The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Portable Equipment Operation interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Portable Equipment Operation Interview

Q 1. Describe your experience operating various types of portable equipment.

Throughout my career, I’ve extensively operated a wide range of portable equipment, from small power tools like drills and saws to larger, more specialized machinery such as generators, welders, and concrete vibrators. My experience encompasses both gas-powered and electric-powered tools across various construction, maintenance, and industrial settings. For instance, I’ve used pneumatic nail guns for framing projects, chain saws for landscaping work, and hydraulic jacks for heavy lifting during equipment repairs. Each piece of equipment demands a unique operating technique and understanding of its capabilities and limitations, which I’ve honed through years of hands-on experience and formal training.

One particularly memorable experience involved using a specialized concrete vibrator to consolidate a large concrete pour for a foundation. Understanding the proper vibration frequency and duration was crucial to avoid cracking and ensuring the structural integrity of the foundation. This required not just operating the equipment but also an understanding of the underlying construction principles.

Q 2. What safety procedures do you follow when operating portable equipment?

Safety is paramount when operating portable equipment. My approach follows a comprehensive protocol, starting with a pre-operational inspection of the equipment itself. I check for any damage, loose parts, or fluid leaks. I then ensure I have the appropriate personal protective equipment (PPE), including safety glasses, hearing protection, gloves, and steel-toed boots, depending on the task. The work area needs to be assessed for hazards, securing the area and ensuring adequate lighting and ventilation. Before starting, I always verify that the equipment is properly grounded and connected to the power source correctly (if applicable). During operation, I maintain a safe distance from moving parts and avoid distractions.

- Pre-Operational Checks: Visual inspection for damage, fluid levels, and secure connections.

- PPE: Consistent use of safety glasses, hearing protection, gloves, etc.

- Work Area Safety: Securing the area, proper lighting, and ventilation.

- Grounding and Power Connection: Ensuring safe power supply.

- Safe Operating Procedures: Maintaining distance from moving parts and avoiding distractions.

Following these procedures consistently has prevented many potential accidents and ensured a safe work environment for myself and others on the team.

Q 3. How do you perform routine maintenance checks on portable equipment?

Routine maintenance is crucial for extending the lifespan and ensuring the safe operation of portable equipment. My maintenance checks typically involve several key steps. First, I visually inspect the equipment for any signs of wear and tear, such as cracks, loose bolts, or damaged cables. I check fluid levels (oil, fuel, etc.), ensuring they are within the manufacturer’s recommended ranges. Next, I clean the equipment, removing any debris or buildup that could interfere with its operation. Depending on the equipment type, I might also check air filters, spark plugs (for gas-powered equipment), or belts and pulleys. Finally, I document all maintenance activities in a log book, noting the date, the type of maintenance performed, and any issues identified.

For example, with a chainsaw, I would check the chain tension, lubricate the chain bar, and inspect the air filter. For a generator, I would check the oil level, fuel level, and the condition of the spark plugs. Consistent and thorough maintenance is a proactive approach that helps prevent costly repairs and downtime.

Q 4. Explain the process of troubleshooting malfunctioning portable equipment.

Troubleshooting malfunctioning portable equipment involves a systematic approach. First, I thoroughly examine the equipment for any obvious issues, such as loose connections, damaged components, or blockages. If a visual inspection doesn’t reveal the problem, I’ll consult the equipment’s operating manual for troubleshooting guidance. This often involves checking fuses, circuit breakers, or other safety mechanisms. If the manual doesn’t provide a solution, I’ll utilize my experience and knowledge to identify potential causes. This might involve testing the power source, checking for fuel delivery problems (in gas-powered equipment), or inspecting electrical components.

If the problem persists, I don’t hesitate to seek assistance from qualified technicians or refer the equipment for professional repair. Attempting repairs beyond my skillset could lead to further damage or create safety hazards. For example, if a power tool suddenly stops working, I would first check the power cord, then the circuit breaker. If the problem persists, I might check the brushes (in a motor-driven tool) before seeking professional help.

Q 5. What are the common causes of equipment failure and how do you address them?

Equipment failure can stem from various causes, often related to neglect, misuse, or wear and tear. Common issues include:

- Lack of Maintenance: Neglecting routine maintenance leads to accumulated wear and tear, ultimately causing failure.

- Improper Use: Operating equipment beyond its design capabilities or using it for unintended purposes can cause damage.

- Environmental Factors: Exposure to harsh weather conditions (extreme temperatures, moisture) can degrade equipment components.

- Component Failure: Mechanical or electrical components can fail due to wear and tear or manufacturing defects.

Addressing these issues requires a multi-faceted approach. Regular maintenance is crucial to prevent wear and tear. Proper training and adherence to operating instructions minimize misuse. Protecting equipment from the elements and storing it appropriately extends its lifespan. Finally, addressing component failures promptly through repair or replacement prevents cascading issues.

Q 6. Describe your experience with different types of portable power sources.

My experience with portable power sources encompasses a variety of types, each with its own advantages and limitations. These include:

- Corded Electric: Reliable and readily available, but limited by cord length and potential tripping hazards.

- Battery-Powered: Provides mobility and convenience, but battery life and recharge times are factors to consider. Different battery chemistries (lead-acid, lithium-ion) offer varying performance characteristics.

- Gas-Powered: Offers high power output and extended runtimes, but requires fuel storage and maintenance.

- Solar-Powered: Environmentally friendly but dependent on sunlight availability and often lower power output.

Selecting the appropriate power source depends on the application. For instance, a cordless drill is ideal for mobility, while a gas-powered generator is suitable for providing power in remote areas lacking a grid connection. I have experience troubleshooting issues with each type, including battery drain, fuel system problems, and electrical faults.

Q 7. How do you ensure the safe transport and storage of portable equipment?

Safe transport and storage are critical for maintaining the equipment’s condition and preventing accidents. For transport, I use appropriate containers or carriers designed to secure the equipment and prevent damage during transit. Larger equipment might require specialized trailers or transport vehicles. For smaller tools, sturdy cases or boxes provide protection. During transport, I ensure that the equipment is properly secured to prevent shifting or movement.

Storage practices are equally important. The equipment should be stored in a clean, dry, and secure location, protected from the elements and unauthorized access. Gas-powered equipment needs to be stored with fuel tanks emptied or stabilized to prevent fire hazards. Sharp tools and equipment are stored in a manner that prevents accidental injury. Regularly cleaning and inspecting stored equipment helps maintain its condition and extend its lifespan. A well-organized storage system simplifies retrieval and helps prevent equipment damage or loss.

Q 8. What are your experience with different types of engines used in portable equipment?

My experience encompasses a wide range of engines used in portable equipment, including gasoline, diesel, propane, and electric motors. Gasoline engines are common in smaller, less demanding applications like lawnmowers and generators due to their readily available fuel and relatively simple design. However, they often lack the torque and fuel efficiency of diesel engines. Diesel engines, on the other hand, are preferred for heavier-duty equipment like excavators and forklifts because of their higher power output and fuel economy. Propane engines are becoming increasingly popular because of their cleaner emissions and potential for reduced operating costs, especially in areas with readily available propane. Finally, electric motors are ideal for applications requiring quiet operation and minimal emissions, such as some types of portable lifts and specialized tools. Each engine type has its own maintenance requirements and operational considerations that I’m well-versed in, from understanding proper fuel mixtures and oil changes to troubleshooting common issues like spark plug failures or fuel injector problems.

For example, I once worked on a project involving a fleet of propane-powered generators for a remote construction site. Understanding the nuances of propane fuel delivery and engine operation was critical to ensuring uninterrupted power supply. Similarly, I’ve diagnosed and repaired issues with diesel engines in heavy equipment, requiring a deep understanding of fuel injection systems and engine diagnostics.

Q 9. How do you handle emergency situations involving portable equipment?

Handling emergencies with portable equipment requires a calm, systematic approach. My first priority is always safety – ensuring the immediate safety of myself and others in the vicinity. This may involve shutting down the equipment immediately, evacuating the area, and alerting emergency services if necessary. Next, I assess the situation to understand the nature of the emergency. Is it a mechanical failure, a safety hazard, or something else? Once the nature of the emergency is understood, I proceed with appropriate actions. This could involve minor repairs if the issue is simple and safe to address, or calling for expert assistance if the problem is beyond my capabilities. Accurate documentation of the incident, including the cause, actions taken, and any resulting damage, is crucial for learning and preventing similar incidents in the future.

For instance, I once responded to a situation where a portable lift malfunctioned, leaving a worker suspended several feet in the air. I immediately ensured the area was safe, used emergency controls to lower the worker safely, and then performed a thorough safety check on the lift before allowing anyone else to use it. Thorough documentation of this event was vital for preventing future occurrences.

Q 10. What are the limitations of different types of portable equipment?

The limitations of portable equipment are varied and depend heavily on the specific type of equipment and its intended use. For instance, smaller portable generators have limitations on power output, making them unsuitable for high-power demands. Similarly, hand-held power tools often have limited runtime before needing recharging or refueling. Portable lifting equipment, like chain hoists or jacks, usually has weight and height limitations that must be strictly observed for safe operation. Environmental factors can also significantly impact operational limits; for example, extreme temperatures can affect battery performance, engine efficiency and the structural integrity of some equipment.

A practical example would be attempting to use a small petrol-powered chainsaw to fell a large, thick tree. The chainsaw’s power limitations and the risk of kickback would make this task dangerous and likely ineffective. Understanding these limitations is paramount to choosing the appropriate equipment for any given task and prioritizing safety.

Q 11. Describe your experience with hydraulic systems in portable equipment.

I have extensive experience with hydraulic systems in portable equipment. These systems rely on pressurized fluid to generate force and movement, enabling powerful and precise control in applications such as portable lifts, excavators and some types of industrial tools. Understanding hydraulic systems means being familiar with components like pumps, valves, cylinders, and hoses. Regular maintenance of these systems is vital, including checking fluid levels, inspecting hoses for leaks, and ensuring proper lubrication. Troubleshooting hydraulic issues often involves identifying leaks, diagnosing pump malfunctions, or checking for blockages within the system.

One instance involved a malfunctioning hydraulic pump in a portable scissor lift. By methodically checking the fluid levels, inspecting the pump itself for damage and checking for any blockages in the lines I successfully diagnosed the problem as a failing pump seal, and recommended its replacement to prevent a potential safety hazard.

Q 12. Explain your understanding of different types of portable lifting equipment.

Portable lifting equipment encompasses a variety of tools designed for lifting and moving loads. These include chain hoists, lever hoists, come-alongs, jacks (hydraulic, screw, and mechanical), and portable cranes. Each type has its own capacity, lifting height, and operational characteristics. Chain hoists offer a high lifting capacity and are relatively simple to operate; however, they require careful attention to prevent chain slippage. Lever hoists provide a mechanical advantage, but their lifting height may be limited. Jacks are useful for lifting heavy objects a short distance, but they must be correctly positioned for stability. Portable cranes offer more versatility than other options but generally require more extensive training and safety precautions for operation. Selecting the correct equipment for a given task depends on the weight of the load, the lifting height required, and the available workspace.

I recall working on a project that involved moving some heavy machinery in a tight space. Choosing the correct type of chain hoist with the right weight capacity and ensuring that it was correctly rigged was absolutely critical for the success and safety of the operation.

Q 13. How do you ensure the accuracy of measurements using portable equipment?

Ensuring accurate measurements when using portable equipment involves several key steps. Firstly, selecting appropriate equipment for the task is crucial. Using a worn or improperly calibrated tool will lead to inaccuracies. Regular calibration and maintenance of equipment are essential, often involving comparing the readings to a known standard. Secondly, the operator needs to understand and follow the manufacturer’s instructions for the tool, including proper setup and operational procedures. Finally, environmental factors such as temperature and humidity can influence measurements; appropriate corrections must be made where necessary. Additionally, multiple measurements should be taken and averaged to reduce random error. For precise measurements, using higher-precision equipment and techniques might be necessary.

In surveying work, for example, using a high-quality laser level and understanding factors like temperature gradients and earth curvature are key to achieving high precision in measurements. Taking multiple measurements and comparing them allows for identifying and mitigating potential errors.

Q 14. What are the environmental considerations when operating portable equipment?

Environmental considerations when operating portable equipment are crucial for both safety and environmental protection. Operating equipment in extreme temperatures can affect engine performance, battery life, and the structural integrity of the equipment. Extreme heat can lead to overheating, while extreme cold can hinder engine starting and potentially damage components. Additionally, the type of fuel used can impact the environment through emissions; using cleaner-burning fuels like propane or choosing electrically powered equipment can mitigate this concern. Noise pollution can also be a significant factor, especially in densely populated areas. Using noise-reducing equipment or employing operational practices to minimize noise levels is important. Finally, potential spills of fuels or other hazardous materials pose an environmental risk, requiring careful handling and containment procedures.

For example, operating a diesel-powered generator in a confined space without proper ventilation could lead to carbon monoxide poisoning. Similarly, a fuel spill could contaminate soil or water sources. I always make it a priority to follow all safety regulations and to use appropriate environmentally conscious practices in my work.

Q 15. How do you maintain accurate records related to portable equipment operation?

Maintaining accurate records for portable equipment operation is crucial for safety, accountability, and regulatory compliance. It ensures traceability of equipment usage, maintenance, and any incidents. My approach involves a multi-faceted system.

Logbooks: Each piece of equipment has a dedicated logbook, meticulously recording date of use, operator’s name, operating hours, location, any maintenance performed, and importantly, any observed malfunctions or near misses. Think of it like a detailed diary for each machine.

Digital Databases: For larger projects or fleets of equipment, I utilize digital databases. This allows for easier data analysis, trend identification, and reporting. Software features like automated reminders for maintenance are invaluable.

Inspection Checklists: Before and after each use, I complete comprehensive checklists detailing the equipment’s condition. This proactive approach prevents problems from escalating. These checklists are then filed with the relevant logbook.

Incident Reporting: Any accidents, near misses, or equipment failures are immediately reported using a standardized incident report form. This enables thorough investigation and prevents future occurrences.

This systematic recording keeps a clear audit trail, simplifying troubleshooting, facilitating maintenance scheduling, and ensuring adherence to safety regulations.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your proficiency in using specific portable equipment (e.g., generators, pumps).

I’m proficient in operating various portable equipment, with extensive experience in generators and pumps.

Generators: I’m experienced with both gasoline and diesel generators, ranging from small, portable units to larger, industrial models. My expertise includes understanding load calculations to prevent overloading, performing routine maintenance like oil changes and air filter replacements, and troubleshooting common issues like starting problems or erratic power output. For instance, during a recent remote site project, I successfully diagnosed a generator’s faulty voltage regulator, preventing a costly shutdown.

Pumps: I’m skilled in operating various pump types, including centrifugal, diaphragm, and submersible pumps. This includes understanding different pump applications (e.g., dewatering, transfer), selecting the appropriate pump for the task, and recognizing signs of wear and tear. In one instance, I utilized a submersible pump to quickly dewater a flooded basement, minimizing property damage.

My experience extends to safe handling procedures, including proper grounding and lockout/tagout procedures to prevent electrical hazards.

Q 17. Describe your experience with different types of portable welding equipment.

My experience with portable welding equipment encompasses various types, including:

Shielded Metal Arc Welding (SMAW): Commonly known as stick welding, I’m proficient in using this versatile technique for various materials and thicknesses. I understand the importance of proper electrode selection based on the base metal and welding position.

Gas Metal Arc Welding (GMAW): Also known as MIG welding, I’m skilled in using this process for faster, more efficient welding, particularly for sheet metal and thinner materials. I understand the critical role of shielding gas selection and wire feed speed adjustments.

Gas Tungsten Arc Welding (GTAW): Or TIG welding, which allows for precise control and high-quality welds. This technique requires more skill and precision, and I’m experienced in its use for critical applications where high-quality welds are paramount.

Beyond the different welding processes, I understand the importance of safety precautions, such as proper ventilation, eye and respiratory protection, and understanding the hazards of working with electricity and high temperatures.

Q 18. What are the regulatory compliance issues related to operating portable equipment?

Operating portable equipment involves several regulatory compliance issues, varying by location and specific equipment type. Key concerns include:

Occupational Safety and Health Administration (OSHA) Regulations: These regulations cover aspects like lockout/tagout procedures, personal protective equipment (PPE) requirements, and safe operating practices. I’m familiar with OSHA standards relevant to portable equipment, and I always ensure compliance.

Environmental Protection Agency (EPA) Regulations: Regulations regarding emissions and waste disposal are important when dealing with generators and other equipment. Proper disposal of used oil and other hazardous materials is always followed.

Local and State Regulations: Specific requirements may vary depending on the location. I always research and comply with any local or state permits or licensing requirements for operating portable equipment.

Staying updated with these regulations is an ongoing process, and I actively seek out training and updates to maintain my knowledge and ensure safe and compliant operation.

Q 19. How do you adapt your operating techniques to different work environments?

Adapting to different work environments is essential for efficient and safe portable equipment operation. My approach involves:

Site Assessment: Before commencing work, I thoroughly assess the worksite for potential hazards, including uneven terrain, confined spaces, electrical hazards, and weather conditions. This proactive assessment allows me to plan accordingly and select the right equipment and safety measures.

Equipment Selection: Choosing the right equipment for the specific task and environment is critical. For example, using a lightweight, portable generator for a residential job versus a heavier-duty, industrial generator for a large construction site.

Safety Precautions: Adjusting safety measures based on the environment is crucial. This includes using appropriate PPE like hard hats, safety glasses, and gloves. In confined spaces, special ventilation or gas detection equipment may be needed.

Weather Considerations: Operating equipment in extreme temperatures or inclement weather requires additional precautions. This could include using weatherproof covers, employing additional safety measures in wet conditions, or postponing work if conditions are too hazardous.

Flexibility and adaptability are key. I always prioritize safety and ensure that my operating procedures are suitable for the unique challenges each site presents.

Q 20. Describe your experience with pre-operational and post-operational procedures.

Pre-operational and post-operational procedures are crucial for ensuring safe and efficient equipment operation and extending the lifespan of the equipment.

Pre-operational Procedures: This includes a thorough inspection of the equipment for damage or leaks, checking fuel levels, ensuring proper grounding, and confirming all safety mechanisms are functioning correctly. A visual inspection for any loose parts or signs of wear is also essential.

Post-operational Procedures: After operation, I ensure the equipment is properly shut down, cleaned, and stored securely. This includes refilling fuel (where applicable), draining water or other fluids, cleaning and lubricating moving parts, and properly storing the equipment to protect it from the elements. Any maintenance needs identified during operation or inspection are also recorded in the logbook.

These procedures, consistently followed, prevent accidents, extend equipment life, and maintain efficiency. They’re not just steps in a process; they’re about proactive maintenance and ensuring safety.

Q 21. How do you prioritize tasks when operating multiple pieces of portable equipment?

Prioritizing tasks when operating multiple pieces of portable equipment requires a systematic approach. My strategy involves:

Task Dependency: Identify tasks with dependencies. Some tasks may require the output of another. For example, a pump might need a generator to power it. These dependent tasks are prioritized first.

Urgency and Importance: Tasks are categorized by urgency and importance. A critical task, like dewatering a flooded area, takes precedence over a less urgent task, such as running a small tool.

Safety Considerations: Safety always comes first. Tasks that pose higher safety risks are given priority to minimize potential hazards.

Resource Allocation: I consider resource constraints such as fuel levels, manpower availability and potential equipment limitations. This ensures efficient utilization of resources and prevents delays.

Planning and Scheduling: I often use a simple schedule or checklist to sequence tasks, ensuring efficient work flow. This helps avoid conflicts and optimize resource allocation.

This structured approach ensures that I efficiently and safely handle multiple pieces of equipment, completing tasks effectively and minimizing downtime.

Q 22. How do you handle unexpected downtime or equipment malfunctions?

Unexpected downtime is a fact of life with portable equipment. My approach is methodical and prioritizes safety. First, I assess the situation – is it a minor issue I can fix, or is it something requiring more expertise or specialized tools? For minor issues, I’ll follow established troubleshooting procedures, often consulting the equipment’s manual. For example, if a generator won’t start, I’ll check fuel levels, spark plugs, and air filters before escalating. If it’s a more serious malfunction, I immediately shut down the equipment, secure the area, and report the issue to my supervisor, clearly outlining the problem and any potential safety hazards. Then, I’ll assist in the repair process, perhaps by documenting the issue or preparing the equipment for transport to a repair facility. Preventing downtime is key; this involves regular preventative maintenance and diligent attention to operating procedures.

Q 23. Explain your understanding of load capacity and safe operating limits.

Load capacity refers to the maximum weight or force a piece of equipment can safely handle. Safe operating limits encompass a wider range of parameters beyond just weight, including things like operating temperature, engine RPMs, and environmental conditions (e.g., extreme heat or cold). Exceeding these limits can lead to equipment failure, injury, or even death. For example, a forklift has a clearly stated load capacity – attempting to lift more than this capacity could result in structural damage or tipping. Similarly, a generator has operating temperature limits; exceeding these limits could cause overheating and engine damage. Understanding these limits is paramount to safe and efficient operation. I always consult the manufacturer’s specifications before operation and carefully monitor the equipment during use, ensuring I stay well within the safe operating limits.

Q 24. Describe your experience working with different types of fuels and lubricants.

My experience spans various fuels and lubricants, from gasoline and diesel for generators and pumps to specialized hydraulic fluids for power tools. I understand the importance of using the correct type and grade of fuel and lubricant for each piece of equipment. Using the wrong fuel can damage the engine, while improper lubricant can lead to premature wear and tear. For example, using diesel fuel in a gasoline engine will cause severe damage, and vice versa. Similarly, using the wrong viscosity of oil can lead to poor lubrication and engine failure. I always check the manufacturer’s recommendations before adding any fuel or lubricant, and I’m meticulous about keeping records of maintenance activities to ensure consistent use of appropriate products.

Q 25. What are your experience with different types of portable compressors?

I’ve worked with various portable compressor types, including reciprocating, rotary screw, and centrifugal compressors. Reciprocating compressors are simpler, well-suited for smaller applications, but can be noisier and less efficient. Rotary screw compressors offer higher efficiency and quieter operation, making them suitable for larger projects. Centrifugal compressors are commonly used for high-volume applications. My experience involves diagnosing issues like low air pressure, leaks, and overheating. For example, I’ve troubleshooting a reciprocating compressor where low air pressure turned out to be a simple issue of a loose air filter. In other instances, a more significant repair was needed – for instance replacing faulty seals in a rotary screw compressor to eliminate leaks.

Q 26. How do you communicate effectively with your team regarding equipment operation?

Effective communication is critical for safety and efficiency. I use clear, concise language, avoiding jargon unless necessary. Pre-operation briefings are key; I ensure everyone understands the tasks, the equipment’s operating procedures, and any potential hazards. During operation, I maintain open lines of communication, using visual signals as needed in noisy environments. For instance, hand signals might be used to guide a forklift operator. After completion, I conduct a thorough debriefing, discussing any issues encountered, lessons learned, and areas for improvement. Documentation of all activities and communications helps maintain accountability and prevent future errors.

Q 27. Describe a time you had to solve a complex problem related to portable equipment.

During a large-scale construction project, a critical piece of equipment, a large air compressor, malfunctioned during a crucial phase. The initial diagnosis pointed to a possible problem with the cooling system. However, simple solutions like checking coolant levels and cleaning the radiator were unsuccessful. This involved methodical troubleshooting. I systematically checked all components including pressure gauges, valves, and safety releases. I discovered a leak in a less accessible part of the compressor that required specialized tools. By carefully dismantling the section, we identified and sealed the leak using a suitable sealant. This meticulous approach, combined with my familiarity with compressor mechanics, enabled a quick resolution, preventing significant project delays and cost overruns.

Q 28. How do you stay up-to-date on the latest safety regulations and best practices?

Staying up-to-date involves a multi-pronged approach. I regularly attend safety training courses and workshops offered by industry associations. I also subscribe to relevant industry publications and online resources, which keep me informed about new regulations and best practices. Manufacturer’s websites are an invaluable source of information on equipment-specific safety procedures. By actively participating in these activities, I maintain a high level of competence and ensure my practices align with current safety standards.

Key Topics to Learn for Portable Equipment Operation Interview

- Equipment Familiarization: Understanding the operation, safety features, and limitations of various portable equipment types (e.g., generators, pumps, welders, compressors).

- Safety Procedures and Regulations: Demonstrating knowledge of OSHA standards, lockout/tagout procedures, and personal protective equipment (PPE) requirements for safe operation.

- Maintenance and Troubleshooting: Explaining routine maintenance tasks, identifying common malfunctions, and outlining basic troubleshooting steps for portable equipment.

- Practical Application: Describing scenarios where you’ve successfully used portable equipment to solve a problem or complete a task efficiently and safely. Highlighting problem-solving skills is crucial.

- Fuel Systems and Management: Understanding different fuel types, appropriate handling procedures, and the importance of fuel efficiency and conservation.

- Environmental Considerations: Demonstrating awareness of environmental regulations and best practices related to noise pollution, emissions, and waste disposal when using portable equipment.

- Emergency Procedures: Explaining actions to take in case of equipment malfunction, accidents, or emergencies involving portable equipment.

- Technical Specifications and Data Interpretation: Showing ability to understand and interpret technical manuals, specifications sheets, and operational data for various equipment.

Next Steps

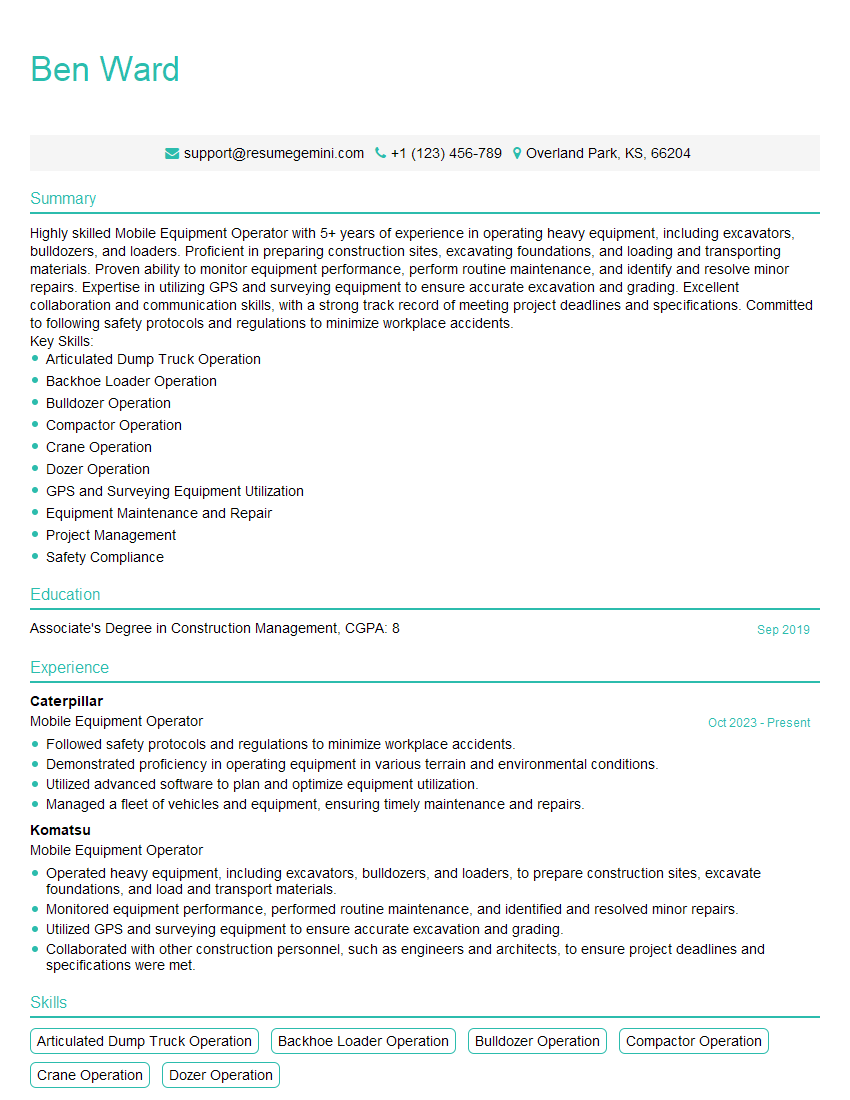

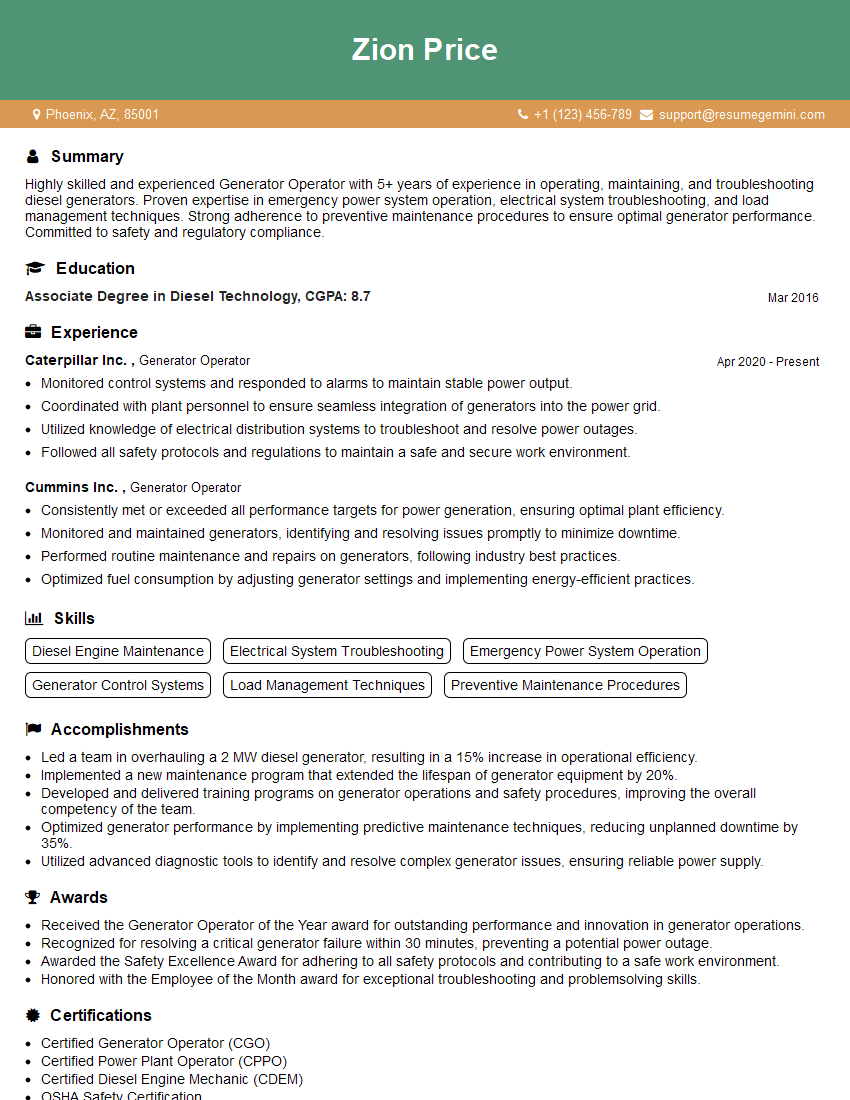

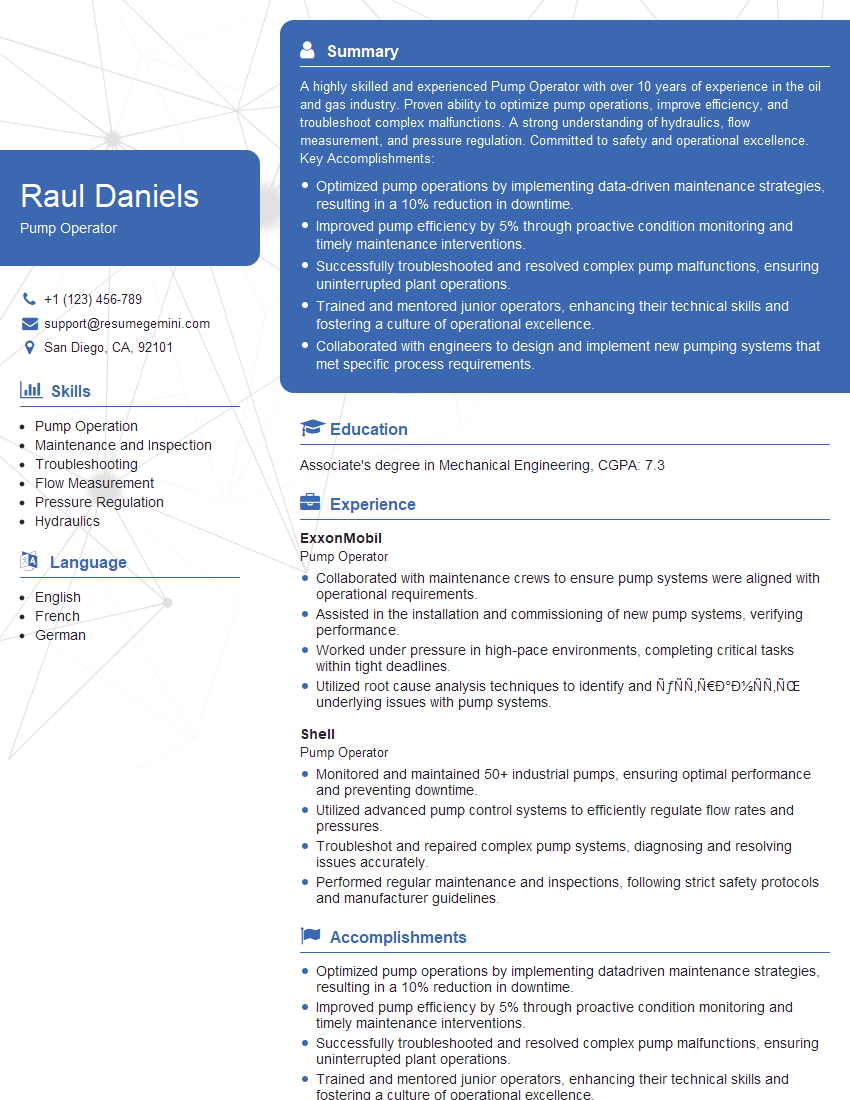

Mastering Portable Equipment Operation opens doors to diverse and rewarding career opportunities in construction, industrial maintenance, and various field service roles. A strong understanding of these skills is highly valued by employers. To maximize your job prospects, focus on creating an ATS-friendly resume that effectively showcases your expertise. ResumeGemini is a trusted resource to help you build a professional and impactful resume. We offer examples of resumes tailored to Portable Equipment Operation to guide you through the process. Investing time in crafting a strong resume will significantly increase your chances of securing your dream job.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good