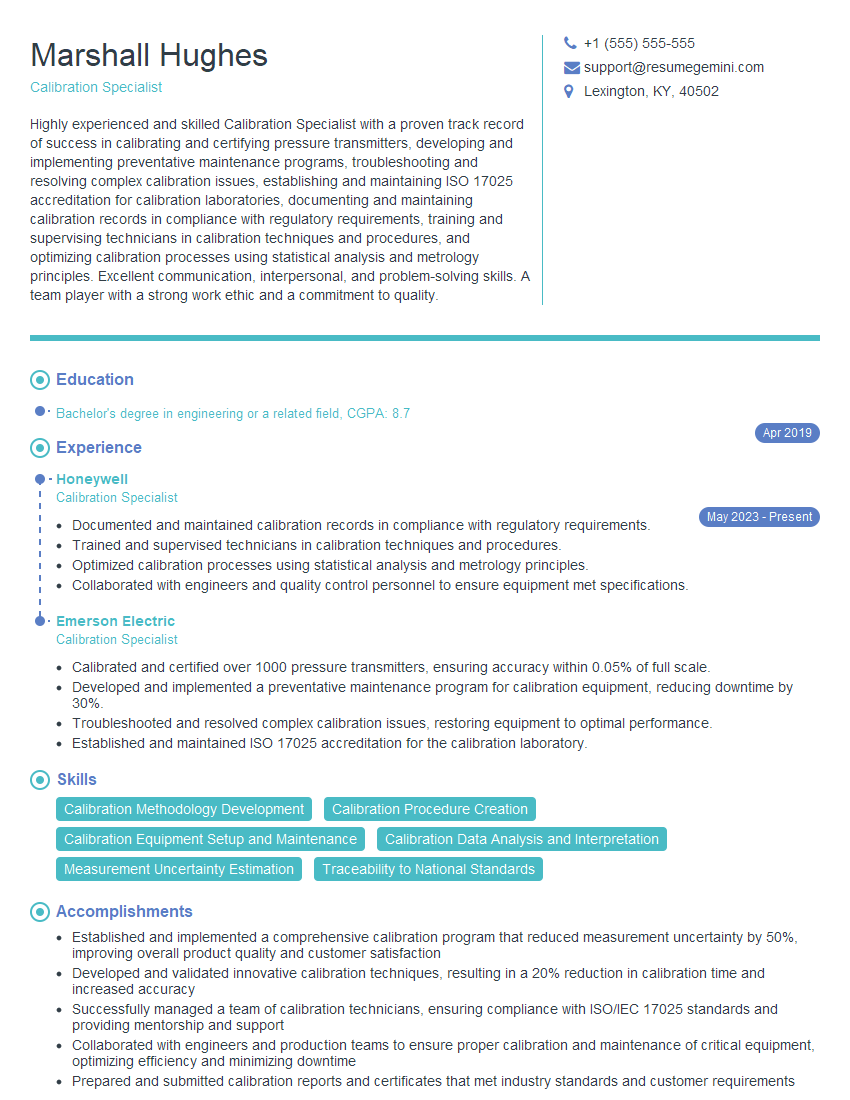

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with different types of calibration certificates.

I’ve worked extensively with various calibration certificates, each with a specific purpose and format. The most common are UKAS (United Kingdom Accreditation Service) and ISO 17025 accredited certificates, which provide the highest level of assurance about the calibration lab’s competence and the accuracy of the results. These certificates usually detail the equipment calibrated, the calibration method used, uncertainty values, and the expiry date.

I’ve also encountered internal or manufacturer’s certificates, which are less rigorous but still provide useful information. The key difference lies in traceability: UKAS/ISO 17025 certificates ensure traceability to national or international standards, guaranteeing the reliability of the results across different labs and organizations. In contrast, internal certificates might not have the same level of traceability, limiting their use in some applications.

Understanding the nuances of different certificates is crucial to ensure the suitability of the calibration for its intended purpose.

Q 17. What are your methods for ensuring the accuracy and reliability of calibration results?

Ensuring the accuracy and reliability of calibration results is paramount. My methods involve a multi-layered approach:

- Using calibrated reference standards: All calibrations are traced back to nationally or internationally recognized standards (like NIST or national metrology institutes). This ensures consistency and comparability across different measurements.

- Employing validated calibration procedures: We adhere to strictly documented procedures to maintain consistency and avoid human error. These procedures outline the steps, equipment used, and acceptance criteria.

- Regular equipment maintenance and verification: Our equipment undergoes regular maintenance and verification checks to ensure its accuracy and functionality. This proactive approach helps prevent unexpected failures and unreliable results.

- Environmental controls: We maintain a controlled environment to minimize the impact of environmental factors on the measurements, such as temperature and humidity.

- Statistical analysis of results: We use statistical methods to analyze the calibration data, identifying any trends or outliers that might indicate a problem with the equipment or the calibration process itself.

Think of it like baking a cake – a precise recipe (procedure), high-quality ingredients (standards and equipment), and controlled baking conditions (environment) are all necessary to achieve a consistently good result.

Q 18. How do you handle out-of-tolerance equipment?

Handling out-of-tolerance equipment requires a structured process. First, the issue is thoroughly investigated to determine the root cause – is it a genuine malfunction, or a problem with the calibration procedure? Once the cause is identified, the equipment is tagged as ‘out of calibration’ and removed from service to prevent further use and potential errors.

Next, repair or adjustment is undertaken, following the manufacturer’s recommendations or our established procedures. After repair, the equipment undergoes recalibration to ensure it meets the specified tolerances. If the equipment consistently fails calibration, it may need to be replaced. Throughout the entire process, meticulous records are maintained, documenting each step, the actions taken, and the results obtained. This ensures traceability and allows for a complete audit trail.

Q 19. Describe your experience working with different calibration standards (e.g., NIST, ISO).

My experience includes working with a range of calibration standards, including those traceable to NIST (National Institute of Standards and Technology) and adhering to ISO 17025 guidelines. NIST standards are considered highly reputable and serve as the basis for many national metrology systems. Working with NIST-traceable standards ensures the highest level of accuracy and reliability in our calibrations.

ISO 17025 sets the international standard for the competence of testing and calibration laboratories. Adhering to this standard provides assurance that our processes are robust and our results are credible. The key is understanding the specific requirements of each standard and applying them correctly to maintain a high level of consistency and accuracy.

Q 20. Explain the importance of proper handling and storage of calibration standards.

Proper handling and storage of calibration standards are critical to maintaining their accuracy and longevity. Think of these standards as precious instruments – their accuracy is compromised by mishandling.

Our procedures emphasize careful handling to avoid damage or contamination. This includes using appropriate tools for handling, avoiding excessive force, and ensuring the standards are always kept clean and protected from environmental factors like dust, moisture, and extreme temperatures. Storage usually involves specialized containers or cabinets designed to maintain stable environmental conditions. Regular inspections are also conducted to detect any signs of damage or deterioration. This meticulous care ensures the integrity of the standards and the reliability of the calibrations they support. It’s all about preserving the investment in these highly accurate devices.

Q 21. How do you ensure the competency of personnel involved in calibration activities?

Ensuring the competency of calibration personnel is achieved through a combination of training, experience, and ongoing assessment. We provide comprehensive training programs that cover the theoretical principles of calibration, the practical application of calibration techniques, and the use of specific equipment. This ensures that our staff has the necessary knowledge and skills to perform calibrations accurately and efficiently. Experienced personnel mentor newer team members, providing practical on-the-job training.

Furthermore, regular competency assessments are conducted through both practical tests and theoretical examinations, ensuring that skills remain up-to-date and that personnel consistently meet the required standards. We also encourage continuous professional development, providing opportunities for staff to attend workshops, conferences, and training courses to maintain their expertise and knowledge of the latest advancements in the field.

Q 22. Describe your experience with calibration audits and inspections.

Calibration audits and inspections are crucial for ensuring the accuracy and reliability of measurement equipment. My experience encompasses planning and executing both internal and external audits, following established procedures and regulatory requirements. This includes reviewing calibration procedures, verifying traceability to national standards, assessing the competence of calibration personnel, and evaluating the effectiveness of the overall calibration management system.

For instance, in a recent audit of a manufacturing facility, I identified a discrepancy in the calibration records for their pressure gauges. This led to a corrective action plan that involved retraining personnel on proper calibration procedures and implementing a more robust record-keeping system. The audit also uncovered a lack of preventative maintenance, which was addressed via a new schedule.

I also have experience with ISO 17025 accreditation audits, ensuring compliance with the stringent requirements for testing and calibration laboratories. These audits involved a thorough review of documentation, processes, and equipment to confirm that the laboratory meets the highest standards of quality and impartiality.

Q 23. What are your strategies for continuous improvement in the calibration process?

Continuous improvement in calibration is paramount. My strategies focus on several key areas. Firstly, data analysis is essential. Regularly reviewing calibration data helps identify trends, such as recurring failures in specific equipment or inconsistencies in calibration procedures. This data-driven approach allows for targeted improvements.

Secondly, I advocate for proactive maintenance. Implementing a preventative maintenance program reduces the likelihood of equipment failures and ensures that instruments remain accurate. This reduces downtime and associated costs.

Thirdly, employee training and development is critical. Regularly updating personnel on best practices, new technologies, and changes in regulations helps maintain a skilled and knowledgeable calibration team.

Finally, I use benchmarking against industry best practices and other calibration labs to identify areas for improvement and adopt innovative techniques. For example, implementing a computerized maintenance management system (CMMS) can streamline the calibration process and improve efficiency. This provides a centralised database for calibration records and maintenance schedules.

Q 24. Explain your understanding of the ISO/IEC 17025 standard.

ISO/IEC 17025 is an internationally recognized standard that outlines the general requirements for the competence of testing and calibration laboratories. It provides a framework for ensuring that laboratories operate in a consistent and reliable manner, producing high-quality results that are accepted internationally.

My understanding of the standard encompasses its various clauses, including management requirements, technical requirements, and quality management systems. This includes aspects such as:

- Traceability to national or international standards: Ensuring all calibration standards are traceable to recognized national metrology institutes.

- Competence of personnel: Ensuring calibration technicians possess the necessary skills and experience.

- Equipment maintenance and calibration: Regular calibration and maintenance of all testing and calibration equipment.

- Quality control: Implementing measures to control and monitor the quality of calibration results.

- Record keeping and documentation: Maintaining comprehensive and accurate records of all calibration activities.

Compliance with ISO 17025 is vital for demonstrating the credibility and reliability of a calibration laboratory’s results. It’s a mark of quality that inspires confidence in clients and stakeholders.

Q 25. How do you determine the appropriate calibration method for a specific instrument?

Determining the appropriate calibration method involves a systematic approach. First, I identify the instrument’s type, its intended use, and its specifications. Then, I consult relevant standards and manufacturers’ recommendations. Factors like measurement uncertainty, accuracy requirements, and the availability of suitable calibration equipment are crucial.

For example, calibrating a high-precision pressure gauge might involve a deadweight tester traceable to national standards, whereas a simple thermometer might be calibrated using a traceable liquid-in-glass thermometer or a calibration bath. The choice depends on factors like the required accuracy and the overall uncertainty budget. Sometimes, a combination of methods or a multi-point calibration is used for increased accuracy and confidence.

Finally, I document the chosen method, ensuring it’s clearly defined and repeatable. This detailed documentation is essential for ensuring traceability and maintaining the integrity of the calibration process. This reduces ambiguities and prevents errors in future calibrations.

Q 26. Describe your experience with different types of measurement sensors and transducers.

My experience spans a wide range of measurement sensors and transducers, including:

- Temperature sensors: Thermocouples, RTDs (Resistance Temperature Detectors), thermistors, infrared thermometers.

- Pressure sensors: Strain gauge pressure transducers, piezoelectric pressure sensors, capacitive pressure sensors.

- Flow sensors: Orifice plates, rotameters, ultrasonic flow meters.

- Force sensors: Load cells, strain gauges.

- Displacement sensors: LVDTs (Linear Variable Differential Transformers), potentiometers, encoders.

For each type, I understand the principles of operation, calibration methods, and potential sources of error. For example, the calibration of a thermocouple requires consideration of its material type and the environmental conditions during the measurement, which can affect accuracy. This practical experience allows me to select appropriate calibration techniques, troubleshoot issues, and ensure accurate measurements.

Q 27. Explain your approach to resolving calibration discrepancies and ensuring data integrity.

Resolving calibration discrepancies and ensuring data integrity are critical aspects of my role. When a discrepancy is detected, a thorough investigation is initiated. This involves reviewing the calibration procedure, checking the equipment’s condition, and verifying the competency of the personnel involved.

If a systemic error is identified in the calibration procedure, it is revised and updated to prevent future discrepancies. If equipment malfunction is the cause, it is repaired or replaced and recalibrated. If the discrepancy stems from human error, additional training may be required.

Maintaining data integrity involves adhering to strict record-keeping practices. Calibration records are carefully documented, including all relevant details, such as the date, time, equipment used, and any observed deviations. Any corrections or adjustments made are also meticulously recorded. A robust data management system helps ensure the long-term accessibility and reliability of calibration data. This traceability ensures that any issue or discrepancy can be quickly identified and resolved, protecting the integrity of all the data gathered.

Key Topics to Learn for Measuring Equipment Calibration Interview

- Understanding Calibration Standards and Traceability: Grasping the importance of national and international standards (e.g., ISO 17025) and how calibration ensures traceability to these standards.

- Calibration Methods and Techniques: Familiarize yourself with various calibration methods (e.g., comparison, substitution, direct calibration) and the appropriate techniques for different types of measuring equipment.

- Uncertainty Analysis and Error Calculations: Understand how to determine measurement uncertainty, propagate errors, and analyze the impact on measurement results. This is crucial for demonstrating competence.

- Calibration Procedures and Documentation: Mastering the creation and implementation of detailed calibration procedures, including accurate record-keeping and generating comprehensive calibration certificates.

- Common Measuring Equipment: Gain proficiency in the calibration of various instruments like multimeters, pressure gauges, thermometers, scales, and dimensional measuring devices. Understand their operating principles and potential sources of error.

- Troubleshooting and Problem Solving: Develop skills in identifying and resolving common calibration issues, including instrument malfunctions and environmental factors influencing accuracy.

- Calibration Software and Data Management: Learn about software used for calibration management, data analysis, and report generation. Familiarity with LIMS (Laboratory Information Management Systems) is beneficial.

- Safety Procedures and Regulations: Demonstrate understanding of relevant safety regulations and procedures related to handling measuring equipment and working in calibration laboratories.

- Calibration Schedules and Planning: Explain the principles of developing effective calibration schedules based on equipment usage, manufacturer recommendations, and regulatory requirements.

Next Steps

Mastering Measuring Equipment Calibration opens doors to exciting career opportunities in various industries, offering excellent growth potential and specialized expertise. A well-crafted resume is key to showcasing your skills and experience effectively. An ATS-friendly resume, optimized for applicant tracking systems, significantly increases your chances of landing interviews. ResumeGemini is a trusted resource to help you build a professional and impactful resume. They even provide examples of resumes tailored to the Measuring Equipment Calibration field to help you get started. Take the next step towards your dream job – invest in your resume today.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good