Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Material Handling Equipment Selection interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Material Handling Equipment Selection Interview

Q 1. Explain the difference between a forklift and a reach truck.

Forklifts and reach trucks are both used for material handling, but they differ significantly in their design and application. Think of a forklift as a strong, all-around workhorse, while a reach truck is a more specialized tool for reaching high places in narrow aisles.

A forklift uses forks that are directly attached to the mast and lift loads vertically. They’re highly versatile, handling various pallet sizes and weights, and are suitable for both indoor and outdoor environments. They’re great for stacking pallets several feet high but don’t excel in tight spaces.

A reach truck, on the other hand, features extending forks that can reach out and pick up pallets from the side. This allows for operation in much narrower aisles compared to a standard forklift. They’re particularly efficient in high-density storage facilities like warehouses with very narrow aisles. The reach mechanism adds to the vertical lift height, facilitating storage in high-bay warehouses.

In short: Choose a forklift for general material handling and versatility; choose a reach truck for maximizing space utilization in narrow-aisle applications.

Q 2. What factors influence the selection of conveyor systems?

Selecting the right conveyor system is crucial for efficient material flow. Several factors need careful consideration, including:

- Material characteristics: Size, weight, shape, fragility of the items being conveyed directly impacts conveyor type (e.g., roller conveyor for heavier items, belt conveyor for lighter, smaller items).

- Throughput requirements: How much material needs to be moved per hour dictates the speed and capacity of the conveyor.

- Layout and space constraints: The physical layout of the facility dictates the type and configuration of the conveyor system. Space limitations might favor roller conveyors over more space-consuming belt conveyors.

- Budget: Different conveyor types vary significantly in cost, impacting the overall project budget.

- Integration with other systems: The conveyor must seamlessly integrate with existing material handling equipment and warehouse management systems (WMS).

- Maintenance requirements: Some conveyor systems require more frequent maintenance than others; this should be considered alongside operational costs.

For example, a high-volume distribution center might utilize a complex network of automated belt conveyors, while a smaller workshop might opt for a simple gravity roller conveyor.

Q 3. Describe the various types of automated guided vehicles (AGVs).

Automated Guided Vehicles (AGVs) are robotic vehicles that move materials autonomously within a facility. There are several types, each with its strengths and weaknesses:

- Unit Load AGVs: These handle large loads (pallets, containers) and typically follow pre-programmed paths using wires embedded in the floor, magnetic tape, or laser guidance systems. They are perfect for moving large quantities of goods between warehouse areas.

- Tugger AGVs: These pull trains of carts or trailers, maximizing efficiency for transporting multiple items simultaneously. Excellent for transporting many smaller items across a longer distance.

- Forklift AGVs: These combine the functionality of a forklift with autonomous navigation, offering flexibility in handling various load types and configurations. They combine the convenience of automation with the versatility of a standard forklift.

- Laser-guided AGVs: These use laser scanners to navigate their environment and are more adaptable to changes in the facility layout than wire-guided systems. They offer higher flexibility compared to wire-guided systems and can handle dynamic environments effectively.

The choice of AGV type depends on the specific application, the layout of the facility, and the type of materials being handled. A large warehouse might use a mix of unit load and tugger AGVs for optimal efficiency.

Q 4. How do you assess the ROI of different material handling equipment options?

Assessing the Return on Investment (ROI) of material handling equipment requires a comprehensive approach. It’s not just about the initial purchase price; it’s about the total cost of ownership (TCO).

Steps to assess ROI:

- Calculate initial investment costs: Include purchase price, installation, and any necessary modifications to the facility.

- Estimate operating costs: Consider energy consumption, maintenance, repairs, and labor costs (reduced labor due to automation should be factored in).

- Project increased productivity: Quantify how the new equipment will improve efficiency, throughput, and reduce labor costs.

- Factor in potential cost savings: Consider reduced damage to goods, less waste, and improved storage space utilization.

- Calculate the ROI: Use standard ROI calculations or discounted cash flow (DCF) analysis to determine the financial return over a defined period (e.g., 5-10 years). Compare the ROI of different equipment options to determine the most cost-effective solution.

Example: If a new automated system costs $100,000 and saves $25,000 annually in labor costs, the ROI could be calculated as (25,000/100,000)*100 = 25% per year.

Q 5. What safety regulations must be considered when selecting and using material handling equipment?

Safety is paramount in material handling. Regulations vary by location, but some common considerations include:

- OSHA (Occupational Safety and Health Administration) regulations: These cover various aspects of equipment operation, including operator training, equipment maintenance, and safe operating procedures. Compliance is mandatory in the US.

- Equipment certifications and inspections: Regular inspections and certifications ensure that equipment is in safe working order. Certificates from relevant safety bodies must be verified.

- Operator training and licensing: Operators need proper training to safely operate the equipment, including understanding of load capacity and safe operating procedures. Licensing requirements also vary by location and equipment type.

- Workplace safety protocols: Clear signage, designated walkways, and speed limits are crucial to create a safe environment. Good housekeeping to eliminate slip hazards are essential.

- Personal Protective Equipment (PPE): Operators must use appropriate PPE such as safety glasses, gloves, and high-visibility clothing.

Ignoring safety regulations can lead to serious accidents, injuries, and costly fines.

Q 6. How do you determine the appropriate capacity and lift height for a forklift?

Determining the appropriate capacity and lift height for a forklift involves careful consideration of the loads being handled and the storage environment.

Capacity:

- Weight of the heaviest load: The forklift’s capacity must exceed the weight of the heaviest load to be lifted, with a safety factor included (typically 10-20% additional capacity).

- Size and stability of the load: Unevenly distributed weight can affect stability and requires careful consideration.

- Operating conditions: Inclines, uneven surfaces, and other environmental factors can impact the effective capacity. This needs to be accounted for in the capacity selection.

Lift Height:

- Height of storage racks: The forklift’s lift height must allow for easy placement and retrieval of goods from the highest storage level.

- Clearance requirements: Sufficient headroom must be available to avoid collisions with ceilings or other obstructions. A safety margin should be added.

- Type of load: The lift height requirements may vary based on the types of goods handled. Consider the type of load, its size, and the required handling techniques.

Failing to properly assess capacity and lift height can lead to equipment damage, accidents, and decreased operational efficiency.

Q 7. Explain the concept of ergonomic design in material handling.

Ergonomic design in material handling focuses on creating a work environment that minimizes physical strain and discomfort for workers. It’s about optimizing the interaction between the worker, the equipment, and the task.

Key considerations include:

- Equipment design: Features like adjustable seats, controls within easy reach, and low-effort steering mechanisms reduce fatigue and risk of injury.

- Workplace layout: Minimizing travel distances, optimizing storage locations, and providing adequate space for maneuvering reduce physical stress.

- Load handling: Using equipment that minimizes manual lifting, reduces awkward postures, and provides proper support for heavy loads prevents injuries. Employing lifting aids and mechanisms is vital.

- Training and procedures: Proper training on safe lifting techniques and the use of material handling equipment is essential to prevent injuries. Standardized safe operational procedures can minimize risks.

Implementing ergonomic principles can lead to a significant reduction in work-related musculoskeletal disorders (MSDs), improved worker productivity, and reduced absenteeism. Think of it as designing the workplace for the human body, not the other way around.

Q 8. What are the advantages and disadvantages of using automated storage and retrieval systems (AS/RS)?

Automated Storage and Retrieval Systems (AS/RS) are highly automated warehouse systems that significantly improve efficiency and reduce labor costs. They use computer-controlled cranes or other automated devices to store and retrieve materials from high-density storage racks.

- Advantages:

- Increased Storage Density: AS/RS allows for much higher storage density compared to traditional methods, maximizing warehouse space utilization.

- Improved Accuracy: Automated systems minimize human error in picking and placement, leading to greater accuracy and reduced order fulfillment times.

- Enhanced Efficiency: AS/RS significantly improves throughput and order fulfillment speed, optimizing warehouse operations.

- Reduced Labor Costs: Automation reduces the need for manual labor, leading to lower labor costs and improved productivity.

- Improved Inventory Control: Real-time tracking of inventory is readily available, providing accurate inventory levels and improved management.

- Disadvantages:

- High Initial Investment: The upfront cost of implementing an AS/RS is substantial, requiring significant capital expenditure.

- Maintenance Costs: Automated systems require regular maintenance and repairs, which can be costly.

- System Complexity: AS/RS are complex systems requiring specialized expertise for operation, maintenance, and programming.

- Limited Flexibility: Once installed, modifying an AS/RS system can be difficult and expensive, limiting flexibility in accommodating future changes in storage needs.

- Single Point of Failure: A malfunction in a critical component can bring the entire system to a halt.

For example, a large e-commerce fulfillment center might benefit from AS/RS to handle a massive volume of small orders efficiently. However, a small warehouse with infrequent orders might find the initial investment prohibitive.

Q 9. How do you calculate the total cost of ownership (TCO) for material handling equipment?

Calculating the Total Cost of Ownership (TCO) for material handling equipment involves considering all costs associated with the equipment over its entire lifespan. It’s more than just the purchase price; it encompasses a holistic view of expenses.

Here’s a breakdown of the key components:

- Initial Investment: Purchase price of the equipment, including taxes and delivery.

- Installation Costs: Expenses for site preparation, installation, and commissioning.

- Operating Costs: Ongoing expenses like energy consumption, maintenance, repairs, and operator salaries.

- Maintenance Costs: Preventive maintenance contracts, replacement parts, and repair services.

- Financing Costs: Interest payments if the equipment was financed through a loan.

- Training Costs: Training for operators and maintenance personnel.

- Insurance Costs: Insurance premiums to cover potential damage or loss.

- Disposal Costs: Costs associated with disposing or recycling the equipment at the end of its useful life.

Example Calculation (Simplified):

Let’s say a forklift costs $20,000, has annual maintenance of $1,000, and an expected lifespan of 10 years. A simplified TCO calculation would be: $20,000 (purchase) + ($1,000/year * 10 years) = $30,000. However, this is a very basic example; a comprehensive TCO analysis would require a more detailed breakdown of all the costs listed above.

Proper TCO analysis is crucial for making informed decisions about equipment selection, enabling businesses to compare different options and select the most cost-effective solution in the long run.

Q 10. Describe different types of pallet racking systems and their applications.

Pallet racking systems are essential for efficient storage in warehouses. Several types exist, each suited for different applications:

- Selective Pallet Racking: This is the most common type, allowing for direct access to each pallet. Ideal for high-turnover items and diverse product ranges. Think of a typical warehouse with aisles between rows of racks.

- Drive-In/Drive-Through Racking: Pallet placement and retrieval occur from one side. Suitable for high-volume storage of similar products with FIFO (First-In, First-Out) or LIFO (Last-In, First-Out) stock rotation. Think of a grocery warehouse storing bulk cases of a single item.

- Push-Back Racking: Pallets are stored on rolling carriages, allowing for higher density compared to selective racking. Best for LIFO storage.

- Double-Deep Racking: Allows for two pallets deep, improving storage capacity compared to selective racking but requiring special equipment for pallet access.

- Flow Racking: Gravity-fed system where pallets roll down inclined lanes. Primarily used for FIFO storage. Think of a distribution center handling perishable goods.

- Cantilever Racking: Suitable for long or bulky items such as lumber or pipes. Pallet storage is not required here.

The choice of pallet racking system depends heavily on factors like warehouse layout, product type, inventory turnover rate, and storage capacity requirements. A proper needs analysis is crucial for optimal selection.

Q 11. What are the key considerations when selecting a warehouse management system (WMS)?

Selecting a Warehouse Management System (WMS) is a critical decision impacting warehouse efficiency and profitability. Key considerations include:

- Scalability: The WMS should be able to adapt to future growth and changing business needs.

- Integration: Seamless integration with existing ERP (Enterprise Resource Planning) systems and other warehouse technologies (e.g., AS/RS, barcode scanners).

- Functionality: The WMS must meet the specific needs of the warehouse, including receiving, putaway, picking, packing, shipping, and inventory management.

- Reporting and Analytics: Comprehensive reporting capabilities to monitor key performance indicators (KPIs) and identify areas for improvement.

- User-Friendliness: The system should be intuitive and easy to use for warehouse staff.

- Vendor Support: Reliable vendor support and maintenance are essential to ensure smooth operation.

- Cost: Evaluate the total cost of ownership, including licensing fees, implementation costs, and ongoing maintenance.

- Security: Robust security measures to protect sensitive data.

For instance, a growing e-commerce company would need a WMS with strong order management capabilities and real-time inventory tracking. A smaller warehouse might opt for a simpler, less expensive system.

Q 12. How do you optimize warehouse layout for efficient material handling?

Optimizing warehouse layout is crucial for efficient material handling. The goal is to minimize travel distances, reduce congestion, and streamline workflows.

Key strategies include:

- Product Location Optimization: Frequently accessed items should be placed closer to shipping docks, reducing travel time. This often utilizes ABC analysis to categorize items based on demand.

- Efficient Aisles and Pathways: Aisles should be wide enough to accommodate equipment but not excessively large to waste space. One-way aisles can improve traffic flow.

- Cross-Docking: Minimize storage time by directly transferring incoming goods to outbound shipping without intermediate storage.

- Vertical Space Utilization: Use vertical space efficiently with high-bay racking systems. Consider the use of mezzanines to create additional floor space.

- Strategic Equipment Placement: Position forklifts, conveyors, and other equipment strategically to minimize travel time between receiving, storage, and shipping areas.

- Simulation and Modeling: Utilize simulation software to test different layouts and optimize workflow before implementation.

Consider a scenario where high-demand items are placed closest to the shipping dock, enabling rapid order fulfillment. By using simulation, you can fine-tune the layout based on predicted daily throughput and minimize congestion and delays.

Q 13. Explain the importance of preventive maintenance for material handling equipment.

Preventive maintenance is critical for maintaining the reliability and longevity of material handling equipment. It involves regularly scheduled inspections and maintenance tasks to prevent breakdowns and extend the lifespan of equipment.

The importance is multifaceted:

- Reduced Downtime: Regular maintenance prevents unexpected breakdowns, minimizing costly downtime and disruptions to operations.

- Extended Equipment Life: Preventive maintenance helps to extend the lifespan of equipment, reducing the need for frequent replacements.

- Improved Safety: Regular inspections identify and address potential safety hazards, creating a safer working environment.

- Lower Repair Costs: Addressing minor issues before they escalate into major problems saves on repair costs in the long run.

- Increased Efficiency: Well-maintained equipment operates at peak efficiency, improving productivity and throughput.

Imagine a forklift experiencing a sudden hydraulic failure mid-shift. This results in lost production time, potential injury, and costly repairs. A preventive maintenance program including regular hydraulic fluid checks could have prevented this.

Q 14. Describe different methods for improving the efficiency of material handling processes.

Improving the efficiency of material handling processes requires a holistic approach focusing on several key areas:

- Process Optimization: Analyze existing workflows to identify bottlenecks and inefficiencies. Implement lean manufacturing principles to streamline processes and eliminate waste.

- Technology Integration: Utilize technology such as WMS, RFID, barcode scanners, and automated guided vehicles (AGVs) to improve accuracy, track inventory, and automate tasks.

- Employee Training: Provide training to warehouse staff on safe and efficient material handling practices, including the proper use of equipment.

- Layout Optimization: Optimize warehouse layout to minimize travel distances and streamline workflows, as discussed earlier.

- Equipment Selection: Select appropriate material handling equipment based on specific needs, including capacity, throughput, and ergonomics.

- Inventory Management: Implement effective inventory control strategies to ensure accurate stock levels and minimize storage costs.

- Cross-Docking: Implementing cross-docking strategies can significantly reduce handling and storage times.

For example, a warehouse could implement RFID tracking to monitor the location of pallets in real time, reducing time spent searching for items. Similarly, improved employee training on efficient picking methods can substantially improve order fulfillment speed.

Q 15. What are the common causes of material handling accidents and how can they be prevented?

Material handling accidents are unfortunately common, stemming from a variety of causes. These can broadly be categorized into human error, equipment malfunction, and inadequate safety procedures.

- Human Error: This is often the leading cause, encompassing issues like improper lifting techniques leading to back injuries, failing to follow lockout/tagout procedures resulting in electrocution or crushing, and distractions causing collisions with equipment.

- Equipment Malfunction: Faulty equipment, inadequate maintenance, or operator misuse can lead to accidents. For example, a forklift with a failing hydraulic system might lead to a load dropping, and a malfunctioning conveyor belt could cause jams and injuries.

- Inadequate Safety Procedures: A lack of clear safety protocols, insufficient training, or ineffective enforcement of safety rules significantly increases the risk of accidents. This could involve insufficient lighting, missing guardrails, or a lack of emergency shut-off procedures.

Prevention requires a multifaceted approach. This involves rigorous training programs emphasizing safe operating procedures for all equipment, regular maintenance and inspections to identify and rectify potential equipment failures promptly, and the implementation of robust safety protocols, including clear signage, emergency response plans, and the use of personal protective equipment (PPE).

For instance, a well-structured training program for forklift operators might include classroom instruction, simulator training, and on-the-job mentorship. Regular inspections of cranes, including thorough visual checks and load testing, are crucial for preventing malfunctions. And lastly, clearly defined emergency procedures and readily accessible emergency shut-off switches are critical for mitigating the severity of accidents should they occur.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you evaluate the performance of material handling equipment?

Evaluating material handling equipment performance involves a holistic approach, examining several key aspects. We shouldn’t just look at speed but also efficiency and safety.

- Throughput: This measures the volume of material moved within a specific timeframe. We can track the number of pallets moved per hour, or the tons of material handled per shift. Lower than expected throughput might point to bottlenecks in the process or equipment inadequacies.

- Utilization Rate: This indicates how effectively the equipment is being used. High utilization indicates efficiency; low utilization suggests idle time, perhaps due to poor scheduling or inadequate equipment.

- Downtime: Tracking downtime due to maintenance, repairs, or breakdowns is crucial. Frequent downtime points to a need for improved maintenance strategies or potential equipment issues.

- Safety Record: This is paramount. The number and severity of accidents associated with a particular piece of equipment provide vital insights into its safety and the effectiveness of associated safety procedures. A high incident rate necessitates a review of safety procedures and potentially equipment upgrades.

- Operating Costs: Analyzing fuel consumption, maintenance costs, repair expenses, and operator wages is necessary for a comprehensive assessment of cost-effectiveness.

Consider this example: A warehouse uses forklifts. By tracking the number of pallets moved per hour (throughput), the percentage of time the forklifts are in operation (utilization), the number of breakdowns (downtime), and any accidents (safety record), along with maintenance costs and fuel expenses (operating costs), we can gain a clear understanding of the forklifts’ performance and identify areas for improvement.

Q 17. What are the key performance indicators (KPIs) for material handling operations?

Key Performance Indicators (KPIs) in material handling are crucial for monitoring efficiency and identifying areas needing improvement. They provide quantifiable metrics to evaluate performance and drive better decision-making.

- Order Fulfillment Rate: Percentage of orders successfully fulfilled on time and in full.

- On-Time Delivery Rate: Percentage of shipments delivered on or before the scheduled time.

- Inventory Turnover Rate: Number of times inventory is sold or used in a given period. High turnover indicates efficient inventory management.

- Damage Rate: Percentage of goods damaged during handling.

- Throughput (as mentioned above): The volume of material moved per unit of time.

- Unit Cost: The total cost of handling material per unit.

- Safety Incident Rate: Number of safety incidents per employee or per hour worked.

Imagine a distribution center. By tracking the order fulfillment rate, they can understand how effectively they are meeting customer demands. A low damage rate highlights careful handling practices, while a high inventory turnover rate indicates efficient stock management and minimizes storage costs.

Q 18. How do you select the right type of crane for a specific application?

Selecting the right crane involves careful consideration of several factors, ensuring the chosen crane is safe, efficient, and suitable for the specific application. Different crane types are suited for different tasks and environments.

- Load Capacity: The weight the crane needs to lift. This is the most fundamental consideration.

- Lifting Height: The vertical distance the crane needs to lift the load.

- Horizontal Reach: The distance the crane can reach horizontally.

- Operating Environment: Indoor or outdoor, hazardous materials, temperature extremes, etc. This influences the type of crane materials and protective features needed.

- Frequency of Use: Continuous operation requires a more robust and reliable crane than one used intermittently.

- Space Constraints: The available space to accommodate the crane’s structure and operational movements.

For example, a manufacturing plant needing to lift heavy loads over a wide area might choose a gantry crane for its high load capacity and reach. A shipyard might use a ship-to-shore crane for loading and unloading cargo from large vessels. An overhead crane would be suitable for a factory assembly line where materials need to be moved along a production line. Each application dictates the best crane type for optimal performance and safety.

Q 19. Explain the concept of lean manufacturing principles in material handling.

Lean manufacturing principles aim to eliminate waste and maximize efficiency. In material handling, this translates to optimizing the flow of materials through the entire process, from receiving to shipping. Key lean principles applied to material handling include:

- Value Stream Mapping: Identifying and visualizing all steps in the material handling process, highlighting areas of waste or inefficiency.

- 5S Methodology: Organizing the workspace to improve efficiency and safety (Sort, Set in Order, Shine, Standardize, Sustain).

- Just-in-Time (JIT) Inventory: Receiving materials only when needed, minimizing storage costs and reducing waste.

- Kaizen (Continuous Improvement): Regularly evaluating the material handling process for improvements, even incremental ones.

- Pull System: Moving materials only when they are requested downstream, eliminating unnecessary movement and storage.

For instance, a factory implementing lean principles might use a Kanban system to signal the need for parts from the warehouse, ensuring they only receive what is immediately required. They might also optimize their warehouse layout to minimize travel distances using value stream mapping, thereby reducing handling time and labor costs.

Q 20. What are the environmental considerations when selecting material handling equipment?

Environmental considerations are increasingly important when choosing material handling equipment. We must consider the equipment’s impact throughout its lifecycle.

- Energy Consumption: Opting for energy-efficient equipment, such as electric forklifts instead of gasoline-powered ones, reduces carbon emissions and operating costs.

- Noise Pollution: Selecting quieter equipment minimizes noise pollution in the workplace, contributing to a better work environment and potentially meeting regulatory requirements.

- Emissions: Reducing emissions of harmful substances into the air is critical, especially when handling hazardous materials. Selecting equipment with low or zero emission capabilities is important.

- Waste Generation: Choosing equipment that is durable and easily repairable minimizes waste at the end of its life cycle. Considering equipment made from recycled materials is another factor.

- Sustainability: Look for certifications (such as LEED) which address the environmental impact of equipment manufacturing and its end-of-life options.

For example, a warehouse might choose electric forklifts to reduce carbon emissions and improve air quality indoors. Investing in durable conveyors with easily replaceable parts minimizes waste during operation and extends the equipment’s lifespan, delaying eventual disposal and potentially recycling certain components.

Q 21. Describe the different types of conveyors and their suitability for different applications.

Conveyors come in a wide variety of types, each suited to specific material handling needs. Choosing the right type is crucial for efficiency and safety.

- Belt Conveyors: These are versatile and widely used for moving a variety of items over long distances. Suitable for high-volume, continuous flow applications like those in manufacturing plants or airports. Variations include inclined belt conveyors for elevating items.

- Roller Conveyors: Simple and cost-effective, ideal for moving heavier items, such as boxes or pallets, over shorter distances. They allow items to be easily moved by gravity or a slight push.

- Chain Conveyors: Used to transport heavier, bulkier, or irregularly shaped items, offering more control and stability than belt or roller conveyors. Common in manufacturing processes handling large components.

- Screw Conveyors: Efficient for moving bulk materials, such as powders, grains, or small parts, over horizontal or inclined distances. They are ideal for applications requiring precise material flow.

- Overhead Conveyors: Hang from the ceiling, freeing up floor space and ideal for moving items between different work stations in a manufacturing plant or storage facility.

A warehouse might use roller conveyors for short-distance movement of pallets, while a manufacturing line might use chain conveyors to handle large parts and a bottling plant could use belt conveyors to move bottles efficiently down the line.

Q 22. How do you manage the lifecycle of material handling equipment?

Managing the lifecycle of material handling equipment involves a structured approach encompassing acquisition, operation, maintenance, and disposal. It’s like caring for a valuable asset – you need a plan from start to finish.

- Acquisition: This stage involves needs assessment, vendor selection, equipment specification, and purchase or lease agreements. Careful consideration of factors like throughput requirements, space constraints, and budget are crucial. For instance, choosing between forklifts and automated guided vehicles (AGVs) depends on the scale and nature of operations.

- Operation: This phase focuses on efficient utilization and operator training. Establishing standard operating procedures (SOPs) and implementing preventative maintenance schedules are key to maximizing equipment lifespan and minimizing downtime. Regular inspections and operator feedback loops are vital for early detection of potential issues.

- Maintenance: Preventative maintenance, including regular servicing, lubrication, and part replacements, is crucial. A well-defined maintenance schedule, often supported by computerized maintenance management systems (CMMS), is essential to predict potential failures and prevent costly breakdowns. This is similar to regular car servicing – small investments prevent major repairs later.

- Disposal: This involves decommissioning, recycling, or resale of equipment at the end of its useful life. Proper disposal is environmentally responsible and may even generate some return on investment. For example, components from older equipment can be repurposed or sold to salvage yards.

Q 23. What are the benefits of using simulation software for material handling system design?

Simulation software provides a powerful tool for designing and optimizing material handling systems before physical implementation, significantly reducing costs and risks. It’s like creating a virtual model of your warehouse to test different scenarios before investing heavily in real-world changes.

- Reduced Costs: Identifying and correcting design flaws in a virtual environment is far less expensive than making physical changes after construction.

- Improved Efficiency: Simulating different equipment layouts and operational strategies helps determine optimal configurations for maximum throughput and efficiency. You can compare the performance of various forklift types or conveyor systems without disrupting ongoing operations.

- Risk Mitigation: Identifying potential bottlenecks or safety hazards before implementation minimizes disruptions and enhances workplace safety. For example, you can simulate pedestrian traffic to ensure safe interaction with automated vehicles.

- Data-Driven Decision Making: Simulation software provides quantifiable data on performance metrics, allowing for informed decision-making based on concrete evidence rather than speculation.

Q 24. Explain the role of technology in improving material handling efficiency.

Technology plays a transformative role in improving material handling efficiency, enabling automation, optimization, and real-time visibility. Think of it as upgrading from a manual filing system to a sophisticated database.

- Automation: AGVs, automated storage and retrieval systems (AS/RS), and robotic systems automate repetitive tasks, increasing speed and accuracy. This reduces labor costs and minimizes human error.

- Optimization: Warehouse management systems (WMS) and material handling software optimize workflows by analyzing data and suggesting improvements to routing, storage, and picking processes. This leads to significant reductions in travel time and handling time.

- Real-time Visibility: RFID and barcode technologies provide real-time tracking of goods, enhancing inventory management, and improving order fulfillment speed and accuracy. Knowing the exact location of every item minimizes searching and speeds up the picking process.

- Data Analytics: Data from various sources (WMS, sensors, etc.) can be analyzed to identify areas for improvement, predict equipment failure, and optimize resource allocation.

Q 25. How do you handle equipment breakdowns and ensure minimal downtime?

Handling equipment breakdowns requires a proactive and reactive approach to minimize downtime. It’s like having a well-equipped emergency response team for your warehouse.

- Preventative Maintenance: Regular scheduled maintenance significantly reduces the likelihood of breakdowns. This includes regular inspections, lubrication, and component replacements.

- Predictive Maintenance: Utilizing sensors and data analytics to predict potential failures allows for proactive repairs before they cause downtime. This is like getting a warning light in your car before something breaks.

- Rapid Response Team: A dedicated team or service contract with a provider ensures swift response times to equipment failures. This ensures minimal disruption to operations.

- Spare Parts Inventory: Maintaining a stock of common spare parts ensures repairs can be done quickly without waiting for replacements. This is like having a well-stocked toolbox readily available.

- Redundancy: Where critical, having backup equipment reduces the impact of downtime. For instance, two forklifts handling a particular process instead of just one.

Q 26. Describe your experience with different types of automated storage systems.

My experience encompasses various automated storage systems, each suited for specific needs and applications. Think of it like choosing the right tool for a particular job.

- AS/RS (Automated Storage and Retrieval Systems): I’ve worked with various AS/RS configurations, including unit load and mini-load systems. These are highly efficient for high-density storage and automated retrieval of palletized goods or smaller items. I’ve been involved in selecting the appropriate system for warehouses with high throughput requirements.

- Vertical Carousel Systems: These are ideal for small parts storage and retrieval, enhancing space utilization and improving order picking efficiency. I’ve helped design systems to optimize item placement for faster access based on demand.

- Horizontal Carousel Systems: These systems are suitable for larger items and provide efficient horizontal access, reducing travel times and improving picking accuracy. I’ve considered their application in situations where vertical space is limited.

- Automated Guided Vehicle (AGV) Systems: I’ve worked with AGV systems integrated with AS/RS for automated transport of goods within a warehouse. This significantly improves material flow and minimizes manual handling.

Q 27. What is your experience with implementing new material handling technologies in a warehouse setting?

Implementing new material handling technologies requires careful planning, execution, and stakeholder management. It’s like orchestrating a complex symphony where all instruments must work together harmoniously.

- Needs Assessment: Thorough analysis of current processes and future requirements is crucial to selecting appropriate technologies. This involves considering capacity, throughput, space constraints, and budget limitations.

- Technology Selection: This involves evaluating different vendors, systems, and technologies based on their capabilities and compatibility with existing systems. Feasibility studies and proof-of-concept tests are important.

- System Integration: Seamless integration with existing WMS and ERP systems is crucial to avoid data silos and maintain operational efficiency. This requires collaboration with IT and operations teams.

- Training and Change Management: Proper training for operators and staff is vital for successful adoption. Addressing concerns and resistance to change is also key for a smooth transition.

- Post-Implementation Evaluation: Monitoring performance metrics post-implementation is essential to ensure the technology delivers the expected benefits and to identify areas for improvement. This involves collecting data, analyzing results, and making necessary adjustments.

Q 28. How do you stay up-to-date with the latest advancements in material handling technology?

Staying updated in the rapidly evolving field of material handling requires a multi-pronged approach. It’s like being a lifelong learner in a dynamic industry.

- Industry Publications and Journals: Regularly reading industry publications and journals helps stay abreast of new technologies and trends. Examples include publications focusing on supply chain management and logistics.

- Conferences and Trade Shows: Attending industry conferences and trade shows allows for networking with other professionals and learning about the latest innovations firsthand. These events showcase cutting-edge technologies and facilitate the exchange of best practices.

- Professional Organizations: Membership in professional organizations such as MHI (Material Handling Industry) provides access to resources, publications, and networking opportunities. These organizations often host webinars and educational programs.

- Online Resources and Webinars: Utilizing online resources such as industry websites, blogs, and webinars provides a wealth of information on new developments. Many vendors and technology providers offer online resources and training materials.

- Vendor Relationships: Maintaining strong relationships with equipment vendors and technology providers ensures access to the latest updates and product information.

Key Topics to Learn for Material Handling Equipment Selection Interview

- Needs Assessment & Material Flow Analysis: Understanding the specific requirements of a facility, including material types, volume, distances, and environmental conditions, to determine the optimal equipment solution. This includes analyzing current processes and identifying bottlenecks.

- Equipment Types & Capabilities: Familiarize yourself with various material handling equipment, including forklifts (various types), conveyors (belt, roller, chain), automated guided vehicles (AGVs), cranes, and robotics. Understand their strengths, weaknesses, and applications in different scenarios.

- Cost-Benefit Analysis & ROI: Evaluating the total cost of ownership (TCO) for each equipment option, considering purchase price, maintenance, operating costs, and potential productivity gains. Justifying your equipment recommendations based on a sound ROI calculation is crucial.

- Safety & Ergonomics: Prioritizing safety regulations and ergonomic considerations in equipment selection. This includes understanding relevant safety standards and how equipment choices can impact worker safety and efficiency.

- Integration & Automation: Understanding how different equipment pieces can integrate seamlessly within a larger system. Explore the possibilities of automation and its impact on efficiency and cost reduction. Consider the implications of warehouse management systems (WMS) integration.

- Maintenance & Lifecycle Management: Understanding the maintenance requirements of different equipment types, and how to plan for preventative maintenance to minimize downtime and extend equipment lifespan. This also includes understanding the lifecycle costs and replacement strategies.

- Environmental Considerations: Analyzing the environmental impact of different equipment choices, such as energy consumption and emissions. Exploring sustainable and eco-friendly options is becoming increasingly important.

- Troubleshooting & Problem Solving: Be prepared to discuss how you would approach common issues or malfunctions related to material handling equipment. Demonstrate your problem-solving skills by describing your approach to diagnosing problems and implementing solutions.

Next Steps

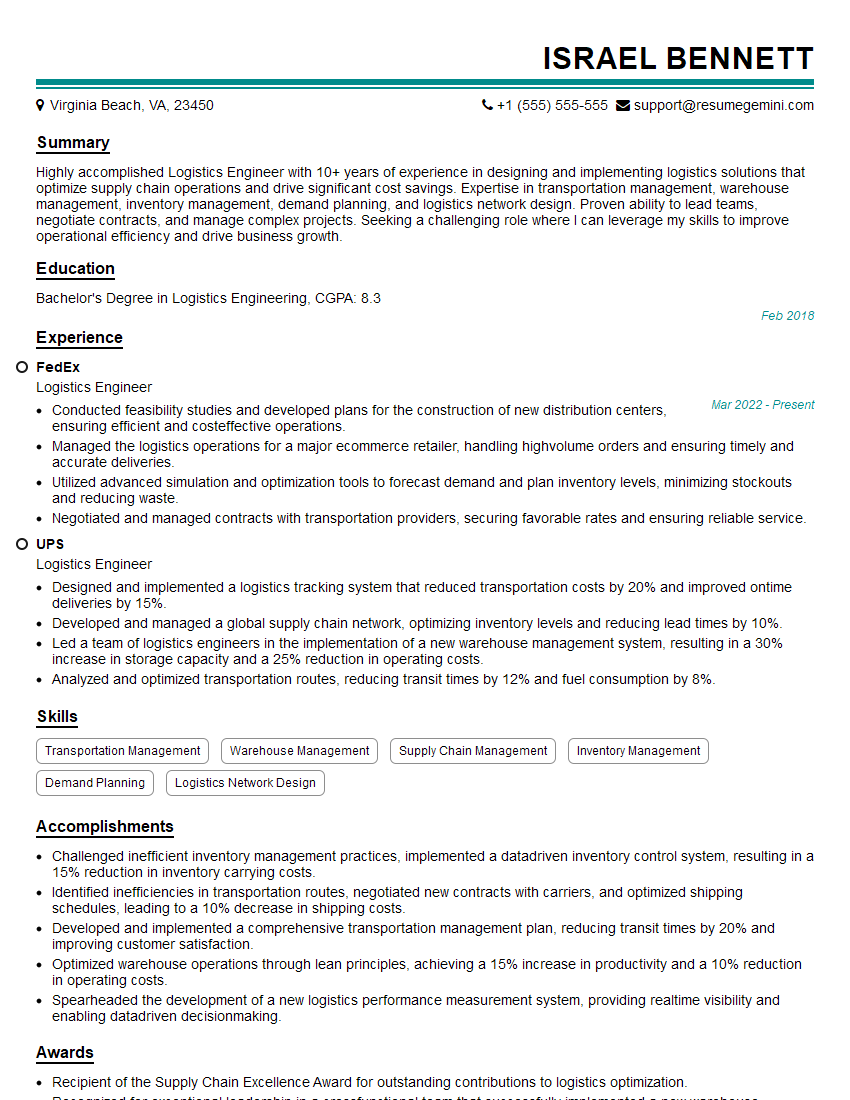

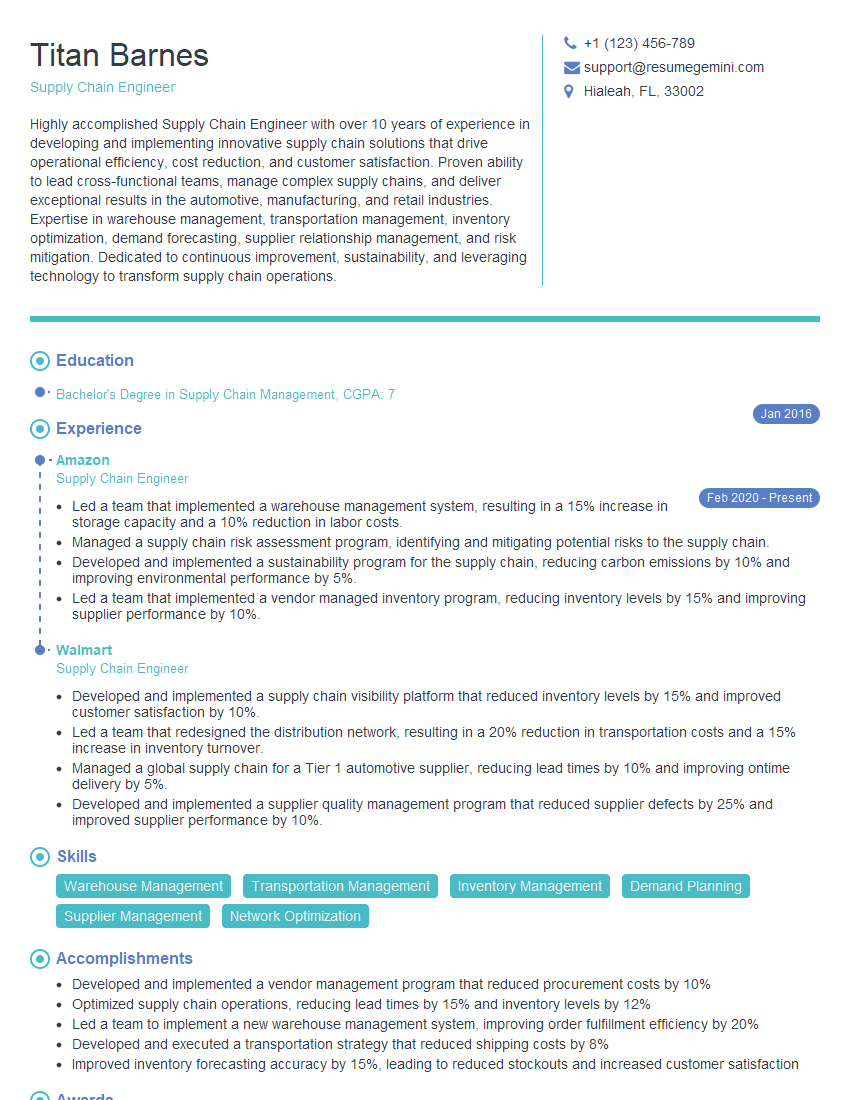

Mastering Material Handling Equipment Selection significantly enhances your career prospects in logistics, warehousing, and manufacturing. A strong understanding of these principles demonstrates valuable problem-solving and analytical skills highly sought after by employers. To maximize your job search success, create an ATS-friendly resume that highlights your relevant skills and experience. ResumeGemini is a trusted resource that can help you build a professional and impactful resume. Examples of resumes tailored to Material Handling Equipment Selection are available to guide you, showcasing best practices for presenting your qualifications effectively.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good