Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Screen Ruling and Dot Gain Analysis interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Screen Ruling and Dot Gain Analysis Interview

Q 1. Explain the concept of screen ruling and its impact on print quality.

Screen ruling refers to the number of lines per inch (lpi) used to create a halftone image in printing. Think of it like a tiny grid overlaid on your image; each square in that grid is filled with dots of varying sizes to represent different tones. Higher lpi means finer detail and smoother transitions between colors, resulting in a sharper, higher-quality print. Conversely, lower lpi leads to a coarser, more pixelated appearance, suitable for applications where fine detail isn’t crucial. The choice of screen ruling is heavily dependent on the printing process (offset, flexography, etc.), paper type, and the desired level of detail in the final product. For instance, high-end magazine printing might use a 175 lpi screen, whereas a simple poster might use only 85 lpi.

The impact on print quality is significant. A screen ruling that’s too low for the detail in the image results in a muddy, indistinct print. A screen ruling that’s too high, especially on a coarse paper, can lead to poor ink lay and a moiré pattern—an unwanted interference pattern of wavy lines.

Q 2. What are the different types of screen rulings and their applications?

There are several types of screen rulings, primarily distinguished by the shape and arrangement of the dots:

- Amplitude-Modulated (AM) Screens: These screens vary the size of the dots to represent tonal values, keeping the dot spacing consistent. This is the most common type used in printing.

- Frequency-Modulated (FM) Screens: These screens use dots of consistent size but vary their spacing to represent tonal values. FM screens often produce smoother gradations and less moiré, particularly at higher resolutions.

- Hybrid Screens: These screens combine aspects of both AM and FM screens to leverage the advantages of each. They aim for the best balance between smoothness and print fidelity.

Applications: AM screens are widely used in offset and flexographic printing due to their relative simplicity and compatibility with existing equipment. FM screens are becoming more prevalent in high-quality printing, particularly where smooth gradations and sharp details are vital, like in packaging or high-end publications. Hybrid screens find their niche in applications needing a balance between these characteristics.

Q 3. How does screen ruling affect dot gain?

Screen ruling directly influences dot gain. Higher screen rulings generally lead to smaller dots, making them more susceptible to dot gain. This is because smaller dots have a larger surface area relative to their volume, increasing the likelihood of ink spreading during the printing process. Conversely, lower screen rulings, with larger dots, tend to experience less dot gain because the ink has less tendency to spread.

Imagine trying to spread a small drop of water on a surface versus a large drop. The small drop will spread more easily. This analogy helps understand why smaller dots (higher lpi) exhibit more dot gain.

Q 4. Define dot gain and its causes.

Dot gain is the increase in the size of a printed dot compared to its size on the film or plate. It’s an unavoidable phenomenon in printing, influencing the overall tonal values and color reproduction of the final image. A 10% dot on the film might print as a 15% dot due to dot gain. This increase isn’t necessarily uniform across all dot sizes.

Causes of Dot Gain:

- Ink Properties: Ink viscosity and tack affect how much the ink spreads during printing.

- Paper Properties: The absorbency and surface texture of the paper influence ink penetration and spreading.

- Printing Pressure: Excessive printing pressure can cause ink to spread and increase dot gain.

- Printing Process: Different printing methods (offset, flexo, screen) have varying degrees of inherent dot gain.

Q 5. Describe the relationship between screen frequency and dot gain.

The relationship between screen frequency (lpi) and dot gain is inversely proportional—to a point. Higher screen frequencies (more lpi) generally result in greater dot gain because smaller dots have more surface area for ink spread, as explained earlier. However, this relationship isn’t strictly linear. Extremely high screen frequencies may not always lead to proportionally higher dot gain, and other factors, such as ink and paper properties, dominate.

Think of it like this: a very fine mesh (high lpi) will allow ink to spread more readily than a coarser mesh (low lpi). But, above a certain point, the ink may not have enough space to spread further, reducing the impact of higher frequency.

Q 6. How do you measure dot gain?

Dot gain is measured using a densitometer, which measures the optical density of printed patches. This instrument measures the percentage of ink coverage, allowing comparison between the intended dot size (on film/plate) and the actual printed dot size. The difference represents the dot gain percentage.

Specialized software can also analyze scanned images of test prints to calculate dot gain. These tools typically use image analysis techniques to accurately measure dot sizes and calculate the gain percentage across a range of tonal values.

Q 7. What are the common methods for controlling dot gain?

Several methods exist for controlling dot gain:

- Controlling Printing Parameters: Optimizing printing pressure, ink viscosity, and drying time can significantly reduce dot gain.

- Using Appropriate Paper: Selecting a paper with a suitable surface texture and absorbency is crucial for minimizing dot gain.

- Employing Dot Gain Compensation (DGC): This involves using software to pre-compensate for expected dot gain during the image creation process. The software adjusts the dot sizes on the film/plate to account for the expected gain during printing, resulting in a more accurate final print.

- Using Specialized Inks: Inks with lower viscosity and improved drying characteristics can help minimize dot gain.

- Choosing the right screen ruling and printing method: Matching the screen ruling to the paper and printing process is essential for optimal results. FM screens, for example, can significantly reduce moire and dot gain compared to traditional AM screens.

Effective dot gain control requires a holistic approach, considering all these aspects to achieve accurate color reproduction and print quality.

Q 8. Explain the impact of paper type on dot gain.

Paper type significantly impacts dot gain, which is the increase in the size of a printed dot compared to its intended size on the plate. Different papers have varying degrees of absorbency and surface smoothness. Think of it like dropping ink onto different surfaces: a rough, absorbent surface (like newsprint) will cause the ink to spread more than a smooth, less absorbent surface (like coated paper).

- Highly absorbent papers: These lead to higher dot gain because the ink is rapidly absorbed into the paper fibers, causing it to spread out and increase the dot’s size. This is why newspapers often appear less sharp and more muted in color.

- Coated papers: Coated papers have a smooth, non-porous surface that minimizes ink absorption. This results in lower dot gain and sharper, more vibrant prints, making them ideal for high-quality images and graphics.

- Uncoated papers: These fall somewhere in between, exhibiting moderate dot gain depending on the specific paper type and its coating (or lack thereof).

Understanding this relationship is crucial for color management. You need to adjust your pre-press settings to compensate for the expected dot gain of the chosen paper to achieve the desired final print output.

Q 9. How does ink type influence dot gain?

Ink type plays a vital role in determining dot gain. The viscosity (thickness), drying properties, and chemical composition of the ink all influence how it interacts with the paper and the printing process. Imagine trying to paint with thick versus thin paint; the thick paint will spread more readily.

- High-viscosity inks: These thicker inks tend to exhibit higher dot gain as they spread more easily on the paper surface.

- Low-viscosity inks: Less viscous inks result in lower dot gain due to their reduced tendency to spread.

- Drying time: Quick-drying inks minimize dot gain because the ink sets quickly, reducing lateral spread. Conversely, slow-drying inks allow more time for the ink to spread, leading to higher dot gain.

The choice of ink is critical for achieving the desired level of dot gain and controlling the overall print quality. Printers often tailor ink formulations to optimize for specific paper types and printing conditions.

Q 10. Describe the role of color management in mitigating dot gain issues.

Color management is essential for mitigating dot gain issues. It involves a systematic process of controlling color from the digital design stage through to the final print. By accurately characterizing the printing system (including the paper and ink), we can compensate for the anticipated dot gain during the pre-press phase.

Software like Adobe Photoshop, Illustrator, and dedicated color management systems (CMS) use color profiles to define the relationship between the digital values and the actual colors produced on a particular printing press with specific paper and ink combinations. These profiles incorporate dot gain information, allowing the system to adjust the digital file before printing, thus minimizing unexpected variations in color and tone.

For example, if we know a particular paper causes 15% dot gain in cyan, the CMS can adjust the cyan values in the digital file to be slightly lighter beforehand, ensuring the final printed cyan reaches the intended density.

Q 11. What is the significance of the printing process on dot gain?

The printing process dramatically influences dot gain. Different printing methods (offset lithography, flexography, screen printing, etc.) have distinct mechanical properties that affect ink transfer and dot reproduction. Even within a single process like offset, the printing pressure, ink-water balance, and the type of printing plate can affect dot gain.

- Offset lithography: Dot gain in offset is significantly affected by the pressure applied during printing. Higher pressure results in increased dot spread. The ink-water balance is also critical; an imbalance can lead to increased dot gain.

- Flexography: Flexo plates typically have a higher dot gain compared to offset plates. This is due to the flexible nature of the plates and the anilox roller’s influence on ink transfer.

- Screen Printing: Screen printing involves a different mechanism for ink deposition, and the mesh screen’s properties, along with the squeegee pressure and ink viscosity, affect the dot’s final size and shape.

Understanding these process-related factors is crucial for controlling and predicting dot gain, and careful press adjustments are necessary to maintain consistent results.

Q 12. How do you interpret dot gain values from a densitometer reading?

A densitometer measures the density of printed areas. We use it to indirectly determine dot gain. We measure the density of solid patches (100% dots) and tints (e.g., 50% dots). The difference between the measured density and the theoretical density (based on the intended dot percentage) provides an indication of dot gain.

For instance, if a 50% tint should theoretically measure 1.00 density, but the densitometer reads 1.20, there’s a 20% dot gain. This suggests the 50% dots have spread to cover approximately 70% of the area. We can use this information to create or fine-tune color profiles to compensate for the observed dot gain in future prints.

Remember that multiple measurements are crucial for accuracy, especially when characterizing the printing process. It’s good practice to take several readings across the sheet and across different print runs.

Q 13. Explain the concept of dot area and its relation to dot gain.

Dot area refers to the actual physical area occupied by a printed dot on the substrate. Dot gain directly affects the dot area. Ideally, a 50% dot would occupy 50% of the intended area. However, due to dot gain, the actual dot area expands beyond the theoretical 50%, perhaps to 60% or more. This increased area directly impacts the perceived color density and tonal reproduction.

The relationship is simple: higher dot gain implies a larger actual dot area compared to the theoretical dot area. This increased area leads to darker printed areas, impacting contrast and potentially making the print appear muddy or less sharp.

Accurate dot area control is essential for maintaining accurate color reproduction and achieving the intended visual appearance of the print.

Q 14. What are the visual effects of excessive dot gain?

Excessive dot gain results in several undesirable visual effects that severely compromise print quality:

- Muddy or Dull Colors: Colors appear darker and less saturated than intended, losing vibrancy and clarity. Midtones become compressed, reducing detail and contrast.

- Loss of Detail and Sharpness: Fine details, especially in images and text, are blurred and less defined because of the spreading of the dots.

- Reduced Contrast: The difference between light and dark areas is diminished, making the image appear flat and lacking in depth. This is particularly noticeable in high-contrast images.

- Color Shifts: Unexpected color shifts can occur, as the increased dot size alters the color balance and perception. For instance, colors may appear more saturated than intended or develop an unwanted tint.

Excessive dot gain is a significant problem in high-quality printing, so meticulous control of the printing process and careful pre-press color management are crucial to avoid these issues.

Q 15. How does dot gain affect color reproduction?

Dot gain, the increase in the size of a printed dot compared to its intended size on the film or plate, significantly impacts color reproduction. Imagine you’re trying to paint a delicate watercolor – if your brush deposits more paint than intended, the colors will appear more saturated and darker. Similarly, excessive dot gain leads to richer, darker colors than desired. This is because larger dots cover more area, resulting in increased ink density. Conversely, low dot gain leads to lighter, less saturated colors.

For instance, a 50% cyan dot intended on the plate might print as a 65% dot due to dot gain. This means the cyan will appear much more vibrant, potentially leading to a color shift away from the intended color profile. Accurate color reproduction necessitates careful control of dot gain throughout the printing process, often using color management systems to compensate for known dot gain characteristics of the printing press and substrates.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe how you would troubleshoot high dot gain in a print job.

Troubleshooting high dot gain involves a systematic approach. First, I’d examine the entire printing process, starting from the prepress stage.

- Prepress: Check the dot shape and size on the film or plate. Irregular or oversized dots will increase dot gain. We need to confirm proper screening angles and frequency. We also need to ensure that the proofing system matches the printing characteristics.

- Press Settings: Examine the press conditions – ink viscosity, ink-water balance, and printing pressure. Excessive ink, insufficient water (in offset printing), or excessive pressure will all contribute to higher dot gain. This often requires precise adjustments, for example, reducing ink density or using a more absorbent blanket.

- Substrate: The type of paper plays a crucial role. Highly absorbent paper will lead to more dot gain than a smooth, coated paper. Using a different paper stock, with lower absorbency might be a viable solution.

- Plate and Blanket Condition: Worn or damaged plates and blankets can impact ink transfer, resulting in inconsistent dot gain. A quick check on the condition of the press plate and blanket is necessary.

I would then utilize colorimetric measurement tools to quantify the dot gain, creating a detailed report for further analysis. The process would require iterative adjustments and testing to optimize the press until the dot gain is within acceptable tolerances.

Q 17. What are the ideal dot gain percentages for different printing processes?

There’s no single ‘ideal’ dot gain percentage that applies universally across all printing processes. It’s highly dependent on the specific printing method, the desired image quality, and the substrate. However, typical ranges are often used as guidelines.

- Offset Printing: A range of 10-15% dot gain is often considered acceptable for high-quality offset printing. Higher values are frequently observed in newsprint printing.

- Digital Printing (e.g., toner-based): Digital printing usually exhibits lower dot gain, often between 5-10%, due to the different ink transfer mechanisms.

- Flexography: Flexo, especially with a high-density ink, might experience higher dot gain, potentially reaching 15-20% or even more, depending on the substrate and ink formulation.

It’s crucial to understand that these values are targets. The actual acceptable range is usually defined within the color profiles used for a specific project, with variations considered during proofing and color correction steps.

Q 18. How does dot gain affect image sharpness and detail?

Dot gain directly impacts image sharpness and detail. Excessive dot gain causes a blurring effect. Think of it like over-sharpening a photo – initially, details seem clearer, but going too far causes a halo effect, making the image look less sharp. Similarly, high dot gain causes dots to merge, obscuring fine details and reducing the overall image resolution. Conversely, insufficient dot gain leads to a thin, washed-out appearance, lacking depth and richness.

For instance, in fine-line illustrations or detailed photographs, high dot gain will result in a loss of definition in thin lines, turning them into thick, blurred strokes. Conversely, low dot gain in a photograph would mean that dark areas appear too light and less detailed.

Q 19. What software or tools are used to measure and analyze dot gain?

Several software and tools are used to measure and analyze dot gain. Densitometers, which measure the density of printed areas, provide an initial assessment, though they don’t directly measure dot size. However, combined with advanced software, they enable accurate dot gain calculations.

Specialized software like X-Rite i1Profiler or other color management software can analyze dot gain using image analysis techniques. These tools capture images of printed samples at high resolution, and then use algorithms to determine the size of individual dots and calculate the percentage increase compared to their intended size. Microscopic analysis can be done to physically measure dot size, while spectrophotometers provide precise color measurements, allowing for a better understanding of the impact of dot gain on color reproduction. These measurements are crucial to create accurate color profiles for specific printing processes.

Q 20. Explain the relationship between dot gain and Total Ink Limit (TIL).

Total Ink Limit (TIL) refers to the maximum total amount of ink that can be applied to a printed substrate without causing issues such as drying problems, excessive ink trapping (ink sitting on top of other inks), or paper deformation. Dot gain directly affects TIL because higher dot gain means more ink is laid down per area, reducing the number of colors and the color saturation you can apply before exceeding the TIL.

For example, if you have a high dot gain, you might need to reduce the total ink percentage in each color to prevent exceeding TIL. This could result in muted colors or a compromise in the overall vibrancy of the print. Therefore, managing dot gain is essential for balancing color vibrancy with the physical limitations of the printing process and substrate.

Q 21. How does substrate (paper) influence screen ruling selection?

The substrate (paper) significantly influences screen ruling (lines per inch, lpi) selection. Highly absorbent paper tends to result in more dot gain. To compensate, a lower screen ruling (fewer lines per inch) might be chosen to minimize the blurring effect caused by excessive dot gain. The lower lpi allows the dots to spread more before merging. This means more ink spread can be accommodated while retaining some image sharpness.

Conversely, smooth, coated papers exhibit less dot gain. This allows for a higher screen ruling (more lines per inch), permitting more detail and finer halftones, resulting in a sharper, more detailed print. In short, the choice of screen ruling is a balancing act between the desired level of detail and the paper’s ink absorption properties, considering its effect on dot gain. Using a finer screen ruling on absorbent paper will result in more dot gain and loss of detail.

Q 22. Discuss the impact of improper press registration on dot gain.

Improper press registration, meaning misalignment of the printing plates, significantly impacts dot gain. Think of it like trying to perfectly stack building blocks – if they’re not aligned, the edges won’t match up cleanly. In printing, misregistration causes overlapping of ink from different color plates. This overlap increases the size of the dots, leading to unintended dot gain and muddiness in the printed image. The effect is particularly noticeable in areas with fine details or sharp color transitions. For example, a perfectly registered image will have crisp text and well-defined lines between colors. In contrast, a misregistered print will show blurred edges, uneven color distribution, and a general loss of sharpness, directly contributing to inconsistent and excessive dot gain across the printed surface. Correcting registration requires careful plate mounting and precise press adjustments.

Q 23. What steps can be taken during prepress to minimize dot gain?

Minimizing dot gain during prepress involves several crucial steps: First, proper screening angle selection is vital. Choosing angles that minimize moiré (interference patterns) reduces the chance of unwanted ink spread. Next, utilizing a calibrated color profile ensures the intended dot size is accurately translated to the printing plate. This is crucial because variations in the profile can cause unexpected dot expansion during printing. Careful selection of the printing inks is also critical. High-viscosity inks tend to spread more, causing greater dot gain than low-viscosity inks. Finally, the use of appropriate proofing methods – such as soft proofing with a calibrated monitor and hard proofing with a proofing system – allows for visual assessment and adjustments to mitigate dot gain before the actual printing. It’s like practicing a musical piece before the concert; prepress actions allow for early error detection and correction.

Q 24. Explain the difference between mechanical and optical dot gain.

Mechanical dot gain and optical dot gain are distinct but related phenomena influencing the final appearance of a printed image. Mechanical dot gain refers to the physical spreading of ink on the substrate during the printing process. Think of it like dropping a drop of water on a paper towel – it spreads out. This physical spread increases the dot’s size. Optical dot gain, on the other hand, is a visual effect where the printed dots appear larger than they actually are due to the scattering and reflection of light from the printed surface. It’s an optical illusion, making the dots look bigger than their physical dimensions. The combination of both mechanical and optical dot gain determines the total dot gain observed in the final print.

Q 25. How does humidity affect dot gain?

Humidity significantly affects dot gain, primarily by influencing the ink’s behavior. High humidity increases the moisture content in the air, which can lead to increased ink absorption into the paper and consequently greater ink spread (mechanical dot gain). This results in larger, softer dots. Conversely, low humidity can lead to slower drying times and potentially increased dot gain as the ink takes longer to set and may spread more before drying. The ideal humidity level for printing depends on the printing process and the type of ink and paper used; maintaining consistent humidity during printing is crucial for consistent dot gain and print quality. It’s like baking a cake; humidity plays a crucial role in the final product’s texture and consistency.

Q 26. Describe a situation where you had to troubleshoot a dot gain problem. What was the solution?

I once encountered a situation where a client’s print job exhibited unexpectedly high dot gain, leading to muddy colors and a loss of detail in the highlights. The problem was particularly noticeable in the lighter areas of the image, almost washing them out. After careful investigation, we found that the problem stemmed from a combination of factors. First, the paper stock used had a higher than expected ink absorbency. Second, the press operator had inadvertently increased the ink density settings slightly more than specified. The solution involved a two-pronged approach: We switched to a lower-absorbency paper with similar color characteristics and adjusted the ink settings on the press, carefully measuring dot gain with a densitometer. This corrected the dot gain problem and produced a print that met the client’s expectations.

Q 27. What are the implications of insufficient dot gain?

Insufficient dot gain can lead to several problems. Firstly, it results in images that appear too thin and lack richness in their tones, leading to a washed-out appearance. The colors appear muted and lack vibrancy, especially in the shadow areas. This is because the dots are too small to effectively reproduce the intended color density. Secondly, it can lead to printing issues and possibly the need for reprints. In extreme cases, highlights may appear almost completely absent of any color, giving an unsatisfactory finish to the print job. It’s like under-seasoning a dish; insufficient dot gain results in a bland, lifeless image.

Q 28. How can you compensate for dot gain during file preparation?

Compensating for dot gain during file preparation involves applying a dot gain compensation curve to the image. This is done using specialized software that digitally reduces the size of the dots in the image file before it’s sent to the printing press. The compensation curve is based on the expected dot gain for the specific printing process, paper stock, and ink used. This process is called dot gain compensation or dot gain correction. It is not a perfect science, however. A densitometer is used during print production to verify the dot gain, allowing for adjustment before a larger print run. This pre-press correction ensures that the final printed image has the intended color density and detail despite the natural dot gain during the printing process. Think of it as preemptively adjusting the recipe to account for ingredients changing during the cooking process.

Key Topics to Learn for Screen Ruling and Dot Gain Analysis Interview

- Understanding Screen Ruling: Explore the principles of screen ruling, including its impact on halftone reproduction, line screen frequency, and its relationship to image sharpness and resolution.

- Dot Gain Analysis: Learn to define and measure dot gain, understanding its causes (ink spread, paper absorption, printing pressure), and its effects on color accuracy and print quality.

- Color Management and Dot Gain: Investigate the interplay between color management systems (CMS) and dot gain compensation. Understand how ICC profiles and other color management tools are used to mitigate dot gain issues.

- Practical Applications: Examine real-world scenarios where understanding screen ruling and dot gain is crucial, such as pre-press quality control, troubleshooting print defects, and optimizing print production workflows.

- Calibration and Profiling: Learn about the importance of accurate color calibration and the creation of device profiles for consistent color reproduction, minimizing the impact of dot gain variations.

- Problem-solving approaches: Develop strategies for identifying and resolving problems related to screen ruling and dot gain, including analyzing print samples, adjusting printing parameters, and utilizing colorimetric measurements.

- Different Printing Processes: Understand how screen ruling and dot gain vary across different printing methods (offset, digital, flexography) and substrates (paper types, coated vs. uncoated).

Next Steps

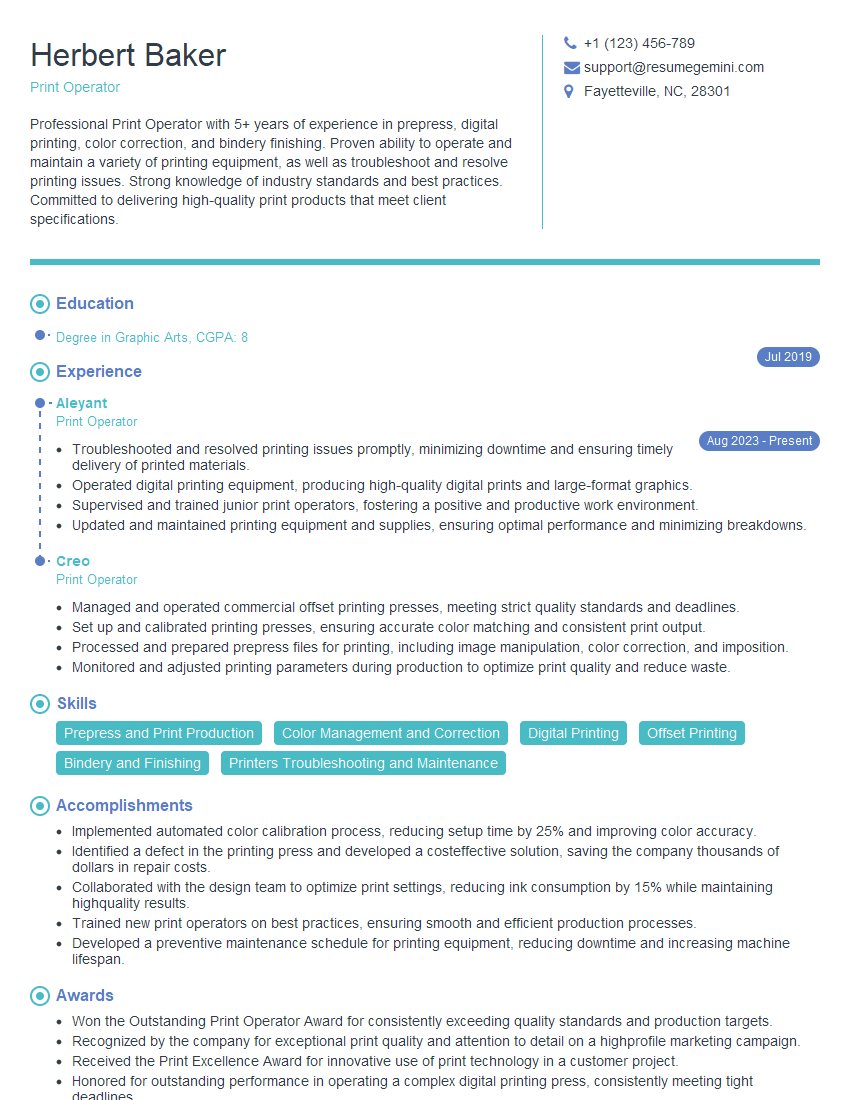

Mastering Screen Ruling and Dot Gain Analysis is vital for career advancement in the print and pre-press industries. A strong understanding of these concepts demonstrates technical proficiency and problem-solving skills highly valued by employers. To significantly boost your job prospects, focus on creating an ATS-friendly resume that highlights your relevant skills and experience. ResumeGemini is a trusted resource to help you build a professional and impactful resume. We provide examples of resumes tailored to Screen Ruling and Dot Gain Analysis to help you craft a compelling application that showcases your expertise.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good