Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Damage Assessment and Repair Planning interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Damage Assessment and Repair Planning Interview

Q 1. Describe your experience in conducting thorough damage assessments.

Conducting a thorough damage assessment involves a systematic approach to identify, document, and analyze all aspects of damage to a structure or property. It’s like performing a detailed medical examination for a building. My process typically begins with a preliminary visual inspection to get an overview of the damage. This is followed by a more detailed investigation, often involving specialized equipment like moisture meters, infrared cameras, and non-destructive testing tools to uncover hidden damage. For example, in a water damage scenario, I’d not only assess the visible water stains but also use moisture meters to determine the extent of moisture penetration within walls and flooring. I meticulously document all findings with detailed photographs, sketches, and written reports, including the location, type, and extent of the damage. This comprehensive documentation forms the foundation for accurate repair planning and cost estimation.

I’ve worked on various projects, from small residential repairs to large-scale commercial damage assessments following natural disasters, always adhering to this rigorous methodology. A recent project involved assessing damage to a historic building after a severe storm. Using drone imagery alongside on-site inspection, we were able to identify roof damage, water ingress, and structural weaknesses not visible from ground level, leading to a more accurate and comprehensive repair plan.

Q 2. Explain your process for prioritizing repairs based on urgency and cost.

Prioritizing repairs is a crucial aspect of damage assessment. It involves balancing urgency, cost, and the overall impact on the structure’s safety and functionality. I employ a matrix approach, considering factors like:

- Safety: Addressing immediate threats to life safety, such as structural instability or hazardous materials exposure, takes top priority.

- Functionality: Repairs essential for restoring basic functionality, like roof leaks affecting interior habitability, are next.

- Cost: While cost is a significant factor, it shouldn’t overshadow safety and functionality.

I typically create a prioritized list, assigning each repair item a severity level (e.g., critical, high, medium, low) and a cost estimate. This helps in allocating resources efficiently and managing project timelines. For instance, in a building with fire damage, securing the structure, preventing further damage from the elements, and removing hazardous materials would be prioritized over cosmetic repairs. A cost-benefit analysis often helps determine the most effective sequence of repairs, ensuring that we get the most value for the budget.

Q 3. How do you determine the root cause of damage in complex scenarios?

Determining the root cause of damage in complex scenarios requires a systematic investigative approach. It’s like solving a detective mystery. I begin by gathering all relevant information, including the history of the structure, weather patterns, maintenance records, and witness accounts (if available). Then, I systematically analyze the damage patterns, searching for clues that indicate the source of the problem. For example, water stains concentrated on one section of a wall might suggest a leak from a specific pipe or faulty plumbing. I utilize various testing methods, such as moisture testing, thermal imaging, and material analysis, to gather more data and verify my hypotheses. Collaboration with other professionals, such as structural engineers or environmental consultants, is often necessary to investigate complex damage mechanisms.

In one project, a building exhibited significant foundation settlement. Through detailed analysis of soil conditions, foundation design, and historical weather data, we determined that the settlement was primarily due to soil erosion exacerbated by a series of heavy rainfall events. This allowed us to recommend targeted solutions addressing the underlying cause rather than simply treating the symptoms.

Q 4. What software or tools do you utilize for damage assessment and repair planning?

I utilize a variety of software and tools to enhance the efficiency and accuracy of damage assessment and repair planning. These include:

- Computer-Aided Design (CAD) software: For creating detailed drawings and 3D models of the damaged areas, aiding in visualization and planning repairs.

- Estimating software: These programs help generate accurate cost estimates for materials and labor based on the scope of work defined in the assessment.

- Project management software: Programs like Microsoft Project or Asana help manage multiple projects, track progress, and ensure efficient resource allocation.

- Specialized software for specific damage types: For instance, software capable of analyzing moisture content in buildings after water damage, or software for assessing structural integrity after seismic activity.

- Drone technology with photogrammetry software: For large-scale damage assessments, particularly after natural disasters, allowing for safe and efficient data acquisition over large areas.

Q 5. How do you estimate the cost of repairs and materials accurately?

Accurate cost estimation is critical for effective project management. It involves a detailed breakdown of all costs associated with the repair project. My process begins with a comprehensive inventory of necessary materials, obtained through detailed assessment of the damage. I obtain multiple quotes from reliable suppliers to ensure competitive pricing. Labor costs are estimated based on the type and complexity of the repairs, considering industry standards and local labor rates. Contingency is also factored in to account for unforeseen expenses or changes in project scope. I use specialized estimating software to streamline this process, generating detailed cost breakdowns which are readily reviewed with clients. Transparency is key—I always explain the rationale behind every cost item included in the estimate.

For example, in a roof repair project, the estimate would detail the cost of new shingles, underlayment, labor for removal and installation, disposal of old materials, and a contingency percentage. This structured approach reduces the risk of cost overruns and ensures client satisfaction.

Q 6. Describe your experience with different types of damage (e.g., water, fire, wind).

My experience encompasses various damage types, each requiring a specialized approach.

- Water damage: This often involves identifying the source of the leak, assessing the extent of moisture penetration, and determining the need for remediation such as drying, mold removal, and structural repairs.

- Fire damage: This necessitates a thorough assessment of structural integrity, smoke and soot damage, and the presence of hazardous materials. Specialized remediation techniques are often required, such as smoke and odor removal and the removal of asbestos-containing materials.

- Wind damage: This can range from minor roof repairs to severe structural damage. Assessment typically involves checking for structural weaknesses, roof penetrations, and damaged cladding.

In each case, I follow established industry best practices and safety protocols. For instance, when dealing with fire damage, I always prioritize the safety of personnel and adhere to strict procedures for hazardous material handling. This ensures the safety of those involved and prevents further damage during the assessment and repair process.

Q 7. How do you manage multiple projects simultaneously in a fast-paced environment?

Managing multiple projects simultaneously in a fast-paced environment requires effective organizational skills and a systematic approach. I use project management software to track deadlines, allocate resources effectively, and maintain clear communication with clients and contractors. Prioritization is paramount—I focus on high-priority tasks and delegate where appropriate. Regular progress meetings are essential to ensure projects stay on track. Clear communication channels with clients, contractors, and subcontractors are crucial to prevent delays and ensure everyone is informed.

I employ a color-coded system within my project management software to visually represent the urgency and status of each project. This allows me to instantly assess the status of multiple projects at a glance and quickly identify potential roadblocks. Regular review and adjustment of project plans are vital to adapt to unforeseen circumstances and ensure efficient project delivery.

Q 8. Explain your approach to communicating assessment findings and repair plans to clients.

Communicating assessment findings and repair plans effectively is crucial for client satisfaction and project success. My approach involves a multi-stage process, starting with a clear and concise initial report summarizing the damage assessment. This report uses plain language, avoiding technical jargon, and includes high-quality photographs and diagrams illustrating the extent of the damage. I then schedule a face-to-face meeting or video conference to discuss the findings in detail, answering any questions the client might have. For the repair plan, I present a step-by-step approach outlining the proposed repairs, materials to be used, timeline, and associated costs. This plan is presented visually appealingly, often using charts and flow diagrams to improve understanding. Finally, I maintain open communication throughout the project, providing regular updates on progress, addressing any concerns promptly, and offering revisions to the plan as needed.

For example, when assessing water damage in a residential property, I would present the client with a report detailing the affected areas (e.g., drywall, flooring, insulation), the cause of the damage, and the potential for mold growth. In the repair plan, I’d detail the steps involved in remediation (e.g., demolition, drying, disinfection, reconstruction), including the specifics of materials and potential timeline delays that could affect the client.

Q 9. How do you handle unexpected issues or challenges during a project?

Handling unexpected issues is a core competency in this field. My approach is proactive, relying on thorough initial assessments to minimize surprises. However, unexpected challenges inevitably arise. When they do, I follow a structured process. First, I thoroughly document the issue, taking photographs and detailed notes. Second, I assess the impact on the project timeline and budget. Third, I explore all possible solutions, considering their cost, feasibility, and impact on the overall project goals. I then present the client with my analysis and recommendations, offering clear and transparent options. Crucially, I emphasize maintaining open communication with the client throughout this process, ensuring they are fully informed and involved in decision-making. A collaborative approach keeps them engaged and mitigates potential frustration.

For instance, if unforeseen structural damage is discovered during demolition, I immediately document it, assess its implications on the repair plan, and explore options like structural engineering consultation and adjusted repair methods. I’ll then discuss these options with the client, explaining the potential impact on costs and timelines, and work collaboratively to find the best solution.

Q 10. Describe your experience with insurance claims and the claims process.

I have extensive experience working with insurance claims, understanding the complexities of the claims process from documentation to settlement. My experience encompasses documenting damage thoroughly to support the claim, providing accurate estimates consistent with insurance industry standards, and communicating effectively with insurance adjusters. I understand the importance of meeting deadlines and adhering to the specific requirements of different insurance companies. I’m proficient in preparing comprehensive reports, including detailed cost breakdowns, supporting documentation (such as photographs, receipts, and expert opinions), and clear explanations of the repairs needed. My goal is to expedite the claims process, ensuring clients receive the appropriate compensation for their losses.

For example, I have successfully navigated complex claims involving significant water damage from burst pipes, where I meticulously documented the extent of the damage, including hidden moisture using specialized equipment, and presented this evidence to the insurance adjuster to secure full coverage for the necessary remediation and repairs.

Q 11. What are your methods for documenting the damage assessment process?

Meticulous documentation is essential for legal and insurance purposes. My documentation process involves several steps. First, I conduct a thorough visual inspection and record observations using detailed notes and high-resolution photographs. I document the location, type, and extent of the damage. Second, I use specialized equipment, such as moisture meters and thermal cameras, to detect hidden damage, documenting the readings and providing visual representations of findings. Third, I create detailed reports, which include photographs, diagrams, and a comprehensive description of the damage, the methodology used for assessment, and the findings. These reports are digitally stored and backed up, ensuring accessibility and archival integrity. I maintain a chain of custody for all documentation, and I’m well-versed in using various software programs to manage and analyze collected data, which ensures accuracy and efficiency.

For example, when assessing fire damage, my documentation would include photographs showcasing the extent of burn damage, soot accumulation, and smoke infiltration. In addition, my reports would include moisture meter readings from affected areas and any additional notes related to smoke damage remediation, including potential air quality testing.

Q 12. How do you ensure the safety of personnel during the damage assessment and repair process?

Ensuring personnel safety is paramount. My approach begins with a thorough site assessment before commencing any work, identifying potential hazards such as structural instability, asbestos, or hazardous materials. I then develop and implement a site-specific safety plan that includes appropriate personal protective equipment (PPE), such as respirators, gloves, and safety glasses, based on identified risks. Regular safety meetings are conducted to reinforce safety protocols and address any concerns. Moreover, all personnel receive appropriate safety training before commencing work. Compliance with all relevant OSHA regulations and best practices is strictly enforced. I maintain detailed records of all safety measures, including safety training records, incident reports, and PPE usage logs.

For example, in a mold remediation project, all personnel would wear appropriate respirators and protective suits to prevent exposure. Access to the affected area would be restricted, and air quality monitoring would be conducted regularly to ensure a safe working environment.

Q 13. What is your experience with regulatory compliance in restoration projects?

Regulatory compliance is critical in restoration projects. My experience encompasses familiarity with a wide range of regulations, including OSHA, EPA, and local building codes. I ensure compliance by following established procedures for handling hazardous materials, asbestos abatement, lead paint removal, and mold remediation. All work is performed according to the relevant regulations, and appropriate permits and licenses are obtained before starting any project. I maintain detailed records of all compliance activities, including waste disposal documentation and certifications related to hazardous material handling. My understanding of the legal implications of non-compliance helps ensure a safe and legally sound approach to every restoration project.

For example, when dealing with asbestos-containing materials, I ensure that certified asbestos abatement contractors are used, all work is conducted according to EPA guidelines, and appropriate air monitoring is performed to confirm the success of the abatement process. All waste materials are properly disposed of in compliance with local and federal regulations.

Q 14. Explain your understanding of building codes and regulations relevant to repairs.

A strong understanding of building codes and regulations is crucial for effective repair planning. My knowledge base encompasses local, state, and national building codes, and I regularly stay updated on changes and amendments. This knowledge guides my assessment and repair plans, ensuring that all repairs meet the required standards for safety, structural integrity, and compliance. I incorporate code-compliant materials and construction methods in all repair plans, and I work closely with building inspectors to ensure that all work is approved and meets code requirements. Understanding building codes ensures the longevity and safety of repaired structures, protecting the client and ensuring the project’s success.

For instance, when repairing fire-damaged structural elements, I’d ensure that all repairs meet the requirements of the relevant building codes for fire resistance and structural integrity, employing appropriate fire-rated materials and construction techniques.

Q 15. How do you manage project budgets effectively?

Effective budget management in damage assessment and repair planning is crucial for project success. It involves a multi-stage process starting with a detailed cost estimate. This estimate considers all aspects, from material costs and labor to permits and potential unforeseen issues. We use specialized software to break down the budget into manageable line items, allowing for close monitoring of expenses against planned allocations.

For example, in a recent project involving water damage restoration to a historic building, we meticulously itemized costs for demolition, mold remediation, structural repairs, and historical restoration. Regular budget reviews are conducted, comparing actual spending to the projected budget, allowing for proactive adjustments if necessary. Any deviations are thoroughly investigated, and corrective actions, such as negotiating better rates with subcontractors or adjusting the scope of work, are implemented. This proactive approach ensures that projects stay within budget and avoid financial setbacks.

Furthermore, contingency planning is vital. A percentage of the overall budget (typically 5-10%) is allocated to cover unexpected expenses. This could be anything from discovering hidden damage to needing specialized equipment. This helps to prevent cost overruns and maintains project financial stability.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are your strategies for mitigating risks associated with damage restoration projects?

Risk mitigation in damage restoration is paramount. We employ a proactive, multi-layered approach. This begins with a thorough initial assessment of the damage, identifying potential risks. This might include structural instability, hazardous materials (like asbestos or lead paint), or environmental factors (like weather conditions).

Our strategies include:

- Detailed Risk Assessment: We use checklists and specialized software to identify potential risks, assigning probability and impact scores. This allows us to prioritize mitigation efforts.

- Contingency Planning: We develop detailed plans to address potential problems, including alternative solutions, backup resources, and emergency contact information.

- Insurance Coordination: We work closely with insurance adjusters to ensure appropriate coverage and timely claim processing.

- Safety Protocols: Strict adherence to safety regulations and protocols is crucial. This includes the use of personal protective equipment (PPE), site security, and regular safety briefings.

- Communication and Collaboration: Open communication among the project team, clients, and subcontractors is essential to quickly identify and address emerging risks.

For instance, in a project involving fire damage, we identified the risk of asbestos in the building materials. We immediately brought in a certified asbestos abatement specialist to safely remove it before any other work could proceed, preventing exposure and potential health hazards. By proactive risk management, we ensure project safety and successful completion.

Q 17. How do you ensure that repairs meet quality standards and industry best practices?

Ensuring quality and adherence to industry best practices is achieved through a rigorous quality control (QC) system. This involves several key steps.

- Detailed Specifications: We create detailed specifications outlining all aspects of the repair work, including materials, techniques, and acceptable tolerances.

- Regular Inspections: We conduct regular inspections throughout the project, using checklists and photographic documentation to monitor progress and identify any deviations from specifications.

- Third-Party Inspections: In high-stakes projects, we often engage third-party inspectors to ensure objectivity and compliance with building codes and industry standards.

- Material Testing: When necessary, materials are tested to ensure they meet the required specifications and quality.

- Documentation: We maintain meticulous records of all work performed, including material certifications, inspection reports, and any changes made during the process.

For example, in a recent project restoring a historical building, we used only approved materials that met the historical preservation standards, using traditional techniques where applicable. Each step of the restoration was carefully documented with photographic evidence, and regular inspections were conducted with the local preservation officer to ensure adherence to all regulations and the highest standards of craftsmanship.

Q 18. Describe your experience with different types of construction materials and methods.

My experience encompasses a wide range of construction materials and methods, including those commonly used in damage restoration.

- Wood: I’m experienced in repairing and replacing various types of wood, from structural timbers to flooring and trim, using appropriate techniques for different species and conditions.

- Drywall: I’m familiar with different types of drywall, repair techniques, and finishing methods. This includes water damage repair, patching, and texture matching.

- Concrete: I have expertise in concrete repair, including patching, crack repair, and structural reinforcement. This also includes understanding different concrete mixes and their properties.

- Masonry: I’m experienced with brick, stone, and block repairs, understanding various mortar types and techniques for matching existing materials.

- Metal: I’m knowledgeable about various metals used in construction (steel, aluminum) and their repair methodologies. This includes rust removal, patching, and painting.

- Roofing: I have experience with different roofing materials (asphalt shingles, tile, metal) and repair methods, including understanding leak detection and repair strategies.

My experience also includes a good understanding of modern construction techniques such as the use of epoxy injections for crack repair, and environmentally friendly materials such as recycled content drywall or sustainably harvested lumber.

Q 19. How do you collaborate with contractors and subcontractors effectively?

Effective collaboration with contractors and subcontractors is central to project success. We foster strong working relationships based on clear communication, mutual respect, and shared goals.

- Detailed Contracts: We use clear, comprehensive contracts that outline the scope of work, payment schedules, timelines, and responsibilities for each party.

- Regular Meetings: We hold regular progress meetings with contractors and subcontractors to track progress, address concerns, and make necessary adjustments.

- Open Communication: We maintain open communication channels to ensure all parties are informed and any issues are promptly addressed. This includes the use of daily reports, email updates, and regular on-site meetings.

- Conflict Resolution Mechanisms: Our contracts include clear processes for resolving conflicts or disputes that may arise.

For example, in a complex multi-contractor project, we held weekly meetings to coordinate the work of different trades. This ensured smooth workflow and prevented delays. We also established a clear communication protocol for reporting any issues or challenges, enabling us to promptly address them before they became major problems.

Q 20. How do you resolve conflicts or disputes that may arise during a project?

Conflicts and disputes are sometimes unavoidable in construction projects. Our approach emphasizes proactive conflict resolution, focusing on communication and collaboration.

- Early Identification: We encourage open communication so that potential conflicts are identified early, preventing them from escalating.

- Mediation: If conflicts do arise, we try to resolve them through informal mediation, bringing involved parties together to find mutually acceptable solutions.

- Contractual Mechanisms: Our contracts include provisions for dispute resolution, including arbitration or litigation as a last resort.

- Documentation: Maintaining meticulous records of all communication, agreements, and changes to the project is crucial to supporting our position in the event of a dispute.

In one case, a dispute arose between the framing contractor and the drywall contractor regarding the timing of their work. Through mediation, we worked with both parties to find a mutually acceptable schedule that ensured the project stayed on track without significant delays. By focusing on understanding each party’s perspective and finding common ground, we successfully resolved the issue.

Q 21. How do you track project progress and ensure timely completion?

Effective project tracking and timely completion require a robust system for monitoring progress. This involves:

- Project Scheduling: We use project management software to create detailed schedules outlining tasks, milestones, and deadlines. This allows us to track progress against the plan.

- Regular Progress Reports: We generate regular reports detailing progress, identifying any delays or potential problems. These reports are shared with clients and stakeholders.

- Performance Monitoring: We monitor the performance of contractors and subcontractors, ensuring they meet agreed-upon timelines and quality standards.

- Change Management: We have a formal process for managing changes to the project scope, ensuring that any changes are properly documented, approved, and reflected in the schedule and budget.

- Risk Management: Ongoing risk monitoring and mitigation are essential to prevent delays and ensure timely project completion.

For instance, in a large-scale renovation project, we used a project management software to track the progress of each phase. Daily updates were recorded and weekly reports were generated, allowing for proactive adjustments to the schedule if needed, ultimately ensuring the project was completed on time and within budget. Using visual tools like Gantt charts also helped us effectively communicate progress to the client.

Q 22. Explain your experience with different types of repair techniques.

My experience encompasses a wide range of repair techniques, categorized broadly by material and damage type. For example, with concrete structures, I’ve utilized techniques like crack injection (using epoxy resins to stabilize cracks), concrete patching (employing different mixes depending on the extent and location of damage), and even complete section replacement in severe cases. For wood structures, I’m proficient in techniques ranging from simple wood repair using fillers and sealants to more complex methods involving sistering (adding new wood members alongside damaged ones) and beam replacement. With drywall, I’ve extensively used techniques like patching, texturing, and painting to seamlessly blend repairs into existing surfaces. Finally, in metalwork repairs, I am experienced in welding, grinding, and applying protective coatings to prevent further corrosion.

- Example: On a recent project involving a historic building, we used lime mortar patching techniques to restore damaged sections of the original brickwork, maintaining the building’s historical integrity.

- Example: In another instance, we employed advanced fiber-reinforced polymer (FRP) composites to strengthen a weakened concrete beam, enhancing its load-bearing capacity and extending its lifespan, a much more sustainable solution than outright replacement.

Q 23. What is your understanding of the various aspects of structural damage?

Understanding structural damage requires a holistic approach, considering various factors. Firstly, we assess the type of damage: is it cracking, settlement, corrosion, or impact damage? Secondly, the location of the damage is crucial; damage in a load-bearing wall is far more critical than in a non-load-bearing partition. Thirdly, we evaluate the severity of the damage, considering the extent of the affected area and the potential for further deterioration. Fourthly, the cause of the damage needs to be identified, such as foundation issues, seismic activity, or material degradation. Finally, understanding the structural implications, involving calculations and possibly using specialized software, is essential to determine the level of risk and the necessary repair strategies. Ignoring any of these aspects can lead to inadequate repairs and potentially dangerous outcomes.

- For instance, a seemingly minor crack in a wall could indicate significant foundation issues if the crack pattern is consistent with settlement.

- Another example: corrosion in a steel beam requires careful evaluation of the extent of the corrosion, considering the potential reduction in load-bearing capacity.

Q 24. Describe your experience with mold remediation or asbestos abatement.

I have extensive experience in both mold remediation and asbestos abatement, adhering strictly to all relevant safety regulations and best practices. Mold remediation involves identifying the source of moisture, removing affected materials, and implementing strategies to prevent future growth. This includes using appropriate personal protective equipment (PPE), HEPA filtration systems, and antimicrobial treatments. Asbestos abatement is a more complex process that requires specialized training and licensing. It involves careful removal of asbestos-containing materials, proper containment and disposal according to EPA guidelines, and post-abatement air monitoring to ensure worker and environmental safety.

Example: In one project, we successfully remediated mold growth in a water-damaged basement, involving the removal of affected drywall, insulation, and flooring, followed by thorough cleaning, drying, and the application of a mold inhibitor. Proper documentation and air quality testing were performed throughout the process to ensure complete remediation.

Example: In another case, a controlled asbestos abatement project was carefully managed using negative air pressure containment, specialized equipment, and meticulous waste disposal to ensure worker and public safety. Post-abatement air quality monitoring confirmed that the project met all regulatory standards.

Q 25. How do you deal with difficult clients or stakeholders?

Handling difficult clients or stakeholders requires patience, clear communication, and a proactive approach. I prioritize active listening to understand their concerns, addressing them directly and honestly. I keep them informed every step of the way, providing regular updates and explaining technical aspects in plain language. When disagreements arise, I aim to find common ground, emphasizing solutions over blame. Documentation of all communications and decisions is crucial. If the situation escalates, I involve project management to facilitate conflict resolution.

For example, if a client is unhappy with the timeline, I explain potential delays and offer alternative solutions, such as prioritizing certain aspects of the project. I view these challenges as opportunities to build trust and strengthen client relationships.

Q 26. Describe your experience with using specialized equipment or technology.

My experience includes the use of various specialized equipment and technology. This includes non-destructive testing (NDT) tools like ground-penetrating radar (GPR) for subsurface investigations, infrared cameras for detecting moisture and thermal anomalies, and moisture meters for assessing the extent of water damage. I’m also proficient in using laser scanners for accurate 3D modeling of structures, helping with precise damage assessment and planning for repairs. For specific repair tasks, I’m familiar with operating equipment such as concrete saws, specialized drilling equipment, and various types of lifting and handling apparatus. I always ensure that equipment is properly calibrated and used safely.

Q 27. How do you ensure the sustainability of restoration projects?

Sustainability is a core principle in our restoration projects. We prioritize the use of environmentally friendly materials, such as recycled content materials and low-VOC paints, whenever possible. We strive to minimize waste through careful planning and efficient material handling, recycling materials where feasible. Energy-efficient solutions are incorporated into repairs wherever appropriate, such as improving insulation or using energy-efficient appliances. We educate clients on sustainable practices for post-repair maintenance and operations, including water conservation and responsible waste disposal. Adopting these strategies not only reduces our environmental impact but also often leads to long-term cost savings for the clients.

Q 28. How do you maintain accurate records and documentation throughout the entire process?

Maintaining accurate records and documentation is paramount throughout the entire process. We use a combination of digital and physical methods. Digital records include photographs, video documentation, 3D scans, and detailed reports created using specialized software. These records are stored securely and are easily accessible to all relevant stakeholders. Physical records include signed contracts, material certifications, test results, and invoices, all maintained in organized files. A detailed chain of custody is established for all samples, test materials, and disposed materials. This meticulous approach ensures transparency, accountability, and facilitates efficient claims processing and future reference.

Key Topics to Learn for Damage Assessment and Repair Planning Interview

- Damage Assessment Methodologies: Understanding various techniques for assessing damage, including visual inspections, non-destructive testing (NDT), and data analysis methods. Consider the limitations of each approach and how to select the most appropriate method based on the situation.

- Repair Planning & Prioritization: Learn to develop comprehensive repair plans, prioritizing critical repairs based on safety, functionality, and cost-effectiveness. Practice creating realistic timelines and resource allocation strategies.

- Cost Estimation and Budgeting: Master the art of accurate cost estimation for repairs, considering materials, labor, and potential unforeseen challenges. Be prepared to discuss different budgeting techniques and risk management strategies.

- Regulatory Compliance and Standards: Familiarize yourself with relevant building codes, safety regulations, and industry best practices related to damage repair. Be prepared to discuss how these standards influence your repair planning process.

- Communication and Collaboration: Damage assessment and repair often involves working with diverse teams. Practice articulating technical information clearly to both technical and non-technical audiences. Discuss strategies for effective collaboration and conflict resolution.

- Software and Technology: Explore commonly used software for damage assessment and repair planning. Highlight your proficiency in relevant tools and demonstrate an understanding of how technology improves efficiency and accuracy.

- Risk Assessment and Mitigation: Develop skills in identifying potential risks associated with the damage and repair process and developing strategies to mitigate those risks. Be prepared to discuss different risk management frameworks.

Next Steps

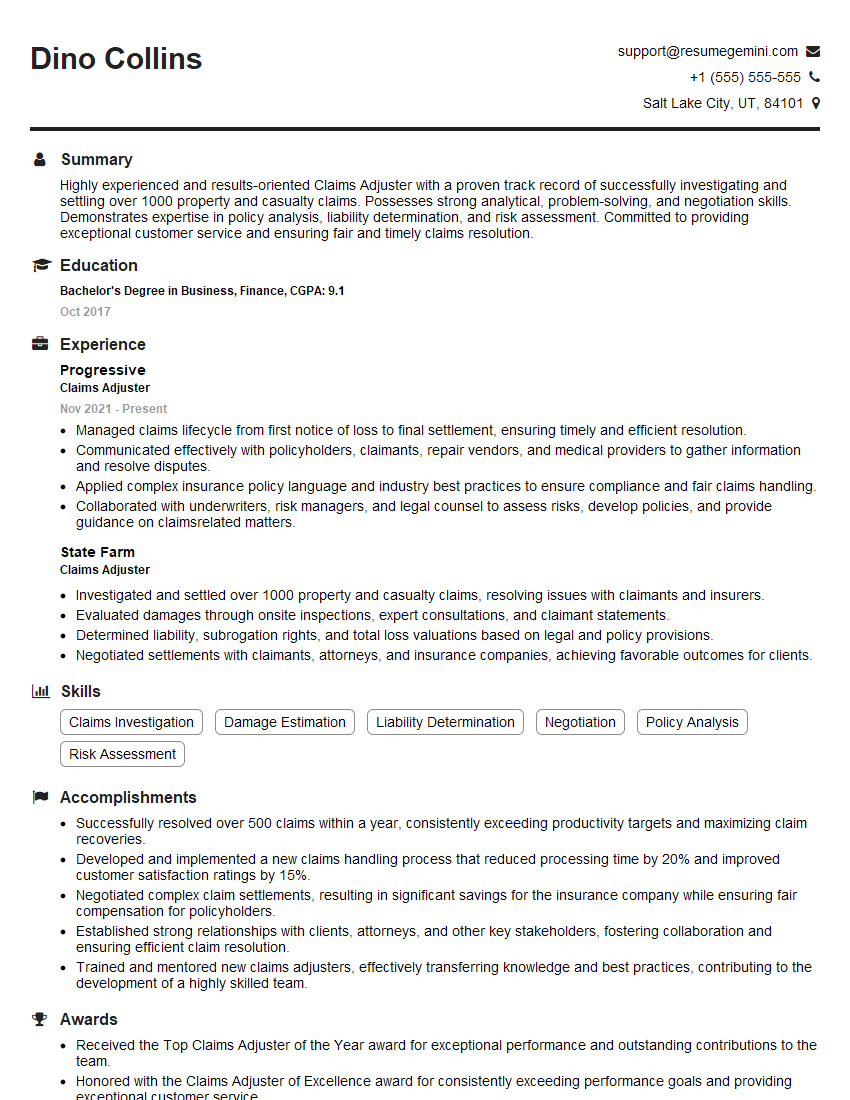

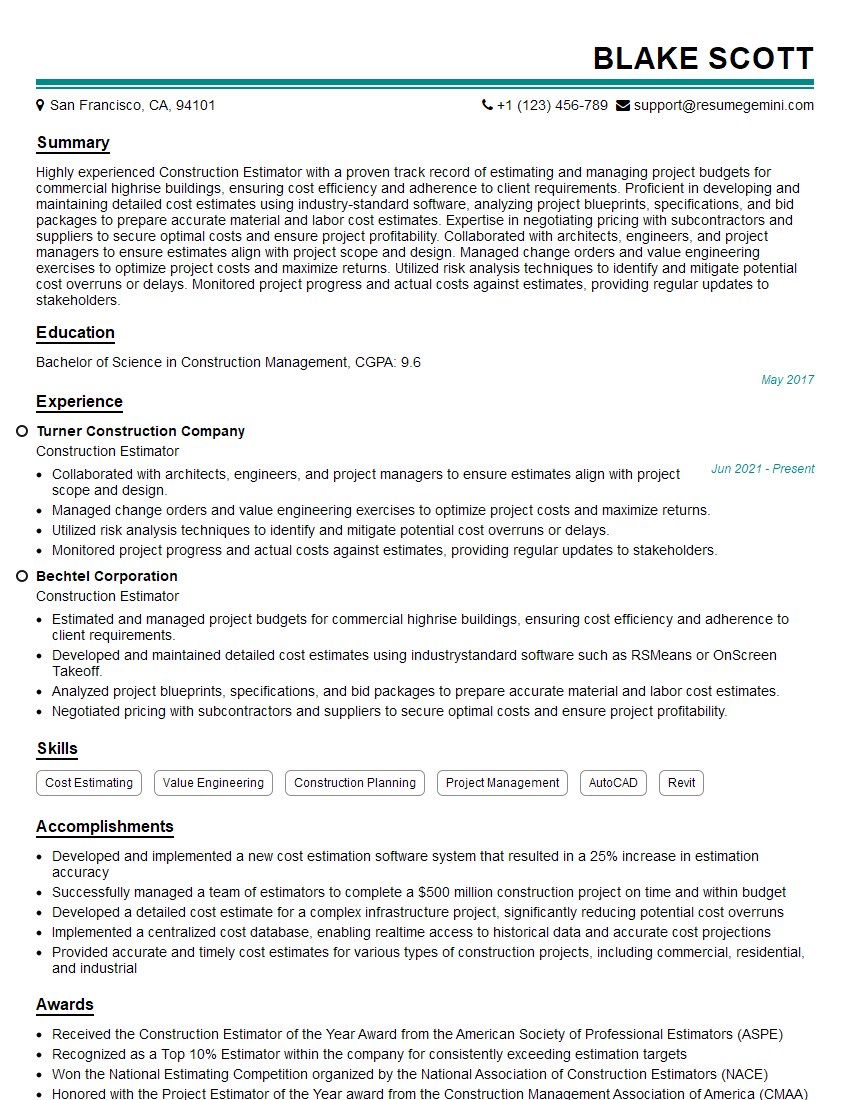

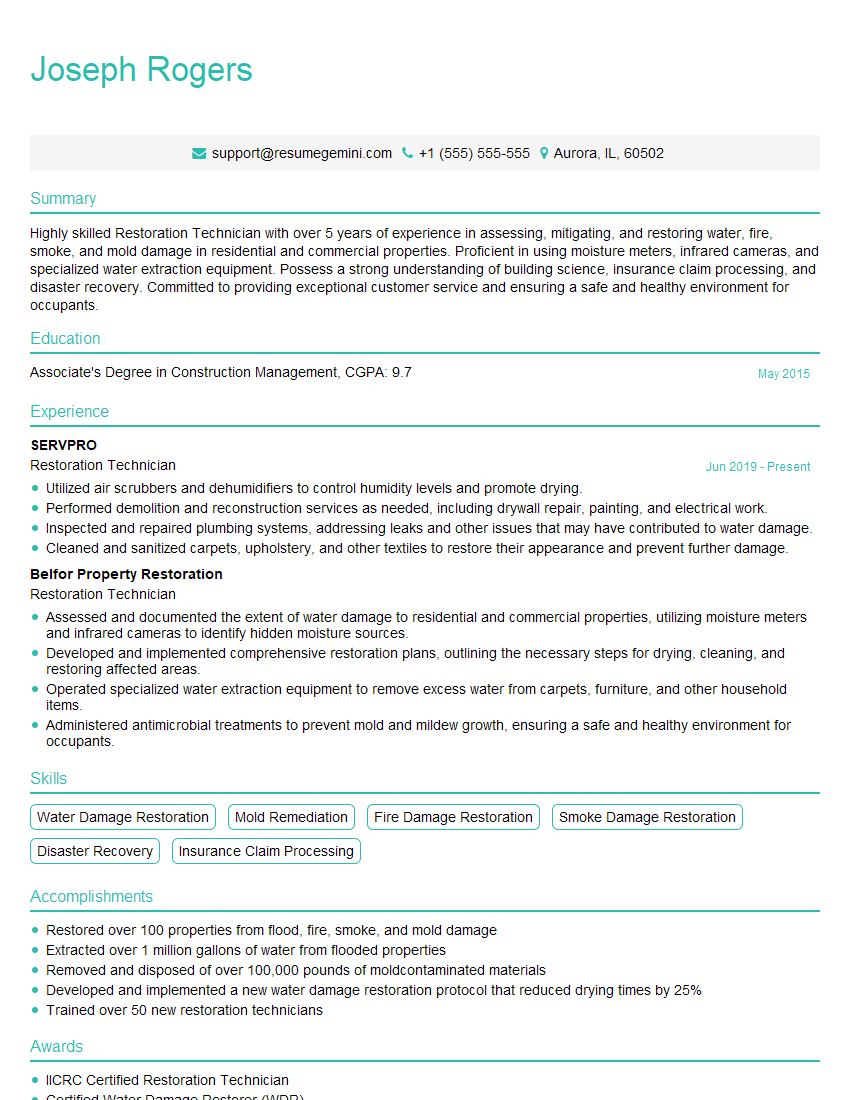

Mastering Damage Assessment and Repair Planning is crucial for career advancement in this dynamic field. It demonstrates a valuable skillset sought after by employers and positions you for greater responsibility and higher earning potential. To significantly improve your job prospects, invest time in crafting a strong, ATS-friendly resume that highlights your relevant skills and experience. ResumeGemini is a trusted resource to help you build a professional resume that stands out. Examples of resumes tailored to Damage Assessment and Repair Planning are provided to guide you through the process. Use these resources to create a compelling narrative that showcases your expertise and secures your next interview!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good