Are you ready to stand out in your next interview? Understanding and preparing for Experience in Multi-Channel Prepress interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Experience in Multi-Channel Prepress Interview

Q 1. Explain your experience with different file formats used in multi-channel prepress (e.g., PDF, TIFF, JPEG, EPS).

In multi-channel prepress, we work with a variety of file formats, each with its strengths and weaknesses. Understanding these nuances is crucial for efficient and accurate output.

- PDF (Portable Document Format): The industry standard for final prepress files. Its versatility allows for embedding fonts, images, and color profiles, ensuring consistency across different platforms. I frequently use PDF/X-1a or PDF/X-4 standards for print, guaranteeing reliable color reproduction.

- TIFF (Tagged Image File Format): A lossless format ideal for high-resolution images, especially those destined for print. Its ability to preserve image quality is indispensable when working with complex imagery or fine details.

- JPEG (Joint Photographic Experts Group): A lossy format suitable for web and screen-based applications, often used for photographs. While efficient in file size, its compression can lead to some quality loss. I carefully manage the JPEG compression level to balance file size and image quality.

- EPS (Encapsulated PostScript): A vector-based format often used for illustrations and logos. It maintains sharp lines and crisp details at any resolution. While less common now than PDF, it remains useful for certain applications.

Choosing the right file format is key. I always consider the final output method and prioritize quality over file size where necessary. For instance, for high-quality offset printing, TIFF or PDF/X-1a are preferred, while JPEG might be suitable for web banners.

Q 2. Describe your workflow for preparing files for different printing methods (offset, digital, large format).

My workflow for preparing files for different printing methods is highly methodical and involves several key stages. It starts with understanding the specific requirements of the printing process, then tailoring the file preparation to optimize results.

- Offset Printing: This involves creating high-resolution files (typically 300 DPI or higher) in PDF/X formats, ensuring proper color profiles (e.g., CMYK) are embedded, and performing thorough preflighting to catch any potential errors before the plates are made. I also consider specific offset printing press capabilities, such as maximum sheet size and color capabilities, to avoid issues like overprinting or misalignment.

- Digital Printing: Workflow is often streamlined, but accuracy is still critical. I prepare files in high-resolution PDF or TIFF formats, often using RGB color profiles for digital presses, and ensure the correct bleed and trim settings are applied for precise cutting. Specific printer settings, such as color space and resolution, are factored into the preparation.

- Large Format Printing: This requires files with high resolution (e.g., 150-300 DPI), often using RGB color space. I pay careful attention to the final output size and ensure sufficient resolution for crisp, clear results, especially with larger print runs or high-detail images. Understanding the media (vinyl, canvas, etc.) is paramount for choosing the correct file format and resolution.

Regardless of the printing method, I always meticulously check for errors, paying close attention to details like bleeds, margins, and color consistency. A consistent approach ensures quality and reduces costly reprints.

Q 3. How do you ensure color consistency across multiple channels (print, web, mobile)?

Maintaining color consistency across print, web, and mobile is a challenge, but crucial for brand identity. My approach relies on a combination of careful color management and profile utilization:

- Color Space Conversion: I use ICC profiles to accurately convert between color spaces (CMYK for print, RGB for web/mobile). The choice of profile is critical; it needs to accurately represent the target output device.

- Proofing: Soft proofing, using the correct ICC profiles on my monitor, gives me a preview of the final printed output. I often perform hard proofing on a calibrated proofer for critical projects, to ensure colors match expectations.

- Calibration & Profiling: Regular calibration of my monitors and printers, and use of up-to-date ICC profiles are paramount to maintain accuracy.

- Standardized Color Palettes: Using a standardized color palette (e.g., Pantone) where possible ensures consistent color across channels. While a web color is never a direct match to a CMYK equivalent, a system based on Pantone or similar gives a common reference point.

Think of it like baking a cake; you must use precise ingredients and follow a recipe carefully to get consistent results. Color management in multi-channel prepress is similar: precise measurements and techniques ensure the final product matches the desired outcome across all platforms.

Q 4. What software and hardware are you proficient with in a multi-channel prepress environment?

My proficiency in software and hardware is extensive, reflecting the diverse demands of multi-channel prepress.

- Software: Adobe Creative Suite (Photoshop, Illustrator, InDesign), Acrobat Pro, Color Management software (e.g., X-Rite i1Profiler), preflighting software (e.g., PitStop Pro), imposition software (e.g., Imposition). I am also familiar with various RIP (Raster Image Processor) software depending on the printer technology.

- Hardware: Calibrated monitors (with colorimeters), high-resolution printers, colorimeters (e.g., X-Rite i1), and spectrodensitometers for accurate color measurement. Familiarity with various printing press types and their specifications also is part of my skill set.

This combination of software and hardware skills allows me to efficiently process various file types, manage color profiles, and ensure the final output meets the highest quality standards.

Q 5. Explain your experience with color management systems and profiles (e.g., ICC profiles).

Color management systems (CMS) and ICC profiles are fundamental in achieving accurate color reproduction. ICC profiles define the color characteristics of a specific device (monitor, printer, scanner). They act like translators, ensuring that color data is interpreted correctly by each device.

- ICC Profile Creation: I’ve been involved in creating and managing ICC profiles for various devices, ensuring their accuracy and relevance. This process involves using a spectrophotometer to measure the color output of the device.

- Profile Embedding: I embed the correct ICC profiles in my prepress files, directing the final output device to interpret color data appropriately.

- Color Space Conversion: A major part of my workflow includes converting colors between different color spaces (e.g., RGB to CMYK) using appropriate ICC profiles to minimize color shifts.

Think of ICC profiles as detailed instructions that tell each device how to accurately reproduce colors. They’re essential for matching colors across different output methods and achieving consistent brand identity.

Q 6. How do you handle preflighting and quality control in multi-channel prepress?

Preflighting and quality control are critical to prevent costly errors in the printing process. My approach involves a multi-stage process:

- Automated Preflighting: I use automated preflighting software to check for common errors such as missing fonts, low-resolution images, and color inconsistencies. This catches many problems before they reach the printing stage.

- Manual Inspection: Even with automated checks, I perform manual visual inspection of files to catch subtle errors that automated systems might miss. This is especially important for intricate designs or complex images.

- Proofing: Soft and hard proofing are essential to verify the final output matches expectations. This catches discrepancies in color, registration, and overall image quality.

- Process Documentation: I maintain detailed records of each step in the process, ensuring traceability and accountability.

A proactive and thorough quality control process is like having a safety net: it safeguards against mistakes and helps achieve the desired quality. Every precaution taken reduces the chance of rework and delays.

Q 7. Describe your experience with trapping and imposition techniques.

Trapping and imposition are vital in prepress for ensuring consistent color and efficient printing.

- Trapping: This technique involves slightly overlapping colors to prevent small gaps from appearing between them. It’s particularly critical when printing with multiple colors, as even slight misregistration can lead to unsightly gaps. I select appropriate trapping methods (spread, choke) based on the printing process and the design specifications.

- Imposition: This is the process of arranging pages in a specific order on a printing sheet to optimize printing efficiency. I use imposition software to create efficient layouts that minimize waste and maximize output, based on sheet size and print run specifications. I ensure correct imposition for both offset and digital print, taking into account paper orientation and booklet folds.

Think of trapping as creating a ‘buffer’ between colors to avoid gaps, and imposition as strategically arranging pages for efficient use of paper and print time. Both are crucial for high-quality and cost-effective print production.

Q 8. How do you optimize files for different output devices and resolutions?

Optimizing files for different output devices and resolutions is crucial for achieving the desired print quality and avoiding costly reprints. It involves understanding the capabilities of each device – from high-resolution inkjet printers to lower-resolution newspaper presses – and preparing the files accordingly. This is often managed through a process of image scaling and resolution adjustments.

For example, a high-resolution image (e.g., 300 DPI) intended for a glossy magazine print will look pixelated and blurry if directly used for a low-resolution newspaper print (e.g., 150 DPI). The solution involves downsampling the image to the appropriate resolution for the newspaper, potentially utilizing image sharpening techniques to maintain acceptable detail. Conversely, an image originally at 72 DPI (suitable for web use) would need to be upscaled for print, a process that often leads to some loss of quality.

The process often involves using prepress software like Adobe Acrobat Pro or dedicated RIP software which allows for careful control over resolution and color profiles. We use color management tools (ICC profiles) to ensure color consistency across various output methods. Different file formats also impact optimization: PDF/X-1a is a standard format for print that ensures reliable color and image quality across platforms. We ensure that all files meet the specifications outlined by our printing partners.

Q 9. What is your experience with digital asset management systems in a prepress environment?

My experience with Digital Asset Management (DAM) systems in a prepress environment is extensive. I’ve worked with several platforms, including [mention specific DAM systems if comfortable – e.g., Bynder, Adobe Experience Manager, etc.], to organize, store, and retrieve digital assets efficiently. A well-functioning DAM system is essential for managing the massive amounts of files involved in multi-channel campaigns. Consider this scenario: we’re managing assets for a large print and digital campaign – hundreds of high-resolution images, vector graphics, and fonts. Without a DAM, finding the correct, version-controlled file could be a time-consuming nightmare, increasing turnaround time and risk of error.

A robust DAM system streamlines this process, enabling version control, metadata tagging (for easy searching by project, client, file type, etc.), and access control features. I also utilize the DAM to track file usage, ensuring we’re not incurring unnecessary storage costs. DAM systems allow for seamless collaboration between designers, prepress operators, and clients, fostering greater transparency and accountability throughout the workflow. In practice, this means avoiding wasted time, reducing errors, and contributing to increased efficiency across our projects.

Q 10. How do you manage and resolve prepress-related issues and bottlenecks?

Managing and resolving prepress issues and bottlenecks requires a proactive and systematic approach. I typically employ a combination of preventative measures and reactive troubleshooting techniques. Preventative measures include careful file preparation guidelines for designers, robust quality control checks at each stage of the process, and regular system maintenance to prevent software or hardware failures.

When bottlenecks or issues arise (e.g., a missing font, a corrupted file, a color mismatch), my approach focuses on identifying the root cause, finding a quick fix, and implementing preventative measures to avoid recurrence. For instance, if a color mismatch occurs, I’ll investigate the source – is it an incorrect color profile, a flawed design file, or a problem with the output device? Once identified, I’ll address the issue directly, then update our workflows to prevent the problem from repeating. This might involve introducing a new color proofing step or clarifying the color profile guidelines for designers. My focus is always on maintaining clear communication with all stakeholders to keep the project on track.

Q 11. Describe your experience with different printing processes and their implications on prepress workflow.

My experience spans various printing processes, including offset lithography, digital printing, screen printing, and large format printing. Each process has unique implications for the prepress workflow. Offset lithography, for instance, requires high-resolution files and careful color management due to its reliance on plates. In contrast, digital printing allows for greater flexibility with variable data and on-demand printing, but requires careful consideration of file formats and color space.

For offset, we would use a specific PDF/X-1a standard for ensuring color accuracy and preparing for the plate-making process. With digital printing, a PDF/X-4 might be more suitable. Screen printing necessitates specialized artwork preparation for the screens, while large-format printing requires considering different media types and their limitations. Understanding these nuances ensures that the files are perfectly prepared for each specific printing process, leading to improved print quality and efficiency. A thorough understanding of the capabilities and limitations of each process is crucial for success.

Q 12. How do you ensure the accuracy of barcodes and variable data printing in multi-channel campaigns?

Ensuring the accuracy of barcodes and variable data printing (VDP) is paramount, particularly in multi-channel campaigns where accurate data is crucial for tracking, personalization, and efficient fulfillment. I have extensive experience implementing rigorous quality checks for these elements. For barcodes, we use barcode verification software to confirm readability and compliance with industry standards (e.g., verifying the barcode’s check digit). This is usually done as part of the preflight check before sending to the printer.

For variable data, we implement a multi-step verification process. This involves verifying the data source itself for accuracy and completeness, conducting test prints to validate the accurate placement and readability of the personalized information, and comparing the output to the source data for any discrepancies. We also create detailed documentation of the data handling and verification process to ensure traceability and auditability. Any issues detected are thoroughly documented and resolved before mass production. This meticulous approach minimizes errors and ensures the success of personalized campaigns.

Q 13. What is your experience with automated prepress workflows and systems?

I have considerable experience with automated prepress workflows and systems, significantly increasing efficiency and reducing errors. These systems often integrate different software components, such as automated imposition software, automated color management tools, and workflow automation platforms (e.g., Enfocus Switch, PitStop Pro). These integrations allow for automated tasks such as trapping, imposition, color conversion, and quality checks. For example, our imposition software automatically arranges pages on a press sheet based on pre-defined parameters, saving significant time and reducing human error.

Automating these repetitive tasks not only increases speed but also improves consistency and reduces the risk of human error. This allows our prepress team to focus on more complex tasks requiring creative problem-solving and quality control, resulting in increased overall productivity and a higher-quality final product. The use of automation also allows for better project tracking and reporting, contributing to improved project management overall. I’m comfortable working with and implementing various automated systems and tailoring them to meet specific project needs.

Q 14. How do you collaborate with designers and other stakeholders in the prepress process?

Collaboration is crucial in the prepress process. I actively foster a collaborative environment by maintaining open communication with designers, clients, and other stakeholders. This often involves regular meetings, shared project folders (often within our DAM system), and clear communication channels (email, instant messaging, project management software). Early and frequent communication is key to preventing issues down the line. For instance, I’ll meet with the designer early in the design process to review the artwork, discuss print specifications, and identify any potential issues before they become major problems.

This proactive approach, combined with detailed feedback and clear expectations, ensures that the final files meet the necessary specifications. I also provide regular progress updates to clients and answer any questions they might have. By fostering a transparent and collaborative environment, we minimize misunderstandings and ensure a smoother, more efficient prepress workflow for all involved parties. It’s all about building trust and a collaborative spirit.

Q 15. How familiar are you with different print finishing techniques and their impact on prepress?

Print finishing techniques significantly impact prepress. Understanding these techniques is crucial for ensuring the final product meets the client’s expectations and is produced efficiently. We need to consider how different finishes affect the imposition, color management, and even the file formats required.

- Die-cutting: This process requires precise die lines to be incorporated into the prepress files, demanding accuracy to avoid costly errors. For example, if a die-cut line is off by even a fraction of a millimeter, it can ruin thousands of pieces.

- Foil stamping/Embossing: These techniques require accurate registration marks in the prepress files to ensure the foil or embossing aligns perfectly with the printed image. Misalignment can be a significant quality issue.

- Laminating: While seemingly simple, the type of lamination (gloss, matte, etc.) affects the final color appearance. Prepress needs to factor in this effect during color proofing and adjustment.

- Perfect Binding/Saddle Stitch: These binding methods require prepress to consider page counts, bleed, and spine thickness. Improper prepress preparation can lead to crooked spines or pages that don’t align.

In my experience, I’ve worked extensively with clients to ensure their finishing specifications are accurately reflected in the prepress workflow. This includes providing clear instructions and templates, utilizing specialized software for die-cutting and embossing design, and performing rigorous quality checks at each stage to avoid costly reprints.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your experience with proofing and approval processes.

Proofing and approval are vital for preventing costly mistakes. My experience involves utilizing a variety of methods, from soft proofs (digital proofs viewed on screen) to hard proofs (physical prints) to ensure color accuracy and design integrity. The process typically follows these steps:

- Soft Proofing: Clients review digital proofs, often using PDF/X-compliant files, allowing for early feedback and corrections. This often utilizes online proofing systems for streamlined collaboration.

- Hard Proofing: A physical print, ideally on the same press and with the same stock as the final print run, provides the most accurate representation of the final product. Any discrepancy between the digital and hard proof will be carefully analyzed and rectified.

- Approval Process: Formal sign-off procedures are employed to ensure that all parties have approved the final proofs before proceeding to printing. This process is documented meticulously.

- Version Control: Every proof version is carefully tracked, providing a clear audit trail. This is vital for identifying revisions, resolving issues, and demonstrating accountability.

In one instance, a client mistakenly approved a soft proof without noticing a minor but impactful font issue. Our rigorous version control and multiple-stage approval process allowed us to identify the issue before the printing process commenced, preventing major financial losses.

Q 17. Describe your experience with managing large-scale prepress projects.

Managing large-scale prepress projects requires meticulous planning and effective team coordination. My experience includes handling projects involving thousands of pages, multiple languages, and various print specifications. Key aspects include:

- Project Planning: Detailed timelines are established, considering deadlines, resource allocation, and potential bottlenecks. Gantt charts or similar project management tools are utilized to track progress.

- Team Collaboration: Effective communication with designers, editors, and printers is crucial. Regular meetings, collaborative software, and clear communication channels are essential.

- Resource Management: Efficiently managing prepress equipment, software licenses, and personnel ensures optimal productivity. This often involves prioritizing tasks and allocating resources strategically.

- Quality Control: Establishing comprehensive quality checks at each stage is critical. This involves meticulous preflighting, proofing, and color management protocols.

One example involved a multi-million-page textbook project with tight deadlines. Through meticulous project management, careful resource allocation, and close team collaboration, we successfully delivered the project on time and within budget, achieving exceptional quality.

Q 18. How do you handle version control and file management in a prepress environment?

Version control and file management are paramount in prepress to avoid confusion and errors. My approach combines robust software solutions with established organizational practices.

- Version Control Software: Utilizing systems like Git or dedicated prepress workflow software allows tracking changes, reverting to previous versions, and collaborating effectively on large projects. File naming conventions are strictly adhered to.

- File Organization: A structured folder system is essential. Projects are organized by client, job number, and file type, ensuring easy retrieval and preventing duplication.

- Metadata Management: Including comprehensive metadata in every file, such as client name, job number, revision number, and file format, allows for efficient searching and organization.

- Backup and Archiving: Regular backups are essential to protect against data loss. Files are archived according to client policies and legal requirements.

For instance, we recently used Git to manage a complex packaging project involving multiple design iterations. The system allowed for seamless collaboration among designers and prepress operators while maintaining a clear record of all changes, facilitating quick problem resolution and easy retrieval of older files if needed.

Q 19. Describe your experience with troubleshooting prepress equipment and software.

Troubleshooting prepress equipment and software is a critical skill. My approach involves a systematic process, combining technical knowledge with problem-solving skills.

- Identify the Problem: Accurately diagnosing the issue is the first step. This may involve analyzing error messages, examining output, and considering recent changes.

- Isolate the Cause: Systematically test different components to pinpoint the source of the problem. This might involve checking connections, drivers, and software configurations.

- Research Solutions: Consult online resources, manuals, or vendor support to find potential solutions. This often involves forum searches, manual examination, or direct contact with technical support.

- Implement Solutions: Apply the identified solutions, carefully testing after each step to ensure the problem is resolved without creating new issues.

- Document the Solution: Maintain records of the problem, the steps taken, and the solution to aid future troubleshooting and prevent recurring problems. This documentation aids the team in knowledge sharing.

For example, I once resolved a color profile mismatch leading to incorrect color output by carefully examining the output and the software settings, ultimately identifying a wrongly assigned color profile. Documenting this process helped the team avoid similar issues in the future.

Q 20. How do you stay up-to-date with the latest trends and technologies in multi-channel prepress?

Staying current in the rapidly evolving multi-channel prepress field requires a proactive approach.

- Industry Publications and Websites: Regularly reviewing industry publications, websites, and blogs keeps me informed about new technologies, software updates, and best practices.

- Conferences and Trade Shows: Attending industry events provides valuable opportunities to network with colleagues and learn about the latest innovations firsthand. This often involves interacting with vendors and other experts.

- Training and Certification: Participating in training courses and pursuing relevant certifications ensures that my skills remain sharp and relevant to current industry standards.

- Professional Organizations: Membership in professional organizations provides access to resources, networking opportunities, and ongoing learning materials.

For example, I recently completed a course on variable data printing, a growing trend that requires understanding new software and workflow techniques. This training enhanced my capabilities and allowed me to offer clients more advanced and cost-effective solutions.

Q 21. What is your experience with PDF/X standards and best practices?

PDF/X standards are essential for ensuring color consistency and reliable data transfer in prepress. My experience includes working extensively with various PDF/X versions, understanding their nuances, and applying best practices.

- PDF/X-1a: Used for CMYK workflows, guaranteeing consistent color reproduction across different devices. Best for print-centric projects where color accuracy is paramount.

- PDF/X-3: Supports both CMYK and spot colors, offering more flexibility for projects with special inks. Offers broader capabilities than PDF/X-1a.

- PDF/X-4: Includes transparency support, simplifying workflows involving layered images and effects. This is a valuable asset for complex designs.

- Best Practices: Prepress utilizes specific tools and settings to create and validate PDF/X files, ensuring they meet the required specifications for print. This often includes preflight checks and color management profiles.

In one project, using PDF/X-4 allowed us to seamlessly integrate complex designs with transparency effects, avoiding common issues with rasterization or color inconsistencies. Adherence to PDF/X standards ensured a smooth and efficient workflow leading to a high-quality final product.

Q 22. Describe a time you had to solve a complex prepress problem. What was the problem and your solution?

One particularly challenging prepress problem involved a client’s last-minute request for a significant design alteration on a high-volume magazine project just hours before the plates were scheduled to be made. The change involved a complex re-arrangement of text and images across multiple pages, impacting pagination and potentially leading to significant delays and increased costs.

My solution involved a multi-pronged approach. First, I immediately assessed the extent of the changes needed and calculated the impact on the existing timeline. Then, I collaborated with the design team to implement the changes efficiently. We leveraged the power of automated prepress software features like automated pagination and imposition tools, which allowed us to quickly adapt the design, ensuring minimal disruption to the overall layout. To minimize manual work and prevent human error, we extensively used templating and scripting tools for consistency. Finally, I coordinated with the printing press to ensure they were informed of the changes and were able to adjust their schedule accordingly. This collaborative approach, combined with efficient use of technology, allowed us to implement the change within the revised deadline, minimizing client disruption and ensuring the project stayed on track.

Q 23. How do you prioritize tasks in a fast-paced prepress environment?

Prioritization in a fast-paced prepress environment is crucial. I use a combination of methods to ensure efficiency. I begin by identifying deadlines and assigning urgency levels to each task based on the client’s requirements and printing schedules. Using a Kanban-style workflow, I visually track the progress of each job, allowing me to quickly identify and address bottlenecks. Tasks are prioritized according to the ‘urgency-importance’ matrix, with critical, time-sensitive jobs taking precedence. I also utilize project management software to effectively allocate resources and track progress. Communication with the team is key. Regular status updates and open channels of communication help anticipate and resolve potential delays proactively.

Q 24. Explain your understanding of different color spaces (RGB, CMYK, etc.) and their applications.

Color spaces are crucial for accurate color representation in prepress. RGB (Red, Green, Blue) is an additive color model used for displaying colors on screens. CMYK (Cyan, Magenta, Yellow, Key/Black) is a subtractive color model used for printing. Understanding the differences is critical. RGB uses light to create color, so it has a broader color gamut than CMYK, which relies on ink. This means colors that look vibrant on screen may appear duller when printed. Therefore, careful color management is crucial. We often work with color profiles (like ICC profiles) that provide a standard for converting between color spaces, minimizing color shifts during the workflow. Other color spaces, like Pantone, provide standardized spot colors used for precise color matching, primarily for branding and special effects. Understanding the strengths and limitations of each color space allows for proper color management throughout the prepress process, ensuring accurate color reproduction in the final printed output.

Q 25. How familiar are you with MIS (Management Information Systems) software used in prepress?

I have extensive experience with various MIS (Management Information Systems) software solutions in prepress. These systems are vital for tracking jobs, managing client information, automating workflows, and generating reports on productivity and profitability. I’m proficient in using software such as [mention specific software examples, e.g., Esko Automation Engine, EFI Radius, etc.], understanding their features for job tracking, estimating, and managing prepress resources effectively. My experience includes using these systems to generate accurate cost estimates, track job progress from intake to completion, manage materials and inventory, and produce comprehensive reports for clients and management. The ability to seamlessly integrate MIS with other prepress software is also essential for streamlining workflow and ensuring accuracy. I’m familiar with data integration, ensuring consistent and accurate information across all systems.

Q 26. Describe your experience with die-cutting and other specialized prepress techniques.

I have significant experience with die-cutting and other specialized prepress techniques. Die-cutting involves creating precisely cut shapes in paper or other substrates using a die. In prepress, this involves creating the die-cutting layout digitally, ensuring the placement of the die lines is accurate and doesn’t interfere with other print elements. I’m familiar with software used to design and prepare these dies, and have worked extensively with various die types. Other specialized techniques I’m experienced with include embossing, debossing, foil stamping, and UV coating. For each, the prepress phase involves creating the necessary digital files to guide the finishing processes. This includes creating precise vector files for dies and establishing parameters for embossing/debossing depth and foil stamping placement. I have experience with both traditional and digital die-making processes and the importance of collaborating closely with finishing departments for optimal results. Thorough prepress planning in these specialized areas is essential to avoid costly errors and ensure the final product meets the client’s expectations.

Q 27. What is your experience with print quality analysis and troubleshooting?

Print quality analysis is a crucial part of my role. I am adept at identifying and troubleshooting various print quality issues. This involves using software like densitometers and spectrophotometers to accurately measure ink density, color accuracy, and dot gain. I am experienced in using these tools to compare print results with digital proofs to identify deviations. I understand the various factors influencing print quality, such as ink formulation, paper type, and press settings. My troubleshooting involves systematically checking these factors and making necessary adjustments during the prepress stage to minimize problems during printing. For example, if color inconsistencies are detected, I can adjust the CMYK values in the digital files, or if dot gain is excessive, I might adjust the screen ruling or ink settings. I create detailed reports documenting these analyses and provide recommendations to improve print quality in subsequent runs.

Q 28. How would you handle a last-minute change request that impacts the prepress timeline?

Handling last-minute change requests requires a calm and efficient approach. My first step is to understand the nature and scope of the change, assessing its impact on the existing timeline and budget. I then immediately communicate with the client, providing them with a realistic assessment of the feasibility and associated costs and time implications of implementing the change. Depending on the complexity and timing, I might utilize available prepress resources to prioritize this change. This might involve utilizing additional team members, adjusting existing schedules, or in extreme cases, using expedited printing options. Transparency with the client is critical; keeping them informed every step of the way manages expectations and maintains a positive working relationship. Clear communication within the team is also necessary to ensure everyone is on board and working towards the revised deadline. Documenting all changes and their impact is critical for future project management and to ensure accuracy in billing.

Key Topics to Learn for Your Multi-Channel Prepress Interview

Ace your next interview by mastering these key areas of multi-channel prepress. Understanding both the theory and practical application will set you apart.

- File Preparation & Management: Understanding various file formats (PDF, TIFF, JPEG, etc.), color spaces (CMYK, RGB, spot colors), resolution requirements, and preflighting techniques for different output methods (print, web, mobile).

- Color Management: Practical application of color profiles, color calibration, and proofing methods to ensure consistent color across all channels. Troubleshooting color discrepancies and understanding the impact of different color models.

- Workflow & Automation: Knowledge of prepress workflows, including job ticketing, imposition, trapping, and the use of automation software to streamline processes and improve efficiency. Understanding the role of different software packages in the workflow.

- Print Production Knowledge: Familiarity with different printing methods (offset, digital, large format), finishing techniques (binding, cutting, laminating), and their implications on file preparation. Understanding print quality issues and their causes.

- Digital Asset Management (DAM): Experience managing and organizing digital assets, including version control, metadata tagging, and efficient retrieval systems for seamless collaboration across teams.

- Proofing and Quality Control: Understanding different proofing methods (soft proof, hard proof), quality control checks, and problem-solving techniques to identify and rectify prepress errors before production.

- Cross-Media Publishing: Experience adapting content for various media (print, web, mobile, email) and ensuring consistency in brand messaging and visual identity across all channels.

Next Steps: Unlock Your Career Potential

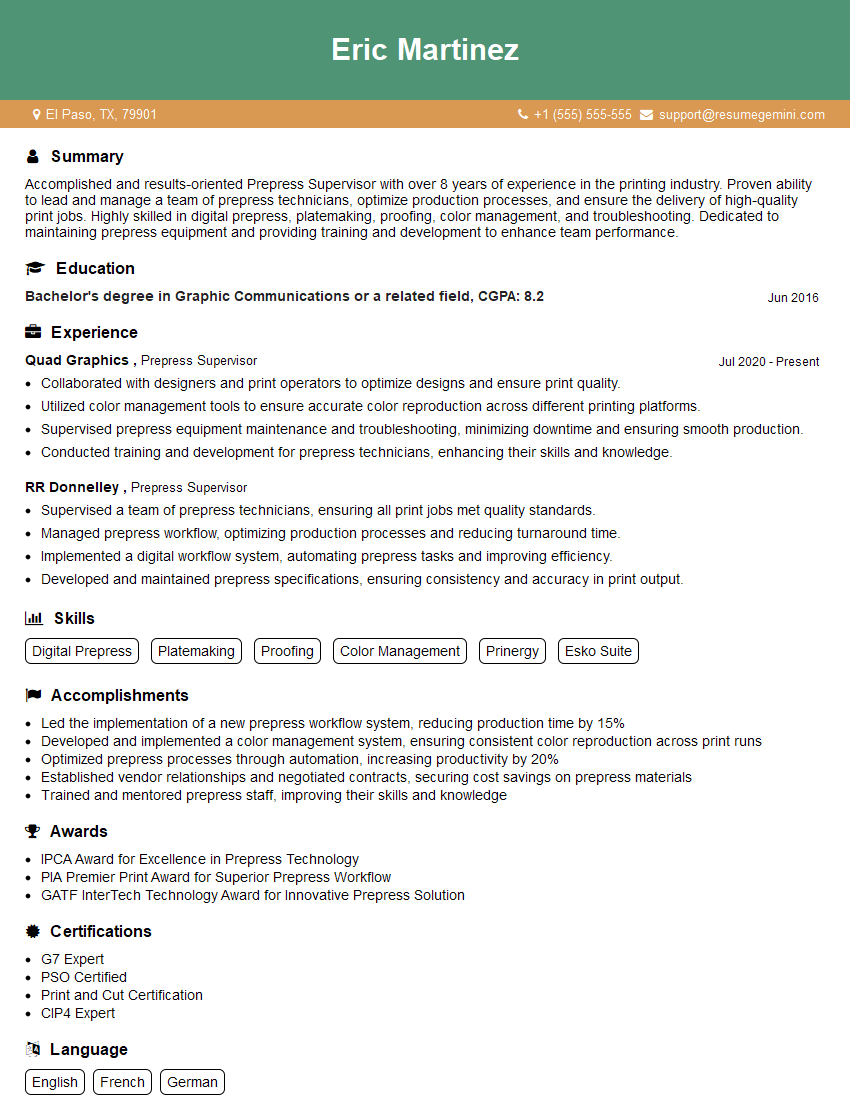

Mastering multi-channel prepress significantly enhances your career prospects within the printing and publishing industries. It demonstrates a valuable skillset highly sought after by employers. To maximize your chances, create a compelling, ATS-friendly resume that highlights your expertise.

ResumeGemini is a trusted resource that can help you build a professional resume that truly showcases your skills. They offer examples of resumes tailored specifically to multi-channel prepress experience, giving you a head start in crafting the perfect application. Take the next step and elevate your job search today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good