The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Hot and Cold Work Environments interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Hot and Cold Work Environments Interview

Q 1. Describe your experience working in extreme temperatures.

My experience with extreme temperatures spans over 15 years, encompassing both hot and cold work environments. I’ve worked on offshore oil rigs in the scorching Gulf heat, where ambient temperatures regularly exceeded 110°F (43°C), and on construction projects in the Canadian winter, enduring temperatures well below 0°F (-18°C). These experiences provided invaluable hands-on knowledge in recognizing, mitigating, and managing the risks associated with extreme temperatures. I’ve learned to adapt my work practices, utilizing specific equipment and techniques depending on the conditions. For instance, in extreme heat, I’ve implemented shorter work cycles with frequent breaks, and in extreme cold, I’ve mastered layering techniques for optimal thermal protection.

Q 2. What safety precautions are crucial in a hot work environment?

Safety precautions in hot work environments are paramount. They center around preventing heat stress and related illnesses. Crucial measures include:

- Hydration: Providing and encouraging frequent consumption of water or electrolyte drinks. Think of it like this: your body is a machine, and it needs fuel (water) to function properly in high heat.

- Rest Breaks: Implementing scheduled breaks in shaded or air-conditioned areas, allowing the body to cool down.

- Protective Clothing: Utilizing light-colored, loose-fitting, and breathable clothing to reflect sunlight and enhance airflow.

- Acclimatization: Gradually increasing exposure to heat to allow the body to adapt. This is like slowly increasing the weight you lift at the gym – your body needs time to adjust.

- Monitoring: Regularly monitoring workers for signs of heat stress, such as dizziness, headache, or nausea.

- Engineering Controls: Employing measures such as ventilation, misting systems, or shaded work areas to lower ambient temperatures.

Failure to adhere to these precautions can lead to serious heat-related illnesses, including heat exhaustion, heat stroke, and even death.

Q 3. How do you mitigate risks associated with working in cold environments?

Mitigating risks in cold environments involves protecting workers from hypothermia and frostbite. Key strategies include:

- Layering Clothing: Using multiple layers of clothing to trap warm air close to the body. Think of it as building an insulating barrier.

- Waterproof Outerwear: Protecting against wind and moisture, which significantly increases heat loss.

- Insulated Footwear: Keeping feet warm and dry to prevent frostbite.

- Scheduled Breaks: Providing frequent breaks in warm shelters or vehicles to allow the body to rewarm.

- Cold Stress Education: Training workers to recognize the signs and symptoms of cold-related injuries.

- Hand and Foot Warmers: Employing chemical hand and foot warmers to maintain dexterity and prevent frostbite.

Proper planning and preparation are essential for working safely in cold conditions. Ignoring these precautions can lead to serious, potentially life-threatening injuries.

Q 4. What are the common hazards of working with high-temperature equipment?

Common hazards of high-temperature equipment include:

- Burns: Contact with hot surfaces, flames, or molten materials can cause severe burns.

- Fire Hazards: Equipment malfunction or sparks can ignite flammable materials, leading to fires.

- Heat Exhaustion/Stroke: Prolonged exposure to high temperatures radiated from equipment can cause heat stress illnesses.

- Eye Injuries: Radiation and sparks from high-temperature equipment can damage eyesight.

- Inhalation Hazards: Exposure to fumes and gases generated during high-temperature processes can cause respiratory problems.

Appropriate safety measures, including PPE like heat-resistant gloves, eye protection, and respiratory equipment, are crucial for preventing these hazards. Regular equipment maintenance and adherence to safety protocols are also paramount.

Q 5. Explain your understanding of heat stress and its prevention.

Heat stress occurs when the body’s cooling mechanisms are overwhelmed by excessive heat. This can lead to a range of illnesses, from mild heat exhaustion to life-threatening heat stroke. Symptoms of heat exhaustion can include heavy sweating, weakness, nausea, and headache. Heat stroke, a more serious condition, involves a high body temperature, altered mental state, and potential loss of consciousness.

Prevention involves the strategies mentioned earlier: adequate hydration, rest breaks, appropriate clothing, acclimatization, and engineering controls. Regular monitoring of workers’ health is also crucial. Think of it like this: if your car overheats, you need to let it cool down. The same principle applies to the human body in extreme heat.

Q 6. How do you recognize and respond to cold-related injuries?

Recognizing and responding to cold-related injuries is critical. Early signs of hypothermia (dangerously low body temperature) include shivering, confusion, and drowsiness. Frostbite, the freezing of body tissue, initially presents as numbness and tingling in affected areas, progressing to pale or bluish skin.

Immediate action is vital. For hypothermia, move the individual to a warm place, remove wet clothing, and provide warm drinks (avoid alcohol). For frostbite, gently rewarm the affected area using warm water (not hot). In both cases, seek medical attention promptly. Early intervention is key in preventing permanent damage.

Q 7. Describe your experience with personal protective equipment (PPE) in extreme temperatures.

My experience with PPE in extreme temperatures is extensive. In hot environments, I’ve utilized lightweight, breathable protective clothing, including heat-resistant gloves and specialized helmets to shield from direct sunlight. In cold conditions, I’ve relied on multi-layered clothing systems, including thermal underwear, insulated jackets, and waterproof outer layers, along with insulated boots and gloves to maintain dexterity while minimizing cold exposure. Proper eye protection is essential in both scenarios – protecting against UV radiation in hot environments and flying debris in cold, potentially snowy conditions.

The selection and proper use of PPE are non-negotiable for working safely in extreme conditions. It is not just about personal safety but the safety of the entire team. Improper use or absence of PPE can lead to serious incidents.

Q 8. How do you maintain equipment efficiency in hot and cold conditions?

Maintaining equipment efficiency in extreme temperatures requires a multi-pronged approach focusing on preventative maintenance, appropriate selection of equipment, and operational adjustments. Think of it like caring for a high-performance athlete – you need to prepare them for the conditions and provide the right support.

Preventative Maintenance: Regular inspections and servicing are crucial. In hot environments, this includes checking for overheating, lubricating moving parts more frequently, and ensuring adequate cooling systems are functioning optimally. For cold environments, this involves checking for freezing points in fluids, ensuring proper insulation, and preventing condensation buildup, which can lead to corrosion.

Equipment Selection: Choosing equipment specifically designed for extreme temperatures is vital. This might involve using specialized lubricants, materials resistant to extreme temperatures (like stainless steel in hot conditions or specialized plastics in cold ones), and robust seals to prevent leaks. For example, in a freezer, using a compressor designed for low-temperature operation is essential.

Operational Adjustments: In hot conditions, you might need to reduce operating loads to prevent overheating or increase ventilation. In cold conditions, you might need to pre-heat equipment before operation to prevent damage from sudden temperature changes or use thermal blankets to maintain temperature.

For instance, I once worked on a project where we had to maintain refrigeration units in a -20°C environment. By implementing regular checks for frost buildup, using specialized low-temperature lubricants, and preheating the units before starting, we successfully avoided costly breakdowns and kept them running efficiently.

Q 9. What are the different types of insulation used in cold storage facilities?

Cold storage facilities utilize various insulation materials to maintain low temperatures, preventing energy loss and ensuring product quality. The choice depends on factors like temperature requirements, cost, and environmental impact. Think of it like building a thermos – you want to minimize heat transfer.

Polyurethane Foam: This is a widely used insulator due to its high R-value (a measure of thermal resistance), low cost, and ease of application. It’s often sprayed onto surfaces or used in panels.

Polyisocyanurate (PIR) Foam: PIR foam offers even higher R-values than polyurethane, making it ideal for very low temperature applications. It’s a more expensive option but provides superior insulation.

Expanded Polystyrene (EPS): This is a cheaper alternative, often used in less demanding applications or as a supplementary layer. It’s less efficient than polyurethane or PIR foam.

Mineral Wool: A natural, sustainable option made from recycled materials. It’s fire-resistant and provides good thermal insulation but is less efficient than foams.

Vacuum Insulated Panels (VIPs): These high-performance panels offer exceptionally high R-values but are more expensive and require careful handling.

The selection of insulation is crucial for minimizing energy consumption and ensuring the long-term viability of the cold storage facility. Incorrect insulation can lead to significant energy waste and product spoilage.

Q 10. Explain your knowledge of HVAC systems and their maintenance.

HVAC (Heating, Ventilation, and Air Conditioning) systems are critical for maintaining comfortable and safe temperatures in various environments. My knowledge encompasses their design, operation, and maintenance, from basic residential systems to large-scale industrial applications. Think of them as the circulatory system of a building.

Understanding System Components: I am familiar with all major components, including compressors, condensers, evaporators, air handlers, and control systems. I understand how they interact to provide heating or cooling.

Maintenance Procedures: This includes regular inspections, filter changes, refrigerant checks, cleaning coils, and lubricating moving parts. Preventive maintenance minimizes breakdowns and extends the lifespan of the system.

Troubleshooting: I can identify and resolve common issues such as refrigerant leaks, malfunctioning components, and electrical problems. My experience extends to diagnosing problems through various methods including visual inspection, pressure readings, and temperature measurements.

For example, I once worked on a large office building where the HVAC system was experiencing frequent shutdowns. Through a systematic diagnostic process, I identified a failing compressor and successfully replaced it, restoring efficient climate control and preventing further disruptions.

Q 11. How do you troubleshoot malfunctions in heating or cooling equipment?

Troubleshooting heating or cooling equipment requires a systematic approach combining observation, diagnostics, and a solid understanding of the equipment’s operation. It’s like being a detective, following clues to solve the mystery of the malfunction.

Safety First: Always disconnect power before starting any troubleshooting. Prioritize safety!

Visual Inspection: Look for obvious problems like leaks, damaged wiring, or loose connections.

Check Controls: Ensure thermostats, switches, and circuit breakers are functioning correctly.

Check Pressure and Temperature: Use gauges to check refrigerant pressure and temperature in cooling systems. Observe water pressure and temperature in heating systems.

Listen for Unusual Noises: Unusual sounds can indicate mechanical problems.

Consult Manuals and Diagrams: Refer to the equipment’s documentation for troubleshooting guides and wiring diagrams.

Systematic Testing: Isolate components and test them individually to pinpoint the faulty part.

For example, if a furnace is not producing heat, I would first check the gas supply, then the igniter, blower motor, and finally the heat exchanger to identify the root cause.

Q 12. What are the regulatory requirements for working in extreme temperatures?

Regulatory requirements for working in extreme temperatures vary depending on location and industry but generally focus on employee safety and well-being. These regulations are designed to prevent heatstroke, hypothermia, and other health issues.

OSHA (Occupational Safety and Health Administration): In the US, OSHA sets standards for workplace safety, including those related to heat and cold exposure. These often involve providing adequate rest breaks, hydration, and personal protective equipment (PPE).

Local Regulations: Many countries and regions have their own specific regulations, often more stringent than federal guidelines. It’s crucial to be aware of all applicable regulations.

Industry-Specific Standards: Certain industries (e.g., construction, agriculture) might have additional safety guidelines for extreme temperature work.

These regulations often include requirements for monitoring temperature and humidity, providing access to water and shade in hot environments, and providing appropriate warm clothing and shelter in cold environments. Regular training and awareness programs are also essential aspects of workplace safety regulations.

Q 13. How do you ensure the safety of yourself and your colleagues in a hot work environment?

Ensuring safety in a hot work environment is paramount. It requires a combination of preventative measures, proactive monitoring, and emergency preparedness. Think of it like mountaineering – you need to be prepared for the challenges.

Hydration and Breaks: Frequent water breaks are crucial to prevent dehydration. Scheduled rest breaks in shaded areas are essential.

Appropriate Clothing: Lightweight, light-colored clothing and hats are recommended to minimize heat absorption. Sunscreen is vital.

Heat Stress Monitoring: Regular monitoring of workers’ health and temperature is necessary. Supervisors must be trained to recognize signs of heat exhaustion or heatstroke.

PPE: Depending on the tasks, PPE may include gloves, eye protection, or protective clothing to prevent burns or other injuries.

Emergency Plan: A well-defined emergency plan, including access to emergency services, should be in place to handle heat-related emergencies effectively.

For example, in a construction project during a heatwave, we implemented mandatory hydration breaks every hour, used shaded rest areas, and had a designated first-aider on-site to monitor worker health. This significantly reduced heat-related incidents.

Q 14. Describe your experience with emergency procedures in extreme temperature conditions.

My experience with emergency procedures in extreme temperature conditions includes dealing with heatstroke and hypothermia cases. These scenarios demand rapid and effective responses.

Heatstroke: My training covers recognizing the symptoms (high body temperature, confusion, rapid pulse), initiating emergency cooling procedures (moving the person to a cool area, applying cold packs, fanning), and calling emergency medical services immediately.

Hypothermia: Similar to heatstroke, I am trained to identify the symptoms (shivering, confusion, slow pulse), initiate rewarming procedures (moving the person to a warm area, providing warm blankets and fluids), and summon emergency medical assistance.

Emergency Drills and Training: I’ve participated in numerous drills and training sessions that simulate these scenarios. This ensures everyone is adequately prepared to respond efficiently and effectively.

In one instance, I had to respond to a heatstroke case on a construction site. By quickly implementing the cooling procedures and contacting emergency services, we were able to stabilize the affected individual before paramedics arrived. This experience reinforced the importance of thorough training and rapid response in such situations.

Q 15. What are the signs and symptoms of heat exhaustion and hypothermia?

Heat exhaustion and hypothermia represent opposite ends of the thermal stress spectrum. Heat exhaustion, stemming from prolonged exposure to high temperatures, manifests as symptoms like heavy sweating, weakness, dizziness, headache, nausea, and rapid pulse. Think of it like your body’s cooling system working overtime and ultimately failing. Severe cases can lead to heat stroke, a life-threatening condition. Hypothermia, on the other hand, arises from excessive heat loss to the environment, usually in cold, wet, or windy conditions. Symptoms range from shivering and confusion to slurred speech, loss of coordination, and eventually unconsciousness. Imagine your body struggling to maintain its core temperature, leading to a shutdown of vital functions. Early recognition of these symptoms is crucial for timely intervention and prevention of serious complications.

- Heat Exhaustion: Heavy sweating, weakness, dizziness, headache, nausea, rapid pulse, muscle cramps

- Hypothermia: Shivering, confusion, slurred speech, loss of coordination, drowsiness, unconsciousness

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you handle unexpected equipment failures in extreme temperatures?

Unexpected equipment failures in extreme temperatures demand a calm, methodical approach. My first priority is safety – securing the area and ensuring personnel are out of harm’s way. Next, I assess the situation: What type of failure occurred? What are the potential hazards (e.g., electrical shock, gas leaks, fire)? I then communicate clearly with my team and supervisors, providing a concise report of the failure and potential risks. Our established emergency protocols will dictate the next steps, which might involve implementing contingency plans, initiating repairs, or requesting specialist support. For example, if a welding machine malfunctions in extreme heat, I wouldn’t attempt a quick fix; I’d shut it down, tag it out of service, and contact maintenance while keeping my team clear from the potentially malfunctioning equipment.

Documentation is crucial. I meticulously record the event, the time, the location, and the actions taken. This data informs future risk assessments and preventative measures.

Q 17. Describe your proficiency in using specific equipment in extreme temperature conditions (e.g., welding equipment, refrigeration tools).

My experience encompasses the safe and efficient use of various equipment in both hot and cold environments. I’m proficient in operating welding equipment, ensuring proper ventilation and using appropriate PPE (Personal Protective Equipment) to mitigate heat stress and eye/skin damage from the intense welding arc. In cold environments, I’m skilled in handling refrigeration tools, understanding the safety precautions needed to prevent frostbite and other cold-related injuries. For example, when welding in high temperatures, I’d use specialized welding masks with enhanced ventilation and utilize cooling vests or take frequent breaks in shaded areas to prevent heat stroke. While working with refrigeration equipment in sub-zero temperatures, I’d wear multiple layers of insulated clothing and utilize hand and foot warmers to prevent frostbite and hypothermia. Regular equipment maintenance, checking for leaks and proper functionality, is crucial in both environments.

Q 18. How do you adapt your work schedule or methods to minimize risks in extreme temperatures?

Adapting work schedules and methods to mitigate extreme temperature risks is paramount. In hot conditions, we’d adjust work hours to avoid the peak heat of the day, scheduling tasks during cooler morning or evening hours. Frequent breaks in shaded or air-conditioned areas are also crucial, along with ensuring ample hydration. Rotating tasks to allow workers to alternate between physically demanding and less strenuous activities minimizes fatigue and heat stress. In cold environments, we would shorten outdoor work durations, implementing frequent warm-up breaks in heated shelters. Proper layering of clothing, using appropriate cold weather gear (gloves, hats, thermal underwear), and regular breaks are vital in preventing hypothermia. We might also employ techniques to minimize exposure, such as windbreaks and shelter.

Q 19. Explain your understanding of thermal stress on materials.

Thermal stress on materials refers to the changes that occur in their physical properties due to temperature variations. Extreme heat can cause materials to expand, weaken, lose their structural integrity, or even melt. Conversely, extreme cold can lead to contraction, embrittlement (making them more prone to fracture), and reduced flexibility. For example, concrete can crack if exposed to rapid temperature changes, while metals can lose their strength at high temperatures and become more brittle at low temperatures. Understanding these effects is crucial in selecting appropriate materials for specific applications and preventing equipment failure. This knowledge guides material selection for specific projects, considering the expected temperature range and potential thermal stresses, ensuring the longevity and safety of our work. For instance, we would not use a material known for becoming brittle in cold weather for outdoor applications in frigid climates.

Q 20. How do you maintain accurate record-keeping in challenging temperature conditions?

Maintaining accurate record-keeping in challenging temperature conditions requires a multi-faceted approach. First, I use waterproof and durable notebooks or electronic devices designed for use in extreme conditions. These ensure records are protected from moisture or damage caused by temperature fluctuations. Entries must be legible and clear, even if made with gloved hands. I use clear, consistent labeling systems and follow a predefined data format for all entries to ensure consistency and ease of access. For example, time stamping each entry with the precise temperature at that time would be critical in analysing the effects of temperature on equipment or processes. Regular backups of electronic data are crucial in case of device failure.

Q 21. What are your strategies for preventing equipment damage in extreme temperatures?

Preventing equipment damage in extreme temperatures requires proactive measures. In hot environments, this means employing shade covers, insulation, and ventilation systems to prevent overheating. Regular maintenance and lubrication are vital, as high temperatures can accelerate wear and tear. Proper storage, shielding equipment from direct sunlight, and using temperature-resistant materials are also essential. In cold environments, preventative measures include using heated enclosures or storage areas, applying anti-freeze solutions to prevent freezing in hydraulic systems, and employing specialized lubricants designed for low temperatures. Regular inspections are crucial to identify any signs of damage or stress early on. For example, we might use specialized thermal grease to prevent heat build-up in electronic components in high-temperature applications, or we’d employ heated storage units for sensitive equipment in sub-zero conditions. Proper training and adherence to safety protocols are paramount.

Q 22. Describe a time you had to quickly adapt to a change in temperature conditions.

Adapting to rapid temperature changes is crucial in my field. For instance, I was once working on a project in a refrigerated warehouse where the temperature suddenly dropped from a comfortable 4°C to -2°C due to a malfunctioning refrigeration unit. My immediate response was to:

- Assess the risk: I checked on my team to ensure everyone was properly dressed and alert for signs of hypothermia.

- Implement immediate mitigation: We immediately moved to a warmer area within the warehouse until the issue could be addressed.

- Communicate the change: I notified my supervisor and maintenance team about the situation, requesting a swift repair and emphasizing the safety of the personnel.

- Adjust work procedures: We shortened the duration of the cold work period, increased our break times, and paid close attention to any signs of cold stress in our team members.

This quick adaptation prevented any serious incidents, highlighting the importance of proactive risk assessment and communication in dynamic temperature conditions.

Q 23. What is your experience with emergency response protocols related to heat stroke or frostbite?

Emergency response is paramount. My experience includes participation in comprehensive training programs covering heat stroke and frostbite, encompassing both recognition and treatment protocols. For heat stroke, we focus on immediate cooling using methods like ice baths, wet towels, and fans. Early recognition of symptoms like confusion, rapid pulse, and high body temperature is vital. In frostbite cases, we emphasize gentle rewarming avoiding rubbing, and prompt medical attention.

We regularly practice simulated emergency scenarios to refine our teamwork and response time. Knowing the exact location of emergency supplies such as first-aid kits and emergency blankets is a fundamental part of our training and daily procedures. Clear communication channels and designated roles during emergencies are key to successful outcomes.

Q 24. How do you ensure proper ventilation in a hot work environment?

Proper ventilation is critical for safety and productivity in hot work environments. This is achieved through a multi-pronged approach:

- Exhaust systems: Industrial exhaust fans and ventilation systems are essential to draw out hot air and replace it with cooler, fresher air. The size and placement of these systems are critical and should be calculated based on the heat load and volume of the workspace.

- Natural ventilation: Where feasible, using open windows and doors can aid in natural airflow. However, this is often limited due to safety or cleanliness concerns.

- Local exhaust ventilation (LEV): In situations involving localized heat sources (e.g., welding), LEV systems are used to capture heat and fumes directly at the source.

- Regular maintenance: Filters and exhaust systems need routine inspection and cleaning to maintain peak efficiency.

- Monitoring: We employ thermal imaging and temperature sensors to continuously monitor air quality and temperature, ensuring ventilation is effectively reducing heat stress.

A well-designed ventilation strategy is not just about comfort; it’s a crucial safety measure in preventing heat-related illnesses and enhancing worker productivity.

Q 25. What are the specific challenges in maintaining quality control in extreme temperatures?

Maintaining quality control in extreme temperatures poses unique challenges. Material properties change with temperature, affecting performance and integrity. For example:

- Dimensional changes: Thermal expansion and contraction can alter the dimensions of components, affecting tolerances and assembly.

- Material degradation: Extreme heat or cold can weaken or damage materials, reducing their lifespan and effectiveness.

- Calibration drift: Measuring equipment might need frequent recalibration to maintain accuracy in changing temperatures.

- Process variations: Chemical reactions and manufacturing processes are sensitive to temperature fluctuations, potentially impacting product quality.

To mitigate these challenges, we implement strict temperature monitoring, use temperature-resistant materials, and employ specialized equipment calibrated for extreme temperature ranges. We also maintain detailed records and employ statistical process control (SPC) methods to detect and correct any deviations from quality standards.

Q 26. Explain your understanding of thermal expansion and contraction in materials.

Thermal expansion and contraction refer to the tendency of materials to change their volume in response to temperature changes. When heated, most materials expand as their particles gain kinetic energy and move further apart. Conversely, cooling causes contraction.

The extent of expansion or contraction depends on the material’s coefficient of thermal expansion (CTE), a material property that defines how much it expands or contracts per degree of temperature change. For example, steel has a higher CTE than concrete, meaning it will expand more significantly than concrete for the same temperature increase. Understanding CTE is vital in engineering applications, as it prevents issues such as stress cracking and dimensional inaccuracies in structures and components that are subjected to fluctuating temperatures.

Consider a bridge: the expansion joints are designed to accommodate the thermal expansion of the bridge deck in summer, preventing damage from stress buildup. Failure to account for thermal expansion can lead to structural failure.

Q 27. How do you handle communication challenges in noisy or hazardous environments?

Communication in noisy or hazardous environments requires careful planning and the use of appropriate tools and techniques. We routinely employ:

- Personal Protective Equipment (PPE): Hearing protection is critical in noisy environments. We also utilize respirators and safety goggles for protection from airborne particles or hazardous substances.

- Visual communication: Hand signals, clear signage, and visual cues are essential in noisy areas where verbal communication is difficult.

- Two-way radios or communication systems: These systems provide clearer communication over distances, even in the presence of significant noise.

- Pre-planned communication protocols: Before commencing work, we establish clear communication channels and signal protocols to ensure consistent and safe communication throughout the task.

- Regular check-ins and confirmation of instructions: Repeated confirmation is vital to make sure everyone understands and is aware of instructions, even in less-than-ideal conditions.

Effective communication is paramount in preventing accidents and ensuring everyone’s safety.

Q 28. Describe your experience working with different types of heating and cooling systems.

My experience encompasses a range of heating and cooling systems, from simple ventilation systems in workshops to sophisticated HVAC (Heating, Ventilation, and Air Conditioning) systems in large industrial settings and refrigerated warehouses. I’m familiar with:

- HVAC systems: These systems control temperature and humidity using various methods like forced-air, radiant heating, and chilled water. We monitor and maintain these systems to ensure they provide a stable and safe working environment. Understanding chiller operation, ductwork layout, and airflow patterns are crucial in this aspect.

- Refrigeration systems: I have significant experience with ammonia-based and other refrigerant systems used in cold storage facilities. Safety protocols for handling refrigerants are rigorously followed.

- Radiant heating/cooling: I understand the principles of radiant heat transfer and have worked with systems utilizing embedded tubes, infrared heaters, or radiant ceilings.

- Emergency heating systems: I’m familiar with backup generators and temporary heating solutions used during power outages to prevent cold stress.

My knowledge extends to the efficient operation, maintenance, and troubleshooting of these systems, ensuring optimal performance and worker safety.

Key Topics to Learn for Hot and Cold Work Environments Interview

- Understanding Heat Stress and Cold Stress: Learn the physiological effects of extreme temperatures on the human body, including heat exhaustion, heat stroke, hypothermia, and frostbite.

- Personal Protective Equipment (PPE) for Extreme Temperatures: Familiarize yourself with various types of PPE designed for hot and cold work, including specialized clothing, respirators, and eye protection. Understand their limitations and proper usage.

- Safety Regulations and Procedures: Study relevant safety standards and regulations related to working in extreme temperatures. This includes emergency procedures, hazard identification, and risk mitigation strategies.

- Practical Application of Safety Measures: Explore real-world examples of how safety protocols are implemented in various industries (e.g., construction, manufacturing, oil and gas). Be prepared to discuss practical scenarios and solutions.

- Environmental Monitoring and Control: Understand the methods used to monitor temperature and humidity levels in the workplace and the techniques employed to control the environment to ensure worker safety.

- Emergency Response and First Aid: Develop a strong understanding of emergency response procedures and basic first aid techniques for heat-related and cold-related illnesses and injuries.

- Work Practices and Techniques: Learn about work practices and techniques optimized for hot and cold environments. This includes scheduling, hydration strategies, and acclimatization procedures.

- Tools and Equipment Considerations: Understand how extreme temperatures affect the operation and maintenance of tools and equipment, and the necessary precautions to take.

Next Steps

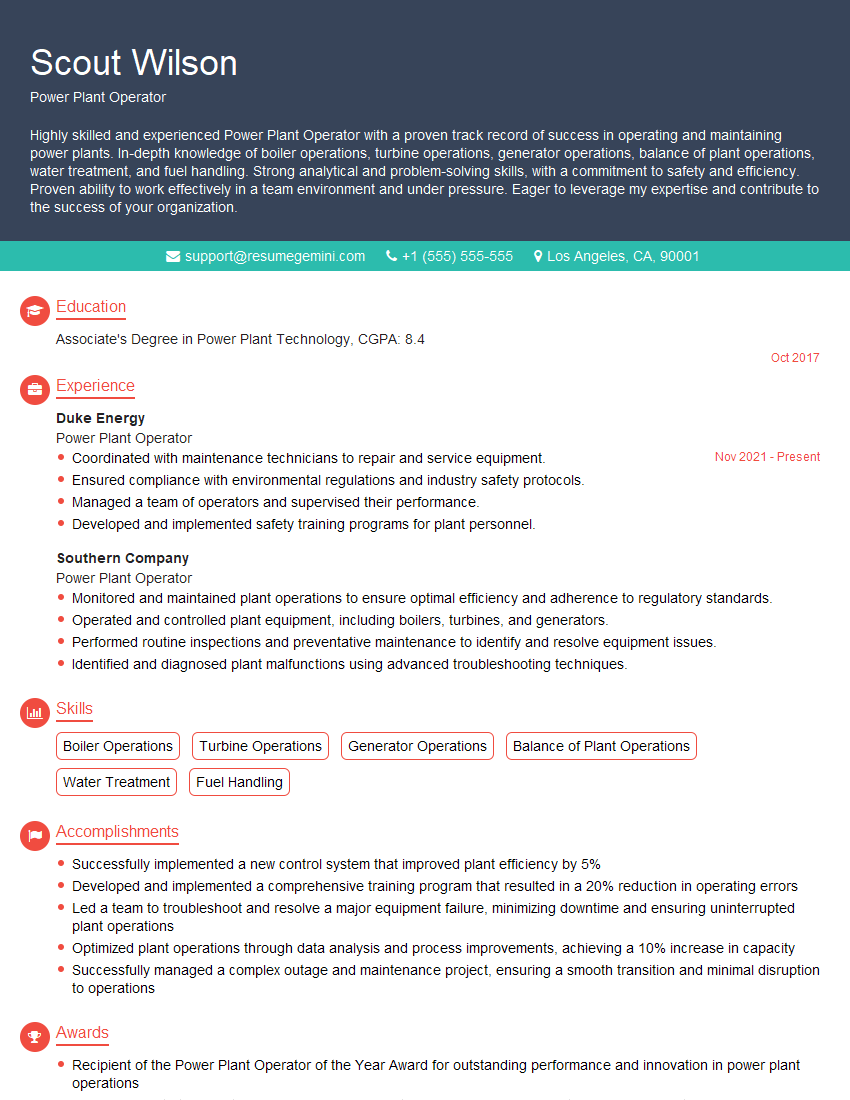

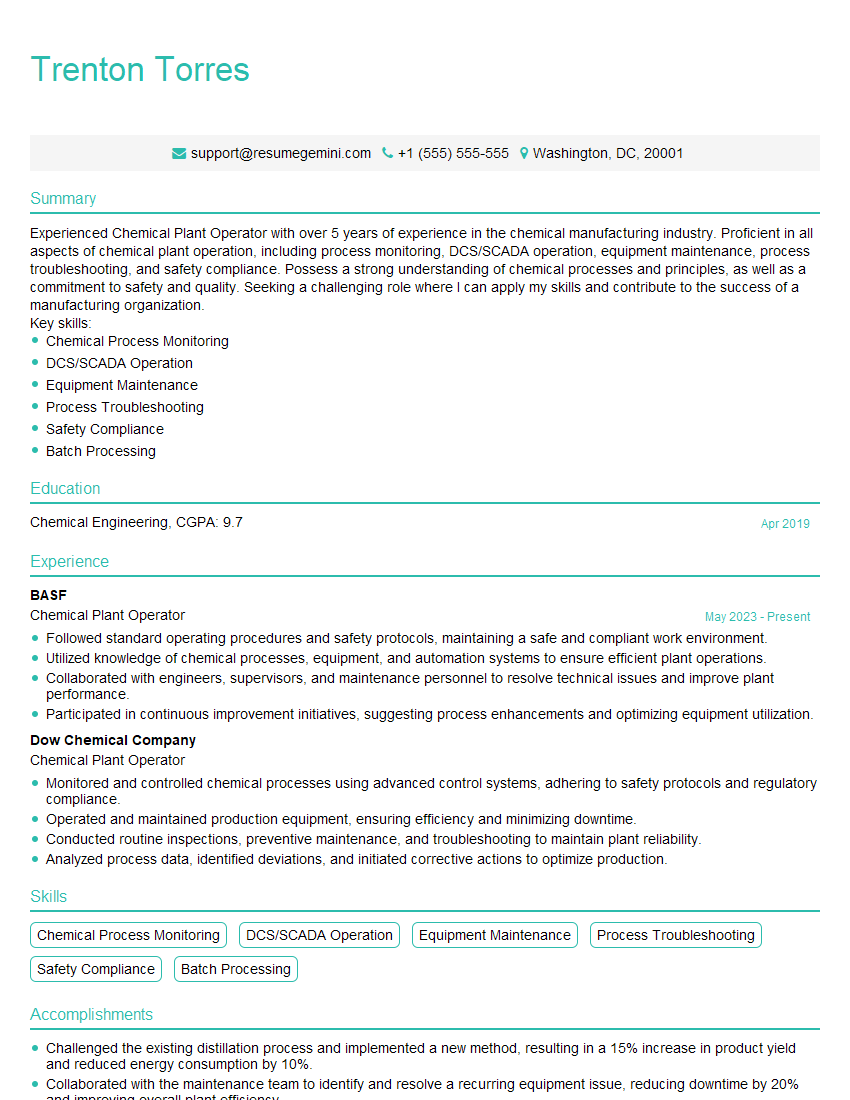

Mastering the knowledge and skills related to Hot and Cold Work Environments significantly enhances your career prospects in many high-demand industries. A strong understanding of safety and practical application is highly valued by employers. To maximize your job search success, it’s crucial to create a compelling and ATS-friendly resume that showcases your expertise. ResumeGemini is a trusted resource to help you build a professional resume that stands out from the competition. Leverage their tools and resources to craft a powerful document that highlights your qualifications effectively. Examples of resumes tailored to Hot and Cold Work Environments are available to guide you further.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good