Are you ready to stand out in your next interview? Understanding and preparing for Instrumentation and Equipment Maintenance interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Instrumentation and Equipment Maintenance Interview

Q 1. Explain the difference between preventative and corrective maintenance.

Preventative maintenance and corrective maintenance are two fundamental approaches to ensuring the smooth operation of instrumentation and equipment. Think of it like this: preventative maintenance is like regularly servicing your car to prevent breakdowns, while corrective maintenance is fixing a flat tire after it’s already happened.

Preventative Maintenance: This involves scheduled inspections, cleaning, lubrication, and part replacements to prevent equipment failure. It’s proactive and aims to extend the lifespan of equipment, reducing downtime and unexpected repairs. A classic example is replacing filters in a process control system according to a pre-defined schedule, preventing them from clogging and affecting the accuracy of readings.

Corrective Maintenance: This is reactive maintenance performed after a piece of equipment has failed. It involves diagnosing the problem, repairing or replacing faulty components, and restoring the equipment to operational status. For instance, if a pressure sensor fails and the process shuts down, corrective maintenance involves identifying the cause of the failure (e.g., a damaged sensor, wiring issue), replacing the sensor, and restarting the process.

The key difference lies in the timing and approach. Preventative maintenance is scheduled and avoids problems, while corrective maintenance addresses problems after they’ve occurred. A well-balanced maintenance program utilizes both approaches strategically.

Q 2. Describe your experience with troubleshooting malfunctioning instrumentation.

Troubleshooting malfunctioning instrumentation is a core part of my expertise. I approach it systematically, using a blend of technical knowledge, diagnostic tools, and experience. My process typically involves the following steps:

- Gather Information: Start by identifying the specific problem. What isn’t working? What are the error messages or abnormal readings? Understanding the context is crucial. For example, is the malfunction intermittent or continuous? Does it affect other parts of the system?

- Visual Inspection: Carefully examine the instrument and its connections for any obvious problems like loose wires, corrosion, or physical damage.

- Utilize Diagnostic Tools: Employ instruments like multimeters, loop calibrators, and specialized diagnostic software to obtain data about the instrument’s performance. This helps narrow down potential causes.

- Consult Documentation: Reference the instrument’s manuals, schematics, and loop diagrams to understand its operational principles and troubleshooting guides.

- Systematic Elimination: Based on gathered data and documentation, eliminate potential causes one by one. This might involve checking sensor readings, signal transmission paths, and power supply integrity.

- Calibration and Adjustment: Once the problem is identified, calibration or minor adjustments may be necessary to restore accuracy and functionality.

For example, I once resolved a persistent temperature measurement inaccuracy in a critical process by systematically checking the thermocouple, its wiring, the signal conditioning unit, and finally discovering a drift in the transmitter’s calibration. A simple recalibration solved the problem, averting significant production downtime.

Q 3. What are the common causes of instrument drift and how do you address them?

Instrument drift, the gradual deviation of an instrument’s output from its true value, is a common issue. Several factors can contribute to this:

- Environmental Factors: Temperature fluctuations, humidity changes, and vibrations can all affect sensor performance and lead to drift. For example, a temperature sensor might provide inaccurate readings if exposed to significant ambient temperature changes.

- Component Aging: Over time, components within the instrument can degrade, causing the instrument’s output to drift. This is particularly true for electronic components that have a limited lifespan.

- Calibration Degradation: Calibration, a crucial step in ensuring accuracy, can degrade over time. The instrument needs recalibration to ensure it remains within specified tolerances.

- Power Supply Issues: Fluctuations or instability in the power supply can affect the instrument’s performance, resulting in drift.

Addressing instrument drift involves several strategies:

- Regular Calibration: Implementing a robust calibration schedule ensures that the instrument remains within its acceptable accuracy limits.

- Environmental Control: Maintaining stable environmental conditions minimizes the impact of external factors on the instrument’s performance.

- Preventive Maintenance: Regular inspections and preventative maintenance help identify and address potential issues before they lead to significant drift.

- Component Replacement: Replacing aging or degraded components can prevent or reduce drift. This is especially crucial for sensors and other critical components.

Q 4. How familiar are you with various calibration techniques?

I am proficient in various calibration techniques, ranging from simple manual methods to sophisticated automated systems. My experience encompasses:

- Manual Calibration: This involves using precision instruments like calibrators and standards to manually adjust the instrument’s output to match known values. This is often suitable for simpler instruments and sensors.

- Automated Calibration: Automated calibration systems use software and specialized equipment to perform calibration processes more efficiently and accurately. These systems automate the testing and adjustment of instruments, significantly speeding up the process and reducing human error.

- In-situ Calibration: This method calibrates the instrument while it remains installed in the process. This reduces the downtime caused by removing the instrument for calibration.

- Multipoint Calibration: This method involves calibrating the instrument at multiple points across its measurement range, providing a more accurate and comprehensive calibration.

Understanding the specific calibration requirements for different instruments and sensors is crucial. For example, a pressure sensor will require different calibration techniques than a flow meter. The choice of calibration technique depends on factors such as the instrument’s type, accuracy requirements, and available resources.

Q 5. Explain your experience with different types of sensors (e.g., pressure, temperature, flow).

My experience with sensors encompasses a wide range of types, including pressure, temperature, and flow sensors, used in various industrial applications. I’m familiar with their operational principles, selection criteria, troubleshooting, and calibration.

- Pressure Sensors: I have worked extensively with different types of pressure sensors, including diaphragm sensors, piezoelectric sensors, and capacitive sensors. I understand the importance of selecting the appropriate sensor based on the pressure range, accuracy requirements, and the process environment. Troubleshooting involves checking for leaks, signal integrity, and sensor calibration.

- Temperature Sensors: My experience includes working with thermocouples, RTDs (Resistance Temperature Detectors), and thermistors. Understanding their characteristics, selection criteria, and signal conditioning is essential for accurate temperature measurement. Troubleshooting often involves checking for wire breaks, correct connection type, and sensor calibration.

- Flow Sensors: I have experience with various flow measurement technologies, such as orifice plates, rotameters, and ultrasonic flow meters. Understanding the principles of each type is key to selecting the appropriate sensor for the application and troubleshooting related problems such as sensor fouling or incorrect installation.

My practical experience involves handling situations like sensor drift, incorrect readings, and complete sensor failures. I utilize a systematic troubleshooting approach to diagnose these issues efficiently, ensuring minimal downtime and accurate process control.

Q 6. Describe your experience with Programmable Logic Controllers (PLCs).

I have extensive experience with Programmable Logic Controllers (PLCs) in industrial automation. I understand their programming, configuration, troubleshooting, and integration with other industrial equipment. My expertise includes:

- PLC Programming: I am proficient in various PLC programming languages, including Ladder Logic, Function Block Diagrams (FBDs), and Structured Text (ST). I can design, implement, and debug PLC programs for various industrial applications.

- PLC Hardware: I am familiar with the architecture and operation of various PLC platforms, including their input/output modules, communication interfaces, and power supplies.

- Troubleshooting: I can effectively troubleshoot PLC-related problems using diagnostic tools and techniques. This includes identifying and resolving issues in the program, hardware, and communication networks.

- Integration: I have experience integrating PLCs with other industrial equipment, such as sensors, actuators, and HMIs (Human-Machine Interfaces).

In one project, I successfully optimized a PLC program for a packaging line, improving its efficiency by 15% and reducing downtime by 10%. This involved analyzing the existing program, identifying bottlenecks, and implementing changes to improve the overall control logic.

Q 7. How do you prioritize maintenance tasks in a high-pressure environment?

Prioritizing maintenance tasks in a high-pressure environment requires a structured approach that balances urgency and criticality. I use a combination of methods to effectively manage this:

- Risk Assessment: Assessing the potential impact of equipment failure helps prioritize tasks based on their criticality. This involves identifying the potential consequences of failure (e.g., safety hazards, production downtime, environmental damage).

- Urgency Assessment: Determining the urgency of each task helps identify those needing immediate attention. Equipment exhibiting immediate signs of failure or those critical for safety need higher priority.

- Maintenance Scheduling Software: Utilizing specialized software helps manage and schedule maintenance tasks effectively, considering factors such as work order completion time, resource availability, and criticality.

- CMMS (Computerized Maintenance Management System): This system is used for managing and tracking maintenance tasks, and generating work orders based on scheduled or unplanned maintenance activities.

- Communication and Coordination: In high-pressure environments, clear communication and coordination with the operations team are essential to ensure effective task scheduling and execution.

For example, in a refinery setting, I might prioritize fixing a leak in a high-pressure pipeline immediately over calibrating a less-critical flow meter. This decision-making process minimizes risk and ensures operational safety. The use of a CMMS helps to track this prioritization and schedule tasks effectively.

Q 8. What safety protocols do you follow when working with industrial equipment?

Safety is paramount in industrial settings. My approach to safety when working with industrial equipment is multi-layered and begins before I even touch the equipment. It involves a thorough risk assessment, adhering to lockout/tagout (LOTO) procedures, using appropriate personal protective equipment (PPE), and strictly following the manufacturer’s operating instructions.

- Risk Assessment: Before commencing any work, I carefully assess potential hazards, including electrical shock, moving parts, high-pressure systems, and hazardous materials. This involves identifying the potential risks, evaluating their likelihood and severity, and determining appropriate control measures.

- Lockout/Tagout (LOTO): LOTO is a crucial safety procedure to prevent unexpected energy release. I always isolate the equipment’s power source (electrical, pneumatic, hydraulic) and apply locks and tags to ensure no one can inadvertently restart the equipment while I’m working on it. This includes documenting who locked out the equipment, the time it was locked out, and the work being performed.

- Personal Protective Equipment (PPE): I consistently use appropriate PPE, such as safety glasses, gloves, hearing protection, steel-toe boots, and sometimes specialized clothing like flame-resistant garments, depending on the task and equipment.

- Following Manufacturer Instructions: I always consult the manufacturer’s manuals and operating procedures for the specific equipment. These provide critical details on safe operating practices, maintenance procedures, and emergency shutdowns.

For example, during a recent valve replacement, I performed a complete LOTO on the system before beginning any disassembly. This prevented a potential release of hazardous chemicals during the procedure. My adherence to safety protocols has resulted in a zero-incident record throughout my career.

Q 9. Describe your experience with different types of valves and actuators.

I have extensive experience with various valve types, including gate valves, globe valves, ball valves, butterfly valves, and check valves. I’m also familiar with different actuator types like pneumatic, hydraulic, and electric actuators. The selection of the right valve and actuator depends heavily on the application and the fluid being controlled.

- Valve Types: Gate valves are excellent for on/off service, while globe valves are better for flow regulation. Ball valves provide quick on/off action, and butterfly valves are often used for larger diameter lines. Check valves prevent backflow. I understand the strengths and weaknesses of each type and can recommend the most appropriate one for a given process.

- Actuator Types: Pneumatic actuators are cost-effective and simple, but require a compressed air supply. Hydraulic actuators provide high force and precise control, but are more complex. Electric actuators offer precise control and are often integrated with control systems, allowing for remote operation and monitoring.

In a recent project, I was tasked with improving the efficiency of a chemical processing plant. By replacing outdated globe valves with more efficient ball valves and installing electric actuators with automated control, we reduced cycle times and minimized manual intervention. The change also improved data acquisition which made predictive maintenance easier.

Q 10. Explain your understanding of loop tuning and control strategies.

Loop tuning is the process of adjusting the control parameters of a control loop to achieve optimal performance. Control strategies dictate how the loop will react to process variations. My understanding encompasses various tuning methods and control strategies.

- Tuning Methods: Common methods include Ziegler-Nichols, Cohen-Coon, and others which utilize responses from the process. These methods involve systematically adjusting parameters like proportional gain (Kp), integral gain (Ki), and derivative gain (Kd) to minimize overshoot, settling time, and offset. The choice of method depends on the process dynamics.

- Control Strategies: PID (Proportional-Integral-Derivative) control is the most common strategy. Proportional control addresses immediate deviations, integral control eliminates offset, and derivative control anticipates future deviations. Other strategies include cascade control, feedforward control, and ratio control, which are selected based on the complexity of the process.

For instance, I once worked on a temperature control loop in a refinery. The initial tuning resulted in significant overshoot and oscillations. By using the Ziegler-Nichols method and carefully adjusting the PID gains, I was able to optimize the loop, reducing energy consumption and improving process stability. This required a thorough understanding of the system’s dynamics and the selection of a suitable control strategy.

Q 11. How do you handle equipment failure during critical operations?

Equipment failure during critical operations requires a swift and methodical response. My approach involves prioritizing safety, assessing the situation, implementing immediate corrective actions, and then initiating a root cause analysis to prevent future occurrences.

- Safety First: The immediate priority is ensuring the safety of personnel and the environment. This may involve shutting down the affected system, evacuating personnel, or activating emergency response protocols.

- Assessment and Corrective Actions: I conduct a rapid assessment to determine the nature and extent of the failure. This often includes visually inspecting the equipment, checking relevant instrumentation, and reviewing process parameters. Immediate corrective actions are then implemented to mitigate the impact of the failure, which may include switching to backup systems or implementing temporary workarounds.

- Root Cause Analysis: After stabilizing the situation, a thorough root cause analysis is conducted to identify the underlying causes of the failure. This often involves reviewing maintenance logs, inspecting the failed components, and interviewing operating personnel. The goal is to identify systemic issues and prevent similar failures in the future.

For example, during a sudden compressor trip, I immediately implemented emergency shutdown procedures, preventing further damage. Through investigation, we found a worn bearing was the culprit. Corrective actions included immediate bearing replacement and a review of the preventive maintenance schedule to ensure more frequent bearing inspections.

Q 12. What experience do you have with documentation and maintenance logs?

Accurate and comprehensive documentation is vital for effective equipment maintenance. My experience involves maintaining detailed maintenance logs, creating equipment specifications, and generating reports using various methods.

- Maintenance Logs: I meticulously document all maintenance activities, including work performed, parts replaced, time spent, and any observations related to equipment condition. This information is critical for tracking equipment history, predicting potential failures, and optimizing maintenance schedules. I use both digital and paper-based systems, depending on the context.

- Equipment Specifications: I’m experienced in creating and updating equipment specifications, including diagrams, schematics, and parts lists. This information is essential for procurement, maintenance, and troubleshooting. My experience includes working with CAD software to create accurate drawings and utilizing databases to track equipment information.

- Reporting: I can generate reports on equipment performance, maintenance costs, and downtime. This data helps assess the efficiency of maintenance programs and identify areas for improvement. I’m proficient in using various software tools for data analysis and report generation.

In my previous role, I implemented a new computerized system for tracking maintenance activities, which significantly improved the accuracy and accessibility of maintenance records. This streamlined reporting and allowed for more data-driven decision-making regarding maintenance schedules and resource allocation.

Q 13. Explain your experience with predictive maintenance techniques.

Predictive maintenance uses data analysis to anticipate equipment failures before they occur, minimizing downtime and improving operational efficiency. My experience includes utilizing various predictive maintenance techniques.

- Vibration Analysis: Analyzing vibration data from equipment can reveal imbalances, misalignment, wear, or other issues that could lead to failures. I use specialized sensors and software to collect and interpret vibration data.

- Infrared Thermography: Infrared cameras detect heat signatures which can indicate overheating components, potential insulation problems, or other problems that could lead to equipment failure. Early detection allows for preventative maintenance.

- Oil Analysis: Regularly analyzing oil samples can reveal the presence of contaminants, wear particles, or other indicators of impending failure. This provides valuable insight into the condition of lubricated components.

- Data Analytics: I employ data analytics to identify patterns and trends within maintenance data, allowing for more accurate predictions of equipment failure. This includes using statistical methods and machine learning techniques.

For example, through vibration analysis on a large pump, we detected an imbalance before it caused a catastrophic failure. This prevented significant downtime and costly repairs. The predictive maintenance program I implemented resulted in a significant reduction in unplanned downtime and improved overall equipment effectiveness.

Q 14. Describe your experience using CMMS (Computerized Maintenance Management Systems).

CMMS (Computerized Maintenance Management Systems) are software applications designed to manage and optimize maintenance activities. I have experience using several CMMS platforms, including [mention specific CMMS software if comfortable – e.g., SAP PM, Maximo, or other industry-standard software].

- Work Order Management: I use CMMS to create, assign, track, and close work orders efficiently. This ensures timely completion of maintenance tasks and helps manage resources effectively.

- Inventory Management: CMMS allows for effective tracking of spare parts and inventory levels, reducing the risk of stockouts and optimizing procurement processes. This ensures parts are available when needed, reducing downtime.

- Preventative Maintenance Scheduling: CMMS helps schedule preventative maintenance tasks based on equipment history, manufacturer recommendations, and predictive maintenance data. This optimizes equipment lifespan and minimizes unplanned downtime.

- Reporting and Analytics: CMMS generates reports on various aspects of maintenance activities, including costs, downtime, and equipment performance. This data is essential for continuous improvement of maintenance strategies.

In a previous role, I implemented a new CMMS system to replace a paper-based system. This resulted in significant improvements in work order tracking, inventory management, and reporting. The improved data accuracy and accessibility also facilitated better decision-making regarding maintenance strategies and resource allocation.

Q 15. How familiar are you with different types of industrial communication protocols (e.g., Profibus, Modbus)?

Industrial communication protocols are the backbone of modern instrumentation systems, allowing various devices to communicate and exchange data. My familiarity spans several widely used protocols, including:

- Profibus: A fieldbus system commonly used in process automation for high-speed data transmission and real-time control. I’ve worked extensively with Profibus DP (Decentralized Peripherals) and Profibus PA (Process Automation) in various plant environments, troubleshooting communication errors and configuring devices.

- Modbus: A simpler, widely adopted protocol known for its ease of implementation and open standard. I’ve used Modbus RTU (Remote Terminal Unit) and Modbus TCP (Transmission Control Protocol) for integrating various sensors, actuators, and PLCs (Programmable Logic Controllers) into supervisory control systems. For example, I once used Modbus TCP to integrate a third-party temperature monitoring system into our existing SCADA system.

- Other protocols: My experience also includes working with Ethernet/IP, Foundation Fieldbus, and HART (Highway Addressable Remote Transducer) protocols, depending on the specific instrumentation and control systems employed.

Understanding these protocols allows me to effectively diagnose communication problems, optimize data exchange, and select the appropriate communication infrastructure for new projects.

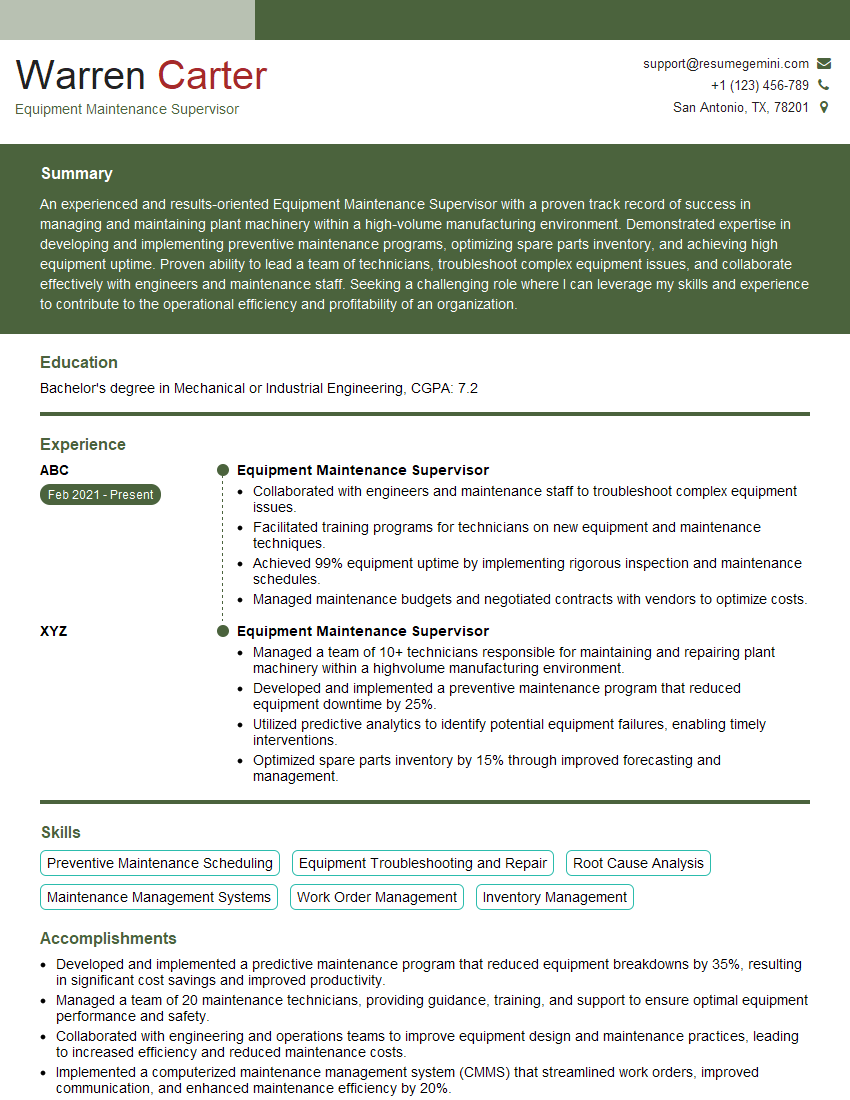

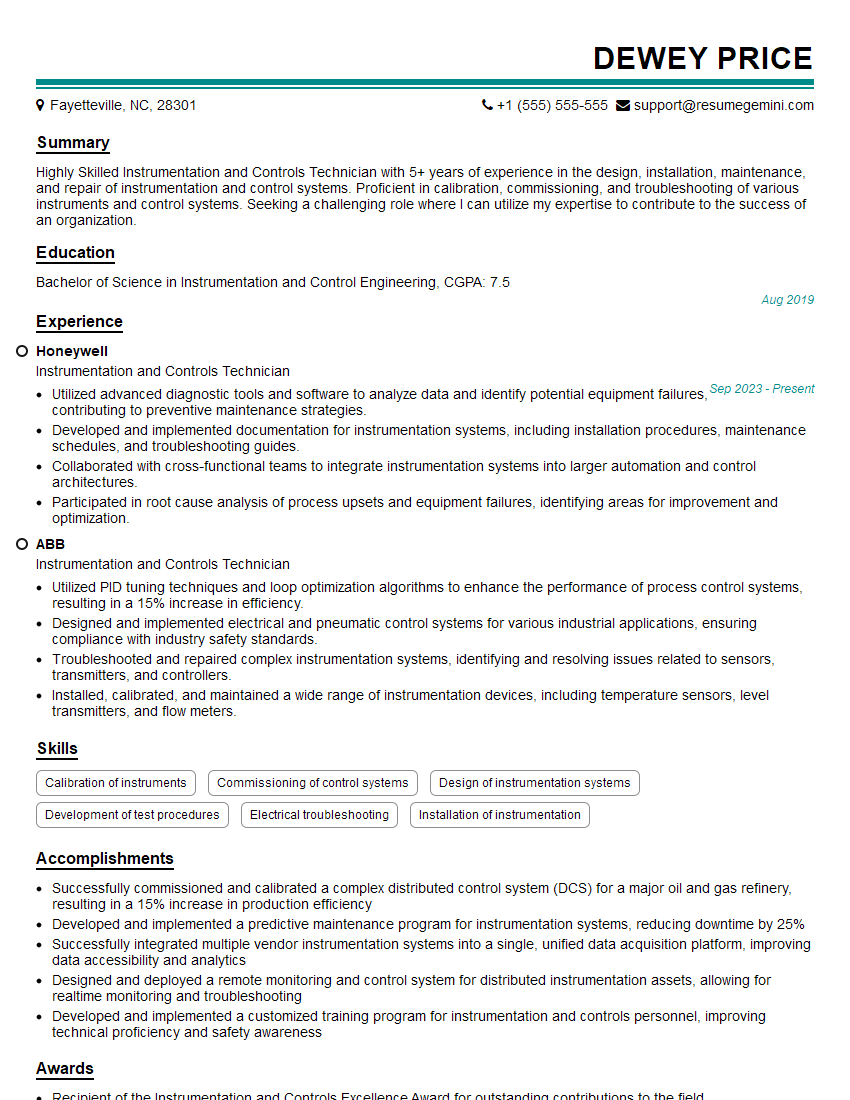

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure the accuracy and reliability of instrumentation readings?

Ensuring accuracy and reliability of instrumentation readings is paramount for effective process control and safe operation. This involves a multi-faceted approach:

- Calibration and Verification: Regular calibration against traceable standards is essential. This ensures readings are within acceptable tolerance limits. We use certified calibration equipment and maintain detailed calibration records to comply with industry standards and regulatory requirements. For instance, I recently recalibrated all flow meters in a chemical processing unit, significantly improving the accuracy of production calculations.

- Regular Maintenance: Preventative maintenance, such as cleaning sensors, checking connections, and replacing worn parts, minimizes errors caused by physical degradation. A preventative maintenance schedule significantly reduces unexpected instrument failures.

- Signal Conditioning: Proper signal conditioning is crucial to eliminate noise and interference. This might involve using filters, amplifiers, and isolation techniques to ensure the signal accurately represents the measured parameter. I once resolved a persistent signal noise problem in a level sensor by installing a proper grounding system.

- Data Validation: Implementing checks and alerts in the control system to detect outliers and inconsistencies in readings provides real-time monitoring and alerts for anomalies. Having a clear understanding of the process parameters aids in determining the credibility of readings.

Combining these strategies ensures that instrumentation consistently provides reliable and accurate data, leading to improved process control and decision-making.

Q 17. Explain your experience with root cause analysis in maintenance.

Root cause analysis (RCA) is a systematic approach to identifying the underlying causes of equipment failures or process deviations, not just the symptoms. My approach typically follows the 5 Whys method, combined with fault tree analysis (FTA) for more complex situations.

Example: During a recent shutdown, a critical valve failed to close properly, leading to a significant process upset. Instead of simply replacing the valve, I used the 5 Whys to investigate:

- Why did the valve fail to close? – Because the actuator failed.

- Why did the actuator fail? – Because the internal gear stripped.

- Why did the gear strip? – Because of excessive wear.

- Why was there excessive wear? – Due to insufficient lubrication.

- Why was there insufficient lubrication? – Because the lubrication schedule wasn’t properly followed.

This revealed the root cause: inadequate lubrication procedures. Addressing this through improved training and a revised maintenance schedule prevented future occurrences, rather than just replacing a faulty component. In more complex scenarios, a Fault Tree Analysis would allow a systematic mapping of all potential causes leading to the failure.

Q 18. Describe a challenging maintenance project and how you overcame it.

One challenging project involved the complete overhaul of an aging ammonia refrigeration system in a food processing plant. The system was critical for maintaining product quality, and downtime was extremely costly. The challenges included aging components, limited space for work, and the inherent dangers of working with ammonia.

My approach involved:

- Detailed Planning: We created a comprehensive project plan, including risk assessments, detailed work schedules, and a spare parts inventory list.

- Phased Approach: We implemented a phased approach, working on sections of the system sequentially to minimize downtime and maintain a safe working environment.

- Collaboration: Close collaboration with the plant’s operations team ensured minimal disruption to production and facilitated effective communication.

- Problem-Solving: We encountered several unexpected issues, such as finding obsolete parts, which required creative solutions, such as finding replacement parts from different vendors and adapting them to fit.

Through meticulous planning, effective teamwork, and creative problem-solving, we successfully completed the project ahead of schedule and within budget, demonstrating that a thorough and methodical approach is crucial when dealing with intricate and high-risk systems.

Q 19. What are your troubleshooting skills for electrical and mechanical issues in instrumentation?

My troubleshooting skills encompass both electrical and mechanical aspects of instrumentation. I approach troubleshooting systematically, using a combination of diagnostic tools and analytical thinking.

Electrical Issues: I use multimeters, oscilloscopes, and loop testers to diagnose problems such as faulty wiring, short circuits, and signal interference. For example, I once diagnosed a faulty thermocouple by using a multimeter to check for continuity and a signal tracing method to identify the break in the wiring.

Mechanical Issues: My skills involve identifying mechanical failures such as leaks, wear and tear, and misalignment. This involves visual inspection, pressure testing, and sometimes destructive testing. I once resolved a persistent leak in a pressure sensor by carefully examining the housing and seals, identifying a hairline crack that wasn’t visible initially.

A key element is the use of preventative maintenance techniques to avoid major problems. For example regular inspection of moving parts, cleaning sensors, and checking for corrosion prevent potential failures.

Q 20. Describe your experience with hazardous materials handling and safety procedures.

Handling hazardous materials requires strict adherence to safety procedures and regulations. My experience includes working with various hazardous substances, including ammonia, refrigerants, and chemicals. I am thoroughly familiar with:

- Safety Data Sheets (SDS): I always consult SDS before handling any hazardous material to understand potential risks, necessary precautions, and emergency procedures.

- Personal Protective Equipment (PPE): I ensure appropriate PPE, such as respirators, gloves, and eye protection, is used at all times. Understanding the various types of PPE and their proper use is a non-negotiable.

- Lockout/Tagout Procedures: I strictly follow lockout/tagout procedures to prevent accidental energy release during maintenance activities. This safeguards both personnel and equipment.

- Emergency Response Plans: I have received training and participated in emergency drills. I am well-versed in emergency procedures, including containment and evacuation strategies.

- Waste Disposal: I ensure compliance with all regulations concerning proper disposal of hazardous waste. This includes proper documentation and adherence to environmental regulations.

Safety is my top priority. My experience has instilled in me a deep understanding of the importance of meticulous adherence to all safety protocols when working with hazardous materials.

Q 21. How proficient are you with interpreting P&IDs (Piping and Instrumentation Diagrams)?

Piping and Instrumentation Diagrams (P&IDs) are essential for understanding the layout and function of process systems. I am highly proficient in interpreting P&IDs. I can readily identify:

- Piping Systems: I understand the flow of materials through pipes, valves, and other equipment.

- Instrumentation: I can identify various instruments, such as sensors, transmitters, controllers, and actuators, and understand their role in the process.

- Control Loops: I can trace control loops, understanding how different instruments interact to regulate the process.

- Equipment Tags and Specifications: I can use equipment tags to locate specific components within the system and access related specifications.

My ability to interpret P&IDs is crucial for troubleshooting, planning maintenance activities, and understanding the overall process flow. For example, using a P&ID, I recently identified the source of a process upset by tracing the control loop involved and diagnosing a malfunctioning valve positioner.

Q 22. How do you stay up-to-date with the latest advancements in instrumentation and maintenance technologies?

Staying current in the rapidly evolving field of instrumentation and maintenance requires a multi-pronged approach. I leverage several key strategies to ensure I’m always up-to-date with the latest advancements. Firstly, I actively participate in professional organizations like ISA (International Society of Automation) and attend their conferences and webinars. These events provide invaluable networking opportunities and expose me to cutting-edge research and practical applications. Secondly, I subscribe to relevant industry journals and publications, such as Control Engineering and Plant Engineering, keeping abreast of new technologies and best practices. Thirdly, I dedicate time to online learning platforms like Coursera and edX, pursuing specialized courses on topics such as advanced process control, predictive maintenance techniques, and new sensor technologies. Finally, I actively seek out opportunities to work with new equipment and technologies, learning firsthand how they function and are maintained. For example, recently I had the opportunity to work with a new laser-based vibration sensor, which significantly improved our predictive maintenance capabilities.

Q 23. Describe your experience with vibration analysis for predictive maintenance.

Vibration analysis is a cornerstone of predictive maintenance, allowing us to identify potential equipment failures before they lead to costly downtime. My experience encompasses various aspects of this technology, from data acquisition to analysis and reporting. I’m proficient in using different types of vibration sensors, including accelerometers and proximity probes, to collect data. I utilize specialized software like those provided by Bently Nevada or SKF to analyze the collected vibration signatures. This involves identifying characteristic frequencies associated with specific faults, such as unbalance, misalignment, or bearing wear. For instance, a high amplitude at a specific frequency could indicate an imbalance in a rotating component. Analyzing the phase and amplitude of these vibrations helps pinpoint the exact location and severity of the problem. Based on the analysis, we can develop a maintenance plan, ranging from simple lubrication to a major overhaul, preventing catastrophic failures and extending the lifespan of critical equipment. In a recent project, we used vibration analysis to predict a bearing failure on a critical pump two weeks before it actually occurred, avoiding a costly production shutdown.

Q 24. Explain your understanding of different types of lubrication systems and their maintenance.

Lubrication systems are vital for the smooth operation and longevity of machinery. Different types of systems exist, each with its own maintenance requirements. These include:

- Grease Lubrication: This is a simple system often used for bearings and other components requiring infrequent lubrication. Maintenance involves regular grease replenishment, ensuring the correct type and quantity are used. Over-greasing can be detrimental, leading to heat buildup and seal damage.

- Oil Lubrication: Oil lubrication, often used in systems with high-speed rotating components, can be either splash, mist, or circulation systems. Maintenance includes regular oil level checks, filtration, and oil analysis to detect contaminants or degradation. Regular oil changes based on the analysis results are crucial.

- Centralized Lubrication Systems: These systems automatically deliver lubricant to multiple points in the machinery. Maintenance involves monitoring the system’s operation, checking for leaks, ensuring proper lubrication delivery, and timely component replacement as needed. These systems often have sophisticated monitoring capabilities requiring specialized knowledge.

Regardless of the system type, proper maintenance involves adherence to manufacturer’s recommendations, keeping accurate records, and performing regular inspections to identify potential issues such as leaks, contamination, or inadequate lubrication. A well-maintained lubrication system is crucial for reducing friction, wear, and extending equipment lifespan.

Q 25. How do you handle conflicting priorities in your maintenance work?

Conflicting priorities are inevitable in a maintenance environment. My approach involves a structured prioritization process that considers urgency, criticality, and potential impact. I use a system that combines a combination of methods. I employ a combination of urgency/impact matrices and a weighted scoring system to determine the order of tasks. For example, a critical piece of equipment nearing failure would take precedence over a routine maintenance task, even if the routine task is scheduled. Effective communication is key; I openly discuss conflicting priorities with supervisors and team members, ensuring everyone understands the rationale behind the chosen course of action. This collaborative approach helps to manage expectations and mitigate potential conflicts. Transparency and clear communication are essential to resolve such issues efficiently and effectively.

Q 26. Describe your experience with working independently and as part of a team.

Throughout my career, I’ve developed strong skills in both independent and team-based work. I’m comfortable working independently, taking ownership of tasks and delivering results with minimal supervision. For instance, I once independently conducted a root cause analysis of a recurring equipment failure, resulting in a significant reduction in downtime. At the same time, I excel in team settings, actively contributing to a collaborative environment and sharing my expertise with colleagues. I thrive in team environments where knowledge sharing is encouraged, and diverse perspectives are valued. For example, I recently led a team to implement a new predictive maintenance program, leveraging the skills and experience of each member to ensure the program’s success. My ability to effectively work both independently and collaboratively makes me a valuable asset to any team.

Q 27. What is your approach to continuous improvement in maintenance practices?

My approach to continuous improvement in maintenance practices is driven by a data-driven methodology. I believe in regularly analyzing key performance indicators (KPIs) such as Mean Time Between Failures (MTBF), Mean Time To Repair (MTTR), and overall equipment effectiveness (OEE). These metrics provide valuable insights into areas needing improvement. Implementing lean principles, such as reducing waste and optimizing workflows, plays a crucial role. Regularly reviewing maintenance procedures, seeking feedback from technicians, and incorporating best practices from industry benchmarks are also critical. For example, we recently implemented a new computerized maintenance management system (CMMS) that improved our scheduling, tracking, and reporting capabilities, leading to a measurable increase in equipment uptime. I also advocate for regular training and upskilling to ensure the team stays abreast of the latest technologies and techniques.

Q 28. How do you ensure compliance with relevant safety and regulatory standards?

Compliance with safety and regulatory standards is paramount in instrumentation and maintenance. My approach is multifaceted and focuses on several key areas. Firstly, I ensure all personnel receive regular training on relevant safety protocols, including lockout/tagout procedures, hazard communication, and personal protective equipment (PPE) usage. Secondly, I maintain detailed records of inspections, calibrations, and maintenance activities, ensuring compliance with regulatory requirements such as OSHA (Occupational Safety and Health Administration) and industry-specific standards. Thirdly, I actively participate in safety audits and inspections, proactively identifying and addressing potential hazards before they cause incidents. Regularly reviewing and updating safety procedures and working instructions is a crucial part of this process. Fourthly, I promote a strong safety culture within the team, encouraging open communication and reporting of near misses and incidents to learn from mistakes and prevent future occurrences. We regularly review accident reports and near misses to identify opportunities for improvement in safety procedures and training. Compliance isn’t just a checklist; it’s an integral part of our daily operations.

Key Topics to Learn for Instrumentation and Equipment Maintenance Interview

- Process Instrumentation: Understanding various instruments like pressure transmitters, flow meters, level sensors, and temperature sensors; their operating principles, calibration techniques, and troubleshooting common issues. Practical application: Diagnosing and resolving a malfunctioning level sensor in a process tank.

- Control Systems: Familiarity with different control loops (PID, cascade, etc.), control valve characteristics, and process control strategies. Practical application: Optimizing a control loop to minimize process variability and improve efficiency.

- Preventive and Predictive Maintenance: Developing and implementing effective maintenance schedules, including lubrication, inspection, and replacement of components. Utilizing predictive maintenance techniques like vibration analysis and infrared thermography. Practical application: Creating a PM schedule for a critical piece of equipment to minimize downtime and extend its lifespan.

- Electrical Systems: Understanding basic electrical principles, wiring diagrams, motor control circuits, and safety procedures related to electrical equipment. Practical application: Troubleshooting a faulty motor starter and safely restoring its operation.

- Safety and Compliance: Adherence to safety regulations, lockout/tagout procedures, and proper handling of hazardous materials. Practical application: Demonstrating knowledge of OSHA regulations and safe work practices in an industrial setting.

- Troubleshooting and Problem-Solving: Developing systematic approaches to diagnosing equipment malfunctions, utilizing diagnostic tools, and implementing effective repair strategies. Practical application: Describing a situation where you successfully troubleshot a complex equipment failure.

- Data Acquisition and Analysis: Understanding how to collect, interpret, and analyze data from process instrumentation to identify trends and optimize performance. Practical application: Utilizing data from a PLC to identify the root cause of a recurring process issue.

Next Steps

Mastering Instrumentation and Equipment Maintenance opens doors to a rewarding career with excellent growth potential in various industries. A strong understanding of these principles is highly sought after and directly translates to higher earning potential and greater career satisfaction. To maximize your job prospects, creating an ATS-friendly resume is crucial. This ensures your application gets noticed by recruiters and hiring managers. We recommend using ResumeGemini, a trusted resource for building professional resumes. ResumeGemini provides examples of resumes tailored to Instrumentation and Equipment Maintenance, helping you showcase your skills and experience effectively. Take the next step in your career journey – build a resume that stands out!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good