Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Laser Projection interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Laser Projection Interview

Q 1. Explain the difference between laser diode and solid-state lasers in projection applications.

Laser diodes and solid-state lasers both find application in projection, but differ significantly in their architecture and characteristics. Laser diodes are semiconductor devices that produce light directly through electroluminescence. They’re compact, relatively inexpensive, and efficient, making them ideal for smaller, lower-power projection systems like pico projectors. Think of them as tiny, highly focused light bulbs.

Solid-state lasers, on the other hand, utilize a gain medium (often a crystal like Nd:YAG or Yb:YAG) that is pumped by another light source, usually a laser diode. This process amplifies the light, resulting in a much more powerful and coherent beam. This makes them suitable for high-brightness, large-scale projection systems like those used in professional cinemas or laser shows. They are like sophisticated light amplifiers, taking a relatively weak input and transforming it into a powerful, high-quality output.

In short, laser diodes are best for compact, low-cost solutions, while solid-state lasers are preferred for high-power, high-quality projection systems needing more brightness and color fidelity. The choice depends heavily on the specific application requirements.

Q 2. Describe the process of laser beam alignment and adjustment.

Laser beam alignment and adjustment are critical for optimal image quality and safety. The process typically involves using precision optical components like mirrors and lenses to steer and focus the laser beams. Think of it as carefully aiming a highly powerful flashlight to precisely hit the intended target.

The steps generally include:

- Initial Alignment: Using alignment tools like a laser pointer or a CCD camera, the coarse alignment of the laser beam path is established to get the beams generally pointing in the right direction.

- Fine Adjustment: Micro-adjustments are made using precision screws or motorized stages to fine-tune the beam position and convergence. This ensures the beams intersect perfectly at the intended point, which is crucial for color mixing in RGB systems.

- Focus Adjustment: Lenses are adjusted to achieve the desired spot size and focus on the projection screen or surface. This determines the sharpness and clarity of the projected image. Too much or too little focus creates a blurry image.

- Power Balancing: For multi-laser systems (like RGB), individual laser powers are adjusted to achieve a balanced color output. This avoids color imbalances where one color is significantly brighter than the others.

The process is iterative, requiring careful measurement and adjustment until the desired results are achieved. Advanced systems use software control and feedback mechanisms for automated alignment and monitoring.

Q 3. What are the key safety precautions when working with high-powered lasers?

High-powered lasers pose significant eye and skin hazards. The most critical safety precaution is always to never look directly into the beam. Even brief exposure can cause permanent eye damage. Imagine focusing the sun’s rays with a magnifying glass – the laser beam is far more concentrated and potentially far more damaging.

Other key precautions include:

- Protective eyewear: Use appropriate laser safety eyewear with optical density ratings that match the laser’s wavelength and power. The eyewear should meet relevant safety standards (like ANSI Z136.1).

- Enclosure and interlocks: High-powered lasers should be operated within enclosures that prevent accidental exposure. Interlocks should ensure the laser cannot be activated unless the enclosure is properly closed.

- Warning signage: Clearly post warning signs indicating the presence of lasers and any associated hazards.

- Controlled environment: Operate the laser in a controlled environment where accidental exposure is minimized. Restrict access to authorized personnel only.

- Emergency procedures: Establish clear emergency procedures in case of accidental exposure. Know where the nearest eye wash station is and have a plan for seeking medical attention.

Regular safety training and adherence to established protocols are essential to prevent accidents and ensure a safe working environment.

Q 4. How do you calibrate a laser projection system for optimal image quality?

Calibrating a laser projection system for optimal image quality involves a multi-step process ensuring accurate color reproduction, uniform brightness, and sharp focus. It’s a bit like fine-tuning a musical instrument to produce the perfect sound.

Steps typically include:

- Color Calibration: Using a colorimeter or spectrophotometer, measure the color output and adjust the laser powers and color correction matrices to achieve accurate color reproduction according to a defined color space (e.g., Rec. 709, DCI-P3).

- Brightness Uniformity: Analyze the brightness across the projected image. Adjust laser power and optical components to minimize any brightness variations or ‘hot spots’. This ensures a consistent image throughout.

- Geometric Correction: Address any distortions or geometric irregularities in the projected image. This often involves software adjustments or adjustments to the scanning mirrors to correct for keystone effect or other distortions.

- Focus and Sharpness Adjustment: Fine-tune the focus to ensure optimal image sharpness across the entire projected area. This might involve adjusting lenses or optical elements.

- Convergence (for multi-laser systems): Ensure perfect overlap of the laser beams to prevent color fringing or misalignment. This is especially crucial in RGB systems.

Calibration is often performed using specialized software and test patterns. The goal is to optimize the system for the specific application and environmental conditions.

Q 5. Explain the principles of laser scanning and its impact on image resolution.

Laser scanning is the process of rapidly deflecting a laser beam across a surface to create an image. Imagine drawing a picture with a very fast, precise, and incredibly bright pen. The speed and precision of this ‘pen’ (the laser beam) directly impact the image resolution.

The laser beam is typically deflected using galvanometer scanners, which are small, high-speed mirrors controlled by electric signals. The resolution of the projected image depends on several factors:

- Scanner speed and accuracy: Higher speed and precision result in finer detail and higher resolution.

- Number of scan lines: More scan lines result in a sharper and more detailed image, similar to increasing the resolution of a computer monitor.

- Laser spot size: The smaller the spot size, the finer the detail that can be projected, and therefore the higher the resolution.

Increasing any of these factors increases the image resolution, but it also typically increases the complexity and cost of the system. A balance must be found between resolution requirements and cost constraints.

Q 6. What are the different types of laser scanners used in projection systems?

Several types of laser scanners are used in projection systems, each with its own advantages and disadvantages:

- Galvanometer scanners: These are the most common type, using small, rapidly rotating mirrors to deflect the laser beam. They are accurate, fast, and relatively inexpensive, making them suitable for a wide range of applications.

- Polygon scanners: These use a rotating polygon mirror with multiple facets. Each facet reflects the beam, creating a series of discrete scan lines. They are often used in high-speed, high-resolution applications, but they can be less precise than galvanometer scanners.

- Resonant scanners: These use a vibrating mirror to create a continuous scan, resulting in very high scan rates. They are particularly suited for dynamic displays or applications requiring extremely fast refresh rates, but their accuracy can be limited.

- Microelectromechanical systems (MEMS) scanners: These use miniature mirrors fabricated using micro-machining techniques. They are compact and can be integrated into smaller devices, but are often limited in their scan range and speed.

The choice of scanner depends on the specific application’s requirements regarding speed, resolution, accuracy, and cost.

Q 7. Describe your experience with different types of laser projection technologies (e.g., RGB, DPSS).

Throughout my career, I’ve worked extensively with various laser projection technologies. My experience includes working with both RGB laser systems and DPSS (Diode-Pumped Solid-State) lasers.

RGB laser systems offer the most vibrant and accurate color reproduction. I’ve been involved in projects using red, green, and blue lasers combined to create a full-color image. The challenge with RGB systems lies in precisely aligning and balancing the three laser beams to avoid color artifacts and ensure color uniformity across the projected image. This requires meticulous calibration and often involves advanced color management techniques. One notable project was the calibration of a large-venue laser projection system for a concert series; achieving accurate color fidelity and a consistent brightness level across the massive screen was a particular challenge.

DPSS lasers, on the other hand, often utilize a single laser source to generate a specific wavelength (e.g., green). I’ve worked with DPSS green lasers in applications where high power and efficiency are paramount. DPSS lasers are often used in combination with other technologies to create a full-color image or to project specific colors. A recent project involved incorporating DPSS lasers into a holographic projection system; the high brightness of these lasers greatly improved the display’s clarity and image quality.

My experience spans both large-scale professional projection systems and smaller, more compact applications. Each technology has its own strengths and weaknesses, and selecting the appropriate laser projection system requires a thorough understanding of both the application’s requirements and the capabilities of different laser technologies.

Q 8. How do you troubleshoot common issues in laser projection systems (e.g., misalignment, color imbalance)?

Troubleshooting laser projection systems involves a systematic approach. Misalignment, for instance, often manifests as blurry or distorted images. This can be addressed by carefully adjusting the laser’s optical path using precision alignment tools. We use specialized optical mounts and software to finely tune the position and angle of the laser source, mirrors, and lenses. Color imbalance, on the other hand, usually points to issues with the laser diodes themselves, or potential issues in the dichroic mirrors used to combine the colors. I start by checking the power output of each individual color (red, green, blue) using a power meter. If one color is significantly weaker, it might require replacing the affected laser diode or cleaning optical surfaces. Sometimes the issue is with the color mixing process, and adjustments to the optical path might be needed. We’d meticulously analyze color profiles generated by a spectrometer to identify and correct these imbalances.

A step-by-step approach is crucial: First, visually inspect the system for any loose connections or obvious damage. Then, systematically check each component for proper functioning using specialized diagnostic tools. Finally, if the problem persists, we can consult the system’s technical specifications and manuals to isolate the fault and initiate repair or replacement.

Q 9. What software and hardware are you familiar with for laser projection control and design?

My experience spans a wide range of software and hardware. For laser projection control, I’m proficient in Pangolin Beyond, a leading software solution widely used in professional laser shows, offering capabilities for creating complex animations, effects, and synchronizing laser output with audio and other media. I also have experience with programs like LaserGrafX, which allows for more precise control over beam parameters and scan head movements. On the hardware side, I’ve worked extensively with various laser sources from manufacturers like Coherent, Spectra-Physics, and IPG, and I am familiar with scanners from Scanlab and Cambridge Technology. These scanners vary in speed, accuracy, and the number of points they can address, impacting the complexity of displays that are possible. For larger installations, I’ve used high-power laser sources coupled with sophisticated beam shaping optics to create large-scale projections on buildings or landscapes.

Q 10. Explain the concept of laser beam modulation and its importance in projection.

Laser beam modulation is the process of controlling the intensity, shape, or other characteristics of a laser beam over time. In projection systems, this is essential for creating images and animations. It’s like controlling the brightness of a lightbulb to create different levels of illumination, but with incredible speed and precision. We modulate the laser’s output using various techniques. For simple on/off switching, we can use electronic shutters. For more complex modulations, we use acousto-optic modulators (AOMs) or electro-optic modulators (EOMs), which rapidly change the refractive index of a crystal, altering the laser beam’s intensity. This allows us to create grayscale images, smooth transitions and fast-changing colors. Without beam modulation, we’d only have a single, static beam of light.

Imagine trying to draw a picture with only a single, always-on light source. You couldn’t create any detail. Modulation allows us to draw incredibly detailed and dynamic images by controlling the laser’s intensity pixel by pixel.

Q 11. How do you ensure the safety of audiences during a laser show?

Ensuring audience safety is paramount in any laser show. This requires a multifaceted approach. First, we perform a thorough risk assessment, considering the laser’s power, wavelength, and potential exposure duration. Based on this assessment, we implement appropriate safety measures. This includes using laser safety eyewear rated for the specific laser wavelengths used, carefully positioning the projectors to minimize direct exposure, and employing interlocks and safety systems to prevent accidental activation or malfunction. For outdoor shows, we often use beam blockers to prevent stray beams from reaching unintended areas. The environment and the laser’s power level dictate the safe viewing distance; audience areas are carefully designated to maintain sufficient separation from the projected beams. Furthermore, clear signage and announcements warn audiences of potential laser hazards.

For example, we might use Class 3R lasers for close-range projections requiring additional safety measures, whereas for larger shows we’d use higher power lasers but implement strict beam management to mitigate risk.

Q 12. What are the limitations of laser projection technology?

Despite its advantages, laser projection technology has limitations. One significant constraint is the cost. High-power, high-quality laser systems, especially those incorporating multiple wavelengths for full-color projection, can be very expensive. Another limitation lies in the potential for atmospheric interference. Smoke, fog, and dust particles can scatter or absorb the laser light, reducing image clarity and brightness. This is particularly problematic in outdoor environments. Also, the lifespan of laser diodes is finite. While advancements are constantly being made, these components do eventually degrade, requiring replacement and increasing maintenance costs. Finally, the relatively high intensity of laser light can pose safety risks if not handled properly, demanding strict adherence to safety protocols.

Q 13. Describe your experience with different projection surfaces and their impact on image quality.

The choice of projection surface significantly impacts image quality. Smooth, matte white surfaces are generally ideal, offering good reflectivity and minimal specularity (glare). However, the surface’s material and texture influence the projected image’s brightness, contrast, and color saturation. I’ve worked with various surfaces: high-gain screens for brighter projections in low-light environments; diffused screens to minimize hot spots and enhance uniformity; and even projected onto natural surfaces like buildings or water features. Each requires a different approach to calibration and setup. Rough surfaces scatter the laser light more, reducing image sharpness and brightness. Conversely, highly reflective surfaces can cause unwanted specular reflections, creating bright spots and reducing overall image quality.

For example, projecting onto a textured brick wall would require different settings than projecting onto a smooth, purpose-built projection screen. The wall would result in a lower-quality, less focused image due to scattering and absorption of the light.

Q 14. Explain the importance of laser beam divergence in projection systems.

Laser beam divergence refers to the widening of the laser beam as it travels. It’s crucial in projection systems because it determines the spot size and intensity at a given distance from the projector. Low divergence means the beam remains relatively narrow over a long distance, ideal for long-throw projections or creating sharp, focused images. High divergence results in a rapidly spreading beam, reducing brightness and sharpness at greater distances. The divergence angle is determined by several factors, including the laser’s wavelength and the diameter of the laser beam’s output aperture (the exit hole). We use beam-shaping optics like collimators and expanders to manipulate beam divergence and optimize it for a particular projection distance and application. A low divergence is crucial for creating well-defined images over large distances while a higher divergence might be better for flood illumination.

Imagine shining a flashlight—a highly divergent beam quickly spreads out, making it less effective at illuminating distant objects. A laser, on the other hand, can have very low divergence, allowing us to project a sharp image onto a screen hundreds of meters away.

Q 15. How do you design a laser projection system for a specific venue or event?

Designing a laser projection system for a specific venue or event involves a meticulous process that considers several key factors. It’s like creating a bespoke suit – you need precise measurements and a deep understanding of the ‘client’ (the venue) to ensure a perfect fit.

- Venue Assessment: This is paramount. We need to understand the dimensions of the projection surface (wall, floor, object), its reflectivity, ambient light levels (natural and artificial), and any obstructions. For example, a large, dark cathedral will require different laser power and projection techniques compared to a brightly-lit outdoor stadium.

- Content Creation: The projected content itself heavily influences the system design. High-resolution video requires a more powerful projector and potentially multiple projectors for seamless blending. A simple graphic might only need a low-power device.

- Projector Selection: The projector’s specifications – lumens (brightness), resolution, laser source type (e.g., RGB, DPSS), and throw ratio (the distance needed to achieve a particular image size) – are chosen based on the venue assessment and content requirements. We need to ensure the projector’s output matches the surface’s characteristics to optimize image quality.

- Optical Alignment and Calibration: Precision is crucial, especially for large-scale projections or complex mapping scenarios. This includes careful positioning of the projectors, lens selection, and precise calibration to ensure accurate color and geometry. We might use specialized software and tools to achieve pixel-perfect alignment.

- Safety Considerations: Laser safety is paramount. We need to calculate the laser class, implement appropriate safety measures (e.g., safety eyewear, beam blockers, warning signs), and adhere to all relevant safety regulations. This is non-negotiable.

For example, in designing a projection system for a historical building façade, we’d start by performing a thorough site survey, taking detailed measurements and analyzing the building’s texture and surface irregularities. This informs our choice of projector, lenses, and mapping software to ensure the projection perfectly conforms to the building’s contours.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with laser projection mapping.

I have extensive experience with laser projection mapping, from small-scale architectural projections to large-scale events. It’s like painting with light, but instead of a brush, we use lasers and sophisticated software.

My experience encompasses:

- 3D Modeling and Texture Mapping: Creating accurate 3D models of the projection surface is essential. We then apply textures and animations to these models, which the projection system uses to accurately project onto the surface, even accounting for its three-dimensional shape and irregularities.

- Software Proficiency: I’m proficient in industry-standard software packages like MadMapper, Resolume, and Notch, which provide powerful tools for creating and controlling complex projection mappings. These tools allow for precise control over the positioning, warping, and blending of multiple projector outputs.

- Color Calibration and Blending: Creating seamless blends between multiple projectors requires careful color calibration and precise geometry correction. This ensures that the overall image appears uniform and free of artifacts at the seams.

- On-site Calibration and Adjustment: Often, adjustments are necessary on-site to account for unforeseen circumstances such as uneven surfaces or variations in ambient light. Real-time adjustments are often required to fine-tune the projection for optimal visual impact.

For example, I recently worked on a projection mapping project for a museum exhibit, where we projected dynamic animations onto a complex, curved sculpture. This involved creating a high-fidelity 3D model, meticulously calibrating the projectors, and ensuring seamless transitions between various animation sequences. The result was a visually stunning and engaging experience for the museum’s visitors.

Q 17. What are the environmental factors affecting laser projection performance?

Environmental factors significantly impact laser projection performance. Imagine trying to paint a picture outdoors on a windy day – the results wouldn’t be ideal. Similarly, several environmental factors can degrade the quality of a laser projection.

- Ambient Light: High levels of ambient light wash out the projection, reducing contrast and visibility. This is particularly problematic in brightly lit outdoor environments. Techniques like increasing projector brightness or using specialized screens can mitigate this.

- Temperature and Humidity: Extreme temperatures can affect the laser’s output power and stability, and high humidity can cause condensation on optical components, degrading image quality. Temperature-controlled enclosures might be necessary in extreme climates.

- Dust and Particles: Dust and airborne particles scatter the laser light, reducing image clarity and potentially damaging the optical components. Regular cleaning and potentially air filtration are important.

- Wind: Wind can affect the stability of the projection, especially for outdoor applications. Windbreaks or sheltered locations might be required.

- Vibration: External vibrations can cause the laser beam to shift or fluctuate, degrading image stability. Isolating the projection system from vibrations is critical in noisy or shaky environments.

For instance, projecting onto an outdoor fountain requires addressing both the water spray’s effect on the projection and the fluctuating ambient light conditions due to the sun’s movement throughout the day. Careful planning and the use of robust equipment are essential.

Q 18. How do you maintain and service laser projection equipment?

Maintaining and servicing laser projection equipment is crucial for optimal performance and longevity. It’s like regular car maintenance – preventive measures prevent costly repairs down the line.

- Regular Cleaning: Optical components (lenses, mirrors) should be regularly cleaned with appropriate lens cleaning solutions to remove dust and debris. Always use the correct methods to avoid scratching.

- Air Filtration: In dusty environments, incorporating air filtration systems helps prevent dust from accumulating on optical components.

- Thermal Management: Ensuring proper ventilation and cooling prevents overheating, which can damage components.

- Calibration Checks: Periodic calibration checks ensure accurate color reproduction and geometric alignment, particularly critical for multi-projector setups.

- Laser Alignment: For optimal performance, lasers require periodic alignment to maintain proper beam focus and stability.

- Software Updates: Regularly updating projector firmware and control software ensures access to bug fixes and performance enhancements.

For example, after a long outdoor projection event, we’d thoroughly clean all optical surfaces, inspect the cooling system, and verify the alignment to ensure everything is in peak condition for the next event. We also maintain a detailed log of all maintenance activities, facilitating proactive preventative maintenance.

Q 19. Explain your understanding of laser speckle and its mitigation techniques.

Laser speckle is a granular interference pattern that appears in laser projections, resembling a grainy texture. It’s caused by the coherent nature of laser light, where the light waves interfere with each other constructively and destructively. Imagine looking at the light reflected from a rough surface – the uneven reflections create a speckled pattern.

Mitigation techniques involve:

- Rotating Diffusers: Rotating a diffuser in the laser beam path effectively averages out the interference pattern, reducing the visibility of speckle. It’s like blurring the image slightly.

- Spatial Light Modulators (SLMs): SLMs can dynamically shape the laser beam profile, further smoothing out the speckle pattern. This offers more sophisticated control over speckle reduction.

- Multiple Laser Sources: Using multiple lasers with slightly different wavelengths or polarization can reduce speckle by averaging out the interference patterns. The individual speckle patterns from each laser are not correlated, resulting in a less noticeable overall speckle.

- Moving the Projection Surface: A slightly moving projection surface can reduce speckle by temporal averaging. This is sometimes applicable, for example, if projecting onto a screen that’s partially flexible and can be gently moved.

The choice of mitigation technique depends on factors such as the application, budget, and the acceptable level of speckle reduction. For high-resolution projections, more sophisticated methods like SLMs might be necessary, while for simpler applications, a simple rotating diffuser could suffice.

Q 20. Describe your experience with different color mixing techniques in laser projection.

Color mixing in laser projection involves combining different laser wavelengths to create a wide range of colors. Unlike traditional RGB projectors that use color wheels, laser projectors can directly generate a wide color gamut. There are several methods:

- Additive Color Mixing: This is the most common method where red, green, and blue lasers are combined to create a wide range of colors. The intensity of each laser is adjusted to achieve the desired color. It’s similar to how pigments mix in painting, except here it’s light.

- Subtractive Color Mixing: This method uses color filters to selectively remove portions of the light spectrum, producing different colors. It’s less common in laser projection but may be used in specific applications.

- Wavelength Mixing: This involves combining multiple laser wavelengths to generate colors that fall outside the traditional RGB gamut. This results in a broader and more vivid color space, leading to more accurate color reproduction.

- Phosphor-Based Laser Projection: Some laser projectors use phosphor wheels to convert blue laser light into various colors. This technology is often more efficient and cost-effective but might not offer the same wide color gamut as direct RGB laser projectors.

My experience includes working with both RGB and wavelength mixing techniques. I’ve had the opportunity to implement advanced techniques in high-end projection systems, requiring careful understanding of wavelength optimization and color calibration to achieve the desired color accuracy and brightness.

Q 21. What are your preferred methods for testing and quality assurance of laser projection systems?

Testing and quality assurance of laser projection systems are essential to ensure optimal performance and reliability. It involves a series of checks to verify that the entire system meets the intended specifications and performs as expected.

- Optical Alignment and Calibration: This verifies that the lasers are correctly aligned, the lenses are focused, and the color and geometric parameters are correctly calibrated. We use specialized tools and software to measure and adjust parameters with high precision.

- Power and Thermal Testing: This assesses the laser power output, stability, and thermal behavior under various operating conditions. We measure these parameters to ensure the system stays within safety and performance standards.

- Image Quality Assessment: This involves evaluating various image quality metrics, including brightness, contrast, resolution, color accuracy, and the presence of artifacts like speckle. We use specialized instruments and software to objectively assess image quality.

- System Integration Testing: For complex systems involving multiple projectors and control systems, integration tests ensure proper communication and functionality between all components. These tests typically involve rigorous simulated projection scenarios.

- On-site Performance Verification: Before the final event, an on-site performance verification ensures the system functions as intended under real-world conditions, including ambient lighting and environmental factors.

For a recent large-scale event, we conducted rigorous testing of the projection system across various parameters. Each projector underwent a detailed optical alignment, and we performed color calibration to ensure perfect consistency across all projectors. The system then underwent simulated projection scenarios to ensure seamless operation before the actual event, which greatly reduced the risk of technical glitches and ensured a successful show.

Q 22. How do you manage the thermal management of high-powered lasers?

Thermal management in high-powered lasers is crucial because the conversion of electrical energy to light generates significant heat, potentially damaging the laser components and impacting performance. Effective cooling prevents overheating and ensures operational stability. This is achieved through various methods, each chosen based on the laser’s power and design.

- Active Cooling: This involves using external mechanisms to remove heat. Common methods include:

- Water Cooling: Circulating chilled water around the laser’s heat sink is highly effective for high-power lasers. We often use closed-loop systems to prevent contamination.

- Air Cooling: High-volume fans or blowers can effectively cool less powerful lasers. Heat sinks with large surface areas are essential.

- Passive Cooling: This relies on the natural dissipation of heat through conduction, convection, and radiation. Often involves designing the laser housing with efficient heat sinks and strategically placing components to maximize airflow.

- Thermoelectric Coolers (TECs): These solid-state devices use the Peltier effect to pump heat away from the laser diode. They’re particularly useful for precise temperature control.

For instance, in a recent project involving a 10kW fiber laser for industrial cutting, we implemented a closed-loop water cooling system with a chiller unit to maintain a consistent operating temperature, crucial for preventing damage to the fiber and maintaining output power.

Q 23. What are the different types of laser safety eyewear?

Laser safety eyewear is categorized by the wavelengths and optical densities (ODs) they protect against. The OD rating indicates how much laser light the eyewear attenuates. Different types exist to address various laser applications:

- Fixed-OD Eyewear: Offers a specific OD for a particular wavelength range. This is suitable for applications with known laser parameters.

- Variable-OD Eyewear: Allows adjustment of the OD, offering greater flexibility across various laser wavelengths and power levels. This is beneficial in laboratories or diverse applications.

- Glasses vs. Goggles: Glasses provide protection for the eyes, while goggles offer broader protection, including the surrounding area of the eyes.

- Wavelength-Specific Eyewear: Designed to filter specific wavelengths, offering maximal protection for the type of laser being used. It’s essential to use the correct eyewear based on the laser’s wavelength to prevent damage.

Choosing the correct eyewear involves careful consideration of the laser’s wavelength, power, and beam type. Mismatched eyewear can lead to severe eye injuries. Always refer to the laser’s safety manual and consult with a laser safety officer.

Q 24. How do you select appropriate laser power for a specific application?

Selecting the appropriate laser power depends heavily on the specific application. Insufficient power leads to poor results, while excessive power can damage materials or create safety hazards.

We consider factors like:

- Material Properties: Different materials absorb laser light differently. Thicker or more reflective materials require higher power.

- Desired Processing Speed: Higher power generally leads to faster processing, but only up to a certain point where the material may be damaged.

- Beam Quality: A higher-quality beam (low M2) allows for tighter focusing and better control, reducing the required power.

- Application Type: Laser cutting needs higher power than laser marking or engraving. Medical applications often use lower powers for precision and to avoid tissue damage.

For instance, laser cutting steel requires considerably higher power than engraving wood. Through detailed simulations and testing, we determine the optimal power balance between efficiency, quality, and safety for any given application.

Q 25. Explain the concept of laser beam homogenization.

Laser beam homogenization transforms a Gaussian (or other non-uniform) beam profile into a more uniform, flat-top profile. This is often crucial for applications needing uniform illumination or material processing across a large area. This process is typically achieved using several different techniques:

- Microlens Arrays: An array of tiny lenses refracts the beam, distributing the power evenly across the target area.

- Diffractive Optical Elements (DOEs): These elements use diffraction to reshape the beam profile. They’re highly efficient for creating tailored beam shapes.

- Rotating Diffusers: Moving diffusers are used to integrate the intensity profile uniformly by using temporal averaging across the target surface.

- Fiber Bundles: Using multiple optical fibers to distribute the light can lead to a more uniform profile, but the output is dependent on the bundle’s configuration.

Imagine trying to illuminate a large canvas with a spotlight; the center would be much brighter than the edges. Homogenization is akin to using a diffuser to create an evenly lit surface. In laser material processing, homogenization guarantees even treatment of the processed area.

Q 26. How do you handle unexpected issues or malfunctions during a live laser show?

During a live laser show, unexpected issues require immediate, decisive action. Our protocols cover various scenarios:

- Redundancy: We use backup systems to minimise downtime. A spare laser projector and control system are always ready.

- Regular Maintenance and Testing: Rigorous pre-show checks and regular maintenance minimise the chance of unexpected problems.

- Emergency Shutdown Procedures: A dedicated emergency stop button and well-defined procedures are in place to instantly disable the lasers in case of malfunction.

- Communication: Clear communication channels between the operators, technicians, and show management are critical for swift response to any incident.

- Troubleshooting: Our team has extensive experience in identifying and resolving laser issues. We have developed flowcharts and quick-reference guides to address many common problems.

In one instance, a power supply malfunctioned during a show. Our backup system was activated instantly, minimizing interruption and maintaining the show’s continuity.

Q 27. Describe your experience with designing and implementing interactive laser projections.

I have extensive experience in designing and implementing interactive laser projections. This involves combining laser projection with sensors and software to create responsive and engaging experiences.

My projects have utilized:

- Motion Tracking: Tracking audience movements or object interactions to trigger dynamic changes in the laser projection.

- Depth Sensing: Using depth cameras to create three-dimensional effects and interactive environments.

- Touchscreens: Allowing users to directly manipulate the laser projection content through touch input.

- Real-Time Processing: Implementing algorithms and software to generate dynamic content based on user input or sensor data, using frameworks like OpenGL or Processing.

For example, I developed an interactive laser installation for a museum, where visitors’ movements triggered changing patterns and colors in a large-scale laser projection. The software was designed to adapt to various levels of audience interaction, making the experience dynamic and enjoyable.

Key Topics to Learn for Laser Projection Interview

- Laser Fundamentals: Understand laser principles, including stimulated emission, population inversion, and different laser types (e.g., gas, solid-state, semiconductor).

- Optical Systems: Master the principles of optical design, including lenses, mirrors, beam shaping, and spatial filtering relevant to projection systems.

- Image Generation and Modulation: Learn about techniques for generating and modulating laser beams to create images, including spatial light modulators (SLMs) and digital micromirror devices (DMDs).

- Projection Technologies: Familiarize yourself with various projection technologies like DLP, LCD, and LCoS, understanding their strengths and weaknesses for different applications.

- Color Reproduction: Gain a solid understanding of colorimetry, color spaces (e.g., RGB, XYZ), and how to achieve accurate color reproduction in laser projection systems.

- Laser Safety and Regulations: Understand relevant safety regulations and procedures for working with lasers, and be prepared to discuss safety protocols.

- System Calibration and Alignment: Be ready to discuss methods for calibrating and aligning laser projection systems for optimal performance and image quality.

- Troubleshooting and Maintenance: Familiarize yourself with common issues in laser projection systems and practical approaches to troubleshooting and maintenance.

- Applications of Laser Projection: Explore various applications, including entertainment (e.g., cinema, stage lighting), medical imaging, industrial applications (e.g., laser marking, material processing), and scientific research.

- Advanced Topics (Optional): Depending on the seniority of the role, consider exploring areas like holographic projection, 3D laser scanning, or adaptive optics.

Next Steps

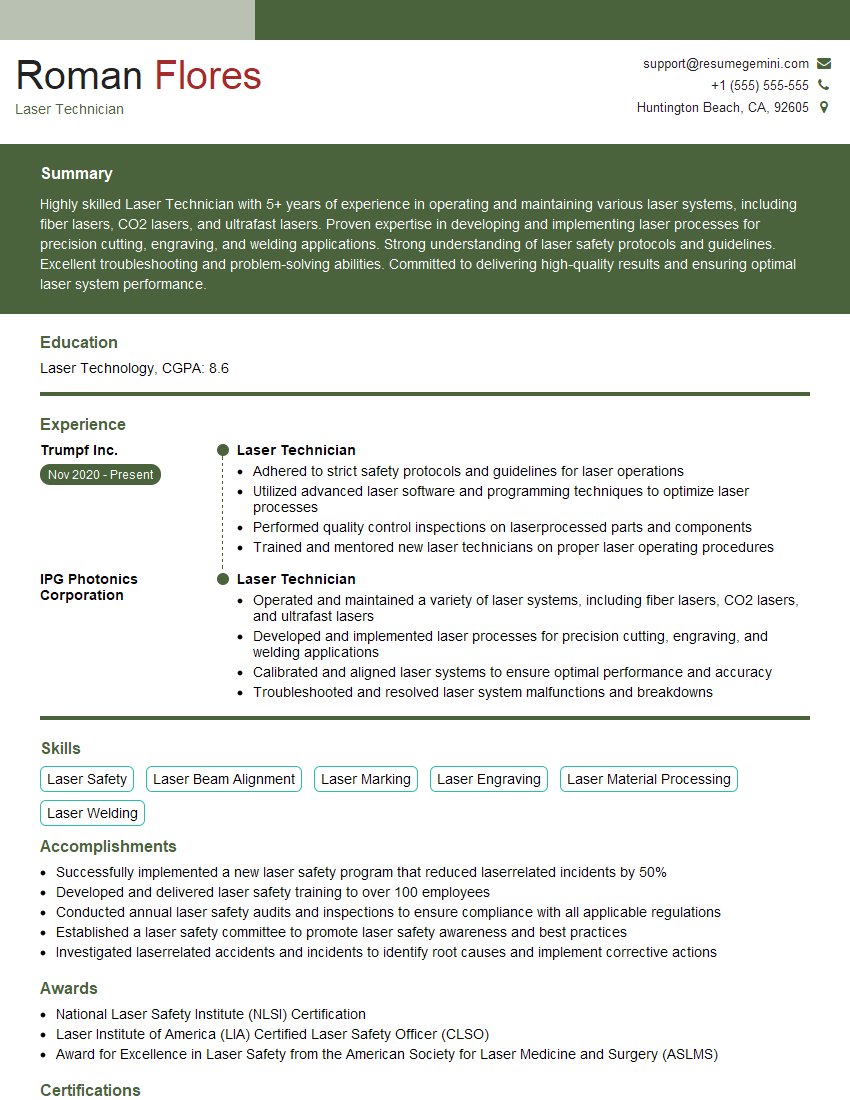

Mastering laser projection opens doors to exciting and innovative careers in various industries. A strong understanding of these core concepts significantly increases your chances of interview success. To further enhance your job prospects, focus on creating an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource to help you build a professional and impactful resume. Examples of resumes tailored to Laser Projection are available to guide you through this process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good