Are you ready to stand out in your next interview? Understanding and preparing for Static Equipment Inspection interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Static Equipment Inspection Interview

Q 1. What are the main API codes relevant to Static Equipment Inspection?

Several API (American Petroleum Institute) codes are crucial for Static Equipment Inspection, providing standards and guidelines for design, fabrication, inspection, and maintenance. Key codes include:

- API 510: Pressure Vessel Inspection Code – This is the cornerstone for inspecting pressure vessels, outlining procedures for internal and external inspections, including visual, non-destructive testing (NDT), and repair assessments.

- API 653: Tank Inspection, Repair, Alteration, and Reconstruction – This code specifically addresses the inspection and maintenance of aboveground storage tanks, detailing various inspection techniques and addressing common tank issues like corrosion and leaks.

- API 570: Piping Inspection Code – While focusing on piping systems, this code is relevant to static equipment as it often involves interconnected piping. Inspecting the piping adjacent to static equipment helps assess the overall integrity of the system.

- API 579: Fitness-For-Service – This code provides a framework for evaluating the remaining life and acceptable level of damage in static equipment. It helps determine whether equipment with identified flaws can continue operating safely.

- API 650: Welded Tanks for Oil Storage – This code is relevant to the design and construction of welded tanks, influencing the inspection procedures necessary for ensuring structural integrity.

These API codes are not only essential for ensuring safety but also for regulatory compliance in the oil and gas industry and other related sectors. Failure to adhere to these standards can lead to significant safety hazards and legal consequences.

Q 2. Describe the different types of Non-Destructive Testing (NDT) methods used in static equipment inspection.

Non-Destructive Testing (NDT) plays a vital role in static equipment inspection, allowing us to assess the integrity of the equipment without causing damage. Several methods are employed:

- Visual Inspection (VT): The most basic, but crucial, method involving a thorough visual examination of the equipment’s surface for cracks, corrosion, dents, and other visible defects. It’s the first step in any inspection.

- Liquid Penetrant Testing (LPT): This method identifies surface-breaking flaws by applying a dye penetrant that seeps into cracks. A developer then draws the penetrant to the surface, making cracks visible.

- Magnetic Particle Testing (MPT): Used on ferromagnetic materials, MPT involves magnetizing the component and applying ferromagnetic particles. These particles accumulate at surface and near-surface cracks, revealing their presence.

- Ultrasonic Testing (UT): This method uses high-frequency sound waves to detect internal flaws. The sound waves reflect off discontinuities, revealing the size, location, and orientation of flaws.

- Radiographic Testing (RT): RT uses X-rays or gamma rays to penetrate the material and create an image on film or digitally. This reveals internal flaws such as cracks, inclusions, and corrosion.

- Eddy Current Testing (ECT): This electromagnetic method detects surface and near-surface flaws in conductive materials. It is particularly useful for detecting corrosion and cracking.

The choice of NDT method depends on factors like the material, type of equipment, and the type of defect suspected. Often, multiple NDT methods are used in combination to provide a comprehensive assessment.

Q 3. Explain the process of conducting a visual inspection of a pressure vessel.

A visual inspection of a pressure vessel is a systematic process, starting with preparation and ending with thorough documentation. Here’s a step-by-step approach:

- Preparation: This involves reviewing the vessel’s history, operating conditions, and previous inspection reports. The area around the vessel should be cleared for safe access.

- External Examination: A detailed visual inspection of the vessel’s exterior is conducted, checking for corrosion, dents, bulging, cracks, leaks, signs of previous repairs, and proper nozzle and fitting installation. Any signs of damage should be carefully documented using photos and sketches.

- Internal Examination (if accessible): If safe and practical, the internal inspection is conducted, checking the shell, heads, nozzles, and internals for similar defects. Any significant corrosion or damage inside should be assessed further using appropriate NDT methods.

- Documentation: Detailed records of all observations are meticulously documented. This includes date, time, inspector’s name, photographs of any defects, sketches indicating the location and severity of defects, and any other relevant information. These records are vital for future inspection and maintenance planning.

- Reporting: A formal report is generated, summarizing the inspection findings, including recommendations for repair or further investigation. The report might include prioritized repairs, suggested NDT testing, and an assessment of the vessel’s remaining life.

Remember, safety is paramount. All inspections should be conducted according to established safety procedures and with appropriate personal protective equipment (PPE).

Q 4. How do you identify and assess corrosion on static equipment?

Identifying and assessing corrosion on static equipment requires a multifaceted approach:

- Visual Inspection: Begin with a thorough visual inspection looking for rust, pitting, scaling, blistering, or other signs of corrosion. The location, extent, and type of corrosion should be noted.

- Measurement: The depth and extent of corrosion are often measured using calibrated tools like depth gauges or ultrasonic thickness gauges. This quantitative data is vital for assessing the severity of corrosion.

- NDT Methods: Depending on the type and location of corrosion, NDT methods like UT or ECT might be employed to determine the extent of corrosion beneath the surface. This is particularly crucial for corrosion that is not readily visible.

- Corrosion Mapping: For extensive corrosion, mapping the corrosion zones is crucial. This involves documenting the location, severity, and extent of corrosion areas. This map is essential for accurately assessing the overall condition of the equipment.

- Metallurgical Analysis (in some cases): For severe or unusual types of corrosion, samples may be taken for laboratory analysis to determine the type of corrosion, the rate of corrosion, and the potential contributing factors.

After collecting all data, the assessment involves comparing the measured corrosion to acceptable limits defined by codes and standards, like API 510, and determining the remaining life and the need for repair or replacement.

Q 5. What are the common causes of pressure vessel failures?

Pressure vessel failures can have catastrophic consequences. Common causes include:

- Corrosion: Both internal and external corrosion weakens the vessel walls, leading to potential failure. This can be exacerbated by factors like the nature of the contained substance and environmental conditions.

- Fatigue: Repeated cyclic loading and unloading can cause microscopic cracks to grow over time, eventually leading to failure. Vibration and pressure fluctuations contribute to fatigue.

- Brittle Fracture: At low temperatures, some materials become brittle and can fail suddenly under stress. This is particularly a concern with high-strength steels.

- Overpressure: Exceeding the vessel’s design pressure can cause catastrophic failure. Failures in pressure relief devices contribute to this.

- Design Defects: Faulty design or inadequate material selection can create weaknesses that lead to failure.

- Fabrication Defects: Welding flaws, improper heat treatment, or other fabrication errors can compromise the vessel’s structural integrity.

- Improper Operation and Maintenance: Lack of proper maintenance, incorrect operation, or neglecting regular inspections can greatly increase the likelihood of failure.

Understanding these causes is critical for implementing preventive measures and ensuring safe operation of pressure vessels.

Q 6. Describe the different types of pressure relief devices and their functions.

Pressure relief devices are safety critical components that protect pressure vessels and other equipment from overpressure. Several types exist:

- Safety Relief Valves (SRVs): These valves automatically open when the pressure exceeds a preset value, relieving excess pressure to the atmosphere or a flare system. They are spring-loaded and designed to reseat once the pressure drops below the setpoint.

- Rupture Disks (RDs): These are disposable devices designed to burst at a specific pressure, providing a single-use pressure relief mechanism. Once ruptured, they need replacement.

- Pressure Safety Valves (PSVs): These are similar to SRVs but often used in applications requiring more precise pressure control or in corrosive environments.

- Vacuum Relief Valves: These valves open when pressure drops below a certain level, preventing vessel collapse due to vacuum conditions.

The selection of an appropriate pressure relief device depends on various factors such as the type of fluid, pressure range, and required flow capacity. Regular inspection and testing of these devices are crucial to ensure their functionality.

Q 7. How do you interpret and evaluate inspection reports?

Interpreting and evaluating inspection reports requires a systematic approach:

- Review the Report’s Structure: Familiarize yourself with the report’s format, ensuring all sections are present and complete (e.g., equipment description, inspection methods, findings, and recommendations).

- Analyze the Inspection Findings: Carefully examine the findings, paying close attention to the type, location, and severity of identified defects. Understand the notations used to describe the defects (e.g., pitting depth, crack length).

- Assess the Severity of Defects: Evaluate the significance of each defect based on industry codes and standards. Consider factors such as the location of the defect, its size, and its potential impact on the equipment’s structural integrity.

- Verify the NDT Results: If NDT methods were employed, carefully examine the results and cross-reference them with visual inspection observations. Ensure the data is consistent and the chosen NDT methods were appropriate.

- Evaluate the Recommendations: Scrutinize the report’s recommendations for repairs, replacements, or further inspections. Ensure that the recommended actions are feasible, cost-effective, and comply with all relevant regulations and standards.

- Overall Assessment: After a thorough review, form a comprehensive assessment of the equipment’s condition, considering both the severity of the defects and the effectiveness of the recommended actions.

This process involves a high degree of professional judgment and experience. A thorough understanding of the applicable codes, standards, and inspection methods is essential. When in doubt, seek guidance from experienced inspectors or engineers.

Q 8. What are the key components of a comprehensive inspection plan for static equipment?

A comprehensive inspection plan for static equipment, like pressure vessels or storage tanks, needs to be meticulously detailed. Think of it as a blueprint for ensuring safety and operational efficiency. It should cover all aspects of the equipment’s lifecycle, from initial construction to eventual decommissioning.

- Equipment Identification and History: Clearly identifying the equipment (e.g., vessel ID, material, design code) and its operational history is crucial. This includes past inspection reports, maintenance records, and any known incidents or repairs.

- Inspection Scope and Frequency: This defines what parts of the equipment will be inspected (internal, external, welds, nozzles) and how often (e.g., annual, bi-annual, based on risk assessment). The frequency is directly related to the equipment’s criticality and operating conditions.

- Inspection Methods and Techniques: This outlines the specific techniques to be used, such as visual inspection, ultrasonic testing (UT), radiographic testing (RT), magnetic particle testing (MT), liquid penetrant testing (PT), and thickness measurements. The choice of methods depends on the material, the type of equipment and the potential failure modes.

- Acceptance Criteria: Clear, measurable criteria need to be defined to determine whether the equipment is fit for service. These criteria are often based on industry codes and standards (e.g., ASME Section VIII, API 650).

- Documentation and Reporting: This section specifies how inspection findings will be documented and reported, ensuring traceability and accountability. Detailed reports, including photos and diagrams, are essential.

- Qualified Personnel: The plan should specify the qualifications and certifications required for personnel conducting the inspection. Trained and certified inspectors are critical for accurate and reliable results.

For example, a high-pressure reactor in a chemical plant would require far more frequent and thorough inspections than a low-pressure storage tank for water.

Q 9. Explain the importance of maintaining accurate inspection records.

Maintaining accurate inspection records is paramount for several reasons. These records are not just paperwork; they are a vital safety and legal component. Imagine a detective investigating a crime scene – they rely on evidence. Similarly, inspection records form the evidence base for equipment integrity.

- Safety: Accurate records enable tracking of equipment condition over time, allowing for early detection of deterioration and prevention of catastrophic failures. This directly translates to improved safety for personnel and the environment.

- Regulatory Compliance: Many industries have strict regulations requiring detailed inspection records. These records demonstrate compliance and can be crucial in case of audits or investigations.

- Predictive Maintenance: Analyzing trends in inspection data can help predict when maintenance or repairs are needed, optimizing maintenance schedules and minimizing downtime. Instead of reactive maintenance (repairing failures), we move towards proactive maintenance based on data.

- Legal Protection: Comprehensive records can be essential in legal proceedings in the event of an accident or equipment failure. They serve as proof of due diligence and can significantly reduce liability.

- Cost Savings: Proactive maintenance based on inspection data prevents larger, more expensive repairs down the line. This ensures that smaller issues are addressed before they evolve into major problems.

Imagine a scenario where a pressure vessel fails without adequate inspection records. It would be significantly more difficult to determine the root cause, impeding the ability to prevent similar failures in other equipment.

Q 10. How do you determine the remaining life of a pressure vessel?

Determining the remaining life of a pressure vessel is a complex process that involves several factors. It’s not simply a matter of subtracting the vessel’s age from some arbitrary lifespan.

- Initial Design Life: The design life is determined based on the material, design codes, operating conditions, and anticipated corrosion rates. This is the starting point.

- Material Degradation: Factors like corrosion, erosion, and fatigue significantly reduce the vessel’s remaining life. Measuring wall thickness reduction due to corrosion is crucial. We utilize techniques like ultrasonic testing to assess this.

- Operating Conditions: Harsh operating conditions such as high temperatures, pressures, or corrosive environments accelerate material degradation and shorten the lifespan.

- Inspection Data: Past inspection reports provide a history of material degradation. We can track corrosion rates and identify areas of concern.

- Remaining Life Assessment Techniques: We can use sophisticated techniques like Finite Element Analysis (FEA) to predict the remaining life, taking into account various factors. This often requires specialized software.

- Industry Standards and Codes: The ASME Boiler and Pressure Vessel Code provides guidance on assessing remaining life. Following these guidelines is essential.

For instance, a pressure vessel operating at high temperatures in a refinery will likely have a shorter remaining life compared to a similar vessel in a less demanding environment. A thorough inspection program, coupled with advanced analysis, is necessary to make an accurate assessment.

Q 11. What are the common types of weld defects found in static equipment?

Weld defects are a major concern in static equipment as they can significantly compromise structural integrity. Many types of weld defects can be identified, each requiring different repair strategies.

- Porosity: Small, gas-filled holes within the weld metal. These reduce the strength and can act as stress concentrators.

- Inclusions: Foreign materials (slag, oxides) trapped within the weld. They weaken the weld and can create brittle areas.

- Lack of Fusion: Failure of the weld metal to properly bond with the base metal. This creates a plane of weakness.

- Lack of Penetration: Incomplete fusion of the weld metal through the joint. Similar to lack of fusion, this leads to reduced strength.

- Undercutting: A groove melted into the base metal at the edge of the weld. This weakens the weld and is considered a significant defect.

- Cracks: Fractures in the weld metal or heat-affected zone (HAZ). Cracks can be extremely dangerous and are often associated with fatigue or brittle fracture.

- Weld Misalignment: Imperfect alignment of the components being welded. This reduces the weld’s effective area.

Detecting these defects requires various Non-Destructive Testing (NDT) methods. For example, radiographic testing (RT) is effective for detecting internal defects like porosity and inclusions, while liquid penetrant testing (PT) is suitable for surface cracks.

Q 12. Describe the procedure for conducting a thickness measurement of a pressure vessel.

Measuring the thickness of a pressure vessel is crucial for assessing its remaining life and ensuring its continued safe operation. Accuracy is paramount. There are several methods to conduct this measurement.

- Ultrasonic Testing (UT): This is a widely used, non-destructive method. An ultrasonic transducer emits high-frequency sound waves that penetrate the material. The time it takes for the waves to reflect back provides the thickness measurement. UT is excellent for measuring thickness from one side, making it ideal for thick-walled vessels.

- Magnetic Thickness Gauges: These gauges measure the thickness of ferromagnetic materials (iron and steel) using magnetic principles. They’re quick and easy to use for surface measurements but are limited to ferromagnetic materials.

- Manual Measurement: This involves using a mechanical gauge, often a micrometer, to measure thickness on exposed surfaces. This is a simple, direct method but is time-consuming and can only be performed on accessible areas.

- Procedure Steps (using UT as an example):

- Clean the surface thoroughly to ensure good acoustic coupling.

- Apply a couplant (gel or water) to improve sound transmission.

- Calibrate the UT instrument using a reference block of known thickness.

- Position the transducer on the vessel surface.

- Measure the thickness at multiple points, following a defined grid pattern.

- Record the measurements and their locations.

- Analyze the data to identify areas of thinning.

It is important to remember to select the appropriate method based on the material, access limitations, and required accuracy. For instance, UT is commonly used for hard-to-reach areas, whereas manual measurement might suffice for readily accessible locations.

Q 13. How do you identify and assess damage due to fatigue in static equipment?

Fatigue damage occurs due to repeated cyclic loading, even if the stresses are well below the material’s yield strength. It’s a gradual process that can lead to catastrophic failure. Identifying and assessing fatigue damage requires a multi-pronged approach.

- Visual Inspection: Look for surface cracks, often initiated at stress concentration points like welds, corners, or holes. Fatigue cracks are typically initiated at the surface and propagate inward.

- Dye Penetrant Testing (PT): PT is useful for detecting surface-breaking cracks, which are often the first sign of fatigue damage. This method highlights surface discontinuities by using a liquid dye.

- Ultrasonic Testing (UT): UT can detect subsurface cracks that are not visible on the surface. The scattered signals from the crack indicate its presence and can give an indication of its depth.

- Fractography: This is a microscopic examination of fracture surfaces to determine the mechanism of failure. The fracture surface of a fatigue failure often has a characteristic appearance with beachmarks or striations that indicate the growth of the crack over time.

- Fatigue Life Prediction: This involves using sophisticated models and analysis to predict the remaining fatigue life of the equipment based on the detected damage and operating conditions.

For instance, a cycling pressure vessel will gradually develop fatigue cracks that might remain undetectable until they reach a critical size. Regular inspections and NDT techniques are necessary to catch these defects at early stages.

Q 14. What is the role of metallurgy in static equipment inspection?

Metallurgy plays a fundamental role in static equipment inspection. Understanding the material properties is essential for assessing the equipment’s integrity and predicting its remaining life. It is not just about the material itself, but how that material will behave under specific conditions.

- Material Identification: Correctly identifying the material (e.g., carbon steel, stainless steel, alloy steel) is crucial for determining its properties, corrosion resistance, and susceptibility to different types of degradation.

- Material Properties: Understanding properties like yield strength, tensile strength, ductility, and hardness is critical for assessing the material’s ability to withstand operating stresses.

- Corrosion Behavior: Metallurgy helps understand how the material will react to the operating environment. This knowledge guides the selection of appropriate corrosion mitigation strategies and allows for the accurate prediction of corrosion rates.

- Fracture Mechanics: Metallurgical analysis can identify factors contributing to brittle fracture. Microstructural examination will help identify potential weakness.

- Weldability: Metallurgy is crucial in determining the weldability of different materials and assessing the quality of welds.

- Heat Treatment: Understanding the effects of heat treatment on material properties helps assess the impact of welding or other thermal processes.

Without metallurgical expertise, accurate assessment of material degradation and prediction of remaining life would be impossible. For example, understanding the susceptibility of a particular stainless steel to chloride-induced stress corrosion cracking is essential for safe operation in a chloride-rich environment.

Q 15. What are the safety precautions necessary during static equipment inspection?

Safety is paramount during static equipment inspections. Before commencing any inspection, a thorough risk assessment is crucial. This involves identifying potential hazards, such as confined space entry, hazardous materials exposure (e.g., flammable gases, toxic substances), and working at heights. Appropriate personal protective equipment (PPE) must be worn, including hard hats, safety glasses, high-visibility clothing, and fall protection harnesses when necessary. Lockout/Tagout (LOTO) procedures must be meticulously followed to ensure equipment is isolated and de-energized before inspection, preventing accidental startup. Regular communication with the team and site supervisors is essential, especially in case of unexpected findings or emergencies. Finally, emergency response plans, including evacuation routes and contact information for emergency services, should be readily available and clearly communicated.

For example, before inspecting a large storage tank, we would ensure the tank is properly purged and inert, LOTO procedures are in place, and entry permits are signed off by authorized personnel. Respiratory protection might be required depending on the tank’s contents.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you handle discrepancies or discrepancies found during an inspection?

Discrepancies found during an inspection are documented meticulously using a standardized inspection report form. This typically includes photographic evidence, detailed descriptions of the defects, their locations, and severity. The next step involves a thorough assessment of the discrepancy’s impact on the equipment’s integrity and operational safety. Minor discrepancies, such as minor corrosion or surface damage, may be addressed through ongoing monitoring or minor repairs. More significant discrepancies, like significant corrosion, cracks, or bulging, necessitate immediate action. This might involve shutting down the equipment, implementing temporary repairs, or initiating a Fitness-For-Service (FFS) assessment to determine if the equipment can continue operating safely. A formal report is issued, outlining the findings, recommended actions, and timelines for remediation. This report is then reviewed and approved by the relevant stakeholders, including operations, maintenance, and engineering personnel. Closeout reports confirm the implemented corrective actions.

For instance, if a significant dent is found on a pressure vessel, we’d immediately isolate it, investigate the root cause, and initiate an FFS assessment to determine if it can continue operation safely or requires repair/replacement. The assessment might involve calculations based on relevant codes and standards, such as ASME Section VIII, Division 1 or 2.

Q 17. Explain the concept of Fitness-For-Service (FFS).

Fitness-For-Service (FFS) is a systematic engineering assessment used to determine if equipment with existing damage can continue to operate safely. Instead of automatically replacing damaged equipment, FFS evaluates the impact of the damage on the equipment’s structural integrity and operational reliability. It uses engineering analysis, codes, and standards to quantify the risk associated with continued operation. The assessment considers various factors, including the type and extent of damage, the material properties, operating conditions, and the consequences of potential failure. If the risk is deemed acceptable, the equipment can continue operating with enhanced monitoring and inspection frequency; otherwise, repair or replacement may be necessary.

Imagine a pipeline with a small crack detected. An FFS assessment would consider the crack’s size, location, pipeline material, operating pressure, and the potential consequences of a failure (e.g., environmental impact, personnel safety). Calculations based on relevant standards will help determine if the pipeline can remain in service or requires immediate repair.

Q 18. What are the key differences between API 510 and API 653?

API 510 and API 653 are both widely used standards for inspecting pressure vessels and tanks, but they differ in their scope and application. API 510, ‘Pressure Vessel Inspection Code: Maintenance, Inspection, Rating, Repair and Alteration,’ covers the inspection, repair, and alteration of in-service pressure vessels. It’s a broader standard encompassing a wider range of tasks. API 653, ‘Tank Inspection, Repair, Alteration, and Reconstruction,’ specifically focuses on the inspection, repair, and alteration of aboveground storage tanks. It provides more detailed guidance on issues specific to tanks, such as corrosion, grounding, and atmospheric venting.

In essence, API 510 addresses a broader range of pressure equipment, while API 653 concentrates specifically on storage tanks. A pressure vessel inspector might use API 510, while a tank inspector might use API 653, or both depending on the specific assets.

Q 19. How do you determine the appropriate inspection frequency for static equipment?

Determining appropriate inspection frequency involves considering several critical factors. These include the equipment’s age, operating conditions (pressure, temperature, and corrosive environment), material properties, history of previous inspections and repairs, and regulatory requirements. Risk-based inspection (RBI) methodologies are commonly used to optimize inspection frequencies. RBI systematically assesses the risk of failure by combining the probability of failure with the consequences of failure. This approach allows for a more targeted and cost-effective inspection strategy, focusing resources on higher-risk equipment. Industry best practices, manufacturer’s recommendations, and relevant codes and standards also provide valuable guidance for setting appropriate inspection intervals.

For instance, a new, low-pressure tank in a non-corrosive environment might have a less frequent inspection schedule compared to an older, high-pressure tank operating in a highly corrosive environment, which would require more frequent and thorough inspections.

Q 20. What are the legal and regulatory requirements for static equipment inspection?

Legal and regulatory requirements for static equipment inspection vary significantly depending on the location, industry, and type of equipment. However, many jurisdictions have regulations based on internationally recognized standards such as ASME codes, API standards, and OSHA regulations. These regulations often mandate regular inspections, detailed documentation, and compliance with specific safety procedures. Failure to comply with these regulations can lead to significant fines, operational shutdowns, and even legal action. It’s crucial to stay updated on all applicable regulations and to ensure that all inspections are conducted in accordance with these requirements. These regulations often dictate minimum inspection frequencies, required inspection methods, and documentation requirements.

For example, in the US, OSHA regulations are crucial for workplace safety, and compliance with ASME codes is essential for pressure vessels. Failure to follow these might result in significant penalties.

Q 21. Describe your experience with different types of static equipment.

Throughout my career, I’ve gained extensive experience inspecting various types of static equipment, including pressure vessels (both vertical and horizontal), storage tanks (aboveground and underground), heat exchangers, reactors, and piping systems. I’m proficient in utilizing various inspection methods, such as visual inspection, non-destructive testing (NDT) techniques (e.g., ultrasonic testing, radiographic testing, magnetic particle testing), and thickness measurements using ultrasonic thickness gauges. My experience spans different industries, including oil and gas, petrochemicals, and pharmaceuticals, exposing me to a wide range of materials, operating conditions, and regulatory requirements. This diverse experience has provided me with a comprehensive understanding of the challenges and best practices associated with inspecting various static equipment types.

Specifically, I’ve worked on projects involving the inspection of large-diameter storage tanks, high-pressure reactors, and complex heat exchanger systems. This experience includes managing inspection teams, preparing detailed inspection reports, and collaborating with engineering teams to develop appropriate repair strategies.

Q 22. What software or tools do you utilize for data analysis in static equipment inspection?

Data analysis in static equipment inspection relies heavily on software capable of handling large datasets and performing complex calculations. I typically utilize a combination of tools depending on the specific needs of the project. This often includes spreadsheet software like Microsoft Excel for initial data entry and basic calculations, but for more in-depth analysis, I leverage dedicated software packages.

For example, I use specialized software like Meridium APM or Aspen InSpec for managing inspection data, generating reports, and tracking equipment condition over time. These platforms allow for trend analysis, predictive modeling, and the identification of potential failure points. They often integrate with data acquisition systems from inspection devices, streamlining the entire process.

Furthermore, I’m proficient in using statistical software such as R or Python (with libraries like Pandas and Scikit-learn) for more advanced statistical modeling and analysis, particularly when dealing with corrosion rates, fatigue life estimations, or identifying correlations between different inspection parameters. This level of analysis allows for more data-driven decision making regarding maintenance schedules and repair strategies.

Q 23. Explain your experience with risk-based inspection (RBI).

Risk-Based Inspection (RBI) is a crucial methodology I employ to optimize inspection activities and allocate resources effectively. It moves away from time-based or prescribed inspection intervals to a more proactive approach focused on identifying and managing the risks associated with equipment failure.

My experience with RBI involves a thorough understanding of the entire process, from initial data gathering and equipment categorization to risk assessment and the development of an optimized inspection plan. This includes performing consequence analysis (what happens if the equipment fails?), probability analysis (how likely is failure?), and vulnerability assessment (what are the contributing factors to failure?). I use specialized RBI software to integrate these elements and generate reports prioritizing which equipment requires immediate attention.

For instance, in a recent project involving a large refinery, we used RBI to identify a specific heat exchanger with a high risk of catastrophic failure due to corrosion. By prioritizing inspections on this particular unit, we were able to detect and address the issue before it escalated, avoiding a costly shutdown.

Q 24. How do you communicate inspection findings effectively to stakeholders?

Effective communication of inspection findings is paramount to ensuring corrective actions are taken promptly and that stakeholders are well-informed. My approach involves tailoring the communication to the audience and using clear, concise language, avoiding technical jargon whenever possible.

I typically create comprehensive reports with clear summaries of findings, including both visual aids like photographs and diagrams, and detailed technical information for engineering teams. For executive-level audiences, I focus on high-level summaries highlighting key risks and recommended actions. I employ various methods of communication, including:

- Formal reports: Detailed documentation of inspection findings, including recommendations.

- Presentations: Visual summaries and discussions during meetings.

- Interactive dashboards: (using tools like Tableau or Power BI) provide dynamic views of equipment health and risk profiles.

- Verbal communication: Direct discussions with engineers, maintenance personnel, and management.

Transparency and proactive communication are vital, ensuring everyone is on the same page and understands the implications of the inspection results.

Q 25. Describe a challenging inspection scenario you faced and how you resolved it.

During an inspection of a large storage tank, we encountered unexpected challenges due to extensive rust and scaling, obstructing access to critical areas for visual inspection. The standard inspection techniques were proving ineffective and jeopardizing the safety of the inspection team.

To overcome this, I first ensured the safety of my team and developed a revised plan. This included using remote inspection techniques, such as drones equipped with high-resolution cameras and specialized lighting, to assess the condition of the tank’s interior walls and base. We also utilized ultrasonic thickness gauging from external access points to measure wall thickness and identify areas of significant corrosion.

The combination of these methods enabled us to gather comprehensive data despite the challenging access. The results were then used to create a detailed report, outlining the necessary repairs and modifications. This approach avoided the risk associated with manual entry into hazardous areas and delivered accurate data in a timely manner.

Q 26. How do you stay updated on the latest industry codes and standards?

Staying current with industry codes and standards is crucial for maintaining competence and ensuring inspections adhere to best practices. I actively engage in several strategies to achieve this:

- Professional memberships: I maintain active membership in organizations like ASME (American Society of Mechanical Engineers) and API (American Petroleum Institute), gaining access to their publications and updates.

- Industry conferences and workshops: Attending conferences allows me to network with peers and learn about emerging trends and technologies.

- Online resources and publications: Regularly reviewing industry journals, technical papers, and online databases, such as those published by regulatory bodies.

- Training courses and certifications: Participating in continuing education programs to enhance my knowledge of new inspection methods and relevant codes.

This multi-faceted approach ensures I’m always up-to-date on the latest advancements and best practices in the field.

Q 27. What are your salary expectations?

My salary expectations are in line with my experience and qualifications in the field of static equipment inspection. Considering my expertise in RBI, proficiency in specialized software, and successful track record in managing complex inspection projects, I am seeking a competitive compensation package in the range of [Insert Salary Range]. I’m open to discussing this further based on the specifics of the role and company benefits package.

Q 28. Why are you interested in this position?

I’m highly interested in this position because it aligns perfectly with my career aspirations and expertise. I’m particularly drawn to [Company Name]’s commitment to safety and its focus on proactive maintenance strategies, which resonate strongly with my own values and work ethic. The opportunity to contribute my skills to a company that values data-driven decision making and continuous improvement is incredibly exciting.

Furthermore, the opportunity to work on [mention specific projects or aspects of the role that interest you] is particularly appealing. I believe my experience and knowledge in RBI and advanced data analysis techniques will be a valuable asset to your team and contribute directly to enhancing the reliability and safety of your static equipment.

Key Topics to Learn for Static Equipment Inspection Interview

- Pressure Vessel Inspection: Understanding codes and standards (ASME Section VIII, API 650, etc.), inspection techniques (visual, non-destructive testing), and common defects.

- Practical Application: Interpreting inspection reports, identifying corrosion, recognizing signs of fatigue and stress cracking, and recommending appropriate repair or replacement strategies.

- Storage Tank Inspection: Assessing tank integrity, understanding grounding and bonding requirements, and identifying potential leaks or environmental hazards.

- Piping Systems Inspection: Identifying potential weaknesses in piping systems, understanding stress analysis concepts, and recognizing corrosion and erosion mechanisms.

- Non-Destructive Testing (NDT) Methods: Familiarity with various NDT techniques (ultrasonic testing, radiographic testing, magnetic particle testing, liquid penetrant testing) and their applications in static equipment inspection.

- Risk Assessment and Management: Evaluating the risks associated with defects and recommending appropriate mitigation strategies.

- Regulatory Compliance: Understanding relevant safety regulations and industry best practices.

- Documentation and Reporting: Properly documenting inspection findings and preparing comprehensive reports.

- Problem-Solving Approach: Analyzing inspection data, identifying root causes of defects, and developing effective solutions.

- Welding Inspection: Understanding welding codes, common welding defects, and inspection techniques for welds in static equipment.

Next Steps

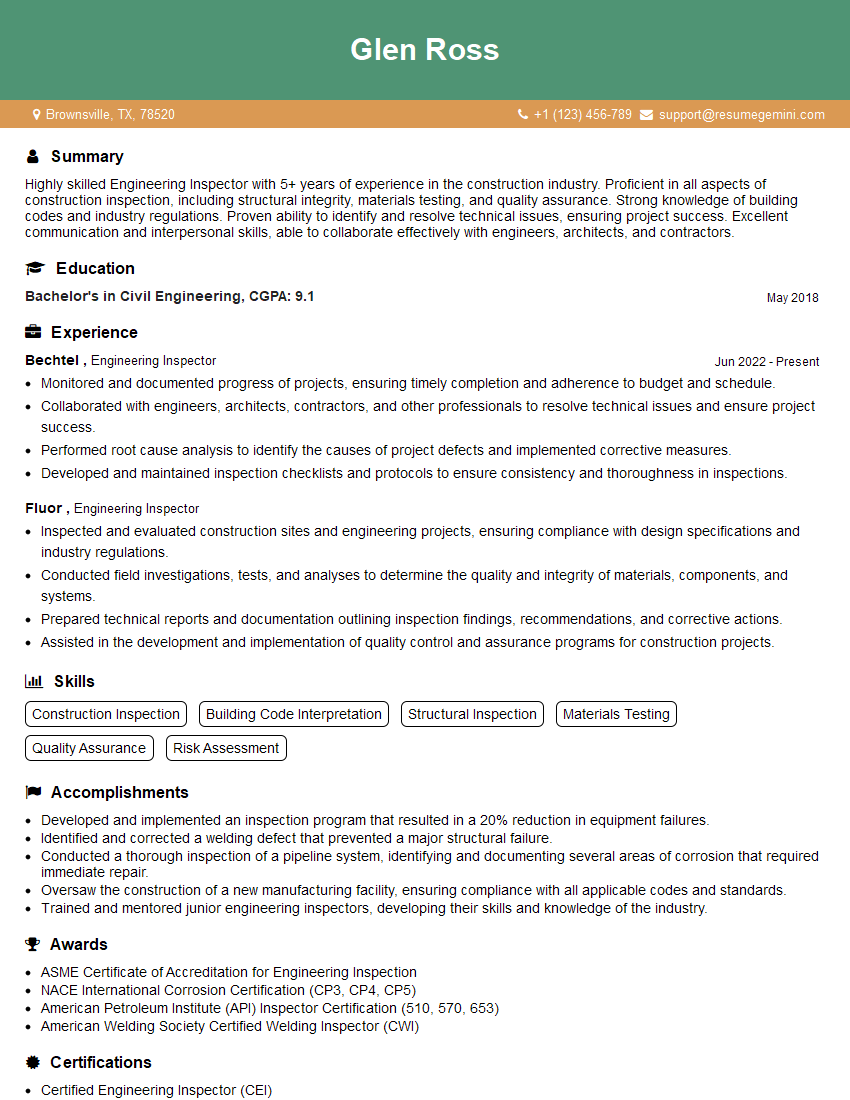

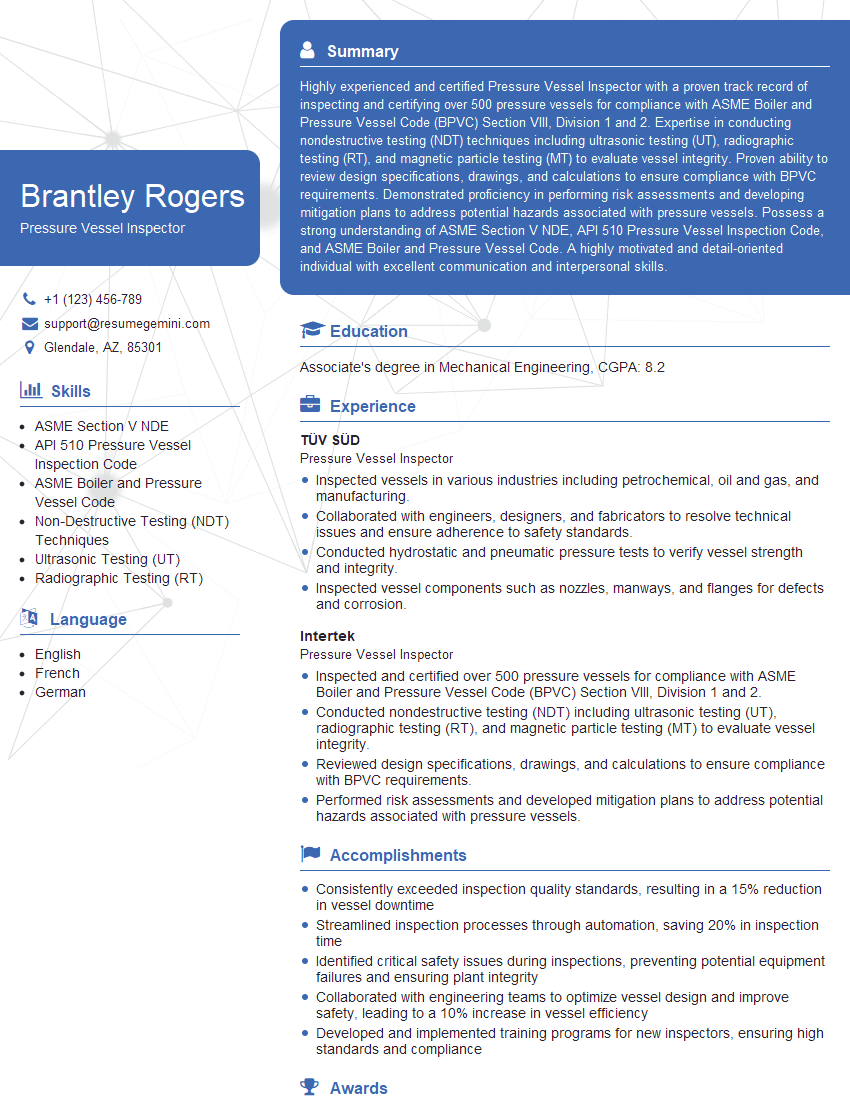

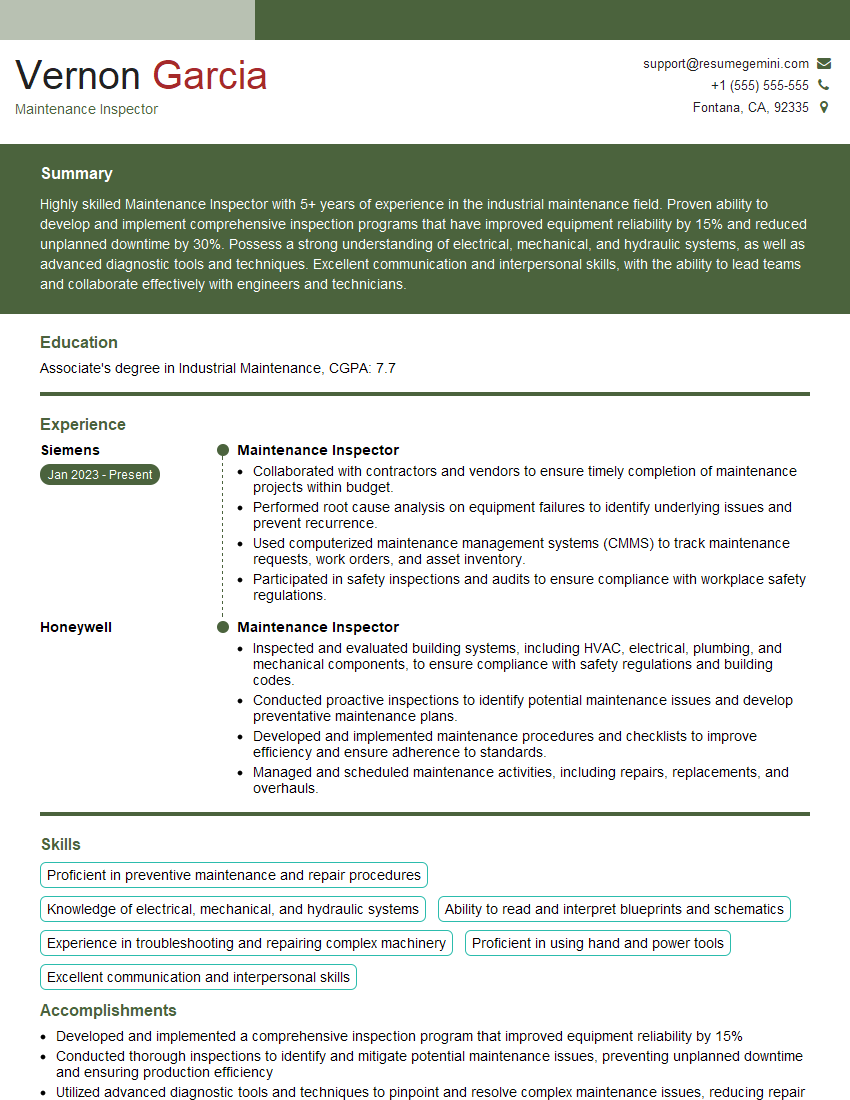

Mastering Static Equipment Inspection opens doors to exciting career opportunities in diverse industries, offering excellent growth potential and high earning prospects. To maximize your chances of landing your dream role, a well-crafted, ATS-friendly resume is crucial. This is where ResumeGemini can help. ResumeGemini provides a powerful platform for creating professional, impactful resumes tailored to specific industries. We offer examples of resumes specifically designed for Static Equipment Inspection professionals to help you showcase your skills and experience effectively. Invest in your future – build a standout resume with ResumeGemini.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good