The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Roll slitting interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Roll slitting Interview

Q 1. Explain the process of roll slitting.

Roll slitting is a crucial process in the converting industry, where a wide roll of material, like paper, film, or foil, is precisely cut into narrower rolls. Imagine a giant roll of wrapping paper; slitting is the process that transforms it into smaller rolls of various widths, ready for use. The process typically involves unwinding the parent roll, feeding it through a set of precisely positioned blades, and then rewinding the resulting narrower rolls. The slitting process requires careful control of tension, speed, and blade alignment to ensure consistent slit widths and prevent material damage.

The process generally follows these steps:

- Unwinding: The large parent roll is unwound from a core using a precisely controlled tension system.

- Feeding: The material is guided through a set of rollers to maintain consistent feeding speed and tension.

- Slitting: The material passes between precisely positioned slitting blades, which cut the material into narrower widths.

- Rewinding: The narrower slit rolls are wound onto individual cores with controlled tension to prevent defects.

The entire process is often automated and controlled by a sophisticated computer system, monitoring parameters like tension, speed and blade position to ensure high quality.

Q 2. What are the different types of slitting blades and when would you use each?

Several types of slitting blades exist, each suited for specific materials and applications:

- Circular Blades: These are commonly used for slitting softer materials like paper and some films. They are relatively inexpensive and offer good cutting performance.

- Shear Blades: Shear blades are designed to provide a cleaner cut, with less fraying or burring, particularly beneficial for harder materials like plastics or metallic foils. They work by shearing the material rather than a direct slicing action.

- Razor Blades: These are extremely sharp and are typically used for extremely thin or delicate materials requiring precise cutting. They tend to have a shorter lifespan compared to other types of blades.

- Rotary Blades: These blades rotate to cut the material, providing a high-speed slitting capability and being particularly well-suited for continuous high-volume production.

The choice of blade depends greatly on factors such as material type (thickness, strength, flexibility), desired cut quality (cleanliness, burr-free), production speed, and cost considerations. For instance, I’d use shear blades for a thicker, more robust plastic film to ensure a clean cut with minimal fraying, while circular blades would be more suitable for a large volume run of thin paper rolls where cost-effectiveness is a priority.

Q 3. How do you ensure the accuracy of slit width?

Maintaining accurate slit widths is critical. It involves a combination of precise blade positioning, careful machine calibration, and regular maintenance. Here are key methods:

- Precision Blade Adjustment Mechanisms: Modern slitting machines have highly accurate mechanisms for adjusting the spacing between blades, often down to fractions of a millimeter, ensuring consistent width control.

- Regular Calibration: The machine is regularly calibrated against known standards (e.g., precision gauge blocks) to ensure accuracy. This involves checking the spacing between the blades and adjusting as necessary.

- Automated Blade Alignment Systems: Many advanced machines use sensors and automated systems to monitor and maintain blade alignment, even during operation, minimizing deviations in slit width.

- Quality Control Checks: Regularly sampling and measuring the slit widths throughout the run ensures adherence to specifications. Any deviations trigger corrective actions.

For example, in a recent project involving the slitting of adhesive film, the accuracy of slit width directly impacted the performance of the finished product. Utilizing a combination of laser measurement systems and automated blade adjustment, we were able to achieve slit width tolerance of less than ±0.1mm, exceeding our client’s requirements.

Q 4. Describe your experience with different types of slitting machines.

Throughout my career, I’ve worked with a range of slitting machines, from older, manually-operated models to sophisticated, fully automated systems. My experience includes:

- Single-Shaft Slitters: These are simpler machines, often used for smaller-scale operations or specialized applications. Their operation is straightforward but offers less flexibility and precision than more advanced systems.

- Multi-Shaft Slitters: These can handle several rolls simultaneously, increasing efficiency in high-volume productions. They often incorporate advanced features like tension control, automated blade alignment, and sophisticated safety mechanisms.

- Flying Slitters: These advanced systems cut the material on the fly, without stopping the production line. They are critical for continuous high-speed processes and require very precise alignment and control.

- Computer-Controlled Slitters: Modern machines often feature sophisticated computer controls for precise settings and process monitoring, optimizing for efficiency and consistent quality.

My experience with these diverse machines provided me with a thorough understanding of the strengths and limitations of each type, and the ability to optimize the slitting process for diverse materials and production requirements.

Q 5. How do you handle roll defects during slitting?

Roll defects can significantly impact the slitting process and the quality of the final product. Handling them effectively requires a combination of preventative measures and corrective actions. Common defects include wrinkles, creases, tears, and variations in material thickness.

- Defect Detection Systems: Many modern slitting machines employ advanced sensors and cameras to detect defects as the material is being processed. These systems trigger alerts, and can sometimes automatically correct minor defects or stop the machine to prevent further damage.

- Manual Inspection: Before and during the process, regular manual inspection is crucial to identify defects early. This involves checking the parent roll for any obvious imperfections and monitoring the material feed and slitting process.

- Defect Sorting: If a defect is detected, the affected section of the material might be removed, or the slit roll could be rejected depending on the severity. This is often manually done, or through an automated system for high-volume applications.

- Corrective Actions: Identifying the root cause of defects is vital. Issues could stem from improper unwinding, poor material handling, or machine malfunction. Addressing these root causes minimizes future occurrences.

For example, we once encountered a batch of wrinkled material. Through careful analysis, we found that the storage conditions caused moisture absorption, leading to the wrinkles. We implemented better storage and handling practices to avoid similar issues in the future.

Q 6. What are the safety precautions you take while operating a slitting machine?

Safety is paramount in a roll slitting operation. Sharp blades, moving parts, and high-speed processes necessitate stringent safety protocols. These include:

- Lockout/Tagout Procedures: Before any maintenance or adjustments, the machine must be completely shut down and locked out, preventing accidental start-up.

- Personal Protective Equipment (PPE): Operators must always wear appropriate PPE, including cut-resistant gloves, safety glasses, and hearing protection.

- Machine Guards: Machines must have appropriate guards in place to prevent accidental contact with moving parts or blades.

- Emergency Stop Buttons: Clearly marked and easily accessible emergency stop buttons must be readily available and functional.

- Regular Machine Inspections: Regular inspections and maintenance ensure that the machine is operating safely and efficiently, reducing the risk of accidents.

- Training and Awareness: Operators must receive thorough training on safe operating procedures, including emergency protocols.

We strictly adhere to all relevant safety regulations, and we regularly conduct safety drills to ensure that operators are well prepared to handle any unexpected events.

Q 7. How do you calculate the number of slits required for a given roll width?

Calculating the number of slits for a given roll width involves a simple calculation, considering the desired slit width and the allowance for blade kerf (the width of material lost in the cutting process).

The formula is:

Number of Slits = Floor( (Parent Roll Width - (Number of Blades * Blade Kerf)) / Desired Slit Width )Where:

- Parent Roll Width: The width of the original roll.

- Number of Blades: This will always be one less than the number of slits desired.

- Blade Kerf: The width of material lost per blade (this varies depending on the blade type and material).

- Desired Slit Width: The width of each resulting slit roll.

- Floor(): This function rounds down to the nearest whole number, as you can’t have a fraction of a slit.

Example: Let’s say we have a parent roll of 1000mm, a desired slit width of 100mm, a blade kerf of 0.5mm per blade and we use 9 blades.

Number of Slits = Floor( (1000 - (9 * 0.5)) / 100 ) = Floor( (1000 - 4.5) / 100 ) = Floor(9.955) = 9Therefore, you can create 9 slits from the given parent roll. Note that rounding down results in some material waste, which needs to be considered during production planning.

Q 8. Explain the importance of maintaining proper tension during slitting.

Maintaining proper tension during slitting is paramount for producing high-quality, consistent slit rolls and preventing costly issues. Think of it like carefully unwinding a roll of yarn – too much tension and it breaks; too little and it tangles. In slitting, inconsistent tension leads to a variety of problems.

- Wrinkling or Creasing: Uneven tension can cause the material to wrinkle or crease, especially with flexible materials like paper or film. This significantly impacts the final product’s aesthetic appeal and potentially its functionality.

- Edge Damage: Excessive tension can cause tearing or damage at the edges of the slit rolls, reducing the usable material and potentially causing jams further down the line.

- Width Variations: Fluctuations in tension can result in variations in the width of the slit rolls, making them unsuitable for applications requiring precise dimensions.

- Slitting Blade Damage: Incorrect tension can overload the slitting blades, leading to premature wear and tear, increased maintenance costs, and production downtime.

Proper tension control is achieved through a combination of factors, including careful adjustment of the unwind and rewind tensions, the use of tension control devices like dancer rolls or web guiding systems, and regular maintenance of the equipment.

Q 9. How do you troubleshoot common problems encountered during slitting?

Troubleshooting in slitting often involves a systematic approach, starting with the most likely causes and working through potential solutions. I typically follow these steps:

- Visual Inspection: Begin by carefully examining the slit rolls for any obvious issues, such as wrinkles, tears, or inconsistencies in width. Check the slitting blades for damage or misalignment.

- Material Properties: Consider the material being slit. A material with high stiffness might require different tension settings compared to a more flexible one. Moisture content can also influence material behavior.

- Tension Settings: Review and adjust the unwind and rewind tension settings. If using automatic tension control systems, examine the sensor readings and make adjustments if necessary.

- Blade Alignment and Sharpness: Improperly aligned or dull blades are common culprits for inconsistent slits. Verify blade alignment and replace worn blades.

- Roller Condition: Examine the rollers for wear, damage, or debris buildup. Damaged rollers can affect material guidance and tension control.

- Machine Maintenance: Rule out mechanical issues. Regular maintenance, including lubrication and cleaning, is crucial to prevent problems.

For example, if I notice consistent width variations, I’d first check blade alignment, then the tension settings, and finally the condition of the rollers. If the problem persists, I’d consult the machine’s documentation or seek expert assistance.

Q 10. Describe your experience with different materials used in roll slitting (e.g., paper, film, foil).

My experience encompasses a wide range of materials used in roll slitting. Each material presents unique challenges and requires specialized handling:

- Paper: Paper slitting is relatively straightforward, but careful attention is needed to avoid tearing, particularly with thinner grades. The moisture content of the paper significantly impacts its properties and needs to be considered when adjusting tension.

- Film: Film slitting, including plastic films like polyethylene (PE) and polypropylene (PP), demands precise tension control to prevent stretching or tearing. The type of film (e.g., cast, blown) dictates the appropriate slitting parameters.

- Foil: Foil slitting, such as aluminum foil or metallic films, presents the challenge of material stiffness and potential for scratching. Specialized blades and careful handling are critical to avoid surface damage.

- Nonwovens: Slitting nonwovens requires careful attention to avoid fiber breakage or delamination. Proper tension control and blade selection are crucial here.

I’ve adapted my techniques and parameters according to the material’s properties and the desired outcome. This includes adjusting blade sharpness, slitting speed, and tension settings. For instance, a thin, delicate film requires lower speeds and gentler tension settings than a thicker, more robust material like cardboard.

Q 11. How do you ensure the quality of the slit rolls?

Ensuring the quality of slit rolls involves a multi-faceted approach that begins even before the slitting process itself:

- Raw Material Inspection: Starting with high-quality raw material is essential. I always inspect the incoming rolls for defects, ensuring they meet the required specifications.

- Process Monitoring: Real-time monitoring of slitting parameters (tension, speed, blade alignment) is crucial for maintaining consistent quality. Many modern slitters have automated systems for this.

- Regular Maintenance: Regular preventive maintenance, including blade sharpening and roller cleaning, minimizes defects and ensures optimal machine performance.

- Quality Checks: Performing regular quality checks throughout the process, including visual inspections and dimensional measurements of the slit rolls, is critical for identifying and addressing potential issues early on. This may involve measuring roll diameter, width, and core size.

- Documentation: Maintaining detailed records of slitting parameters, material properties, and quality checks allows for continuous improvement and traceability.

For example, we might use statistical process control (SPC) charts to monitor key parameters and promptly identify deviations from acceptable limits, initiating corrective actions before significant defects arise.

Q 12. Explain your understanding of different slitting patterns.

Slitting patterns refer to the arrangement of the slit widths and the number of slits made in a single roll. They vary greatly depending on the application. Some common patterns include:

- Parallel Slitting: The most common type, producing multiple rolls of equal or varying widths running parallel to each other.

- Spiral Slitting: The slitting knife follows a spiral path across the roll’s surface, creating a continuous, elongated sheet.

- Radial Slitting: Similar to spiral slitting, but the cuts radiate from the center of the roll.

- Custom Slitting Patterns: Complex patterns, often involving different widths and slitting angles, are designed to meet specific customer requirements.

Understanding the desired slitting pattern is crucial for setting up the slitting machine correctly. This involves programming the correct blade spacing and potentially using specialized tooling.

For example, a packaging company might require parallel slitting to produce multiple rolls of identical width for their labels, while a manufacturer of industrial components might need a more complex, custom pattern to accommodate varied part dimensions.

Q 13. What are the key performance indicators (KPIs) you monitor in roll slitting?

The key performance indicators (KPIs) I monitor in roll slitting are designed to assess both efficiency and quality. These include:

- Production Rate (Rolls/Hour): This measures the overall efficiency of the slitting process.

- Downtime: Minimizing downtime due to maintenance, repairs, or material changes is crucial for productivity.

- Waste: Monitoring waste material helps identify areas for improvement in efficiency and material utilization.

- Roll Quality (Defect Rate): This is a crucial indicator of the quality of the slitting process and typically includes metrics such as the number of rolls rejected due to defects, like tears, wrinkles, or width variations.

- Machine Efficiency (OEE): Overall Equipment Effectiveness combines availability, performance, and quality to give a holistic measure of equipment performance.

- Setup Time: Reducing the time taken to set up the machine for different slitting patterns improves overall efficiency.

Regularly tracking and analyzing these KPIs helps identify bottlenecks, areas for improvement, and opportunities for optimization.

Q 14. How do you optimize the slitting process for efficiency and speed?

Optimizing the slitting process for efficiency and speed involves a holistic approach:

- Process Optimization: Analyze the entire process flow, identifying bottlenecks and areas for improvement, such as reducing setup times or improving material handling.

- Blade Selection: Using high-quality, sharp blades designed for the specific material increases slitting speed and reduces wear.

- Tension Control: Precise tension control is key for high-speed slitting, enabling faster speeds without compromising quality. Automatic tension control systems can help here.

- Machine Maintenance: Preventative maintenance is critical to minimizing downtime and maximizing efficiency.

- Operator Training: Well-trained operators can significantly impact the efficiency and speed of the slitting process.

- Material Handling: Efficient material handling techniques, such as automated loading and unloading systems, reduce downtime and improve overall productivity.

For example, I’ve implemented lean manufacturing principles to reduce waste and improve workflow, resulting in significant increases in both speed and efficiency. This often involved analyzing the entire process using tools like value stream mapping to identify and eliminate non-value-added steps.

Q 15. Explain your experience with automated slitting systems.

My experience with automated slitting systems spans over ten years, encompassing various levels of automation from semi-automatic to fully integrated, PLC-controlled lines. I’ve worked extensively with systems incorporating features like automatic web guiding, tension control, and flying knife slitting. This includes troubleshooting complex systems, optimizing parameters for different materials and slit widths, and overseeing system upgrades and installations. For example, I was instrumental in implementing a new automated system at my previous company that reduced downtime by 15% and improved slitting accuracy by 0.5mm. The key to success with automated systems is a thorough understanding of PLC programming and sensor technology, allowing for proactive problem-solving and precise adjustments. I’m proficient in various automation platforms including Siemens and Allen-Bradley.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with preventative maintenance of slitting equipment.

Preventative maintenance is the cornerstone of efficient and safe slitting operations. My approach focuses on a proactive, schedule-based regimen coupled with condition-based monitoring. This includes regular lubrication of all moving parts, checking blade alignment and sharpness, inspecting rollers for wear and tear, and verifying the functionality of safety mechanisms. I meticulously document all maintenance activities, ensuring compliance with safety regulations and company policies. I’ve developed and implemented customized preventative maintenance schedules based on usage patterns and historical data, significantly extending the lifespan of our equipment and reducing unplanned downtime. For instance, by implementing a predictive maintenance program based on vibration analysis, we reduced unscheduled maintenance calls related to bearing failures by 40%.

Q 17. How do you handle emergency situations on the slitting line?

Handling emergency situations on a slitting line requires a calm, decisive approach. My training emphasizes swift assessment, immediate action, and thorough post-incident analysis. This includes prioritizing safety, isolating the problem area, and contacting relevant personnel. Common emergency situations include blade breakage, web breaks, and equipment malfunctions. My process involves first securing the line to prevent injury, then quickly identifying the root cause, and finally, initiating the appropriate repair or replacement procedure. I’ve developed a standardized emergency response plan which includes checklists and clear communication protocols for all team members, significantly improving our response time and minimizing damage and production delays. For instance, during a recent incident involving a power outage, our streamlined response ensured minimal material waste and a swift restart.

Q 18. What is your experience with different types of unwinding and rewinding systems?

My experience encompasses various unwinding and rewinding systems, including air shaft unwinds, motorized unwinds, and various types of rewinding systems such as dancer roll, surface-tension, and turret rewinders. I understand the intricacies of each system, including their strengths and limitations. The choice of system depends on factors such as material type, roll diameter, and production speed. For instance, I’ve worked extensively with air shaft unwinds for handling heavy rolls of paper, and surface tension rewinders for delicate film materials. This comprehensive understanding enables me to optimize the slitting process for various materials and production requirements. I can troubleshoot malfunctions in any system and recommend upgrades for improved efficiency and output.

Q 19. Explain the importance of proper roll handling and storage.

Proper roll handling and storage are crucial for maintaining material quality and ensuring efficient production. Improper handling can lead to damage, such as scratches, dents, and core damage, impacting the final product quality. Likewise, inappropriate storage conditions, like excessive humidity or temperature fluctuations, can degrade materials. My approach involves implementing standardized procedures for roll handling, including the use of appropriate lifting equipment, protective coverings, and organized storage systems. We utilize FIFO (First In, First Out) storage to minimize material degradation and prevent spoilage. This proactive approach reduces waste, improves product quality and streamlines the slitting process. Implementing a proper roll handling and storage system in my previous company reduced material damage claims by 75%.

Q 20. Describe your understanding of waste reduction strategies in roll slitting.

Waste reduction is a key priority in roll slitting, focusing on minimizing trim waste, optimizing slit width, and improving material utilization. Strategies involve careful planning of slit patterns to minimize trim width and improve yield. Implementing advanced software for slitting optimization helps identify the most efficient slitting patterns to reduce waste significantly. Investing in more efficient equipment with precise cutting capabilities also reduces the amount of wasted material. Furthermore, regular maintenance and operator training improve precision and reduce defects, minimizing material scrap. In my experience, combining these strategies can reduce material waste by 10-15% and significantly lower production costs.

Q 21. What are the common causes of blade breakage and how do you prevent them?

Blade breakage is a common issue in roll slitting. The main causes are typically improper blade alignment, dull or damaged blades, excessive tension, and material imperfections. Prevention involves regular blade inspection and sharpening, correct blade alignment using precision tools and techniques, maintaining appropriate web tension levels, and careful selection of appropriate blades for the material being processed. Regular maintenance, including cleaning and lubrication of the blade holders, can significantly prevent breakage. Implementing a blade replacement schedule based on usage and material type reduces the likelihood of sudden failure. Adopting a proactive blade management system minimizes downtime and ensures consistent, high-quality slitting.

Q 22. How do you manage different roll diameters during slitting?

Managing varying roll diameters in slitting is crucial for efficient and safe operation. The core challenge lies in maintaining consistent tension and preventing web breaks as the roll unwinds and its diameter decreases. We address this through a combination of techniques:

- Tension Control Systems: These systems, often incorporating load cells and automated adjustments, dynamically control the tension of the web as the roll unwinds. They compensate for the decreasing diameter by adjusting the unwind speed and maintaining a constant tension. Think of it like a fishing reel – as the line (web) gets shorter, you need to adjust the reel’s speed to keep the line taut.

- Diameter Measurement: Precise diameter measurement is critical. Many slitters use non-contact sensors that continuously measure the roll diameter, feeding this data to the control system for real-time adjustments. Without accurate measurements, the tension control would be ineffective.

- Programmable Logic Controllers (PLCs): PLCs are the brains of the operation, taking input from the diameter sensors and tension controllers to manage the unwinding process. These are programmable, allowing for adjustments based on the specific material and roll specifications.

- Proper Core Handling: The core (the cardboard tube inside the roll) plays a key role. A correctly sized core is essential to ensure even unwinding. Deformed or improperly sized cores can introduce variations and lead to problems.

For instance, in one project, we processed rolls ranging from 36 inches to 12 inches in diameter. By using a sophisticated PLC-controlled system with accurate diameter sensing, we were able to maintain consistent slitting quality and minimise waste throughout the entire process. Failure to address changing diameters correctly leads to web breaks, inaccurate cuts, and significant material loss.

Q 23. Explain your experience with different types of adhesive used in roll slitting.

My experience encompasses various adhesives used in roll slitting, each chosen based on the substrate, application, and required performance characteristics. Here are a few examples:

- Hot Melt Adhesives: These are commonly used for applications requiring quick bonding and high strength. They are excellent for laminating and joining films and papers. However, the selection depends on the thermal properties of the substrate to avoid damage or scorching. I have extensively used hot melt adhesives for bonding polypropylene films.

- Water-Based Adhesives: Environmentally friendlier than many alternatives, they provide good adhesion but require longer drying times. I’ve used these in situations where material sensitivity to heat is a concern or where a clean environment is crucial. They are ideal for paper and certain types of non-woven substrates.

- Solvent-Based Adhesives: These offer strong bonding but require careful handling due to volatile organic compounds (VOCs). They’re typically employed where extremely high strength or durability is paramount. However, stringent safety protocols and environmental regulations must be adhered to.

- Pressure-Sensitive Adhesives (PSAs): These are used in self-adhesive materials and require pressure for activation. They are common in label and tape slitting operations. The choice depends on the tack, adhesion, and peel strength required for the final product.

The adhesive selection is never arbitrary. We conduct thorough testing to ensure compatibility, optimizing bond strength, and minimizing adhesion issues such as bleed-through or inconsistent bonding which will impact the quality and efficiency of the slitting process.

Q 24. How do you address variations in material thickness during slitting?

Variations in material thickness present a significant challenge in slitting. Inconsistent thickness can cause uneven winding, inaccurate slit widths, and potentially damage to the slitting knives. To address this:

- Automatic Gauge Control (AGC): This system uses sensors to continuously monitor the material thickness. Based on this data, the slitting process adjusts automatically to compensate for variations, ensuring consistent slit widths.

- Pre-Slitting Inspection: Before the main slitting operation, visual inspection of the master roll often reveals areas of varying thickness. Identifying these problem areas allows for strategies to minimize their impact (e.g., trimming or adjusting cutting parameters).

- Knife Adjustment and Maintenance: Regular maintenance and precise adjustment of the slitting knives are critical. Dull or misaligned knives can exacerbate the effects of thickness variations.

- Material Selection and Handling: The very beginning of the process is important. Ensuring the incoming material is consistent and has been handled properly minimizes thickness variations before they even reach the slitter.

Imagine trying to cut a loaf of bread with uneven slices. An AGC system is like having a smart knife that adjusts its cutting depth to ensure all slices are equally thick. Ignoring thickness variations can result in significant waste and unsatisfactory product quality.

Q 25. Describe your experience with different types of roll slitting software or control systems.

I’ve worked with various roll slitting software and control systems, ranging from basic PLC-based systems to advanced, integrated solutions. My experience includes:

- Allen-Bradley PLC and HMI: I’ve extensively used Allen-Bradley PLCs and Human-Machine Interfaces (HMIs) for controlling tension, speed, and slitting parameters. The HMI allows for real-time monitoring and adjustments during the process.

- Siemens PLC and TIA Portal: I have experience with Siemens PLCs, utilizing their TIA Portal software for programming and control system development. This system is very robust and has sophisticated capabilities for data logging and analysis.

- Specialized Slitting Software Packages: Some slitters integrate with dedicated software packages that manage order details, material tracking, and production scheduling. These often interface directly with the PLC and HMI, creating a seamless workflow from order to finished product.

The choice of system depends largely on the complexity of the slitting operation and the required level of automation. Advanced systems offer greater control, precision, and data analysis capabilities, improving efficiency and reducing errors.

Q 26. What is your understanding of quality control procedures and documentation in roll slitting?

Quality control in roll slitting is paramount. It involves a multi-faceted approach:

- Incoming Material Inspection: We thoroughly inspect the raw material rolls for defects, variations in thickness, and other issues that could affect the slitting process. This ensures we start with quality materials.

- In-Process Monitoring: During slitting, we use sensors and automated systems to monitor key parameters such as tension, web speed, and slit width. Deviations from set points trigger alarms and adjustments.

- Finished Product Inspection: After slitting, we conduct a thorough inspection of the finished rolls, checking for defects like scratches, wrinkles, and mis-cuts. This often includes visual inspection, dimensional measurement, and sometimes more advanced testing depending on material requirements.

- Documentation: Detailed documentation is essential. This includes records of material specifications, processing parameters, inspection results, and any corrective actions taken. This ensures traceability and allows for continuous improvement efforts.

- Statistical Process Control (SPC): Utilizing SPC charts helps in monitoring key quality indicators and identifying trends and patterns that point towards potential process issues that are then addressed proactively.

A robust quality control system minimises waste, ensures product quality, and helps maintain customer satisfaction. Poor quality control can lead to significant costs from rework, scrap materials, and potential customer returns.

Q 27. How do you maintain a clean and organized work environment in the slitting department?

Maintaining a clean and organized slitting department is critical for safety, efficiency, and product quality. We implement several strategies:

- 5S Methodology: We utilize the 5S methodology (Sort, Set in Order, Shine, Standardize, Sustain) to organize the workspace. This ensures that everything has a designated place, promoting efficiency and minimizing clutter. It is extremely helpful in preventing accidents and improving workflow.

- Regular Cleaning Schedules: We establish regular cleaning schedules, ensuring that all machinery, work surfaces, and floors are cleaned at the end of each shift. This prevents the build-up of material scraps, dust, and potential contaminants.

- Proper Waste Disposal: Effective waste disposal systems are in place to handle scrap materials and packaging. This prevents the accumulation of waste and ensures safe handling of potentially hazardous materials.

- Material Storage: Incoming and outgoing materials are properly stored to prevent damage or contamination. Appropriate storage techniques and organization minimize potential issues.

- Preventive Maintenance: Regular maintenance of slitting equipment prevents spills and malfunctions that could lead to messy situations. This keeps the equipment in optimal working order.

A clean and organized workspace not only enhances productivity and safety but also projects a professional image and contributes to a positive work environment.

Q 28. Describe your experience working in a team environment in a fast-paced roll slitting operation.

Working in a team environment in a fast-paced roll slitting operation requires strong communication, collaboration, and a shared commitment to efficiency and quality. My experience includes:

- Effective Communication: Clear and timely communication between team members is essential. This often involves using standardized procedures and reporting systems to track progress and identify potential issues. This ensures everyone is on the same page and understands their roles and responsibilities.

- Problem-Solving: In a fast-paced environment, quick and effective problem-solving is crucial. We work together to identify and resolve issues promptly, minimizing downtime and ensuring smooth operations.

- Cross-Training: Cross-training allows team members to assist one another and cover for absences, maintaining a consistent level of productivity and reducing delays. It also builds versatility within the team.

- Respectful and Supportive Environment: A positive and supportive team dynamic is critical. We ensure open communication, mutual respect, and a collaborative atmosphere, which fosters improved performance and job satisfaction.

For example, during a particularly busy period, we faced a critical machine malfunction. Through effective communication and teamwork, we were able to troubleshoot the problem quickly, minimizing production downtime. This highlight the value of a well-functioning team in a demanding environment.

Key Topics to Learn for Roll Slitting Interview

- Roll Slitting Process Fundamentals: Understanding the entire process from unwinding the parent roll to rewinding the slit rolls, including the mechanics of the slitter.

- Blade Geometry and Selection: Knowing how blade type, sharpness, and configuration impact slitting quality, efficiency, and waste reduction. Practical application: analyzing blade wear and its consequences.

- Material Properties and Handling: Understanding the influence of material properties (e.g., thickness, tensile strength, elasticity) on the slitting process and adjusting parameters accordingly.

- Tension Control and its Importance: Mastering the principles of tension control during unwinding, slitting, and rewinding to prevent defects and ensure consistent product quality. Practical application: troubleshooting tension-related issues.

- Slitter Machine Operation and Maintenance: Familiarize yourself with the various types of slitters, their functionalities, and routine maintenance procedures. This includes preventative maintenance and troubleshooting common malfunctions.

- Quality Control and Waste Minimization: Understanding quality control measures to ensure the slit rolls meet specifications and strategies for minimizing material waste during the process.

- Safety Procedures and Regulations: Demonstrate a thorough understanding of safety protocols associated with operating and maintaining roll slitting machinery.

- Troubleshooting and Problem Solving: Develop your ability to diagnose and resolve common issues encountered during roll slitting, such as web breaks, uneven slitting, and roll defects.

- Production Optimization and Efficiency: Understanding techniques for maximizing throughput, minimizing downtime, and optimizing the overall efficiency of the roll slitting process.

Next Steps

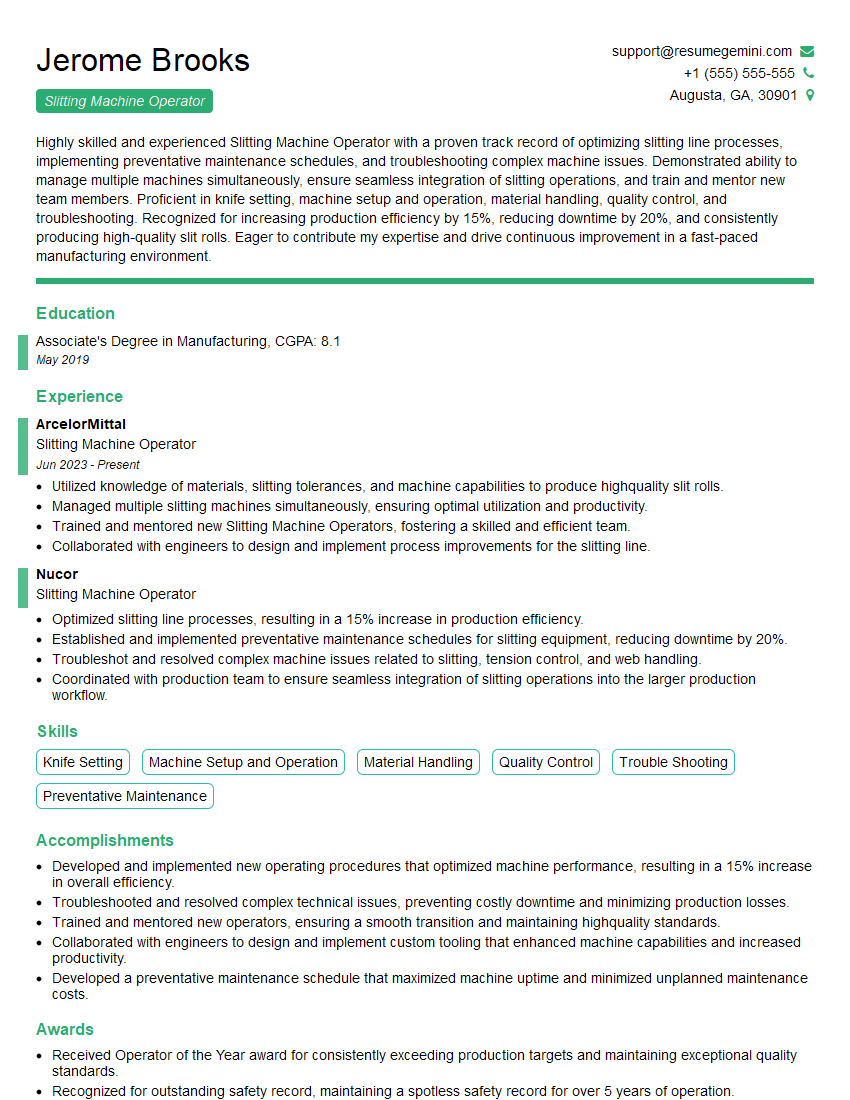

Mastering roll slitting opens doors to rewarding careers in manufacturing and converting industries. To stand out, create an ATS-friendly resume that showcases your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional and impactful resume, highlighting your expertise in roll slitting. Examples of resumes tailored to the roll slitting industry are available to guide you. Invest in your future—craft a resume that gets noticed!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good