Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Interferometers interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Interferometers Interview

Q 1. Explain the Michelson interferometer’s operating principle.

The Michelson interferometer operates on the principle of wave interference. A light source is split into two beams using a partially reflective mirror (beamsplitter). Each beam travels a different path, reflected by separate mirrors, before being recombined at the beamsplitter. The path difference between the two beams determines the interference pattern observed at the output. If the path difference is a multiple of the wavelength, constructive interference occurs, resulting in a bright fringe. If the path difference is an odd multiple of half the wavelength, destructive interference occurs, leading to a dark fringe.

Imagine dropping two pebbles into a calm pond. The resulting ripples interfere with each other, creating areas of higher and lower wave amplitude. The Michelson interferometer does something similar with light waves. The pattern of bright and dark fringes directly reflects the path difference, making it a precise tool for measuring distances and changes in distances at the sub-wavelength level.

Q 2. Describe the difference between a Michelson and a Mach-Zehnder interferometer.

Both Michelson and Mach-Zehnder interferometers are based on wave interference, but their optical configurations differ. The Michelson interferometer uses a single beamsplitter to split and recombine the light beams, resulting in a common path for both beams after the beamsplitter. This is simpler to align but can be sensitive to vibrations. The Mach-Zehnder interferometer uses two separate beamsplitters, one to split the light and another to recombine it. This creates completely separate paths for the two beams, providing better spatial separation and reduced sensitivity to vibrations. However, it’s more complex to align.

Think of it like this: a Michelson interferometer is like a simple crossroads – the traffic (light beams) momentarily share the same path. In contrast, a Mach-Zehnder interferometer is like a complex highway system with separate lanes (beams) that converge at a later point. The choice depends on the application; high sensitivity demands the stability of the Mach-Zehnder design, while simplicity often favors the Michelson.

Q 3. What are the common sources of error in interferometric measurements?

Interferometric measurements are highly sensitive, making them susceptible to various errors. Common sources include:

- Environmental factors: Temperature fluctuations cause changes in the refractive index of air, leading to path length variations. Vibrations affect the mirror positions, changing the interference pattern. Air currents also cause refractive index changes.

- Mechanical misalignments: Imperfect alignment of the mirrors or beamsplitter introduces errors in the path length measurement.

- Source limitations: The coherence length of the light source limits the accuracy of measurements for large path differences. Incoherent light sources will not produce discernible interference patterns.

- Detector noise: Noise in the detector used to record the interference pattern contributes to measurement uncertainty.

- Polarization effects: Changes in polarization of the light beams can affect the interference pattern.

Minimizing these errors requires careful control of the environment and high-quality optical components.

Q 4. How do you compensate for environmental effects (temperature, vibrations) in interferometry?

Compensation for environmental effects is crucial for accurate interferometry. Several techniques are employed:

- Temperature control: Using thermally stable materials and enclosures, along with active temperature regulation (e.g., Peltier coolers) minimizes temperature fluctuations.

- Vibration isolation: Passive isolation systems (e.g., vibration damping tables) and active vibration cancellation systems significantly reduce the impact of vibrations on the interferometer.

- Active feedback control: Systems that monitor environmental factors (temperature, pressure) and actively adjust the interferometer’s path length to compensate for changes improve the precision.

- Vacuum chambers: Using vacuum chambers eliminates air currents and reduces the influence of air density variations.

- Phase-shifting interferometry: By introducing a known phase shift in one of the beams, and acquiring multiple interference patterns, these techniques can greatly reduce the influence of environmental factors.

Q 5. Explain the concept of fringe visibility and its significance.

Fringe visibility, also known as contrast, quantifies the clarity of the interference fringes. It’s defined as the ratio of the difference between the maximum and minimum intensity to their sum. A high visibility (close to 1) indicates well-defined, sharp fringes, representing good coherence and minimal noise. Low visibility indicates poorly defined, washed-out fringes, indicating poor coherence, excessive noise, or significant path length differences exceeding the coherence length.

Think of it like the contrast on a monitor. High visibility is like a clear, sharp image, while low visibility is like a blurry, faded image. In interferometry, high fringe visibility is essential for accurate measurements because it improves the signal-to-noise ratio and allows for more precise determination of the path difference.

Q 6. What are different types of interferometer and their respective applications?

Many types of interferometers exist, each optimized for specific applications:

- Michelson Interferometer: Precision length measurement, optical testing.

- Mach-Zehnder Interferometer: Refractive index measurements, flow visualization, optical fiber characterization.

- Fabry-Perot Interferometer: High-resolution spectroscopy, wavelength measurement.

- Sagnac Interferometer: Rotation sensing (gyroscopes), fiber optic gyroscopes.

- Fizeau Interferometer: Surface testing, optical flatness measurement.

- Twyman-Green Interferometer: Optical component testing (lenses, mirrors).

The choice of interferometer depends on the specific application and the required sensitivity, accuracy, and complexity.

Q 7. How do you calibrate an interferometer?

Calibrating an interferometer involves establishing a known relationship between the interference pattern and a physical quantity, such as length or refractive index. This often involves using a standard of known length (e.g., a gauge block with precisely known dimensions) or a medium of known refractive index. The interferometer’s output is then compared to the known standard, allowing for adjustments to ensure accurate measurements.

For example, to calibrate a Michelson interferometer for length measurement, you would introduce a gauge block of known length into one arm. The resulting shift in the interference pattern is then used to determine the interferometer’s scale factor, translating fringe counts into length units. This procedure must account for the wavelength of the light source used. Regular calibration using traceable standards is crucial to maintain measurement accuracy.

Q 8. Describe the process of phase shifting interferometry.

Phase-shifting interferometry (PSI) is a powerful technique used to extract quantitative information from interferograms, transforming the visual fringe pattern into precise measurements of surface topography or refractive index variations. Instead of just visually analyzing the fringe pattern, PSI introduces a controlled phase shift between the interfering beams, generating a series of interferograms. These multiple interferograms, each with slightly different fringe positions, are then mathematically processed to determine the exact phase at each point in the image.

The process typically involves introducing a known phase shift, often by moving one of the interferometer mirrors using a piezoelectric transducer (PZT). Common phase-shifting algorithms include the four-step algorithm and the five-step algorithm. The four-step algorithm, for example, involves shifting the phase by 90 degrees between each acquisition. These shifted interferograms are then combined using a mathematical algorithm, typically a Fourier transform, to calculate the absolute phase at each pixel. This absolute phase directly corresponds to the optical path difference between the two interfering beams, allowing for precise measurements of surface height or refractive index variations.

For example, in optical metrology, PSI is used to measure the surface roughness of precision-engineered parts with nanometer-level accuracy. By analyzing the resulting phase map, we can obtain a 3D representation of the surface profile, vital for quality control in manufacturing high-precision components.

Q 9. Explain the concept of coherence length and its impact on interferometer performance.

Coherence length refers to the distance over which a light source maintains a consistent phase relationship. In simpler terms, it’s the length over which the light waves ‘stay in step’ with each other. For interferometry to work effectively, the optical path difference between the two interfering beams must be less than the coherence length of the light source. If the path difference exceeds the coherence length, the interference fringes become washed out and the signal-to-noise ratio significantly degrades, rendering accurate measurements impossible.

Imagine throwing two pebbles into a still pond. The resulting ripples represent the light waves. If you throw the pebbles very close together, the ripples will overlap and interfere with each other, creating a clear interference pattern. However, if you throw the pebbles far apart, the ripples will be too spread out and the interference pattern will be less distinct or nonexistent. Similarly, in interferometry, a longer coherence length allows for larger optical path differences before the interference fringes are lost.

Lasers generally have much longer coherence lengths than other sources like LEDs, making them ideal for interferometry applications requiring high precision and long optical path differences, such as in fiber optic sensing or long-range distance measurements. The choice of light source directly impacts the design and capabilities of the interferometer. For instance, a Michelson interferometer used for measuring surface profile with a low coherence light source, the system would need to be more compact to minimize path length differences.

Q 10. How is spatial filtering used in interferometry?

Spatial filtering in interferometry is a technique used to improve the quality of the interference pattern by removing unwanted spatial frequencies or noise. This is typically accomplished using a spatial filter, often a pinhole placed at the focal plane of a lens. The lens focuses the light from the interferometer onto the pinhole. Only the light that passes through the pinhole reaches the detector, while other light components (scattering, diffraction from imperfections) are blocked. This selectively allows the passage of light originating from specific regions of the source and removes unwanted noise or artifacts.

Consider an analogy: imagine you’re trying to listen to a specific instrument in an orchestra. Spatial filtering acts like selectively focusing on that instrument, blocking out the sounds of the other instruments, making the sound of interest clearer and easier to hear. Similarly, in interferometry, spatial filtering enhances the clarity and contrast of the interference fringes, resulting in more accurate measurements.

Spatial filtering is particularly crucial in applications where the quality of the wavefront is critical. For instance, in testing the quality of optical components such as lenses or mirrors, spatial filtering helps to separate the effects of aberrations from the interference patterns caused by the surface features being measured.

Q 11. What are the advantages and disadvantages of different types of light sources used in interferometry (e.g., lasers, LEDs)?

The choice of light source significantly impacts interferometer performance. Lasers, with their high spatial and temporal coherence, provide high-contrast fringes and excellent signal-to-noise ratio. However, they can be expensive and their high intensity can damage sensitive components. LEDs, on the other hand, are cheaper, safer, and offer a wider range of wavelengths, but their lower coherence length limits their application to short-optical-path-difference interferometers. Superluminescent diodes (SLDs) present a compromise between lasers and LEDs.

- Lasers: Advantages include high coherence length, monochromatic light for clear fringes, and high intensity. Disadvantages are cost, potential damage to components, and limited wavelength options. Example: HeNe lasers are commonly used in classical interferometers.

- LEDs: Advantages include low cost, safety, and multiple wavelengths available. Disadvantages include short coherence length, low intensity, and broader spectral width resulting in lower fringe contrast. Example: Used in low-cost, short-path interferometers for basic measurements.

- SLDs: Advantages offer a broader spectral width than lasers while maintaining a longer coherence length than LEDs. Disadvantages are still higher in cost than LEDs.

The best light source depends on the specific application. For high-precision measurements requiring long optical paths, lasers are preferred. For less demanding applications or situations where cost is a major factor, LEDs might suffice.

Q 12. How do you analyze interferograms?

Analyzing interferograms involves extracting quantitative information from the fringe patterns. This can be done using various methods, ranging from simple visual inspection (for qualitative analysis) to sophisticated mathematical algorithms (for quantitative analysis). Visual inspection is suitable for identifying gross defects or estimating fringe spacing, but it’s limited in accuracy.

Quantitative analysis usually involves the following steps:

- Image Acquisition: Capturing a high-quality image of the interferogram using a suitable camera.

- Fringe Tracking: Identifying and tracing the position of individual fringes. This can be done manually or automatically using image processing techniques.

- Phase Calculation: Determining the phase at each point in the image using phase-shifting interferometry (PSI) or other techniques. This converts the fringe pattern into a representation of optical path differences.

- Data Processing: Applying algorithms to remove noise, calibrate the data, and correct for systematic errors.

- Visualization: Displaying the results as a 3D surface plot, contour map, or other suitable representation.

Software packages dedicated to fringe analysis are often used for advanced analysis. These packages perform tasks such as noise reduction, phase unwrapping (removing 2π ambiguities in the phase data), and data visualization.

Q 13. Explain the role of optical components like beam splitters, mirrors, and lenses in interferometers.

Optical components play crucial roles in shaping and manipulating the light beams within an interferometer. Their precise alignment and characteristics are vital for accurate interference measurements.

- Beam splitters: These divide the incoming light beam into two beams of roughly equal intensity, creating the two interfering beams. Different types of beam splitters (e.g., polarizing beam splitters, non-polarizing beam splitters) are used depending on the application. They determine the power distribution in the two arms of the interferometer.

- Mirrors: These reflect the light beams, directing them towards the point of interference. High-quality mirrors with excellent reflectivity are essential to ensure high fringe contrast. The positioning of the mirrors is critical in defining the optical path difference.

- Lenses: Lenses are used for beam shaping, collimation (making the light beam parallel), and focusing the light onto the detector. The choice of lens depends on the desired beam profile and the working distance. They are also essential for spatial filtering.

For example, in a Michelson interferometer, a beam splitter separates the incoming beam into two arms. Each arm contains a mirror that reflects the light back towards the beam splitter, where the two beams interfere. Lenses can be included to collimate the beams or focus them onto a detector. The precise alignment and quality of these components are critical to obtain high-quality interference fringes and accurate measurements.

Q 14. Describe different techniques for fringe analysis.

Fringe analysis techniques encompass a range of methods for extracting quantitative data from interferograms. The choice of technique depends on the nature of the fringes and the desired accuracy.

- Phase-shifting interferometry (PSI): This is a widely used technique that involves introducing a controlled phase shift between the interfering beams, generating a series of interferograms. Mathematical algorithms are then used to calculate the phase at each point in the image.

- Fourier transform profilometry (FTP): This technique is particularly useful for analyzing complex fringe patterns with high spatial frequencies. It utilizes a Fourier transform to separate the fringe information from the background noise.

- Temporal phase unwrapping: This method addresses the problem of 2π ambiguities in the phase data by tracking the phase changes over time. It’s effective when the phase changes smoothly over time.

- Spatial phase unwrapping: This method utilizes algorithms to connect discontinuous phase regions in a spatial manner. It requires a good initial estimate of the phase to avoid propagation of errors.

- Direct fringe analysis: This method involves directly measuring the position and spacing of the fringes using image processing techniques.

Each method has its strengths and limitations. PSI is known for high accuracy but requires precise control of the phase shift. FTP is robust against noise but can be sensitive to variations in illumination. The best technique depends on factors such as the application, the type of interferometer, and the characteristics of the interferogram.

Q 15. How do you interpret the phase information obtained from an interferogram?

Interpreting the phase information from an interferogram is crucial to understanding the optical path difference between two interfering beams. Essentially, the interferogram – a pattern of bright and dark fringes – represents contours of constant optical path difference. Each fringe shift corresponds to a change in optical path length of one wavelength (λ). Therefore, analyzing the fringe pattern allows us to reconstruct the shape or variations in refractive index of the object under test.

For instance, consider a simple Michelson interferometer measuring the flatness of a mirror. A perfectly flat mirror will produce straight, equally spaced fringes. Deviations from flatness, even at the nanometer scale, will manifest as distortions in the fringe pattern. By carefully analyzing the fringe spacing and shape, we can quantitatively determine the surface profile of the mirror using sophisticated algorithms. This involves techniques like phase-shifting interferometry, where the phase difference is precisely measured at multiple steps, allowing for highly accurate calculations, even in the presence of noise.

In more complex scenarios, like analyzing the refractive index distribution of a transparent sample, the fringe pattern indicates variations in optical path length which are directly related to the refractive index changes across the sample. Sophisticated algorithms and mathematical models are used to map these variations.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the applications of interferometry in surface profilometry?

Interferometry is a cornerstone of surface profilometry, offering incredibly high-precision measurements of surface topography. Techniques like Fizeau, Michelson, and Twyman-Green interferometry are commonly used. In these methods, the surface under test is compared to a reference surface (often a highly precise flat or sphere). The resulting interference pattern reveals the height variations between the two surfaces.

For example, in semiconductor manufacturing, interferometry is crucial for inspecting the smoothness of wafers. Any defects or imperfections, even down to angstrom levels, will be clearly visible in the interferogram. Similarly, in precision optics, interferometry is indispensable for testing the quality of lenses and mirrors. By analyzing the fringe pattern, manufacturers can detect irregularities like surface roughness, waviness, and defects that would affect the optical performance.

The applications range across diverse fields including: quality control in manufacturing, research into surface science, the creation of micro- and nano-scale structures, and even in the study of biological samples. The level of precision attainable – down to fractions of a wavelength of light – makes interferometry a powerful tool for surface characterization.

Q 17. Explain how interferometry is used in optical testing.

Interferometry is a powerful technique in optical testing, allowing for the precise characterization of optical components. It’s used to evaluate the quality and performance of lenses, mirrors, prisms, and other optical elements by measuring deviations from ideal shapes and surfaces. The principle remains consistent: comparing a test component against a reference surface using interference.

For instance, in testing the quality of a lens, a Twyman-Green interferometer might be used. The lens is placed in one arm of the interferometer, and the interference pattern generated reveals any aberrations (deviations from perfect wavefronts) present in the lens. The pattern provides a direct measure of wavefront error – a critical parameter determining the image quality delivered by the lens. By analyzing this pattern, optical engineers can quantify aberrations such as spherical aberration, coma, astigmatism, and distortion.

Similarly, in testing the flatness of a mirror, a Fizeau interferometer is commonly used. Deviations from perfect flatness directly translate into variations in fringe spacing in the interferogram. These deviations help identify and quantify surface irregularities. Optical testing with interferometry extends to measuring the parallelism of optical surfaces and the quality of optical coatings.

Q 18. Describe the use of interferometry in measuring refractive index.

Interferometry provides a precise method for measuring the refractive index of a material. The technique relies on the relationship between the refractive index and the optical path length. By measuring the change in optical path length when light passes through the material, we can calculate its refractive index.

One common method involves using an interferometer to measure the phase shift experienced by a beam of light passing through a sample of known thickness. The phase shift is directly proportional to the optical path difference, which is in turn related to the refractive index (n) and thickness (t) of the sample: Optical Path Difference = n*t. By precisely measuring the phase shift, we can deduce the refractive index. This can be achieved through various methods, including phase-shifting interferometry, which provides a robust and accurate approach even when working with low-contrast fringes.

This approach is used widely in characterizing optical materials and studying the properties of gases and liquids. Knowing the refractive index is critical in designing optical systems, because it directly impacts how light propagates through the material. For example, this method is critical in ensuring accurate performance in optical fibers.

Q 19. How is interferometry used in the semiconductor industry?

Interferometry plays a vital role in the semiconductor industry, offering non-destructive and highly precise measurements critical for various manufacturing steps. The extreme precision required in semiconductor fabrication makes interferometry indispensable for quality control and process optimization.

Specifically, interferometry is extensively used for:

- Wafer surface inspection: Detecting surface defects, imperfections, and variations in thickness at the nanometer scale.

- Lithography process control: Measuring the critical dimensions of features created during lithography, ensuring they meet specifications.

- Metrology of thin films: Determining the thickness and uniformity of deposited layers.

- Wafer flatness testing: Assessing the planarity of wafers to ensure compatibility with lithographic processes.

For instance, during wafer fabrication, interferometric techniques monitor the thickness of deposited layers, ensuring that they adhere to stringent specifications. This precise control is crucial for the proper functioning of integrated circuits. Moreover, it is used to monitor the process and ensure the quality of individual wafers at each step. The applications span various stages from wafer preparation through final device testing.

Q 20. What are the limitations of interferometry?

While interferometry offers unparalleled precision, it does have limitations:

- Sensitivity to vibrations and environmental conditions: Even minor vibrations or air turbulence can significantly affect the interference pattern, leading to measurement errors. This often requires sophisticated vibration isolation systems and controlled environments.

- Multiple reflections and scattering: In some samples, multiple reflections or scattering of light can complicate the interpretation of the interferogram, requiring advanced analysis techniques.

- Limitations in surface roughness: Interferometry is most effective for measuring smooth surfaces. Highly rough surfaces can produce poorly defined interference patterns, making accurate measurements challenging.

- Phase unwrapping ambiguity: In interpreting phase maps derived from interferograms, phase unwrapping algorithms are needed. These can be susceptible to errors, particularly for complex fringe patterns. Careful selection of these algorithms is therefore important.

- Cost and complexity: Interferometric systems can be expensive and require specialized expertise to operate and analyze data.

These limitations necessitate careful consideration of the application and the selection of appropriate interferometric techniques and analysis methods.

Q 21. Explain the concept of heterodyne interferometry.

Heterodyne interferometry enhances the precision and robustness of traditional interferometry by employing two laser beams with slightly different frequencies. This frequency difference generates a beat signal – a detectable signal resulting from the interference of the two beams. Measuring this beat signal allows for highly sensitive detection of changes in optical path difference.

Imagine two waves with slightly different frequencies interfering. The resulting wave will have a slowly varying amplitude – this is the beat signal. The frequency of this beat signal is directly proportional to the frequency difference between the two laser beams. By detecting the frequency of this beat signal, we can precisely measure the changes in optical path difference and thus enhance the accuracy of measurements significantly. This eliminates the need for high resolution in the detection of spatial fringe patterns which makes the method less sensitive to environmental noise and vibration.

Applications of heterodyne interferometry include precision displacement measurement, velocity measurement, and high-resolution surface profilometry. Its advantage lies in its ability to measure small changes in optical path length very precisely even in conditions where classical interferometry might fail due to environmental perturbations. It finds significant use in areas requiring sub-nanometer accuracy, such as in advanced metrology and high precision manufacturing.

Q 22. How can you improve the accuracy of interferometric measurements?

Improving the accuracy of interferometric measurements involves addressing several key aspects of the system. Think of it like trying to measure the width of a hair with a ruler – even the slightest movement or imperfection will affect your result. Similarly, in interferometry, environmental factors, instrument limitations, and data analysis techniques all play a crucial role.

- Environmental Control: Minimizing vibrations, temperature fluctuations, and air currents is paramount. Active vibration isolation systems, temperature-controlled enclosures, and enclosed optical paths are common solutions. For instance, in a precision metrology lab, we might use a massive granite table to dampen vibrations and keep the interferometer isolated from external disturbances.

- High-Quality Optics: Using high-quality, precisely manufactured optical components is crucial. Imperfections in the mirrors or beamsplitters introduce errors into the interference pattern. Regular cleaning and careful handling of these components are essential.

- Precise Wavelength Control: The accuracy of the measurement is directly tied to the stability and precision of the laser wavelength used. Laser stabilization techniques, such as frequency locking to a reference cavity, enhance accuracy significantly.

- Advanced Signal Processing: Sophisticated signal processing algorithms can remove noise and artifacts from the interferogram, leading to more precise fringe analysis and subsequent measurements. Techniques such as phase unwrapping and Fourier transforms are critical here. We’ll discuss this further in the next answer.

- Calibration and Verification: Regular calibration against known standards is vital to ensure the accuracy of the interferometer. This involves comparing measurements with certified artifacts or using traceable standards.

Q 23. What are some common troubleshooting techniques for interferometers?

Troubleshooting interferometers involves a systematic approach, combining careful observation with methodical testing. It’s like detective work, carefully examining clues to pinpoint the problem.

- Visual Inspection: Start by visually inspecting the entire setup. Look for misalignments, loose connections, dust on optics, or damage to components. Sometimes, the simplest solution is the best. I once spent hours troubleshooting a complex signal only to realize a tiny speck of dust had settled on a crucial mirror.

- Laser Check: Verify that the laser is operating within its specifications. Check its power, stability, and wavelength. A fluctuating or unstable laser is a common source of error.

- Alignment Verification: Precise alignment of optical components is crucial. Use alignment tools to verify that mirrors and beamsplitters are properly positioned. Misalignment causes fringe distortion and inaccurate measurements.

- Environmental Factors: Check for environmental factors like vibrations, temperature variations, and air currents. These can significantly impact the stability and accuracy of the interference pattern.

- Signal Analysis: Examine the interferogram for artifacts such as noise, drifts, or unexpected patterns. These often indicate problems with the instrument or the environment. A systematic analysis using appropriate software tools is vital here.

- Software Diagnostics: Many interferometer systems have built-in diagnostics. Utilizing these diagnostic tools can help identify and isolate problems quickly.

Q 24. Discuss the role of signal processing in interferometric data analysis.

Signal processing plays a crucial role in extracting meaningful information from the raw interferometric data. The raw data, the interferogram, is often noisy and complex, requiring sophisticated techniques to extract precise measurements. Imagine trying to interpret a blurry photograph—you need to enhance and process it to see the details clearly. It’s the same with interferometry.

- Noise Reduction: Various filtering techniques, such as Fourier transforms, wavelet transforms, and median filtering, are used to reduce noise in the interferogram. This enhances the signal-to-noise ratio, allowing for more accurate measurements.

- Phase Unwrapping: The interferogram represents phase variations, but phase data is often wrapped to the range [0, 2π]. Phase unwrapping algorithms reconstruct the absolute phase from the wrapped phase. This step is crucial for accurate surface profile reconstruction.

- Data Calibration: Calibration techniques are used to correct for systematic errors in the measurements. This might involve subtracting background signals or correcting for instrument-specific biases.

- Data Interpolation: Interpolation techniques are used to fill in missing data points or improve the resolution of the data. This can be essential for reconstructing fine surface details.

- Frequency Analysis: Fourier transform analysis can be used to identify periodicities in the data or to analyze the spectral content of the signal.

Many software packages offer tools for these processes, which often include interactive visualizations for detailed analysis.

Q 25. Describe your experience with specific interferometer software packages.

Throughout my career, I’ve extensively utilized several interferometer software packages, each with its own strengths and weaknesses. My experience includes:

- Zygo MetroPro: This is a widely used software package for analyzing data from Zygo interferometers. I’ve used it for various applications, including surface roughness analysis and optical component testing. Its user-friendly interface and powerful analysis tools are particularly valuable.

- PhaseMap: I’ve employed PhaseMap in projects requiring detailed phase unwrapping and sophisticated data processing. It provides robust algorithms and excellent tools for managing large datasets.

- MATLAB with custom scripts: For more specialized applications, I frequently used MATLAB to develop custom signal processing algorithms and data analysis pipelines. This offers flexibility and control tailored to unique experimental requirements.

My proficiency extends to scripting and automating data analysis workflows using these packages, which is crucial for efficient handling of large-scale datasets and repetitive tasks.

Q 26. Explain your experience with different types of interferometer configurations.

My experience encompasses a range of interferometer configurations, each suited for different applications. The choice of configuration depends heavily on the specific measurement task.

- Michelson Interferometer: This is a classic configuration widely used in various applications, including optical testing and distance measurement. I’ve used it extensively in characterizing optical components like lenses and mirrors.

- Mach-Zehnder Interferometer: I’ve utilized this configuration in applications involving the study of transparent samples or for testing optical fibers. Its flexibility in beam path manipulation is valuable.

- Fizeau Interferometer: This is particularly useful for testing flat surfaces with high precision. I’ve employed it in projects involving the characterization of high-precision optical flats and mirrors.

- Twyman-Green Interferometer: I’ve used this configuration, a variation of the Michelson interferometer, for testing optical components such as lenses and prisms. Its ability to separate the test beam and reference beam makes it suitable for a wide variety of applications.

My experience isn’t limited to these standard configurations. I am also familiar with more specialized designs, such as those used in fiber optic sensing and laser-based displacement measurements.

Q 27. What are some emerging trends in interferometry technology?

The field of interferometry is constantly evolving, with several exciting emerging trends shaping its future:

- Compact and Portable Interferometers: Miniaturization and the use of integrated optics are leading to the development of compact and portable interferometers. This expands the accessibility and applicability of interferometry to various fields.

- Digital Holography: Digital holography techniques are providing new capabilities for three-dimensional surface characterization and particle imaging. This allows for the capturing of both amplitude and phase information, offering richer and more detailed measurements.

- Improved Sensors and Detectors: Advances in sensor technology are leading to enhanced sensitivity and faster data acquisition rates. This allows for more precise measurements and the analysis of faster dynamic processes.

- Artificial Intelligence and Machine Learning: AI and ML are being applied to improve data analysis and automate the interpretation of interferometric data. This can significantly reduce the time required for data processing and analysis, ultimately increasing efficiency.

- Quantum Interferometry: Research in quantum interferometry is exploring the use of entangled photons to achieve significantly enhanced measurement precision. This opens up possibilities for pushing the limits of measurement accuracy to unprecedented levels.

These trends suggest that interferometry will continue to play a critical role in various scientific and engineering disciplines, driving innovation and providing more sophisticated and accessible measurement capabilities.

Key Topics to Learn for Interferometers Interview

- Fundamentals of Wave Interference: Master the principles of constructive and destructive interference, including path difference and phase shifts. Understand how these principles underpin interferometer operation.

- Types of Interferometers: Become familiar with Michelson, Mach-Zehnder, Fabry-Perot, and Sagnac interferometers. Know their unique characteristics, applications, and limitations.

- Optical Components: Gain a solid understanding of key components such as beam splitters, mirrors, lenses, and detectors. Be prepared to discuss their function and impact on interferometer performance.

- Practical Applications: Explore diverse applications, including precision metrology (measuring surface roughness, displacement), optical coherence tomography (OCT) in medical imaging, gravitational wave detection (LIGO), and optical fiber sensing.

- Signal Processing and Data Analysis: Understand how interference fringes are generated and analyzed. Be prepared to discuss techniques for noise reduction, data interpretation, and extracting meaningful measurements.

- Sources of Error and Mitigation Strategies: Identify common sources of error in interferometry (e.g., vibrations, thermal fluctuations, misalignment). Discuss techniques for minimizing these errors and improving measurement accuracy.

- Advanced Concepts (depending on the role): Consider exploring topics like coherence length, spatial resolution, polarization effects, and non-linear effects in interferometry.

Next Steps

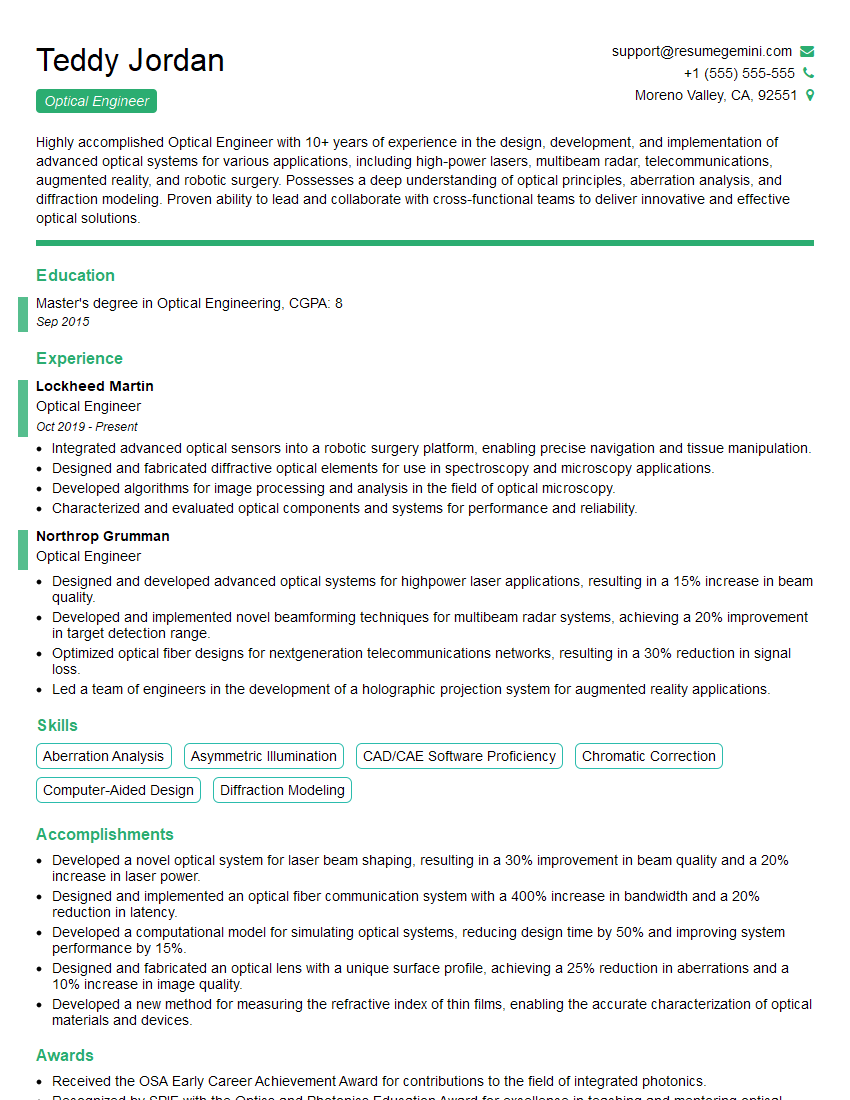

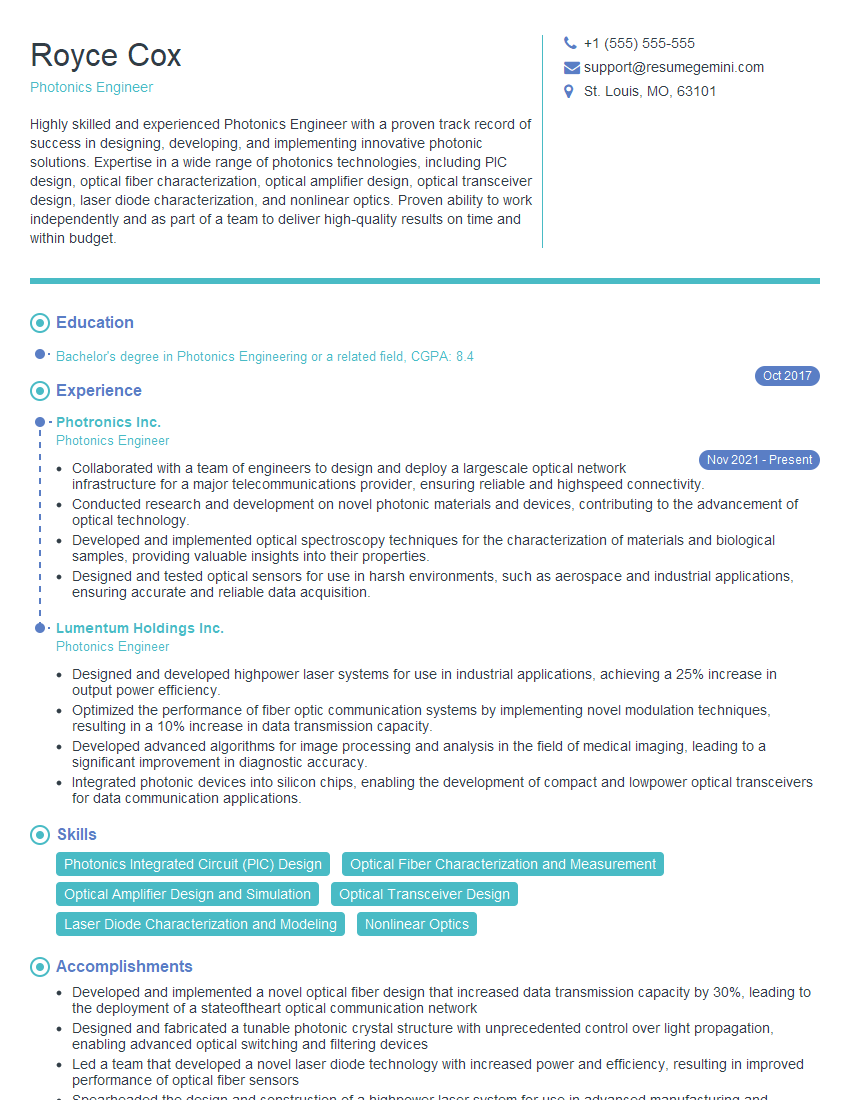

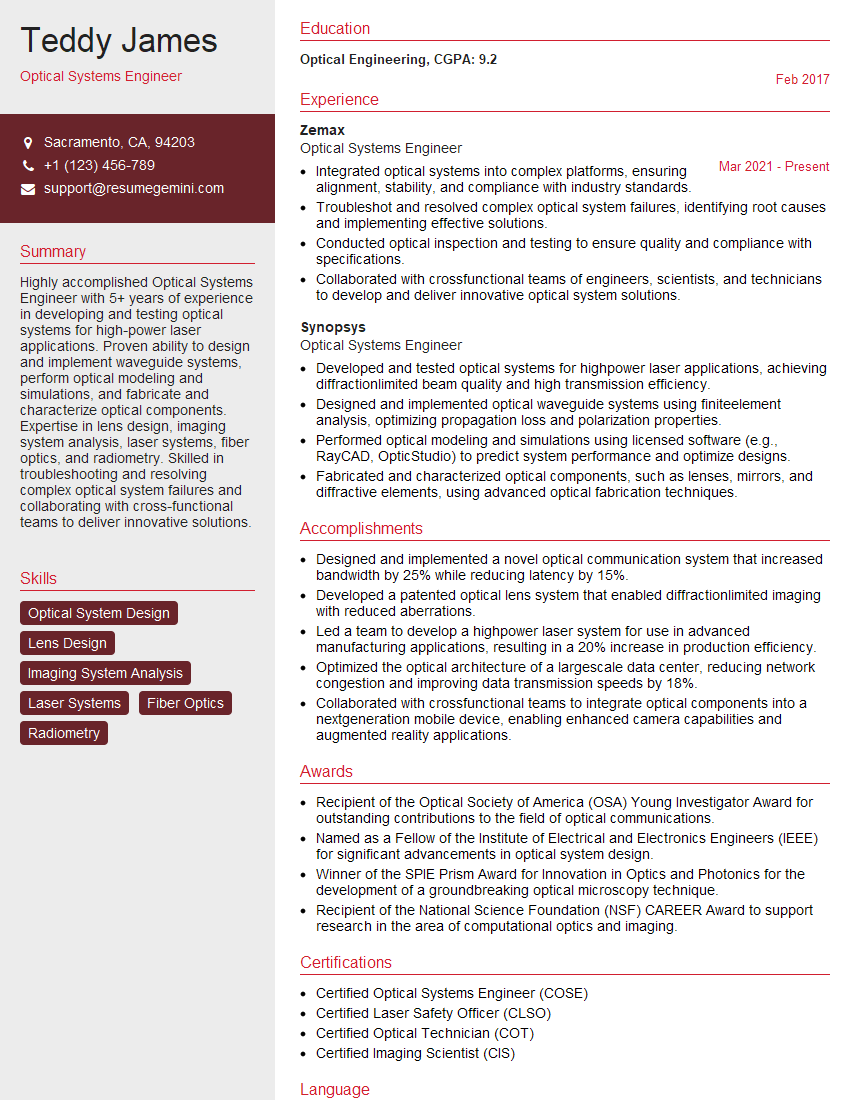

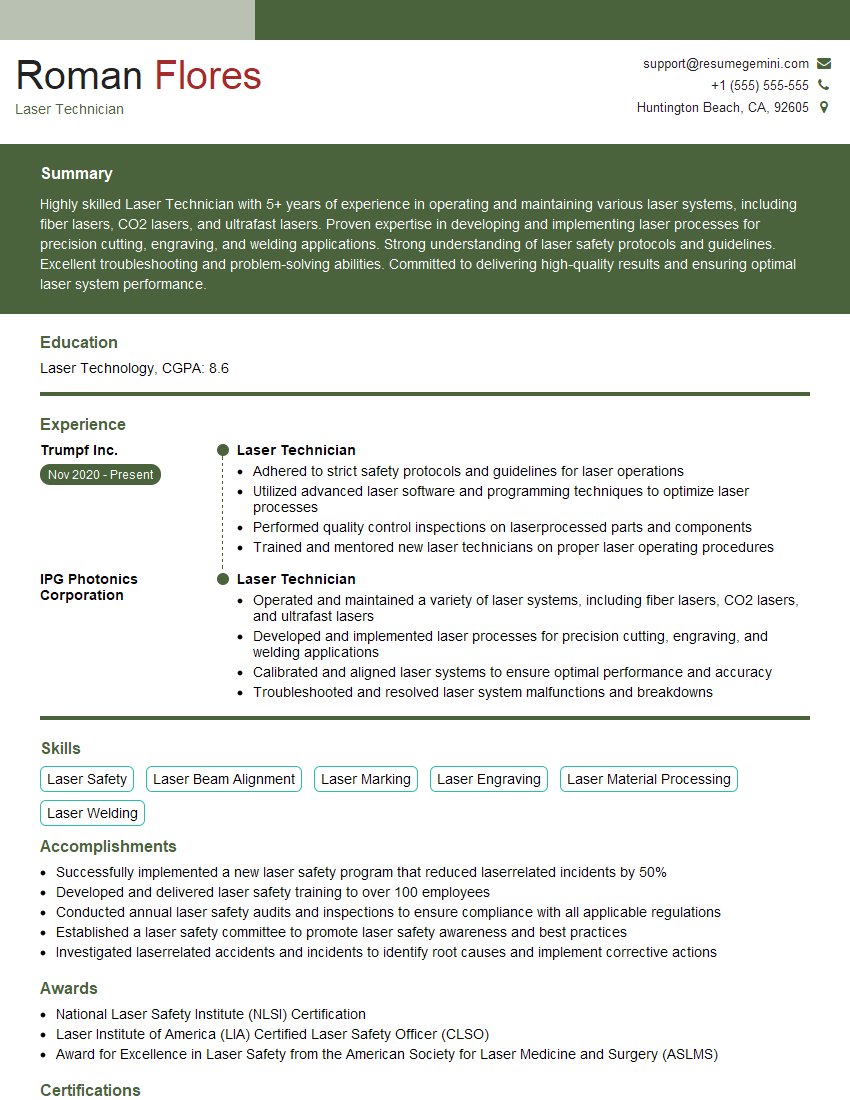

Mastering interferometry opens doors to exciting careers in cutting-edge fields like physics, engineering, and biomedical research. A strong understanding of these principles is crucial for securing your dream role. To maximize your job prospects, create a compelling and ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional resume tailored to the specific demands of the interferometry field. Examples of resumes tailored to Interferometer roles are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good