Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Materials Management and Inventory Control interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Materials Management and Inventory Control Interview

Q 1. Explain the difference between FIFO and LIFO inventory methods.

FIFO (First-In, First-Out) and LIFO (Last-In, First-Out) are two fundamental methods for costing inventory. They impact how you value your goods and, consequently, your financial statements. The core difference lies in the order in which inventory is assumed to be sold.

FIFO: Imagine a bakery. The first loaves of bread baked are the first ones sold. FIFO assumes that the oldest inventory items are the ones sold first. This means the cost of goods sold (COGS) reflects the cost of the oldest inventory, leaving the newer, potentially more expensive inventory on hand. In times of inflation, FIFO results in a lower COGS and a higher net income because older, cheaper goods are expensed.

LIFO: Now, imagine a hardware store that just received a large shipment of nails at a higher price. LIFO assumes the newest inventory items are sold first. So, the COGS will reflect the cost of the most recent purchase, leaving older, possibly cheaper inventory on hand. During inflation, LIFO shows a higher COGS and a lower net income because the latest, more expensive goods are expensed.

Example: Let’s say you buy 10 units at $10 and later 10 units at $12. If you sell 5 units using FIFO, your COGS is 5 * $10 = $50. Using LIFO, your COGS is 5 * $12 = $60. This difference directly impacts your profitability reporting.

Choosing between FIFO and LIFO depends on various factors, including industry regulations, tax implications, and the need to accurately reflect the current market value of inventory.

Q 2. Describe your experience with inventory management software.

I have extensive experience with various inventory management software, including enterprise resource planning (ERP) systems like SAP and Oracle, and specialized inventory management systems like NetSuite and Fishbowl Inventory. My experience encompasses all aspects of software implementation – from initial requirements gathering and vendor selection to system configuration, user training, and ongoing maintenance.

In my previous role at [Previous Company Name], I spearheaded the implementation of NetSuite to replace our legacy system. This involved mapping our existing inventory processes to the software, customizing workflows to fit our specific needs, and ensuring seamless data migration. I also played a key role in developing custom reports and dashboards to provide real-time visibility into inventory levels, turnover rates, and other critical KPIs. This project resulted in a significant reduction in inventory carrying costs and improved forecasting accuracy.

My expertise extends beyond simply using the software; I understand the underlying principles of inventory management and can effectively leverage the software’s capabilities to optimize our inventory control processes.

Q 3. How do you calculate inventory turnover rate?

The inventory turnover rate is a crucial metric that measures how efficiently a business manages its inventory. It shows how many times the inventory is sold and replaced over a specific period. A higher turnover rate generally indicates strong sales and efficient inventory management, while a low rate might signal overstocking or slow-moving items.

The formula for calculating the inventory turnover rate is:

Inventory Turnover Rate = Cost of Goods Sold / Average InventoryThe Cost of Goods Sold (COGS) represents the direct costs associated with producing goods sold during a specific period. The Average Inventory is the average value of inventory held during that same period. It’s calculated by adding the beginning and ending inventory values and dividing by two. For a more accurate picture, you could use monthly average inventory.

Example: If your COGS for the year was $100,000, and your average inventory was $25,000, your inventory turnover rate would be $100,000 / $25,000 = 4. This signifies that your inventory was sold and replaced four times during the year.

Q 4. What are the key performance indicators (KPIs) you track in inventory control?

Effective inventory control relies on monitoring several key performance indicators (KPIs). The specific KPIs I track are tailored to the specific business needs, but some key ones consistently include:

- Inventory Turnover Rate: As discussed previously, this measures how efficiently inventory is sold and replenished.

- Inventory Holding Cost: This represents the total cost of storing and maintaining inventory, including storage space, insurance, taxes, and obsolescence.

- Stockout Rate: This is the percentage of orders that cannot be fulfilled due to insufficient inventory. High stockout rates impact customer satisfaction and sales.

- Order Fill Rate: This measures the percentage of orders filled completely and on time. It’s related to the stockout rate but emphasizes the timely fulfillment aspect.

- Inventory Accuracy: This refers to how closely the recorded inventory levels match the physical inventory. A high accuracy rate is crucial for effective management.

- Lead Time: The time it takes to receive inventory after placing an order. A shorter lead time allows for better inventory planning.

By consistently monitoring these KPIs, I can identify areas for improvement and implement strategies to optimize inventory management, reducing costs and enhancing customer satisfaction.

Q 5. How do you handle inventory discrepancies?

Inventory discrepancies – the difference between recorded and physical inventory counts – are inevitable but need to be addressed promptly and methodically. My approach involves a multi-step process:

- Identify the Discrepancy: Through cycle counting or a full physical inventory count, identify the magnitude and location of the discrepancy.

- Investigate the Cause: This is the most crucial step. Possible causes include data entry errors, theft, damage, misplacement, or inaccurate receiving procedures. I would analyze the data to understand the pattern of the discrepancy—is it a specific item, location, or time of year?

- Implement Corrective Actions: Once the root cause is identified, implement solutions. This might involve improving data entry procedures, enhancing security measures, improving stockroom organization, or retraining staff.

- Document Findings and Actions: Maintain thorough records of the discrepancy, the investigation process, corrective actions taken, and any resulting adjustments to inventory records.

- Monitor for Recurrence: Regularly review inventory data to check for similar discrepancies in the future. This helps prevent recurring issues.

For example, if a significant discrepancy is found in a specific aisle, we might need to improve lighting and shelving organization in that area. If errors stem from data entry, improved training or double-checking mechanisms might be necessary.

Q 6. Explain your experience with cycle counting.

Cycle counting is a crucial inventory control technique where a small portion of the inventory is counted regularly, rather than performing a full physical inventory count less frequently. It provides a more continuous and accurate view of inventory levels than relying solely on annual or semi-annual counts.

My experience with cycle counting involves implementing and managing a structured program. This includes:

- Developing a Counting Schedule: Establish a regular cycle counting schedule based on item value, usage frequency, and risk of obsolescence. High-value items are counted more frequently.

- Assigning Responsibilities: Delegate the task to specific team members or allocate tasks based on their expertise.

- Using Technology: Utilize barcode scanners and inventory management software to streamline the counting process and ensure accurate data capture.

- Reconciling Counts: Comparing the counted quantities with the system records, investigating and correcting any discrepancies.

- Analyzing Results: Regularly analyzing cycle counting data to identify trends, problem areas, and inefficiencies.

This continuous process ensures inventory accuracy, minimizes disruptions, and allows for early detection of discrepancies, preventing larger problems later.

Q 7. Describe your process for managing obsolete inventory.

Obsolete inventory is a significant challenge for any business. It ties up capital, occupies valuable storage space, and ultimately represents a loss. My process for managing obsolete inventory involves:

- Identification: Regularly review slow-moving or non-moving inventory items. Utilize inventory management software to identify items that haven’t been sold within a defined period.

- Analysis: Determine the reasons for obsolescence. This could be due to changes in market demand, technological advancements, or product design changes.

- Disposition Strategies: Explore options for managing the obsolete inventory. These include:

- Selling at a discount: Sell to liquidators or through online marketplaces.

- Donating to charity: If tax laws permit, donate to organizations that can use them.

- Recycling or disposing: Safely dispose of or recycle items that are beyond salvage.

- Repurposing or cannibalization: Use components of obsolete products in other manufacturing processes.

- Implementing Preventative Measures: After disposing of the obsolete inventory, analyze what led to the obsolescence. Implement strategies to prevent similar situations in the future, such as forecasting, improved demand planning, and more effective purchasing policies.

By implementing a proactive approach to obsolete inventory management, we can minimize losses, free up storage space, and improve overall inventory efficiency.

Q 8. How do you ensure accurate inventory data?

Accurate inventory data is the bedrock of efficient materials management. It’s like having a perfectly accurate map for your warehouse – without it, you’re navigating blind. Ensuring accuracy involves a multi-pronged approach:

Regular Cycle Counting: Instead of a full inventory count annually, we conduct frequent cycle counts of specific sections or items. This allows us to catch discrepancies early and minimize disruption.

Barcode/RFID Technology: Utilizing barcode scanners or RFID tags dramatically reduces manual data entry errors and speeds up the inventory process. Imagine the difference between manually writing down every item in a warehouse versus instantly scanning each one.

WMS Integration: A robust Warehouse Management System (WMS) acts as the central nervous system, automatically updating inventory levels with every transaction – receipts, shipments, and internal transfers. This real-time visibility is key.

Data Reconciliation: Regularly comparing inventory data from different sources (e.g., physical counts, system records, purchase orders) helps identify and resolve discrepancies.

Employee Training: Thorough training ensures employees properly use inventory management procedures and equipment, minimizing human error.

For example, in my previous role, we implemented a cycle counting program that reduced inventory discrepancies by 40% within six months. This led to significant cost savings by preventing stockouts and reducing waste.

Q 9. What are the benefits of implementing a just-in-time (JIT) inventory system?

Just-in-Time (JIT) inventory is a lean manufacturing approach that aims to minimize inventory holding costs by receiving materials only when needed for production. It’s like ordering groceries just before you need them for dinner, rather than stocking up for a month.

Reduced Storage Costs: Less inventory means less warehouse space required, significantly cutting down on rent, utilities, and maintenance.

Lower Inventory Holding Costs: Minimizing the time inventory sits on the shelf reduces obsolescence risk and lowers insurance, taxes, and potential spoilage costs.

Improved Cash Flow: Capital tied up in inventory is freed up, improving liquidity and boosting financial flexibility.

Enhanced Efficiency: JIT encourages continuous improvement and streamlined processes to ensure efficient production flow.

Reduced Waste: Less inventory means less chance of obsolescence, damage, or spoilage.

However, JIT requires strong supplier relationships and reliable delivery schedules. A disruption in the supply chain can severely impact production. Implementing JIT successfully requires careful planning and close collaboration with suppliers.

Q 10. How do you manage supplier relationships to ensure timely delivery?

Managing supplier relationships is crucial for timely delivery. It’s about building trust and fostering a collaborative partnership, not just a transactional relationship. My approach involves:

Strategic Supplier Selection: Choosing reliable and capable suppliers with proven track records of on-time delivery.

Regular Communication: Maintaining open communication channels to share forecasts, track orders, and promptly address any potential issues.

Collaborative Forecasting: Working closely with suppliers to develop accurate forecasts, ensuring they have the necessary resources and capacity to meet our demands.

Performance Monitoring: Tracking key performance indicators (KPIs) such as on-time delivery rates, lead times, and defect rates to identify areas for improvement and hold suppliers accountable.

Long-Term Contracts: Establishing mutually beneficial long-term agreements with key suppliers ensures stability and reduces negotiation overhead.

In one instance, by proactively communicating a production surge to our key supplier, we secured their commitment to prioritize our orders, preventing a potential bottleneck and maintaining timely production schedules.

Q 11. Explain your experience with forecasting inventory needs.

Forecasting inventory needs is a critical skill, balancing the need to meet demand with minimizing excessive inventory. It’s like predicting the weather—you can’t be perfectly accurate, but you can improve your predictions with the right tools and data. My approach uses a combination of methods:

Historical Data Analysis: Examining past sales data to identify trends, seasonality, and growth patterns.

Market Research: Staying informed about market conditions, competitor activities, and industry trends to anticipate shifts in demand.

Statistical Forecasting Techniques: Employing methods like moving averages, exponential smoothing, or ARIMA models to generate quantitative forecasts.

Qualitative Methods: Incorporating expert opinions, sales force input, and customer feedback to refine forecasts.

Demand Planning Software: Utilizing specialized software to automate forecasting, optimize inventory levels, and simulate various scenarios.

For example, I once used a combination of historical data and market research to predict a significant increase in demand for a particular product due to a new marketing campaign. This enabled us to proactively increase inventory levels, preventing a stockout and capitalizing on the increased demand.

Q 12. How do you handle stockouts?

Stockouts are a costly disruption, impacting customer satisfaction and potentially losing sales. Handling them requires a swift and effective response:

Immediate Assessment: Quickly determine the severity and scope of the stockout, identifying the affected products and quantities.

Root Cause Analysis: Investigate the reasons for the stockout—was it due to inaccurate forecasting, supply chain issues, or unexpected demand spikes? This is crucial for preventing future occurrences.

Customer Communication: Proactively communicate with affected customers, explaining the situation and providing alternative solutions or estimated delivery times.

Expedited Replenishment: Implement emergency procedures to expedite the replenishment of the stock, prioritizing the most critical items.

Alternative Sourcing: If regular suppliers can’t meet immediate demand, explore alternative sourcing options to fill the gap.

In a previous role, we experienced an unexpected surge in demand for a seasonal product. We immediately communicated the situation to customers, offering similar alternatives while simultaneously expediting shipments from our supplier. This minimized the negative impact on customer satisfaction and sales.

Q 13. What strategies do you use to minimize inventory holding costs?

Minimizing inventory holding costs is a key objective in materials management. These costs include storage, insurance, taxes, obsolescence, and potential spoilage. Strategies to reduce these costs include:

Optimize Inventory Levels: Using forecasting and inventory management techniques to maintain optimal inventory levels, balancing the need to meet demand with minimizing excess stock.

Efficient Warehouse Layout: Designing an efficient warehouse layout improves storage space utilization, reducing the need for excessive space and associated costs.

Improve Inventory Turnover: Focus on improving the speed at which inventory is sold or used, reducing the time it spends in storage. This requires efficient production and sales processes.

Negotiate Better Pricing: Negotiate favorable pricing with suppliers to reduce the cost of goods, consequently lowering the overall cost of inventory.

Implement FIFO (First-In, First-Out): Employing FIFO helps to minimize the risk of obsolescence by ensuring that older inventory is used first.

By implementing these strategies, we were able to reduce our inventory holding costs by 15% in one organization, freeing up capital for other business initiatives.

Q 14. Describe your experience with warehouse management systems (WMS).

Warehouse Management Systems (WMS) are essential for efficient inventory control. Think of a WMS as the central brain of your warehouse, coordinating all aspects of inventory management. My experience includes implementing and managing WMS in various settings. This involves:

System Selection and Implementation: Choosing the right WMS based on business needs and integrating it with existing ERP and other systems.

Data Migration: Accurately migrating existing inventory data into the new system to ensure data integrity.

User Training: Training warehouse staff on how to use the WMS effectively to maximize its benefits.

Process Optimization: Leveraging the WMS to optimize warehouse processes, such as receiving, putaway, picking, and shipping.

Performance Monitoring: Continuously monitoring system performance and identifying areas for improvement.

In one project, we implemented a new WMS that resulted in a 20% reduction in order fulfillment time and a 10% decrease in picking errors, significantly improving efficiency and customer satisfaction. The system provided real-time visibility into inventory levels, enabling proactive management and minimizing stockouts.

Q 15. How do you prioritize inventory items for replenishment?

Prioritizing inventory replenishment involves strategically focusing on items with the highest impact on business operations. This isn’t simply a matter of what’s running low; it considers factors like demand, lead time, and cost. I typically use a multi-criteria approach.

- Criticality: Items essential for production or customer service are prioritized, even if the stock isn’t critically low. Imagine a car manufacturer – they’ll prioritize engine parts over less crucial components.

- Demand Forecasting: I rely on accurate demand forecasts, factoring in seasonality, trends, and promotions. A sudden surge in demand for a specific item automatically jumps it up the priority list.

- Lead Time: Items with long lead times (time from ordering to receiving) are prioritized earlier, allowing ample buffer time. Think about sourcing materials from overseas – these need to be ordered well in advance.

- Cost: High-value items, even if demand is relatively low, may still need prioritization due to the significant financial impact of a stockout. A high-end component in a sophisticated piece of equipment is a prime example.

- Stock Levels: While important, this is often a secondary factor, as the other elements mentioned can override simple stock levels. A simple reorder point system coupled with the other considerations forms a robust process.

By combining these criteria, we ensure a balanced approach to replenishment, minimizing stockouts of critical items while avoiding overstocking less important ones. This process often involves using specialized software or ERP systems to automate the prioritization based on pre-defined rules and parameters.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your experience with ABC analysis?

ABC analysis is a fundamental inventory management technique that categorizes items based on their consumption value. It’s a vital tool for optimizing inventory control and resource allocation. My experience includes implementing and refining ABC analysis across various industries.

The process involves ranking items based on their annual consumption value, typically expressed as a percentage of the total annual consumption value. This results in three categories:

- A-items: These represent a small percentage of total items (typically 20%) but account for a large percentage of the total consumption value (often 80%). These items require close monitoring, tight controls, and potentially just-in-time inventory strategies.

- B-items: These represent a moderate percentage of items and consumption value. They require moderate control and inventory management practices.

- C-items: These constitute a large percentage of items (often 50-70%) but contribute to a relatively small percentage of the total consumption value. They can often be managed with simpler methods and less frequent monitoring.

In practice, I’ve used ABC analysis to identify high-value items requiring more rigorous forecasting and control, thereby reducing storage costs and minimizing the risk of stockouts for crucial components. For instance, in a manufacturing setting, the critical raw materials will likely fall in the ‘A’ category, while nuts and bolts might belong to the ‘C’ category. This focused approach significantly improves efficiency and resource allocation.

Q 17. Explain your experience with root cause analysis in inventory issues.

Root cause analysis (RCA) is crucial for resolving recurring inventory issues and preventing them from happening again. It’s not about applying a band-aid; it’s about digging deep to understand the underlying problems. My experience involves utilizing various RCA methodologies, including the ‘5 Whys’ technique and the ‘fishbone’ diagram.

Example: Let’s say we have consistent overstocking of a specific part. A typical superficial response would be to simply reduce the order quantity. However, using RCA, we might ask:

- Why is there overstocking? Because the forecast was inaccurate.

- Why was the forecast inaccurate? Because the forecasting model didn’t account for seasonality.

- Why didn’t the model account for seasonality? Because it was not properly configured.

- Why was it not properly configured? Because of a lack of training for the team responsible for forecasting.

- Why was there a lack of training? Because there was no allocated budget for training.

By systematically questioning the problem, we get to the root cause – insufficient training budget – a solvable issue. We then implement corrective actions, such as budgeting for employee training, improving the forecasting model, and better inventory control protocols to prevent future overstocking. This systematic approach ensures long-term solutions instead of merely treating symptoms.

Q 18. How do you manage inventory during peak seasons?

Managing inventory during peak seasons requires careful planning and execution. It’s about striking a balance between meeting increased demand and avoiding excessive inventory that ties up capital and storage space after the peak season.

My approach involves a multi-pronged strategy:

- Accurate Demand Forecasting: This is paramount. Historical data and market trends are meticulously analyzed to predict demand accurately. We factor in promotional campaigns and any external market influences. This forecast is crucial for ordering the right quantity of goods well before the peak season.

- Safety Stock Optimization: Higher safety stock levels might be necessary to account for potential supply chain disruptions or unexpected surges in demand. But, this should be strategically optimized to avoid unnecessary holding costs.

- Strategic Sourcing: Building strong relationships with suppliers is essential, especially during peak seasons. This enables securing the needed goods with preferential treatment or flexible delivery schedules.

- Warehouse Optimization: Efficient warehouse layout, inventory tracking systems, and staff training become crucial. Ensuring speedy order fulfillment becomes paramount during these busy periods.

- Vendor Managed Inventory (VMI): In some cases, I’ve utilized VMI where the supplier manages the inventory levels on our behalf, based on our consumption data. This alleviates a lot of the pressure from our internal teams.

The key is proactive planning and close monitoring of inventory levels throughout the peak season. Post-peak season, a thorough analysis of actual versus forecasted demand is conducted to refine future forecasts.

Q 19. How do you ensure the security and safety of inventory?

Ensuring inventory security and safety is a multifaceted process requiring a combination of physical and procedural safeguards. It’s about protecting the company’s assets and maintaining operational integrity.

My approach emphasizes:

- Physical Security: This includes secure warehouse facilities with access controls (e.g., surveillance cameras, security personnel, restricted access points), proper storage conditions (temperature, humidity) for sensitive items, and robust measures against theft or vandalism.

- Inventory Tracking and Management System: A reliable inventory management system with real-time tracking capabilities is essential for accurately monitoring inventory levels, identifying discrepancies, and detecting potential losses. This system should integrate with other systems like order management and warehouse management.

- Regular Audits: Regular physical inventory counts and audits are performed to reconcile physical inventory with the system records, detect any discrepancies, and identify areas for improvement in security protocols. This helps detect shrinkage and potential losses early on.

- Employee Training and Procedures: Employees handling inventory are trained on proper procedures, including security protocols and best practices for handling different types of goods. Clear accountability measures help deter theft or negligence.

- Insurance: Appropriate insurance coverage protects against loss or damage due to unforeseen circumstances, like fire, theft, or natural disasters.

A comprehensive approach combining these measures establishes a strong security framework, safeguarding inventory from loss, damage, and unauthorized access.

Q 20. What is your experience with lean manufacturing principles?

Lean manufacturing principles focus on eliminating waste and maximizing efficiency in all aspects of production. My experience implementing lean principles in inventory management has yielded substantial improvements in various settings.

Key principles I’ve applied include:

- Just-in-Time (JIT) Inventory: This aims to receive materials only when needed, minimizing storage costs and reducing the risk of obsolescence. It requires close coordination with suppliers and accurate demand forecasting.

- Kanban System: This visual inventory control system helps manage the flow of materials and signals when replenishment is needed. It’s particularly useful in managing the flow of parts between different stages of production.

- Value Stream Mapping: This technique helps identify and eliminate non-value-added activities in the inventory management process, from ordering to storage to delivery, leading to streamlined operations.

- 5S Methodology: This focuses on workplace organization and cleanliness, leading to improved efficiency and reduced risk of damage or loss. This improves the speed of material handling and reduces search times for inventory.

- Continuous Improvement (Kaizen): This approach emphasizes continuous improvement of processes through incremental changes and employee involvement. Regular reviews of processes and continuous feedback from the team can lead to small but significant improvements over time.

By applying these principles, we can significantly reduce lead times, minimize waste, and enhance the overall efficiency of inventory management, leading to cost savings and improved customer service.

Q 21. How do you handle damaged or defective inventory?

Handling damaged or defective inventory involves a systematic process that balances cost considerations with compliance requirements. It’s important to act quickly and methodically.

My approach involves:

- Identification and Segregation: Damaged or defective items are quickly identified and segregated from good inventory to prevent further damage or contamination. Clear labeling is crucial at this stage.

- Root Cause Analysis: To prevent recurrence, the cause of damage or defects is investigated. This might involve examining processes, supplier performance, or storage conditions. This information is fed back into the prevention systems.

- Dispositioning: Options include repair (if cost-effective), return to the supplier (if possible under warranty), salvage (selling as is at a reduced price), or disposal (following environmental regulations). The most economically and ethically viable approach is selected.

- Documentation: Thorough documentation of the damaged or defective items, root cause analysis, and the chosen disposition method is maintained for tracking and auditing purposes. This ensures traceability and accountability.

- Cost Accounting: The costs associated with damaged or defective inventory (including disposal, repair, etc.) are carefully tracked and analyzed to identify areas for improvement and cost reduction.

Careful management of damaged inventory not only reduces losses but also allows for learning and process improvement, minimizing the frequency of such occurrences in the future. We balance environmental responsibility with the cost of handling.

Q 22. Describe your experience with implementing inventory control policies.

Implementing effective inventory control policies requires a multi-faceted approach. It begins with selecting the right methodology, often choosing between just-in-time (JIT), economic order quantity (EOQ), or material requirements planning (MRP) depending on the nature of the business and its products. For instance, a JIT system works well for businesses with high demand and short lead times, minimizing storage costs. Conversely, an MRP system is suitable for businesses with complex production processes and multiple components.

After selecting the methodology, I focus on defining key performance indicators (KPIs) like inventory turnover rate, carrying costs, and stockout rates. These KPIs provide crucial data for monitoring performance and identifying areas for improvement. This is followed by the establishment of clear ordering procedures, including setting reorder points and lead times. This ensures that the stock doesn’t fall below a critical level, preventing disruptions in production or sales. Finally, rigorous tracking and reporting systems are implemented to ensure adherence to policies and provide visibility into inventory levels.

In a previous role, I successfully implemented an EOQ model for a manufacturing company, resulting in a 15% reduction in carrying costs within six months. This involved analyzing historical demand data to determine optimal order quantities and negotiating better terms with suppliers to reduce lead times.

Q 23. How do you collaborate with other departments to manage inventory effectively?

Effective inventory management is a collaborative effort. My approach involves proactive communication and close working relationships with various departments. With the procurement department, I coordinate forecasts to ensure timely acquisition of materials, aligning procurement strategies with production schedules. This prevents stockouts and minimizes storage costs. With the production department, I collaborate closely on production planning, ensuring that sufficient raw materials are available to meet production targets. This minimizes downtime and delays. Similarly, with the sales and marketing departments, I discuss sales forecasts to anticipate demand fluctuations and adjust inventory levels accordingly. This improves customer satisfaction by reducing lead times and preventing stockouts.

For example, in one project, I worked with the sales team to analyze seasonal demand patterns for a key product. This allowed us to proactively adjust inventory levels, resulting in a significant reduction in obsolete stock and increased profitability.

Q 24. What are your strategies for improving inventory accuracy?

Improving inventory accuracy is crucial for efficient inventory management. My strategies focus on a combination of technological solutions and process improvements. I advocate for implementing a robust inventory management system (IMS) using barcode or RFID technology for accurate tracking of goods. This helps eliminate manual data entry errors, a common cause of inaccuracy. Cycle counting, a regular partial inventory count, is another effective method. Instead of conducting a full inventory count annually, cycle counting allows for frequent checks on smaller sections of the inventory, identifying discrepancies early on.

Furthermore, regular staff training is essential. This ensures that everyone understands and adheres to inventory management procedures, including proper receiving, storage, and issuing practices. Finally, I employ root cause analysis to investigate any discrepancies found during cycle counting or stocktakes. This helps identify the source of the error and implement corrective measures to prevent recurrence.

In my experience, implementing a combination of cycle counting and RFID technology improved inventory accuracy by 20% within the first year in a previous company.

Q 25. How do you utilize data analytics to optimize inventory management?

Data analytics plays a vital role in optimizing inventory management. I leverage various analytical tools and techniques to gain valuable insights from inventory data. This includes using statistical forecasting models like ARIMA or exponential smoothing to predict future demand more accurately. These models consider historical data and seasonality to provide reliable forecasts, allowing for proactive inventory adjustments. I also utilize ABC analysis, categorizing inventory items based on their value and consumption rate. This allows for focused attention on high-value items, ensuring better control and minimizing risks associated with these crucial items.

Furthermore, I analyze data on lead times, carrying costs, and stockout rates to identify areas for improvement in the supply chain. This can involve negotiating better terms with suppliers to reduce lead times or optimizing storage strategies to minimize carrying costs. Data visualization tools are also crucial; they provide clear and concise presentations of key metrics, making it easier to identify trends and patterns that might otherwise be missed.

Q 26. Describe a time you had to resolve a significant inventory problem.

In a previous role, we faced a significant inventory problem due to a supplier’s delay in delivering a critical component. This resulted in a production halt and potential order fulfillment issues. My immediate response involved a three-pronged approach:

- Immediate Problem Mitigation: I contacted alternative suppliers to identify potential sources for the component, securing emergency supplies to resume production immediately.

- Root Cause Analysis: I collaborated with the procurement team to investigate the reasons behind the supplier’s delay. We identified a lack of contingency planning in our supplier relationship management strategy.

- Preventive Measures: We revised our supplier selection criteria to prioritize reliability and implemented a multi-sourcing strategy for critical components, significantly reducing the risk of future disruptions.

By implementing these steps, we managed to minimize production downtime, prevent significant financial losses, and improve our overall supply chain resilience. This experience highlighted the importance of proactive risk management and diversified sourcing in inventory management.

Q 27. What are your salary expectations?

My salary expectations are in the range of $X to $Y per year, depending on the overall compensation package and the specific responsibilities of the role. This range is based on my experience, skills, and the current market rates for professionals with my expertise in materials management and inventory control. I am open to discussing this further and am confident that my contributions will provide significant value to your organization.

Key Topics to Learn for Materials Management and Inventory Control Interview

- Demand Forecasting & Planning: Understanding different forecasting methods (e.g., moving average, exponential smoothing) and their application in predicting future demand to optimize inventory levels. Practical application includes analyzing historical sales data and market trends to create accurate forecasts.

- Inventory Control Techniques: Mastering techniques like Economic Order Quantity (EOQ), Just-in-Time (JIT) inventory, and safety stock calculations. Practical application includes determining optimal order quantities to minimize costs while ensuring sufficient stock availability.

- Inventory Management Software & Systems: Familiarity with Enterprise Resource Planning (ERP) systems and other inventory management software used to track inventory levels, manage orders, and generate reports. Practical application includes demonstrating proficiency in using such systems for data analysis and decision-making.

- Supply Chain Management Principles: Understanding the entire supply chain process, from procurement to delivery, and how effective materials management impacts overall efficiency. Practical application includes analyzing potential bottlenecks and proposing solutions to improve supply chain performance.

- Warehouse Management & Logistics: Knowledge of warehouse layout, inventory organization, and efficient material handling techniques. Practical application includes optimizing warehouse space utilization and improving order fulfillment processes.

- Cost Accounting & Inventory Valuation: Understanding different inventory costing methods (e.g., FIFO, LIFO) and their impact on financial statements. Practical application includes calculating inventory costs and analyzing their effects on profitability.

- Risk Management & Contingency Planning: Identifying potential risks associated with inventory management (e.g., obsolescence, damage, theft) and developing strategies to mitigate these risks. Practical application includes creating contingency plans to handle unexpected events, like supply chain disruptions.

Next Steps

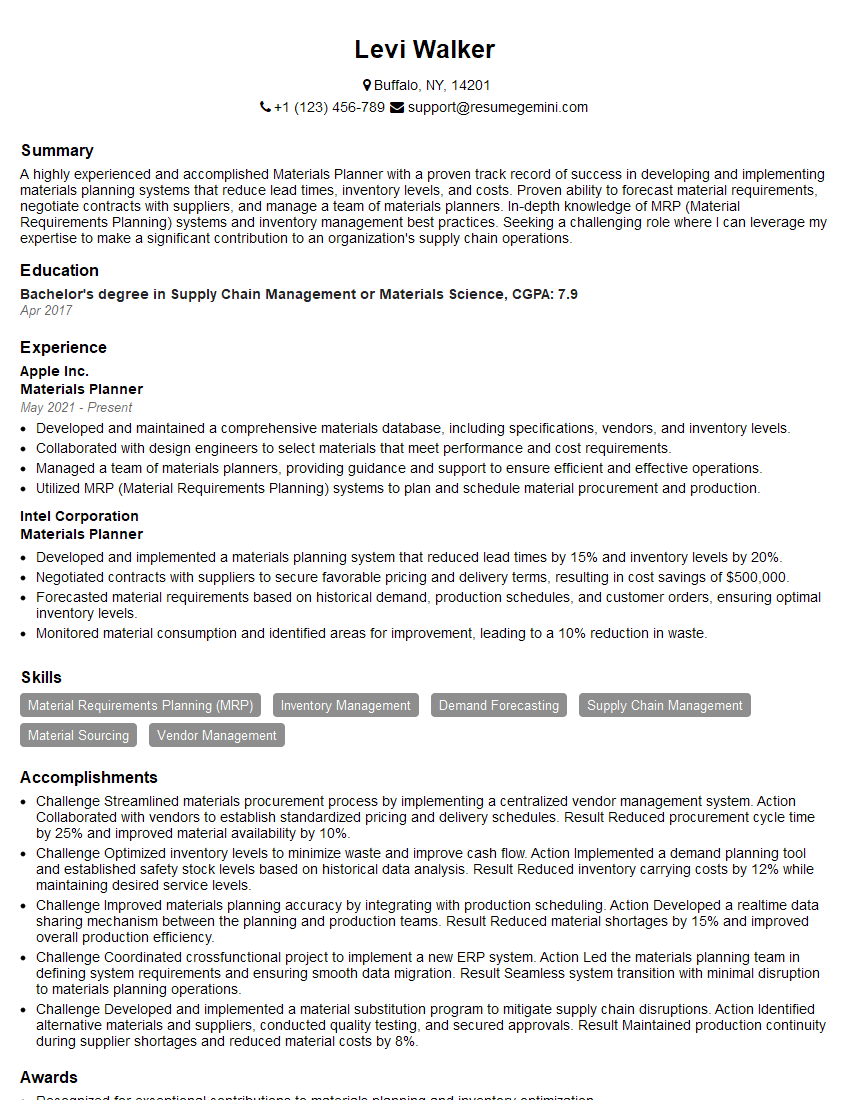

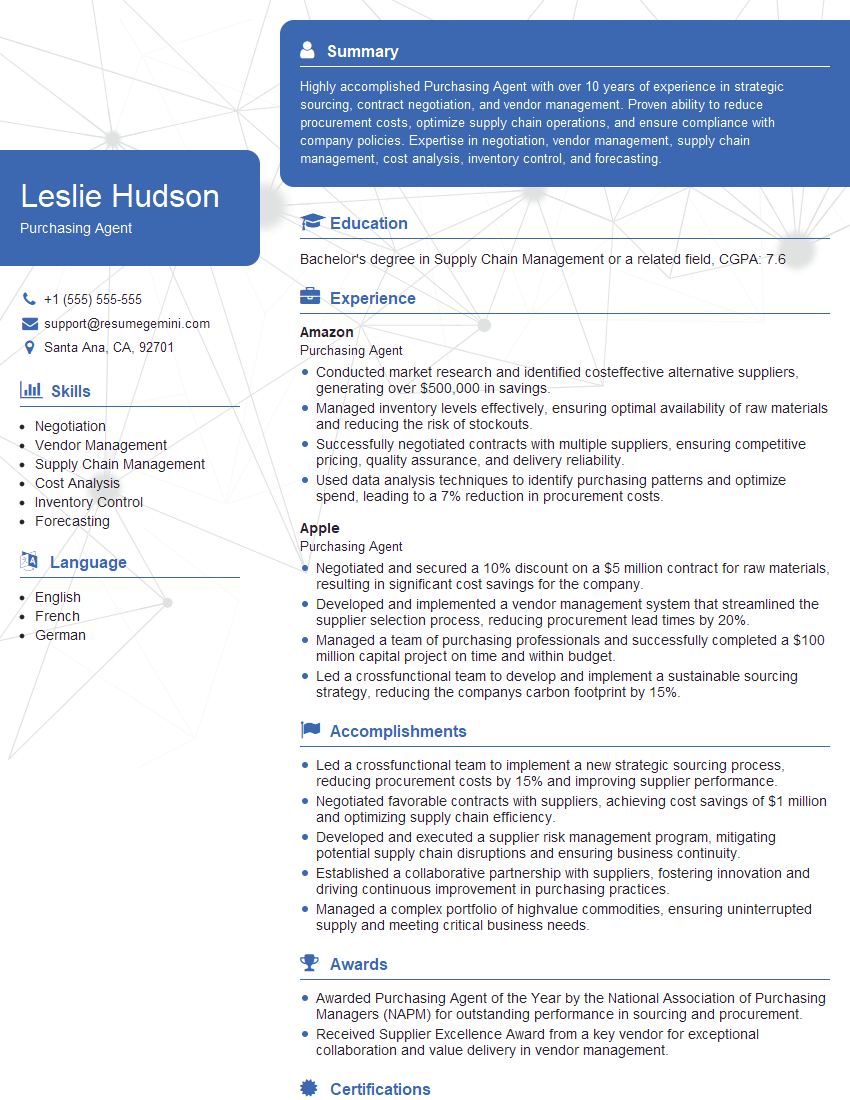

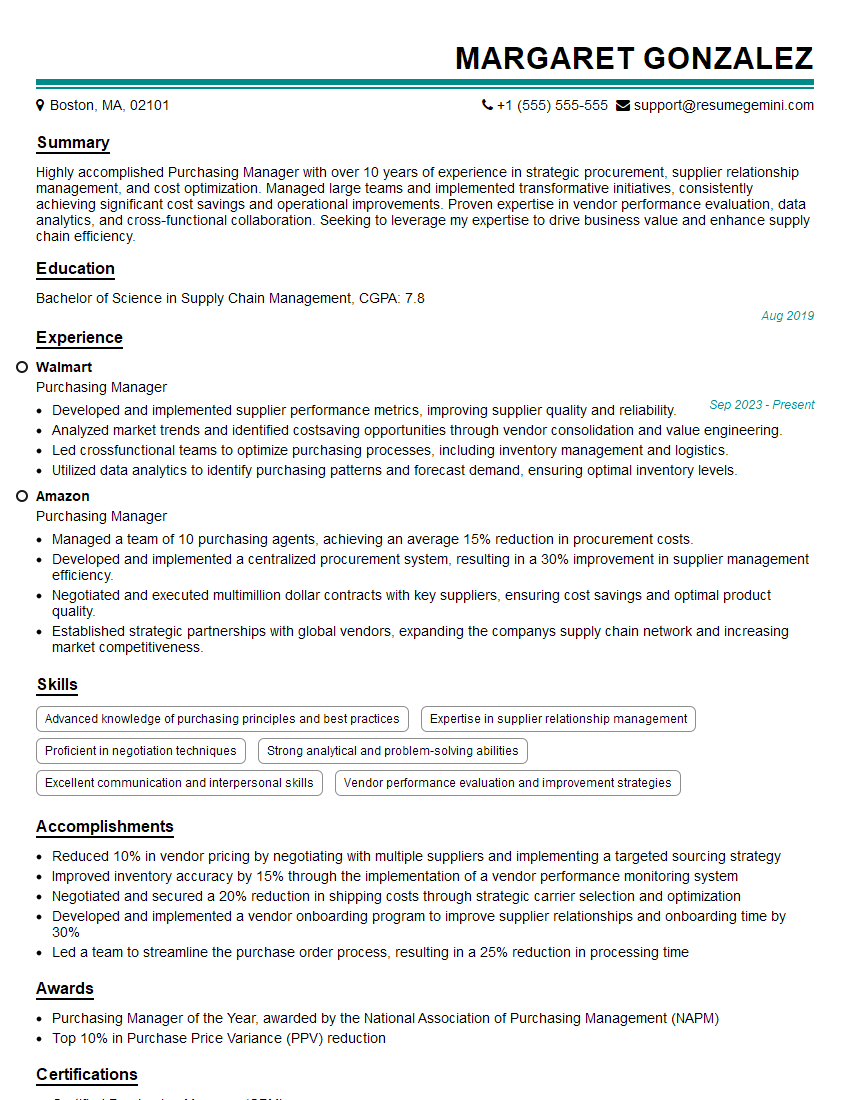

Mastering Materials Management and Inventory Control opens doors to rewarding careers with significant growth potential. These skills are highly sought after across various industries, leading to increased earning potential and career advancement opportunities. To significantly boost your job prospects, create a compelling and ATS-friendly resume that highlights your qualifications effectively. We highly recommend using ResumeGemini to build a professional and impactful resume. ResumeGemini offers a user-friendly platform and provides examples of resumes tailored to Materials Management and Inventory Control positions, helping you showcase your skills and experience in the best possible light.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good