The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Kodak Prinergy Workflow interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Kodak Prinergy Workflow Interview

Q 1. Explain the architecture of the Kodak Prinergy Workflow system.

Kodak Prinergy Workflow is a modular system, meaning its architecture is built from interconnected components that can be customized to fit various printing needs. Think of it like a sophisticated assembly line for print production. At its core, it uses a client-server model. The server manages the workflow engine, the database, and all the processing components, while clients (usually workstations) interact with the server to submit jobs, monitor progress, and perform other tasks.

- Job Submission Stations: These are the workstations where pre-press operators submit jobs, preparing files for printing. They can be integrated with other software applications.

- Workflow Engine: This is the ‘brains’ of the operation. It orchestrates the entire process, routing jobs through various modules based on pre-defined rules and settings.

- Prepress Modules: These modules handle tasks like color management, trapping, imposition, and screening. Each module is independent but communicates seamlessly with the workflow engine.

- Device Integration: Prinergy connects directly to various output devices (CTP platesetters, digital presses) using JDF/JMF (Job Definition Format/Job Messaging Format) for automated communication and data transfer.

- Database: Stores job information, user settings, and other crucial data for tracking and reporting.

- Management Console: A central interface for administrators to manage the system, monitor jobs, and configure settings.

This modular design allows for scalability and flexibility. A small print shop might only need a basic setup, while a large enterprise might require a highly customized, complex system with multiple servers and workstations.

Q 2. Describe your experience with Prinergy’s color management tools.

My experience with Prinergy’s color management tools is extensive. I’ve worked with its robust profile-based color management system extensively, creating and maintaining ICC profiles for various substrates and printing devices. This ensures accurate color reproduction across the entire workflow, minimizing variations between proofing and final prints. I’m proficient in using Prinergy’s tools to manage color spaces, apply color transformations, and perform color proofing. For example, I’ve successfully implemented a G7 calibrated workflow in several print environments, significantly improving color consistency and reducing color discrepancies.

I’ve also utilized Prinergy’s tools for spectral color measurement data integration. This allows for very precise color matching by importing spectral data from spectrophotometers, enabling more accurate color control, especially crucial for critical color applications like packaging printing.

Q 3. How do you troubleshoot common Prinergy workflow errors?

Troubleshooting Prinergy errors requires a systematic approach. I typically start by reviewing the error logs, which provide valuable clues about the source of the problem. This is akin to looking at a car’s diagnostic trouble codes. These logs contain information on the time, date, and location of the error, as well as specific error codes.

- Check the Error Logs: Examine the Prinergy server and client logs for specific error messages and timestamps.

- Verify Job Settings: Ensure that the job settings (e.g., color space, resolution, output device) are correctly configured. Incorrect settings are a common source of errors.

- Inspect Input Files: Examine the input files for potential issues like corrupted data, missing fonts, or unsupported file formats. A simple visual inspection can reveal issues such as missing images.

- Check Device Status: Verify the status of the connected output devices (CTP, digital press) to ensure they’re online and functioning correctly. A simple ping test can confirm connectivity.

- Restart Services: If necessary, restart the relevant Prinergy services or the entire server. This often resolves temporary glitches.

- Contact Kodak Support: For complex or persistent errors, contact Kodak’s support team. They have access to advanced diagnostic tools.

Experience allows for quicker identification of the source. For example, frequent ‘out of memory’ errors often suggest the need for server upgrades.

Q 4. What is your experience with Prinergy Connect?

Prinergy Connect is a web-based interface that provides remote access and monitoring capabilities for the Prinergy workflow. It enables users to submit jobs, check job status, and view reports from anywhere with an internet connection. This is particularly beneficial for collaborative projects or when managing multiple print sites. I have used Prinergy Connect to oversee the progress of jobs across different locations, providing real-time feedback and resolving potential bottlenecks remotely.

I’ve used Prinergy Connect’s reporting features to track key performance indicators (KPIs), such as job turnaround time and resource utilization. This data has been invaluable for optimizing workflow efficiency. For example, by analyzing reports showing consistent delays in a particular prepress module, we identified the need for increased server resources to improve overall throughput.

Q 5. Explain your understanding of Prinergy’s imposition capabilities.

Prinergy offers powerful imposition capabilities, enabling the creation of complex layouts for various sheet sizes and printing configurations. It provides a wide range of pre-built imposition templates for common formats, and also allows the creation of custom templates for specific requirements. Think of it as a sophisticated ‘page arrangement’ tool, far beyond simple page-by-page printing.

I’ve used Prinergy’s imposition tools to create layouts for various applications, including books, brochures, and packaging. The software’s ability to handle different page sizes, orientations, and imposition schemes (e.g., signatures, saddle-stitch) is key. The software’s ability to automatically generate imposition plans, including bleed, gutter, and other finishing requirements, significantly speeds up the prepress process, reducing manual effort and potential errors.

For example, creating a 64-page book requires careful planning to minimize waste and maximize efficiency. Prinergy’s imposition tools enable quick and accurate generation of the necessary imposition plan, ensuring the final product is printed correctly and cost-effectively. The ability to preview the imposition before sending the job to the platesetter is also crucial in preventing errors.

Q 6. Describe your experience with JDF/JMF in a Prinergy environment.

JDF/JMF (Job Definition Format/Job Messaging Format) is the backbone of automated communication within Prinergy and between Prinergy and connected devices. JDF is a standard for describing a job’s specifications (e.g., file types, color space, imposition), while JMF handles the communication and data transfer between components. Imagine it as a universal language for the entire print workflow. It facilitates seamless integration and automation.

In a Prinergy environment, JDF/JMF allows for automated job routing, status updates, and data transfer. This eliminates manual intervention and reduces the risk of errors. For example, when a job is submitted to Prinergy, the JDF describes all aspects of the job, allowing the workflow engine to automatically route it through the appropriate modules without manual intervention. Similarly, JMF provides real-time updates on the job’s progress, alerting operators of any issues.

My experience includes configuring JDF/JMF connections with various devices like platesetters and digital presses. This includes troubleshooting connection issues, customizing JDF definitions to accommodate specific device requirements, and ensuring that all devices communicate effectively within the workflow.

Q 7. How do you manage and maintain color consistency across different printing devices using Prinergy?

Maintaining color consistency across different printing devices is crucial for achieving consistent results. Prinergy facilitates this through a combination of techniques, primarily relying on calibrated color profiles and standardized color workflows.

- ICC Profile Creation and Management: Accurate ICC profiles for each device (presses, platesetters, proofers) are essential. These profiles characterize the color characteristics of each device, ensuring that color appears consistently across the workflow.

- G7 Calibration: Adopting G7 (a standardized color calibration methodology) helps ensure consistent color across different printing devices, minimizing visual differences and enhancing reproducibility. I’ve successfully implemented G7 workflows across multiple print operations.

- Color Proofing: Soft proofing (on screen) and hard proofing (physical prints) are vital for verifying color accuracy before final printing. This allows for adjustments before committing to a large-scale print run.

- Device-to-Device Calibration: By carefully aligning the color reproduction characteristics of different devices, the overall color consistency improves. This often involves fine tuning the profiles to achieve a balance.

- Regular Monitoring and Adjustment: Color consistency isn’t a ‘set and forget’ process. Regular monitoring and occasional recalibration of profiles are needed to maintain accuracy due to environmental factors and device wear.

For example, I’ve successfully implemented a process where, on a regular schedule, test prints are made on each device and compared to ensure minimal deviations from the target color profile. This helps to proactively identify and address potential color variations before they become a major problem.

Q 8. Explain your experience with Prinergy’s automated workflow features.

Prinergy’s automated workflow is the backbone of efficient large-scale print production. It streamlines tasks from initial job submission to final output, minimizing manual intervention and maximizing productivity. Think of it as an automated assembly line for print jobs. My experience encompasses leveraging features like automated imposition, preflighting, color management, and job ticketing. For example, I’ve implemented automated rules in Prinergy that automatically select the correct imposition scheme based on the job specifications (e.g., sheet size, number of pages, and product type). This prevents human error and ensures consistency. Another example involves setting up automated preflight profiles that identify potential problems – like missing fonts or low-resolution images – early in the process, avoiding costly reprints. This automation significantly reduces turnaround time and allows for efficient resource allocation.

Q 9. How do you handle large-volume print jobs in Prinergy?

Handling high-volume print jobs in Prinergy effectively relies on strategic planning and the intelligent use of its features. This starts with proper job organization and the use of hot folders for automated job ingestion. We carefully define job queues based on priority and output device. For instance, we might have separate queues for high-speed web presses and smaller, more specialized presses. Prinergy’s job splitting and parallel processing capabilities become essential here. Imagine a 1000-page catalog: Instead of processing it as a single monolithic job, Prinergy can split it into smaller, manageable chunks that are processed concurrently across multiple processors. Monitoring job progress via Prinergy’s real-time dashboards is crucial for identifying and resolving bottlenecks. Leveraging features like automated imposition and preflighting, as previously described, further enhance throughput. Regularly reviewing job logs helps identify recurring issues and fine-tune the workflow for optimal performance.

Q 10. Describe your experience with Prinergy’s proofing tools.

Prinergy offers robust proofing tools, crucial for ensuring client approval before proceeding with costly printing. I have extensive experience using both soft proofing (on-screen) and hard proofing (physical prints). Soft proofing in Prinergy allows for accurate color representation through calibrated monitors and ICC profiles, ensuring what is seen on-screen closely resembles the final printed output. I’ve worked extensively with creating custom proofing profiles for different clients and substrates, accommodating their unique color requirements. Hard proofing, when required, is meticulously managed to ensure that the proof accurately mirrors the intended print. This involves utilizing calibrated printers and standardized paper stocks. I’ve used Prinergy’s proofing capabilities to efficiently communicate color expectations and get client sign-off, eliminating the risk of costly reprints due to color discrepancies. Moreover, Prinergy’s ability to generate annotations and markups on proofs facilitates clear communication and problem-solving during client review.

Q 11. What is your experience with Prinergy’s archiving and retrieval features?

Prinergy’s archiving and retrieval system is vital for long-term project management and version control. It allows for secure storage of digital assets including job tickets, imposition settings, PDF files, and color profiles, all with a robust metadata system. This simplifies the process of retrieving past jobs for reprint orders or revisions. We use a structured archiving strategy, categorizing jobs by client, project, and date, ensuring easy searchability. The system is also invaluable for auditing purposes, readily providing a history of every job processed. I’ve personally used this feature to quickly locate files for reprint requests, sometimes years after the initial print job, drastically reducing turnaround times and saving valuable time and resources. The security features integrated within Prinergy’s archive ensures the confidentiality and integrity of our client’s data.

Q 12. How do you ensure accurate color reproduction in Prinergy?

Accurate color reproduction is paramount. In Prinergy, this is achieved through a multi-faceted approach focusing on color management. It begins with the calibration of all devices – monitors, scanners, and printers – using ICC profiles. These profiles describe the color characteristics of each device, allowing Prinergy to accurately translate colors across the entire workflow. We employ standardized color spaces, such as CMYK, and ensure consistent use throughout the process. Additionally, I leverage Prinergy’s color correction tools to fine-tune color balance and ensure accurate reproduction of specific color palettes. This often involves using reference colors and working closely with clients to define their specific color expectations. Regular color checks and quality control measures further solidify accurate color reproduction throughout the production process. My experience includes establishing and maintaining our company’s color standards and educating the team on best practices for color management within Prinergy.

Q 13. Explain your understanding of the different output modules in Prinergy.

Prinergy supports a range of output modules tailored for diverse printing technologies. These modules translate the processed digital files into instructions for different printing devices. Common examples include modules for offset presses, digital presses, large-format printers, and even flexographic presses. Each module has specific settings to optimize the output for the targeted device. For instance, the offset module considers factors like the press type, ink characteristics, and screening angles to produce optimal print quality. The digital press module might focus on optimizing resolution and color gamut for specific digital platforms. My experience involves configuring and troubleshooting various output modules, ensuring that the settings are optimized for the specific output device and printing requirements of each job. Understanding the nuances of each module is key to generating high-quality prints from a variety of devices.

Q 14. How do you optimize Prinergy’s workflow for specific printing requirements?

Optimizing Prinergy’s workflow for specific printing requirements involves a tailored approach based on factors like the type of print job, the press being used, and client expectations. This starts with designing an efficient job structure – organizing jobs logically within the system. Customizing preflight profiles to address specific issues – such as checking for bleed or specific color spaces – ensures early error detection. Selecting the correct output module and fine-tuning its settings for the specific printing device is also crucial. In scenarios involving specialized printing such as high-end packaging, we might need to incorporate extra steps like incorporating specific spot colors or advanced color management techniques, adjusting the workflow accordingly. Regularly analyzing job statistics and logs allows us to identify areas for improvement and fine-tune the workflow for greater efficiency and reduced turnaround times. The key is adaptability and a deep understanding of how Prinergy’s tools can be leveraged for different scenarios.

Q 15. Describe your experience with Prinergy’s job ticketing and tracking system.

Prinergy’s job ticketing and tracking system is the backbone of its workflow efficiency. It allows for meticulous control over every job, from initial submission to final output. Think of it as a sophisticated, centralized inbox for all printing projects. Each job receives a unique ticket, acting as its digital identity throughout the entire process.

My experience encompasses creating and modifying tickets, assigning resources (operators, presses), tracking job progress through various stages (prepress, press, finishing), and monitoring deadlines. I’m adept at using the system’s search and filtering capabilities to locate specific jobs quickly, crucial for managing large volumes of work. For example, I can easily filter jobs by client, due date, or even specific color profiles used. This ensures accountability and helps pinpoint bottlenecks in the workflow. The system also generates detailed reports on job status, turnaround times, and costs, assisting in operational analysis and optimization.

I’ve used the system to manage jobs ranging from simple business cards to complex, multi-page publications, and consistently found it invaluable for maintaining order and accuracy across all projects. The ability to track revisions and approvals within the ticket itself significantly reduces the chance of errors and miscommunication.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you handle discrepancies between digital proofs and final prints?

Discrepancies between digital proofs and final prints are unfortunately a common challenge in print production. My approach involves a systematic investigation to isolate the root cause. I first visually compare the proof and print, noting the specific differences – is it color, sharpness, or registration issues? This is often done using color measurement tools like a spectrophotometer to obtain objective data.

Next, I examine the job ticket for any potential factors such as incorrect color profiles, improper RIP settings, or issues with the printing press. I check the output device calibration and maintenance logs. Was the media used in the final print the same as what was used for the proof? Sometimes the discrepancy might be due to slight variations in media properties from different batches.

If the issue is with color, I might revisit the color management settings within Prinergy, ensuring that the correct ICC profiles are used throughout the workflow, from the initial design file to the final output. I collaborate with the press operators and prepress technicians to identify and rectify any problems in the equipment or settings. Documentation of each step is vital, not only for resolving the immediate issue but also for preventing similar problems in the future. The aim is to establish clear corrective actions and incorporate them into standard operating procedures.

Q 17. What is your experience with Prinergy’s integration with other MIS systems?

My experience includes seamlessly integrating Prinergy with various MIS (Management Information Systems) platforms. This integration is essential for efficient data flow between the prepress workflow and business management systems. This integration typically involves JDF (Job Definition Format) or other industry-standard communication protocols.

For example, I’ve worked with systems where job information created in the MIS system – client details, order specifications, delivery dates – is automatically transferred to Prinergy. This eliminates redundant data entry, reducing the risk of errors and saving considerable time. Conversely, Prinergy’s job status, costs, and completion data are automatically sent back to the MIS system, providing real-time updates to the business management team. This integration provides a comprehensive overview of the entire production process, from order placement to invoicing.

The specific integration methods vary depending on the MIS system, but the core goal remains consistent: automated data exchange to streamline operations and improve accuracy.

Q 18. Explain your experience with Prinergy’s reporting and analytics features.

Prinergy’s reporting and analytics features are indispensable for monitoring performance, identifying bottlenecks, and optimizing the workflow. I’ve extensively used these features to generate reports on various aspects of production, such as job turnaround times, press utilization, and overall production costs.

For instance, I’ve used Prinergy’s reporting to analyze press downtime, identifying recurring issues and implementing preventative maintenance schedules. By tracking turnaround times, I’ve identified opportunities to improve efficiency, such as streamlining certain steps in the workflow or optimizing operator training. Cost reports help in making informed decisions about resource allocation and pricing strategies.

The data-driven insights provided by these reports are invaluable for continuous improvement. I regularly review these reports, not only to detect immediate issues, but to identify longer-term trends that could impact future productivity. This allows for proactive adjustments rather than reactive problem-solving.

Q 19. How do you manage user access and permissions within Prinergy?

Managing user access and permissions in Prinergy is crucial for security and efficient workflow management. The system offers granular control, allowing for the assignment of specific roles and permissions to each user. This ensures that only authorized personnel can access sensitive data and perform certain actions.

For instance, prepress operators might have access to job submission and processing functionalities, while press operators might only have access to the information related to jobs assigned to their specific machines. Administrators, on the other hand, have comprehensive access and control over the entire system. This role-based access control minimizes the risk of accidental or malicious data alteration.

I have experience in configuring user accounts, assigning permissions, and auditing user activity. Regular audits ensure compliance and identify potential security vulnerabilities. This meticulous approach to access control maintains data integrity and protects the overall workflow.

Q 20. Describe your experience with migrating to a newer version of Prinergy.

Migrating to a newer version of Prinergy requires a planned and systematic approach to minimize disruption to the workflow. My experience involved a thorough assessment of the current system, identifying potential compatibility issues with existing hardware and software. A crucial step is creating a detailed migration plan, including timelines, resource allocation, and training schedules.

The migration process itself often involves several phases, starting with a thorough backup of the current system. This is followed by the installation of the new version, rigorous testing, and verification that all functionalities are working as expected. User training is essential to ensure a smooth transition and to familiarize users with any changes in the user interface or workflow. We often conduct parallel running of both the old and new versions for a period before completely decommissioning the old system.

The migration to a newer version offers the benefit of improved features, enhanced performance, and better security. A well-planned migration minimizes downtime and ensures a seamless transition to the updated system, resulting in improved productivity and efficiency.

Q 21. What are the advantages of using Prinergy over other workflow systems?

Prinergy offers several advantages over other workflow systems. Its strengths lie in its robust feature set, scalability, and integration capabilities. The system’s sophisticated color management tools are a significant advantage, ensuring accurate and consistent color reproduction across different devices and media.

Compared to some competitors, Prinergy often boasts a more intuitive user interface, making it easier for operators to learn and use effectively. Its extensive automation capabilities reduce manual intervention, saving time and minimizing errors. The comprehensive reporting and analytics features provide invaluable insights for optimizing the workflow and improving business decisions.

Its strong integration capabilities with various MIS and other third-party systems streamline the overall print production process, improving communication and data flow. Finally, Kodak’s extensive support network ensures that users have access to expert assistance when needed. These combined features lead to higher efficiency, better quality control, and reduced production costs.

Q 22. How do you monitor and maintain Prinergy system performance?

Monitoring and maintaining Prinergy system performance is crucial for smooth workflow and optimal print production. It involves a multi-faceted approach encompassing regular checks and proactive measures.

- System Monitoring Tools: Prinergy offers built-in monitoring tools that track CPU usage, memory consumption, disk I/O, and network traffic. Regularly reviewing these metrics helps identify bottlenecks and potential issues before they escalate. For example, consistently high CPU usage might point to a processing-intensive job or a need for hardware upgrades.

- Log File Analysis: Analyzing Prinergy’s log files is essential for diagnosing errors and performance degradation. Specific error messages provide valuable clues for troubleshooting. We often use log analysis tools to filter and categorize logs for efficient identification of recurring problems.

- Scheduled Maintenance: Implementing a scheduled maintenance routine is critical. This includes regular software updates, database backups, and disk defragmentation. Proactive maintenance prevents unexpected downtime and ensures the system remains stable and efficient.

- Performance Tuning: Optimizing system parameters, such as the number of concurrent jobs and resource allocation, is key. This often involves collaborating with IT to ensure sufficient resources are allocated to Prinergy. For instance, adjusting the number of threads used for image processing can significantly improve speed.

- Capacity Planning: Anticipating future needs and scaling resources accordingly is a proactive approach to performance optimization. This involves careful consideration of job volume, file sizes, and processing demands.

Think of it like maintaining a car – regular check-ups, oil changes, and addressing issues promptly prevent major breakdowns and keep it running smoothly. Consistent monitoring and proactive maintenance are key to optimal Prinergy performance.

Q 23. How do you troubleshoot connectivity issues within the Prinergy workflow?

Troubleshooting connectivity issues in a Prinergy workflow requires a systematic approach. It starts with identifying the affected components and isolating the problem.

- Identify the Scope: First, determine whether the problem is isolated to a single workstation, a specific device (e.g., a particular RIP), or a broader network issue. A workstation might experience connectivity problems while other parts of the workflow function normally. This helps narrow the search area.

- Check Basic Connectivity: Verify basic network connectivity using standard tools like

pingandtracerouteto check network path and identify potential bottlenecks or broken links. These commands help pinpoint the point of failure in the network communication. - Prinergy’s Internal Diagnostics: Prinergy provides built-in tools for checking connections to devices such as RIPs, color servers, and output devices. These tools can help to identify specific connectivity problems with printers or other components.

- Firewall and Security Settings: Check firewall rules and security settings to ensure they aren’t blocking necessary ports or communication between Prinergy components. Often, firewalls block communication between different segments of a network, disrupting the workflow.

- Driver and Software Updates: Ensure all drivers for connected devices are up to date and compatible. Outdated or incompatible drivers are a common source of connectivity issues.

- Network Infrastructure: Examine the network infrastructure for problems like cable faults, switch malfunctions, or overloaded network segments. These might require the help of your IT department.

For example, I once resolved a connectivity issue with a specific RIP by simply restarting the RIP server. In another instance, a network switch needed replacing after identifying a faulty port. A methodical approach, starting with basic checks and progressively narrowing down the potential causes, is key to efficient troubleshooting.

Q 24. Explain your experience with Prinergy’s imposition and nesting features.

Prinergy’s imposition and nesting features are powerful tools for optimizing sheet usage and improving production efficiency. I’ve extensively used them for various projects.

- Imposition: Prinergy offers a wide range of imposition templates and tools for creating precise page layouts on a sheet. I’ve worked with various imposition schemes, including signatures, booklets, and other complex layouts, adjusting margins, bleeds, and other critical details. We often use pre-made templates which are further customized to meet specific job requirements. This ensures the final product aligns perfectly with the design specifications.

- Nesting: Prinergy’s nesting capabilities are critical for maximizing sheet utilization, particularly in high-volume jobs. The software intelligently arranges jobs on sheets to minimize waste and optimize production speed. I’ve often fine-tuned nesting parameters to balance sheet coverage with the need for precise registration and cut marks.

- Template Creation and Management: I’ve created and managed imposition and nesting templates, tailoring them for specific substrates, press configurations, and project requirements. A well-organized template library speeds up future jobs with similar requirements. Using consistent templates maintains brand identity and quality throughout all our printed materials.

- Automation: Integration with JDF/JMF allows for automated imposition and nesting based on job specifications. This eliminates manual intervention, reducing the risk of errors and significantly improving efficiency.

For instance, I optimized a packaging job using Prinergy’s nesting tools, reducing material waste by 15% and saving the client considerable costs. Mastering these features is crucial for cost-effective and efficient print production.

Q 25. Describe your experience working with different types of print substrates in a Prinergy environment.

Experience with diverse print substrates in a Prinergy environment is essential for producing high-quality prints. Substrate selection and its impact on the workflow must be carefully considered.

- Substrate Profiles: Prinergy allows the creation of substrate profiles, which define the specific characteristics of various materials like paper, card stock, and other specialized substrates. These profiles include details such as thickness, color, and surface texture, which influence color management and print settings.

- Color Management: Accurate color management is critical when working with diverse substrates. Different substrates absorb and reflect ink differently. Therefore, creating profiles which properly address these characteristics is important for color consistency across various materials. This often involves using spectrophotometers and color measurement tools to create accurate color profiles.

- RIP Settings: RIP settings, including screening, halftoning, and ink optimization, need to be adjusted based on the substrate properties. For instance, heavier substrates might require higher ink densities to maintain vibrancy.

- Press Configuration: The press configuration, such as ink type and drying system, also interacts significantly with the substrate. These press specifics need to be considered when preparing and optimizing the print job.

- Troubleshooting: Identifying and resolving issues related to substrate handling, such as paper jams or misfeeds, often requires a deep understanding of the interactions between the substrate, the press, and the workflow.

For instance, I once encountered a problem with color consistency when printing on a textured card stock. By adjusting the substrate profile and RIP settings, I was able to achieve accurate and consistent color reproduction across the print run. Understanding these interactions is essential for consistent high-quality output.

Q 26. How do you utilize Prinergy’s automation tools to improve efficiency?

Prinergy’s automation tools are game-changers for boosting efficiency. I’ve leveraged these extensively to streamline various aspects of the workflow.

- Hot Folders: Automating job submission using hot folders eliminates manual intervention, speeding up the process and reducing errors. Jobs dropped into a specific folder are automatically processed by Prinergy, applying predefined settings and routing them to the appropriate output devices.

- JDF/JMF Workflow: Utilizing JDF/JMF (Job Definition Format/Job Messaging Format) enables seamless integration with MIS (Management Information Systems) and other prepress systems. This creates a fully automated workflow, where job information, settings, and instructions are exchanged automatically between different systems. This allows for tracking, reporting, and resource allocation efficiencies.

- Presets and Templates: Creating and using presets and templates for common tasks, such as imposition and color management, saves time and ensures consistency. Predefined settings can be applied automatically to jobs matching specific criteria, ensuring consistency and speed.

- Scripting and Customization: For advanced automation, Prinergy allows for scripting and customization. This enables automation of complex tasks that might not be readily available through built-in features. This requires advanced coding expertise within a specific scripting language.

One example is automating the imposition and nesting process for a large-scale magazine printing job using JDF/JMF integration. This reduced the turnaround time by 40% compared to manual processing. Automation through Prinergy is key to high-throughput and efficient operations.

Q 27. What strategies do you use to optimize Prinergy’s resource utilization?

Optimizing Prinergy’s resource utilization is vital for maintaining efficiency and minimizing costs. It’s a balancing act between performance and resource consumption.

- Resource Allocation: Carefully allocating system resources such as CPU, memory, and disk space is crucial. This might involve adjusting the number of concurrent jobs that Prinergy processes to avoid overloading the system. Monitoring resource usage provides valuable insight into potential bottlenecks.

- Job Prioritization: Setting job priorities can ensure that urgent jobs are processed first, optimizing the use of available resources. Critical jobs are processed first, improving customer satisfaction and meeting tight deadlines.

- Database Optimization: Regular database maintenance, including indexing and cleanup, ensures efficient data retrieval and processing. Maintaining database integrity and optimizing its performance is critical for smooth operations.

- Hardware Optimization: Matching hardware resources to the expected workload is critical. This includes selecting appropriate CPUs, memory, and storage systems to support efficient processing of jobs. Upgrading or expanding hardware may be necessary to accommodate increasing processing demands.

- Software Updates: Installing software updates and patches not only improves security and stability but can also enhance performance. Updates often include performance optimization and bug fixes.

For instance, I improved a client’s Prinergy system’s performance by 20% by optimizing database settings and adjusting resource allocation based on job priorities. This resulted in faster turnaround times and reduced costs.

Q 28. Describe a challenging Prinergy workflow issue you faced and how you resolved it.

One of the most challenging issues I faced involved a significant drop in Prinergy’s processing speed. Jobs were taking considerably longer than usual, causing delays and bottlenecks in production.

Initially, I suspected a hardware problem. However, after investigating with system monitoring tools, I discovered that the issue wasn’t hardware-related. Instead, I found an unusually large number of temporary files accumulating on the server’s hard drive. This was consuming substantial disk I/O resources, causing the significant slowdowns. The root cause was identified as an issue within a custom script that wasn’t properly cleaning up temporary files after job processing.

My solution involved a multi-step approach:

- Identify the Root Cause: Through careful analysis of the system logs and monitoring tools, I pinpointed the problematic script and its role in the temporary file buildup.

- Develop and Implement a Fix: I modified the script to include proper cleanup routines, ensuring that temporary files were deleted after each job’s completion.

- Testing and Validation: After implementing the fix, I rigorously tested the system to ensure the problem was resolved and that the script operated correctly. This involved submitting various test jobs of different sizes and complexities.

- Preventive Measures: To prevent this from happening again, I implemented more robust error handling within the script and established a more rigorous testing procedure for any future script changes.

This experience reinforced the importance of thorough log analysis, proactive system monitoring, and a methodical approach to troubleshooting. By combining technical expertise with a structured problem-solving methodology, I successfully resolved a critical issue that threatened production deadlines.

Key Topics to Learn for Kodak Prinergy Workflow Interview

- Workflow Architecture: Understand the overall structure and components of the Prinergy Workflow system, including its modular design and how different modules interact.

- Job Ticket Creation and Management: Learn how to create, modify, and manage job tickets efficiently, including preflighting and imposition techniques. Practice creating complex jobs with various specifications.

- Color Management: Master the color management aspects of Prinergy, including profile creation, conversion, and proofing. Understand the importance of color consistency throughout the workflow.

- Automation and Scripting: Explore the automation capabilities of Prinergy using scripting languages (if applicable in your target role). This demonstrates advanced problem-solving skills.

- Prepress Operations: Gain practical experience with prepress tasks within Prinergy, such as trapping, imposition, and quality control checks. Be ready to discuss your approach to solving common prepress challenges.

- Troubleshooting and Problem Solving: Develop your ability to diagnose and resolve common issues within the Prinergy Workflow. Be prepared to discuss your problem-solving methodology.

- Production Planning and Optimization: Understand how Prinergy can be used to plan and optimize production schedules, improving efficiency and reducing bottlenecks.

- Integration with Other Systems: Familiarize yourself with how Prinergy integrates with other MIS (Management Information Systems) and pre-press software, and how data flows between systems.

- Security and User Management: Understand the security features of Prinergy and best practices for user management and access control.

Next Steps

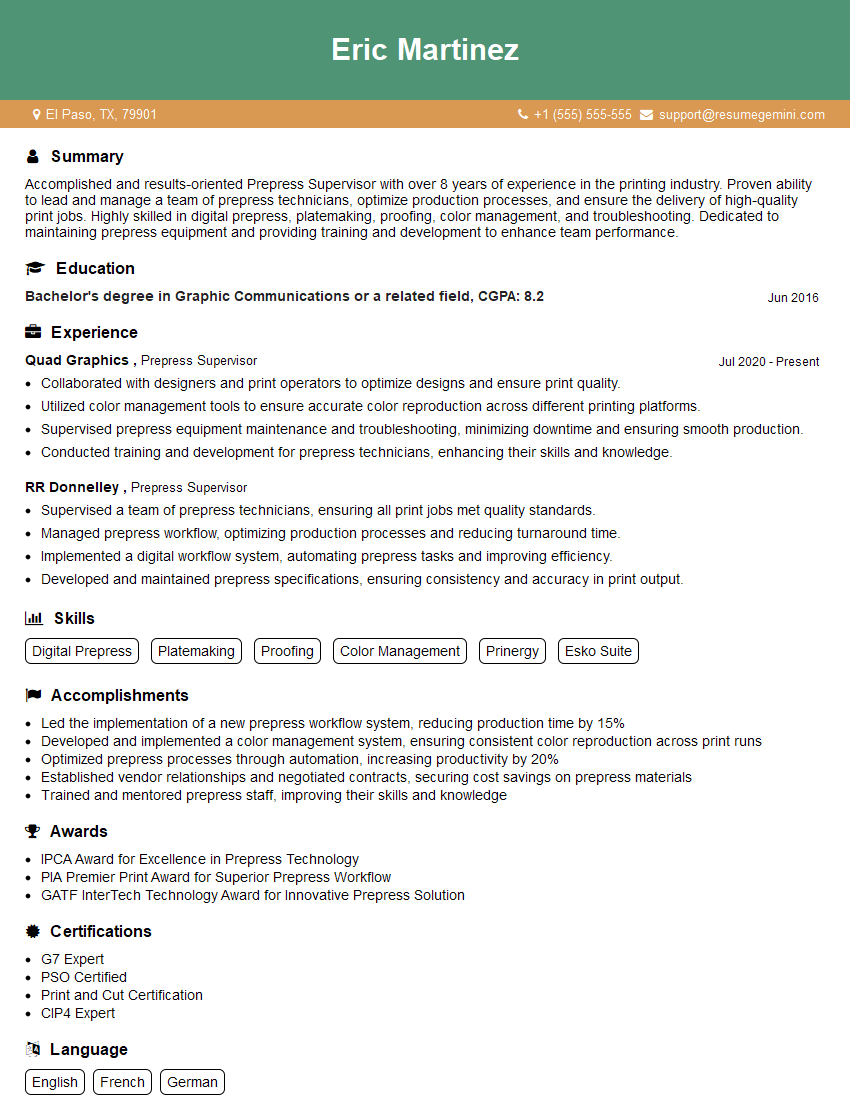

Mastering Kodak Prinergy Workflow significantly enhances your career prospects in the print and publishing industry, opening doors to exciting roles with increased responsibility and earning potential. To maximize your job search success, creating a well-structured, ATS-friendly resume is crucial. We highly recommend using ResumeGemini to craft a professional and impactful resume that showcases your Prinergy skills effectively. ResumeGemini provides the tools and resources to help you build a superior resume, and we provide examples of resumes tailored to Kodak Prinergy Workflow positions to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good