Cracking a skill-specific interview, like one for Pressroom, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Pressroom Interview

Q 1. Explain the difference between sheetfed and web printing.

The core difference between sheetfed and web printing lies in how the paper is fed into the press. Think of it like this: sheetfed is like using individual sheets of paper from a ream, while web printing is like using a continuous roll of paper, similar to a giant roll of toilet paper.

- Sheetfed printing: Uses individual sheets of paper, typically fed one at a time into the press. This is ideal for shorter print runs, higher-quality jobs, and projects requiring specialized paper stocks or finishing techniques. Examples include business cards, brochures, and high-end magazines.

- Web printing: Uses a continuous roll of paper (the web) that is fed through the press at high speed. This method is perfect for mass production, high-volume projects like newspapers, magazines with large print runs, and direct mail pieces. It’s generally more cost-effective for large quantities but offers less flexibility in paper stock choices.

In essence, sheetfed is more precise and versatile, while web is faster and more economical for large jobs. The choice depends entirely on the specific project requirements.

Q 2. Describe your experience with color calibration and profiling.

Color calibration and profiling are crucial for ensuring consistent and accurate color reproduction throughout the printing process. My experience involves using spectrophotometers to measure color accurately and creating ICC profiles for various substrates and inks. This ensures that the colors on screen match the final printed product. For example, I’ve worked extensively with X-Rite i1iSis and similar devices for precise color measurement. I’ve also used software like GMG ColorProof to create accurate profiles that account for the specific characteristics of our presses, inks, and paper. This process is iterative; I regularly check and adjust profiles to maintain consistency as inks, paper, or even environmental conditions change.

I’ve successfully managed color consistency across multiple projects, from intricate packaging designs to large-scale marketing materials, through diligent profile creation and monitoring. A specific instance involved a project requiring Pantone-matched colors for a high-end product packaging. Through precise color calibration, we successfully achieved a perfect match, avoiding costly reprints and maintaining brand integrity.

Q 3. How do you troubleshoot common pressroom problems, such as misregistration or color inconsistencies?

Troubleshooting pressroom problems requires a systematic approach. Misregistration (images not aligning correctly) and color inconsistencies are common issues. Here’s how I approach them:

- Misregistration: I start by checking the grippers, ensuring they’re gripping the sheets properly. Then, I inspect the feeder and delivery systems for any mechanical issues. Sometimes, the problem lies in the press settings, requiring adjustments to the timing and register settings. I meticulously examine each stage of the printing process to pinpoint the source of the misalignment.

- Color inconsistencies: This can stem from various factors: ink density, dot gain (spread of ink dots), incorrect ink mixing, or problems with the press itself. I analyze the color using a spectrophotometer, comparing it against the target values. This data helps pinpoint whether the issue is with ink formulation, press conditions (like dampening or temperature), or a problem in the prepress stages.

I always document my troubleshooting steps, including measurements and adjustments, so we can quickly rectify similar issues in the future. This meticulous record-keeping is critical for maintaining consistent quality and improving our pressroom efficiency.

Q 4. What are your methods for maintaining pressroom equipment and ensuring safety?

Maintaining pressroom equipment and ensuring safety are paramount. My methods encompass both preventative maintenance and reactive problem-solving. Preventative maintenance involves regular cleaning, lubrication, and inspections according to the manufacturer’s recommendations. This includes checking rollers, blankets, and other critical components for wear and tear. We have a detailed schedule for these checks and meticulously document all maintenance activities.

Safety protocols are strictly enforced. We follow all OSHA guidelines, using appropriate personal protective equipment (PPE) like safety glasses, gloves, and hearing protection. Regular safety training sessions keep everyone informed of potential hazards and safe operating procedures. The pressroom is kept clean and organized to prevent accidents. Moreover, we have clear procedures for handling ink and chemicals, including proper disposal and storage.

Q 5. Explain your experience with different types of inks and coatings.

I have experience working with various types of inks, including:

- UV inks: These inks cure instantly upon exposure to UV light, offering quick drying times and vibrant colors. They are excellent for applications requiring a high gloss finish.

- Conventional inks: These require drying time, and the drying process depends on the absorption of the paper and the environment. They are cost-effective but slower in production.

- Water-based inks: Environmentally friendly and generally safer for operators, water-based inks are ideal for applications requiring a softer finish.

Similarly, I’ve worked with a range of coatings including aqueous, UV, and varnish coatings, each offering different levels of protection, gloss, and tactile properties. The selection of ink and coating depends on the substrate, the desired outcome, and the overall printing process.

Q 6. How familiar are you with different paper stocks and their suitability for various printing methods?

My knowledge of paper stocks extends to various types, including coated, uncoated, and specialty papers. Understanding paper’s weight, texture, absorbency, and finish is crucial for selecting the appropriate paper for each printing method. For instance, coated papers are ideal for high-resolution images, providing a smooth surface for sharp details. However, they may not be suitable for all printing methods or techniques. Uncoated papers offer a more natural texture and are often used for applications where a less glossy finish is desired.

I’ve worked with a diverse range of paper stocks, from lightweight newsprint to heavy-weight card stock. Selecting the right paper depends on factors like the printing method (sheetfed vs. web), the type of ink being used, the desired aesthetic effect, and the budget. A project requiring a luxurious feel might call for a premium paper stock, while a large-volume newspaper might necessitate a cost-effective newsprint.

Q 7. Describe your experience with pre-press processes and their impact on pressroom operations.

Pre-press processes are essential; they directly impact the quality and efficiency of pressroom operations. My experience includes working closely with pre-press teams to ensure the files are properly prepared for printing. This involves checking color profiles, ensuring the files are at the correct resolution, and verifying the imposition (arrangement of pages on a sheet). Any issues detected during pre-press will significantly impact the pressroom, potentially leading to delays, waste, and rework.

For example, a poorly prepared file with low resolution images would necessitate a reprint or result in disappointing quality in the final printed product. Conversely, a well-prepared file with accurate color profiles, correct imposition, and high-resolution images ensures a smooth and efficient printing process in the pressroom, leading to minimal waste and higher productivity.

Q 8. How do you monitor and control the quality of printed output?

Monitoring and controlling print quality involves a multi-step process starting even before the press runs. It begins with rigorous pre-press checks, ensuring the digital files are accurate, color profiles are correct, and the plates are properly made. During the press run, we constantly monitor several key aspects:

- Color consistency: We use spectrophotometers to measure the density and color values against the target values, making adjustments to ink levels and dot gain as needed. For example, if a Pantone color is off, we might adjust the ink key or trap settings.

- Registration: We check that colors are accurately aligned to avoid misregistration, a common problem resulting in blurry images. Regular checks throughout the run are crucial. This often involves using a registration target printed on the sheet.

- Print sharpness and detail: We visually inspect the printed output for any blurring, dot gain issues, or other imperfections. We might use magnification tools for detailed analysis.

- Paper quality and consistency: We monitor the paper feed to prevent jams and ensure uniform paper thickness.

Post-press, we conduct a final quality check, which includes examining the finished product for any defects or inconsistencies that might have been missed during the press run. This often includes spot checking for color accuracy and visual defects across multiple sheets. We also use standardized quality control charts to track performance over time and identify any trends that might need addressing.

Q 9. What are your strategies for managing pressroom workflow and productivity?

Managing pressroom workflow and productivity requires a structured approach. My strategies focus on optimization and efficiency at each stage. I utilize a combination of techniques:

- Job scheduling and prioritization: We prioritize jobs based on deadlines, material requirements, and machine capabilities. Software solutions are vital for this, enabling efficient scheduling and minimizing downtime.

- Lean manufacturing principles: We identify and eliminate waste in the process, streamlining workflows and reducing unnecessary steps. This includes optimizing makeready times and minimizing waste in materials.

- Preventive maintenance: Regular maintenance is crucial to keep the presses running smoothly, preventing unexpected downtime. This prevents costly repairs and ensures continuous operation.

- Operator training and cross-training: Well-trained operators are essential. I support ongoing training programs to enhance skills and ensure staff are proficient on all equipment. Cross-training enables efficient resource allocation and reduces the impact of absences.

- Data-driven decision making: We utilize data collected from the presses (e.g., run speeds, waste rates, downtime) to identify bottlenecks and optimize performance. This allows for continuous improvement.

For example, we might analyze the makeready time for a specific job and identify opportunities to reduce it, perhaps by improving the platemaking process or standardizing set-up procedures. This data informs continuous improvement efforts.

Q 10. Describe your experience with pressroom maintenance and preventative maintenance schedules.

Pressroom maintenance is a critical aspect of ensuring smooth operations and high-quality output. My experience encompasses both routine and preventative maintenance. I follow a rigorous schedule, typically documented in a CMMS (Computerized Maintenance Management System), which includes:

- Daily checks: Daily visual inspections of all presses, checking for leaks, unusual noises, and any signs of wear and tear.

- Weekly maintenance: More in-depth cleaning and lubrication of key components, checking ink systems, and adjusting rollers.

- Monthly maintenance: More comprehensive checks, including alignment checks, sensor calibrations, and preventative replacement of worn parts.

- Quarterly/Annual maintenance: Major servicing, including complete overhaul of critical parts, potential upgrades, and performance testing. This often involves external technicians specializing in particular equipment.

We meticulously document all maintenance activities, recording dates, tasks performed, and any issues discovered. This helps us track equipment performance, predict potential problems, and ensure compliance with manufacturer’s recommendations. This data also informs the CMMS system, assisting with predictive maintenance based on historical data. For instance, if we notice a particular part tends to fail after a specific number of cycles, we can replace it proactively, preventing unexpected downtime.

Q 11. How do you handle pressroom emergencies or breakdowns?

Handling pressroom emergencies requires a quick and efficient response. Our procedures involve:

- Immediate assessment: Determine the nature and severity of the breakdown.

- Safety first: Ensure the safety of personnel and equipment before attempting any repairs. This includes shutting down the machine and securing the area.

- Troubleshooting: Attempt basic troubleshooting based on existing knowledge and diagnostic tools. We frequently use diagnostic manuals and contact the manufacturer’s support lines.

- Calling in support: If the issue cannot be resolved internally, we contact qualified service technicians immediately. This might involve contacting the press manufacturer or a specialized service provider.

- Alternative solutions: If a quick repair isn’t possible, we explore alternative solutions, such as rerouting the job to a different press or finding a nearby print shop to complete the job.

- Documentation: Thoroughly document the breakdown, repair process, and any downtime incurred. This data helps in identifying recurring problems and preventing future incidents.

For instance, if a paper jam occurs, we’ll follow established procedures to clear the jam safely and quickly, making sure the process does not damage the paper or the machine. If a more serious mechanical failure happens, our documented procedures help ensure a rapid and organized response, minimizing disruption to our workflow.

Q 12. What safety protocols do you follow in the pressroom?

Safety is paramount in the pressroom. We strictly adhere to a comprehensive safety protocol covering several areas:

- Personal Protective Equipment (PPE): Mandatory use of safety glasses, hearing protection, and appropriate clothing. Gloves are also required when handling inks and chemicals.

- Lockout/Tagout procedures: Strict adherence to lockout/tagout procedures when performing maintenance or repairs to ensure that equipment is completely shut down and secured before any work is carried out.

- Machine guarding: Ensuring all moving parts are properly guarded to prevent accidental injury.

- Fire safety: Regular fire drills, easily accessible fire extinguishers, and a clear evacuation plan.

- Chemical handling: Proper storage, handling, and disposal of inks and other chemicals. This includes the use of appropriate spill kits and following all relevant safety data sheets (SDS).

- Regular training: All staff receive comprehensive safety training, including refresher courses, emphasizing safe work practices and emergency procedures.

We conduct regular safety inspections to identify potential hazards and address them promptly. Our safety record is paramount, and we prioritize a culture of safety awareness and responsibility amongst all team members.

Q 13. How familiar are you with various printing techniques, like offset, digital, or flexographic?

I am very familiar with various printing techniques, including offset, digital, and flexographic printing. I understand their strengths and weaknesses, enabling me to recommend the most appropriate technique for a given job.

- Offset printing: Excellent for high-volume, high-quality color printing, especially for projects requiring precise color reproduction and fine detail. I have extensive experience in setting up and operating offset presses.

- Digital printing: Ideal for short-run, personalized, or on-demand printing. This is particularly useful for variable data printing and quick turnaround times. I am proficient in operating several digital printing platforms.

- Flexographic printing: Well-suited for printing on flexible substrates like plastic films, pouches, and labels. I understand the complexities of flexographic printing, including anilox rollers, plate mounting, and ink selection.

My experience encompasses all three techniques, allowing me to offer clients informed advice on selecting the best printing method based on factors such as print volume, substrate, quality requirements, and budget constraints. I can effectively oversee projects using a blend of these techniques where appropriate.

Q 14. Explain your understanding of ink density and its impact on print quality.

Ink density refers to the concentration of ink on the printed substrate. It directly impacts the overall print quality. It’s measured using a densitometer, providing numerical values that indicate the amount of ink applied.

Impact on print quality:

- Color accuracy: Correct ink density is crucial for achieving accurate color reproduction. Too little ink leads to weak, pale colors, while excessive ink can result in muddy or over-saturated colors.

- Image sharpness: Proper ink density contributes to sharp, crisp images. Inadequate ink density results in a lack of detail and poor contrast. Conversely, excessive ink can lead to dot gain (spreading of ink dots), blurring the image and reducing sharpness.

- Print durability: The correct ink density affects the durability and longevity of the printed product. Sufficient ink ensures that the print is resistant to fading, scratching, or smudging.

- Drying time: Higher ink density can lead to increased drying time, potentially causing smudging or set-off (ink transferring to the back of the next sheet).

In practice, we carefully monitor and control ink density throughout the printing process, using densitometers to measure and adjust ink levels as needed. This involves precise adjustments to the ink keys and, in some cases, even the screen ruling or dot size. We aim to achieve the optimal density for the specific job, balancing color accuracy, sharpness, and drying time to deliver the highest quality printed output.

Q 15. Describe your experience with different types of printing plates.

My experience encompasses a wide range of printing plates, each with its own strengths and weaknesses. I’ve worked extensively with conventional plates, like those made from aluminum and coated with photosensitive emulsions. These are relatively inexpensive but require careful handling to avoid scratches and damage. I’m also proficient with CTP (Computer-to-Plate) plates, which are imaged directly from a digital file, eliminating the need for film. These offer higher precision and faster turnaround times, leading to significant efficiency gains. My experience also includes working with flexographic plates, used for flexible packaging and labels, which require different processing and mounting techniques. Finally, I have familiarity with thermal plates, known for their ease of use and quick processing speeds. The choice of plate depends heavily on the printing press, the job’s specifications, and the budget.

For instance, in a high-volume, short-run job requiring quick turnaround, CTP plates would be the optimal choice. Conversely, for a long-run job with a less stringent deadline, conventional plates might be more cost-effective. Understanding these nuances is crucial for optimizing the printing process and maximizing efficiency.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you manage waste and ensure efficient use of materials in the pressroom?

Waste management and material efficiency are paramount in a pressroom. We implement a multi-pronged approach. Firstly, we meticulously plan our jobs, ensuring accurate estimations of materials needed to minimize waste from the outset. We use sophisticated software for pre-press planning which helps optimize plate usage and paper consumption. Secondly, we meticulously track ink usage, carefully monitoring ink levels and cleaning procedures to reduce ink waste. We employ color management systems that ensure accurate color reproduction from the very start, preventing costly reprints due to color discrepancies. Thirdly, we recycle used materials, including paper scraps, plates, and cleaning solvents. We also implement a strict procedure for cleaning and maintaining the press, extending its lifespan and reducing the need for frequent replacements.

For example, we’ve implemented a system where scrap paper is sorted and baled for recycling, while used plates are sent to specialized recycling facilities. This not only reduces our environmental impact but also reduces operational costs.

Q 17. Explain your experience with quality control procedures and documentation.

Quality control is ingrained in every stage of our pressroom operations. We adhere to strict ISO standards, maintaining detailed documentation at each step. This includes pre-press checks of the digital files for resolution, color profiles, and bleed areas. During the printing process, regular checks are conducted to monitor color accuracy, registration, and print quality using specialized measuring tools. Post-press checks involve inspecting the finished product for any defects or inconsistencies before packaging and delivery. All these checks are meticulously documented, with deviations logged and addressed immediately. Our documentation includes detailed reports on print parameters, material usage, and quality control results. This allows for tracking of performance, identifying areas for improvement, and ensuring consistent high quality.

For instance, if a color variation is detected during the run, we immediately adjust the press settings and document the corrective action taken. This meticulous documentation helps us maintain a high standard of quality and track any recurring issues.

Q 18. What software programs are you proficient in related to pressroom operations?

I’m proficient in various software programs crucial for pressroom operations. My expertise includes pre-press software like Adobe Acrobat, Photoshop, and Illustrator for file preparation and color management. I’m also skilled in RIP software (Raster Image Processor) such as EFI Fiery and Kodak Prinergy which are used for processing and outputting digital files to printing plates. Furthermore, I’m adept at using press control software to manage and monitor press parameters such as ink levels, speed, and registration during the printing process. Finally, I utilize MIS (Management Information System) software for tracking jobs, materials, and costs.

Q 19. How do you interpret and implement pressroom instructions and specifications?

Interpreting and implementing pressroom instructions and specifications requires careful attention to detail and a methodical approach. I begin by thoroughly reviewing the job ticket, which includes details such as the required quantity, paper type, ink colors, and finishing requirements. Then, I meticulously check the provided digital files against the specifications ensuring they meet the required resolution and color profiles. During the setup phase, I verify all settings on the printing press, including ink densities, registration marks, and drying conditions. Throughout the printing process, I continuously monitor the output, making adjustments as needed based on color readings and visual inspection. Any deviations from the specifications are immediately reported and documented. This meticulous approach ensures that the final product aligns perfectly with client expectations.

For example, if the job ticket specifies a Pantone color, I ensure that the color is accurately matched using spectrophotometer readings and adjustments to the ink settings on the press.

Q 20. Describe your experience with managing a pressroom team.

My experience in managing a pressroom team involves fostering a collaborative and efficient work environment. I believe in clear communication, ensuring every team member understands their responsibilities and how their work contributes to the overall goal. I delegate tasks effectively based on individual strengths and skills, providing necessary training and support. I prioritize safety, ensuring strict adherence to safety protocols and providing regular safety training. I conduct regular team meetings to discuss challenges, improvements, and new technologies, promoting a culture of continuous improvement. Conflict resolution is handled proactively, addressing concerns openly and fairly. Regular performance evaluations and feedback are essential to improve performance and individual growth. Finally, I encourage teamwork and a sense of shared responsibility, promoting a positive and motivated team atmosphere.

For example, I’ve implemented a system of regular ‘5S’ audits to maintain a clean and organized workspace, directly contributing to safety and efficiency.

Q 21. How do you stay up-to-date with the latest printing technology and industry trends?

Staying current in the dynamic printing industry is crucial. I actively participate in industry conferences and workshops to learn about the latest printing technologies and best practices. I subscribe to relevant trade publications and online resources, keeping myself updated on emerging trends. I also network with other printing professionals, exchanging knowledge and insights. I actively seek out training opportunities on new software and equipment, and encourage my team to do the same. This commitment to continuous learning ensures that our pressroom employs the most efficient and innovative techniques.

For instance, I recently attended a workshop on the implementation of UV LED curing technology, which significantly improved our drying process and reduced energy consumption.

Q 22. Describe your problem-solving approach when dealing with complex pressroom issues.

My approach to solving complex pressroom issues is systematic and data-driven. I start by thoroughly analyzing the problem, identifying the root cause rather than just treating the symptoms. This involves carefully examining the print samples, checking press settings, reviewing production logs, and consulting with the press operators to gather all relevant information. I use a structured problem-solving methodology, similar to the DMAIC (Define, Measure, Analyze, Improve, Control) approach used in Six Sigma. For example, if we’re experiencing consistent color variations, I wouldn’t just adjust the inks; I’d investigate potential causes like ink viscosity, paper inconsistencies, or even environmental factors like temperature and humidity. Once the root cause is identified, I develop and implement a solution, carefully documenting the process for future reference and to prevent recurrence. After implementation, I meticulously monitor the results to ensure the problem is resolved and the solution is effective.

Q 23. How do you prioritize tasks and manage time effectively in a fast-paced pressroom environment?

Prioritization and time management in a fast-paced pressroom are crucial. I utilize several techniques. First, I employ a Kanban-style system, visually tracking jobs in progress, prioritizing them based on deadlines and urgency. This allows me to quickly identify bottlenecks and re-allocate resources effectively. Secondly, I proactively anticipate potential delays or challenges, communicating openly with the team to adjust schedules and avoid last-minute rushes. For instance, if a particular job requires specialized materials, I’ll ensure their availability well in advance. Finally, I delegate tasks effectively, matching skills and responsibilities to the team members best suited to handle them. I also continuously monitor progress and adjust priorities as needed, ensuring the overall workflow remains efficient and on schedule. This proactive and adaptable approach is vital in maintaining productivity and meeting deadlines in a dynamic environment.

Q 24. Explain your experience with pressroom setup and makeready processes.

My experience with pressroom setup and makeready is extensive. I’m proficient in all aspects, from pre-press checks to final adjustments. This includes accurately setting up the press according to job specifications, ensuring correct paper alignment and registration, and meticulously configuring ink densities and water levels. I’m experienced with various types of plates (CTP, analog) and understand the importance of proper plate mounting and clamping. A recent example involved a challenging job with intricate details and tight registration requirements. Through careful plate preparation, precise adjustments to the impression cylinder, and continuous monitoring during the makeready process, we achieved perfect registration and exceptional print quality, exceeding client expectations. Makeready time was significantly reduced by optimizing the setup process based on historical data and analyzing potential sources of delay.

Q 25. Describe your experience working with different types of printing presses.

I have hands-on experience with a range of printing presses, including Heidelberg Speedmaster (various models), Komori Lithrone, and several sheetfed and web offset presses. My expertise extends to understanding the unique capabilities and limitations of each press type, allowing me to select the optimal machine for specific jobs. For example, a large-format job with high-quality photographic images might best be handled on a Heidelberg XL, whereas a high-volume job with simpler designs could be efficiently produced on a smaller, faster press. This knowledge enables me to optimize the production process, minimizing waste and maximizing efficiency while maintaining print quality standards. My understanding also includes troubleshooting press-specific issues and performing routine maintenance.

Q 26. How do you ensure consistent color accuracy across different print runs?

Maintaining consistent color accuracy across different print runs is critical. This involves a multi-faceted approach. Firstly, I rely on robust color management systems, using spectrophotometers and software to accurately measure and profile colors. This ensures that the colors on screen accurately match the printed output. Secondly, I carefully control the press variables impacting color consistency, including ink viscosity, ink density, and the type and condition of the printing plates. Regular ink and roller cleaning is vital to prevent color contamination. I also closely monitor the paper’s properties, as variations can impact color reproduction. Thirdly, I utilize standardized color charts and reference guides throughout the print process for comparison and correction. This constant monitoring and adjustment ensures accurate color reproduction, even across multiple runs and different batches of paper.

Q 27. What is your experience with pressroom automation and its impact on efficiency?

I have significant experience with pressroom automation, specifically with automated plate changing systems, automated ink and water adjustments, and pre-press automation workflows. These technologies significantly improve efficiency by reducing makeready times and minimizing human error. Automated plate changing, for instance, has reduced our makeready time by approximately 30%, increasing throughput and decreasing production costs. The implementation of automated ink and water controls has improved color consistency and reduced waste due to precise adjustments based on pre-set parameters. While automation enhances efficiency, it’s essential to maintain a balance between technology and human expertise. Experienced press operators remain crucial for monitoring the automated systems, troubleshooting issues, and making adjustments as needed.

Q 28. How do you handle customer complaints or concerns related to print quality?

Handling customer complaints or concerns regarding print quality requires a professional and empathetic approach. I begin by carefully listening to the customer’s concerns, seeking to understand the specifics of their complaint. Then, I thoroughly examine the printed product, comparing it against the specifications and proofing materials. If the issue is related to print quality, I systematically investigate the possible causes, such as incorrect color reproduction, registration problems, or substrate issues. Depending on the nature of the problem, I may propose solutions, such as reprinting the job or offering a discount. Open and honest communication is essential throughout the process, keeping the customer informed every step of the way. In instances where the issue isn’t our fault, I provide a comprehensive explanation while still maintaining a customer-focused and professional attitude. Documentation of the entire process, from the initial complaint to the resolution, ensures effective tracking and future improvement.

Key Topics to Learn for Pressroom Interview

- Press Release Creation & Distribution: Understand the entire lifecycle, from crafting compelling narratives to utilizing distribution channels effectively. Consider the nuances of different media outlets and their target audiences.

- Media Relations & Outreach: Explore strategies for building and maintaining relationships with journalists and media personalities. Practice articulating key messages concisely and persuasively.

- Crisis Communication Management: Learn how to develop and implement effective crisis communication plans. Practice proactive risk assessment and reactive response strategies.

- Content Strategy & Planning: Understand the importance of aligning content with organizational goals. Explore different content formats and their effectiveness in achieving communication objectives.

- Social Media & Digital Pressrooms: Learn how to leverage social media platforms to amplify press releases and engage with stakeholders. Understand the best practices for managing a digital pressroom.

- Metrics & Reporting: Familiarize yourself with key performance indicators (KPIs) used to measure the success of pressroom activities. Practice analyzing data and drawing insightful conclusions.

- Legal & Ethical Considerations: Understand the legal and ethical implications of press releases and media communication. Practice navigating potential conflicts of interest.

- Technology & Tools: Become familiar with common pressroom technologies and tools used for media monitoring, distribution, and engagement.

Next Steps

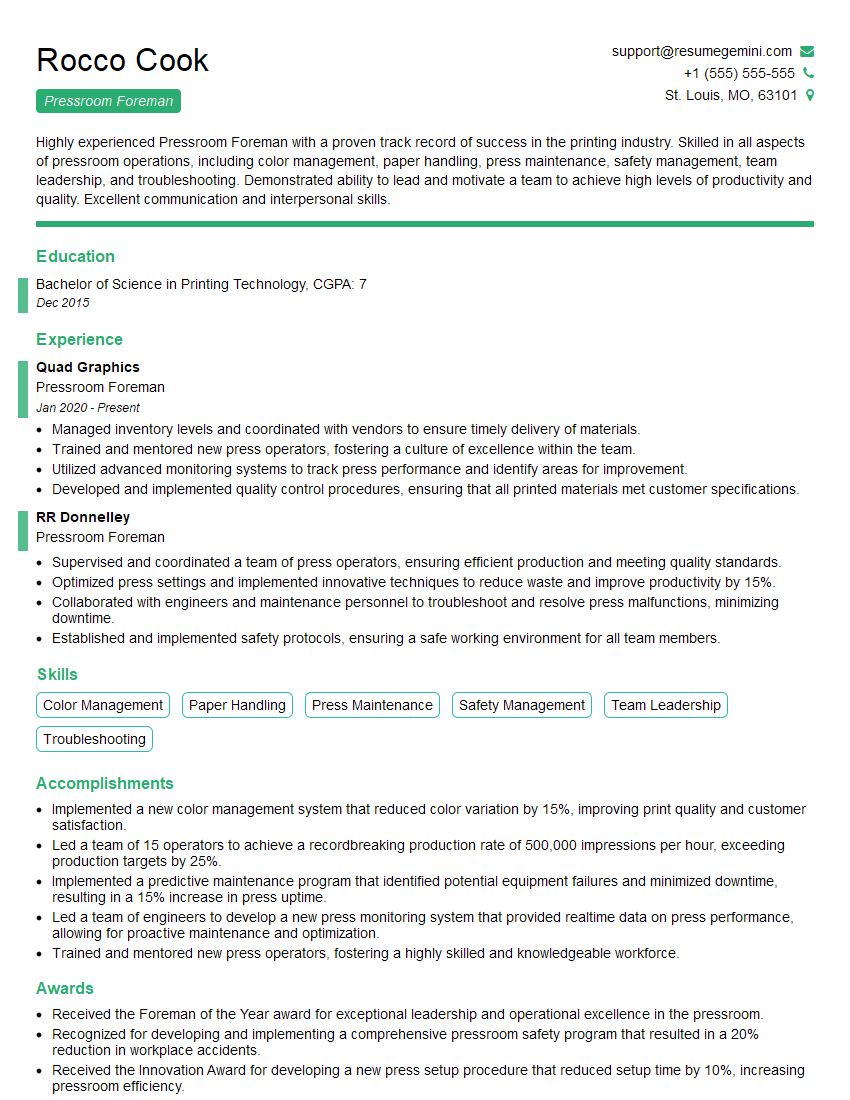

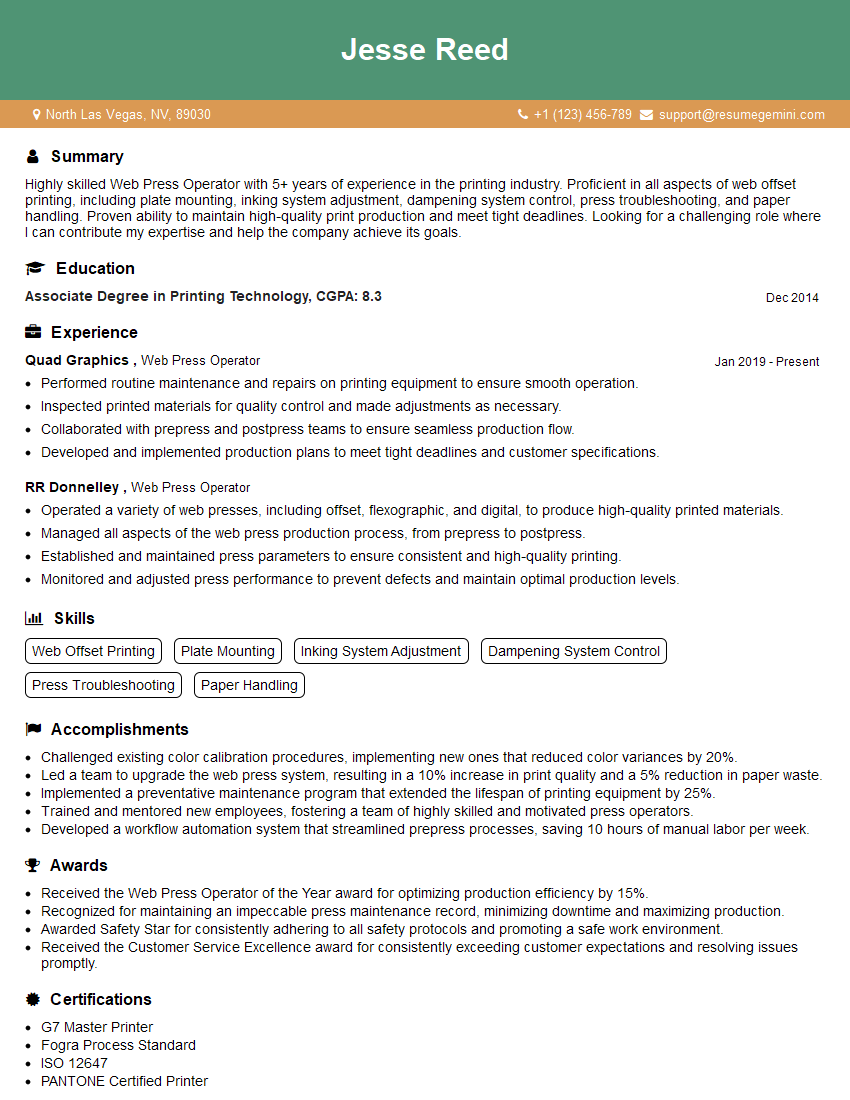

Mastering Pressroom skills significantly enhances your career prospects in public relations, communications, and marketing. A strong understanding of these concepts opens doors to exciting opportunities and allows you to contribute strategically to an organization’s success. To maximize your chances, create an ATS-friendly resume that effectively highlights your qualifications. We highly recommend using ResumeGemini, a trusted resource for building professional and impactful resumes. Examples of resumes tailored to Pressroom roles are available to help guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good