Unlock your full potential by mastering the most common Preventive Maintenance and Equipment Troubleshooting interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Preventive Maintenance and Equipment Troubleshooting Interview

Q 1. Describe your experience with different types of preventive maintenance schedules (e.g., PM, PdM, RCM).

Preventive maintenance (PM) schedules aim to prevent equipment failures through regular inspections and servicing. I have extensive experience with various types, including:

- Time-Based PM: This involves performing maintenance at fixed intervals (e.g., every 1000 operating hours or every six months). It’s simple to implement but might lead to unnecessary maintenance for well-performing equipment or insufficient maintenance for equipment under heavy stress. For example, I’ve used this schedule successfully for maintaining conveyor belts in a warehouse, lubricating them and inspecting for wear at set intervals.

- Condition-Based PM (CbPM) or Predictive Maintenance (PdM): This involves monitoring the equipment’s condition using sensors or other diagnostic tools to determine when maintenance is truly needed. This is much more efficient and cost-effective than time-based PM. For instance, I’ve implemented vibration analysis on critical pumps to predict bearing failures before they occur, avoiding costly downtime.

- Reliability-Centered Maintenance (RCM): This is a more sophisticated approach that focuses on identifying the failure modes and their effects on the equipment and the overall system. It prioritizes maintenance tasks based on the potential consequences of failure and the cost of preventing it. I’ve led RCM studies on complex processing equipment, identifying critical components and developing tailored maintenance plans to minimize the risk of catastrophic failures and maximize uptime.

My experience encompasses adapting these schedules to diverse industrial settings, considering factors like equipment criticality, cost of maintenance, and the potential consequences of failure.

Q 2. Explain the difference between predictive, preventive, and corrective maintenance.

The three maintenance strategies—corrective, preventive, and predictive—differ significantly in their approach to equipment maintenance.

- Corrective Maintenance: This is reactive; repairs are only performed after a failure occurs. Think of it as putting out fires. While it’s unavoidable to some extent, it’s the most expensive and disruptive. A simple example is fixing a broken pump after it fails, leading to production downtime.

- Preventive Maintenance: This is proactive; maintenance is performed at scheduled intervals to prevent failures. It’s like regular car servicing. This reduces the likelihood of failures but might still lead to unnecessary maintenance if equipment’s condition is not thoroughly assessed.

- Predictive Maintenance: This is the most advanced approach; maintenance is scheduled based on real-time equipment condition monitoring. It’s like having a doctor perform regular checkups to detect and address health issues before they become severe. This approach allows for precise timing of maintenance, minimizing unnecessary downtime and resource consumption.

In practice, a blended approach, combining elements of all three, often yields the best results, balancing cost and risk.

Q 3. How do you prioritize maintenance tasks in a high-pressure environment?

Prioritizing maintenance tasks under pressure requires a structured approach. I typically use a combination of techniques, including:

- Criticality Analysis: I assess the impact of each equipment failure on production, safety, and overall operations. Critical equipment receives top priority. This involves considering the potential cost of downtime, safety risks, and impact on production targets.

- Risk Assessment: This involves evaluating the likelihood of failure for each piece of equipment, and the potential severity of the consequences of a failure. I use this to create a risk matrix, prioritizing equipment and tasks based on both likelihood and severity.

- Urgency/Importance Matrix: This matrix helps to categorize tasks based on their urgency and importance. This helps to ensure that the most urgent tasks are addressed promptly while still considering the importance of each task in the long term.

- CMMS System Integration: A well-maintained CMMS system allows efficient scheduling and tracking of work orders, facilitating prioritization based on various criteria. I’ve used this to effectively manage hundreds of maintenance requests simultaneously.

In a high-pressure environment, clear communication and teamwork are essential. Regular updates and transparent decision-making help to keep everyone informed and engaged.

Q 4. What CMMS systems are you familiar with? Describe your experience using them.

I’m proficient in several CMMS (Computerized Maintenance Management System) platforms, including SAP PM, Maximo, and UpKeep. My experience ranges from system implementation and configuration to daily usage for work order management, preventative maintenance scheduling, inventory control, and reporting.

In SAP PM, for instance, I’ve successfully configured and customized maintenance plans for large-scale industrial facilities, integrating them with other ERP modules. In Maximo, I’ve worked on optimizing work order routing and resource allocation to reduce response times and improve efficiency. UpKeep, being a cloud-based system, has been instrumental in streamlining communication and providing real-time insights into equipment performance across multiple sites. In each case, I’ve focused on leveraging the system’s features to enhance maintenance effectiveness and reduce overall maintenance costs.

Q 5. Describe your experience with root cause analysis techniques (e.g., 5 Whys, Fishbone diagram).

Root cause analysis (RCA) is crucial for preventing recurring equipment failures. I’m experienced with several techniques, including:

- 5 Whys: This iterative questioning technique helps to drill down to the root cause of a problem by repeatedly asking “Why?” until the underlying issue is identified. For example, if a pump fails, the 5 Whys might reveal a lack of proper lubrication as the root cause.

- Fishbone Diagram (Ishikawa Diagram): This visual tool helps to identify potential contributing factors to a problem by categorizing them into various categories (e.g., manpower, machinery, materials, methods, environment). It provides a structured way to brainstorm and explore multiple potential causes.

I always ensure proper documentation of RCA findings to prevent future incidents. Implementing corrective actions based on the root cause analysis is critical to avoid repetition.

Q 6. How do you troubleshoot electrical faults in industrial equipment?

Troubleshooting electrical faults requires a systematic approach and safety precautions. I always start with a visual inspection, checking for obvious signs of damage like burnt wires, loose connections, or corrosion. Next, I use appropriate testing equipment like multimeters, insulation testers, and clamp meters to diagnose the problem.

My process typically involves:

- Isolating the faulty circuit: This involves switching off power to the affected equipment and using test equipment to pinpoint the location of the fault.

- Testing components: Testing individual components like motors, relays, sensors, and wiring harnesses with a multimeter to identify shorts, opens, or other abnormalities.

- Checking control circuits: Examining PLC programs, control wiring, and safety interlocks for programming errors or malfunctions.

- Analyzing waveform patterns (oscilloscopes): For more complex issues, an oscilloscope can be helpful in analyzing voltage and current waveforms to detect intermittent faults or unusual patterns.

Safety is paramount. I always follow lockout/tagout procedures before working on any electrical equipment.

Q 7. How do you troubleshoot mechanical faults in industrial equipment?

Troubleshooting mechanical faults is also a systematic process, often starting with a visual inspection to identify obvious issues like leaks, wear, or misalignment.

My approach typically involves:

- Identify symptoms: Determine the specific problem, such as excessive vibration, unusual noise, or loss of power. This may involve observing the equipment in operation and collecting data like vibration readings.

- Inspect components: Check for wear and tear on bearings, seals, gears, belts, and other components. This often requires using tools such as dial indicators or stroboscopes for precise measurements and observations.

- Check lubrication: Ensure proper lubrication and check for leaks or contamination. Insufficient or improper lubrication is a common cause of mechanical failures.

- Analyze vibration: If excessive vibration is present, vibration analysis is critical. Vibration analysis tools can help to identify the source and severity of the vibration, allowing for targeted repairs.

- Check alignment: Misalignment of shafts, gears, or other rotating components is also a frequent cause of mechanical problems. Precision measurement tools are used to ensure proper alignment.

Once the root cause is identified, appropriate repairs are performed using the correct tools and techniques, followed by testing to ensure the problem is resolved. Thorough documentation of the fault, repair, and lessons learned is crucial for future prevention.

Q 8. Explain your experience with hydraulic and pneumatic systems troubleshooting.

My experience with hydraulic and pneumatic systems troubleshooting spans over ten years, encompassing diverse industrial settings. I’m proficient in diagnosing and resolving issues related to leaks, pressure drops, component failures, and control system malfunctions. Troubleshooting these systems requires a systematic approach. For instance, in a hydraulic system, a pressure drop might indicate a leak in a hose, a faulty pump, or a problem with a valve. I begin by visually inspecting the system for obvious leaks or damage. Then, I use pressure gauges and other diagnostic tools to pinpoint the exact location and cause of the pressure drop. Similarly, in a pneumatic system, I’d look for air leaks using soapy water, check for blockages in the lines, and test the functionality of valves and actuators. My approach always involves understanding the system’s schematic and applying my knowledge of fluid mechanics and control theory.

For example, I once diagnosed a recurring pressure drop in a hydraulic press used for forging. Initial visual inspection revealed no leaks. By carefully analyzing the system’s pressure readings at different points, I discovered a gradual deterioration of the pump’s seals. Replacing the seals resolved the issue permanently. Understanding the pressure-flow relationships inherent to both hydraulic and pneumatic systems is key to effectively resolving such issues.

Q 9. What safety protocols do you follow during maintenance and troubleshooting?

Safety is paramount in all maintenance and troubleshooting activities. My approach adheres strictly to a multi-layered safety protocol. This begins with a thorough risk assessment, identifying potential hazards such as high-pressure systems, energized equipment, and hazardous materials. I always utilize the appropriate personal protective equipment (PPE), including safety glasses, gloves, hearing protection, and safety shoes. Furthermore, I ensure the equipment is properly locked out and tagged out before any maintenance or repair work begins. This procedure prevents accidental start-up and potential injuries. Regular training on safety procedures and emergency response ensures I’m up-to-date on best practices. I also maintain a clear communication channel with colleagues to inform them of ongoing maintenance and potential risks.

For example, before working on a high-pressure hydraulic system, I would ensure that the system is depressurized completely and verified with a pressure gauge. I’d then lock out and tag out the power source, preventing any accidental operation. This ensures that no one can inadvertently turn on the equipment while I’m working on it.

Q 10. How do you identify and address potential safety hazards during maintenance?

Identifying and addressing potential safety hazards requires a proactive and meticulous approach. I start by conducting a thorough visual inspection of the equipment and its surroundings. This helps identify obvious hazards, such as exposed wires, damaged components, or leaking fluids. Then, I consult the equipment’s safety data sheets (SDS) and relevant regulations to understand potential chemical hazards or other safety-related concerns. I also consider environmental factors, such as poor lighting or slippery surfaces, that can increase the risk of accidents. Once potential hazards are identified, I implement control measures, including using PPE, setting up barricades, using proper ventilation, or employing other safety protocols to mitigate the risks.

For instance, when working on a machine with rotating parts, I’d ensure that the machine is properly locked out and tagged out, and that appropriate guards are in place. If dealing with potentially hazardous chemicals, I would ensure proper ventilation and wear the correct PPE, as stipulated in the SDS.

Q 11. Describe your experience with interpreting equipment schematics and technical manuals.

Interpreting equipment schematics and technical manuals is a critical skill for effective troubleshooting. I’m proficient in reading various types of schematics, including hydraulic, pneumatic, electrical, and mechanical diagrams. I understand how these diagrams represent the physical layout and functional relationships within a system. Technical manuals provide valuable insights into the equipment’s operation, maintenance procedures, and troubleshooting guides. My ability to interpret these documents allows me to quickly identify components, trace signal paths, and understand the overall system architecture. I’m also comfortable using computer-aided design (CAD) software to visualize and analyze complex systems.

For example, using a hydraulic schematic, I can trace the path of hydraulic fluid from the reservoir to the actuator, identifying valves, filters, and other components along the way. This allows me to pinpoint potential points of failure based on observed symptoms.

Q 12. How do you document maintenance activities and findings?

Accurate and thorough documentation is crucial for maintaining equipment history and facilitating future maintenance. I meticulously document all maintenance activities and findings using a combination of digital and paper-based methods. This includes creating detailed work orders that clearly describe the work performed, parts replaced, and any observations or recommendations. I also use digital tools for recording data, including sensor readings, images, and videos, as well as software for generating reports and tracking maintenance schedules. My documentation style prioritizes clarity and conciseness, ensuring that all relevant information is easily accessible for future reference.

Typical documentation includes details like date, time, equipment ID, problem description, troubleshooting steps, parts used, and final resolution. I also include any photos or videos that would help illustrate the problem and its solution. This detailed record-keeping is essential for tracking trends, identifying recurring problems, and planning preventative maintenance strategies.

Q 13. Explain your experience working with different types of sensors and instrumentation.

My experience encompasses a wide range of sensors and instrumentation used in industrial settings. This includes pressure sensors, temperature sensors, flow sensors, proximity sensors, level sensors, and various types of actuators. I’m familiar with both analog and digital signal processing, and understand how to interpret sensor readings to diagnose equipment malfunctions. I’m also proficient in calibrating and troubleshooting sensors to ensure accurate measurements. Understanding the principles of sensor operation, including their limitations and potential sources of error, is crucial for accurate diagnostics.

For instance, if a temperature sensor in a furnace is malfunctioning, I would first check the sensor’s wiring and connections, then use a calibration tool to verify its accuracy. If necessary, I would replace the sensor with a known good one. Understanding the different types of sensors and their respective applications allows me to select the correct sensor for a given application and interpret its output accurately.

Q 14. Describe a time you had to troubleshoot a complex equipment failure. What steps did you take?

One time, I encountered a complex failure in a large industrial conveyor system. The system suddenly stopped operating, causing significant production downtime. The initial diagnosis pointed towards a potential motor failure, but after careful inspection, I ruled that out. My systematic approach began with reviewing the system’s schematics and reviewing the maintenance logs. I systematically checked each component, starting with the power supply and moving sequentially through the control system. I used multimeters to test voltage and current levels, and found that the problem originated not in the main motor, but a smaller auxiliary motor responsible for tensioning the conveyor belt. This motor had overloaded, tripping a safety circuit breaker, which wasn’t immediately obvious.

The solution involved not only replacing the auxiliary motor but also investigating why it had overloaded. Through further investigation and analysis of the operational data, we identified that the conveyor belt had been improperly aligned, resulting in increased friction and stress on the auxiliary motor. By realigning the belt, we not only resolved the immediate issue but also prevented future occurrences. This experience highlighted the importance of a systematic approach, careful analysis of data, and considering all possible causes before concluding a diagnosis.

Q 15. How do you determine the root cause of recurring equipment failures?

Pinpointing the root cause of recurring equipment failures requires a systematic approach. It’s not enough to simply fix the immediate problem; we need to understand why it failed in the first place. My process typically involves these steps:

Data Collection: I meticulously gather data from various sources – maintenance logs, operator reports, sensor readings (temperature, vibration, pressure), and even visual inspections. The more data, the better the chance of identifying patterns.

Failure Analysis: Once the data is collected, I analyze it to identify trends and commonalities. For example, repeated failures might point to a design flaw, inadequate lubrication, or operator error. I often use Pareto charts to visualize the frequency of different failure modes.

5 Whys Analysis: This powerful technique helps delve deeper into the cause. By repeatedly asking ‘why’ (at least five times), we can uncover the underlying root cause. For instance, if a pump fails due to overheating (1st why), we ask why it overheated (2nd why), leading to potential issues with inadequate cooling (3rd why), which might be caused by clogged filters (4th why), eventually identifying poor filter maintenance as the root cause (5th why).

Corrective Actions: Based on the root cause analysis, I develop and implement corrective actions. These actions might involve design modifications, improved maintenance procedures, operator training, or replacement of faulty components. It is crucial to document these actions thoroughly.

Verification: After implementing the corrective actions, I monitor the equipment closely to verify their effectiveness and ensure the problem is truly resolved. This often involves setting up appropriate key performance indicators (KPIs) to track the impact of the changes.

For instance, I once investigated recurring failures in a conveyor system. Through data analysis and the 5 Whys method, we discovered that improper lubrication, due to insufficient training for maintenance personnel, was the culprit. Implementing targeted training and improving lubrication schedules completely eradicated the problem.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the key performance indicators (KPIs) you use to measure the effectiveness of maintenance programs?

Effective maintenance programs are measured through various KPIs. These metrics provide insights into the program’s efficiency, effectiveness, and overall impact on operational performance. Here are some key KPIs I utilize:

Mean Time Between Failures (MTBF): This measures the average time between equipment failures. A higher MTBF indicates improved reliability.

Mean Time To Repair (MTTR): This measures the average time required to repair failed equipment. A lower MTTR suggests more efficient maintenance processes.

Overall Equipment Effectiveness (OEE): This holistic metric considers availability, performance, and quality to assess the overall efficiency of the equipment.

Maintenance Costs: Tracking maintenance costs helps assess the efficiency and effectiveness of the program. This includes labor, parts, and other associated expenses.

Safety Incidents: A critical KPI is the number of safety incidents related to maintenance activities. A low number indicates a safe and effective maintenance program.

Preventive Maintenance Compliance Rate: This KPI measures the percentage of scheduled preventive maintenance tasks completed on time. A high compliance rate indicates a well-managed and disciplined program.

By tracking these KPIs regularly, we can identify areas for improvement and optimize our maintenance strategies. For example, a consistently high MTTR might indicate a need for better training, improved parts inventory management, or updated maintenance procedures.

Q 17. How do you manage spare parts inventory for your maintenance program?

Spare parts inventory management is crucial for minimizing downtime and ensuring efficient maintenance. I use a combination of strategies:

ABC Analysis: This categorizes parts based on their criticality and usage. ‘A’ items (high-value, frequently used) require tight control, ‘B’ items (medium-value, moderately used) need moderate control, and ‘C’ items (low-value, infrequently used) require minimal control. This helps prioritize inventory management efforts.

Economic Order Quantity (EOQ): This model helps determine the optimal order quantity for minimizing inventory holding costs and ordering costs. It considers factors like demand, ordering costs, and storage costs. Software tools can automate these calculations.

Just-in-Time (JIT) Inventory: For less critical parts, a JIT approach can minimize storage space and reduce holding costs. This involves ordering parts only when they’re needed.

Vendor Managed Inventory (VMI): For frequently used parts, I work with vendors to manage inventory levels directly. They monitor usage, replenish stock, and ensure a consistent supply.

Regular Inventory Audits: Periodic audits are crucial for verifying stock levels, identifying obsolete parts, and detecting discrepancies.

For example, in a previous role, we implemented an ABC analysis and significantly reduced inventory costs by optimizing stock levels for ‘C’ items, while ensuring adequate stock for critical ‘A’ items. Using EOQ helped find the sweet spot to balance ordering and storage costs for ‘B’ category items.

Q 18. Describe your experience with lubrication and oil analysis.

Lubrication is fundamental to equipment reliability, and oil analysis provides valuable insights into equipment condition. My experience encompasses both aspects:

Lubrication Management: I’m proficient in developing and implementing lubrication schedules based on equipment manufacturer recommendations and industry best practices. This includes selecting the appropriate lubricants, implementing proper lubrication techniques (e.g., grease gun usage, oil change procedures), and maintaining detailed lubrication records.

Oil Analysis: I regularly utilize oil analysis to monitor the condition of lubricating oil. This involves collecting oil samples, sending them to a laboratory for analysis, and interpreting the results. Key parameters include viscosity, acidity, particle contamination, and the presence of wear metals. Significant deviations from baseline values can indicate potential problems, such as excessive wear, contamination, or lubricant degradation.

For example, in a previous project involving heavy machinery, regular oil analysis identified increased wear metal concentration in the hydraulic oil of an excavator. This early warning allowed for timely repairs, preventing a catastrophic failure and significant downtime.

Q 19. How do you ensure compliance with regulatory standards and safety regulations during maintenance?

Ensuring compliance with regulatory standards and safety regulations during maintenance is paramount. My approach is multifaceted:

Lockout/Tagout (LOTO) Procedures: I strictly enforce LOTO procedures to prevent accidental equipment start-up during maintenance. This involves properly isolating energy sources and using appropriate lockout devices.

Permit-to-Work Systems: For high-risk activities, I use permit-to-work systems to ensure that all necessary safety precautions are in place before commencing work. This involves authorizations from relevant personnel and detailed risk assessments.

Safety Training: I ensure that all maintenance personnel receive thorough training on relevant safety regulations, hazard identification, and safe work practices. Regular refresher courses are conducted.

Personal Protective Equipment (PPE): I enforce the use of appropriate PPE, such as safety glasses, gloves, hearing protection, and hard hats, to minimize the risk of injuries.

Regular Inspections: I conduct regular inspections of the workplace and equipment to identify potential hazards and ensure compliance with safety standards.

Documentation: I maintain detailed records of all maintenance activities, including safety procedures followed, to demonstrate compliance.

For instance, we implemented a comprehensive LOTO program in our facility, significantly reducing the risk of accidents and ensuring regulatory compliance.

Q 20. How familiar are you with vibration analysis and its application in predictive maintenance?

Vibration analysis is a powerful predictive maintenance technique. I have extensive experience in its application:

Data Acquisition: I use handheld or permanently mounted vibration sensors to collect vibration data from rotating equipment (motors, pumps, fans, etc.). The data is often acquired using specialized data collectors.

Data Analysis: The collected data is analyzed to identify characteristic vibration frequencies and amplitudes. This analysis can reveal potential problems like imbalance, misalignment, bearing defects, or looseness. Software packages are commonly used for spectral analysis and identifying fault signatures.

Trend Analysis: I track changes in vibration levels over time to identify emerging problems before they lead to major failures. This allows for proactive maintenance and prevents unexpected downtime.

For instance, using vibration analysis, I detected a subtle bearing defect in a critical pump long before it resulted in a failure. This allowed for a planned replacement, minimizing downtime and avoiding expensive emergency repairs. The software helped pinpoint the specific bearing to change and reduced downtime considerably.

Q 21. What are your experiences with thermal imaging and its application to preventive maintenance?

Thermal imaging is another valuable tool in preventive maintenance. It allows for the detection of overheating components, which often precede equipment failures:

Inspection Techniques: I use thermal cameras to scan equipment and identify areas of excessive heat. This can reveal problems such as loose connections, insulation failures, bearing defects, and electrical faults. Proper technique involves understanding emissivity and making adjustments when necessary.

Data Interpretation: Thermal images provide visual representation of temperature variations. I analyze these images to identify hotspots and compare temperatures to baseline values or manufacturer recommendations. Significant deviations indicate potential problems.

Preventive Actions: By identifying overheating components early, I can implement corrective actions to prevent failures. This might involve tightening connections, replacing faulty insulation, or repairing damaged bearings.

In a recent application, thermal imaging revealed an overheating electrical connection in a motor control panel. This was not detectable through conventional inspection methods. Addressing this issue prevented a potential fire hazard and subsequent equipment failure.

Q 22. How do you handle situations where equipment malfunctions lead to production downtime?

My approach to equipment malfunctions causing production downtime is systematic and prioritizes rapid resolution while minimizing further damage. First, I immediately assess the situation: is it a complete shutdown, or a partial reduction in output? What are the safety implications? I then follow a structured troubleshooting process. This involves:

- Safety First: Securing the area and ensuring the safety of personnel is paramount.

- Data Gathering: Collecting all relevant data – error codes, sensor readings, operator observations – to understand the root cause.

- Preliminary Diagnosis: Based on the gathered data, I form a hypothesis about the cause of the malfunction. For example, if a conveyor belt stops, I might suspect a motor failure, a sensor malfunction, or a power supply issue.

- Verification & Testing: I systematically test my hypothesis through visual inspection, component testing, and diagnostic tools. This might involve checking power connections, fuses, motor windings, or sensor readings.

- Repair or Replacement: Once the problem is identified, I prioritize the quickest, safest solution. This could involve repairing a faulty component, replacing a broken part, or implementing a temporary workaround to restore partial functionality.

- Root Cause Analysis (RCA): After the immediate issue is resolved, I conduct a thorough RCA to prevent future occurrences. This involves identifying underlying factors such as inadequate lubrication, operator error, or design flaws. I document my findings for future reference.

- Reporting and Documentation: I meticulously document the entire process, including the fault, troubleshooting steps, repairs made, and the RCA, for analysis and future improvements.

For instance, during my time at Acme Manufacturing, a sudden power surge caused a critical CNC machine to malfunction. Following this protocol, we quickly identified a blown fuse, replaced it, and restored production within 30 minutes. The RCA revealed a weakness in the power protection system, leading to upgrades that prevented similar incidents.

Q 23. What are some common causes of equipment failure in your field of experience?

Equipment failures stem from various sources. In my experience, some of the most common include:

- Wear and Tear: Mechanical components naturally degrade over time due to friction, vibration, and stress. Bearings, belts, gears, and seals often require regular replacement.

- Lubrication Issues: Inadequate lubrication leads to increased friction, overheating, and premature wear. This is especially critical for rotating machinery.

- Environmental Factors: Extreme temperatures, humidity, dust, and corrosive substances can significantly impact equipment lifespan and performance. Proper environmental controls and protective measures are essential.

- Improper Operation: Operator error, such as overloading equipment or neglecting safety procedures, can lead to malfunctions and damage.

- Electrical Failures: Short circuits, faulty wiring, and power fluctuations can damage electrical components, leading to malfunctions or complete shutdowns.

- Fluid Contamination: Contaminants in hydraulic or lubricating fluids can cause premature wear and damage to critical components.

- Design Flaws: Sometimes, equipment malfunctions arise from inherent design weaknesses or limitations not identified during the manufacturing process.

For example, in a previous role, repeated failures of a specific pump were traced to inadequate filtration of the hydraulic fluid. Implementing a more robust filtration system significantly reduced the frequency of failures and associated downtime.

Q 24. How do you balance preventive maintenance with the need to keep production running?

Balancing preventive maintenance (PM) with production demands is crucial for maximizing efficiency and minimizing downtime. A well-structured PM program proactively addresses potential issues *before* they disrupt operations. The key is optimization. This involves:

- Prioritization: Critical equipment requiring minimal downtime for maintenance receives higher priority for PM activities. We use a risk-based approach, categorizing equipment by its criticality and the potential impact of failure.

- Scheduling: PM tasks are scheduled during off-peak production hours or planned maintenance windows to minimize interference with operations. This requires careful coordination with production scheduling teams.

- Preventive Task Optimization: PM tasks themselves are optimized to minimize time and resource consumption. This includes using efficient techniques, utilizing advanced diagnostic tools, and improving the overall maintenance process.

- Predictive Maintenance: Utilizing advanced techniques like vibration analysis, oil analysis, and thermal imaging can help predict potential failures *before* they occur. This allows for targeted maintenance interventions, reducing the need for extensive unscheduled downtime.

- Continuous Improvement: Regular review and analysis of PM data are essential to improve the program’s effectiveness, adjust schedules, and optimize resource allocation. This could involve analyzing MTTR (Mean Time To Repair) and MTBF (Mean Time Between Failures) data.

Think of it like regular car maintenance. Regular oil changes and inspections help prevent major breakdowns and extend the car’s life. Similarly, a well-structured PM program for equipment minimizes costly and disruptive failures.

Q 25. Describe your experience with developing and implementing preventive maintenance plans.

I have extensive experience in developing and implementing preventive maintenance plans. My approach starts with a thorough assessment of the equipment inventory, focusing on criticality and failure modes. Then:

- Equipment Analysis: I analyze each piece of equipment to determine its maintenance requirements, including lubrication schedules, component inspections, and replacement intervals. Manufacturer recommendations and historical data are crucial resources.

- Task Definition: Specific PM tasks are defined, including detailed procedures, required tools, and safety precautions. This ensures consistency and accuracy in maintenance execution.

- Schedule Creation: A comprehensive PM schedule is developed, considering equipment criticality, production schedules, and resource availability. This often involves utilizing Computerized Maintenance Management Systems (CMMS).

- Resource Allocation: The necessary resources, including personnel, tools, spare parts, and materials, are allocated to ensure the successful execution of the PM plan. This includes forecasting spare parts needs to prevent delays.

- Training and Documentation: Maintenance technicians receive thorough training on the PM procedures and the use of any specialized tools or equipment. Clear and detailed documentation is essential for consistency and knowledge transfer.

- Implementation and Monitoring: The PM plan is implemented, and key metrics, such as downtime, repair costs, and equipment availability, are closely monitored to evaluate its effectiveness. Regular review and adjustments are made as needed.

In my previous role, I developed a PM program that reduced equipment downtime by 15% within the first year. This involved implementing a CMMS, optimizing task schedules, and improving communication between maintenance and production teams.

Q 26. How do you use data analysis to improve the effectiveness of maintenance programs?

Data analysis is crucial for improving the effectiveness of maintenance programs. By leveraging data from various sources, including CMMS, sensor readings, and historical maintenance records, we can gain valuable insights into equipment performance and identify areas for improvement. My approach involves:

- Data Collection: Gathering data on equipment performance, including run time, downtime, maintenance history, and failure modes. This involves integrating data from various sources into a central database.

- Data Analysis: Using statistical methods and data visualization tools to identify trends, patterns, and anomalies in equipment performance. This might include analyzing MTTR, MTBF, and overall equipment effectiveness (OEE).

- Predictive Modeling: Using historical data to develop predictive models that anticipate potential equipment failures. This allows for proactive maintenance interventions, minimizing unexpected downtime.

- Root Cause Analysis: Using data analysis to identify the root causes of equipment failures. This helps to prevent similar failures in the future and improve the overall reliability of the equipment.

- Performance Monitoring: Continuously monitoring key performance indicators (KPIs) to track the effectiveness of maintenance programs and identify areas for improvement.

For example, by analyzing historical data on pump failures, we identified a correlation between pump failures and ambient temperature. This led to implementing temperature control measures, significantly reducing pump failures and associated downtime.

Q 27. Describe your experience with training and mentoring other maintenance technicians.

I have a strong track record of training and mentoring other maintenance technicians. My approach is hands-on and focuses on both theoretical knowledge and practical skills development. I believe in:

- On-the-Job Training: Pairing new technicians with experienced personnel for hands-on learning and mentorship. This provides practical experience and allows for immediate feedback.

- Structured Training Programs: Developing and delivering structured training programs covering various aspects of maintenance, including safety procedures, troubleshooting techniques, and equipment-specific knowledge.

- Mentorship and Coaching: Providing ongoing mentorship and coaching to help technicians develop their skills, problem-solving abilities, and leadership potential. This often involves regular one-on-one sessions to discuss challenges and career goals.

- Knowledge Sharing: Fostering a culture of knowledge sharing and collaboration among team members. This can involve sharing best practices, troubleshooting techniques, and lessons learned.

- Continuous Learning: Encouraging continuous learning and professional development through workshops, conferences, and online courses.

I’ve successfully trained and mentored several junior technicians, helping them progress to senior roles within the organization. My approach has consistently resulted in improved team performance and reduced maintenance errors.

Q 28. How do you stay up-to-date with the latest technologies and best practices in maintenance?

Staying up-to-date in the rapidly evolving field of maintenance requires continuous learning and engagement. My strategy involves:

- Professional Organizations: Active membership in professional organizations such as the Society for Maintenance & Reliability Professionals (SMRP) to access resources, publications, and networking opportunities.

- Industry Publications and Journals: Regularly reading industry publications and journals to stay informed about the latest technologies and best practices. This keeps me abreast of new equipment and maintenance techniques.

- Conferences and Workshops: Attending industry conferences and workshops to learn from experts and network with peers. This allows for first-hand exposure to advanced maintenance strategies and technologies.

- Online Courses and Webinars: Utilizing online learning platforms and webinars to acquire knowledge in specific areas of maintenance, such as predictive maintenance, CMMS software, or advanced diagnostic techniques.

- Manufacturer Training: Participating in training programs offered by equipment manufacturers to gain in-depth knowledge of specific equipment and its maintenance requirements.

By combining these methods, I ensure that my knowledge and skills remain current, enabling me to implement the most effective and efficient maintenance strategies.

Key Topics to Learn for Preventive Maintenance and Equipment Troubleshooting Interview

- Preventive Maintenance Schedules & Planning: Understanding the creation and implementation of effective PM schedules, including frequency analysis, resource allocation, and risk assessment.

- Root Cause Analysis (RCA) Techniques: Applying methods like the 5 Whys, Fishbone diagrams, and Fault Tree Analysis to pinpoint the underlying causes of equipment failures and prevent recurrence.

- Predictive Maintenance Strategies: Utilizing technologies like vibration analysis, infrared thermography, and oil analysis to predict potential equipment failures before they occur.

- Equipment Specific Knowledge: Demonstrating a thorough understanding of the machinery and systems relevant to the target role (e.g., hydraulic systems, electrical systems, pneumatic systems).

- Maintenance Documentation & Reporting: Accurately recording maintenance activities, generating reports, and using CMMS (Computerized Maintenance Management Systems) effectively.

- Safety Procedures & Regulations: Highlighting knowledge of relevant safety protocols, lockout/tagout procedures, and industry regulations (OSHA, etc.).

- Troubleshooting Methodologies: Explaining systematic approaches to diagnosing and resolving equipment malfunctions, including the use of diagnostic tools and manuals.

- Cost-Benefit Analysis of Maintenance Strategies: Evaluating the economic impact of different maintenance approaches and justifying decisions based on ROI (Return on Investment).

- Continuous Improvement Initiatives: Discussing the importance of implementing continuous improvement processes to optimize maintenance practices and reduce downtime.

Next Steps

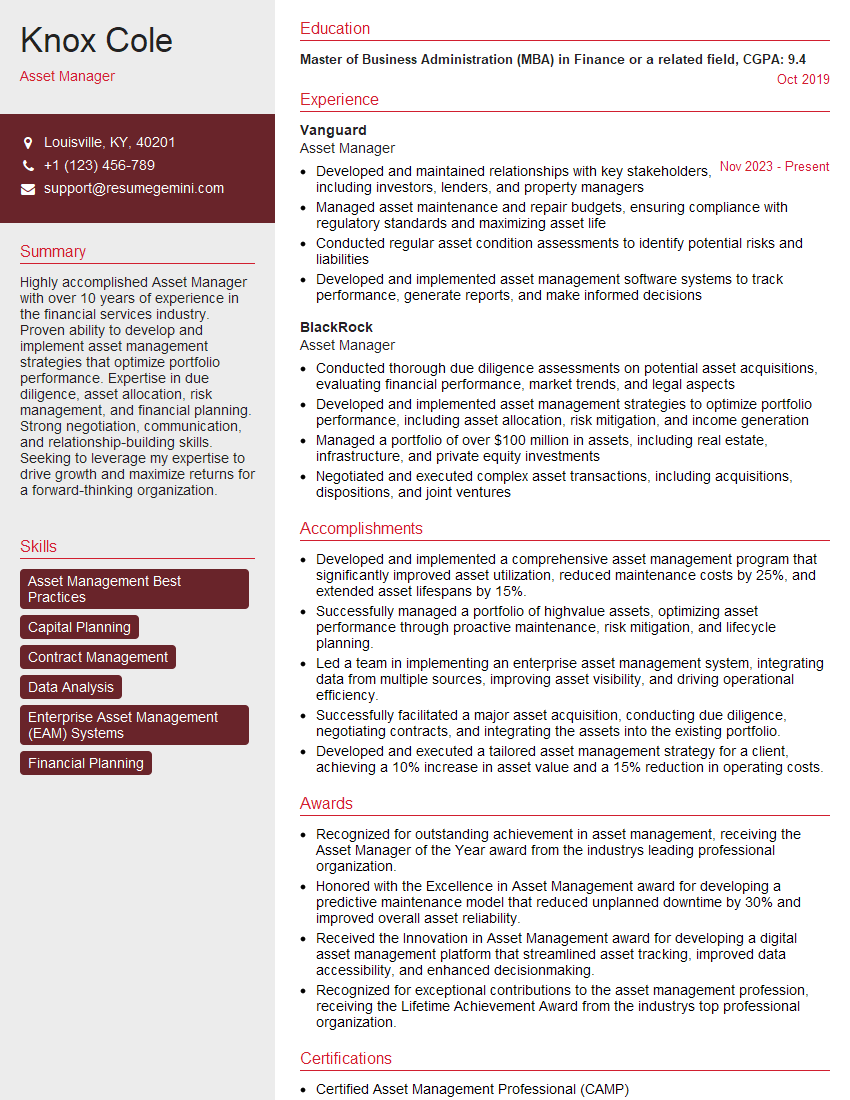

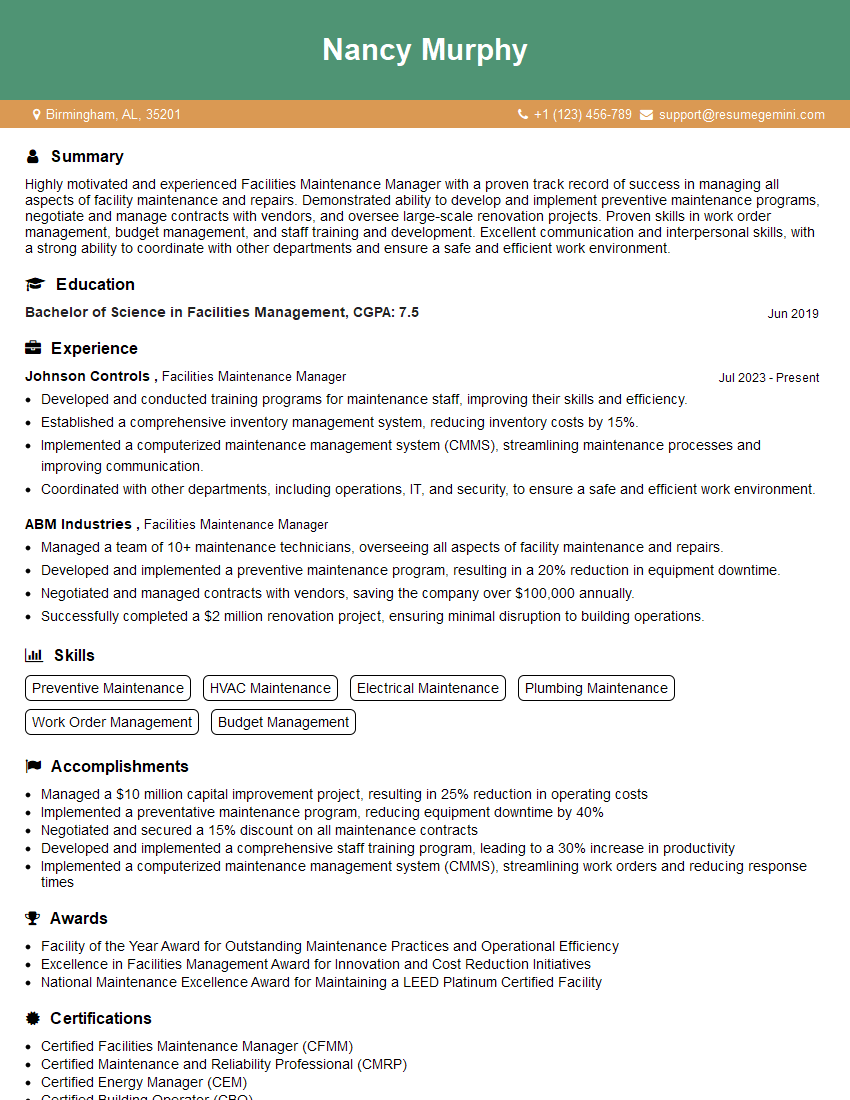

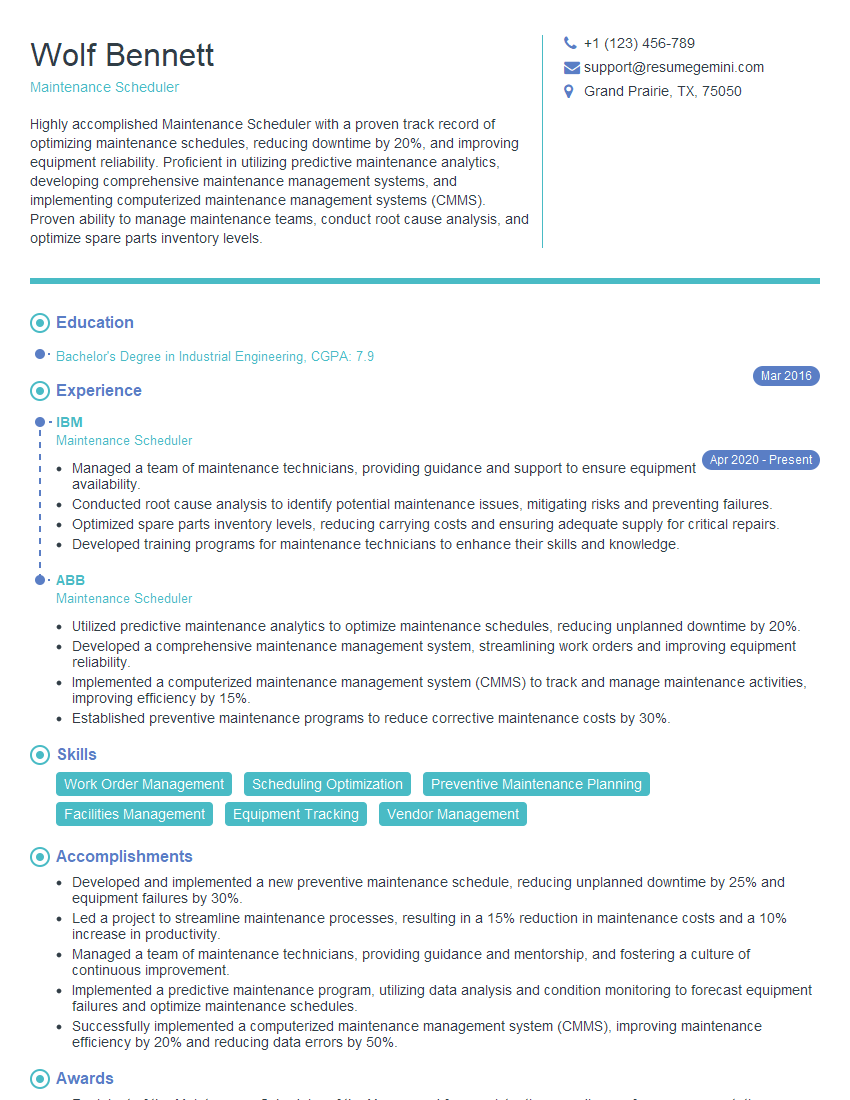

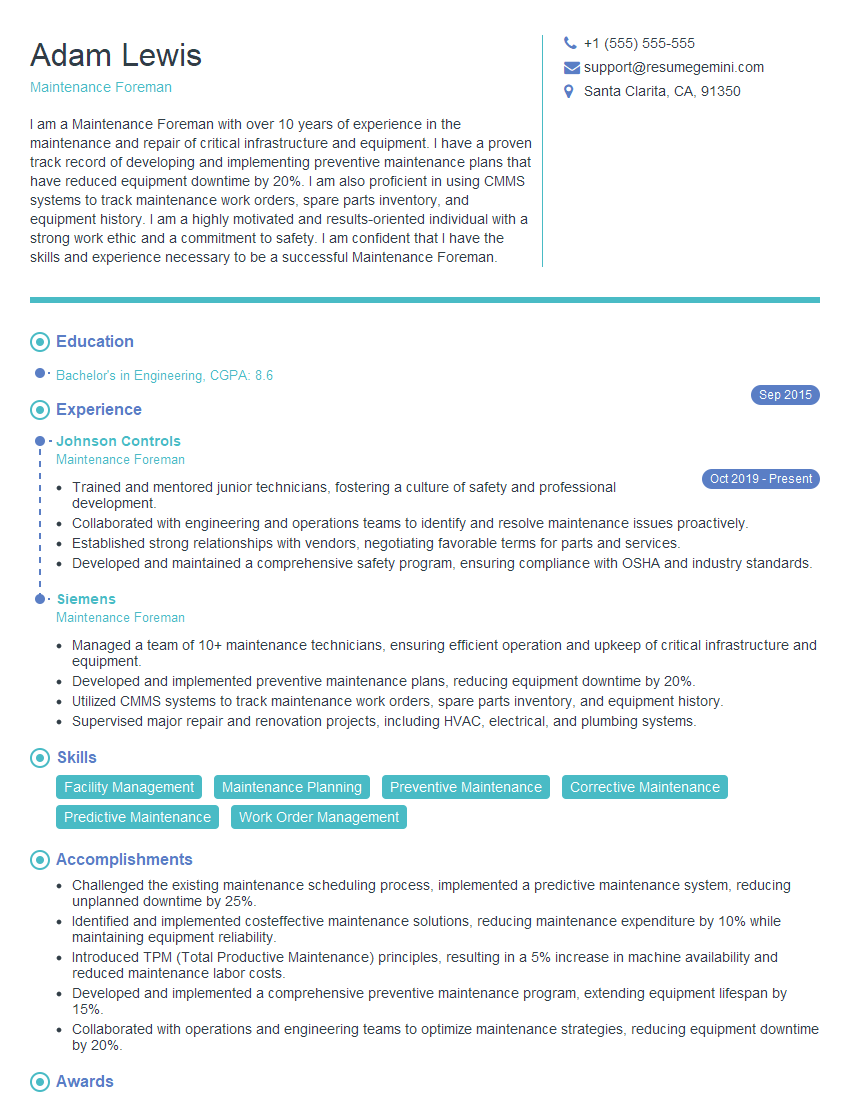

Mastering Preventive Maintenance and Equipment Troubleshooting is crucial for career advancement in today’s competitive industrial landscape. Proficiency in these areas directly translates to increased efficiency, reduced operational costs, and improved safety. To stand out from other candidates, it’s essential to present your skills effectively. Creating an ATS-friendly resume is key to ensuring your application gets noticed by recruiters. We highly recommend using ResumeGemini to build a professional and impactful resume that showcases your expertise in Preventive Maintenance and Equipment Troubleshooting. ResumeGemini offers examples of resumes tailored to this specific field to guide you through the process. Invest time in crafting a compelling resume – it’s your first impression and a significant step towards securing your dream role.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi I am a troller at The aquatic interview center and I suddenly went so fast in Roblox and it was gone when I reset.

Hi,

Business owners spend hours every week worrying about their website—or avoiding it because it feels overwhelming.

We’d like to take that off your plate:

$69/month. Everything handled.

Our team will:

Design a custom website—or completely overhaul your current one

Take care of hosting as an option

Handle edits and improvements—up to 60 minutes of work included every month

No setup fees, no annual commitments. Just a site that makes a strong first impression.

Find out if it’s right for you:

https://websolutionsgenius.com/awardwinningwebsites

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good