Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Irrigation Maintenance interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Irrigation Maintenance Interview

Q 1. Explain the different types of irrigation systems.

Irrigation systems come in various types, each suited for different landscapes and water needs. The choice depends on factors like terrain, plant type, water availability, and budget.

- Drip Irrigation: This highly efficient method delivers water directly to plant roots through a network of tubes and emitters. It minimizes water waste and is ideal for gardens, orchards, and landscapes with diverse plant types. Think of it like giving each plant a personal drink! I’ve successfully implemented drip systems in several residential projects, significantly reducing water consumption while maximizing plant health.

- Sprinkler Irrigation: This system uses sprinklers to spray water over a larger area. It’s common for lawns and larger fields. There are several sub-types, including rotary sprinklers (like the ones you see on golf courses), impact sprinklers (using a spinning head to project water further), and pop-up sprinklers (which are mostly submerged until activated). I’ve had extensive experience troubleshooting malfunctions in pop-up sprinkler systems, often due to debris clogging the mechanisms.

- Flood Irrigation: This traditional method involves flooding an entire field with water. While cost-effective, it’s less efficient than other systems, leading to significant water loss through runoff and evaporation. It’s generally used in flat, large-scale farming.

- Subsurface Irrigation: Water is applied below the soil surface through a network of perforated pipes. This minimizes evaporation and weeds while maintaining consistent soil moisture. It is especially beneficial in arid and semi-arid regions and is becoming increasingly popular in advanced landscape design.

Q 2. Describe your experience with troubleshooting irrigation system malfunctions.

Troubleshooting irrigation malfunctions requires a systematic approach. My experience involves a multi-step process: First, I carefully listen to the client’s description of the problem. Then, I visually inspect the system, checking for obvious issues like broken pipes, clogged emitters, or malfunctioning sprinklers. Next, I utilize specialized tools like pressure gauges to measure water pressure at various points in the system. I also check the controller programming and wiring to ensure everything is correctly set. For example, I once diagnosed a problem where a section of lawn wasn’t being watered. It turned out a simple wire connection at the valve had come loose. In other cases, I’ve found that roots had grown into and clogged the drip lines, requiring replacement.

Often, using a combination of visual inspection and pressure testing will quickly pinpoint the problem. I always document my findings and repairs thoroughly.

Q 3. How do you diagnose and repair leaks in an irrigation system?

Diagnosing and repairing leaks involves careful observation and methodical testing. I typically start with a visual inspection, looking for wet spots, muddy areas, or unusually saturated soil. Next, I use a pressure test, turning on specific zones to isolate the leaking section. I might use a listening device to pinpoint the location of underground leaks. Once the leak is located, repair techniques vary depending on the type of pipe and the severity of the damage. Smaller leaks in PVC pipes can often be repaired with specialized glue and fittings. Larger leaks or damaged sections might require excavation and pipe replacement.

A recent experience involved a buried main line leak that resulted in significant water loss. Using a sophisticated leak detection device, I pinpointed the problem and minimized the excavation required. Careful backfilling after the repair is critical to prevent future problems.

Q 4. What are the common causes of low water pressure in an irrigation system?

Low water pressure is a common irrigation system problem with several potential causes. These include:

- Clogged filters or screens: Sediment, debris, or algae can restrict water flow. Regular cleaning is crucial.

- Partial blockage in pipes: Roots, debris, or mineral deposits can restrict water flow within the pipes themselves.

- Faulty valves: A malfunctioning valve can restrict or completely shut off water flow to a specific zone.

- Low water pressure from the main water supply: Problems with the municipal supply or a restricted main line can impact the entire irrigation system.

- Leaks in the system: A leak can significantly reduce overall system pressure.

Diagnosing the cause involves systematically checking each potential problem area, using pressure gauges at different points in the system. I’ve found that often the culprit is a seemingly minor clog which can be easily rectified.

Q 5. Explain your process for maintaining irrigation controllers.

Maintaining irrigation controllers is essential for efficient and reliable system operation. My process typically involves:

- Regular inspection: Checking the controller’s display for any error messages or unusual readings.

- Battery backup testing: Ensuring the battery backup is functioning correctly.

- Software updates: Applying any necessary software updates to improve functionality and address bugs.

- Cleaning: Removing dust and debris from the controller’s exterior and internal components.

- Seasonal adjustments: Modifying the watering schedule to match the changing weather conditions and plant needs. This often involves shortening or lengthening watering times or adjusting the frequency.

- Calibration: Checking the timer’s accuracy and adjusting if necessary.

I always emphasize preventative maintenance to minimize the risk of malfunctions. For example, I recommend a thorough controller inspection at least twice a year—before and after the main growing seasons.

Q 6. How do you test and calibrate irrigation valves?

Testing and calibrating irrigation valves ensures they operate correctly and provide the desired water flow. The process involves several steps:

- Visual inspection: Checking for any physical damage or signs of wear and tear.

- Manual operation: Manually opening and closing the valve to check for smooth operation and ensure it is fully opening and closing.

- Flow measurement: Using a flow meter to measure the actual water flow through the valve. This data is compared to the valve’s rated capacity.

- Pressure testing: Measuring the pressure drop across the valve to ensure it’s within acceptable limits. Excessive pressure drop indicates a problem.

- Adjustment (if needed): Minor adjustments may be possible on some valve types. However, more significant issues typically require valve replacement.

If a valve fails the tests, it should be repaired or replaced to maintain consistent water distribution and prevent over-watering or under-watering of specific zones.

Q 7. Describe your experience with backflow preventer maintenance.

Backflow preventers are crucial safety devices that prevent contaminated water from flowing back into the potable water supply. Maintenance is vital to ensure their proper functioning. My experience involves:

- Regular inspection: Visual inspection for any damage or leaks, and checking the test cocks to ensure they are easily accessible and not obstructed.

- Annual testing: Annual testing is essential and usually performed by a licensed professional. The test confirms the backflow preventer is preventing backflow effectively. The test method varies depending on the backflow preventer type.

- Cleaning: Depending on the backflow preventer model, some require regular cleaning to remove sediment or debris.

- Repair or replacement: If the backflow preventer fails testing, it may need to be repaired or replaced. It’s crucial to adhere to all local codes and regulations when installing or repairing backflow preventers.

Neglecting backflow preventer maintenance can have serious health and safety consequences; therefore, I emphasize its importance to my clients and always recommend professional testing.

Q 8. What are the different types of irrigation sprinkler heads and their applications?

Irrigation sprinkler heads come in various types, each designed for specific applications. The choice depends heavily on factors like the landscape, water pressure, and desired water distribution pattern.

- Rotating Sprinklers: These heads rotate 360 degrees, ideal for large, open areas like lawns or sports fields. They offer even coverage but may be less efficient on sloped terrains. Examples include gear-driven and impact sprinklers.

- Spray Sprinklers: These emit water in a specific pattern (e.g., a circle, square, or rectangle) and are suitable for smaller areas or for targeting specific plant groupings. They are generally used where even coverage within a defined area is important.

- Rotor Sprinklers: These high-pressure sprinklers create a long, arc-shaped spray, perfect for longer distances and larger areas. They are energy-efficient for larger areas due to their coverage but require higher water pressure than spray sprinklers.

- Pop-up Sprinklers: These heads are partially or fully hidden underground, retracting when not in use and enhancing aesthetic appeal. Different types exist based on spray patterns and flow rates.

- Patterned Sprinklers: These are designed to create specific water patterns to suit diverse landscapes, helping avoid over-watering or under-watering specific areas.

For example, I recently worked on a project where we used a combination of rotor sprinklers for the main lawn area and spray sprinklers for the flowerbeds, optimizing water usage and achieving even coverage across the entire landscape.

Q 9. How do you determine the proper water pressure for an irrigation system?

Determining the proper water pressure is crucial for efficient and effective irrigation. Too little pressure leads to inadequate coverage, while too much can damage the system or cause water waste. We typically use a pressure gauge to measure the pressure at different points in the system.

The process involves several steps:

- Check Manufacturer Specifications: Start by reviewing the specifications of the sprinklers and other components to determine their recommended pressure ranges.

- Measure Static Pressure: This is the pressure in the system when the water is not flowing. Measure this at the main water source.

- Measure Dynamic Pressure: This is the pressure when the system is running. Measure this at various points throughout the system, particularly at the furthest sprinkler.

- Adjust Pressure Regulators: If the pressure is too high or too low, adjust the pressure regulators to bring the pressure within the optimal range. Pressure regulators are valves that control the amount of water pressure going to various sections of the system.

- Observe Sprinkler Performance: After adjusting the pressure, observe the spray pattern and range of each sprinkler. Make adjustments as needed until all the sprinklers are performing optimally.

Imagine a scenario where the pressure is too low. Sprinklers won’t reach the desired distance and some areas could remain dry. Conversely, excessive pressure can cause the sprinklers to malfunction, leading to uneven watering or even damage to the sprinkler heads themselves.

Q 10. Explain the importance of water conservation in irrigation management.

Water conservation is paramount in irrigation management, both for environmental sustainability and economic reasons. Overwatering leads to wasted resources and can damage plants. Efficient irrigation methods conserve water while maximizing plant health.

We achieve this through:

- Proper System Design: Selecting appropriate sprinkler heads and optimizing their placement minimizes water waste.

- Regular Maintenance: Addressing leaks, broken sprinklers, and clogged emitters prevents water loss.

- Soil Moisture Monitoring: Using soil moisture sensors ensures that water is only applied when needed.

- Weather-Based Irrigation: Integrating weather data into the irrigation schedule allows for adjustments based on rainfall and evapotranspiration.

- Efficient Irrigation Techniques: Using drip irrigation or other water-efficient techniques reduces water consumption compared to traditional methods.

For instance, I helped a client reduce their water consumption by 30% by implementing a weather-based irrigation system and fixing several leaks in their existing infrastructure. This not only saved them money but also contributed to more responsible water use.

Q 11. What are your methods for identifying and resolving drainage issues?

Identifying and resolving drainage issues is critical to prevent waterlogging and soil erosion. A systematic approach helps pinpoint the problems efficiently.

My methods involve:

- Visual Inspection: Looking for signs of ponding water, soggy patches, or eroded areas.

- Grading Assessment: Checking the slope of the land to ensure proper drainage.

- Soil Analysis: Determining soil type and drainage capacity; clay soils drain poorly compared to sandy soils.

- Pipe Inspection: Inspecting irrigation pipes for blockages or damage that might impede drainage.

- French Drain Installation (if needed): Installing a subsurface drainage system, often involving perforated pipes and gravel, to direct excess water away from problem areas.

- Swale Creation: Creating shallow ditches to divert surface runoff.

In one instance, I noticed ponding around a specific area of a lawn after rainfall. A closer examination revealed a clogged drainage pipe. Once cleared, the problem was resolved, preventing potential root rot and damage to the turf.

Q 12. How do you use soil moisture sensors to optimize irrigation scheduling?

Soil moisture sensors provide real-time data on soil water content, enabling precise irrigation scheduling. This eliminates the guesswork involved in traditional methods and prevents both under-watering and overwatering.

The process involves:

- Sensor Installation: Sensors are strategically placed within the root zone of the plants.

- Data Collection: The sensors transmit data wirelessly or through a wired connection to a control system.

- Threshold Setting: Setting predetermined moisture levels to trigger irrigation. This typically involves establishing a lower threshold (below which irrigation begins) and an upper threshold (above which irrigation stops).

- Irrigation Scheduling: The control system uses the sensor data to adjust the irrigation schedule, ensuring that water is applied only when necessary.

- Calibration and Monitoring: Regularly calibrating the sensors and monitoring their performance guarantees accurate data and optimal irrigation.

Using soil moisture sensors allows for significant water savings. Instead of relying on fixed schedules, we irrigate only when the soil moisture levels fall below the predefined threshold, reducing water waste and improving plant health.

Q 13. What experience do you have with drip irrigation systems?

I have extensive experience with drip irrigation systems, known for their water efficiency and targeted water delivery. These systems deliver water directly to the plant roots through a network of tubes and emitters, minimizing evaporation and runoff.

My experience includes:

- System Design: Planning the layout and selecting appropriate components based on site conditions and plant requirements.

- Installation: Laying out the tubing, installing emitters, and connecting the system to the water source.

- Maintenance and Repair: Troubleshooting problems such as clogged emitters, leaks, and broken tubing, ensuring optimal performance.

- Pressure Regulation: Ensuring proper pressure throughout the system using pressure regulators to prevent damage or uneven watering.

I recently worked on a large-scale drip irrigation project for a vineyard, carefully designing the system to meet the specific water needs of different grape varietals. This resulted in significant water savings and improved yield.

Q 14. Describe your experience with repairing or replacing pumps.

Repairing and replacing pumps is a regular part of irrigation system maintenance. Pumps are crucial for providing the necessary water pressure and flow. My experience covers various types of pumps, including submersible and centrifugal pumps.

My approach includes:

- Diagnosis: Identifying the cause of the malfunction, which could range from a faulty motor to a clogged impeller.

- Repair: Performing necessary repairs, which may involve replacing parts such as bearings, seals, or impellers. This often involves disassembling, cleaning, and reassembling the pump.

- Replacement: If repair isn’t feasible or cost-effective, recommending and installing a replacement pump that meets the system’s requirements.

- Testing and Calibration: After repair or replacement, testing the pump’s performance to ensure it delivers the desired pressure and flow.

I once had to diagnose a malfunctioning submersible pump in a well. After careful investigation, I discovered that the impeller was severely clogged with sand. Cleaning the impeller restored the pump’s functionality and saved the client a costly pump replacement.

Q 15. How do you handle emergency irrigation repairs?

Emergency irrigation repairs demand immediate action to minimize water loss and crop damage. My approach involves a rapid assessment of the situation, prioritizing safety, and implementing a quick fix followed by a more thorough repair.

Step 1: Assessment: I first locate the source of the problem, whether it’s a burst pipe, malfunctioning valve, or power outage. I take photos and notes to document the damage. Step 2: Immediate Action: Depending on the issue, this might involve shutting off the main valve to stop water flow, temporarily patching a hole with a clamp or sealant, or resetting a tripped breaker. Step 3: Temporary Fix: For more significant damage, I might install a temporary bypass using readily available materials until a permanent repair can be made. Step 4: Permanent Repair: Once the emergency is under control, I perform a thorough repair, ensuring the system is functioning optimally. I document the repair process, including parts replaced and steps taken, and communicate with relevant stakeholders about the incident and the repair process.

For example, I once dealt with a major pipe burst during a heatwave. By quickly shutting off the main valve and utilizing temporary patching, I prevented significant water loss and saved the client thousands of dollars in crop damage while we worked on a permanent replacement.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What safety procedures do you follow while working on irrigation systems?

Safety is paramount in irrigation maintenance. My procedures always begin with a thorough risk assessment, which includes identifying potential hazards like electrical shock, chemical exposure, and moving machinery. I always wear appropriate personal protective equipment (PPE), including safety glasses, gloves, steel-toe boots, and high-visibility clothing.

- Lockout/Tagout Procedures: Before working on any electrical components, I follow strict lockout/tagout procedures to prevent accidental energization. This involves turning off power, locking the switch, and tagging it with a warning label.

- Chemical Handling: When handling fertilizers or pesticides, I always wear appropriate protective gear, follow manufacturer’s instructions, and ensure proper disposal of chemicals.

- Excavation Safety: If excavation is necessary, I follow OSHA regulations for safe digging practices, calling 811 to locate underground utilities before starting any digging.

- Emergency Preparedness: I always have a first aid kit on hand and know the location of emergency exits and contact numbers.

I regularly review safety procedures and participate in safety training to remain current on best practices.

Q 17. What is your experience with irrigation system design software?

I have extensive experience using irrigation design software such as AutoCAD, WaterCad, and IrriCad. These programs allow for precise design and modeling of irrigation systems, optimizing water distribution and minimizing water waste. I’m proficient in creating detailed system layouts, calculating water requirements, and sizing pipes and pumps.

Using these software packages, I can create 3D models, analyze water flow patterns, and design efficient irrigation layouts tailored to specific site conditions and crop needs. For example, I used WaterCad to model a complex irrigation network for a large vineyard, optimizing the system’s pressure and flow rates, and ensuring that all vines received adequate water. This resulted in increased yield and reduced water consumption.

Q 18. Explain your understanding of water rights and regulations.

Understanding water rights and regulations is crucial for responsible irrigation management. These regulations vary by location but typically involve obtaining permits, adhering to water usage limits, and following specific procedures for water diversion and application. It’s essential to understand your state’s specific laws concerning water rights, which often involve factors like water availability, land ownership, and environmental protection.

I work closely with local water authorities to ensure compliance with all relevant regulations. This involves obtaining necessary permits, regularly reporting water usage, and implementing water conservation measures. For instance, I helped a client navigate the complex permitting process for a new irrigation system by preparing all the necessary documentation and coordinating with water resource agencies, ensuring they met all regulatory standards and approvals before any construction began. Ignoring regulations can result in hefty fines and legal repercussions.

Q 19. How do you schedule and prioritize maintenance tasks?

Scheduling and prioritizing maintenance tasks is a key aspect of efficient irrigation management. My approach involves creating a comprehensive maintenance schedule based on system complexity, climate conditions, and equipment lifespan. This schedule includes routine tasks like inspecting valves, cleaning filters, and checking for leaks, along with more extensive tasks such as pump maintenance and system upgrades.

Prioritization is based on factors such as potential system failure impact, seasonal needs, and resource availability. For example, cleaning clogged filters might be prioritized during peak growing season to prevent water shortages. I use a combination of digital scheduling tools and physical checklists to ensure all tasks are completed efficiently and on time. Using this approach enhances efficiency, reduces downtime, and prolongs the lifespan of the irrigation system, leading to lower operating costs.

Q 20. What are your methods for documenting maintenance activities?

Detailed documentation is essential for effective irrigation management. My documentation methods encompass various approaches, all focused on maintaining accurate and readily accessible records. This includes using digital and physical logs, detailed reports, and digital imaging.

- Digital Logs: I utilize specialized software or spreadsheets to record maintenance activities, noting the date, time, task performed, parts replaced, and any issues encountered. This digital approach ensures that information is easily accessible and searchable.

- Physical Logs: I maintain detailed paper logs which are kept on-site for easy access, even during power outages. This is a backup for my digital records.

- Detailed Reports: After completing a task, I create a formal report summarizing the findings, any necessary repairs or adjustments, and recommendations for future maintenance.

- Digital Imaging: Photographs or videos can offer invaluable visual records, showing the before and after of repairs or the condition of equipment.

This comprehensive documentation ensures that maintenance history is readily available, assisting in future troubleshooting, warranty claims, and overall system management.

Q 21. Describe your experience with different types of irrigation controllers (e.g., smart controllers).

My experience encompasses a wide range of irrigation controllers, from basic time clocks to sophisticated smart controllers. Understanding the capabilities and limitations of each type is vital for selecting the optimal solution for a specific irrigation system.

- Basic Time Clocks: These controllers are simple to use and cost-effective but offer limited flexibility in scheduling and water management. They often rely on fixed schedules and don’t account for weather conditions.

- Weather-Based Controllers: These integrate with weather sensors to adjust irrigation schedules based on rainfall, temperature, and evapotranspiration. They reduce water waste by only irrigating when needed.

- Smart Controllers: These advanced controllers provide sophisticated control options, often featuring remote access, soil moisture monitoring capabilities, and integration with other smart systems. They optimize water use and enhance efficiency, allowing for precise management of the irrigation system via mobile devices.

For example, I recently upgraded a client’s system from a basic timer to a smart controller with soil moisture sensors. This change resulted in a 30% reduction in water usage without affecting crop yield, saving the client money on water bills and contributing to water conservation efforts.

Q 22. How do you calculate water usage and identify potential inefficiencies?

Calculating water usage and identifying inefficiencies in an irrigation system involves a multi-pronged approach combining measurement, analysis, and system understanding. It’s like figuring out your household budget – you need to know where the money (water) is going.

Firstly, we use water meters to measure the total water volume used over a specific period. This gives us a baseline. Then, we break down the usage by zone or section of the irrigation system, often using flow meters or even simple timing calculations (knowing the flow rate of each sprinkler and the runtime).

Identifying inefficiencies involves looking for several key indicators:

- High water usage per square foot: This could indicate overwatering, leaking lines, or inefficient sprinkler heads.

- Inconsistent watering: Some areas might be receiving too much water while others are underwatered, signifying a problem with pressure regulation, sprinkler distribution, or uneven terrain.

- Runoff: Excessive runoff means water isn’t being absorbed by the soil, wasting water and possibly causing erosion. This often points to poor soil preparation or inappropriate irrigation techniques.

- High evaporation rates: Watering during the hottest part of the day leads to significant water loss through evaporation. We can adjust watering schedules to mitigate this.

By carefully analyzing these data points, we can identify areas of improvement and implement corrective measures, such as replacing broken sprinklers, adjusting sprinkler heads, implementing soil amendments to improve water retention, or optimizing the irrigation schedule. For instance, in one project, we identified a significant leak by comparing the metered water usage to the calculated water needs based on evapotranspiration and soil type, resulting in a 20% reduction in water consumption.

Q 23. What is your experience with different irrigation piping materials?

My experience encompasses a wide range of irrigation piping materials, each with its own strengths and weaknesses. The choice of material depends heavily on factors like water pressure, soil conditions, budget, and the lifespan desired.

- Polyethylene (PE): This is a popular choice due to its flexibility, resistance to corrosion, and relatively low cost. It’s ideal for smaller systems and areas with difficult terrain.

- Polyvinyl chloride (PVC): PVC is strong, durable, and resistant to chemicals, making it suitable for high-pressure systems and areas with harsh conditions. However, it’s less flexible than PE.

- Chlorinated polyvinyl chloride (CPVC): CPVC offers even higher temperature and pressure resistance than PVC, ideal for hot climates or systems with high water pressure. It’s a more expensive option.

- Aluminum: Aluminum piping is lightweight and relatively strong, making it a good choice for certain applications, but it’s susceptible to corrosion in certain soil conditions.

- Galvanized steel: Galvanized steel is very durable and can withstand high pressures, but it’s prone to rust and corrosion over time. It’s typically used in larger commercial settings.

In my experience, properly selecting and installing the right piping material is critical to system longevity and efficiency. I’ve seen instances where using inappropriate materials led to costly repairs, leaks, and system failures. A thorough site assessment and understanding of the long-term implications of each material is key to making the best choice.

Q 24. How do you manage and maintain an inventory of irrigation parts and supplies?

Maintaining an organized inventory of irrigation parts and supplies is crucial for efficient maintenance and timely repairs. Imagine a mechanic without tools – the job becomes incredibly difficult and time-consuming.

We use a combination of methods to manage our inventory:

- Computerized inventory management system: This software tracks all parts, their quantity, cost, supplier information, and usage history. This allows us to forecast needs and order parts proactively.

- Physical inventory organization: Parts are categorized and stored in a well-organized warehouse or storage area, making it easy to locate what’s needed. Clear labeling and a logical shelving system are crucial.

- Regular stock checks: We conduct regular physical inventory checks to verify the accuracy of our computer system and identify potential shortages. This prevents delays due to missing parts.

- Supplier relationships: Strong relationships with reliable suppliers ensure prompt delivery of parts and minimize downtime. We negotiate favorable pricing and payment terms.

This system allows us to respond quickly to repairs, minimize downtime, and accurately estimate costs for projects. For example, during a recent storm that caused significant damage to an irrigation system, our organized inventory system allowed us to quickly procure the needed parts and restore functionality within a minimal timeframe.

Q 25. Describe your experience with working with different types of soils and their water requirements.

Understanding soil types and their water requirements is fundamental to efficient irrigation. Different soils retain water differently and have varying drainage characteristics. It’s like watering different types of plants – a cactus needs far less water than a fern.

My experience includes working with a variety of soils, including:

- Sandy soils: These soils drain quickly, requiring more frequent but less intense watering. We might use drip irrigation or other water-efficient methods.

- Clay soils: Clay soils retain water well but can become waterlogged if overwatered. We need to adjust watering schedules accordingly, using longer, less frequent watering cycles.

- Loamy soils: Loamy soils offer a good balance of drainage and water retention. These are generally easier to manage but still require monitoring and adjustments based on weather conditions.

I use soil testing to determine the soil type and its water-holding capacity. This information, along with weather data (temperature, rainfall, evapotranspiration), is incorporated into the irrigation schedule. Ignoring soil type often leads to inefficient water use, plant stress, or even water damage. In one case, by adapting our irrigation strategy to match the soil’s water retention capabilities, we reduced water consumption by 15% without impacting plant health.

Q 26. What are your troubleshooting skills regarding irrigation system sensors and components?

Troubleshooting irrigation system sensors and components requires a systematic approach, similar to diagnosing a car problem. We need to identify the symptoms, isolate the potential causes, and then test our theories.

My troubleshooting process generally involves:

- Visual inspection: Checking for obvious problems such as broken wires, leaks, or damaged components.

- Sensor testing: Using a multimeter to test the output signal of sensors (e.g., soil moisture sensors, rain sensors) to determine if they’re functioning correctly.

- Pressure testing: Checking water pressure at various points in the system to identify pressure drops that may indicate leaks or blockages.

- Flow meter checks: Measuring the flow rate of water through different sections of the system to detect restrictions or leaks.

- Control system diagnostics: Using the irrigation system’s control panel or software to diagnose any errors or malfunctions in the system’s logic.

For instance, I recently resolved an issue where a zone wasn’t activating by systematically checking the solenoid valve, the control wires, and finally, identifying a faulty connection in the control box. Experience allows me to rapidly isolate the problem and minimize downtime.

Q 27. How do you ensure the efficient use of fertilizers and chemicals in an irrigation system?

Efficient fertilizer and chemical application through an irrigation system, often called fertigation, requires precision and careful planning. It’s like adding specific nutrients to a plant’s diet, ensuring optimal growth.

Key aspects of efficient fertigation include:

- Accurate measurements: Precisely measuring the amount of fertilizer or chemical to be injected into the system is paramount to avoid over-application or under-application. Using calibrated equipment is essential.

- Proper injection equipment: Appropriate injectors are needed to ensure even distribution of the chemicals throughout the irrigation system. Regular maintenance of this equipment is critical.

- Water quality monitoring: Regular testing of the water source is necessary to ensure that it’s compatible with the fertilizers and chemicals being used.

- Soil testing: Knowing the soil’s nutrient levels allows us to tailor the fertilizer application to meet the specific needs of the plants.

- Scheduling and timing: The application of fertilizers and chemicals should be timed to maximize their effectiveness and minimize potential environmental impacts.

In one project, by implementing a precise fertigation system tailored to the soil and crop requirements, we achieved a 10% increase in crop yield while reducing fertilizer use by 15%. This illustrates the effectiveness of a well-planned fertigation approach.

Q 28. Describe your experience in working with different types of irrigation scheduling software.

My experience with irrigation scheduling software includes working with various platforms, each with unique features and capabilities. This software is like a sophisticated recipe book for watering, allowing for precise control and optimization.

I’ve worked with software packages that allow for:

- Weather-based scheduling: These programs use real-time weather data (temperature, rainfall, evapotranspiration) to adjust the irrigation schedule dynamically.

- Soil moisture monitoring integration: Some systems integrate with soil moisture sensors to provide real-time feedback on soil moisture levels and optimize watering accordingly.

- Zone-specific control: This allows for independent control of different irrigation zones, enabling tailoring watering schedules to specific plant types or soil conditions.

- Data logging and reporting: Comprehensive data logging and reporting capabilities allow us to track water usage, fertilizer application, and other relevant parameters to monitor efficiency and identify potential problems.

The choice of software depends heavily on the size and complexity of the irrigation system, the budget, and the specific needs of the client. Properly using this software can significantly improve efficiency, reduce water consumption, and ensure optimal plant health. In one instance, switching to weather-based scheduling reduced water use by 20% compared to a fixed-schedule system.

Key Topics to Learn for Your Irrigation Maintenance Interview

- Irrigation System Components: Understand the function and maintenance of pumps, valves, pipes, controllers, sensors, and sprinklers or drip emitters. Be prepared to discuss their common malfunctions and troubleshooting techniques.

- Water Management & Conservation: Discuss strategies for efficient water use, including pressure regulation, leak detection, and scheduling optimization. Be ready to explain how you would identify and address water waste in a system.

- Hydraulic Principles: Demonstrate your understanding of water pressure, flow rate, and head loss. Be able to explain how these principles affect irrigation system design and performance.

- Troubleshooting & Repair: Describe your experience diagnosing and repairing common irrigation problems, such as clogged emitters, broken pipes, malfunctioning controllers, and low water pressure. Highlight your problem-solving skills.

- Preventative Maintenance: Explain your approach to preventative maintenance, including scheduling, inspection procedures, and record-keeping. Showcase your understanding of proactive maintenance to minimize downtime and extend system lifespan.

- Safety Procedures: Discuss your knowledge of relevant safety regulations and procedures related to working with water, machinery, and chemicals used in irrigation maintenance.

- System Design & Installation (if applicable): If relevant to your experience, be prepared to discuss your knowledge of irrigation system design principles, including layout, pipe sizing, and component selection.

Next Steps

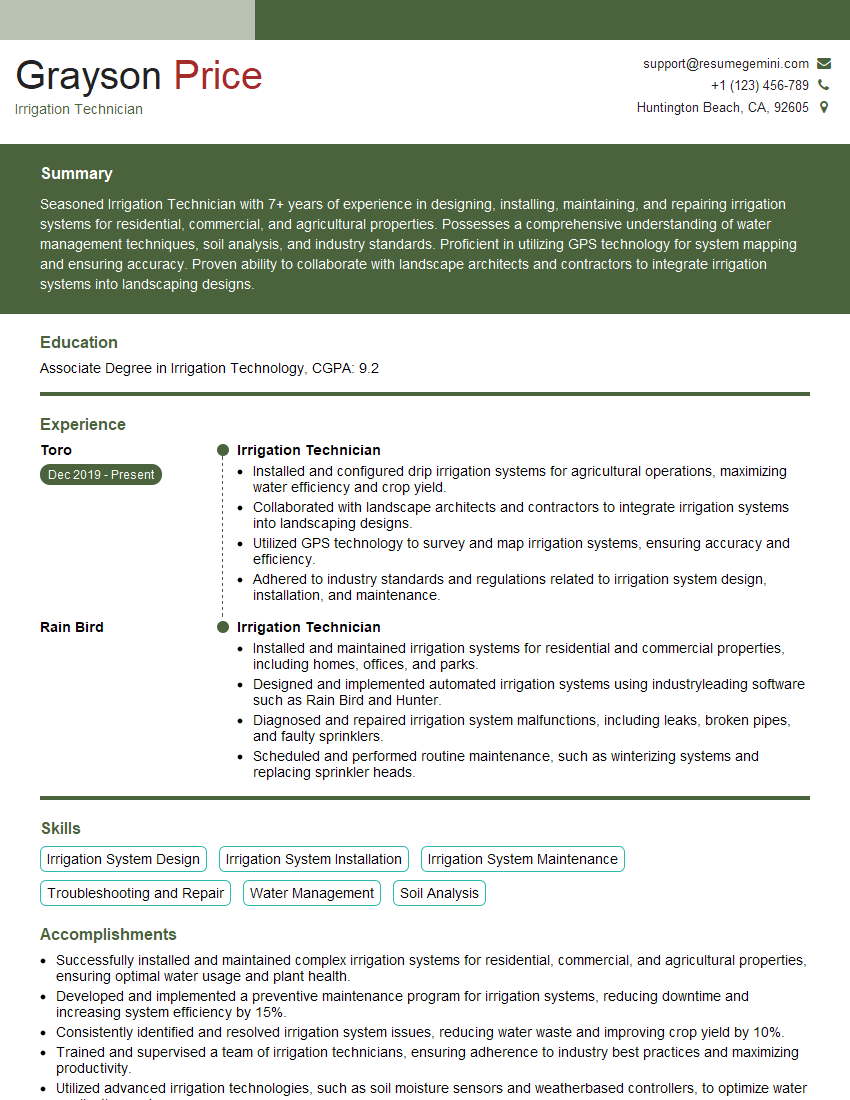

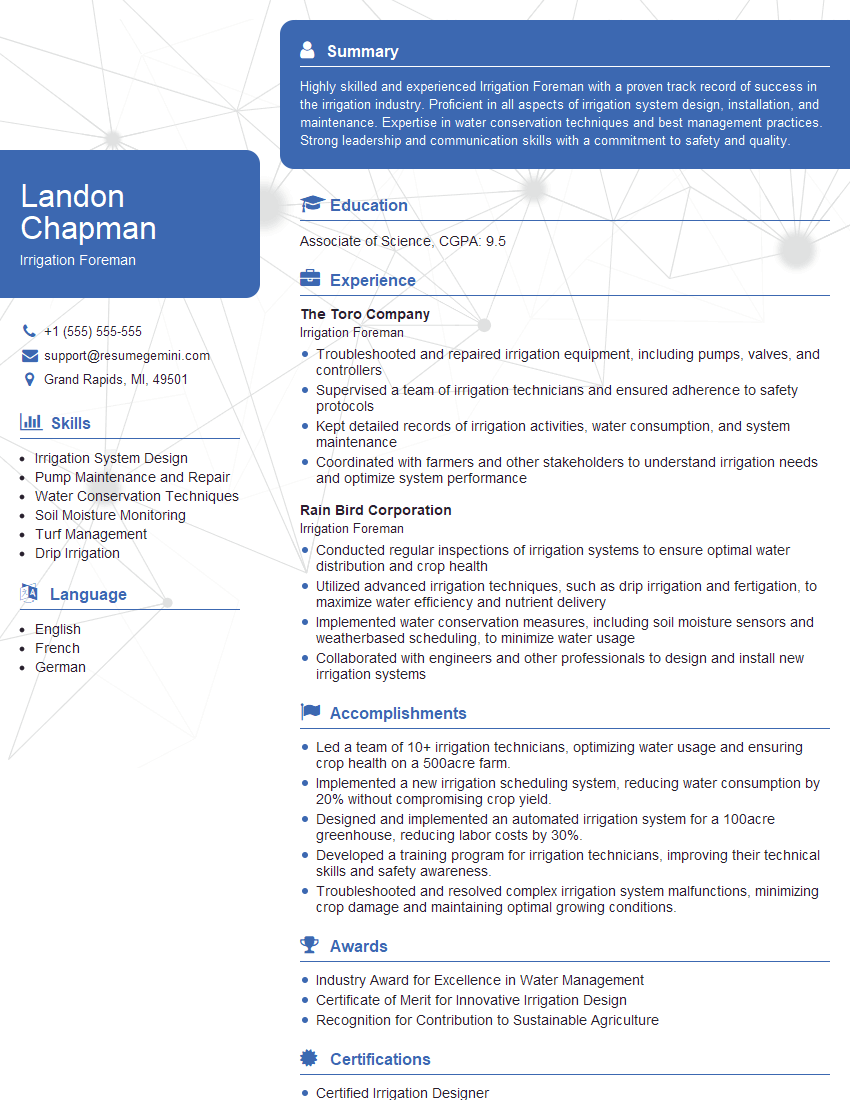

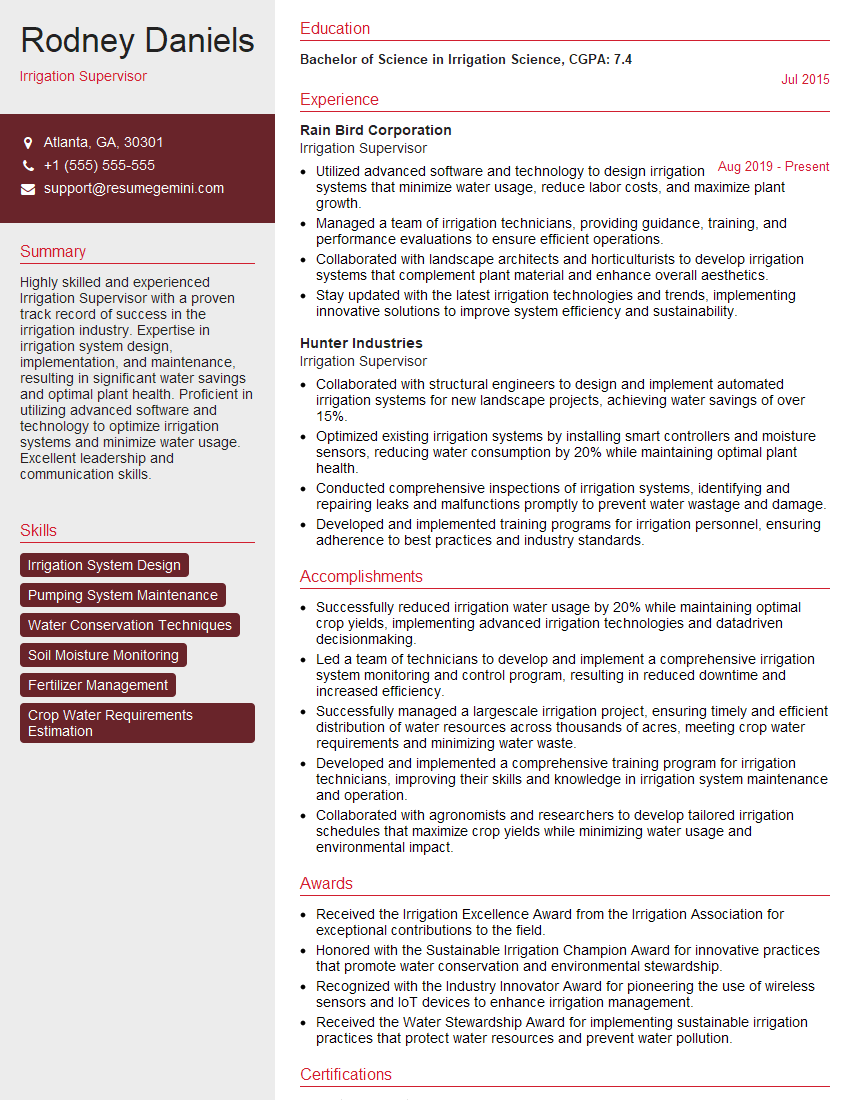

Mastering irrigation maintenance opens doors to a rewarding career with excellent growth potential. As the demand for efficient and sustainable water management increases, skilled professionals like you are highly sought after. To maximize your job prospects, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional and impactful resume. We offer examples of resumes tailored to Irrigation Maintenance to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good