Unlock your full potential by mastering the most common Medical Device Quality Assurance (MDQA) interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Medical Device Quality Assurance (MDQA) Interview

Q 1. Explain the difference between a CAPA and a Corrective Action.

A Corrective Action (CA) addresses a specific problem that has already occurred, focusing on fixing the immediate issue. A Corrective and Preventive Action (CAPA) is a broader, more proactive system. While it includes Corrective Actions, it also incorporates Preventive Actions to stop similar problems from happening in the future. Think of it this way: a CA is like fixing a flat tire, while a CAPA is like investigating why the tire went flat in the first place and implementing changes to prevent future flats – maybe by improving tire maintenance or choosing more durable tires.

- Corrective Action (CA): Fixes the immediate problem. Example: A batch of medical devices fails a quality test. The CA would be to identify and remove the defective batch from circulation.

- Preventive Action (PA): Prevents recurrence of the problem. Example: After discovering a flaw in the manufacturing process that led to the defective batch, a PA would involve modifying the process to prevent similar defects.

- CAPA: Encompasses both CA and PA, addressing the root cause and preventing future occurrences. Example: A full investigation reveals the root cause of the defective batch was due to inadequate operator training. The CAPA would include retraining operators and implementing stricter quality checks.

Q 2. Describe your experience with ISO 13485.

I have extensive experience working within the framework of ISO 13485:2016, the internationally recognized standard for medical device quality management systems. In my previous role at [Previous Company Name], I was directly involved in the implementation and maintenance of our ISO 13485 certified QMS. This included:

- Developing and maintaining quality management system documentation, including procedures, work instructions, and records.

- Conducting internal audits to ensure compliance with the standard and identifying areas for improvement.

- Participating in management review meetings to assess the effectiveness of the QMS and identify opportunities for improvement.

- Leading and participating in CAPA investigations.

- Managing and tracking non-conformances, corrective actions, and preventive actions.

- Supporting regulatory inspections and audits.

My experience encompasses all aspects of the standard, from risk management and design control to process validation and post-market surveillance. I’m proficient in interpreting and applying the specific requirements outlined in the standard, and I understand its importance in ensuring the safety and effectiveness of medical devices.

Q 3. What is a Design History File (DHF), and what are its key components?

A Design History File (DHF) is a comprehensive collection of documents that provides a complete history of a medical device’s design and development process. It serves as evidence that the device meets its intended purpose and regulatory requirements. Think of it as a detailed birth certificate and medical history for the device, chronicling its development from concept to final design.

- Design Input: User needs, market requirements, regulatory requirements.

- Design Output: Specifications, drawings, test protocols and results.

- Design Reviews: Records of design review meetings, outcomes, and decisions.

- Risk Management Files: Hazard analysis, risk assessment, risk controls.

- Verification and Validation Plans and Reports: Demonstrating that the design meets its requirements.

- Design Changes and Modifications: Documentation of changes made to the design, the justification for the changes, and verification and validation of those changes.

Q 4. Explain the process of conducting a risk assessment for a medical device.

Conducting a risk assessment for a medical device involves a systematic process of identifying potential hazards, analyzing the likelihood and severity of those hazards, and implementing controls to mitigate risks. A common methodology is the Failure Mode and Effects Analysis (FMEA).

- Hazard Identification: Identify all potential hazards associated with the device, including its intended use and foreseeable misuse. This might involve brainstorming, reviewing similar devices, and consulting relevant standards.

- Risk Analysis: Assess the likelihood and severity of each identified hazard. This is often done using a risk matrix, assigning numerical values to likelihood and severity, then multiplying them to get a risk priority number (RPN).

- Risk Control: Develop and implement controls to mitigate the identified risks. Controls can be design changes, warnings, instructions for use, or training. The effectiveness of controls must be verified and validated.

- Risk Evaluation: Re-assess the risks after implementing controls to determine if they are adequately mitigated. This often involves re-calculating RPN values to see if they’re acceptably low.

- Documentation: All aspects of the risk assessment must be thoroughly documented.

Example: A risk assessment for an infusion pump might identify hazards such as inaccurate dosing, malfunctioning alarms, and infections. Controls might include redundant safety mechanisms, clear alarm systems, and sterilization protocols.

Q 5. How do you ensure traceability throughout the medical device lifecycle?

Ensuring traceability throughout the medical device lifecycle is crucial for maintaining quality, accountability, and regulatory compliance. This is achieved through a robust documentation system and the use of unique identifiers.

- Unique Device Identification (UDI): Using UDI systems, which assign unique identifiers to devices, enabling tracking through the entire lifecycle.

- Document Control System: Implementing a system for creating, reviewing, approving, and revising documents, ensuring each version is clearly identified and accessible.

- Change Control System: A system for managing changes to design, manufacturing processes, and other aspects of the device, tracing who made the changes, why, and the impact of those changes.

- Batch/Lot Tracking: Maintaining accurate records of manufacturing batches, allowing for identification and tracking of specific units in case of recalls or other issues.

- Supplier Management: Tracking materials and components from suppliers, ensuring that they meet quality standards.

These elements create a chain of custody and allow quick and accurate tracing in case of problems, enabling efficient root-cause analysis and recall management.

Q 6. What are the key requirements of 21 CFR Part 820?

21 CFR Part 820, the Quality System Regulation (QSR) from the FDA, outlines the requirements for quality systems for medical device manufacturers in the United States. Key requirements include:

- Device Master Record (DMR): A compilation of specifications, testing procedures, and other critical information for the device.

- Device History Record (DHR): A record of the manufacturing process, including materials used, test results, and other critical data for each device produced.

- Design Controls: A formal process to ensure that the device meets its intended use and user needs, including risk management, design verification, and design validation.

- Corrective and Preventive Actions (CAPA): A system to identify, investigate, and correct issues, as well as prevent recurrence.

- Nonconforming Material Control: A process for handling materials or devices that do not meet specifications.

- Quality Audits: Regular audits of the quality system to verify compliance with regulations and company procedures.

- Personnel Training: Ensuring that personnel are adequately trained to perform their tasks.

Compliance with 21 CFR Part 820 is essential for selling medical devices in the United States and demonstrates to regulatory bodies a commitment to patient safety.

Q 7. Describe your experience with internal audits and corrective actions.

I possess significant experience in conducting internal audits and implementing corrective actions. In my previous role, I led and participated in numerous internal audits, covering various aspects of the quality system, including design controls, manufacturing processes, and CAPA management. My auditing approach is systematic and thorough, using checklists and documented procedures to ensure comprehensive coverage.

When discrepancies or non-conformances are identified during audits, I follow a structured approach to corrective actions:

- Identify the root cause: Using techniques like 5 Whys or fishbone diagrams to understand the underlying reasons for the non-conformity.

- Develop and implement corrective actions: Defining specific actions to address the root cause and prevent recurrence.

- Verify the effectiveness of corrective actions: Monitoring and measuring the effectiveness of the implemented actions to ensure the problem is resolved and does not reoccur.

- Document everything: Maintaining detailed records of the audit findings, corrective actions, and their effectiveness.

My focus is not just on fixing immediate problems, but on implementing lasting improvements to the quality system, thereby minimizing future risks and improving product quality and patient safety. For instance, a recurring issue of incorrect labeling discovered during an audit could lead to a corrective action involving retraining staff, improving labeling procedures and implementing stricter checks.

Q 8. Explain the difference between verification and validation in medical device development.

Verification and validation are distinct but equally crucial processes in medical device development, both aimed at ensuring the device meets its intended use. Think of it like baking a cake: verification is making sure you’re following the recipe correctly (does the process work as planned?), while validation is confirming the cake tastes good and meets the customer’s expectations (does the final product meet the user needs?).

Verification focuses on confirming that each design and manufacturing step adheres to the defined specifications. It’s about process integrity. For example, verifying that a specific welding process consistently meets the required strength parameters. This involves inspecting processes, procedures, and outputs against pre-defined requirements. We use methods like inspections, tests, and reviews at each stage of the development process to verify compliance.

Validation, on the other hand, confirms that the final product fulfills its intended use and meets the user needs. It focuses on the outcome. For example, validating that the welded medical device can withstand the pressures encountered during its intended use. This involves testing the completed device to ensure its performance and safety.

In short, verification ensures you built it right, and validation ensures you built the right thing.

Q 9. What are some common quality metrics used in Medical Device QA?

Several key quality metrics are used in Medical Device QA to monitor and improve product and process quality. These metrics can be categorized into various groups, focusing on different aspects of the product lifecycle. Some common examples include:

- Defect Rate: The number of defective units produced per total units produced. A lower defect rate indicates better quality control. For example, a defect rate of 0.5% means 0.5 out of every 100 devices is defective.

- Yield: The percentage of good units produced relative to the total units started. High yield is a goal. A 98% yield means only 2% of units were scrapped or reworked.

- Customer Complaint Rate: The number of customer complaints received per total units shipped. A lower rate suggests higher customer satisfaction and fewer product issues in the field.

- Process Capability (Cp/Cpk): This statistical measure indicates how well a manufacturing process meets specified tolerances. Cp/Cpk values above 1.33 generally indicate a capable process.

- Mean Time Between Failures (MTBF): For finished devices, this metric measures the average time a device operates before it fails. A higher MTBF indicates greater reliability.

- First Pass Yield: Measures the proportion of units passing inspection on the first attempt, indicating process efficiency.

The specific metrics used will vary depending on the device, its intended use, and the regulatory requirements.

Q 10. How would you handle a non-conformity discovered during manufacturing?

Discovering a non-conformity during manufacturing requires immediate and decisive action to prevent further issues and ensure patient safety. My approach would involve these steps:

- Immediate Containment: Isolate the non-conformity and prevent any further production or distribution of affected units. This might involve quarantining the suspect batch.

- Investigation: Conduct a thorough investigation to identify the root cause of the non-conformity. This might involve reviewing manufacturing records, inspecting the affected units, and interviewing operators.

- Corrective and Preventive Actions (CAPA): Develop and implement corrective actions to address the immediate issue and preventive actions to prevent it from happening again. This could involve process adjustments, operator retraining, equipment maintenance, or material substitutions. Documentation is critical here.

- Non-Conforming Material Disposition: Determine the appropriate disposition of the non-conforming units. This could involve rework, repair, scrapping, or quarantine pending further investigation. All decisions need to be documented and approved.

- Verification of Corrective Actions: Verify that the implemented CAPA effectively resolves the root cause and prevents recurrence. This typically involves re-inspection and retesting of the process and products.

- Documentation: Meticulous documentation is essential throughout the entire process, including all investigation findings, CAPA implementation, verification results, and any deviations from established procedures. This documentation forms part of the quality system record.

Throughout this process, I would maintain open communication with relevant stakeholders, including management, regulatory agencies (as necessary), and potentially affected customers.

Q 11. Describe your experience with statistical process control (SPC).

Statistical Process Control (SPC) is a powerful tool used in manufacturing to monitor and improve process consistency. I have extensive experience implementing and interpreting control charts, specifically Shewhart charts (X-bar and R charts, for example), to track key process parameters and identify potential issues before they lead to non-conformities.

In my previous role, we used SPC to monitor the critical dimension of a catheter’s tip during manufacturing. By plotting the measurements on control charts, we could quickly identify any shifts or trends indicating potential process drift. This allowed us to proactively address issues like tool wear or material inconsistencies, preventing the production of devices outside the specified tolerances. The result was a significant reduction in the defect rate and increased process efficiency.

My understanding of SPC extends beyond simple chart interpretation. I’m also proficient in calculating process capability indices (Cp, Cpk) to assess process performance against specifications. This data-driven approach ensures we continually strive for improved process control and consistent product quality.

Q 12. What is your understanding of design control?

Design control is a systematic approach to managing the design and development of medical devices. It’s a crucial aspect of MDQA, ensuring that the device meets its intended use, safety, and performance requirements. It’s a structured process with defined stages and activities to manage risks and changes. Think of it as a blueprint for creating a safe and effective medical device.

Key elements of design control include:

- Design Input: Defining the needs and expectations for the device, translating user needs into specific requirements.

- Design Output: Verifying the final design meets the design input requirements, and ensuring design verification and validation activities are performed.

- Design Review: Formal reviews at various stages of the design process to assess progress, identify risks, and ensure compliance.

- Design Verification: Testing and inspection activities to verify that the design meets its pre-defined specifications.

- Design Validation: Testing and inspection activities to confirm that the design meets the intended use and user needs.

- Design Changes: A documented change control process to manage changes to the design throughout the product lifecycle.

- Design Transfer: Transferring the approved design to manufacturing, ensuring that the manufacturing process will consistently produce devices conforming to the design.

Adherence to a robust design control process is essential to mitigate risks and demonstrate compliance with regulatory requirements. Failing to follow design control properly can lead to significant issues, including device recalls and regulatory sanctions.

Q 13. What is a root cause analysis, and what methods are you familiar with?

Root cause analysis (RCA) is a systematic process to identify the underlying causes of a problem, rather than just addressing the symptoms. It’s crucial for preventing recurrence of issues and improving the overall quality system. Imagine a car breaking down – you wouldn’t just replace the flat tire; you’d investigate why it went flat to prevent future incidents.

Several methods are employed for RCA. I’m familiar with the following:

- 5 Whys: A simple, iterative questioning technique to drill down to the root cause by repeatedly asking “Why?”

- Fishbone Diagram (Ishikawa Diagram): A visual tool that categorizes potential causes and their relationships to the problem.

- Fault Tree Analysis (FTA): A deductive, top-down approach that uses logic gates to show how various events can combine to cause a failure.

- Failure Mode and Effects Analysis (FMEA): A proactive method to identify potential failure modes, assess their severity, and implement preventive measures.

The choice of RCA method depends on the complexity of the problem and the information available. Regardless of the method, a thorough and well-documented RCA is essential to identify effective corrective and preventive actions.

Q 14. Explain your experience with complaint handling and investigations.

Complaint handling and investigations are critical in maintaining patient safety and product quality. My experience includes receiving, investigating, and resolving complaints related to medical devices. The process involves these key steps:

- Complaint Receipt and Recording: Documenting all details of the complaint, including the type of device, date of incident, user details, and a description of the problem.

- Preliminary Assessment: Determining the severity of the complaint and its potential impact on patient safety. This often triggers an immediate investigation.

- Investigation: Conducting a thorough investigation, which may involve reviewing device history records, interviewing users, and analyzing the failed device. The goal is to identify the root cause(s) of the complaint.

- Corrective and Preventive Action (CAPA): Implementing actions to address the root cause of the complaint and prevent future occurrences. This may involve design changes, process improvements, or operator training.

- Complaint Closure: Once the investigation is completed and CAPA implemented and verified, the complaint is closed. The entire process is thoroughly documented and reviewed.

- Reporting: Regular reporting of complaints to management and regulatory agencies (as required) is also crucial. This data helps identify trends and prioritize areas for improvement.

In my previous role, we successfully investigated a complaint about a malfunctioning infusion pump. The investigation revealed a design flaw that was corrected, preventing similar incidents. This demonstrates the importance of effective complaint handling and its impact on patient safety and product improvement.

Q 15. How do you ensure compliance with relevant medical device regulations?

Ensuring compliance with medical device regulations, such as FDA’s 21 CFR Part 820 and ISO 13485, is paramount. It’s not just about ticking boxes; it’s about building a robust quality management system (QMS) that’s ingrained in every aspect of the product lifecycle. This involves a multi-faceted approach:

- Regulatory Knowledge: Staying updated on the latest regulatory changes and interpretations is crucial. This includes understanding specific requirements for the device classification (Class I, II, or III). We utilize tools like regulatory databases and professional networks to ensure this.

- Risk Management: Implementing a thorough risk management process (e.g., using ISO 14971) allows us to proactively identify, analyze, and mitigate potential hazards associated with the device. This is documented and reviewed regularly.

- Quality System Implementation: We meticulously follow our established QMS, ensuring all processes are documented, controlled, and regularly audited. This involves processes for design control, CAPA (Corrective and Preventive Actions), and internal audits.

- Record Keeping: Maintaining meticulous records of all design, manufacturing, and testing activities is essential for traceability and demonstrating compliance. We utilize electronic document management systems to streamline this process and ensure data integrity.

- Audits and Inspections: Regular internal audits and preparing for external regulatory audits are key to identifying areas for improvement and verifying compliance. I’ve personally led numerous internal audits and participated in several successful FDA inspections.

For example, during a recent project involving a Class II medical device, we implemented a robust design control process, rigorously documenting design inputs, outputs, and verification and validation activities. This proactive approach ensured our design met all regulatory requirements and minimized the risk of non-compliance.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with supplier management and auditing.

Supplier management and auditing are critical for ensuring the quality and safety of medical devices. My experience involves a comprehensive approach that goes beyond simply selecting vendors. It’s about building a collaborative relationship based on trust and shared responsibility for quality.

- Supplier Selection: We use a rigorous process for selecting suppliers, considering factors like their quality system, manufacturing capabilities, and track record. This typically involves reviewing their quality certifications (e.g., ISO 13485) and conducting pre-qualification audits.

- Supplier Audits: I have conducted numerous supplier audits, both on-site and remotely, assessing their compliance with our requirements and regulatory expectations. These audits cover areas such as their QMS, manufacturing processes, and quality records.

- Ongoing Monitoring: Simply auditing isn’t enough. We maintain ongoing monitoring of our suppliers through regular performance reviews, reviewing their quality metrics, and addressing any identified issues promptly. This proactive approach ensures consistent quality from our supply chain.

- Corrective Actions: If non-conformances are found, I actively work with suppliers to implement effective corrective and preventive actions (CAPAs) to prevent recurrence.

In one instance, a supplier’s manufacturing process deviated from our specifications, resulting in a batch of components with unacceptable variation. Through a collaborative investigation and implemented CAPA, we quickly resolved the issue and prevented future problems.

Q 17. What is your experience with change control procedures?

Change control procedures are essential for maintaining the integrity of the design and manufacturing process while minimizing the risk of introducing defects. A well-defined change control process ensures that any modifications are thoroughly evaluated and approved before implementation.

- Change Request Initiation: All changes, whether they are minor updates or significant design modifications, must be formally documented via a change request. This includes detailing the reason for the change, its potential impact, and the proposed solution.

- Change Impact Assessment: A thorough assessment is conducted to evaluate the potential impact of the change on the device’s safety, efficacy, and compliance. This often includes risk analysis using tools like Failure Mode and Effects Analysis (FMEA).

- Change Review and Approval: The change request is reviewed and approved by a designated change control board, comprised of representatives from various departments including engineering, quality, and regulatory affairs. This ensures a multidisciplinary perspective on the proposed change.

- Implementation and Verification: Once approved, the change is implemented, and appropriate verification and validation activities are performed to ensure the change achieves its intended purpose and maintains product quality and compliance.

- Documentation: The entire change control process is meticulously documented, including the change request, impact assessment, review minutes, and verification/validation results.

For example, a recent change request involved updating the software for a medical device. Our rigorous change control process ensured the updated software was thoroughly tested and verified before release, minimizing the risk of introducing defects that could compromise patient safety.

Q 18. Explain your understanding of product lifecycle management (PLM) in the context of medical devices.

Product Lifecycle Management (PLM) in the medical device industry is a critical system that manages the entire lifecycle of a medical device, from initial concept to end-of-life. It integrates data and processes across various departments, ensuring traceability, compliance, and efficient collaboration.

- Design Control: PLM supports design control by providing a centralized repository for design documents, drawings, and specifications. This facilitates efficient collaboration among engineers and ensures version control.

- Manufacturing Process Management: PLM enables efficient management of manufacturing processes, including bill of materials (BOM), work instructions, and quality records. This ensures consistency and traceability throughout production.

- Regulatory Compliance: PLM simplifies regulatory compliance by providing a structured system for managing documentation required for submissions to regulatory authorities. This ensures traceability and facilitates audits.

- Collaboration and Communication: PLM fosters efficient communication and collaboration between various stakeholders involved in the device development and production, reducing delays and ensuring everyone is working from the same information.

- Data Management: Centralized data management within a PLM system significantly improves data integrity and reduces the risk of data loss or inconsistencies. This is crucial in a highly regulated industry like medical devices.

In practice, PLM helps streamline processes, reducing the time and resources required for product development and regulatory submissions. It also helps improve collaboration between different departments and external partners. In my experience, using a PLM system has significantly improved our ability to manage complex medical device projects while adhering to strict regulatory requirements.

Q 19. How do you manage document control in a medical device setting?

Document control in a medical device setting is crucial for maintaining the accuracy, integrity, and accessibility of all documentation related to design, manufacturing, and quality. It’s not just about storage; it’s about a complete lifecycle management system.

- Document Creation and Approval: A formal process for document creation, review, and approval is essential. This usually involves a workflow that ensures documents are reviewed by appropriate personnel before release.

- Document Version Control: A system for managing document revisions is necessary to prevent the use of outdated documents. This often includes version numbering, revision dates, and a clear process for identifying the current approved version.

- Document Storage and Retrieval: Secure and easily accessible storage is critical. Electronic document management systems (EDMS) are commonly used to store documents electronically, ensuring easy retrieval and version control.

- Document Distribution: Controlled distribution of documents ensures that only authorized personnel have access to relevant documents. An EDMS provides this control, tracking who has access and when.

- Document Retention and Disposal: A policy defining document retention periods and disposal procedures is vital for compliance. This policy ensures that records are retained for the appropriate duration and disposed of securely once no longer needed.

For example, we utilize an EDMS that automatically tracks document versions, approvals, and access, ensuring only the approved version of a document is used and that the audit trail is readily available. This streamlines our document control and enhances compliance.

Q 20. Describe your experience with quality system training programs.

Quality system training programs are fundamental for ensuring that all personnel involved in the design, manufacturing, and distribution of medical devices understand and comply with the quality system requirements. Effective training is not a one-time event; it’s an ongoing process.

- Needs Assessment: We begin with a thorough needs assessment to identify the training needs of different personnel based on their roles and responsibilities. This ensures that training is targeted and relevant.

- Curriculum Development: We then develop comprehensive training programs covering relevant regulations, quality system procedures, and job-specific requirements. This may involve creating training materials, presentations, or interactive modules.

- Training Delivery: Training is delivered using various methods, including classroom instruction, online modules, and on-the-job training, tailored to the learning styles of participants. This ensures maximum engagement and knowledge retention.

- Training Verification: We verify that participants have understood the training material through assessments, tests, or practical exercises. This ensures that employees have retained the necessary knowledge and skills.

- Training Records: We maintain comprehensive records of all training activities, including participant lists, training materials, and assessment results. This documentation demonstrates compliance with regulatory requirements and helps track employee training progress.

For instance, we developed a comprehensive training program on Good Documentation Practices (GDP) for all personnel involved in documentation activities. This improved the quality and consistency of our documentation, enhancing compliance with regulatory requirements.

Q 21. How do you ensure data integrity in a medical device quality system?

Data integrity in a medical device quality system is crucial for ensuring the accuracy, completeness, and reliability of all data used in design, manufacturing, and testing. Compromised data integrity can lead to inaccurate conclusions, potentially resulting in defective products and patient safety issues.

- Data Governance: A robust data governance framework is essential for establishing clear roles, responsibilities, and processes for data management. This ensures data quality from creation to archiving.

- System Validation: All systems used to collect, process, and store data must be validated to ensure their accuracy and reliability. This involves demonstrating that the systems perform as intended and produce reliable results.

- Access Control: Access to data should be controlled and restricted to authorized personnel only. This prevents unauthorized modification or deletion of data, maintaining its integrity. Role-based access control is often implemented.

- Audit Trails: Complete and secure audit trails are essential for tracking all changes and access to data. This allows for investigation in case of discrepancies or data integrity issues.

- Data Backup and Recovery: Regular data backups and a robust data recovery plan are crucial for preventing data loss and ensuring business continuity. This safeguards against data loss due to system failures or other unforeseen events.

For example, we use an electronic batch record system (EBR) for manufacturing. This system ensures complete data traceability, automatically logs changes, and helps prevent data manipulation. The system is validated to ensure it consistently generates accurate and reliable data.

Q 22. What experience do you have with post-market surveillance?

Post-market surveillance (PMS) is a critical process in medical device regulation, focusing on monitoring the safety and performance of a device after it’s been released to the market. It’s about proactively identifying potential problems and taking corrective action before they escalate into widespread harm.

In my previous role at [Company Name], I was directly involved in developing and implementing our PMS plan. This included establishing procedures for collecting and analyzing data from various sources, such as complaint reports, field safety corrective actions (FSCAs), and post-market clinical follow-up studies. For example, we implemented a system for tracking complaints using a dedicated software, categorizing them by severity and type of adverse event. This allowed us to quickly identify trends and potential issues. We also conducted periodic reviews of PMS data to assess the effectiveness of our plan and identify areas for improvement.

One specific example involved a particular implant where we noticed an increase in reported cases of a specific complication. By analyzing the data, we were able to isolate a potential root cause and collaborate with the design and manufacturing teams to implement a design change that mitigated the risk. This proactive approach prevented a potentially larger recall and ensured patient safety. My experience includes analyzing data, identifying trends, reporting to regulatory bodies, and managing corrective and preventive actions (CAPAs).

Q 23. Explain your understanding of the different types of medical device recalls.

Medical device recalls are classified by their severity and urgency, typically categorized as Class I, II, and III. Think of it like a traffic light system for medical device safety.

- Class I Recalls (Red Light): These are the most serious, involving a reasonable probability that use of the device will cause serious adverse health consequences or death. Imagine a faulty heart pacemaker that could malfunction and stop the heart—that’s a Class I recall. Immediate action is required.

- Class II Recalls (Yellow Light): These involve a reasonable probability that use of the device will cause temporary or medically reversible adverse health consequences. For instance, a drug delivery system that delivers an incorrect dose might fall under this category. Corrective action is needed, but the risk is less immediate than a Class I recall.

- Class III Recalls (Green Light): These are the least serious, involving a remote probability of adverse health consequences. This might be a minor labeling issue that doesn’t affect the device’s function directly. Although less urgent, corrective action is still necessary.

My experience encompasses all three classes, from participating in the investigation and remediation efforts for a Class I recall involving a faulty catheter to managing a Class II recall related to labeling inaccuracies. This experience includes working with regulatory bodies, notifying healthcare providers and patients, implementing corrective actions, and documenting all steps meticulously for future reference and audit trail.

Q 24. Describe your experience with implementing a quality management system (QMS).

Implementing a Quality Management System (QMS), such as one compliant with ISO 13485, is fundamental to ensuring a medical device company consistently delivers safe and effective products. It’s essentially a roadmap for quality, outlining how a company manages all aspects of its operations to meet regulatory requirements and customer expectations.

In my experience at [Previous Company], I led the implementation of a new ISO 13485-compliant QMS. This involved several key steps, including:

- Gap Analysis: Assessing our existing systems against the ISO 13485 requirements to identify areas needing improvement.

- Documentation Development: Creating and implementing standard operating procedures (SOPs), work instructions, and other essential documents.

- Training: Educating employees on the new QMS and their responsibilities within the system.

- Internal Audits: Conducting regular internal audits to verify compliance and identify areas for improvement.

- Management Review: Regularly reviewing the effectiveness of the QMS with senior management.

The project involved a significant amount of cross-functional collaboration, requiring me to work closely with various teams including engineering, manufacturing, regulatory, and quality control. The successful implementation resulted in improved efficiency, reduced errors, and increased compliance.

Q 25. How do you stay updated on current medical device regulations and standards?

Staying current with medical device regulations and standards is paramount in this field. It’s a dynamic landscape, with frequent updates and changes.

My strategy is multifaceted:

- Subscription to Regulatory Newsletters and Databases: I subscribe to newsletters and databases from organizations like the FDA, EMA, and industry associations such as AAMI and MDMA. These provide updates on new regulations, guidance documents, and industry best practices.

- Participation in Industry Conferences and Webinars: Attending conferences and webinars allows me to network with peers, learn about new technologies and regulatory developments directly from experts, and gain insights into current industry challenges.

- Professional Development Courses and Certifications: I actively pursue continuing education opportunities to enhance my knowledge and stay abreast of the latest regulations and technologies.

- Monitoring Regulatory Agency Websites: I regularly check the websites of relevant regulatory agencies for updates and announcements.

This holistic approach ensures I remain informed about the latest changes and proactively adapt our QMS and processes accordingly.

Q 26. How would you handle a situation where a regulatory requirement conflicts with a company policy?

A conflict between a regulatory requirement and company policy is a serious matter that requires careful consideration and a structured approach. The regulatory requirement always takes precedence.

My approach would involve the following steps:

- Documentation: Thoroughly document the conflict, including specific references to the conflicting regulation and company policy.

- Escalation: Immediately escalate the issue to senior management and the regulatory affairs team.

- Risk Assessment: Conduct a thorough risk assessment to evaluate the potential consequences of non-compliance with the regulatory requirement.

- Resolution: Explore options for resolving the conflict. This may involve revising the company policy to align with the regulatory requirement or seeking clarification from the regulatory agency.

- Communication: Clearly communicate the situation and proposed solutions to all relevant stakeholders.

- Implementation: Implement the agreed-upon solution and ensure that all relevant procedures and documentation are updated.

- Verification: Verify that the implemented solution addresses the conflict and ensures compliance with the regulatory requirement.

Transparency and proactive communication are key to effectively navigating such conflicts and preventing negative consequences.

Q 27. Describe your experience with conducting internal audits in a medical device company.

Internal audits are a vital part of a robust QMS. They provide an independent assessment of a company’s compliance with its established procedures and regulatory requirements. They’re not about finding fault but rather about identifying areas for improvement and preventing problems.

In my previous role, I led and participated in numerous internal audits. My experience includes:

- Planning and Scoping: Defining the audit scope, objectives, and timeline based on risk assessment.

- Conducting Audits: Reviewing documents, observing processes, and interviewing personnel to assess compliance with regulatory requirements, SOPs, and internal policies. I utilize checklists and audit programs to ensure consistency and thoroughness.

- Identifying Non-conformances: Documenting any non-conformances or areas where improvement is needed. This includes objectively describing the finding and its impact.

- Reporting: Preparing audit reports summarizing findings, including recommendations for corrective and preventive actions (CAPAs).

- Follow-up: Following up on CAPAs to ensure they’re implemented and effective.

I have experience auditing various areas, including design control, manufacturing processes, and complaint handling, ensuring all aspects of the QMS are consistently evaluated and improved.

Q 28. What is your experience with using quality management software?

Experience with quality management software (QMS software) is essential in modern MDQA. This software streamlines many processes making them more efficient and transparent.

I’m proficient in using [mention specific software, e.g., MasterControl, Veeva Vault, etc.]. My experience includes using the software to manage documents, track CAPAs, handle complaints, and manage audits. The software’s capabilities for automated workflows, data analysis, and electronic signatures significantly improve efficiency and reduce paperwork. For example, using the system’s automated features for CAPA management, I was able to reduce the average time to resolve issues by 25%, improving overall responsiveness and efficiency in addressing quality issues.

Furthermore, I understand the importance of selecting and implementing QMS software that aligns with regulatory requirements and the organization’s specific needs. This involves considering factors like integration with other systems, scalability, user-friendliness, and security.

Key Topics to Learn for Medical Device Quality Assurance (MDQA) Interview

- Quality Management Systems (QMS): Understand ISO 13485, its requirements, and how it’s implemented in a medical device company. Consider the practical application of risk management within the framework of a QMS.

- Risk Management: Familiarize yourself with risk analysis methodologies like FMEA (Failure Mode and Effects Analysis) and its use in identifying and mitigating potential hazards in medical device design and manufacturing. Practice applying these methods to hypothetical scenarios.

- Regulatory Affairs: Gain a solid understanding of FDA regulations (21 CFR Part 820) and other relevant international regulations. Explore how these regulations impact the design, development, and post-market surveillance of medical devices.

- CAPA (Corrective and Preventive Actions): Learn the CAPA process, from identifying non-conformances to implementing effective corrective actions and preventing recurrence. Practice developing a CAPA plan for a given scenario.

- Auditing: Understand internal and external audit processes, including preparation, execution, and reporting. Explore different audit types and their objectives.

- Quality Control and Testing: Familiarize yourself with various quality control techniques and testing methodologies used in the medical device industry. Consider the importance of statistical process control.

- Documentation and Traceability: Master the importance of meticulous record-keeping and traceability throughout the entire product lifecycle. Understand how this contributes to regulatory compliance and product safety.

- Supplier Management: Learn the critical aspects of managing suppliers to ensure the quality of components and materials used in medical device manufacturing. Understand supplier audits and quality agreements.

Next Steps

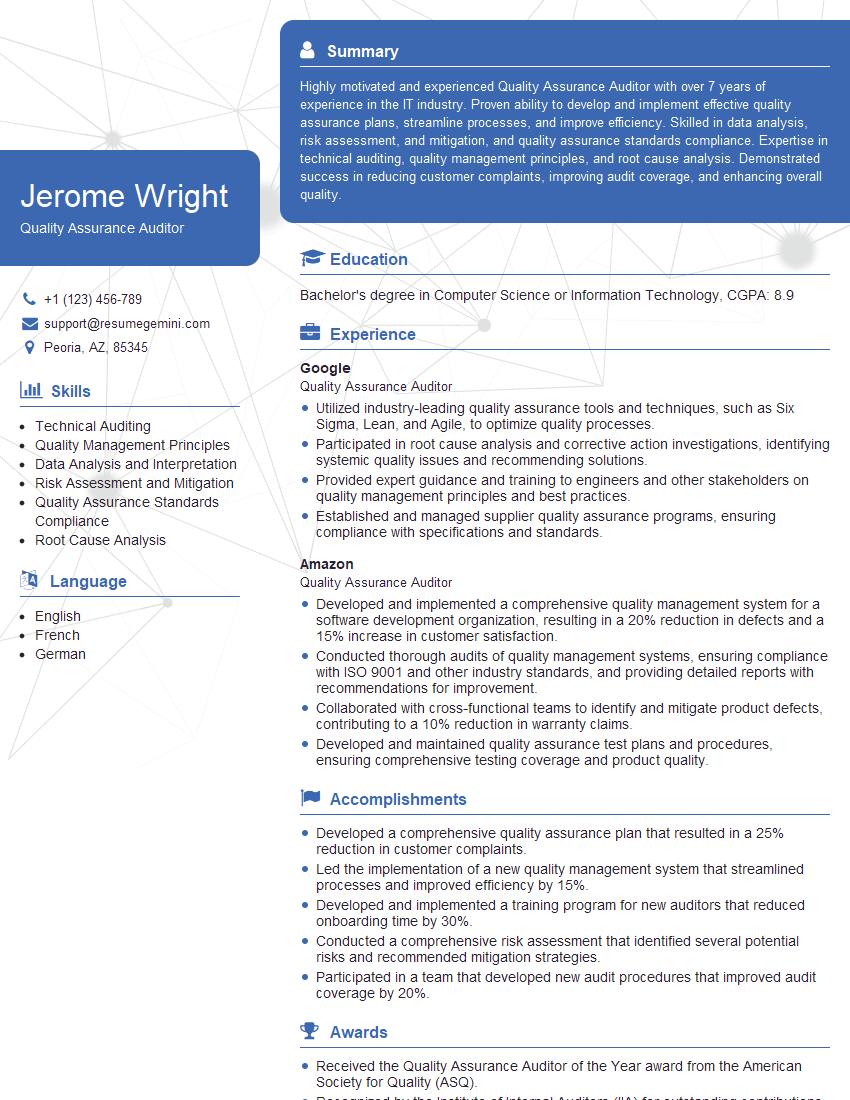

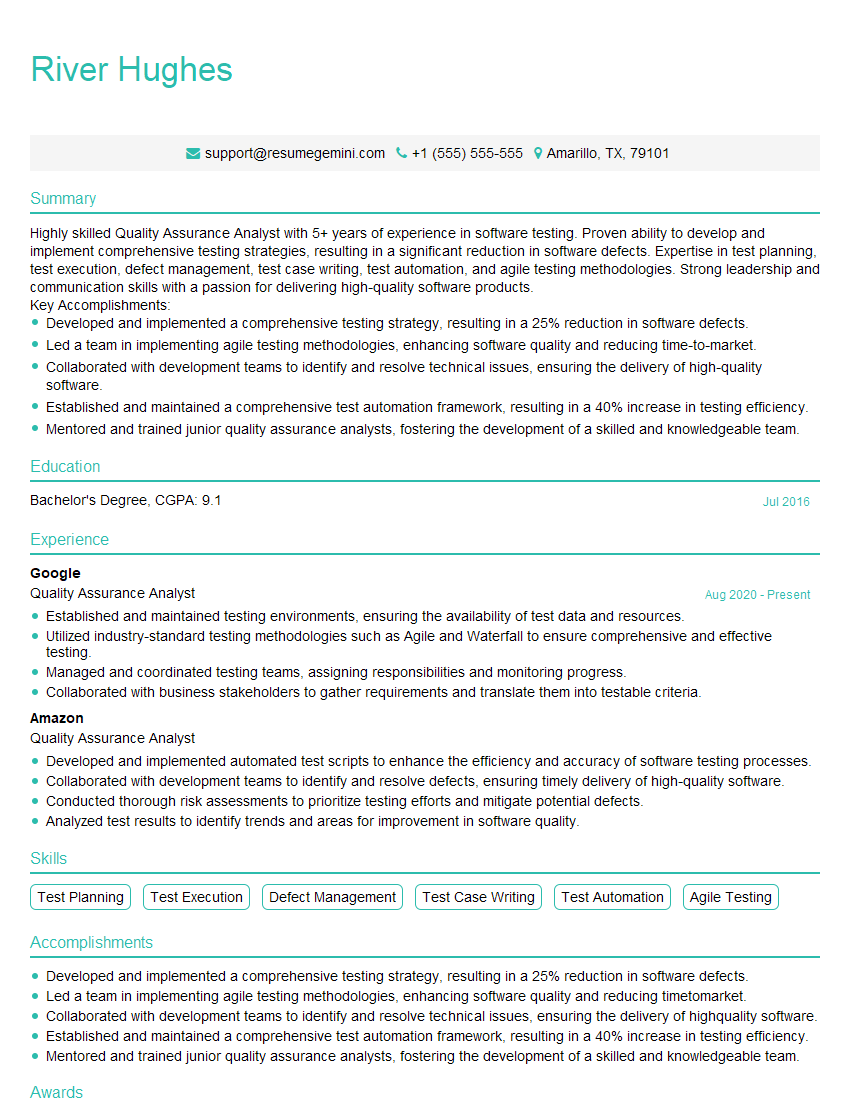

Mastering Medical Device Quality Assurance (MDQA) principles opens doors to a rewarding and impactful career, offering opportunities for professional growth and significant contributions to patient safety. A strong resume is crucial in showcasing your skills and experience to potential employers. Creating an ATS-friendly resume significantly increases your chances of getting your application noticed. We recommend using ResumeGemini, a trusted resource for building professional resumes, to craft a compelling document that highlights your MDQA expertise. Examples of resumes tailored to Medical Device Quality Assurance (MDQA) roles are available to help guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good