Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Control Valve Troubleshooting interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Control Valve Troubleshooting Interview

Q 1. Explain the different types of control valves and their applications.

Control valves are the workhorses of process automation, precisely controlling the flow of fluids. They come in various types, each suited to different applications. The choice depends on factors like fluid properties, pressure, temperature, and required flow characteristics.

- Globe Valves: These are the most common type, featuring a disc that moves vertically to regulate flow. They’re excellent for throttling applications (precise flow control) and offer good shut-off capabilities. Think of a faucet – it’s essentially a globe valve.

- Ball Valves: A rotating ball with a hole through it controls flow. They are typically used for on/off service, offering quick opening and closing times. Imagine a simple switch for fluid flow.

- Butterfly Valves: A rotating disc partially blocks flow. They are ideal for large-diameter lines where quick on/off operation is needed, but their throttling capabilities are less precise than globe valves. Think of a damper in a ventilation system, controlling airflow.

- Diaphragm Valves: A flexible diaphragm isolates the fluid from the actuator mechanism, which is especially useful for handling corrosive or viscous fluids. These are commonly found in chemical processing.

- Pinch Valves: A flexible sleeve is compressed to restrict flow, allowing for excellent shut-off and gentle handling of delicate materials. They are commonly used in the food and pharmaceutical industries.

Choosing the right valve is crucial for optimal process control and equipment lifespan. A poorly selected valve can lead to inefficiencies, wear, and potential safety hazards.

Q 2. Describe the function of a valve positioner.

A valve positioner is a small, self-contained device that improves the accuracy and responsiveness of a control valve. Imagine you’re trying to adjust a valve manually—it might be difficult to get the exact setting you need, especially if the valve is large or has friction. The positioner acts as a ‘smart assistant’. It receives a signal from the control system indicating the desired valve position and then precisely positions the valve accordingly.

It does this by monitoring the actual valve position using a feedback mechanism (like a potentiometer or LVDT) and comparing it to the desired position. Any discrepancy is corrected by adjusting the actuator’s power, ensuring the valve reaches and maintains the correct position, regardless of variations in pressure, friction, or other external factors. It enhances accuracy, reduces hysteresis (sticking), and provides faster response times leading to more efficient process control.

Q 3. How do you troubleshoot a control valve that is not opening fully?

A control valve that’s not opening fully is a common problem with several potential causes. Troubleshooting involves a systematic approach:

- Check the actuator: Is it receiving the correct signal? Is there sufficient air pressure (for pneumatic actuators) or power (for electric actuators)? Test the actuator separately to rule out any issues there. A simple visual inspection for any obvious damage or leaks is a good starting point.

- Examine the valve stem: Is it bent, damaged, or sticking? Check for binding or obstructions preventing full travel. Sometimes debris in the valve or stem can cause this.

- Inspect the valve trim: Is the plug or ball obstructed by debris or scale buildup? The valve may require cleaning, maintenance, or even replacement of the trim.

- Check for external constraints: Is anything physically preventing the valve from opening fully (e.g., pipes too close, mounting issues)?

- Verify the controller output: Ensure the controller signal is reaching its maximum value to provide full opening. This might involve checking wiring, controller parameters, and signal strength.

- Assess the packing gland: Too much packing gland compression might also restrict the valve stem movement.

By methodically checking these points, you can usually pinpoint the root cause and fix the problem. Remember safety first; isolate the valve before any maintenance.

Q 4. How do you troubleshoot a control valve that is leaking?

A leaking control valve can indicate various issues, impacting process efficiency and safety. Troubleshooting involves identifying the type of leak and its source:

- Stem leak: This is leakage around the valve stem. It’s usually caused by worn or damaged packing, a faulty packing gland, or improper packing gland adjustment. Tightening the gland may resolve minor leaks, but severely damaged packing often requires replacement.

- Body leak: Leakage from the valve body indicates a problem with the valve seat or internal seals. This might be due to corrosion, erosion, or damage to the sealing components. This typically requires replacing the affected parts. This is often a more serious issue and requires full valve overhaul.

Troubleshooting steps involve visual inspection, identifying the leak type, and then addressing the specific cause. Leak detection solutions like dye penetrants can be useful to pinpoint small leaks. Remember, any leaking valve should be addressed promptly to prevent process upsets and costly material losses. If unsure, always consult the valve’s maintenance documentation and consider contacting a service professional.

Q 5. Explain the concept of valve trim and its importance.

Valve trim refers to the internal components of a control valve that directly interact with the fluid flow, determining its flow characteristics. It includes the plug, ball, or disc and the seat (where the moving element contacts to regulate flow). The trim is critical to the valve’s performance. The choice of trim material impacts durability, corrosion resistance, and flow characteristics.

Proper trim selection is essential for achieving accurate control and minimizing wear and tear. Different trim designs (e.g., linear, equal percentage, quick-opening) provide different flow characteristics to match the specific process requirements. For instance, a linear trim would provide equal increments of flow change per incremental change in valve position while equal percentage trims give equal percentage flow changes per unit of stem travel. Choosing the right trim ensures optimal control, reduces energy consumption, extends valve lifespan, and minimizes potential maintenance issues.

Q 6. What are the common causes of control valve noise?

Control valve noise is often an indicator of a problem and can be caused by several factors. Identifying the source is crucial for effective troubleshooting:

- Cavitation: This occurs when the pressure of the fluid drops below its vapor pressure, creating bubbles that implode, generating noise and potentially damaging the valve. It often sounds like a crackling or rattling.

- Flashing: Similar to cavitation, flashing happens when a liquid changes to vapor within the valve due to pressure drop. It usually presents as a hissing sound.

- Turbulence: Excessive flow velocity within the valve can create turbulence, leading to noise. This is common in valves that are undersized or incorrectly sized for the flow conditions.

- Vortex shedding: This occurs when vortices (swirling flow patterns) are generated downstream of the valve, creating a characteristic whistling sound.

- Mechanical problems: Loose parts, worn components, or an improperly adjusted valve can generate noise. This could manifest as clicking, grinding, or other mechanical sounds.

Addressing valve noise often involves reducing the flow velocity, changing the valve trim or adjusting the control strategy. For example, changing a valve trim to one designed for better control at the operating conditions or installing a silencer can resolve the issues.

Q 7. How do you identify a failing actuator?

Identifying a failing actuator requires careful observation and testing. Symptoms can vary depending on the actuator type (pneumatic or electric):

- Pneumatic Actuators: Look for leaks in air lines, unusual air consumption, sluggish response to control signals, unusual noises, or inability to reach the commanded position. Inspect for external damage and check the air supply pressure and cleanliness.

- Electric Actuators: Check for signs of overheating, unusual noises (grinding, buzzing), failure to respond to control signals, or erratic movements. Inspect for damaged wiring, a faulty motor, or issues with the limit switches (if applicable).

Troubleshooting often involves checking the power supply, inspecting the actuator for physical damage, verifying the control signals, and monitoring its performance. If the problem persists, a more in-depth analysis might be required, potentially including disassembly and inspection of the internal components of the actuator. If you are not qualified to do this, consult a qualified technician.

Q 8. Describe the different types of actuators used in control valves.

Control valves rely on actuators to convert control signals into mechanical movement, opening or closing the valve. Several types exist, each with strengths and weaknesses:

- Pneumatic Actuators: These use compressed air to power the valve. They’re robust, reliable, and relatively inexpensive, making them common in hazardous areas due to their inherent safety. Think of them like a tiny air-powered piston. A change in air pressure translates directly to valve position.

- Electric Actuators: Driven by electricity, these offer precise control and are often easier to integrate with automated systems. They’re ideal for applications needing precise positioning and remote control. However, they can be more susceptible to power failures.

- Hydraulic Actuators: Employing hydraulic fluid under pressure, these provide immense power for large valves controlling high flows or pressures. They are very strong but generally more complex and expensive than pneumatic or electric alternatives. Imagine a powerful hydraulic jack—similar principles are at play here.

- Electro-hydraulic Actuators: Combining the precision of electric signals with the power of hydraulics. These offer a good balance of control and power, especially useful in demanding industrial processes.

The choice of actuator depends heavily on factors such as the process conditions, the size of the valve, safety requirements, and budget. For instance, a large valve controlling high-pressure steam might necessitate a hydraulic actuator, while a smaller valve in a less demanding application might suffice with a pneumatic or electric actuator.

Q 9. What are the different types of valve characteristics (linear, equal percentage, etc.)?

Valve characteristics describe the relationship between valve stem position and flow rate. They dictate how the flow changes as the valve opens. The most common types are:

- Linear: Flow rate changes linearly with valve position. A 50% open valve results in 50% of the maximum flow. Simple and easy to understand, but may not be optimal for all applications.

- Equal Percentage: Flow rate increases by an equal percentage for each equal increment of valve stem travel. This characteristic provides better control at both low and high flow rates. Think of it as a logarithmic scale for flow – small adjustments at low flows have a big impact, while large adjustments at high flows have less of an effect.

- Quick Opening: Provides rapid flow changes with small stem movements, suitable for applications requiring fast on/off control or where quick responses are needed. This type isn’t often used in precise control situations.

Choosing the right characteristic depends on the process. For instance, equal percentage is preferable for processes with highly variable flow demands, while linear might suffice for situations with relatively constant flows.

Q 10. Explain the importance of proper valve sizing.

Proper valve sizing is crucial for optimal control and efficient operation. An undersized valve will struggle to handle the required flow, leading to excessive pressure drop, cavitation (formation of vapor bubbles), noise, and potential damage. Conversely, an oversized valve is less responsive and might exhibit poor control, wasting energy and potentially affecting process stability. Imagine trying to drain a bathtub with a tiny teacup versus a large bucket – the bucket is significantly more efficient.

Accurate sizing ensures the valve can handle the designed flow rates while minimizing pressure drop and energy consumption. This involves careful consideration of factors such as flow rate, pressure drop, fluid properties, valve type, and piping configuration. Specialized sizing software and engineering calculations are commonly used to determine the appropriate valve size.

Q 11. How do you determine the appropriate control valve type for a specific application?

Selecting the appropriate control valve involves a systematic process based on several factors:

- Fluid Properties: Viscosity, density, temperature, corrosiveness, abrasiveness—all influence valve material and design selection.

- Process Requirements: Flow rate, pressure, and required control accuracy are essential considerations.

- Operating Conditions: Ambient temperature, pressure fluctuations, potential for fouling or cavitation all affect valve performance.

- Safety Requirements: Hazardous environments might necessitate valves with specific features like fire-safe designs.

- Maintenance Considerations: Ease of access, maintainability, and spare parts availability should be factored in.

Often, engineers use a combination of process specifications, industry standards, and manufacturer’s guidelines to make the best choice. For instance, a corrosive liquid would necessitate a valve with a compatible material of construction, such as stainless steel or a specialized alloy.

Q 12. What are the key parameters to consider when selecting a control valve?

Selecting a control valve necessitates considering a range of parameters:

- Valve Body Material: Chosen based on the fluid’s corrosive or abrasive nature, temperature, and pressure.

- Valve Type: Globe, ball, butterfly, or others, each suited to different applications and flow characteristics.

- Actuator Type and Size: Pneumatic, electric, or hydraulic, sized to provide sufficient power for the intended service.

- Valve Trim: The internal components affecting flow characteristics (linear, equal percentage, etc.).

- Valve Sizing: Determining the correct valve size to handle the flow and pressure conditions.

- Positioner: Improves accuracy and responsiveness by providing feedback to the actuator.

- Safety Features: Fail-safe mechanisms (fail-open or fail-closed) to address safety concerns.

For example, a high-pressure steam application requires a valve with a robust body material and potentially a positioner for precise control.

Q 13. Describe the process of calibrating a control valve.

Calibrating a control valve ensures it operates accurately within its specified range. This is a critical step to guarantee proper control. The process generally involves these steps:

- Verify the Valve’s Mechanical Operation: Check for proper valve stem movement, leaks, and any mechanical obstructions.

- Establish the Valve’s Full Travel: Determine the exact positions corresponding to fully open and fully closed states.

- Input Signal Calibration: Adjust the actuator so that it responds correctly to the control signal (e.g., 4-20 mA or 3-15 psi) at both extremes and at various intermediate points.

- Output Verification: Measure the actual valve stem position for various input signals, verifying the linearity or characteristic curve.

- Documentation: Record calibration results, including date, time, and any observed deviations.

Specialized calibration tools and software are often used to automate the process and improve accuracy. Regular calibration is crucial for maintaining optimal control performance and preventing unexpected process upsets.

Q 14. How do you troubleshoot a control valve that is cycling?

A cycling control valve repeatedly opens and closes, indicating a control problem rather than a valve malfunction. Troubleshooting involves systematically checking various components and parameters:

- Check for Controller Tuning Issues: Improperly tuned controllers can cause oscillations and cycling. Adjust the proportional, integral, and derivative (PID) parameters to optimize the control loop.

- Examine the Process for Disturbances: Significant fluctuations in the process variable (temperature, pressure, flow) can cause the valve to hunt for the setpoint.

- Assess the Sensor for Accuracy and Reliability: A faulty sensor can provide incorrect readings to the controller, causing the valve to react inappropriately.

- Inspect the Actuator for Proper Operation: Air leaks in pneumatic actuators, electrical faults in electric actuators, or mechanical issues can disrupt the valve’s smooth operation.

- Verify the Valve’s Positioning Mechanism: Sticking, binding, or other mechanical problems can prevent the valve from reaching its desired position.

- Check for Process Limitations: In certain processes, rapid cycling might be unavoidable due to inherent lags and limitations.

A systematic approach, using process knowledge and diagnostic tools, is vital in pinpointing the root cause of the cycling and implementing the appropriate corrective action. Often, a combination of factors contributes to this issue.

Q 15. Explain the concept of control valve rangeability.

Control valve rangeability is a crucial characteristic that defines a valve’s ability to handle a wide range of flow rates. It’s essentially the ratio of the maximum flow rate to the minimum controllable flow rate. A higher rangeability indicates greater flexibility, meaning the valve can effectively control both large and small flows with acceptable accuracy. Think of it like a car’s transmission; a wider range allows for smoother control across various speeds. For example, a valve with a rangeability of 50:1 can control flows from 1% to 50% of its maximum capacity. This is vital in process control where you might need precise control over small flows during start-up and full flow during normal operation.

Rangeability is influenced by several factors, including the valve’s design (e.g., globe, ball, butterfly), the actuator’s capacity, and the valve’s trim (the internal components affecting flow). Choosing a valve with appropriate rangeability is vital for optimal performance and efficiency. A valve with insufficient rangeability might struggle to control low flows accurately, leading to process instability or even damage to equipment. Conversely, a valve with excessive rangeability might be unnecessarily large and costly.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the common maintenance tasks for control valves?

Regular maintenance is paramount for ensuring the reliable and safe operation of control valves. Common tasks include:

- Visual inspection: Checking for leaks, damage, corrosion, and proper alignment.

- Actuator check: Verifying proper operation, lubrication, and air pressure (for pneumatic actuators).

- Valve stem inspection: Checking for wear, damage, and proper packing gland adjustment to prevent leaks.

- Valve body inspection: Checking for erosion, corrosion, and build-up of debris in the valve body and trim.

- Calibration: Verifying that the valve’s position matches the controller’s signal and adjusting accordingly. This often involves using specialized calibration tools and documenting the results.

- Lubrication: Applying appropriate lubricants to moving parts to reduce friction and wear.

- Cleaning: Removing debris and contaminants from the valve body and internal components. The cleaning method depends on the process fluid. Sometimes specialized cleaning solvents are required.

The frequency of these tasks depends on the valve’s operating conditions, the process fluid, and the manufacturer’s recommendations. A proactive maintenance schedule, rather than a reactive approach, is key to maximizing valve life and minimizing downtime.

Q 17. How do you diagnose problems using loop drawings and instrumentation diagrams?

Loop drawings and instrumentation diagrams are essential tools for troubleshooting control valves. They provide a visual representation of the entire control loop, showing the interconnection between the valve, sensor, transmitter, controller, and other components. By analyzing these diagrams, you can trace the signal path and identify potential problems.

Step-by-step diagnosis:

- Identify the problem: Determine the specific issue, such as a valve not opening or closing fully, erratic movement, or inaccurate positioning.

- Follow the loop: Trace the signal path from the sensor (measuring the process variable) through the transmitter, controller, and finally to the actuator. Check each component along the way.

- Check signals: Use appropriate instruments (e.g., multimeter, pressure gauge) to verify the signals at different points in the loop. This allows you to pinpoint where the signal is deviating from the expected value. For example, if the controller is sending the correct signal to the actuator, but the valve isn’t moving, the problem is likely within the valve itself or its actuator.

- Analyze readings: Interpret the signal readings in the context of the loop drawing and instrumentation diagram. Unexpected values can help isolate the faulty component.

- Isolating the problem:Once the faulty component is identified, more specific diagnostic techniques can be applied based on the identified component. For example, a pressure test for leaks in a pneumatic actuator or a voltage check for the electropneumatic converter.

An example would be a scenario where the process temperature is consistently higher than the setpoint. By following the loop diagram, you could check the temperature sensor, its transmitter output, the controller’s setpoint and output, and finally the valve position. Any deviation from the expected value at each step indicates the location of the problem.

Q 18. Explain the difference between pneumatic and electropneumatic actuators.

Both pneumatic and electropneumatic actuators control the position of a control valve, but they differ significantly in how they receive and process control signals.

- Pneumatic actuators are directly powered by compressed air. The control signal is an air pressure signal from the controller, which directly moves the valve stem. Think of it as a simple air-powered piston. They are relatively simple, reliable, and intrinsically safe, particularly in hazardous environments. However, they can be less precise than electropneumatic actuators and require a compressed air supply.

- Electropneumatic actuators use an electrical signal as the input. This signal is processed by an I/P (current-to-pressure) converter, which converts the electrical signal into a proportional pneumatic signal to drive the valve. This combination provides the advantages of both electrical and pneumatic systems. The electrical signal allows for precise control and easier integration with digital systems, while the pneumatic actuation offers the simplicity and safety features of pneumatic systems. They are more versatile and precise but add the complexity of the I/P converter and the need for both electrical and pneumatic power sources.

Imagine a water tap: a pneumatic actuator is like directly controlling the water flow using a lever that is connected to a pressure-driven piston. An electropneumatic actuator is like controlling the tap with an electric switch that regulates the air pressure actuating the lever.

Q 19. What safety precautions should be taken when working on control valves?

Safety is paramount when working on control valves. Procedures should always adhere to company safety protocols and relevant industry standards (e.g., OSHA). Essential safety precautions include:

- Lockout/Tagout (LOTO): Isolating the valve from the process by locking out the power source (electrical or pneumatic) before starting any work. This prevents accidental activation, protecting the technician and preventing process upsets.

- Personal Protective Equipment (PPE): Using appropriate PPE, including safety glasses, gloves, and hearing protection, depending on the valve and process fluid.

- Confined space entry permits: If working in a confined space, ensure appropriate permits and safety measures are in place.

- Hot work permits: If any hot work (welding, cutting) is involved, obtain the necessary permits and follow fire safety precautions.

- Understanding process fluids: Being aware of the hazardous properties of the process fluids and taking appropriate precautions to avoid exposure (e.g., toxic, flammable, corrosive).

- Emergency response planning: Having an emergency plan in place in case of unexpected events or accidents. Knowing the location of emergency shut-off valves and procedures is crucial.

A thorough risk assessment is a vital step before commencing any work on control valves. This helps identify potential hazards and develop appropriate control measures. Never compromise on safety; it’s the top priority.

Q 20. How do you interpret control valve performance data?

Control valve performance data, typically gathered through a control system, provides critical insights into the valve’s operational efficiency and health. This data can include:

- Valve position: Indicates the actual position of the valve stem at any given time. Deviations from expected position could indicate mechanical issues.

- Control signal: Represents the signal from the controller to the actuator. Discrepancies between the control signal and the valve position suggest problems in the actuator or valve itself.

- Process variable: The measured value of the controlled variable (e.g., temperature, pressure, flow). Significant deviations from the setpoint indicate a control problem, which could be valve-related.

- Valve flow characteristic: Data reflecting the valve’s actual flow characteristics which can be compared against its expected flow characteristic to reveal problems such as wear or internal blockages.

Analyzing this data helps identify potential problems like sticking, leakage, hysteresis (differences between opening and closing characteristics), and poor response times. Trend analysis of the data over time can identify gradual deterioration or impending failures. Statistical process control (SPC) charts are often used to visualize this data and detect anomalies. For instance, a consistently high pressure drop across the valve despite relatively low flow could indicate internal blockage or valve wear. By interpreting performance data proactively, maintenance can be scheduled to prevent major failures and improve overall process efficiency.

Q 21. Describe your experience with different control valve manufacturers.

Throughout my career, I’ve worked extensively with various control valve manufacturers, including Fisher, Emerson (Rosemount), Masoneilan, and Yokogawa. Each manufacturer offers a wide range of valves designed for different applications and process conditions. My experience spans troubleshooting and maintenance of their respective products, encompassing pneumatic, electropneumatic, and even some specialized types like cryogenic valves. For example, I’ve encountered situations where Fisher’s unique valve trim designs required specific maintenance procedures unlike those for Emerson’s valves. I also have experience with their respective diagnostic software and tools.

My experience with these manufacturers extends beyond just product maintenance. It includes understanding their design philosophies, material specifications, and associated documentation. This understanding enables me to effectively diagnose and resolve valve issues with minimal downtime, and it enhances communication with vendor support when necessary. I’ve even been involved in selection processes, recommending the most suitable valve based on the process requirements and a detailed evaluation of available options from different manufacturers.

Q 22. What software or tools do you use to diagnose control valve problems?

Diagnosing control valve problems often involves a combination of software and hardware tools. On the software side, I frequently utilize process historian software like OSI PI or Aspen InfoPlus.21 to analyze historical process data, looking for trends or anomalies preceding the valve malfunction. This helps me identify potential root causes by correlating valve behavior with upstream or downstream process variables. For example, a sudden change in flow rate before a valve begins to fail could indicate a problem with the process itself, not just the valve.

Hardware tools are also essential. I use handheld digital multimeters to check for voltage, current, and resistance in the valve’s electrical circuits. Smart communicators can interface directly with valve positioners and provide valuable diagnostic information, such as valve stem travel, feedback signals, and error codes. Finally, vibration analyzers help identify mechanical issues like cavitation or sticking components. The combination of software-based data analysis and direct hardware diagnostics provides a comprehensive picture of the problem.

Q 23. How do you handle emergency situations involving control valves?

Emergency situations demand swift and decisive action. My first priority is always safety. I’ll immediately isolate the affected valve to prevent further damage or risk to personnel. This might involve closing a manual block valve upstream or downstream, depending on the process requirements and safety protocols. Next, I’ll assess the severity of the situation – Is there a risk of product loss, environmental release, or equipment damage? This dictates the urgency of repair or replacement. Depending on the situation, I might implement temporary workarounds (like manual control) while awaiting a permanent solution. Clear communication with operators and maintenance teams is crucial throughout the process, ensuring everyone is informed and understands the steps being taken.

I’ve had instances where a sudden failure in a critical control valve led to a rapid increase in pressure. Immediate isolation prevented a potential rupture and subsequent damage. The rapid response minimized downtime and ensured safety. Documentation of the event, including root cause analysis and corrective actions, is vital to prevent future occurrences.

Q 24. Explain the concept of feedback control in relation to control valves.

Feedback control is the cornerstone of automated process control and is fundamentally how control valves operate. Imagine a thermostat controlling room temperature. The thermostat (controller) compares the desired temperature (setpoint) with the actual temperature (measured by a sensor). The difference between these two values (error) is then used to adjust the heating system (final control element, which in this analogy is the control valve). If the room is too cold, the controller signals the heating system to increase output; if it’s too hot, the output is reduced.

In control valve applications, the controller receives a setpoint signal (desired flow rate, pressure, level, etc.). A sensor provides feedback on the actual process variable. The controller continuously compares the setpoint and feedback and adjusts the valve position accordingly to minimize the error. This continuous adjustment is what maintains the process variable at or near the desired setpoint. Proper tuning of the controller is essential for stable and efficient operation, avoiding oscillations or sluggish response.

Q 25. What are some common causes of control valve failure?

Control valve failures stem from various causes, broadly categorized into mechanical, pneumatic, and electrical issues. Mechanical problems include things like stem corrosion, packing gland leaks, damaged valve seats, and cavitation damage due to high-velocity fluid flow. Pneumatic issues might arise from leaks in the air supply, diaphragm rupture, or issues with the positioner. Electrical problems commonly involve faulty solenoids, wiring issues, or problems with the electronics in smart positioners. Furthermore, improper sizing and selection of valves for the specific application can also contribute to premature failure.

For example, I once encountered a valve failure caused by plugging from particulate matter in the process stream. This illustrates the importance of considering process fluid properties during valve selection. Another common cause is incorrect valve positioner tuning, which leads to excessive wear and tear or unstable operation (hunting). Identifying the root cause requires a systematic approach.

Q 26. Describe your experience with different types of valve packing.

My experience encompasses a range of valve packing materials, each with its own advantages and limitations. Common materials include PTFE (polytetrafluoroethylene), graphite, and various types of braided packing. PTFE is excellent for its chemical resistance and low friction, making it suitable for many applications. However, it can be prone to extrusion at higher pressures. Graphite packing provides good sealing and lubrication but may require more frequent adjustments. Braided packings, often made from materials like asbestos (now largely phased out) or aramid fibers, offer a robust solution, but their chemical compatibility needs careful consideration.

The selection of packing material is driven by the specific process fluid and operating conditions. For example, in a high-temperature application, a material with good thermal stability is crucial. In applications involving aggressive chemicals, chemically resistant materials like PTFE are preferred. When dealing with fugitive emissions, environmentally friendly and low-emission packings are often prioritized.

Q 27. How do you troubleshoot a control valve that is hunting (oscillating)?

A control valve hunting (oscillating) indicates a problem with the control loop. This means the valve is repeatedly opening and closing, unable to settle on a stable position. My troubleshooting approach begins with examining the process data using the aforementioned process historian software. I look for patterns in the valve position, process variable, and controller output. Often, aggressive controller tuning is the culprit. An overly responsive controller (high gain) can amplify small disturbances, resulting in oscillations. Overly fast integral or derivative actions can also contribute to hunting.

I’ll then check the valve itself for mechanical problems, such as stiction (sticking friction), which can create deadbands in the valve response. Air leaks in pneumatic systems, or electrical noise in the instrumentation loop, are also potential issues. Adjusting controller parameters (reducing gain, slowing integral and derivative times), addressing mechanical issues in the valve, and ensuring reliable signal quality usually resolves hunting. Step-by-step adjustment of the controller parameters, while observing the valve’s response, is essential to achieve stability.

Q 28. How do you determine the root cause of a control valve malfunction?

Determining the root cause of a control valve malfunction is a systematic process. It involves a methodical investigation, employing several techniques. I start by gathering information from the operators and maintenance personnel. This may include details of when the problem started, any recent maintenance activities, and any unusual observations. Next, I’ll review the process historian data to analyze trends and identify potential correlations between valve performance and other process parameters.

Then, I’ll perform a thorough inspection of the valve, its positioner, and associated instrumentation. I’ll check for obvious signs of damage, leaks, or wear and tear. Using the tools mentioned earlier (multimeter, smart communicator, vibration analyzer), I’ll conduct detailed testing of the electrical and pneumatic components. Finally, I document all findings and propose a solution that addresses the root cause, not just the symptoms. Sometimes, further analysis, including laboratory testing of samples, might be necessary to pin down the exact nature of the problem. For example, a failure analysis on a corroded valve stem might reveal the exact corrosive agent, leading to improved material selection or process changes in the future.

Key Topics to Learn for Control Valve Troubleshooting Interview

- Understanding Control Valve Principles: Grasp the fundamental operating principles of various control valve types (e.g., globe, ball, butterfly, etc.), including their characteristics and limitations.

- Troubleshooting Methodologies: Familiarize yourself with systematic troubleshooting techniques, such as using flowcharts, process diagrams, and root cause analysis to effectively diagnose valve malfunctions.

- Instrumentation and Diagnostics: Learn how to interpret readings from pressure gauges, flow meters, and other instrumentation to identify the source of control valve problems. Understand the use of diagnostic tools.

- Actuator Issues: Develop a strong understanding of common actuator problems (pneumatic, electric, hydraulic), including troubleshooting techniques specific to each type.

- Valve Positioners: Learn the function and troubleshooting of valve positioners, including calibration and adjustment procedures.

- Leak Detection and Repair: Master techniques for identifying and repairing leaks in various valve components, including packing glands and valve bodies.

- Control Loop Tuning and Optimization: Understand the relationship between control valve performance and overall process control loop optimization. Know how valve characteristics impact loop stability.

- Safety and Maintenance Procedures: Be prepared to discuss safe working practices, lockout/tagout procedures, and routine maintenance tasks related to control valves.

- Common Valve Failures: Study the causes and effects of common control valve failures, such as sticking, cavitation, and erosion.

- Practical Application: Be ready to discuss real-world scenarios where you’ve applied your troubleshooting skills. Examples from past projects or experiences will be highly valuable.

Next Steps

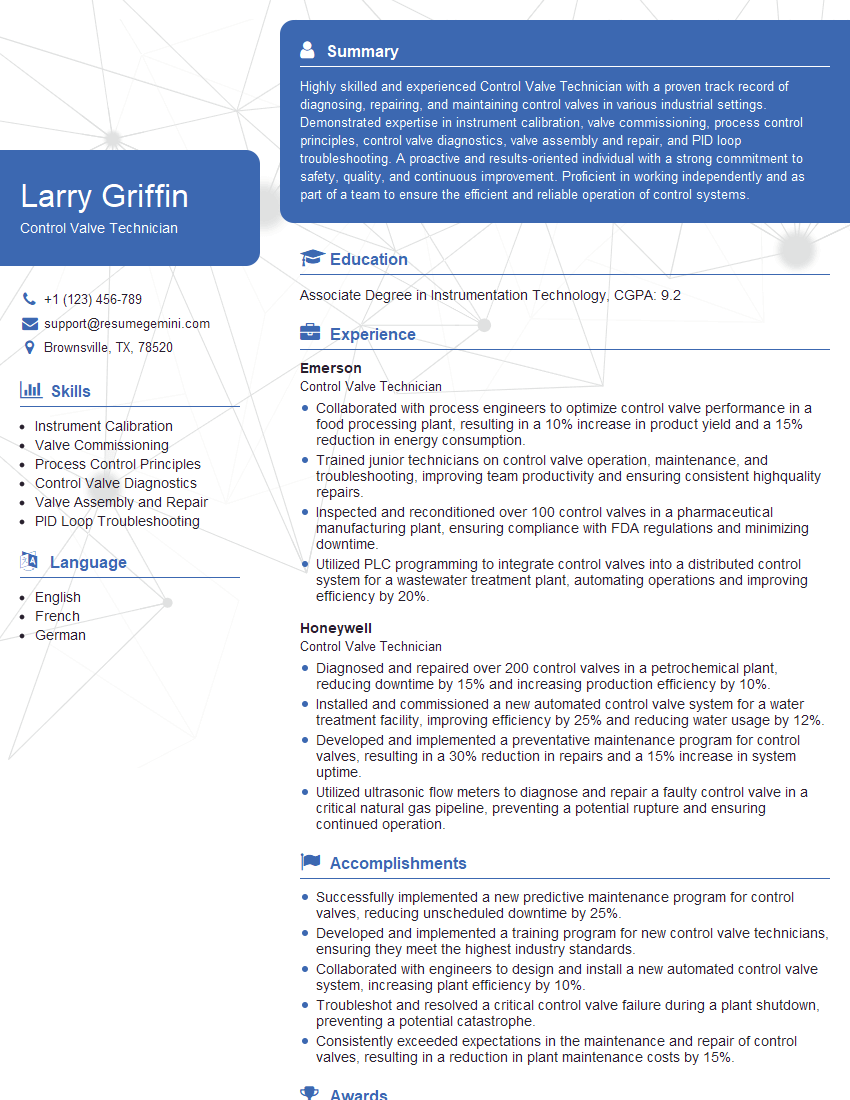

Mastering Control Valve Troubleshooting is crucial for career advancement in process automation and industrial maintenance. A strong understanding of these skills demonstrates technical proficiency and problem-solving abilities highly sought after by employers. To significantly increase your job prospects, focus on crafting an ATS-friendly resume that effectively highlights your skills and experience. ResumeGemini is a trusted resource that can help you build a professional and impactful resume, ensuring your application gets noticed. Examples of resumes tailored to Control Valve Troubleshooting are available to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good