Cracking a skill-specific interview, like one for Grading Leveling, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Grading Leveling Interview

Q 1. Explain the process of calculating earthwork volumes.

Calculating earthwork volumes involves determining the amount of soil that needs to be cut (excavated) or filled (added) to achieve the desired final grade. This is crucial for cost estimation, resource planning, and efficient project execution. We typically use the ‘average-end-area’ method or more sophisticated techniques like the ‘prismoidal’ formula for greater accuracy.

Average-End-Area Method: This is a simple yet widely used method. Imagine two cross-sections of the earthwork at different points along a length (L). Calculate the area of each cross-section (A1 and A2). The volume (V) is then approximated as:

V = (A1 + A2)/2 * LPrismoidal Formula: For greater precision, especially with irregular cross-sections, the prismoidal formula is employed. It considers the areas at the beginning, middle, and end of the section:

V = L/6 * (A1 + 4Am + A2)where Am is the area of the middle cross-section.

Example: Let’s say we have two cross-sections with areas of 100 sq ft and 150 sq ft, 50 feet apart. Using the average-end-area method, the volume would be (100 + 150)/2 * 50 = 6250 cubic feet.

Q 2. Describe different methods for determining cut and fill quantities.

Determining cut and fill quantities involves comparing the existing ground levels (as-is) with the proposed final grade (to-be). Several methods exist, with varying degrees of complexity and accuracy.

- Cross-section Method: This classic method involves creating cross-sections of the site at regular intervals. The difference between the areas of the as-is and to-be cross-sections at each point reveals the cut or fill volume.

- Grid Method: This method uses a grid of points over the site to determine elevations. Software then interpolates the data to create a 3D model, facilitating accurate cut and fill calculations.

- Volume Calculation Software: Specialized software packages use sophisticated algorithms to analyze digital terrain models (DTMs) derived from survey data. These tools significantly reduce manual effort and provide precise cut and fill quantities.

Choosing the best method depends on the project’s complexity, site conditions, and available resources. For smaller, simpler projects, the cross-section method might suffice. Larger, complex projects often benefit from grid methods and specialized software to handle vast datasets.

Q 3. What are the key considerations when designing a grading plan?

Designing a grading plan requires careful consideration of numerous factors to ensure a safe, functional, and aesthetically pleasing site. Key considerations include:

- Site Topography: Understanding the existing land contours is paramount. This forms the basis for determining cut and fill quantities.

- Drainage: Proper drainage is essential to prevent erosion and water damage. The grading plan should ensure adequate runoff pathways away from structures and toward designated drainage points.

- Soil Conditions: The type of soil greatly impacts grading design. Compaction characteristics, bearing capacity, and potential for settlement must be considered.

- Environmental Regulations: Compliance with local and national environmental regulations is critical. This includes erosion and sediment control measures.

- Structural Considerations: The grading plan must accommodate foundations, pavements, and other site structures. Sufficient space needs to be allocated for utilities.

- Accessibility and Aesthetics: The design should provide safe and convenient access to all areas of the site while maintaining a visually appealing landscape.

A well-designed grading plan is a balance between achieving the desired functional outcomes and minimizing environmental impact.

Q 4. How do you account for soil compaction in grading calculations?

Soil compaction significantly affects grading calculations because compacted soil occupies less volume than loose soil. Failing to account for compaction leads to inaccurate earthwork estimates and potential cost overruns.

We typically handle soil compaction by applying a compaction factor. This factor represents the reduction in volume due to compaction. For instance, a compaction factor of 15% means that the volume of compacted soil will be 15% less than the volume of loose soil. This factor varies based on soil type and compaction methods. We would multiply the calculated volume of loose soil by (1 – compaction factor) to determine the compacted volume.

Example: If the calculated cut volume is 1000 cubic yards of loose soil and the compaction factor is 15%, the actual compacted volume would be 1000 * (1 – 0.15) = 850 cubic yards.

It’s crucial to work closely with geotechnical engineers to determine appropriate compaction factors for the specific soil conditions on the site.

Q 5. What are the common types of surveying equipment used in grading projects?

Various surveying instruments are employed in grading projects to accurately measure and map the terrain. These include:

- Total Stations: These electronic instruments measure distances and angles precisely, facilitating accurate data collection for creating detailed topographic maps.

- GPS (Global Positioning System): GPS receivers are used for positioning and surveying, especially in large-scale projects. They provide high-precision measurements of coordinates.

- Levels and Level Rods: These traditional surveying instruments measure elevations accurately, allowing for precise determination of ground levels.

- Digital Leveling Systems: These combine the precision of traditional leveling with digital data recording and analysis, streamlining the workflow.

- 3D Scanners: These advanced technologies capture high-density point cloud data, providing a comprehensive 3D model of the site, enabling very precise volume calculations and visualization.

The choice of equipment depends on the project’s scale, accuracy requirements, and budget. For smaller projects, levels and total stations may suffice. Larger, complex projects often benefit from the use of GPS and 3D scanners for enhanced efficiency and accuracy.

Q 6. Explain the importance of proper drainage in grading design.

Proper drainage is paramount in grading design for several reasons:

- Erosion Control: Improper drainage leads to surface runoff, which erodes topsoil and can damage structures. Effective drainage systems minimize erosion and protect the environment.

- Foundation Stability: Excess water around foundations can cause settlement and structural damage. Proper grading ensures water flows away from building foundations.

- Landscaping and Aesthetics: Poor drainage leads to waterlogged areas, making the landscape unattractive and potentially harming vegetation. Well-designed drainage systems contribute to a healthy and attractive landscape.

- Public Safety: Poor drainage can create unsafe conditions, such as muddy pathways or areas prone to flooding. Proper drainage ensures site safety for workers and the public.

Grading design includes incorporating features like swales, ditches, and underground drainage systems to manage runoff effectively. The design should direct water to safe disposal points, such as storm drains or retention ponds.

Q 7. How do you handle unforeseen site conditions during grading?

Unforeseen site conditions, such as encountering unexpected rock formations or subsurface utilities, are common challenges in grading projects. Effective handling requires a proactive approach:

- Thorough Site Investigation: A comprehensive site investigation, including geotechnical surveys and utility locates, helps minimize surprises. However, some unforeseen conditions can still arise.

- Contingency Planning: The project plan should include contingency measures to address potential unexpected conditions, such as extra time or budget allocation.

- Regular Monitoring: Close monitoring of the excavation process helps identify any deviations from the planned design or unexpected conditions. This enables prompt corrective actions.

- Flexible Design: The grading plan should be adaptable to accommodate changes based on discovered conditions. Flexibility is essential to manage unexpected events efficiently.

- Professional Expertise: Experienced engineers and contractors are crucial for assessing the impact of unforeseen conditions and developing effective solutions. They can quickly adapt the plan to maintain the project’s goals and manage the associated costs.

Responding effectively to unforeseen conditions requires a combination of preemptive measures, close monitoring, and a willingness to adjust plans as needed. This minimizes disruptions and ensures project success.

Q 8. Describe your experience with different types of soil and their impact on grading.

Soil type significantly impacts grading. Different soils have varying strengths, densities, and drainage characteristics, all crucial for successful grading. For example, sandy soils are easily compacted but can be prone to erosion, requiring careful consideration of slope stability. Clay soils, on the other hand, are more difficult to compact and can retain water, potentially leading to instability or settlement issues.

My experience encompasses working with a wide range of soils, from well-drained gravels ideal for rapid drainage in highways to expansive clays requiring specialized techniques to prevent cracking and settlement in residential foundations. I’ve utilized soil testing data (grain size analysis, Atterberg limits, compaction tests) to inform my design choices, selecting appropriate compaction methods and slope angles to mitigate risks associated with each soil type. For instance, in a project involving expansive clay, we employed terracing and used geosynthetics to stabilize slopes and prevent future settlement issues. In contrast, for sandy soil, we incorporated erosion control measures like vegetation and retaining walls to prevent runoff and soil loss.

Q 9. What are the common challenges encountered in grading projects, and how do you overcome them?

Grading projects face many challenges. Unforeseen subsurface conditions (like buried utilities or unexpected rock formations) are common and necessitate design adjustments on the fly. Accurate surveying and precise earthwork calculations are essential to prevent over-excavation or under-excavation, which can lead to cost overruns and schedule delays. Weather conditions can also disrupt progress.

To address these, I employ a multi-pronged approach. Thorough site investigations, including geophysical surveys and test pits, help identify hidden obstacles. We use advanced surveying techniques (like GPS and total stations) for precise measurements. Furthermore, rigorous quality control checks during excavation and compaction ensure adherence to design specifications. Contingency planning for adverse weather conditions, including developing alternative schedules, is vital. For example, on one project, we discovered an uncharted underground gas line. Immediately, I stopped work, notified the appropriate utility company, revised the design to avoid the line, and managed to minimize the project delay through efficient communication and collaboration.

Q 10. How do you ensure accuracy and precision in grading measurements?

Accuracy and precision in grading measurements are paramount. Errors can lead to drainage problems, structural instability, and safety hazards. I employ several strategies to ensure this. Firstly, I use high-precision surveying equipment like robotic total stations and GPS systems for data acquisition. These tools offer centimeter-level accuracy, far exceeding the tolerances required in most grading projects.

Secondly, rigorous quality control processes are implemented. Independent checks and comparisons of data from different sources are routine. Software solutions are employed to perform calculations and generate design drawings, minimizing human error. We also use digital level data to create detailed grading models that provide a visual representation of the terrain allowing us to analyze the data better. Finally, regular site inspections and meticulous record-keeping are essential for monitoring progress and detecting any deviations from the plan. For instance, in one project, using robotic total stations and regular quality checks allowed us to maintain a vertical accuracy within ±5 mm over a large site, ensuring smooth drainage and preventing issues with building foundations.

Q 11. Explain the role of AutoCAD or other CAD software in grading design.

AutoCAD and other CAD software are indispensable tools in grading design. They allow for the creation of detailed 3D models of the site, enabling visualization and analysis of proposed grading plans.

We use CAD to import survey data, create contours, design grading surfaces, calculate earthwork volumes, and generate construction drawings. This enhances communication with contractors and ensures that everyone is working from the same set of accurate information. The ability to perform ‘what-if’ scenarios (e.g., altering slopes to minimize earthwork) is highly beneficial. Moreover, AutoCAD’s annotation features facilitate clear communication of design intent, minimizing misinterpretations and potential errors. For example, we can create cross sections and plan views that clearly show the proposed grades, cut and fill areas, and the locations of drainage structures.

Q 12. Describe your experience with different grading methods (e.g., cut and fill, bench grading).

My experience encompasses various grading methods. Cut and fill is the most common, involving excavating material from high areas (‘cut’) and using it to fill low areas (‘fill’). This method aims to balance earthwork volumes, minimizing the need for importing or exporting material. Bench grading, on the other hand, involves creating a series of level platforms or benches on steep slopes. This reduces the overall slope angle, improving stability and preventing erosion.

The choice of method depends on factors such as site topography, soil conditions, and project requirements. For example, in a hilly site with expansive soil, bench grading might be preferred to enhance stability. For a flat site requiring minimal changes, cut and fill may suffice. In a large-scale project, I might use a combination of these methods to optimize earthwork and achieve the desired final grade. On one project, we employed bench grading to create terraces for a residential development on a steep hillside, ensuring stable building platforms and minimizing erosion risk. On another project, a large highway project, a combination of cut and fill with careful compaction protocols ensured the structural integrity of the roadway and avoided future settlement issues.

Q 13. How do you manage the environmental impact of grading projects?

Environmental protection is crucial in grading projects. Uncontrolled grading can lead to soil erosion, water pollution, and habitat destruction.

To mitigate these impacts, I incorporate several strategies. Erosion and sediment control measures (like silt fences, check dams, and straw bales) are implemented during and after grading activities. Stormwater management plans are developed to minimize runoff and prevent pollutants from entering waterways. We strive to minimize disturbance to existing vegetation and wildlife habitats. Where unavoidable, mitigation measures such as replanting native species are implemented. Careful consideration is given to the disposal of excavated material, ensuring compliance with waste management regulations. For example, in one project near a sensitive wetland, we implemented stringent erosion control measures, including the use of biodegradable erosion control blankets and careful placement of sediment basins, to prevent any negative impact on water quality and aquatic life.

Q 14. How do you ensure compliance with relevant regulations and standards in grading work?

Compliance with regulations and standards is paramount. This involves understanding and adhering to local, state, and federal regulations related to grading, erosion control, stormwater management, and environmental protection.

We maintain detailed records of all work performed, including surveying data, design documents, and construction logs. We coordinate with regulatory agencies throughout the project lifecycle, ensuring that all permits and approvals are obtained. Regular inspections are performed to verify compliance with permits and specifications. I stay updated on the latest regulations and standards through professional development and collaboration with other experts in the field. For example, one project required compliance with strict environmental regulations related to endangered species habitat protection. This involved detailed pre-construction surveys, collaboration with environmental consultants, and the implementation of a specialized habitat restoration plan.

Q 15. What are the key safety considerations in grading operations?

Safety is paramount in grading operations. Think of it like this: you’re moving massive amounts of earth, operating heavy machinery, and working in potentially unstable conditions. Negligence can have severe consequences.

- Employee Safety: This includes providing proper personal protective equipment (PPE) like hard hats, safety glasses, high-visibility clothing, and steel-toe boots. Regular safety training and toolbox talks emphasizing safe operating procedures for equipment like excavators, bulldozers, and graders are crucial. We also need to establish clear communication protocols to prevent accidents.

- Site Safety: Proper site preparation involves identifying and mitigating hazards like unstable slopes, underground utilities, and potential exposure to harmful materials (asbestos, for example). Establishing clear boundaries, signage, and traffic control measures is essential. Regular site inspections are mandatory to ensure adherence to safety protocols.

- Equipment Safety: Regular maintenance and inspections of all equipment are crucial to prevent malfunctions. Operators should be properly trained and certified. Implementing lockout/tagout procedures for maintenance ensures safety.

- Environmental Safety: Erosion and sediment control measures are vital to minimize environmental impact. This might include silt fences, check dams, and proper drainage management. We also need to adhere to any relevant environmental regulations.

For instance, on a recent project, we discovered a previously unmapped gas line. Immediate work stoppage and notification of the utility company prevented a potentially catastrophic accident. This highlights the importance of thorough site surveys and proactive hazard identification.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with using GPS and other surveying technologies.

I have extensive experience using GPS and other surveying technologies for grading projects. This includes real-time kinematic (RTK) GPS systems, total stations, and laser scanning. Think of these tools as precision instruments that allow us to capture and analyze terrain data with remarkable accuracy.

RTK GPS, for instance, provides centimeter-level accuracy, essential for precise grading. I’ve used this technology to create detailed topographic surveys, design grading plans, and monitor the progress of earthworks during construction. I’m proficient in using surveying software like AutoCAD Civil 3D and Trimble Business Center to process and interpret this data.

Total stations are another vital tool, particularly useful in areas with poor GPS reception. They allow for precise measurement of distances, angles, and elevations. Laser scanning, on the other hand, provides a fast and efficient method for capturing vast amounts of 3D point cloud data, which is crucial for complex grading projects.

In one particular project, using RTK GPS data, we were able to pinpoint and correct a subtle slope anomaly that might have otherwise caused drainage issues. This demonstrates how advanced surveying technologies dramatically improve both the accuracy and efficiency of grading projects.

Q 17. How do you create a comprehensive grading plan from a site survey?

Creating a comprehensive grading plan starts with a thorough analysis of the site survey data. Imagine it as a blueprint for sculpting the land. It’s a multi-step process:

- Data Analysis: I begin by reviewing the site survey data, including topography, existing structures, utilities, and environmental constraints. This often involves using specialized software like AutoCAD Civil 3D to process the data and create a 3D model of the site.

- Design Considerations: Next, I incorporate the project’s design requirements, including building footprints, road alignments, drainage systems, and other essential elements. This involves understanding the overall site design and how the grading will support it.

- Grading Design: I then develop the grading design itself, determining the optimal earthwork volumes, cut and fill areas, and slopes required to achieve the desired elevations and drainage patterns. This often involves using modeling software to simulate different scenarios and optimize the design for efficiency and cost-effectiveness.

- Drainage Design: A crucial aspect is planning for proper drainage. This includes designing swales, ditches, and other drainage features to prevent water accumulation and erosion.

- Permitting and Regulations: Finally, the grading plan must comply with all relevant local codes and regulations. This might involve consultations with engineers and authorities to ensure the plan meets all requirements.

A good grading plan isn’t just about moving earth; it’s about creating a functional and aesthetically pleasing landscape while adhering to safety and regulatory guidelines. I always strive for a design that minimizes environmental impact and optimizes construction efficiency.

Q 18. Explain your process for preparing a detailed grading report.

A detailed grading report serves as the roadmap for the construction process. It’s more than just numbers; it’s a comprehensive document that conveys all relevant information to contractors and stakeholders. My process typically includes:

- Executive Summary: A concise overview of the project, its objectives, and key findings.

- Site Description: A detailed description of the site, including its location, topography, and existing features.

- Grading Design: A comprehensive explanation of the grading design, including drawings, cross-sections, and calculations of cut and fill volumes.

- Drainage Plan: A detailed description of the drainage system, including its components and design specifications.

- Erosion and Sediment Control: A plan for mitigating erosion and sediment during and after construction.

- Cost Estimates: Detailed estimates of the cost of earthworks and other related activities.

- Construction Sequence: A proposed sequence of construction activities, taking into account logistical and safety considerations.

- Appendices: Supporting documents, such as site surveys, engineering calculations, and permit approvals.

I ensure the report is clear, concise, and easy to understand, using both text and visuals to convey the information effectively. The goal is to provide the construction team with everything they need to complete the grading work safely and efficiently.

Q 19. How do you coordinate with other trades during the grading phase of a project?

Coordinating with other trades is essential for a successful grading project. It’s like orchestrating a symphony, ensuring all instruments play in harmony. Effective communication is key. This begins with pre-construction meetings to discuss the scope of work, timelines, and potential conflicts. I usually:

- Provide Clear Plans: I ensure the grading plans are readily accessible to all relevant parties and clearly indicate locations of underground utilities, building foundations, and other key elements that affect other trades’ work.

- Regular Communication: I maintain open communication with contractors responsible for utilities, foundations, paving, and landscaping, keeping them updated on progress and addressing any emerging issues promptly.

- Establish Clear Boundaries: I work closely with the contractors to establish clear boundaries and staging areas to ensure safe and efficient execution of work by different trades.

- Conflict Resolution: I actively mediate any conflicts or misunderstandings that may arise between different trades, prioritizing a collaborative approach to problem-solving.

For instance, on one project, we coordinated with the foundation contractor to ensure that the excavation for the building’s footings was completed in a way that avoided undermining the newly graded slopes. This proactive approach prevented delays and cost overruns.

Q 20. How do you manage conflicts or discrepancies in survey data?

Discrepancies in survey data can be challenging but are not uncommon. It’s like finding a puzzle piece that doesn’t quite fit. My approach involves a systematic investigation:

- Data Verification: I first verify the accuracy of the survey data by comparing different datasets and checking for inconsistencies. This may involve reviewing field notes, GPS data logs, and other relevant documentation.

- Field Verification: If discrepancies persist, I conduct field verification to check the accuracy of the survey data in the field. This may involve using a total station or GPS to re-survey the affected areas.

- Resolution Strategies: Once the source of the discrepancy is identified, we determine the appropriate resolution strategy. This may involve revising the original survey data, adjusting the grading design, or even undertaking additional surveys.

- Documentation: All discrepancies and their resolutions are carefully documented to ensure transparency and accountability. This is crucial for future reference.

In one instance, we discovered a discrepancy between the existing topographic survey and a recent survey. A subsequent field check revealed that the difference was due to recent earth movements caused by heavy rainfall. We adjusted the grading plan accordingly to accommodate the changed ground conditions.

Q 21. Describe your experience working with different grading contractors.

My experience working with grading contractors spans various scales and specializations. I’ve collaborated with both large, established firms and smaller, specialized contractors. Each experience offers unique insights. I’ve learned that successful collaboration hinges on clear communication, mutual respect, and a shared understanding of project goals.

I prioritize selecting contractors based on their experience, safety record, and technical capabilities. I also value their responsiveness and willingness to collaborate. Regular meetings and site visits are essential to maintain open communication and address any emerging challenges promptly. Effective management of expectations and clear contractual agreements are equally important for project success.

On one project, a smaller, specialized contractor proved to be incredibly efficient at managing delicate earthworks in a challenging terrain. Conversely, a larger firm was more effective in coordinating logistics and managing the large-scale earthmoving required on another project. Choosing the right contractor for the job depends on the project’s specific needs and context.

Q 22. How do you develop a realistic schedule for completing a grading project?

Developing a realistic grading project schedule requires a meticulous approach, combining detailed planning with realistic estimations. It’s not just about crunching numbers; it’s about understanding the inherent uncertainties of earthwork.

- Detailed Site Assessment: Begin with a thorough site analysis, including soil conditions, accessibility, existing utilities, and environmental factors. This informs the complexity and duration of each task.

- Task Breakdown: Break down the project into smaller, manageable tasks. This could include clearing and grubbing, excavation, earthmoving, compaction, and final grading. Each task gets its own time estimate.

- Resource Allocation: Consider the availability of equipment and personnel. Overly optimistic scheduling based on idealized resource availability is a common pitfall. Account for potential delays due to equipment malfunction or personnel shortages.

- Contingency Planning: Unexpected weather events, material delays, or unforeseen site conditions are inevitable. Build a reasonable buffer into the schedule – typically 10-20% – to account for these variables. This is crucial for realistic estimations.

- Critical Path Method (CPM): Employing a project management technique like CPM helps identify critical path activities – those that directly impact the overall project duration. Focusing on these activities helps prevent delays.

- Regular Monitoring and Adjustment: Regularly monitor progress against the schedule. Weekly or bi-weekly progress meetings are essential to identify and address potential issues proactively. Adjust the schedule as needed, based on actual progress and any unforeseen circumstances.

For example, on a recent project involving a large residential development, we underestimated the time required for rock excavation. By incorporating lessons learned and more detailed site investigation, we improved future schedule accuracy.

Q 23. How do you control costs associated with grading work?

Controlling grading project costs requires a proactive and multi-faceted approach, starting long before the first bucket of dirt is moved. It’s about intelligent planning and rigorous execution.

- Accurate Quantity Takeoffs: Precisely estimating earthwork volumes is critical. Inaccurate estimations lead to significant cost overruns. Utilizing 3D modeling software and experienced personnel are key here.

- Competitive Bidding: Secure multiple bids from reputable contractors and equipment rental companies to ensure competitive pricing. Don’t always choose the cheapest; assess their experience and reputation.

- Efficient Equipment Use: Optimize equipment selection and deployment. Using the right equipment for the job minimizes downtime and maximizes efficiency. For example, using larger equipment for large-scale projects saves time and cost compared to smaller units.

- Material Management: Careful planning of material sourcing, transportation, and disposal minimizes costs. Identifying suitable borrow pits and disposal sites nearby reduces transportation expenses.

- Waste Minimization: Minimize material waste through precise grading and efficient earthmoving techniques. Proper compaction reduces the need for additional fill material.

- Value Engineering: Regularly review the project design and specifications to identify opportunities for cost reduction without compromising quality. For example, modifying the design to minimize earthwork volume can reduce the project’s overall cost.

I once saved a client significant money by suggesting a slight modification to the grading design. It reduced the amount of imported fill required by 15%, resulting in substantial cost savings.

Q 24. Describe your experience with various types of erosion control measures.

Erosion control is paramount in grading projects. I’ve extensive experience with a range of techniques, tailored to specific site conditions and project requirements.

- Sediment Basins/Sediment Traps: These structures intercept and settle sediment-laden runoff, preventing soil erosion from reaching waterways.

- Check Dams: Small, temporary dams installed in channels to slow water flow and reduce erosion.

- Straw Bale Barriers: Effective for stabilizing slopes and filtering runoff, they’re readily available and biodegradable.

- Hydroseeding: Applying a slurry of seed, mulch, and fertilizer helps establish vegetation quickly, binding soil and preventing erosion.

- Riprap: Using rocks or stones to protect slopes and channels from erosion, especially effective in high-velocity flow areas.

- Geotextiles: Synthetic fabrics used to filter sediment, reinforce slopes, and control erosion.

- Vegetative Covers: Planting appropriate vegetation is a crucial long-term solution. Native plants are best suited for local conditions.

On one project, we utilized a combination of sediment basins, hydroseeding, and geotextiles to effectively control erosion on a steep slope, exceeding environmental regulations.

Q 25. What are your methods for quality control and assurance in grading?

Quality control and assurance (QA/QC) are integral to successful grading projects. It ensures the project meets specifications and avoids costly rework.

- Regular Inspections: Frequent inspections during all stages – from initial clearing to final grading – are essential. This helps catch and correct any issues early on.

- Accurate Surveying: Precise surveying using levels and total stations is crucial to ensure grades are accurate and meet design specifications. Regular checks with the design plans are necessary.

- Compaction Testing: Regular compaction tests ensure soil density meets project requirements, which is vital for structural stability and long-term performance. We use nuclear density gauges and plate load testing methods.

- Documentation: Maintaining detailed records of all work performed, including surveying data, compaction test results, and inspection reports, is vital for QA/QC.

- Third-Party Inspection: Engaging a third-party inspector provides an independent assessment of the project’s quality, increasing confidence in meeting specifications.

- Corrective Actions: Implementing a process for identifying and rectifying any deviations from the design or specifications is vital. This prevents small issues from escalating into significant problems.

We once discovered a compaction issue during a routine inspection. Early identification allowed for timely correction, preventing significant rework and project delays.

Q 26. Explain your experience with using leveling instruments (e.g., levels, total stations).

I’m proficient in using various leveling instruments, essential for accurate grading. My experience includes:

- Automatic Levels: These instruments provide precise elevation measurements over long distances, essential for establishing benchmarks and setting grades.

- Total Stations: These sophisticated instruments combine distance measurement, angle measurement, and data recording capabilities, enabling rapid and accurate data acquisition for larger projects. They are particularly useful for generating topographic surveys and 3D models.

- Global Navigation Satellite Systems (GNSS): I’m also experienced with GNSS technology, using RTK (Real-Time Kinematic) systems for highly accurate positioning, especially helpful in remote areas or challenging terrain.

- Data Processing Software: Proficient in using software to process data collected from these instruments, generating contour maps, cross-sections, and volume calculations. Examples include AutoCAD Civil 3D and other similar CAD software.

I’ve successfully utilized these instruments on numerous projects, ensuring accurate grading and minimizing rework.

Q 27. How do you assess the stability of slopes after grading?

Assessing slope stability after grading is crucial for safety and longevity. It’s a multi-step process involving:

- Visual Inspection: A thorough visual examination of the slope identifies any obvious signs of instability, such as cracking, erosion, or settlement.

- Soil Testing: Soil samples are taken to determine soil properties, including shear strength, cohesion, and angle of internal friction. These properties are key inputs for slope stability analysis.

- Slope Stability Analysis: Using software and established geotechnical principles, we conduct slope stability analysis. This involves calculating the factor of safety (FOS), a ratio indicating the stability of the slope. An FOS greater than 1.5 is typically considered acceptable, though this depends on the project and local regulations.

- Instrumentation: In some cases, we install inclinometers and piezometers to monitor slope movement and pore water pressure over time. This provides real-time data on slope behavior.

- Mitigation Measures: If the slope stability analysis indicates a risk of failure, mitigation measures such as terracing, retaining walls, or geotechnical stabilization techniques are implemented to increase the slope’s stability.

In one instance, a slope stability analysis revealed a potential issue. We implemented terracing and additional vegetation, significantly enhancing the long-term stability of the slope.

Q 28. Describe your experience in using earthmoving equipment and techniques.

My experience encompasses a wide range of earthmoving equipment and techniques:

- Bulldozers: Proficient in operating various bulldozer types for clearing, stripping, and rough grading. I understand the nuances of different blade types and their applications.

- Excavator: Experienced in operating excavators for precise excavation, trenching, and loading operations. Familiarity with various attachments (e.g., rippers, breakers) enhances versatility.

- Scrapers: Skilled in using scrapers for efficient mass earthmoving over long distances, optimizing cycle times and minimizing fuel consumption.

- Graders: Proficient in using motor graders for fine grading, achieving precise elevations and slopes. Experience in maintaining blade profiles and adjusting settings for various applications.

- Loaders: Experienced in operating wheel loaders and backhoes for material handling, loading trucks, and other support activities.

- Compaction Equipment: Proficient in operating vibratory rollers and other compaction equipment to achieve optimal soil density.

- GPS-Guided Equipment: Experience in utilizing GPS-guided equipment for precise grading and increased efficiency. Reduces reliance on traditional methods and improves accuracy.

I’ve worked on projects ranging from small residential sites to large-scale infrastructure projects, adapting my techniques and equipment selection to each project’s specific needs.

Key Topics to Learn for Grading Leveling Interview

- Fundamental Principles: Understanding the core concepts behind grading leveling, including its purpose, benefits, and different methodologies.

- Data Analysis & Interpretation: Analyzing datasets to identify trends, outliers, and potential biases affecting grading accuracy. This includes proficiency in statistical methods relevant to grading data.

- Methodologies & Algorithms: Familiarization with various grading leveling techniques, their strengths and weaknesses, and when to apply each. This could include Item Response Theory (IRT) based models or other statistical approaches.

- Software & Tools: Practical experience with software commonly used for grading leveling, data manipulation, and visualization (mentioning specific software is avoided to remain general and applicable to various contexts).

- Quality Control & Assurance: Implementing procedures to ensure the reliability and validity of grading leveling processes, including identifying and mitigating sources of error.

- Ethical Considerations: Understanding the ethical implications of grading leveling and ensuring fairness and equity in the process.

- Communication & Collaboration: Effectively communicating technical concepts to both technical and non-technical audiences, and collaborating with colleagues on grading leveling projects.

- Problem-Solving & Troubleshooting: Identifying and resolving challenges that may arise during the grading leveling process, demonstrating analytical and problem-solving skills.

Next Steps

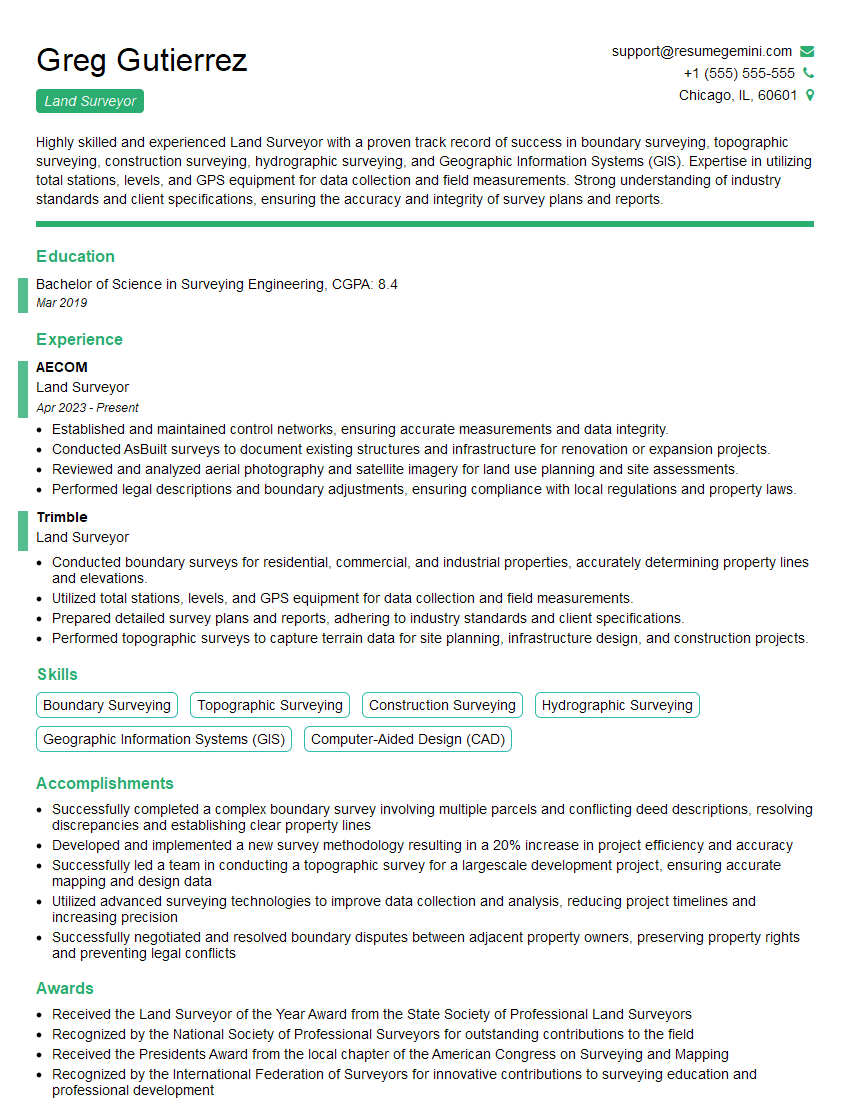

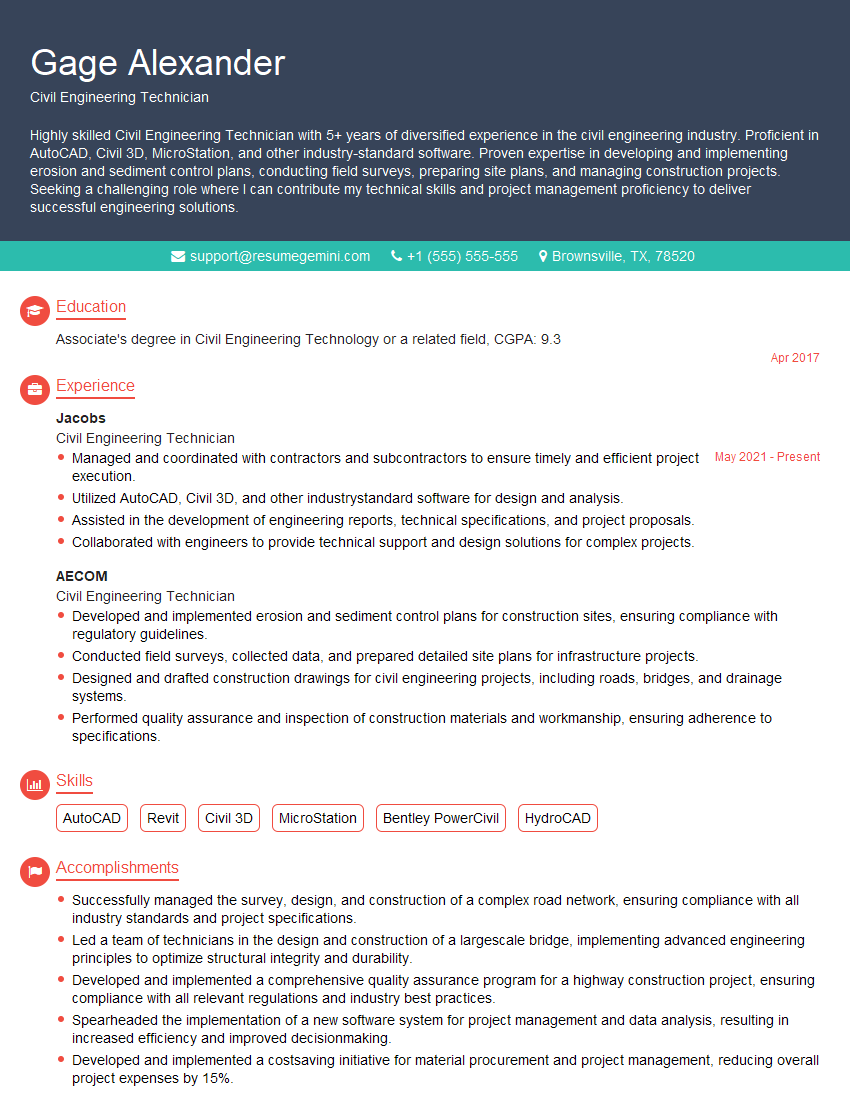

Mastering Grading Leveling opens doors to exciting career opportunities in fields demanding meticulous data analysis and a keen eye for detail. It demonstrates your proficiency in statistical methods and your commitment to accurate and fair assessment practices. To significantly boost your job prospects, crafting an ATS-friendly resume is crucial. This ensures your application gets noticed by recruiters and hiring managers. We highly recommend using ResumeGemini to build a professional and impactful resume tailored to highlight your Grading Leveling expertise. ResumeGemini provides examples of resumes specifically designed for roles in Grading Leveling, giving you a head start in creating a compelling application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good