Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Pneumatic and Hydraulic Systems Maintenance interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Pneumatic and Hydraulic Systems Maintenance Interview

Q 1. Explain the difference between a pneumatic and a hydraulic system.

The core difference between pneumatic and hydraulic systems lies in the working fluid they use. Pneumatic systems utilize compressed air, while hydraulic systems use incompressible liquids, typically oil. This fundamental difference leads to significant variations in their performance characteristics, applications, and maintenance requirements.

Think of it like this: a pneumatic system is like blowing up a balloon – the air is compressible, meaning its volume changes under pressure. A hydraulic system is more like a water-filled syringe – the water is practically incompressible, resulting in consistent and powerful force transmission.

Q 2. Describe the working principle of a pneumatic cylinder.

A pneumatic cylinder operates on the principle of converting compressed air energy into linear mechanical motion. Compressed air is introduced into the cylinder through a valve, forcing a piston to move. This movement can be single-acting (moving in one direction only, typically relying on springs for return) or double-acting (moving in both directions, controlled by air pressure). The piston’s movement is controlled by precisely managing the air pressure and flow through the valve.

Imagine a bicycle pump: pushing down on the handle compresses the air, driving the piston and creating force. That’s essentially how a pneumatic cylinder works, but on a larger and more controlled scale.

Q 3. What are the advantages and disadvantages of pneumatic systems?

Advantages of Pneumatic Systems:

- Safety: Compressed air is relatively safe compared to hydraulic fluids, especially in the case of leaks.

- Cost-effectiveness: Initial setup costs are often lower than hydraulic systems.

- Simplicity: Pneumatic systems are generally simpler to design, install, and maintain.

- Cleanliness: They are inherently cleaner, making them suitable for food processing and other sensitive environments.

Disadvantages of Pneumatic Systems:

- Lower Force and Power: They generally produce lower forces compared to hydraulic systems for the same size components.

- Compressibility: Air’s compressibility can lead to inconsistencies in force and speed.

- Affected by Temperature and Humidity: Performance can be affected by environmental conditions.

- Noise: They often generate more noise during operation.

Q 4. What are the advantages and disadvantages of hydraulic systems?

Advantages of Hydraulic Systems:

- High Force and Power: They can generate significantly higher forces and power compared to pneumatic systems.

- Precise Control: Offer more precise control over speed and position.

- High Power-to-Weight Ratio: Can achieve higher power output with smaller and lighter components.

- Consistent Performance: Less susceptible to variations in temperature and humidity.

Disadvantages of Hydraulic Systems:

- Safety Concerns: Leaks of hydraulic fluids can pose safety and environmental hazards.

- Higher Cost: Generally more expensive to design, install, and maintain.

- Complexity: More complex systems require specialized expertise.

- Maintenance: Requires regular maintenance including fluid changes and component inspections.

Q 5. Explain the concept of Pascal’s Law and its relevance to hydraulic systems.

Pascal’s Law states that pressure applied to a confined fluid is transmitted undiminished throughout the fluid in all directions. In hydraulic systems, this principle is fundamental to force multiplication. By applying a relatively small force to a small area of a hydraulic fluid, a much larger force is generated over a larger area elsewhere in the system.

A simple example: imagine a hydraulic jack used to lift a car. A small force applied to the input piston generates a much larger force at the output piston, capable of lifting the weight of the car. This is all thanks to Pascal’s Law ensuring equal pressure transmission throughout the confined fluid.

Q 6. How do you troubleshoot a leaking hydraulic cylinder?

Troubleshooting a leaking hydraulic cylinder involves a systematic approach. First, isolate the leak source – is it from the rod seals, the piston seals, or the cylinder body itself?

- Visual Inspection: Carefully inspect the cylinder for visible signs of leakage.

- Pressure Test: Isolate the cylinder and pressurize it with the hydraulic fluid to pinpoint the exact location of the leak.

- Identify the Faulty Component: Once the leak source is identified (e.g., a damaged seal), the faulty component needs to be determined.

- Repair or Replacement: If the damage is minor (like a small scratch), cleaning and lubrication might suffice. Otherwise, seal replacement or complete cylinder overhaul might be necessary.

- Fluid Analysis: After repairs, consider a hydraulic fluid analysis to check for contamination.

Remember safety precautions! Always depressurize the system before attempting any repairs.

Q 7. What are common causes of pneumatic system failures?

Common causes of pneumatic system failures include:

- Leaks: Leaks in hoses, fittings, or the cylinder itself can lead to reduced pressure and system failure.

- Contamination: Dirt, dust, or moisture in the compressed air can damage components like valves and cylinders.

- Valve Malfunction: Valves that fail to open or close properly can disrupt system operation.

- Air Compressor Issues: Problems with the air compressor (e.g., insufficient pressure or lubrication) can affect the system’s overall performance.

- Wear and Tear: Over time, components can wear down due to normal use, requiring replacement or maintenance.

- Improper Maintenance: Lack of regular maintenance, such as lubrication and cleaning, can accelerate wear and lead to failure.

Regular inspections and preventative maintenance are key to avoiding these problems.

Q 8. How do you identify and address air leaks in a pneumatic system?

Identifying air leaks in a pneumatic system is crucial for maintaining efficiency and preventing damage. Leaks lead to reduced pressure, slower actuation speeds, and increased energy consumption. We use a multi-pronged approach:

Visual Inspection: Carefully examine all fittings, tubing, and components for visible signs of leaks, such as hissing sounds or escaping air. Pay close attention to connections, as these are common leak points.

Soap Solution Test: Mix a solution of soapy water and apply it to suspected leak areas. Bubbles will readily form at the point of a leak, clearly indicating its location. This is a simple yet highly effective method.

Pressure Drop Test: With the system pressurized, monitor the pressure gauge over time. A gradual pressure drop indicates a leak. This helps isolate the leak if the visual inspection is inconclusive.

Ultrasonic Leak Detectors: For hard-to-find leaks or very small leaks, an ultrasonic leak detector can be invaluable. These devices detect the high-frequency sound waves produced by escaping compressed air.

Addressing leaks involves tightening loose connections, replacing damaged components, or repairing leaks with specialized repair kits, depending on the severity and location of the leak. For instance, a simple loose fitting can often be solved with a wrench. However, a damaged hose will need replacing.

Q 9. Explain the function of a pressure regulator in a pneumatic system.

A pressure regulator in a pneumatic system is like a faucet for compressed air. It controls and maintains a constant downstream pressure, regardless of fluctuations in the upstream supply pressure. This is critical for consistent operation of pneumatic actuators and tools. Imagine a robotic arm: the pressure regulator ensures the arm moves with the same force, even if the air compressor’s output pressure varies slightly.

The regulator achieves this through a mechanism that senses the downstream pressure and adjusts an internal valve to control the air flow. Common types include diaphragm-type regulators and piston-type regulators, differing primarily in their operating mechanisms. A spring provides the set point and the diaphragm/piston moves proportionally to maintain downstream pressure at the set point.

Q 10. Explain the function of a pressure relief valve in a hydraulic system.

A pressure relief valve in a hydraulic system acts as a safety device, preventing dangerously high pressure build-up. Think of it as a pressure safety valve on a boiler. If the system pressure exceeds a preset limit, the valve opens automatically, releasing hydraulic fluid to protect the system components from damage or catastrophic failure. This is essential to avoid equipment damage or even injury.

These valves are typically spring-loaded, with the spring force setting the pressure threshold. Once the system pressure surpasses the set point, the spring is overcome, and the valve opens, allowing fluid to bypass the system and usually return to the reservoir. Different types exist, such as direct-acting and pilot-operated valves, each with its own advantages.

Q 11. What are the different types of hydraulic pumps?

Hydraulic pumps are the heart of a hydraulic system, providing the power to move hydraulic fluid. Several types exist, each with its own characteristics and applications:

Gear Pumps: Relatively simple and inexpensive, these pumps use meshing gears to move fluid. They’re suitable for lower-pressure applications.

Vane Pumps: These pumps use rotating vanes within a cylindrical housing to displace fluid. They are more efficient than gear pumps for moderate pressure applications.

Piston Pumps: These are the workhorses for high-pressure applications. They use reciprocating pistons to displace large volumes of fluid. Subtypes include axial piston pumps (pistons arranged parallel to the shaft) and radial piston pumps (pistons arranged radially around the shaft).

The choice of pump depends on factors such as the required pressure, flow rate, viscosity of the fluid, and budget considerations.

Q 12. What are the different types of pneumatic valves?

Pneumatic valves control the flow of compressed air in a pneumatic system. There is a wide variety of types, categorized by their function and operating mechanism:

Directional Control Valves: These valves control the direction of airflow, such as starting, stopping, or reversing the motion of a pneumatic actuator. Examples include 3/2 way, 4/2 way and 4/3 way valves.

Pressure Control Valves: These valves regulate the pressure of the compressed air, like pressure regulators and relief valves (as discussed previously).

Flow Control Valves: These valves restrict the flow rate of compressed air, providing precise control over the speed of pneumatic actuators.

Shut-off Valves: Simple on/off valves that completely stop or allow the flow of air.

These valves can be actuated manually, electrically (solenoids), pneumatically (using air pressure), or hydraulically.

Q 13. Describe the function of a hydraulic accumulator.

A hydraulic accumulator is like a rechargeable battery for a hydraulic system. It stores energy in the form of pressurized hydraulic fluid, providing a buffer for pressure fluctuations and surges. This is particularly important in applications where peak demands exceed the pump’s capacity, like in heavy machinery operation.

The accumulator helps to: (1) Compensate for pressure drops during peak demand, ensuring consistent system performance; (2) Absorb shock loads, protecting the system from sudden pressure changes; (3) Provide emergency power in case of pump failure; and (4) Reduce the workload on the pump, thus increasing its lifespan. Common types include bladder accumulators (using a flexible bladder to separate the fluid from a gas charge) and diaphragm accumulators (similar but using a flexible diaphragm).

Q 14. How do you select the appropriate pneumatic or hydraulic components for a specific application?

Selecting appropriate pneumatic or hydraulic components requires careful consideration of several factors:

System Requirements: Determine the required pressure, flow rate, and power for the application. For example, a heavy-duty press will demand higher pressure and flow rate than a simple clamping device.

Environmental Conditions: Consider factors like temperature, humidity, and the presence of corrosive substances. This is crucial for ensuring component durability and safety.

Component Compatibility: Ensure the selected components are compatible with each other in terms of materials, pressure ratings, and connection types.

Cost Considerations: Balance performance requirements with budget constraints. Some components are more expensive but more robust or efficient.

Maintenance Requirements: Consider the ease of maintenance and repair for the chosen components. Components needing frequent maintenance can lead to higher downtime and costs.

Using appropriate selection criteria helps in choosing components that optimize system performance and reliability while adhering to safety standards. For example, we need to select components with pressure ratings exceeding the maximum working pressure of the system.

Q 15. Explain the importance of regular maintenance for pneumatic and hydraulic systems.

Regular maintenance of pneumatic and hydraulic systems is paramount for ensuring safe, efficient, and reliable operation. Neglecting maintenance leads to a cascade of problems, from reduced productivity and increased downtime to catastrophic failures and potential safety hazards. Think of it like regularly servicing your car – you wouldn’t drive it for years without oil changes or tire rotations, right? The same principle applies here.

- Increased Efficiency and Productivity: Regular lubrication, cleaning, and component checks prevent wear and tear, maintaining optimal system performance and minimizing downtime.

- Extended System Lifespan: Preventive maintenance significantly extends the operational life of components, reducing the need for costly replacements.

- Improved Safety: Identifying and addressing potential leaks, worn parts, or faulty components before they lead to failures prevents accidents and injuries.

- Reduced Energy Consumption: Well-maintained systems operate more efficiently, minimizing energy waste and reducing operational costs.

- Predictive Maintenance: Regular inspections allow for early detection of potential problems, enabling proactive repairs and avoiding unexpected breakdowns.

For example, a small leak in a hydraulic cylinder might seem insignificant initially, but over time it can lead to significant fluid loss, reduced power, and eventual cylinder failure. Regular inspection and timely repair prevent this escalation.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with preventive maintenance procedures.

My experience with preventive maintenance encompasses a wide range of procedures, from basic visual inspections to complex system diagnostics. In my previous role at a manufacturing plant, I was responsible for developing and implementing a comprehensive preventive maintenance program for our pneumatic and hydraulic machinery. This involved creating a detailed schedule based on manufacturers’ recommendations and historical data analysis.

- Visual Inspections: Regularly inspecting hoses, fittings, and cylinders for leaks, cracks, or damage.

- Fluid Level Checks: Monitoring hydraulic fluid levels and quality, ensuring proper filtration and timely replacements.

- Pressure and Flow Testing: Using pressure gauges and flow meters to verify that system components are operating within their specified parameters.

- Component Lubrication: Applying appropriate lubricants to moving parts to reduce friction and wear.

- Filter Replacement: Regularly changing filters to prevent contaminants from damaging components.

- Leak Detection: Employing techniques like ultrasonic leak detection or dye penetrant testing to identify even minor leaks.

For instance, we implemented a system where we used color-coded labels to indicate when each component was last serviced, ensuring no component was overlooked during our maintenance rounds. This streamlined our process and improved efficiency significantly.

Q 17. What are the safety precautions you take when working with pneumatic and hydraulic systems?

Safety is my utmost priority when working with pneumatic and hydraulic systems. These systems operate under high pressure, and improper handling can lead to serious injuries. My safety practices always follow a strict protocol:

- Lockout/Tagout Procedures: Before performing any maintenance, I always implement lockout/tagout procedures to isolate the system from power sources, preventing accidental activation.

- Personal Protective Equipment (PPE): I consistently wear appropriate PPE, including safety glasses, gloves, and hearing protection.

- Pressure Relief: Before working on any pressurized component, I ensure that all pressure is relieved from the system.

- Leak Detection Procedures: Using appropriate leak detection methods helps identify and address leaks safely and effectively.

- Awareness of Hazardous Materials: I am aware of the potential hazards associated with hydraulic fluids and handle them responsibly, following all safety regulations and disposal procedures.

- Emergency Shutdown Procedures: I am familiar with the location and operation of all emergency shutdown switches and procedures.

For example, I once encountered a situation where a high-pressure hose was about to fail. By following the lockout/tagout procedure and carefully relieving the pressure, I prevented a potential explosion and injury.

Q 18. How do you interpret pneumatic and hydraulic schematics?

Interpreting pneumatic and hydraulic schematics is crucial for understanding the system’s operation and troubleshooting malfunctions. Schematics provide a visual representation of the system’s components, their connections, and the flow of fluids or air. I am proficient in reading and interpreting both ISO and ANSI standards for these schematics.

Understanding the symbols used is essential. For instance, a circle with a cross inside represents a valve, while a triangle typically indicates a pressure regulator. Understanding the flow directions, pressure indicators, and component designations helps determine the system’s behavior.

I typically approach interpreting schematics by systematically analyzing:

- Component Identification: First, identify all components and their functions (cylinders, valves, pumps, etc.).

- Flow Paths: Trace the fluid pathways from source to actuators, noting flow control elements along the way.

- Control Logic: Analyze the control circuits, understanding how different inputs affect the operation of valves and actuators.

- Pressure and Flow Regulation: Identify the pressure and flow regulation components and understand how they influence the system’s performance.

Example: A simple schematic might show a compressor supplying air to a pressure regulator, which feeds a 3/2 way valve controlling the air to a pneumatic cylinder. This visual representation provides the information necessary to understand the sequence of events within the system.

Q 19. Explain your experience with troubleshooting using diagnostic tools.

My experience with troubleshooting pneumatic and hydraulic systems relies heavily on utilizing various diagnostic tools. This extends beyond simply visually inspecting components; it involves the systematic use of instrumentation to pinpoint the exact root cause of a malfunction.

- Pressure Gauges: Measuring pressure at different points in the system helps identify pressure drops, blockages, or leaks.

- Flow Meters: Determining the flow rate at various points assists in identifying restrictions or blockages.

- Temperature Sensors: Monitoring temperatures can reveal problems such as excessive friction or overheating.

- Multimeters: Used to check for electrical faults in control circuits, such as relay malfunctions or sensor failures.

- Data Acquisition Systems: These advanced systems allow for real-time monitoring and logging of system parameters, aiding in identifying intermittent problems.

- Ultrasonic Leak Detectors: Used to pinpoint the location of leaks by detecting the high-frequency sound waves created by escaping air or fluid.

For example, I once diagnosed a recurring problem in a hydraulic press by using a data acquisition system. The system recorded pressure fluctuations that revealed a faulty pressure relief valve that would intermittently fail, causing the press to underperform. The data allowed for a targeted replacement of the faulty valve, preventing further downtime and costly repairs.

Q 20. Describe your experience with repairing pneumatic and hydraulic components.

My experience in repairing pneumatic and hydraulic components is extensive. I am proficient in disassembling, inspecting, repairing, and reassembling various components, adhering to strict safety procedures and using specialized tools.

- Cylinder Repair: Repairing or replacing seals, piston rods, and other internal components.

- Valve Repair: Diagnosing and repairing leaks, malfunctions in spool valves, or other internal components.

- Pump Repair: Replacing seals, bearings, and other components that improve pump efficiency.

- Hose and Fitting Replacement: Replacing worn or damaged hoses and fittings to prevent leaks.

- Filter Element Replacement: Regularly replacing filters to prevent contaminants from clogging or damaging components.

I remember repairing a crucial pneumatic valve in a packaging machine that had failed. By carefully disassembling the valve, cleaning it thoroughly, and replacing a worn seal, I avoided the need for an expensive replacement, getting the machine back online quickly.

Q 21. How do you handle emergency situations related to pneumatic or hydraulic system failures?

Handling emergency situations requires a calm, methodical approach. My experience has taught me to prioritize safety above all else.

- Immediate Shutdown: The first step is always to safely shut down the system, isolating it from power and pressure.

- Safety Assessment: Assess the situation to ensure no immediate danger exists for personnel.

- Damage Control: If possible, take steps to prevent further damage or escalation of the problem (e.g., containing a fluid leak).

- Problem Identification: Attempt to identify the source of the failure, noting any immediate clues.

- Emergency Repair or Replacement: If the system failure cannot be immediately rectified, a temporary fix will be used to restore limited functionality or a component will be replaced.

- Notification: Report the incident to relevant personnel and document the event.

In one instance, a high-pressure hydraulic line ruptured, causing a significant fluid leak. I immediately shut down the system, contained the leak with absorbent materials, and notified the safety team before beginning the repair. Proper procedure prevented a serious safety incident and minimized environmental impact.

Q 22. What are the common types of hydraulic fluids and their properties?

Hydraulic fluids are the lifeblood of a hydraulic system, transmitting power and lubricating components. Common types include mineral oils, synthetic oils, and water-glycol fluids. Each has unique properties influencing its suitability for specific applications.

- Mineral Oils: These are the most common and cost-effective, offering good lubricity and viscosity characteristics. However, they are susceptible to oxidation and degradation at high temperatures.

- Synthetic Oils: These offer superior performance at extreme temperatures and pressures, exhibiting better oxidation resistance and longer lifespan. They are more expensive than mineral oils, but their longevity can offset this cost in the long run. Examples include phosphate esters and polyalkylene glycols (PAGs).

- Water-Glycol Fluids: These are environmentally friendly and fire-resistant, making them suitable for applications where fire safety is paramount. However, they are more prone to corrosion and require specialized system components.

The selection of hydraulic fluid depends on factors such as operating temperature range, system pressure, the materials of the system components (to avoid incompatibility), and environmental considerations.

Q 23. What is the significance of viscosity in hydraulic systems?

Viscosity is the measure of a fluid’s resistance to flow. In hydraulic systems, it’s crucial because it directly impacts several key aspects of system performance and reliability:

- Pump Efficiency: The viscosity affects the pump’s ability to move the fluid. Too high a viscosity increases energy consumption, while too low a viscosity can lead to cavitation (formation of vapor bubbles).

- Leakage: Proper viscosity ensures that seals can effectively prevent leakage, thus maintaining system pressure and preventing fluid loss. Incorrect viscosity can lead to excessive wear on seals and potential system failure.

- Lubrication: Hydraulic fluid lubricates system components, reducing friction and wear. Appropriate viscosity is essential to provide an adequate lubrication film between moving parts.

- Heat Transfer: Viscosity influences the fluid’s ability to dissipate heat. High viscosity can hinder effective heat transfer, potentially leading to overheating.

Maintaining the correct viscosity at the operating temperature is critical. This often involves using viscosity modifiers or selecting fluids with suitable viscosity-temperature characteristics.

Q 24. Explain the concept of hydraulic filtration and its importance.

Hydraulic filtration is the process of removing contaminants such as dirt, water, and wear particles from hydraulic fluid. This is absolutely vital for maintaining the system’s reliability and longevity.

Contaminants can cause several problems:

- Increased wear: Abrasive particles can scratch and damage precision components.

- Reduced efficiency: Contaminants can clog valves and restrict fluid flow.

- Seal failure: Contaminants can accelerate seal degradation and lead to leaks.

- Corrosion: Water contamination can lead to rust and corrosion.

Filtration systems usually involve filters of varying pore sizes, and the choice depends on the cleanliness level required. Regular filter maintenance, including replacement of filter elements, is essential. Implementing a robust filtration strategy, which could involve multiple filtration stages, significantly extends the lifespan and reliability of the hydraulic system.

Q 25. What are the different types of pneumatic actuators?

Pneumatic actuators convert compressed air energy into mechanical motion. Common types include:

- Single-Acting Cylinders: Extend with compressed air and retract using a spring or gravity. Simple and cost-effective, but limited to one direction of motion.

- Double-Acting Cylinders: Extend and retract using compressed air. Offers more control and flexibility of movement.

- Rotary Actuators: Convert rotary motion from compressed air, commonly used for rotational tasks.

- Grippers: Use compressed air to open and close, often used in robotic automation and material handling.

The selection of a pneumatic actuator depends on factors like the required force, stroke length, speed, and the application’s specific needs. For example, a single-acting cylinder might suffice for a simple clamping mechanism, while a double-acting cylinder with position feedback would be necessary for a more complex robotic arm.

Q 26. What is the difference between open-center and closed-center hydraulic systems?

The key difference between open-center and closed-center hydraulic systems lies in how the hydraulic fluid flows when the actuators are not actively working:

- Open-Center Systems: Fluid flows freely back to the reservoir when the actuators are not operating. This is simpler and generally less expensive, but can lead to higher energy consumption due to continuous fluid flow through the system.

- Closed-Center Systems: Fluid is contained within the system, even when the actuators are at rest. This is more energy-efficient and provides better control, especially for applications requiring precise positioning and holding forces. It is typically more complex and expensive.

Imagine a water slide: An open-center system is like a constantly flowing water slide – water keeps flowing regardless of whether anyone is sliding down. A closed-center system is like a water slide with a valve controlling the water flow – the water only flows when someone starts sliding.

Q 27. Explain your experience with different types of hydraulic seals.

My experience encompasses a wide range of hydraulic seals, each with its specific application and advantages:

- O-rings: The most common and versatile type, providing a simple and effective seal for a wide range of applications. I have extensive experience in selecting the appropriate material (e.g., nitrile, Viton) based on the operating fluid, temperature, and pressure.

- U-cups: Suitable for reciprocating applications, offering better resistance to extrusion compared to O-rings. I’ve used these in hydraulic cylinders where dynamic sealing is critical.

- Lip Seals: Effective at sealing against rotating shafts, crucial in pump applications to prevent leakage. Proper installation and lubrication are key to their performance. I’ve dealt with various types, including single-lip and double-lip seals.

- Hydraulic Seal Kits: In complex applications, I have dealt with seal kits containing multiple seals, such as O-rings, backup rings, and wear rings, providing comprehensive sealing solutions. Proper kit selection is critical for avoiding leaks and component damage.

Proper seal selection and maintenance are critical to prevent leakage and ensure the longevity of a hydraulic system. Improper selection or installation can lead to costly downtime and repairs.

Q 28. Describe your experience with programmable logic controllers (PLCs) in relation to pneumatic and hydraulic systems.

Programmable Logic Controllers (PLCs) are integral to modern pneumatic and hydraulic systems, providing automated control and monitoring capabilities. My experience includes using PLCs to:

- Control Actuator Movement: I’ve programmed PLCs to control the sequencing and timing of pneumatic and hydraulic cylinders, valves, and other actuators, allowing for precise and synchronized movement. This typically involves ladder logic programming.

- Monitor System Parameters: PLCs can monitor pressure, temperature, and position feedback from sensors, providing real-time data for diagnostic purposes and preventing potential issues. I have experience troubleshooting faults using PLC data logging.

- Implement Safety Features: PLCs can implement safety interlocks and emergency stop functions, ensuring system safety and preventing accidents. This is crucial in industrial settings to protect personnel and equipment.

- Human-Machine Interface (HMI) Integration: I’ve integrated PLCs with HMIs to provide operators with an intuitive interface for controlling and monitoring the system. This enables effective system operation and facilitates troubleshooting.

Example Ladder Logic (Illustrative): //This is a simplified example and may not work without proper PLC configuration.// Input: Start Button (I:1/0)// Output: Cylinder Extend (O:1/1)//---------------------------------I:1/0 --|---| O:1/1

PLC programming is crucial for efficient and safe operation of pneumatic and hydraulic systems. My experience encompasses various PLC brands and programming languages, providing a solid base for troubleshooting and implementing automation.

Key Topics to Learn for Pneumatic and Hydraulic Systems Maintenance Interview

- Fluid Power Fundamentals: Understanding Pascal’s Law, pressure, flow, and their relationships in both pneumatic (compressed air) and hydraulic (liquids) systems. This forms the bedrock of your understanding.

- Component Identification and Function: Become proficient in identifying and explaining the function of key components like compressors, pumps, valves (directional control, pressure control, flow control), actuators (cylinders, motors), and filters. Practice visualizing how these interact within a system.

- Troubleshooting and Diagnostics: Develop your ability to systematically troubleshoot system malfunctions. This includes understanding common failure points, using diagnostic tools (pressure gauges, flow meters), and applying logical problem-solving techniques to identify root causes.

- Safety Procedures and Regulations: Demonstrate a strong understanding of safety protocols related to high-pressure systems, including lockout/tagout procedures, proper handling of fluids, and personal protective equipment (PPE) usage. Safety is paramount in this field.

- Preventive Maintenance: Explain the importance of regular maintenance schedules, including lubrication, filter changes, leak detection, and component inspections. Understanding preventative maintenance is key to minimizing downtime and maximizing system lifespan.

- System Design and Schematics: Learn to interpret pneumatic and hydraulic schematics, understanding the flow of fluids and the interaction between components. Being able to read and understand these diagrams is crucial for effective maintenance.

- Practical Application: Think about real-world examples from your experience. How have you applied these concepts in previous roles? Be ready to discuss specific instances where you diagnosed and repaired a pneumatic or hydraulic system.

Next Steps

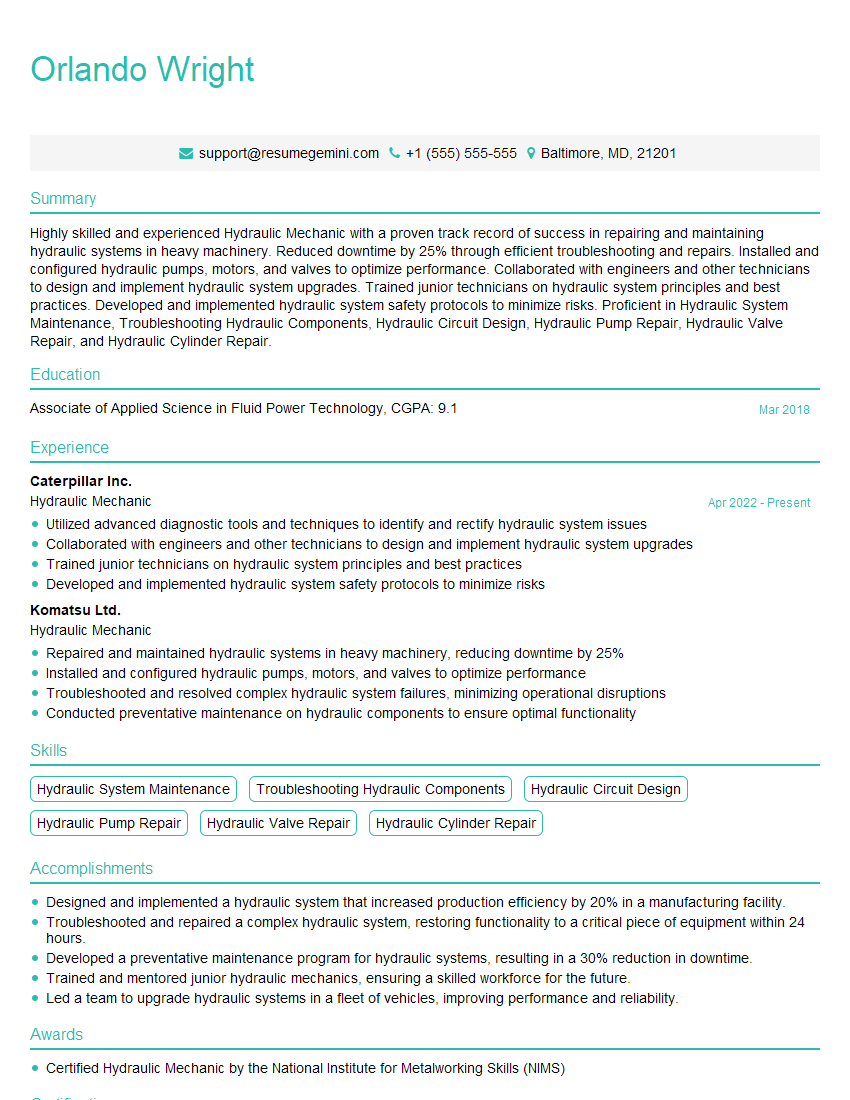

Mastering Pneumatic and Hydraulic Systems Maintenance opens doors to rewarding and stable careers in various industries. Your expertise is highly valued, and continuous learning will ensure your continued success. To maximize your job prospects, it’s crucial to present your skills effectively. Creating an ATS-friendly resume is essential for getting your application noticed by recruiters. ResumeGemini is a trusted resource to help you build a professional and impactful resume that highlights your abilities. Examples of resumes tailored to Pneumatic and Hydraulic Systems Maintenance professionals are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good