The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to bindery equipment interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in bindery equipment Interview

Q 1. What are the different types of bookbinding methods?

Bookbinding methods encompass a variety of techniques to secure pages together, creating a durable and aesthetically pleasing finished product. The choice of method depends on factors like the number of pages, budget, desired look, and intended use. Common methods include:

- Perfect Binding: Used for magazines, softcover books, and journals. Pages are glued to a cover along the spine.

- Saddle Stitch Binding: Suitable for booklets and brochures with a low page count. Pages are folded and stapled in the center fold.

- Wire-O Binding: Creates a professional look for calendars, notebooks, and reports. Pages are punched with holes and bound with a double-loop wire.

- Spiral Binding (Coil Binding): Common for documents, reports, and presentations. Pages are punched with holes and bound with a plastic or metal coil.

- Case Binding: A high-quality method for hardcover books, involving sewing the pages together, adding endsheets, and applying a cover.

- Hard Cover Binding: A robust method for long-lasting books and requires significant equipment and expertise.

Each method offers unique advantages and limitations, making the selection crucial for the final product’s quality and functionality.

Q 2. Explain the process of perfect binding.

Perfect binding is a popular method for creating softcover books and magazines. The process involves several key steps:

- Gathering and Collating: Sheets of printed pages are precisely collated in the correct order.

- Three-Knife Trimming: The collated pages are trimmed to ensure a clean, even edge.

- Roughening the Spine: The spine edge of the pages is roughened using a sanding or abrading machine, creating a surface ideal for adhesive.

- Applying Adhesive: A thin layer of hot melt adhesive is applied to the roughened spine. This adhesive is specifically formulated for bookbinding and creates a strong bond.

- Cover Attachment: The prepared pages are carefully attached to the book cover, ensuring even adhesion along the spine.

- Pressing: The bound book is then placed under pressure to ensure a strong and even bond, removing any air bubbles and allowing the glue to set completely.

- Finishing: The final step might include trimming the edges of the cover to create a neat and professional look.

Think of it like making a really strong, flat sandwich where the pages are the filling and the cover is the bread, all held together with special glue.

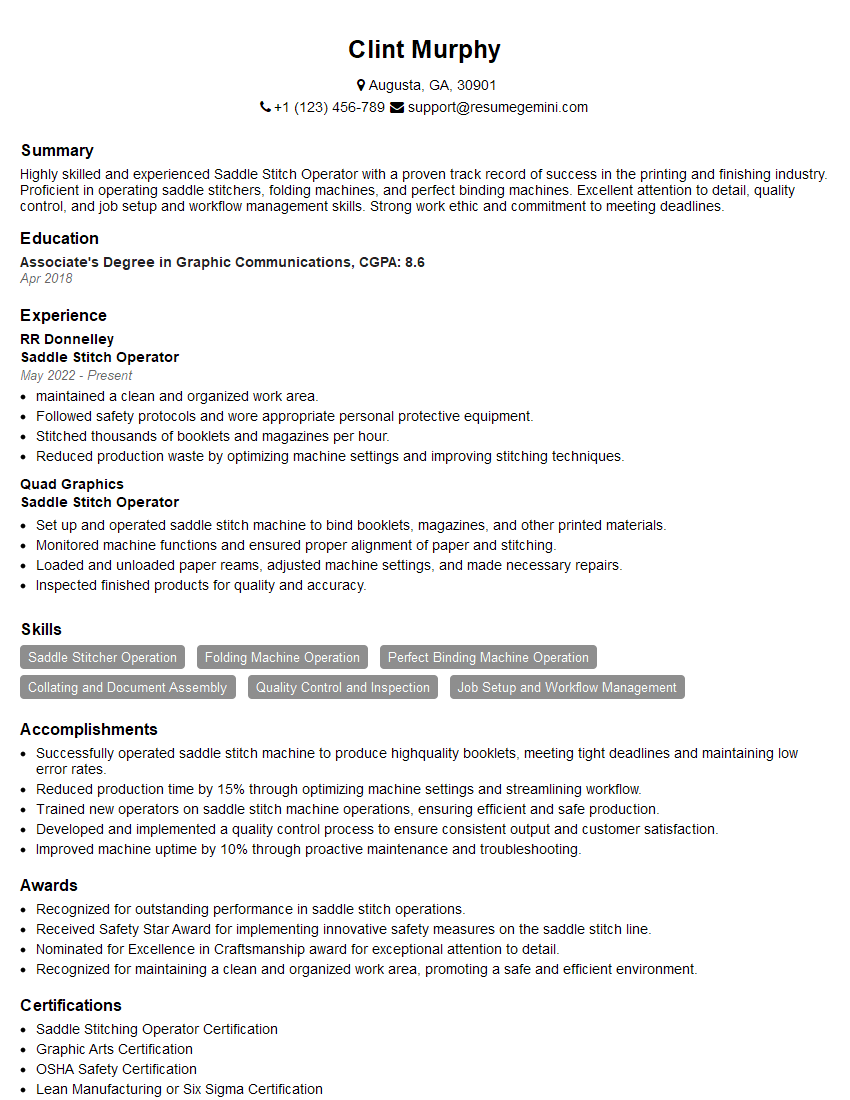

Q 3. Describe the operation of a saddle stitch machine.

A saddle stitch machine is a simple yet effective piece of bindery equipment used for binding documents with a low page count, such as brochures or booklets. The process is straightforward:

- Folding: The pages are folded in half, creating a central fold.

- Collating: The folded pages are then precisely stacked and collated.

- Stapling: The collated pages are fed into the saddle stitch machine where multiple wire staples are driven through the central fold, securing the pages together.

Imagine it like stapling multiple sheets of paper together in the middle – simple, quick, and cost-effective, but limited to relatively thin documents. The machine’s operation relies on precise timing and alignment to ensure the staples are correctly placed and securely fasten the pages.

Q 4. How does a three-knife trimmer work?

A three-knife trimmer is a crucial piece of bindery equipment that creates a perfectly square and even edge on blocks of paper. It uses three synchronized blades to precisely trim three sides (top, bottom, and one side) simultaneously. The process is as follows:

- Loading: The stack of papers or bound books is accurately placed onto the trimmer’s cutting bed.

- Alignment: Using precision guides, the stack is aligned to ensure a straight and even cut.

- Cutting: At the operator’s command, the three blades descend simultaneously, cutting the stack with speed and precision.

- Unloading: The neatly trimmed block is then removed from the trimmer.

The three knives work in perfect coordination, preventing any shifting or uneven cuts. It’s like a super-precise guillotine for paper, ensuring a professional finish.

Q 5. What are the common causes of jams in a folding machine?

Jams in folding machines are a common frustration, often stemming from several factors:

- Paper Misfeeds: This is the most frequent cause, arising from issues like crumpled sheets, incorrect paper size or weight, or problems with the paper feed mechanism.

- Incorrect Folding Settings: Incorrectly set folding plates or rollers can lead to jams, as the paper may not be folded correctly.

- Mechanical Issues: Worn rollers, broken belts, or misaligned components can affect the smooth functioning of the folding machine and lead to jams.

- High-Moisture Content Paper: Paper with high moisture content tends to stick together and can cause jams.

Regular maintenance, including cleaning the paper path and checking for worn parts, is vital to prevent jams.

Q 6. How do you troubleshoot a malfunctioning stitching head?

Troubleshooting a malfunctioning stitching head requires a systematic approach:

- Visual Inspection: Start by carefully examining the stitching head for any visible damage, such as bent needles, broken parts, or misalignment.

- Check Needle Condition: Ensure the needles are properly inserted, sharp, and free from damage. Bent or dull needles are a common cause of malfunctions.

- Check Lubrication: Adequate lubrication is crucial for the smooth operation of the stitching head. Apply the recommended lubricant.

- Check the Staple Supply: Ensure a consistent supply of staples.

- Check the Timing and Alignment: If the problem persists, check the timing and alignment of the stitching head components. This typically requires a technician.

Remember, safety first! Always disconnect the power before performing any maintenance or troubleshooting.

Q 7. Explain the difference between spiral and wire-O binding.

Both spiral and wire-O binding are popular methods for creating notebooks, calendars, and other documents that require pages to lay flat. However, they differ in their appearance and functionality:

- Spiral Binding (Coil Binding): Uses a continuous plastic or metal coil that is inserted through punched holes along the spine. This method allows the book to lay flat completely, but the coil can be easily removed.

- Wire-O Binding: Employs a double-loop wire that is inserted through punched holes. The wire is more secure than a coil and is less likely to come loose, but the book does not lay completely flat.

The choice between them often comes down to aesthetic preferences and the required level of security. Spiral binding is generally cheaper, while Wire-O offers a more professional and durable finish.

Q 8. What safety precautions should be followed when operating bindery equipment?

Safety is paramount when operating bindery equipment. Think of it like driving a powerful vehicle – you need training and vigilance. Before starting any machine, always ensure you’ve received proper training and understand the specific safety procedures for that model. Never operate equipment while fatigued or under the influence of drugs or alcohol.

- Lockout/Tagout Procedures: Always use lockout/tagout procedures before performing any maintenance or cleaning. This prevents accidental start-ups.

- Personal Protective Equipment (PPE): Always wear appropriate PPE, including safety glasses, hearing protection, and cut-resistant gloves. Some machines may require additional protective gear.

- Proper Clothing: Avoid loose clothing or jewelry that could get caught in moving parts.

- Emergency Stops: Familiarize yourself with the location and operation of all emergency stop buttons and switches.

- Clear Work Area: Keep the work area clear of obstructions and ensure adequate lighting.

- Machine Guards: Never operate a machine with missing or damaged safety guards. Report any issues immediately.

For example, before cleaning a paper cutter, always lock out the power supply, ensuring it is completely disconnected before touching any moving parts. This prevents accidental blade closure and serious injury.

Q 9. How do you ensure the quality of bound materials?

Ensuring the quality of bound materials is a multifaceted process involving careful attention to detail throughout the entire binding process. It starts with the quality of the incoming paper and continues through each stage. Think of it as baking a cake – using poor ingredients will result in a poor final product.

- Paper Inspection: Before binding, inspect the paper for defects, creases, or inconsistencies. This prevents flaws from propagating through the final product.

- Proper Setup: Ensure that all bindery machines are properly set up for the specific job requirements, including paper size, weight, and binding type. Incorrect settings can lead to misaligned pages, poorly adhered sections, and other defects.

- Regular Maintenance: Regular maintenance of the equipment is crucial to ensure proper function and prevent defects. A well-maintained machine will consistently produce quality results.

- Consistent Operator Technique: Skilled operators play a key role in maintaining consistent quality. Proper training and experience minimize errors.

- Quality Checks at Each Stage: Perform quality checks after each stage of the binding process to identify and correct any problems early on. This is far more efficient than discovering problems only after the entire job is complete.

- Final Inspection: Conduct a final inspection of the finished bound materials to ensure that the binding is secure and the pages are properly aligned. This includes a visual check as well as testing the spine’s durability.

For instance, if you’re using a perfect binder, regularly checking the glue rollers’ condition will prevent issues with improper adhesive application and ensure a strong, lasting binding.

Q 10. What are the common maintenance procedures for a perfect binder?

Regular maintenance is essential for a perfect binder to ensure efficient operation and high-quality output. Think of it like servicing your car – regular checkups prevent major breakdowns.

- Cleaning: Regularly clean the glue system, including the glue pot, rollers, and applicator. Removing dried glue prevents clogs and ensures even glue distribution.

- Roller Inspection and Replacement: Inspect the glue rollers for wear and tear. Replace them as needed to maintain even glue application and prevent poor binding quality.

- Clamp Adjustment: Adjust the clamps to ensure that they apply even pressure to the book block for consistent binding.

- Knife Adjustment: Regularly check and adjust the knife to ensure that it makes a clean, even cut. A dull knife can lead to uneven trimming and poor quality.

- Lubrication: Lubricate moving parts according to the manufacturer’s recommendations. This reduces friction and wear and tear, extending the lifespan of the machine.

- Belt Tension: Check and adjust belt tension. Loose belts can cause slipping and inconsistent performance.

For example, a build-up of dried glue on the glue rollers will lead to uneven adhesive application, resulting in pages falling out of the bound book. Regular cleaning prevents this problem.

Q 11. Describe the process of setting up a folding machine for a specific job.

Setting up a folding machine involves a series of steps to ensure accurate and efficient folding. Imagine setting up a complex origami project – precision is key. Each step is critical to a successful fold.

- Identify Paper Specifications: Determine the paper size, weight, and type. This information dictates the folding settings.

- Select Folding Pattern: Choose the appropriate folding pattern (e.g., half-fold, letter-fold, etc.) based on the job requirements.

- Adjust the Feed Tray: Adjust the feed tray to accommodate the paper size and ensure smooth paper feeding.

- Adjust Folding Rollers and Plates: Carefully adjust the folding rollers and plates to align with the selected folding pattern. This ensures a clean, crisp fold.

- Set Folding Knife Position: Position the folding knife or blade accurately based on the required fold depth. Incorrect positioning can lead to improper folds.

- Test Run: Perform a test run using a few sheets of paper to verify that the settings are correct. Adjust as needed to optimize the fold.

- Monitor the Process: Monitor the machine during operation to identify and address any inconsistencies or problems. This might include variations in folds or paper jams.

For instance, if folding a letter-sized sheet into thirds, the folding rollers and plates must be meticulously aligned to create three precisely sized panels. Improper alignment will result in uneven folds and an unprofessional final product.

Q 12. How do you handle different paper weights and sizes on a cutting machine?

Handling different paper weights and sizes on a cutting machine requires careful adjustment of the machine’s settings. Think of it like adjusting a saw – you’d use a different blade and technique for cutting wood vs. metal.

- Blade Selection: Use the appropriate blade for the paper weight. Heavier paper requires a sharper, more durable blade.

- Cutting Depth Adjustment: Adjust the cutting depth to ensure a clean, even cut without damaging the paper. Heavier papers require a slightly deeper cut than lighter ones.

- Table Adjustment: Adjust the cutting table to ensure that the paper is held securely and level during the cutting process. This is essential to prevent slippage and uneven cuts.

- Back Gauge Adjustment: Accurately set the back gauge to the desired cutting length. This ensures precision and consistency.

- Side Gauge Adjustment: Adjust the side gauge to align the paper properly with the blade. This avoids skewed cuts and minimizes waste.

- Speed Adjustment: Adjust the cutting speed to match the paper weight. Heavier paper may require a slower cutting speed to prevent damage or inaccurate cuts.

For example, when cutting heavy cardstock, a slower cutting speed is necessary to avoid tearing. This contrasts with cutting thin paper, which can be cut at a higher speed without compromising quality.

Q 13. What are the advantages and disadvantages of different binding methods?

Various binding methods offer different advantages and disadvantages, each suited to specific needs. Choosing the right method depends on the project’s requirements and budget.

| Binding Method | Advantages | Disadvantages |

|---|---|---|

| Perfect Binding | Cost-effective for large volumes, aesthetically pleasing, allows for lay-flat pages. | Spine is vulnerable to damage, not suitable for very thick books. |

| Saddle Stitch Binding | Simple, inexpensive, suitable for thin documents. | Limited page capacity, pages don’t lay flat. |

| Wire-O Binding | Durable, allows for 360-degree lay-flat, visually appealing. | More expensive than saddle stitch, suitable for thinner documents. |

| Case Binding | High-quality, durable, suitable for thick books, professional look. | Most expensive, more complex production process. |

| Spiral Binding | Economical, pages lay flat, easy to turn. | Less professional look, visible binding mechanism. |

For instance, a thesis might be best served by case binding due to its thickness and need for durability, while a simple brochure might use saddle stitch binding due to its simplicity and low cost.

Q 14. How do you calculate the cost of binding a specific job?

Calculating the cost of a binding job involves several factors. It’s similar to calculating the cost of a construction project – you need to consider materials, labor, and overhead.

- Material Costs: Include the cost of paper, glue, thread, wire, or other binding materials.

- Labor Costs: Account for the time spent on each step of the binding process, including preparation, machine operation, and finishing.

- Machine Costs: Include costs associated with the equipment, such as depreciation, maintenance, and power consumption.

- Overhead Costs: Factor in overhead costs such as rent, utilities, and administrative expenses.

- Profit Margin: Add a profit margin to cover your business expenses and generate revenue.

The formula for calculating the cost might look something like this:

Total Cost = (Material Costs + Labor Costs + Machine Costs + Overhead Costs) / (1 - Profit Margin)For example, to calculate the cost of a perfect binding job, you’d factor in the cost of the glue, the operator’s time, the machine’s running costs, and your business overhead. A clear understanding of all costs ensures accurate pricing and profitable operations.

Q 15. What are the common materials used in bookbinding?

Bookbinding utilizes a variety of materials, each playing a crucial role in the final product’s durability and aesthetics. The core components are, of course, the paper itself – ranging from lightweight newsprint to heavy-duty cardstock, depending on the project. Then there are the cover boards, typically made from sturdy materials like cardboard, chipboard, or even more luxurious options like linen-covered boards. These provide structure and protection. Adhesives are essential, acting as the binding agent, and these can vary greatly (more on that later). Finally, we have threads, often used in sewn bindings for increased strength and longevity, and decorative elements such as cloth, foil, and ribbons for aesthetic enhancements.

- Paper: Different weights and finishes (coated, uncoated) impact the overall feel and print quality.

- Cover Boards: The choice influences the book’s rigidity and overall look.

- Adhesives: The type of adhesive determines the binding method and its strength.

- Threads: Sewn bindings rely on strong, durable threads to hold the pages together.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the importance of proper paper alignment in the binding process.

Precise paper alignment is paramount in bookbinding, impacting both the aesthetic appeal and the functionality of the finished product. Misaligned pages result in an unprofessional, uneven appearance. More critically, inconsistent alignment can cause problems during the binding process, leading to difficulties in the adhesive application, uneven pressure during the pressing stage, and ultimately a poorly bound book that might fall apart easily. Imagine trying to glue pages together that are consistently off-center – the adhesive wouldn’t distribute evenly, leading to weak binding and unsightly gaps.

Think of it like building a brick wall; each brick must be perfectly aligned for stability and visual appeal. Similarly, in bookbinding, precise alignment of pages ensures a strong, even binding that stands the test of time.

Q 17. How do you identify and resolve issues related to inaccurate collating?

Inaccurate collating, where pages are not arranged in the correct order, is a common problem that can derail an entire project. Identifying the issue often involves a careful visual inspection of the gathered signatures (sets of pages folded and gathered together). Inconsistencies in page numbering or the presence of duplicate or missing pages are clear indicators. Sometimes, a simple manual check of a few signatures will reveal the problem; in larger jobs, however, more advanced methods like automated page verification systems can be employed.

Resolving the problem depends on the scale of the error. Small errors can be corrected manually; larger ones might necessitate re-collating entire sections or even the whole job. Preventive measures include double-checking the collating process, utilizing automated collating equipment with verification systems, and implementing rigorous quality checks at each stage of the process. Investing in well-maintained equipment is also crucial.

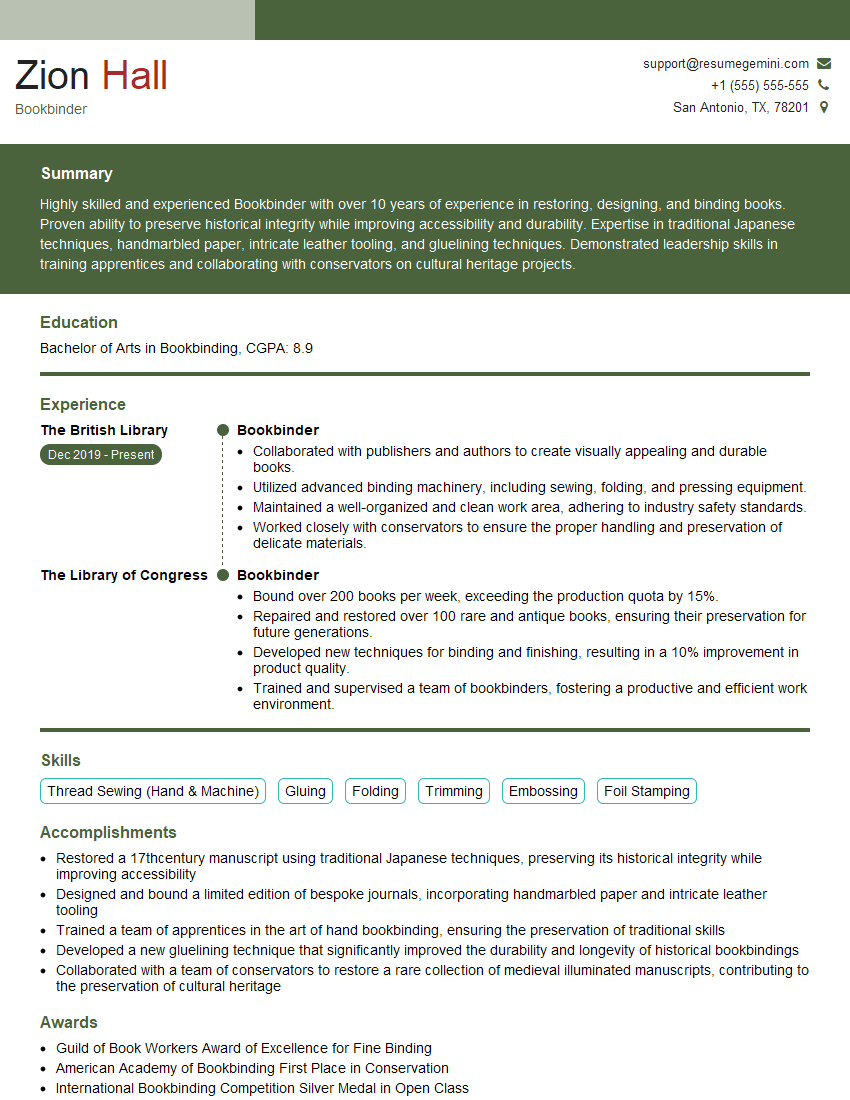

Q 18. What is the role of the gathering machine in the bookbinding process?

The gathering machine is a critical component in modern bookbinding, responsible for the efficient and accurate assembly of folded and collated sections (signatures) into the correct order for binding. It automatically gathers the signatures, ensuring that the pages are arranged in the proper sequence. This process drastically speeds up production compared to manual gathering, which is prone to human error. Think of it as a highly organized assembly line for book pages. Without a gathering machine, the process would be far slower, more prone to mistakes, and significantly less efficient, especially for high-volume projects.

Many gathering machines incorporate sophisticated sensors and mechanisms to detect and report errors in the page sequence, further minimizing the risk of inaccurate collating.

Q 19. Describe the different types of adhesives used in bookbinding.

Bookbinding employs a range of adhesives, each suited for different binding methods and materials. Hot melt adhesives are commonly used for their quick setting time and strong bond, ideal for perfect binding. PUR (polyurethane reactive) adhesives offer superior flexibility and durability, making them suitable for demanding applications. Case-making adhesives are specifically designed for attaching covers to book blocks. The choice of adhesive is crucial; an inappropriate adhesive can weaken the binding, leading to pages falling out or a less durable book. For example, a hot melt adhesive might not be suitable for a book requiring high flexibility, while a PUR adhesive might be overkill for a simple pamphlet.

- Hot Melt: Fast, strong, but can be brittle.

- PUR: Flexible, strong, and durable, but requires specialized equipment.

- Case-making Adhesives: Designed for adhering covers.

Q 20. How do you maintain the sharpness of cutting blades?

Maintaining the sharpness of cutting blades is essential for clean, precise cuts and preventing damage to the materials. Regular sharpening is key; the frequency depends on the usage and the type of blade. For many types of blades, honing (using a honing steel or similar tool) is a regular maintenance step, while sharpening (using a grinding wheel or professional sharpening service) is done less frequently. The process involves carefully guiding the blade across the honing/grinding surface, maintaining a consistent angle. Improper sharpening can damage the blade permanently. It’s often best to rely on experienced professionals for sharpening high-quality blades.

Ignoring blade sharpness leads to uneven cuts, frayed edges, and potential damage to the materials being cut. It’s a crucial preventative maintenance task ensuring the quality and efficiency of the cutting process.

Q 21. What are the signs of wear and tear on bindery equipment?

Recognizing wear and tear on bindery equipment is crucial for preventing costly breakdowns and ensuring consistent quality. Signs include excessive noise, vibrations, or slow performance. Look for loose parts, damaged belts or rollers, uneven cuts, misaligned components, and unusual smells (indicating potential overheating). Regular lubrication and cleaning can greatly extend equipment life. Worn or damaged blades are another common sign, often leading to inconsistent cuts and jams. Also, check for any indications of electrical problems such as sparking or unusual heating, which could indicate a safety hazard.

Ignoring these signs can lead to production delays, poor-quality products, and even safety hazards. A regular preventative maintenance schedule is crucial for minimizing problems and maximizing the lifespan of your bindery equipment.

Q 22. Explain the importance of regular maintenance for bindery equipment.

Regular maintenance for bindery equipment is paramount for ensuring consistent, high-quality output, minimizing downtime, and extending the lifespan of your machines. Think of it like regular servicing for your car – neglecting it leads to costly repairs and potential breakdowns.

- Preventative Maintenance: This involves scheduled cleaning, lubrication, and inspections to identify and address potential issues before they become major problems. For example, regularly cleaning the rollers on a folding machine prevents paper jams and ensures crisp folds. Ignoring this can lead to damaged paper, costly repairs, and production delays.

- Corrective Maintenance: This addresses issues that have already arisen. Regular preventative maintenance minimizes the need for corrective maintenance, significantly reducing downtime and repair costs. A good example is promptly addressing a misaligned stitching head on a saddle stitcher to avoid damaging books and wasting materials.

- Predictive Maintenance: This uses data and sensors to anticipate potential problems. Modern bindery equipment often has integrated sensors that monitor performance, flagging potential issues before they impact production. For example, a sensor might detect unusual vibrations in a perfect binder, indicating a potential problem with the glue system before it leads to a major malfunction.

A well-maintained bindery operates smoothly, producing high-quality finished products efficiently, maximizing return on investment and minimizing frustration.

Q 23. How do you handle a situation where a machine breaks down during production?

When a machine breaks down during production, a swift and organized response is critical. My approach involves a structured process focused on minimizing disruption and ensuring a rapid return to full operation.

- Safety First: Secure the area, ensuring the safety of personnel. This is the absolute top priority.

- Assessment: Quickly assess the nature of the breakdown. Is it a simple jam? Or does it require specialized expertise?

- Troubleshooting: Attempt basic troubleshooting steps, based on the machine’s manual and my experience. This could involve checking power, clearing jams, or verifying connections.

- Escalation: If the problem persists, I’ll escalate it to the appropriate personnel, whether it’s an in-house technician or the manufacturer’s service team.

- Alternative Solutions: While waiting for repairs, I’ll explore alternative solutions, potentially rerouting work to other machines or temporarily adjusting the production schedule.

- Documentation: Meticulous documentation of the breakdown, troubleshooting steps, and repairs is crucial for future preventative measures and warranty claims.

In one instance, a critical component on a high-speed folder failed during a large print run. By following this process, I was able to quickly assess the problem, contact the vendor, and have a replacement part shipped overnight. The downtime was minimized, and the project stayed on schedule.

Q 24. What are the environmental considerations related to bindery operations?

Environmental considerations are increasingly important in bindery operations. We must minimize waste, reduce energy consumption, and limit our environmental footprint.

- Waste Reduction: Implementing efficient cutting and trimming practices minimizes paper waste. We can also explore recycling programs for paper scraps and other materials. This includes exploring sustainable sourcing of materials.

- Energy Efficiency: Choosing energy-efficient bindery equipment and optimizing machine settings reduces energy consumption. Turning off machines when not in use and implementing energy-saving modes are key.

- Emissions Reduction: Using low-VOC (Volatile Organic Compound) glues and inks minimizes harmful emissions into the air. Properly disposing of chemical waste is another crucial aspect.

- Water Conservation: Some bindery processes use water. Implementing water-saving techniques wherever possible is beneficial.

By embracing sustainable practices, we not only protect the environment but also enhance our brand image and reduce operational costs. This is becoming increasingly important as our customers and clients are more environmentally conscious.

Q 25. What experience do you have with different types of bindery software?

My experience with bindery software spans various systems, ranging from simple job management tools to integrated prepress and workflow solutions.

- Job Management Systems: I’m proficient in using software for tracking jobs, managing deadlines, and generating reports. This helps maintain a smooth workflow and minimizes errors.

- Prepress Integration: I have experience with software that integrates with prepress systems, allowing for automated imposition and efficient data transfer to bindery equipment. This eliminates manual data entry and reduces errors.

- Workflow Automation: I have worked with sophisticated software packages that automate many of the bindery processes, from job scheduling to quality control. This enhances efficiency and reduces manual intervention.

Specific software experience includes [List specific software packages you have used – e.g., Heidelberg Prinect, Kodak Prinergy, etc.]. I am comfortable learning and adapting to new software as needed.

Q 26. Describe your experience with automated bindery systems.

I have extensive experience with automated bindery systems, including high-speed perfect binders, three-knife trimmers, and automated gathering systems. Automation significantly enhances efficiency and consistency in the bindery process.

- Perfect Binding: I’ve operated and maintained high-speed perfect binding machines, understanding their intricacies, from glue application to book sectioning. Automation in this area leads to higher production speeds and consistent binding quality.

- Three-Knife Trimmers: My experience includes the setup and operation of automated three-knife trimmers for precise trimming of books and brochures. Automated systems ensure consistent results and reduce waste.

- Gathering Systems: I’m familiar with automated gathering systems that ensure accurate page sequencing and gathering, eliminating manual errors and dramatically increasing speed and efficiency.

Working with automated systems requires a deep understanding of their mechanics, programming, and troubleshooting. My experience enables me to optimize these systems for maximum throughput and minimal downtime.

Q 27. How do you ensure efficiency and productivity in a bindery setting?

Efficiency and productivity in a bindery setting require a holistic approach, focusing on process optimization, equipment utilization, and team management.

- Process Optimization: Streamlining workflows, eliminating bottlenecks, and implementing lean manufacturing principles are crucial. This could involve re-organizing the bindery floor to improve material flow or adjusting job sequencing for optimal machine utilization.

- Equipment Utilization: Maximizing machine uptime through preventative maintenance and efficient scheduling is key. This includes ensuring all equipment is running at optimal speed and efficiency.

- Waste Reduction: Minimizing waste through precise cutting, efficient material handling, and recycling practices directly contributes to increased productivity and reduced costs.

- Teamwork & Training: A well-trained and motivated team is essential. Regular training on new equipment and procedures is needed to maintain a high level of competency and ensure smooth collaboration.

For example, in a previous role, I implemented a new job scheduling system that reduced turnaround times by 15% and increased overall productivity by 10% through better machine utilization.

Q 28. What are your strategies for managing a bindery team effectively?

Managing a bindery team effectively involves fostering a culture of collaboration, communication, and continuous improvement.

- Clear Communication: Maintaining open and clear communication channels is crucial. Regular team meetings, feedback sessions, and one-on-one discussions are essential.

- Motivation and Training: Providing opportunities for training and development enhances skill levels and boosts employee morale. Recognition and rewarding good performance is also important.

- Delegation and Empowerment: Delegating tasks appropriately and empowering team members to take ownership increases responsibility and engagement.

- Problem-Solving: Encouraging a proactive approach to problem-solving, where team members identify and propose solutions, fosters a collaborative environment.

- Safety: Prioritizing safety through regular safety training and enforcing safety protocols is essential.

I believe in building strong relationships with my team members, creating an environment where they feel valued, supported, and empowered to contribute their best work. A well-managed team is the backbone of a productive and successful bindery operation.

Key Topics to Learn for Bindery Equipment Interviews

- Paper Handling and Feeding Mechanisms: Understand different paper types, their properties (weight, grain, moisture content), and how these affect feeding and processing in various bindery machines. Explore different feeding mechanisms (e.g., friction, vacuum, air suction) and their applications.

- Finishing Techniques: Master the practical applications of various finishing techniques such as folding (different fold types), stitching (saddle stitch, side stitch, etc.), trimming, perfect binding, case binding, and wire-o binding. Be prepared to discuss the advantages and disadvantages of each method.

- Bindery Equipment Operation and Maintenance: Gain a thorough understanding of the operation and maintenance of common bindery machines (e.g., folders, stitchers, trimmers, perfect binders). This includes preventative maintenance, troubleshooting common malfunctions, and safety procedures.

- Quality Control and Troubleshooting: Learn to identify common bindery defects (e.g., misfeeds, jams, poor fold quality, inaccurate cuts) and implement effective troubleshooting strategies. Understand quality control measures to ensure consistent output.

- Workflow and Production Optimization: Explore how different bindery processes integrate into a larger workflow. Understand the concepts of efficiency, throughput, and ways to optimize production processes to minimize downtime and maximize output.

- Safety Regulations and Procedures: Familiarize yourself with relevant safety regulations and procedures related to operating and maintaining bindery equipment. This is crucial for demonstrating responsibility and professionalism.

Next Steps

Mastering bindery equipment opens doors to rewarding careers in print production, publishing, and related fields. A strong understanding of these processes is highly valued by employers, leading to increased job opportunities and career advancement. To enhance your job prospects, creating a compelling and ATS-friendly resume is essential. ResumeGemini is a trusted resource to help you build a professional resume that highlights your skills and experience effectively. We provide examples of resumes tailored to the bindery equipment industry to help you get started. Take the next step towards your dream career today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).