Preparation is the key to success in any interview. In this post, we’ll explore crucial Bindery and Finishing interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Bindery and Finishing Interview

Q 1. Explain the difference between saddle stitch and perfect binding.

Saddle stitch and perfect binding are both common bookbinding methods, but they differ significantly in their construction and suitability for different projects. Think of saddle stitching as stapling, but more refined, and perfect binding as creating a more seamless, professional-looking spine.

Saddle Stitch Binding: This method involves folding sheets of paper in half and securing them through the fold line using wire staples. It’s best suited for documents with a low page count (typically under 64 pages) and a relatively thin paper stock. Magazines, brochures, and booklets often use saddle stitch binding. The resulting product lies relatively flat when open, making it easy to read.

Perfect Binding: This method involves gluing the edges of folded sheets of paper together to create a block. The spine is then roughed up or prepared for adhesion, and a cover is wrapped around the block and glued to the spine. Perfect binding is ideal for books, journals, and publications with higher page counts and heavier paper stock. It offers a more robust and professional finish compared to saddle stitching. Unlike saddle-stitched documents, perfect-bound books have a more noticeable spine and don’t lie as flat when open.

In short, choose saddle stitch for thin, low-page count documents that need to lay flat, and perfect binding for thicker, higher page-count documents requiring a more robust and professional look.

Q 2. Describe your experience with various types of folding machines.

My experience encompasses a wide range of folding machines, from simple hand-fed folders to sophisticated, automated high-speed systems. I’ve worked extensively with:

- Single-fold machines: These are ideal for smaller jobs and simple folding patterns. I’m proficient in adjusting the various paper paths and registration settings to ensure accurate and consistent folds.

- Multiple-fold machines: These machines allow for more complex folding patterns like letter folds, gate folds, and parallel folds. My expertise includes programming these machines to handle different paper sizes and weights efficiently and accurately. I’ve had success troubleshooting jams and maintaining optimal performance, including understanding the impact of paper quality on machine efficiency.

- Rotary folding machines: These high-speed machines are perfect for large-scale projects. I’m experienced in setting up and operating these machines, including performing preventative maintenance and resolving any issues that arise during operation.

I’m also familiar with the intricacies of different paper feeding mechanisms, including friction feeders, air-blast feeders, and sheet-fed systems, and understand how the choice of feeder impacts both speed and the quality of the final fold.

Q 3. What are the common issues encountered during die-cutting and how do you troubleshoot them?

Die-cutting, while producing intricate shapes and designs, presents several common issues. These often relate to the die itself, the materials being cut, or the machine settings.

- Die breakage: This can be caused by dull blades, excessive pressure, or improper material handling. Troubleshooting involves inspecting the die for damage, replacing worn blades, and adjusting the machine pressure. I always ensure proper lubrication and adhere to strict maintenance schedules to prevent this.

- Inconsistent cuts: This might be due to inconsistencies in the material, improper die registration, or uneven pressure. Solutions include checking the material for inconsistencies, adjusting the die registration, and ensuring even pressure across the cutting surface. Careful attention to paper alignment in the machine is crucial.

- Material sticking to the die: This usually happens when the material is too sticky or the die isn’t properly cleaned. Troubleshooting involves using release agents, cleaning the die regularly, and adjusting the cutting pressure. Selecting appropriate materials for the die-cutting process is also crucial.

- Skewing or misalignment: This points to issues with material feeding or machine alignment. This requires careful adjustment of the machine and feed system, potentially checking for any vibrations or inconsistencies.

A systematic approach to troubleshooting, starting with a visual inspection and working through potential causes, is critical to resolving die-cutting issues efficiently. Accurate record-keeping of settings for successful jobs is also very helpful.

Q 4. How do you ensure the quality control of a finished product in bindery?

Quality control in bindery is paramount. My approach involves a multi-stage process encompassing visual inspection, measurement, and testing at various points of production.

- Incoming Material Inspection: I meticulously inspect paper and cover stock for defects like blemishes, inconsistencies, and damage before even beginning the binding process. This minimizes issues down the line.

- Process Monitoring: I continuously monitor the machines to ensure proper settings and consistent output. This includes regular checks of cuts, folds, and glue application.

- Visual Inspection of Finished Products: Each finished product undergoes a thorough visual inspection for any imperfections such as misaligned pages, crooked spines, or damaged covers. A sampling process helps manage volumes efficiently.

- Measurement and Testing: I use precision measuring tools to verify page counts, spine thickness, and other crucial dimensions. I also assess the binding strength by testing the durability of the bond.

- Documentation and Reporting: All quality control findings are documented. This allows for tracking of defects, identifying areas for improvement, and highlighting successful techniques.

By implementing these checks, I ensure that the final product meets the required specifications and maintains the highest quality standards.

Q 5. What safety procedures do you follow when operating bindery machinery?

Safety is my utmost priority when operating bindery machinery. I strictly adhere to the following procedures:

- Personal Protective Equipment (PPE): I always wear appropriate PPE, including safety glasses, gloves, and hearing protection, depending on the machine being used. Safety shoes with steel toes are also essential.

- Machine Guards: I ensure that all machine guards are securely in place before starting any operation to prevent accidental contact with moving parts.

- Lockout/Tagout Procedures: I follow proper lockout/tagout procedures when performing maintenance or repairs on any equipment to prevent accidental start-ups.

- Proper Training: I am fully trained and certified to operate all the bindery machinery I use. I am always vigilant and alert while using the machinery.

- Housekeeping: I maintain a clean and organized workspace to minimize tripping hazards and prevent accidents.

- Emergency Procedures: I’m familiar with the location and use of emergency shut-off switches and fire extinguishers.

By adhering to these safety practices, I create a safe working environment for myself and my colleagues.

Q 6. Explain your experience with different types of paper and their suitability for various finishing techniques.

My experience with different paper types and their suitability for various finishing techniques is extensive. Paper selection significantly impacts the final product’s quality and appearance.

- Coated papers: These papers, with their smooth surface, are ideal for high-quality printing and vibrant colors. They work well with many finishing techniques, including die-cutting, embossing, and foil stamping, but can sometimes be challenging to fold cleanly.

- Uncoated papers: These papers offer a more natural feel and texture. They’re suitable for a wide range of applications but might not be as ideal for sharp, precise die-cutting. They are preferable for applications requiring a rustic or handcrafted look and feel.

- Cardstock: Thicker than standard paper, cardstock is often used for covers and inserts, offering greater durability. It’s excellent for embossing, debossing, and other specialty finishes, but it needs to be carefully considered for the capabilities of particular folding machines.

- Specialty papers: Papers with textures, metallic finishes, or other unique properties require specific finishing techniques. For example, delicate papers may need hand-finishing to avoid damage.

Understanding the properties of different paper types and their interaction with various finishing techniques is crucial for successful project completion. Choosing the right paper based on the design and intended finishing is a key aspect of my work.

Q 7. Describe your experience with troubleshooting malfunctions on a perfect binding machine.

Troubleshooting a perfect binding machine requires a systematic approach and a good understanding of its mechanics. Common issues include:

- Glue application problems: Uneven glue application can lead to pages falling out. I would check the glue tank level, ensure the rollers are clean and properly adjusted, and inspect the glue temperature. I’d also check the uniformity of glue application along the spine.

- Spine preparation issues: Insufficient roughening of the spine can result in a weak bind. I would inspect the roughening mechanism and ensure it is correctly functioning and operating at optimum performance.

- Cover misalignment: Incorrect positioning of the cover can cause an uneven finish. Careful adjustment of the cover placement mechanisms is necessary.

- Mechanical malfunctions: Issues like a jammed mechanism might require careful diagnosis and possible parts replacement. Safety procedures are always followed, and any repairs that require more than basic knowledge and expertise are always handled by qualified technicians. I would thoroughly investigate the cause of any jam, noting paper feed issues as a primary cause.

My approach involves systematically checking each component, starting with the simplest solutions before moving to more complex repairs. Thorough cleaning and lubrication of the machine are also key preventative measures.

Q 8. How do you calculate the cost-effectiveness of different binding methods?

Calculating the cost-effectiveness of different binding methods requires a multifaceted approach, going beyond simply comparing the price per unit of each binding type. We need to consider factors such as production volume, material costs, labor costs, equipment amortization, and the desired quality and longevity of the final product.

For example, saddle stitch binding is incredibly cheap for low-volume projects with a relatively low page count. However, its suitability is limited by page number and the inability to use heavier paper stock. Perfect binding, on the other hand, is more expensive per unit but allows for higher page counts and more diverse paper choices. It’s far more cost-effective than saddle stitch for larger projects.

A thorough cost analysis would involve:

- Material Costs: This includes the cost of the cover stock, paper, adhesives, and any other materials specific to the binding method.

- Labor Costs: The time required for each step of the binding process, including setup, operation, and finishing touches.

- Equipment Costs: Amortization of equipment costs over its lifespan, factoring in maintenance and repairs.

- Waste Calculation: Quantifying materials wasted during the process which directly impacts profitability.

- Volume Consideration: Cost per unit generally decreases with higher volume. We need to factor in potential economies of scale.

By meticulously evaluating these factors, we can create a comparative cost analysis for each binding method, allowing us to choose the most cost-effective option for a given project.

Q 9. What is your experience with different types of laminating?

My experience encompasses both thermal and UV laminating. Thermal lamination involves using heat to activate an adhesive layer on a plastic film, fusing it to the printed material. This process is excellent for documents requiring protection from minor scuffs and moisture, while offering a relatively matte finish. It’s ideal for projects where a more tactile, less glossy surface is preferred.

UV laminating, however, utilizes ultraviolet light to cure a liquid adhesive, creating a highly durable, glossy finish. UV lamination provides superior scratch and UV protection, making it perfect for projects requiring long-term durability and a high-quality, vibrant look, such as high-end brochures or books that are meant to be kept for many years. It results in a noticeably glossy finish.

The choice between thermal and UV lamination depends entirely on the project’s requirements. In my experience, I’ve worked extensively with both, selecting the appropriate method depending on budget constraints, desired aesthetic appeal, and the level of protection needed for the finished product.

Q 10. How do you maintain and clean bindery equipment?

Maintaining and cleaning bindery equipment is crucial for optimal performance and longevity. A regular preventative maintenance schedule is essential, tailored to the specific equipment in use. This includes daily, weekly, and monthly cleaning and inspection routines.

Daily Maintenance: This usually involves removing debris and paper scraps from the machine, checking for any signs of malfunction or wear and tear, and lubricating moving parts as needed. For example, a three-hole punch needs to be routinely checked for paper jams and its cutting mechanism cleaned of stray paper fibers that can dull the punches.

Weekly Maintenance: More in-depth cleaning might be required, including a thorough cleaning of all components with appropriate cleaning solutions. This could involve disassembling certain parts for a more thorough cleaning, depending on the machine and manufacturer’s guidelines.

Monthly Maintenance: This often involves inspections by a trained technician, who can perform more complex maintenance tasks, lubricate components, and identify potential problems before they escalate. The frequency of these inspections depends on usage and wear.

Proper cleaning and maintenance procedures significantly extend the lifespan of the equipment, reducing downtime and preventing costly repairs.

Q 11. What are the different types of covers used in bookbinding?

The choice of cover for a book greatly impacts its overall look, feel, and durability. Several types of covers are used, each serving a different purpose and offering a unique aesthetic.

- Paperboard Covers: These are economical options, offering sufficient protection for lower-priced books or publications. They come in various weights and finishes.

- Hardcover Covers: These are more durable and offer superior protection. They are usually made of heavier paperboard or cloth-covered boards. Hardcover covers provide a more premium feel and better longevity, often employed in high-end books and textbooks.

- Leatherette Covers: These mimic the look and feel of leather at a fraction of the cost. They offer a stylish and durable option suitable for a variety of applications.

- Leather Covers: These are premium covers known for their durability, luxurious appearance, and tactile appeal. They’re the epitome of luxury binding but are significantly more expensive.

- Soft Covers: Also known as paperback covers, these are typically made from paper or thin cardstock, offering an economical option for mass-market books or magazines.

The selection of the cover material is made based on the budget, expected lifespan, and the desired aesthetic of the final product. For instance, a high-end art book might use a leather cover, while a paperback novel would use a cheaper paper cover.

Q 12. How familiar are you with different types of adhesives used in bookbinding?

Various adhesives are employed in bookbinding, each possessing unique properties that make them suitable for specific applications. The choice depends on factors like bond strength, drying time, flexibility, and resistance to moisture and temperature variations.

- Polyvinyl Acetate (PVA) Emulsions: These are water-based adhesives, commonly used in perfect binding. They are economical, relatively easy to use, and provide good adhesion. Their water solubility can be a limitation in humid conditions.

- Hot Melt Adhesives: These are thermoplastic adhesives that are applied in a molten state and solidify upon cooling. They offer rapid bonding and high strength, useful in case binding and certain types of perfect binding.

- Animal Glues: Historically widely used, these are now less common due to their cost and sensitivity to moisture. They offer excellent bond strength but require longer drying times.

- PUR (Polyurethane Reactive) Adhesives: These are high-performance adhesives that form strong, flexible bonds, resistant to moisture and degradation. They’re frequently used in demanding applications needing superior durability.

My experience includes working with all these types of adhesives, selecting the appropriate one based on the project specifications and the binding method employed. For instance, PUR adhesives are frequently chosen for high-quality, long-lasting books, while PVA emulsions are often selected for perfect binding of larger runs due to their cost-effectiveness.

Q 13. Explain the process of three-hole drilling and its application.

Three-hole drilling is a common bindery process that creates three equidistant holes along the spine of a document, typically for insertion into a binder mechanism. It’s essential for creating documents that need to be easily opened and closed repeatedly, allowing pages to lay flat while also providing a secure binding method.

The process involves using a three-hole punch machine with precisely aligned punches. Documents are aligned correctly on the machine and the lever is engaged to punch the holes simultaneously. The distance between holes is standardized to ensure compatibility with most binder mechanisms. The hole spacing depends on the size of the document being prepared. A common standard for letter-sized documents is 1.5 inches apart.

Applications:

- Report Binding: Three-hole punching is the standard for office reports, allowing easy insertion into ring binders.

- School Work: Binders and three-hole punched folders are commonly used in schools for organization of paperwork.

- Document Archiving: Three-hole punching allows documents to be easily stored and retrieved from archival binders.

Accuracy in hole placement is vital for seamless binder operation. An improperly punched document can lead to binding difficulties or even damage to the binder.

Q 14. What is your experience with automated bindery equipment?

I possess significant experience operating and maintaining various automated bindery equipment, including high-speed perfect binders, saddle stitchers, three-hole punching machines, and automated cutting and folding systems. Automation significantly increases production efficiency and consistency compared to manual processes.

For example, working with an automated perfect binder involves setting up the machine to the correct specifications for the project (cover size, page count, adhesive type, etc.). The machine automatically feeds the pages, applies adhesive, and applies the cover. This reduces human error and increases the speed of production drastically. Similarly, high-speed saddle stitchers are capable of processing thousands of brochures per hour.

My experience also includes troubleshooting automated equipment, conducting routine maintenance, and ensuring optimal performance. This includes regular calibrations and preventative maintenance checks to prevent costly downtime. Proficiency in automated bindery equipment is crucial for handling large-scale printing projects efficiently and effectively.

Q 15. Describe your experience with working with different substrates beyond paper (e.g., plastic, cardstock).

My experience extends beyond traditional paper substrates to encompass a wide range of materials used in bindery and finishing. I’ve worked extensively with various plastics, including PVC and polypropylene, for applications such as brochures, point-of-sale displays, and durable menus. These often require specialized techniques to ensure proper adhesion and prevent damage during the finishing process. Similarly, I’m proficient in handling different weights and types of cardstock, from standard index cards to thick, textured boards used in high-end packaging. This includes understanding the unique properties of each material, such as its thickness, rigidity, and susceptibility to scoring or creasing, to choose the most appropriate finishing techniques.

For instance, when working with thick cardstock for premium invitations, I might use a heavier-duty die-cutting machine and a more robust scoring wheel to ensure clean, crisp cuts and folds without cracking the material. Conversely, when working with thinner plastics, I’d adjust the pressure and speed of the cutting or creasing tools to prevent warping or tearing. The key is adaptability and a deep understanding of the material’s behavior under different stresses.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you manage production schedules in a busy bindery environment?

Managing production schedules in a fast-paced bindery is all about organization, prioritization, and effective communication. I utilize project management software to track all incoming jobs, their due dates, and resource allocation. This allows for a clear visual representation of the workflow, helping anticipate bottlenecks and potential delays. For example, I’ll often use a Kanban board to visualize the progress of each project through the various stages of the bindery process.

Critical to this process is proactive communication with the client. If I foresee a potential delay, I’ll immediately notify the client and propose alternative solutions, maintaining transparency throughout. Within the team, daily stand-up meetings are crucial to address any immediate issues, share updates, and ensure everyone is aligned on priorities. We also regularly review our efficiency metrics to identify areas for improvement and optimize our workflow to handle the busy periods smoothly.

Q 17. How do you handle customer complaints related to finishing quality?

Handling customer complaints regarding finishing quality requires a calm, professional approach. The first step is to actively listen to the client’s concerns, acknowledging their frustration and demonstrating empathy. Then, I carefully examine the finished product, comparing it to the original specifications and identifying the source of the issue.

This often involves checking for inconsistencies in cutting, folding, binding, or other finishing processes. Once the root cause is identified, I work collaboratively with the client to find a suitable solution. This could involve reworking the affected items, offering a partial refund, or providing a discount on future orders. Detailed documentation of the issue, resolution, and customer feedback is crucial for continuous improvement. It’s important to view customer complaints not just as problems, but as opportunities to improve our processes and prevent similar issues in the future.

Q 18. Describe your experience with different types of cutting machines and their applications.

My experience encompasses a variety of cutting machines, each suited for different applications. I’m proficient with guillotine cutters for precise, straight cuts of large quantities of paper or cardstock. These are ideal for trimming pages to a specific size or preparing materials for binding. I also have extensive experience with die-cutting machines, which allow for intricate shapes and designs, perfect for creating custom packaging, invitations, or promotional materials. These machines utilize custom-made dies to cut, emboss, or deboss materials, providing highly versatile finishing options.

Furthermore, I’m familiar with rotary cutters, often used for cutting continuous rolls of materials, such as labels or stickers, and smaller, more specialized cutters for tasks such as scoring, perforating, or creasing. The choice of machine depends entirely on the project’s specific requirements. For example, a guillotine cutter is efficient for large-scale trimming, but a die-cutting machine is essential for complex, custom shapes. A strong understanding of each machine’s capabilities allows for optimized workflow and selection of the right tool for the job.

Q 19. How do you ensure the accurate alignment of pages during the finishing process?

Accurate page alignment is paramount in the finishing process. Several techniques contribute to achieving this. Firstly, precise imposition during the printing stage is essential. This involves carefully arranging pages on the printing sheet to minimize the need for excessive manipulation during finishing. Secondly, using high-quality imposition software helps to create precise templates, ensuring pages are correctly aligned prior to printing.

During the binding process, machines like perfect binders and saddle stitchers often have built-in mechanisms for page alignment. Regular maintenance and calibration of these machines are crucial to ensure their continued accuracy. For manual processes such as folding, experienced operators play a significant role in visually checking and adjusting alignment. Regular quality checks throughout the finishing process, including random sampling and visual inspections, help to identify and rectify any alignment issues before they become major problems. Finally, employing quality control measures to address any discrepancies ensures the final product meets the highest standards.

Q 20. What are the key performance indicators (KPIs) you monitor in a bindery setting?

Key Performance Indicators (KPIs) in a bindery setting focus on efficiency, quality, and cost-effectiveness. These include:

- Throughput: The number of jobs completed per unit of time (e.g., jobs per hour or per day). This measures the overall productivity of the bindery.

- On-time delivery rate: The percentage of jobs delivered on or before their scheduled due date, reflecting the bindery’s reliability.

- Waste reduction: The amount of material waste generated during the finishing process, indicating efficiency in material usage.

- Defect rate: The percentage of finished products with defects, showcasing the quality of the work performed. A low defect rate is essential.

- Machine uptime: The percentage of time that machinery is operational, showing the efficiency of equipment usage.

- Cost per job: The overall cost associated with completing a specific job, highlighting cost efficiency.

Regular monitoring of these KPIs helps identify areas for improvement, optimize processes, and maintain a high standard of efficiency and quality.

Q 21. How do you handle large-volume finishing projects efficiently?

Handling large-volume finishing projects efficiently requires careful planning and execution. This begins with a thorough review of the project specifications, including the quantity, type of finishing required, and the available resources. Breaking down the project into smaller, manageable tasks makes it easier to allocate resources effectively and track progress. For example, instead of tackling the entire project at once, we might divide it into batches for cutting, folding, and binding, assigning specific teams or machines to each task.

Automation plays a crucial role. Utilizing automated equipment, such as high-speed collators, perfect binders, and folding machines, significantly increases throughput. Lean manufacturing principles can further improve efficiency by eliminating waste and streamlining processes. Finally, proactive communication with the client throughout the project, including regular updates on progress and any potential challenges, ensures a smooth and efficient execution, leading to timely delivery.

Q 22. Describe your experience with pre-flighting and quality assurance checks in bindery operations.

Pre-flighting in bindery operations is crucial for ensuring a smooth and efficient process. It’s essentially a quality assurance check performed before the actual bindery process begins. This involves verifying that the printed sheets are correctly collated, the imposition is accurate, and that the document is ready for the chosen finishing method. Think of it like a pilot pre-flighting an airplane – checking everything before takeoff to prevent issues in the air.

My experience encompasses a multi-faceted approach to pre-flighting. This includes visually inspecting the printed sheets for defects, ensuring proper page order, verifying the accuracy of signatures (sets of pages folded together), and checking for any inconsistencies that might hinder downstream processes. I utilize both manual checks and automated software solutions (discussed in the next question) to perform thorough pre-flighting to minimize errors and waste. For example, I’d carefully review a 32-page booklet to ensure that pages 1-32 are in the correct order and that there are no missing pages or misprints before sending it to the folding machine.

Quality assurance goes beyond pre-flighting. It involves ongoing monitoring throughout the bindery process, including regular checks on the finished product for quality, accuracy and consistency. This may involve spot-checking finished products for proper binding, folding, trimming, and overall presentation. Identifying potential problems early, during pre-flighting or throughout the process, prevents costly rework and maintains high standards for the client.

Q 23. What software programs are you familiar with for bindery operations or related tasks?

I’m proficient in several software programs relevant to bindery operations and related tasks. These include:

- Pre-press software: Such as Adobe Acrobat Pro, for checking PDF files for errors and making adjustments. This includes checking bleeds, color profiles, and ensuring the document is correctly formatted for the intended finishing process.

- Bindery-specific software: Some high-speed finishing equipment comes with its own software for setup, job management and monitoring, allowing for efficient programming of the machine for different jobs.

- MIS (Management Information Systems): I have experience using MIS systems to track jobs, manage inventory, and generate reports on production efficiency and costs. These systems help optimize resource allocation and streamline workflow within the bindery.

- Spreadsheet software (Excel, Google Sheets): Crucial for tracking materials, costs, and scheduling. I’ve frequently used spreadsheets to create production schedules, calculate materials needed, and track job progress.

Familiarity with these tools allows me to efficiently manage jobs, predict potential issues, and optimize the overall workflow for maximum efficiency and quality.

Q 24. How would you resolve a jam in a high-speed folding machine?

Resolving a jam in a high-speed folding machine requires a systematic approach, prioritizing safety. The first step is to always turn off the machine and ensure it’s completely powered down before attempting any intervention. Safety is paramount – never reach into a running machine.

Next, I would:

- Identify the location of the jam: Carefully examine the machine to pinpoint where the paper is jammed. High-speed folders often have multiple rollers and folding sections.

- Access the jammed area: Most machines have access panels to allow safe access to the internal mechanisms.

- Carefully remove the jammed paper: Use appropriate tools, like tweezers or a soft brush, to gently remove the jammed paper. Avoid tearing or creasing the paper, as this can damage the machine.

- Inspect for damage: After removing the jam, thoroughly inspect the rollers, belts and other components for any damage caused by the jam.

- Clear any debris: Remove any small pieces of paper or debris that might remain in the machine.

- Test the machine: Before resuming operation, run a small test batch to ensure the machine is functioning correctly.

If I am unable to resolve the jam, I would consult the machine’s manual or seek assistance from a qualified technician.

Q 25. What is your understanding of different finishing processes for digital printing versus offset printing?

Finishing processes differ slightly between digital and offset printing, primarily due to the differences in the printing methods themselves. Offset printing typically involves larger print runs and often uses heavier paper stocks, leading to a wider array of finishing options. Digital printing, known for its shorter runs and faster turnaround, may have limitations on certain heavier processes.

Offset Printing Finishing: Often includes more extensive and heavy-duty processes, such as:

- Perfect Binding: Common for books and magazines, involves gluing the edges of the pages together.

- Saddle Stitch Binding: Used for booklets and brochures, pages are folded and stapled along the spine.

- Case Binding: A more robust method, used for hard-cover books, involves applying a cover to the text block.

- Wire-O Binding: Uses metal wire to bind pages together, creating a durable and lay-flat document.

Digital Printing Finishing: While many of the above options are also available, digital printing often favors processes like:

- Cutting and Creasing: Precise cutting and creasing to create unique shapes and folds for smaller-scale projects.

- Die-cutting: Creating custom shapes and designs in paper stock.

- Folding: Various folding patterns, including simple parallel folds to complex Z-folds and gate-folds.

- Lamination: Applying a protective film for durability and visual appeal.

The choice of finishing method depends on the specific project requirements, print run size, budget, and desired aesthetic.

Q 26. Explain the importance of proper setup and adjustment of bindery equipment.

Proper setup and adjustment of bindery equipment is absolutely critical for quality, efficiency, and safety. Improper setup can lead to misaligned folds, inaccurate cuts, poor binding, increased waste, and even machine damage. Think of it like tuning a musical instrument; it needs precise calibration to perform optimally.

Proper setup includes:

- Correct paper feeding: Ensuring the paper is fed correctly and consistently to prevent jams and misfeeds.

- Accurate adjustments of cutting guides and rollers: Precise adjustments are essential for accurate cuts and consistent folds.

- Calibration of folding sections: Each folding section needs precise adjustment to create crisp, well-defined folds.

- Regular maintenance: Regular lubrication, cleaning, and inspection of components help prevent malfunctions and extend the life of the equipment.

By diligently following the manufacturer’s instructions and performing regular checks, you minimize errors and optimize the performance of the bindery equipment. This ultimately leads to reduced waste, higher-quality output, and increased production efficiency.

Q 27. How familiar are you with waste reduction strategies in the bindery process?

Waste reduction in bindery operations is a significant concern, both environmentally and economically. My approach to waste reduction integrates various strategies:

- Accurate job planning and pre-flighting: Minimizes errors early in the process, reducing the need for re-runs and wasted materials.

- Efficient job scheduling and sequencing: Optimizes workflow, minimizing downtime and maximizing production.

- Careful monitoring and adjustments: Continuous monitoring of the machines helps identify potential problems quickly, limiting waste.

- Proper maintenance of equipment: Well-maintained equipment operates more efficiently, reducing waste due to machine malfunctions.

- Effective material management: Proper storage and handling of materials prevents damage and spoilage.

- Using software and data analytics to identify bottlenecks and improve workflow: Allows to make data-driven decisions to reduce waste.

- Recycling programs: Implementing a robust recycling program for paper scraps and other waste materials.

Waste reduction isn’t just about saving money; it’s about being environmentally responsible. By implementing these strategies, we create a sustainable bindery operation that minimizes environmental impact while improving profitability.

Q 28. Describe a situation where you had to adapt quickly to a change in the bindery process.

In one instance, we experienced a sudden and unexpected change in a large-scale book binding project. The client unexpectedly requested a change in the binding method from perfect binding to case binding, just a few days before the scheduled completion date. This required a complete shift in our workflow and machinery usage.

To adapt quickly, I first collaborated with the team to assess the feasibility of the change within the tight deadline. We re-evaluated the schedule, adjusting tasks and prioritizing the necessary steps. We then quickly trained the team on the new case binding procedures. This included hands-on practice and reviewing the specific requirements for the new binding method. We also coordinated with our suppliers to ensure timely delivery of the additional materials required for case binding.

By effectively communicating with the team and implementing a revised strategy, we were able to successfully complete the project on time and to the client’s satisfaction, demonstrating flexibility and adaptability under pressure.

Key Topics to Learn for Bindery and Finishing Interview

- Gathering and Preparing Materials: Understanding different paper types, weights, and finishes; preparing materials for efficient processing.

- Folding Techniques: Mastering various folding methods (e.g., letter fold, gate fold, parallel fold); troubleshooting folding machine issues.

- Stitching and Binding: Knowledge of different binding methods (e.g., saddle stitch, perfect bind, wire-o); understanding the strengths and limitations of each method.

- Cutting and Trimming: Operating cutting and trimming machines; ensuring accuracy and precision in cutting; understanding safety protocols.

- Finishing Processes: Familiarity with lamination, coating, embossing, and other finishing techniques; understanding their applications and effects.

- Quality Control: Inspecting finished products for defects; understanding quality standards and implementing corrective actions; utilizing quality control tools and processes.

- Machine Operation and Maintenance: Basic troubleshooting and preventative maintenance of common bindery and finishing equipment; understanding safety procedures.

- Production Planning and Scheduling: Understanding workflow optimization; estimating production times and resource allocation.

- Workflow Efficiency and Problem Solving: Identifying bottlenecks in the production process; proposing solutions to improve efficiency and reduce waste.

- Safety Regulations and Procedures: Adherence to safety regulations in a bindery and finishing environment; understanding and applying safe operating procedures for all machinery.

Next Steps

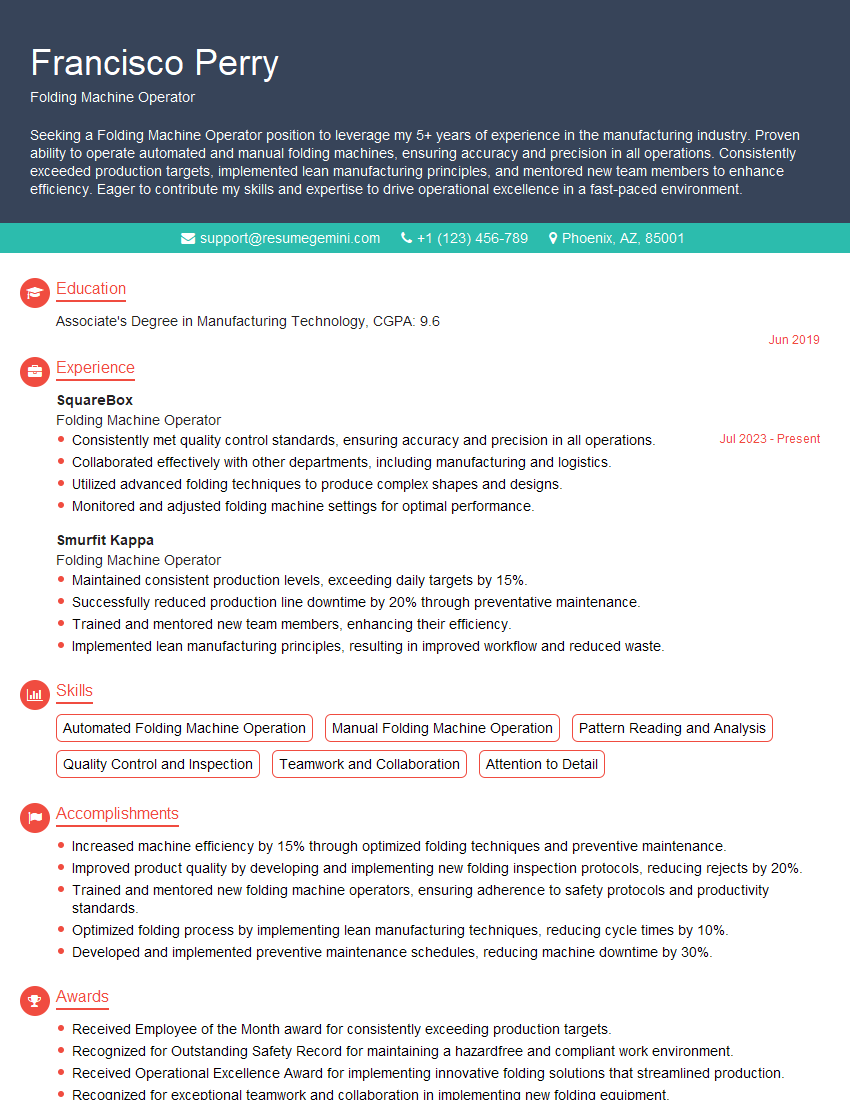

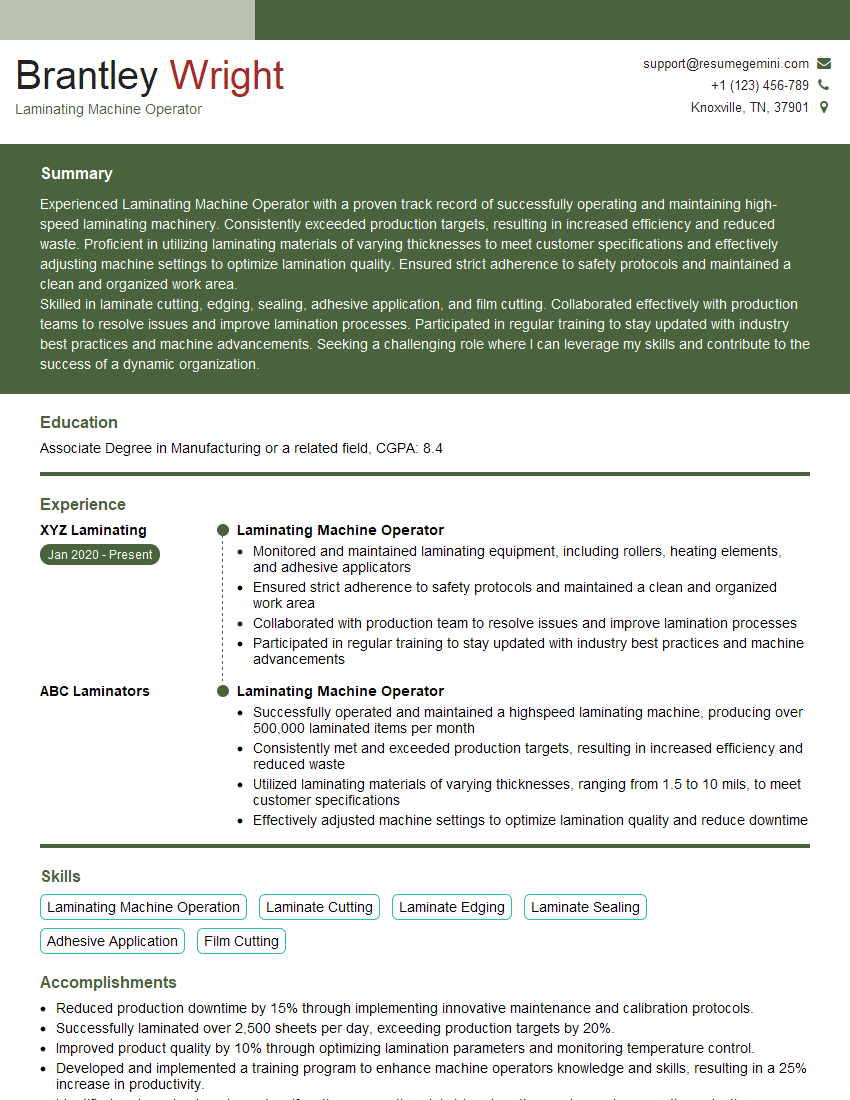

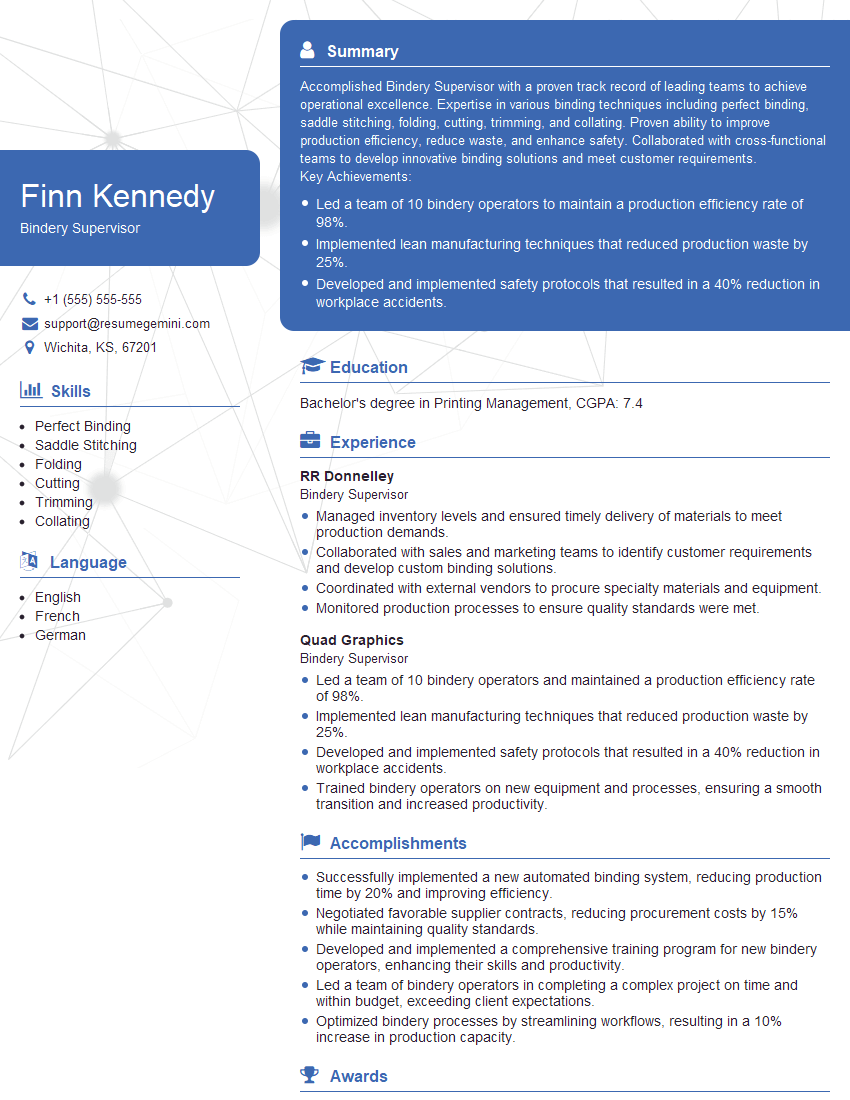

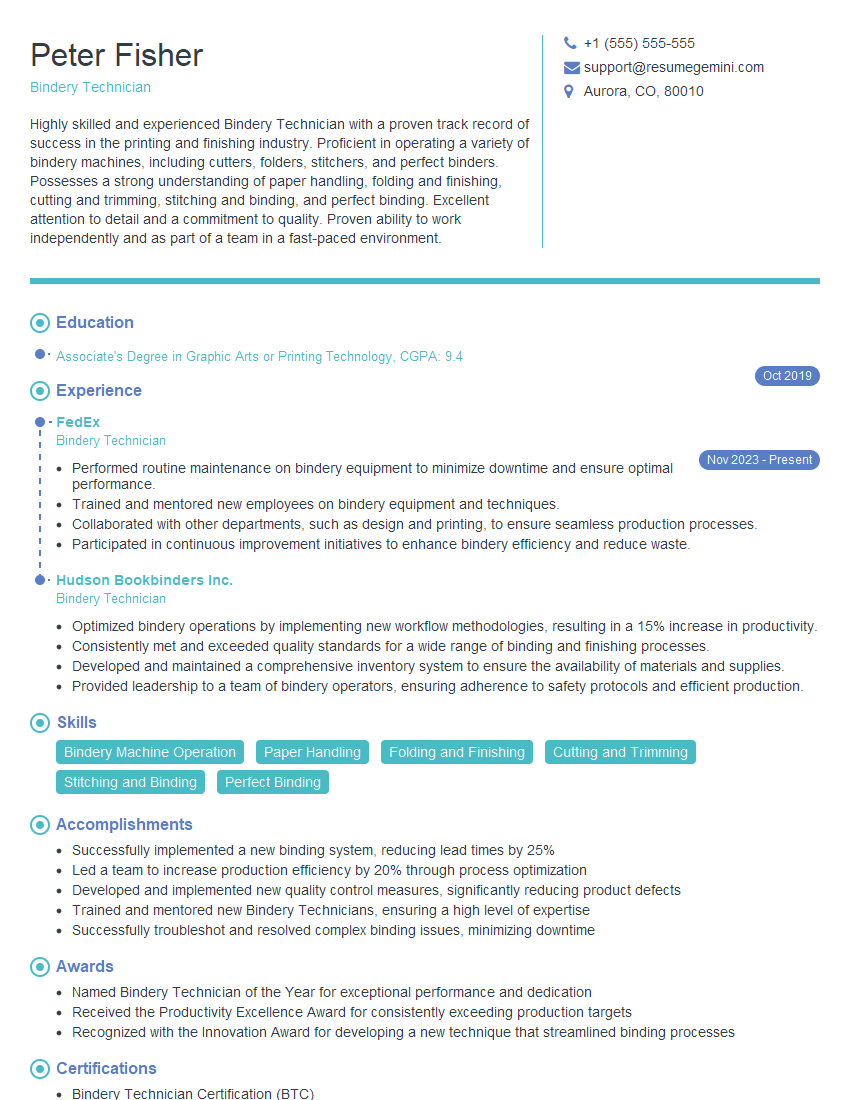

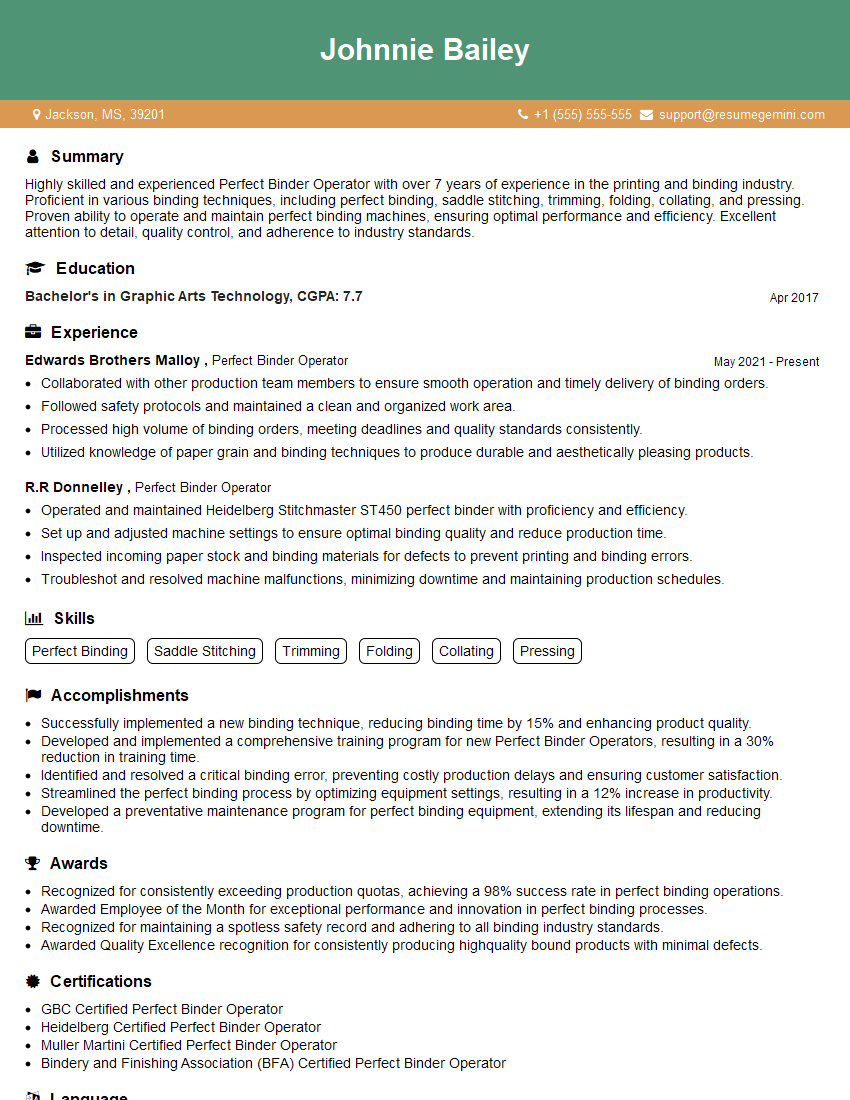

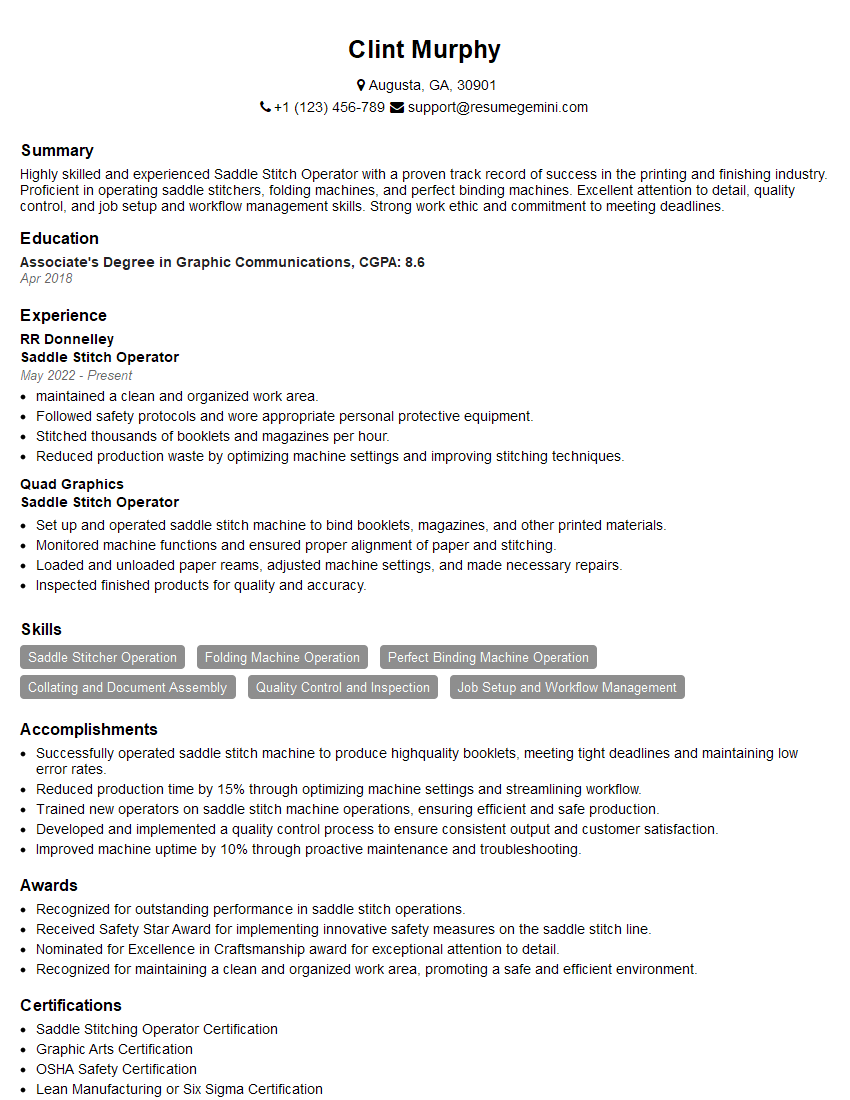

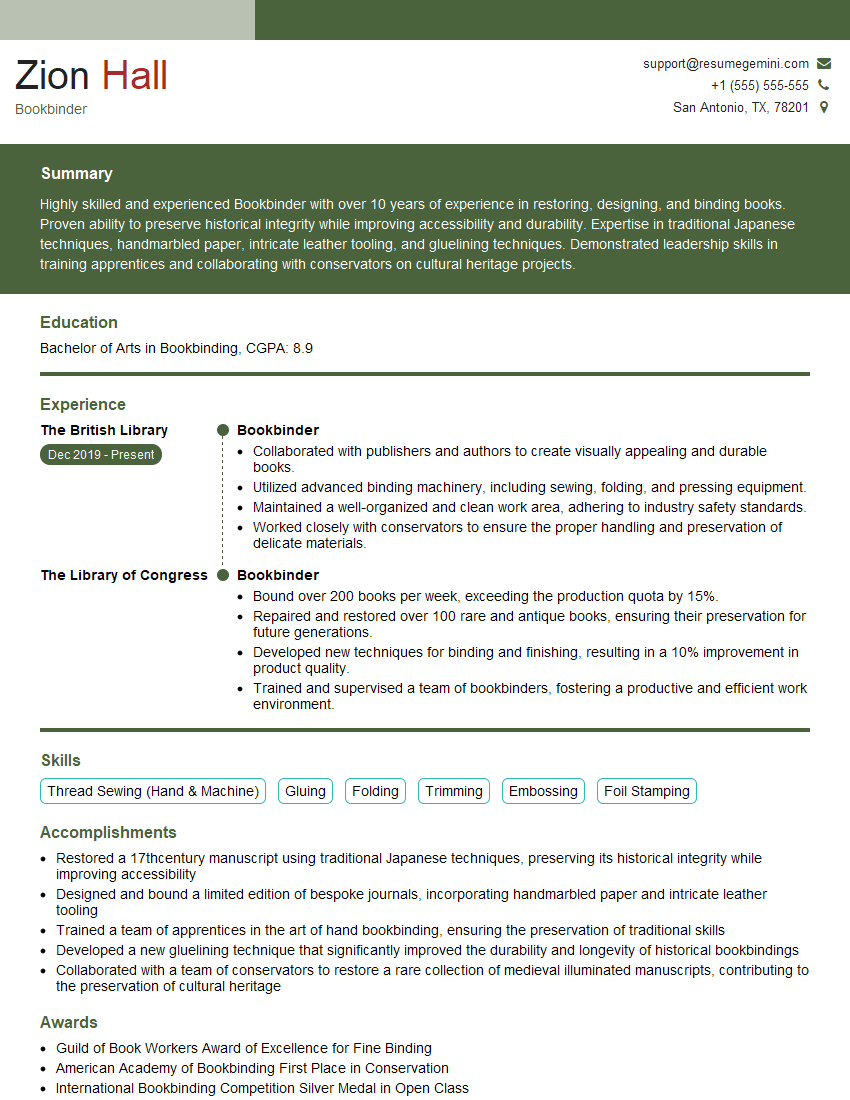

Mastering Bindery and Finishing opens doors to a rewarding career with excellent growth potential within the printing and publishing industries. To maximize your job prospects, create a compelling and ATS-friendly resume that highlights your skills and experience. ResumeGemini is a trusted resource that can help you build a professional resume that stands out. They provide examples of resumes tailored to Bindery and Finishing to guide you. Investing time in crafting a strong resume is a crucial step in securing your dream job in this exciting field.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good