Preparation is the key to success in any interview. In this post, we’ll explore crucial Packing and Grading interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Packing and Grading Interview

Q 1. Explain the importance of proper packing procedures.

Proper packing procedures are paramount for ensuring product safety, maintaining quality, and optimizing logistics. Think of it like this: a well-packed product is like a well-protected traveler – it arrives at its destination safe and sound. Improper packing can lead to damage, spoilage, and ultimately, financial losses.

- Product Protection: Packaging acts as a barrier against physical damage (bumps, shocks, vibrations), moisture, and contamination. For example, fragile items require cushioning, while perishable goods need temperature control.

- Brand Presentation: Attractive and well-designed packaging enhances brand image and consumer appeal. Imagine a luxury item delivered in a flimsy box – it diminishes the perceived value.

- Efficiency and Logistics: Efficient packing minimizes space, reduces weight, and simplifies handling during transportation and storage. This translates into lower shipping costs and less risk of damage during transit.

- Compliance and Regulations: Proper packing often adheres to legal requirements for safety, labeling, and environmental protection. This avoids fines and legal issues.

Q 2. Describe your experience with different types of packaging materials.

My experience encompasses a wide range of packaging materials, each suited to different product types and handling requirements.

- Corrugated Cardboard: A ubiquitous choice for its strength, cost-effectiveness, and recyclability. I’ve used various grades and thicknesses depending on the product’s weight and fragility. For instance, heavier electronics require double-walled cardboard for extra protection.

- Plastic Films: Including shrink wrap, stretch film, and bubble wrap, these offer moisture and dust protection. Shrink wrap provides a snug fit, while bubble wrap is ideal for cushioning fragile items. I’ve used these extensively for protecting items during shipping.

- Foam Packaging: PE foam and polyurethane foam are effective for cushioning and shaping products. Custom-cut foam inserts are particularly useful for fragile electronics or glassware, ensuring a snug and secure fit.

- Wood Crates and Pallets: These are indispensable for heavy or bulky goods requiring robust protection during long-distance shipping. I’ve worked with various wood types and construction methods, prioritizing durability and stability.

- Specialized Packaging: This includes vacuum-sealed bags for food preservation, insulated containers for temperature-sensitive products, and anti-static bags for electronics. Selecting the right specialized packaging is crucial for product integrity.

Q 3. How do you ensure accurate product grading?

Accurate product grading is crucial for ensuring quality and consistency. It’s about objectively evaluating the products against predetermined standards. This involves a systematic approach that incorporates visual inspection, measurement, and often, testing.

- Establishing Grading Standards: Before grading, clear standards must be defined based on factors like size, weight, color, quality, and any defects. These standards might be industry-specific or company-specific.

- Visual Inspection: This is often the first step, focusing on visible attributes like appearance, blemishes, or damage. For example, in produce grading, visual inspection checks for bruises, discoloration, or imperfections.

- Measurements and Testing: Depending on the product, measurements (length, width, weight) and tests (strength, ripeness) may be conducted to ensure compliance with grading criteria. For example, fruits may be weighed, and electronics could undergo functionality tests.

- Calibration and Quality Control: Ensuring the accuracy of measuring instruments and the consistency of the grading process is vital. Regular calibration and internal audits help maintain quality control.

- Documentation: Grading results should be accurately documented and traced back to the source for traceability and accountability. This could involve barcodes, labels, or digital databases.

Q 4. What are the common challenges in packing and grading, and how do you overcome them?

Challenges in packing and grading are common, but proactive measures can minimize their impact.

- Damage during Handling: Improper handling can cause damage even with good packaging. Solution: Implement training programs for handling personnel, use appropriate handling equipment, and reinforce packaging integrity.

- Inconsistent Grading: Subjectivity in grading can lead to inconsistencies. Solution: Establish clear grading standards, provide comprehensive training to graders, and implement regular audits and calibration of measurement tools.

- Time Constraints: Meeting deadlines while maintaining quality can be challenging. Solution: Optimize workflows, use efficient equipment, and allocate sufficient personnel to handle peak periods.

- Material Costs: Balancing packaging cost with protection can be tricky. Solution: Explore different packaging materials and designs to find cost-effective solutions that still provide adequate protection.

- Variations in Product Size and Shape: Non-uniform products pose packing challenges. Solution: Use flexible packaging materials or custom-designed inserts to accommodate variations.

Q 5. What are your preferred methods for identifying damaged or defective products?

Identifying damaged or defective products relies on a multi-sensory approach and well-defined procedures.

- Visual Inspection: Careful observation for visible damage (dents, cracks, scratches), discoloration, or other defects is crucial. This often involves using good lighting and magnification where necessary.

- Physical Examination: Beyond visual inspection, tactile examination can detect subtle damage or defects not readily visible. For example, gently pressing on a product might reveal softness or structural weaknesses.

- Functional Testing: For certain products, functional testing may be necessary to determine if damage has affected performance. For example, testing electronics to ensure functionality after handling.

- Automated Systems: In high-volume operations, automated systems with cameras, sensors, and weight scales can quickly and accurately detect defects and inconsistencies.

- Sampling: Random sampling allows for the inspection of a representative subset of the batch, providing a statistically valid assessment of product quality.

Q 6. How do you handle discrepancies between product quantity and packing lists?

Discrepancies between product quantity and packing lists require a meticulous investigation to identify the root cause and rectify the situation.

- Inventory Reconciliation: A thorough recount of the packed items is the first step. This should be done carefully and systematically, double-checking against the packing list.

- Production Records Review: Examination of production records can reveal potential issues such as errors in counting or packaging at the source.

- Packaging Process Audit: A review of the packaging process can pinpoint procedural errors or equipment malfunctions that may have led to discrepancies.

- Damage Assessment: Check for any damaged items that may have been missed during the initial packaging process. Such damage may lead to inaccurate counts if items have been broken and discarded.

- Documentation and Reporting: Detailed documentation of the discrepancy, including the investigation steps and corrective actions, is critical for preventing future occurrences and for maintaining accuracy in inventory control. This would also support reporting to clients regarding the discrepancies.

Q 7. Describe your experience using different types of packing equipment.

My experience includes operating and maintaining a variety of packing equipment, ranging from simple hand tools to automated systems.

- Hand Tools: I’m proficient with taping machines, box cutters, and other manual tools, frequently used for smaller-scale operations or specialized tasks.

- Automated Packaging Machines: I’ve worked with automated systems like case sealers, stretch wrappers, and robotic palletizers, significantly increasing efficiency and throughput in high-volume settings. This includes understanding preventative maintenance and troubleshooting procedures for these systems.

- Weighing and Measuring Equipment: Experience with scales, dimensioners, and other measuring instruments ensures accurate product grading and efficient packing.

- Labeling and Marking Systems: Proficient in operating and maintaining labeling machines that affix barcodes, labels, and other identifying markers onto products, aiding tracking and identification.

- Material Handling Equipment: I have experience using forklifts and other material handling equipment to move and stage materials during packing processes, while prioritizing safety.

Q 8. How do you maintain a clean and organized packing area?

Maintaining a clean and organized packing area is paramount for efficiency, safety, and quality control. Think of it like a well-organized kitchen – if everything has its place, you can work faster and more accurately. My approach involves several key strategies:

- Designated Zones: Clearly defined areas for receiving materials, packing supplies, in-process goods, and finished products prevent clutter and confusion. For example, I’d have a separate station for each product type, ensuring correct packaging materials are readily available.

- Regular Cleaning Schedule: A daily cleaning routine is crucial. This includes sweeping or vacuuming the floor, wiping down surfaces, and properly disposing of waste. I’d implement a system – perhaps a checklist – to ensure consistency.

- Inventory Management of Supplies: Adequate storage for packing materials (boxes, tape, fillers, etc.) is essential. Using FIFO (First-In, First-Out) method helps prevent expired materials from being used and optimizes space.

- 5S Methodology: Applying the 5S methodology (Sort, Set in Order, Shine, Standardize, Sustain) provides a structured framework for organization and cleanliness. This is a highly effective, widely used method for optimizing workplaces. For example, regularly sorting through unused packing materials will improve workflow significantly.

- Employee Training: All packing personnel are trained on proper cleaning procedures and the importance of maintaining a tidy workspace. This includes proper disposal of waste and the importance of keeping the area free from tripping hazards.

Q 9. How do you prioritize tasks in a high-volume packing environment?

Prioritizing tasks in a high-volume packing environment requires a systematic approach. I typically use a combination of techniques:

- Order Prioritization: Rush orders and orders with critical deadlines always take precedence. This requires a clear communication system to ensure everyone is aware of the priorities.

- Order Sequencing: Similar orders (e.g., similar product types or sizes) are grouped together to optimize workflow. This minimizes the need for frequent equipment changes and reduces errors.

- Visual Management Tools: Kanban boards or other visual aids help track progress and identify bottlenecks. A simple whiteboard with order numbers and their status is a great starting point.

- Team Communication: Maintaining open communication amongst the team is essential. Regular briefings will keep everyone informed and allow for adjustments as needed. This includes clear communication of any unexpected changes.

- Data-Driven Decisions: Analyzing historical data on packing times and order volumes helps predict peak periods and allows for proactive staffing adjustments. For instance, if we observe a predictable increase in orders on Tuesdays, we can adjust our staffing accordingly.

Q 10. Explain your understanding of quality control procedures in packing and grading.

Quality control in packing and grading is crucial to ensure customer satisfaction and maintain brand reputation. My understanding encompasses several aspects:

- Pre-Packing Inspection: Products are visually inspected for defects, damage, and inconsistencies before packing. This is often done at the grading stage, with defective items being separated.

- Accurate Labeling and Documentation: Accurate labels with clear information (product name, quantity, weight, etc.) and accompanying documentation are essential. This includes checking batch numbers and expiration dates to minimize any errors.

- Proper Packaging: Appropriate packaging materials (boxes, cushioning, seals) are used to protect products during transit, preventing damage. This depends on the fragility of the product and the distance being shipped.

- Random Sampling and Spot Checks: Periodic random sampling ensures that the quality remains consistent throughout the packing process. I often incorporate this into a random sampling system – for example, every tenth box could be checked more thoroughly.

- Post-Packing Inspection: A final check of packed boxes, including seals and labels, is performed before dispatch. This is particularly important for orders containing fragile or expensive items.

Any discrepancies found are immediately addressed, and corrective actions are implemented to prevent recurrence. This may involve retraining staff or adjusting packing procedures. Documentation of these procedures is crucial for traceability.

Q 11. Describe your experience with inventory management systems.

My experience with inventory management systems includes using both simple spreadsheet-based systems and more sophisticated software solutions. I am proficient in using systems to track inventory levels, monitor stock movement, manage supplies, and generate reports. My experience includes:

- Spreadsheet-Based Systems: I’ve effectively used spreadsheets (Excel, Google Sheets) for smaller-scale operations, tracking inventory levels, re-order points, and stock values. While simple, these systems are very useful for monitoring smaller inventory systems.

- Software Solutions: I’m familiar with various enterprise resource planning (ERP) systems and dedicated inventory management software. These systems offer more advanced features like automated re-ordering, real-time tracking, and integrated reporting.

- Data Analysis: I can analyze inventory data to identify slow-moving items, optimize stock levels, and predict future demand. This allows proactive adjustments to ordering to avoid stockouts and waste.

- Barcode/RFID Integration: I’m experienced working with systems that integrate barcode or RFID technology for efficient tracking of inventory. This reduces errors, increases efficiency, and speeds up the inventory count.

Choosing the right inventory management system depends on the scale and complexity of the operation. For example, a small business might use a simple spreadsheet, while a larger enterprise requires a comprehensive ERP system.

Q 12. How do you ensure efficient workflow in a packing line?

Efficient workflow in a packing line hinges on several key factors:

- Ergonomic Design: The packing line should be designed ergonomically to minimize strain and maximize efficiency. This includes proper workstation height, sufficient lighting, and easy access to supplies.

- Standardized Procedures: Clear, standardized packing procedures are essential. All team members should understand their roles and responsibilities. This also ensures consistency and reduces errors.

- Balanced Workload: The workload should be distributed evenly among team members to prevent bottlenecks and ensure fairness. This might involve adjusting the number of personnel at each station.

- Process Optimization: Regularly reviewing and optimizing the packing process is key. Identifying and eliminating unnecessary steps can significantly improve efficiency.

- Cross-Training: Cross-training personnel allows for flexibility and coverage in case of absences or unexpected changes in workload. This allows for efficient adjustment when needed.

- Regular Maintenance: Equipment should be regularly maintained to minimize downtime. This includes preventative maintenance schedule for packing equipment and prompt repairs when necessary.

Q 13. How do you handle rush orders or unexpected changes in schedules?

Handling rush orders or unexpected schedule changes requires flexibility and adaptability. My approach involves:

- Immediate Communication: Communicating the changes immediately to the entire team is crucial. Transparency is key to smooth and effective change management.

- Prioritization and Re-scheduling: Re-prioritizing tasks based on deadlines and urgency is necessary. This may involve rescheduling existing orders to accommodate rush orders.

- Resource Allocation: Adjusting resource allocation (personnel, equipment, materials) to meet the new demands is essential. This may involve re-assigning tasks or bringing in extra help.

- Flexibility and Adaptability: The team needs to be flexible and adaptable to handle unexpected changes. This involves clear communication and a willingness to work as a team to solve problems.

- Process Adjustment: If necessary, the packing process might be slightly adjusted to accommodate the rush order. However, these adjustments must ensure quality is not compromised. This may involve prioritizing the packing of the high-priority items over other items.

In addition, learning from these unexpected changes helps to refine our processes and improve our response times in the future. After each occurrence, a brief team meeting should be done to discuss what happened, what could have been done better, and to brainstorm ways to prevent similar issues in the future.

Q 14. What are your strategies for preventing product damage during packing and shipping?

Preventing product damage during packing and shipping requires a multi-faceted approach:

- Appropriate Packaging Materials: Choosing the right boxes, cushioning materials (bubble wrap, packing peanuts, air pillows), and tape is crucial. This selection depends on product fragility and shipping distance.

- Proper Packing Techniques: Products should be packed securely to prevent movement during transit. Fragile items should be individually wrapped and placed in a way to avoid impact.

- Labeling and Handling Instructions: Clear labels with “fragile” or “handle with care” instructions should be affixed to boxes. This helps ensure proper handling throughout the shipping process.

- Suitable Shipping Containers: Using sturdy shipping containers that are appropriate for the size and weight of the products is critical. This includes pallets, crates, and boxes that are appropriate for the method of shipment.

- Quality Control Checks: Regular checks of packed boxes before shipment ensure that products are adequately protected. The team must be trained to properly identify potentially damaged items.

- Environmental Considerations: Protecting items from extreme temperatures, moisture, and other environmental factors may be necessary, depending on the product and shipping method. This may include thermal packaging or other measures.

Regularly reviewing packaging procedures and incorporating feedback from shipping and receiving departments helps identify potential problem areas and improve our strategies.

Q 15. How do you stay updated on industry best practices for packing and grading?

Staying current in the dynamic field of packing and grading requires a multi-pronged approach. I regularly engage with industry publications like Packaging World and Modern Materials Handling, attending webinars and conferences offered by organizations such as the Institute of Packaging Professionals (IoPP). These resources provide insights into the latest technologies, regulations, and best practices. Furthermore, I actively participate in online forums and professional networking groups, exchanging ideas and experiences with other experts in the field. This continuous learning allows me to adapt to evolving industry standards and implement the most efficient and effective techniques.

For example, recently I learned about a new automated packing system that significantly reduces labor costs and improves packing consistency. By attending a trade show and subsequently reading several industry articles, I was able to understand its capabilities and potential application in various packing scenarios.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience working with different types of products.

My experience spans a wide range of products, from delicate electronics requiring specialized cushioning and anti-static packaging to heavy industrial components needing robust protection against damage during transit. I’ve worked with perishable goods, such as fresh produce, requiring temperature-controlled environments and rapid processing to maintain quality, as well as non-perishable items with varying shapes, sizes, and fragility. This diversity has honed my skills in adapting packing and grading methodologies to the specific needs of each product category.

For instance, while packing delicate glassware, I implemented a multi-layered packing system using bubble wrap, foam inserts, and sturdy cardboard boxes to minimize breakage during shipping. In contrast, when working with heavy machinery parts, I focused on secure bracing and strapping to prevent shifting and damage during transport.

Q 17. How do you ensure the safety of yourself and your colleagues in the packing area?

Safety is paramount in any packing environment. My approach centers around proactive hazard identification and mitigation. This involves regular safety training for myself and my team, emphasizing proper lifting techniques, the use of personal protective equipment (PPE) like gloves, safety glasses, and steel-toed boots, and adherence to company safety protocols. I also routinely inspect the work area for potential hazards, such as spills, damaged equipment, or obstructed walkways, immediately reporting and rectifying any issues to prevent accidents. Furthermore, I promote a culture of safety awareness within the team, encouraging open communication and immediate reporting of any concerns.

For example, if a box appears unstable or overloaded, I’ll immediately stop the packing process and find a solution, rather than risking injury. We frequently conduct team safety drills to reinforce proper procedures.

Q 18. What metrics do you use to measure your efficiency in packing and grading?

Efficiency in packing and grading is measured through several key metrics. These include units packed per hour (UPH), which indicates individual productivity, and overall packing line efficiency, determined by comparing the actual output to the targeted output. Defect rates, representing the percentage of incorrectly packed or graded items, are crucial for quality control. We also track order fulfillment accuracy, ensuring the correct items are packed for each order. Finally, waste reduction, measured by the amount of excess packaging materials used, is a significant indicator of efficiency and sustainability.

For instance, if our target UPH is 100 units, but we consistently achieve 120, it demonstrates high individual efficiency. Low defect rates and high order fulfillment accuracy complement this efficiency measure.

Q 19. How do you identify and address potential safety hazards in the packing area?

Identifying and addressing safety hazards requires a proactive approach. This starts with regular workplace inspections, focusing on potential trip hazards, electrical hazards, ergonomic issues, and proper use of machinery. We utilize a formal hazard identification process, such as a Job Safety Analysis (JSA), to systematically evaluate tasks and identify potential risks. Implementing corrective actions ranges from simple adjustments like improved lighting or better organization of materials to more significant measures such as machine guarding or process redesign. Regular safety training and open communication channels ensure that everyone is aware of potential hazards and knows how to report them.

For example, if we find that a particular packing task leads to repetitive strain injuries, we could implement ergonomic changes such as adjustable work surfaces or provide more frequent breaks to address the issue.

Q 20. Explain your experience with barcode scanning and labeling.

I possess extensive experience with barcode scanning and labeling, utilizing various scanning devices and label printers. This includes accurate data entry using barcode scanners, ensuring that every item is correctly identified and tracked throughout the packing process. I’m proficient in troubleshooting scanner issues and managing label inventory, ensuring seamless operation. My experience also encompasses generating and interpreting barcode data for inventory management and order tracking. This enhances efficiency by streamlining the packing and shipping process and reducing errors. I also have experience with different labeling software and understanding various barcode symbologies.

For example, I can readily configure a label printer to print various labels according to product specifications and manage inventory to prevent label shortages during peak production periods.

Q 21. How do you manage multiple tasks and responsibilities simultaneously?

Managing multiple tasks effectively involves a structured approach. I prioritize tasks based on urgency and importance, using methods like a to-do list or project management software to stay organized. I break down complex tasks into smaller, manageable steps, making them less overwhelming. I also leverage time management techniques, such as time blocking, to allocate specific time slots for different activities. Multitasking is less about doing many things at once and more about efficiently switching between focused periods on various tasks. Open communication with colleagues and supervisors helps ensure collaboration and prevents conflicts or missed deadlines.

For example, if I need to manage both packing orders and inventory simultaneously, I might allocate specific time blocks for each task, ensuring both areas receive adequate attention. Prioritizing urgent orders first helps to maintain efficiency.

Q 22. How do you handle customer complaints related to packing issues?

Handling customer complaints regarding packing issues requires a systematic approach focusing on empathy, efficient investigation, and timely resolution. First, I acknowledge the customer’s frustration and assure them that their concern is important. Then, I gather detailed information about the issue, including photos of the damaged packaging or product, the order number, and a description of the problem. This allows me to understand the root cause—was it poor packaging materials, improper handling, or damage during transit?

Next, I investigate internally. This might involve reviewing packing procedures with the team, inspecting the packaging materials used for that specific order, and even reviewing warehouse handling records. Once the cause is identified, I propose a solution – this might be a replacement shipment, a refund, or a discount on future orders, depending on the severity and nature of the problem. Crucially, I follow up with the customer to ensure their satisfaction and to prevent similar issues in the future. For instance, if repeated complaints stem from a specific supplier’s packaging materials, I would work with procurement to source a higher-quality alternative.

Q 23. How do you maintain accuracy and consistency in your packing and grading work?

Maintaining accuracy and consistency in packing and grading demands meticulous attention to detail and adherence to standardized procedures. We implement a comprehensive quality control system, including regular checks on weighing scales, dimension verifiers, and labeling machines to ensure accuracy. Clear, concise, and visually appealing Standard Operating Procedures (SOPs) are provided to every team member, with training and regular refresher courses offered.

Visual aids, checklists, and even gamification techniques (like friendly competition between teams for accuracy rates) are used to improve performance and maintain consistency. Statistical Process Control (SPC) charts are utilized to track key metrics like packing speed, error rate, and compliance with grading standards. Any deviations from the established norms trigger immediate investigation and corrective actions, ensuring that the quality remains consistently high. For example, if the weight of a product consistently falls below the acceptable range, we examine the source of the issue—whether it’s a faulty machine, inconsistent product supply, or an error in the SOPs—and adjust accordingly.

Q 24. Describe your experience with different types of packaging machinery.

My experience encompasses a wide range of packaging machinery, including automated and semi-automated systems. I’m proficient with conveyors, palletizers (both robotic and manual), shrink wrappers, case erectors, and various types of labeling machines (thermal transfer, inkjet). I’m familiar with operating and troubleshooting different models from leading manufacturers such as [Manufacturer A] and [Manufacturer B].

My experience extends to both high-speed, high-volume production lines found in large distribution centers and smaller, more flexible systems used in specialized packaging operations. I understand the importance of proper machine maintenance, preventative measures, and safe operating procedures. For instance, I was once tasked with implementing a new robotic palletizer. This involved not only learning the specifics of the machine itself, but also designing a workflow that integrated seamlessly with our existing conveyor systems, ensuring a smooth transition and preventing potential bottlenecks.

Q 25. How do you adapt to different types of packing materials and equipment?

Adaptability is crucial in this field. I have experience with a variety of packing materials, from corrugated cardboard boxes and plastic films to specialized packaging for fragile or temperature-sensitive goods (e.g., insulated containers with dry ice for pharmaceuticals). I can quickly learn the specific handling requirements of new materials, whether it’s adjusting the settings on a shrink wrapper for a different film thickness or modifying packing procedures to accommodate a new type of box.

Similarly, I can adapt my techniques to different equipment. Switching from one type of palletizer to another, for example, might require adjusting the pallet patterns and layer configurations. I approach this by studying the equipment’s manual and any provided training materials, performing test runs with small batches of products, and always prioritizing safety and efficiency. If I encounter unfamiliar equipment, I thoroughly research its functionality and seek guidance from experienced colleagues or manufacturers’ representatives before operating it.

Q 26. How do you ensure compliance with safety regulations in the packing area?

Safety is paramount in any packing and grading environment. I strictly adhere to all company safety protocols and regulatory standards, including OSHA guidelines. This includes wearing appropriate Personal Protective Equipment (PPE) such as safety shoes, gloves, and eye protection. I’m familiar with lockout/tagout procedures for machinery maintenance, and I’m trained to identify and report any hazardous conditions, such as spills, damaged equipment, or fire hazards.

I actively participate in safety training programs and promote a culture of safety awareness among my colleagues. We conduct regular safety audits of the packing area to identify and rectify potential hazards. For instance, we implemented a new system for storing heavy boxes to reduce the risk of back injuries. We also installed clear signage to alert workers to potential hazards and implemented a more systematic approach to waste disposal, preventing accidents caused by clutter and trip hazards.

Q 27. Explain your experience with warehouse management systems.

My experience with warehouse management systems (WMS) includes using various software platforms to manage inventory, track orders, and optimize warehouse operations. I’m proficient in using WMS to generate picking lists, assign tasks to employees, and monitor the progress of orders through the packing and shipping process. I’m familiar with different modules of WMS, such as inventory control, order management, and warehouse automation interfaces.

I’ve worked with both cloud-based WMS and on-premise systems, understanding their respective advantages and limitations. For example, I used a WMS to optimize our warehouse layout to minimize travel time for pickers, leading to a significant improvement in order fulfillment efficiency. I’m also adept at integrating WMS data with other enterprise resource planning (ERP) systems to ensure seamless data flow across different departments, improving overall business efficiency.

Q 28. Describe your problem-solving skills related to packing and grading issues.

Problem-solving is a core skill in packing and grading. I approach issues systematically, using a structured approach that includes identifying the problem, analyzing the cause, developing solutions, implementing the best solution, and verifying the outcome. For example, if we experience a consistent increase in damaged goods, I wouldn’t simply blame the packaging materials. I would investigate multiple factors: handling practices, the condition of the packaging equipment, the supplier’s quality control measures, and even transit conditions.

I utilize data analysis to identify trends and patterns, and I’m comfortable using various problem-solving methodologies such as the 5 Whys technique to drill down to the root cause. I also value collaboration; I actively involve other team members in the problem-solving process, leveraging their expertise to develop comprehensive and effective solutions. My goal is not only to resolve the immediate issue but also to implement preventive measures to avoid similar problems in the future. This could involve revising SOPs, training employees, or making changes to equipment or procedures.

Key Topics to Learn for Your Packing and Grading Interview

- Understanding Quality Standards: Learn about different grading systems (e.g., size, weight, color, condition) and how to apply them consistently. Consider the impact of inconsistent grading on efficiency and customer satisfaction.

- Efficient Packing Techniques: Explore various packing methods (e.g., hand packing, machine packing, specialized packaging) and their suitability for different products. Practice optimizing packing speed and minimizing waste.

- Safety Procedures and Regulations: Familiarize yourself with relevant health and safety protocols, including proper lifting techniques, hygiene practices, and the use of personal protective equipment (PPE). Be prepared to discuss your experience maintaining a safe work environment.

- Inventory Management and Tracking: Understand the importance of accurate inventory control and tracking systems. Explore methods for minimizing stock loss and optimizing inventory levels.

- Troubleshooting and Problem-Solving: Prepare to discuss how you’ve handled issues such as damaged goods, equipment malfunctions, or discrepancies in inventory. Highlight your ability to identify problems, find solutions, and prevent future occurrences.

- Teamwork and Communication: Packing and grading often involve teamwork. Be ready to discuss your collaborative skills and ability to communicate effectively with colleagues and supervisors.

- Technological Proficiency: Explore your familiarity with any relevant technologies used in packing and grading, such as barcode scanners, automated packing machines, or inventory management software.

Next Steps

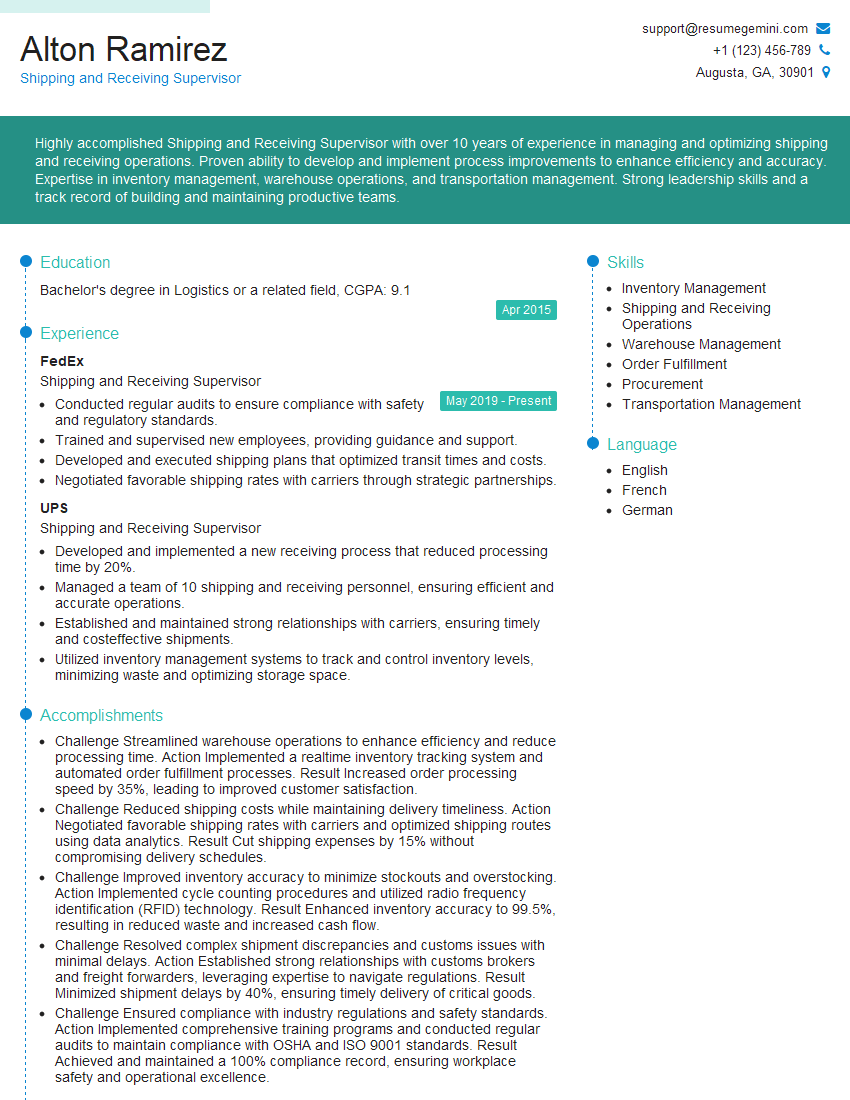

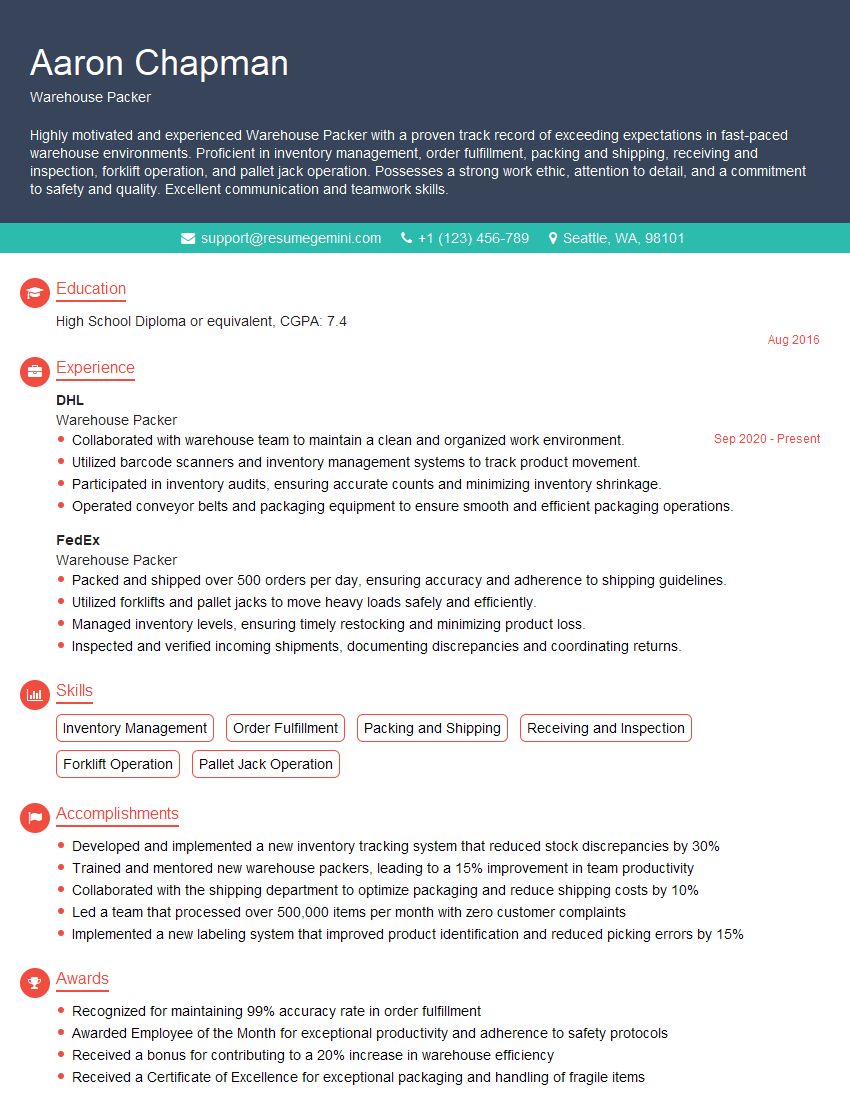

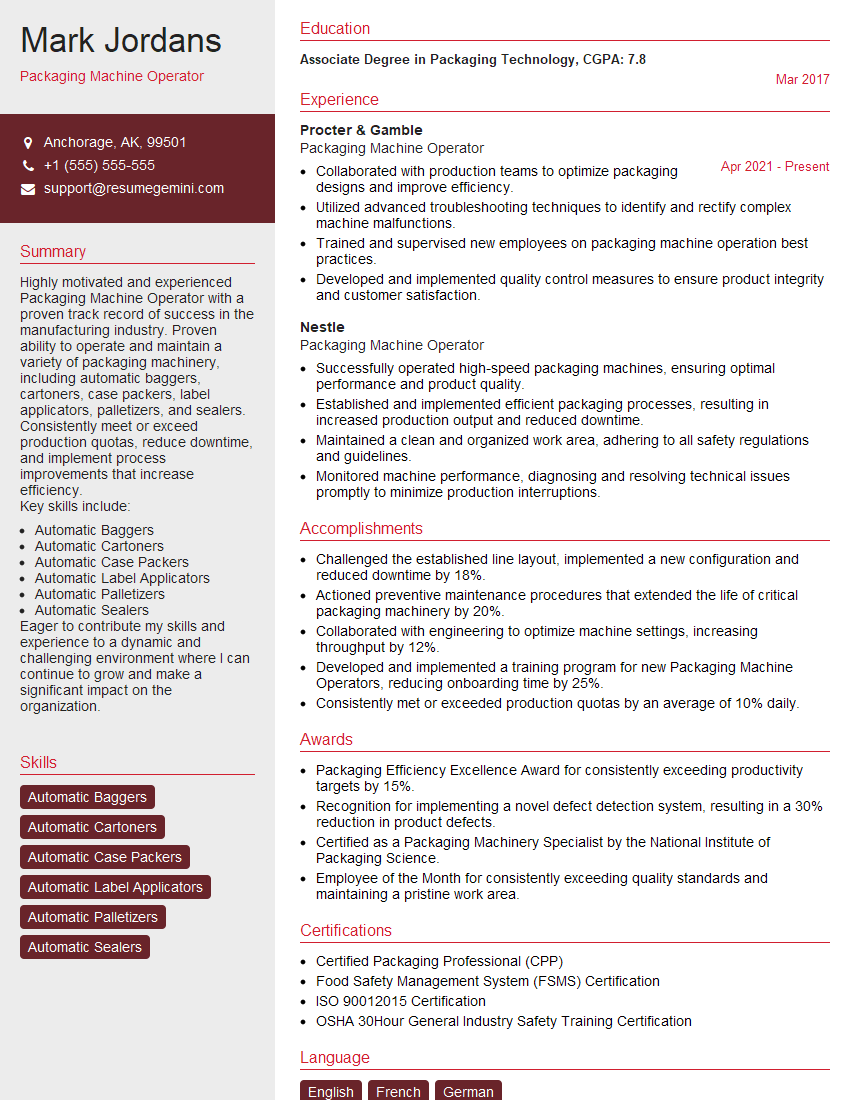

Mastering packing and grading skills opens doors to various roles within logistics, manufacturing, and agriculture, offering opportunities for advancement and increased earning potential. A strong resume is crucial for showcasing your abilities to potential employers. Creating an ATS-friendly resume is key to getting your application noticed. ResumeGemini is a trusted resource to help you build a professional resume that highlights your skills and experience effectively. Examples of resumes tailored to the Packing and Grading field are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good