Unlock your full potential by mastering the most common Basic Machinery Operation interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Basic Machinery Operation Interview

Q 1. Describe your experience operating machinery in a manufacturing setting.

Throughout my five years at Acme Manufacturing, I’ve operated a variety of machinery, including CNC milling machines, lathes, and robotic welding systems. My responsibilities ranged from setting up and programming machines to running production runs and performing basic maintenance. For example, on the CNC milling machine, I programmed complex parts using CAD/CAM software, ensuring precision and minimizing waste. With the lathes, I gained proficiency in turning and facing operations, producing parts to tight tolerances. Working with the robotic welding system involved programming weld paths and monitoring the quality of the welds, contributing to a significant increase in production efficiency.

I’m comfortable with both high-volume production runs and smaller, more specialized projects requiring adjustments to machine settings and tooling. My experience includes working with different materials, including steel, aluminum, and plastics, and I’m adept at selecting the appropriate tooling and machine settings for each material.

Q 2. Explain the safety procedures you follow when operating machinery.

Safety is paramount in any machinery operation. My safety procedures always begin with a thorough pre-operational inspection of the machine and surrounding area, checking for loose parts, obstructions, and any signs of damage. I always wear the appropriate Personal Protective Equipment (PPE), including safety glasses, hearing protection, and steel-toed boots, and often use gloves depending on the material being handled.

Before starting any machine, I ensure all safety guards are in place and functioning correctly. I never operate machinery if I’m fatigued or under the influence of drugs or alcohol. I always follow the manufacturer’s instructions and the company’s safety protocols, which include lockout/tagout procedures for maintenance and repair. Furthermore, I maintain a clean and organized workspace to prevent accidents. If I encounter any safety concerns during operation, I immediately stop the machine and report the issue to my supervisor.

Q 3. How do you identify and report equipment malfunctions?

Identifying equipment malfunctions often involves a combination of visual inspection and listening for unusual sounds. Things to look for include unusual vibrations, strange noises (grinding, squealing, or knocking), unusual smells (burning or overheating), leaking fluids, or any visible damage to the machine or its components. For example, a high-pitched squeal from a lathe might indicate a worn bearing, while unusual vibrations could signify a problem with the spindle.

Once a malfunction is identified, I immediately stop the machine and report the issue using the company’s established reporting system, usually a written log or a digital reporting system. My report includes a detailed description of the malfunction, the time it occurred, any potential contributing factors, and the machine’s operational status before the problem occurred. I will also include photos or videos if necessary. The goal is to provide enough information for the maintenance team to quickly diagnose and rectify the problem, minimizing downtime.

Q 4. What is your experience with preventative maintenance of machinery?

Preventative maintenance is crucial for ensuring efficient and safe machine operation. My experience includes performing routine inspections, lubricating moving parts, cleaning components, and changing filters, all according to the manufacturer’s recommended schedules. I’m familiar with using various types of lubricants and greases and understand the importance of selecting the right product for each application. For example, regular lubrication of bearings prevents premature wear and tear, significantly extending the machine’s lifespan.

I also assist with more complex preventative maintenance tasks, such as replacing worn-out belts or checking the alignment of rotating parts, often working alongside the maintenance team. My proactive approach ensures that potential problems are identified and addressed before they lead to costly breakdowns and production delays.

Q 5. Describe your experience troubleshooting machinery problems.

Troubleshooting machinery problems requires a systematic approach. I begin by gathering information – observing the symptoms, reviewing operational logs, and talking to colleagues who may have witnessed the problem. Then, I use a logical process of elimination to identify the root cause. For example, if a machine is not functioning correctly, I might check the power supply, the control system, and the various mechanical components, ruling out each potential cause one by one.

My approach often involves using diagnostic tools such as multimeters to test electrical circuits, pressure gauges for hydraulic or pneumatic systems, and vibration sensors to detect mechanical issues. If I’m unable to resolve the problem, I consult the machine’s manual, online resources, or seek assistance from more experienced technicians. My goal is to fix the problem effectively and efficiently, minimizing downtime and ensuring the machine is safe to operate. I always document the troubleshooting process and the solution implemented.

Q 6. What is your understanding of basic mechanical principles?

My understanding of basic mechanical principles is extensive, encompassing concepts such as levers, gears, pulleys, hydraulics, and pneumatics. I understand how these principles apply to machinery operation, including force transmission, mechanical advantage, power transfer, and energy efficiency. For instance, I understand how gear ratios affect speed and torque, or how hydraulic systems utilize fluid pressure to generate mechanical force.

This knowledge helps me diagnose problems, understand machine capabilities and limitations, and make informed decisions about machine selection and operation. For example, I can assess the appropriate size of a hydraulic cylinder needed to lift a specific load based on Pascal’s Law and the area of the cylinder.

Q 7. How familiar are you with different types of machinery controls?

I’m familiar with various types of machinery controls, ranging from simple manual controls like handwheels and levers to complex computer numerical control (CNC) systems and programmable logic controllers (PLCs). My experience includes operating machines with push-button controls, dial controls, and touch-screen interfaces.

I’m comfortable interpreting control panel displays, understanding indicator lights, and using diagnostic software to monitor machine performance and identify potential problems. I understand the safety implications of different control systems and the importance of following established operating procedures for each type of control.

Q 8. What is your experience working with computerized machinery?

My experience with computerized machinery is extensive, encompassing both CNC (Computer Numerical Control) and PLC (Programmable Logic Controller) controlled systems. I’m proficient in operating CNC milling machines, lathes, and robotic arms, programming simple G-code for CNC machines, and troubleshooting basic PLC programs. For instance, at my previous role at Acme Manufacturing, I was responsible for operating a CNC milling machine that produced precision parts for aerospace components. This involved loading the machine with raw materials, inputting the correct G-code program, monitoring the machining process for any errors, and performing quality checks on the finished parts. I also have experience with HMI (Human-Machine Interface) systems, which are crucial for interacting with and monitoring these sophisticated machines. This includes understanding and interpreting data displayed on the HMI, diagnosing issues, and making necessary adjustments to optimize machine performance.

Q 9. How do you ensure quality control in a machine operation role?

Quality control in machine operation is paramount. My approach involves a multi-layered strategy. First, I meticulously follow all Standard Operating Procedures (SOPs) to ensure consistent and high-quality output. Second, I utilize various measuring instruments—calipers, micrometers, dial indicators—to verify dimensions and tolerances against specifications. Third, I regularly inspect the machine itself, checking for signs of wear and tear or malfunction to prevent defective production. Finally, I maintain detailed records of production runs, including any deviations or adjustments made, allowing for continuous improvement and identification of potential systemic issues. For example, during a production run of threaded rods, I noticed slight variations in thread pitch. By using a micrometer and comparing against the blueprint, I identified a minor tool wear issue, leading to timely replacement and avoidance of further defects. This proactive approach minimizes waste and guarantees the highest level of product quality.

Q 10. Describe a time you had to adapt to a new piece of machinery.

At my previous job, we transitioned from an older, manually operated press brake to a new, digitally controlled hydraulic press brake. The initial learning curve was steep as the new machine incorporated advanced features like automatic bending programs and precise pressure control. I approached this by first thoroughly reviewing the machine’s manual and attending a manufacturer-led training session. I then practiced on simpler bending tasks, gradually increasing complexity until I felt comfortable. I found the key was to break down the process into smaller, manageable steps. Instead of trying to master everything at once, I focused on understanding each individual function before integrating them. This methodical approach allowed me to quickly adapt and eventually become highly proficient in operating the new machine, improving efficiency and reducing production time.

Q 11. Explain your experience with different types of manufacturing processes.

My experience encompasses a variety of manufacturing processes, including subtractive manufacturing (like milling and turning), additive manufacturing (3D printing), and forming processes (press braking, sheet metal bending). I’ve worked with various materials, including metals (steel, aluminum), plastics, and composites. In subtractive manufacturing, I’m skilled in operating CNC machines to create precise parts from raw materials. In additive manufacturing, I have experience using FDM (Fused Deposition Modeling) 3D printers for prototyping and small-batch production. And in forming processes, I have experience in bending, punching, and shearing sheet metal using both manual and automated machinery. This diverse experience gives me a comprehensive understanding of the different manufacturing methods and the best approach for various applications. Understanding the strengths and limitations of each process is crucial for efficient and cost-effective manufacturing.

Q 12. How do you maintain a safe and organized work environment?

Maintaining a safe and organized work environment is crucial for both efficiency and safety. My approach is proactive and multifaceted. I ensure that all machinery is properly maintained and regularly inspected, adhering strictly to safety protocols. This includes using appropriate Personal Protective Equipment (PPE) and following lockout/tagout procedures when working on or near machinery. Furthermore, I keep my workspace clean and organized, with tools and materials stored in designated areas. This minimizes the risk of accidents and improves workflow. For example, I regularly clean up oil spills and ensure that cables are properly managed to prevent tripping hazards. A well-organized workplace not only enhances safety but also significantly boosts productivity and minimizes downtime.

Q 13. Describe your understanding of standard operating procedures (SOPs).

Standard Operating Procedures (SOPs) are detailed, step-by-step instructions for performing specific tasks. They are essential for ensuring consistency, quality, and safety in machine operation. My understanding of SOPs extends beyond simply following them. I appreciate their role in standardizing operations, reducing errors, and maintaining high quality. I am also able to review and contribute to SOP updates based on experience and improved methods. If I encounter a situation not covered in the SOP, I would carefully assess the situation and follow established safety protocols while reporting the discrepancy to my supervisor. My experience shows that strict adherence to SOPs and proactive reporting minimize potential risks and improve overall efficiency.

Q 14. What is your experience with using measuring instruments?

I am proficient in using a range of measuring instruments, including:

- Vernier calipers: For precise measurement of internal and external dimensions.

- Micrometers: For highly accurate measurements of small distances.

- Dial indicators: For checking surface flatness and alignment.

- Height gauges: For determining the height of workpieces.

- Angle gauges: For measuring angles.

I understand the importance of proper calibration and the limitations of each instrument. For example, when measuring a machined part for accuracy, I would use a micrometer for the most precise dimensions, while vernier calipers could be used for a quick, less-precise check. Accurate measurement is crucial for ensuring that the produced parts meet the required specifications and quality standards. Incorrect measurements can lead to significant problems down the line, so proficiency with these tools is paramount.

Q 15. How do you ensure the accuracy of your work while operating machinery?

Ensuring accuracy in machinery operation is paramount for safety and quality. My approach is multi-faceted and begins even before I start the machine. It involves a meticulous pre-operation checklist, careful calibration of tools and settings, and constant monitoring during operation.

- Pre-operation Checklist: Before operating any machine, I always perform a thorough check of all components, ensuring everything is properly lubricated, tightened, and free from any obstructions. This includes visually inspecting for any damage or wear and tear.

- Calibration and Setup: Accuracy often hinges on proper calibration. I carefully follow the manufacturer’s instructions for setting up the machine, including adjusting speed, feed rates, and tolerances based on the specific job requirements. For example, when using a lathe, I meticulously check the tool offset to ensure the final workpiece meets the specified dimensions.

- Constant Monitoring and Adjustment: Throughout the operation, I continuously monitor the machine’s performance, watching for any deviations from the expected output. If any discrepancies are noticed, I immediately stop the machine to investigate the cause and make necessary adjustments before resuming work. This might involve minor tool adjustments, checking material feed, or even recalibrating the machine if needed.

- Regular Maintenance: Preventative maintenance is key to accuracy. Regular cleaning, lubrication, and inspection of machine components minimizes wear and tear, preventing inaccuracies that could arise from malfunctioning parts.

For instance, during a milling operation, I once noticed slight inconsistencies in the depth of cut. By systematically checking each component – from the machine’s feed mechanism to the milling bit itself – I identified a slightly loose clamp causing the vibration. Tightening it resolved the issue and restored accuracy.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with different types of production materials.

My experience encompasses a wide range of production materials, from common metals like steel and aluminum to plastics, composites, and even some specialized alloys. I’m comfortable working with various material forms, including sheets, bars, rods, and castings.

- Metals: I have extensive experience working with various grades of steel, including mild steel, stainless steel, and tool steel, each requiring different cutting speeds, feed rates, and tooling. I understand the properties of each metal and how they affect the machining process.

- Plastics: Working with plastics requires different techniques to prevent melting or deformation. I’m familiar with various types of plastics, such as ABS, polycarbonate, and acrylic, and I adjust cutting parameters accordingly.

- Composites: I have experience working with fiberglass-reinforced polymers and carbon fiber composites, understanding the unique challenges posed by their layered structure and the potential for damage during machining.

Understanding the properties of each material is crucial. For example, machining aluminum requires higher speeds and lighter cuts than steel to avoid generating excessive heat and damaging the workpiece. I always consult material datasheets and adjust my machine parameters accordingly.

Q 17. How do you manage your workload when operating multiple machines?

Managing workloads across multiple machines requires a structured and organized approach. It’s not simply about speed, but about efficient task prioritization and minimizing downtime.

- Prioritization: I prioritize tasks based on deadlines, urgency, and complexity. Jobs with shorter deadlines or critical parts often take precedence.

- Time Management: I use time-management techniques to allocate time efficiently across machines. This includes setting realistic expectations, estimating processing times, and scheduling breaks strategically.

- Workflow Optimization: I optimize my workflow by sequencing tasks to minimize idle time. For instance, while one machine is processing a long-running job, I can use the downtime to prepare materials or perform maintenance on another machine.

- Batch Processing: Where possible, I use batch processing techniques to handle similar operations efficiently, minimizing setup times between jobs.

In a previous role, I managed three CNC milling machines simultaneously. By carefully planning my workflow and prioritizing tasks based on deadlines, I consistently met production targets and minimized any delays. I also proactively identified potential bottlenecks to prevent them from affecting overall productivity.

Q 18. What is your approach to problem-solving during machinery operation?

My approach to problem-solving during machinery operation is systematic and data-driven. I follow a structured process to identify, diagnose, and resolve issues efficiently.

- Identify the Problem: The first step is to accurately identify the problem. This involves observing the machine’s behavior, checking for error messages, and gathering relevant data, such as dimensional measurements or quality reports.

- Diagnose the Cause: Once the problem is identified, I investigate the possible causes. This often involves checking machine settings, inspecting tools and components, and reviewing the production process for any deviations.

- Develop Solutions: Based on the diagnosis, I develop and evaluate potential solutions. This may involve adjusting machine parameters, replacing faulty components, or modifying the production process.

- Implement and Test: I carefully implement the chosen solution and thoroughly test it to ensure it resolves the problem without creating new ones.

- Document and Learn: Finally, I document the problem, its cause, and the solution implemented. This helps in preventing similar issues in the future and contributes to continuous improvement.

For example, I once encountered a recurring jamming issue on a press brake. By systematically investigating the problem – from checking the material feed to inspecting the brake’s die alignment – I discovered a minor misalignment in the dies. After correcting the alignment, the problem was resolved.

Q 19. How do you prioritize tasks when operating multiple machines?

Prioritizing tasks when operating multiple machines is crucial for efficiency. My approach uses a combination of factors to ensure optimal workflow.

- Due Dates: Jobs with the closest deadlines always take priority. I use a visual system, such as a whiteboard or digital Kanban board, to track deadlines and progress.

- Urgency: Jobs that are critical for subsequent operations or have higher impact on overall production are prioritized.

- Setup Time: I consider the setup time required for each job. If a machine is already set up for a similar job, that task will be prioritized to minimize setup time.

- Machine Capability: I match tasks to the most appropriate machine to optimize efficiency. Some machines might be better suited for certain types of operations.

- Material Availability: I ensure materials are readily available before starting a job to prevent delays.

For instance, if I have a large batch of identical parts to produce and another urgent, smaller job, I’ll prioritize the larger batch to maximize efficiency. After setting up the machine, I can quickly switch to the smaller, urgent task once a sufficient number of the larger batch has been completed.

Q 20. What is your experience working under pressure?

I thrive under pressure. My experience has shown me that maintaining composure and a systematic approach are key to successful performance in high-pressure situations. I’ve handled numerous scenarios requiring quick thinking and decisive action under tight deadlines.

- Structured Approach: I maintain a calm and organized approach, focusing on completing tasks one at a time and breaking down complex problems into smaller, manageable steps.

- Time Management: I’m adept at prioritizing tasks and managing my time efficiently under pressure. I often use time-boxing techniques to allocate specific time slots to each task.

- Communication: In high-pressure situations, clear and concise communication with colleagues and supervisors is essential to keep everyone informed and coordinated.

- Problem-Solving: My ability to quickly diagnose and resolve problems efficiently is a strength, allowing me to address unexpected challenges with confidence and speed.

In one instance, a critical component failed unexpectedly during a high-volume production run. I quickly identified the issue, implemented a temporary workaround, and communicated the situation to the team. This ensured minimal disruption to the production schedule and allowed us to promptly address the root cause.

Q 21. How do you maintain the cleanliness and efficiency of the machines you operate?

Maintaining the cleanliness and efficiency of machines is crucial for both safety and productivity. My approach involves a combination of preventative measures and regular maintenance.

- Regular Cleaning: I routinely clean the machines after each use, removing any debris, chips, or dust. This is essential for preventing buildup that can affect the machine’s performance and cause malfunctions.

- Lubrication: Regular lubrication of moving parts is vital for smooth operation and preventing wear and tear. I follow the manufacturer’s recommendations for lubrication schedules and types of lubricants.

- Inspection: Regular visual inspections are performed to check for any signs of wear, damage, or loose components. This allows for early detection of potential problems before they escalate.

- Preventative Maintenance: Following the manufacturer’s guidelines for preventative maintenance is essential. This might include replacing worn-out parts, tightening bolts, or performing more extensive servicing tasks.

I treat cleaning and maintenance not just as a chore, but as a proactive measure that enhances efficiency and minimizes downtime. A clean and well-maintained machine is much more likely to operate accurately and reliably, resulting in higher quality output and reduced risk of accidents.

Q 22. Describe your experience with machine maintenance logs or documentation.

Maintaining accurate machine maintenance logs is crucial for ensuring equipment longevity and preventing unexpected downtime. My experience involves meticulously documenting all maintenance activities, including preventative maintenance schedules, repairs, parts replacements, and any observed anomalies. I’m proficient in using both digital and paper-based systems. For digital systems, I’m familiar with CMMS (Computerized Maintenance Management Systems) software, which allows for efficient tracking, analysis, and reporting of maintenance data. For example, in my previous role at Acme Manufacturing, we utilized a CMMS to track the performance of our CNC milling machines. This included recording regular lubrication checks, tool changes, and any necessary repairs, all timestamped and linked to specific machine IDs. This system helped us identify recurring issues, allowing for proactive maintenance and minimizing downtime. In instances where digital systems weren’t available, I ensured our paper-based logs were equally thorough, including details like date, time, performed actions, parts used, and technician signatures. Clear, concise documentation is essential for traceability and facilitates efficient troubleshooting for future maintenance events.

Q 23. How do you comply with safety regulations when operating machinery?

Complying with safety regulations is paramount in machinery operation. My approach is multi-faceted and starts with a thorough understanding of all relevant safety protocols, including OSHA guidelines and company-specific safety procedures. Before operating any machine, I always ensure I’ve received the necessary training and possess the required certifications. This is followed by a comprehensive pre-operation inspection of the machine itself, checking for any loose parts, damaged components, or leaks. I always wear appropriate personal protective equipment (PPE), such as safety glasses, hearing protection, and gloves, as required by the task. Furthermore, I maintain a clean and organized workspace, free from obstructions that could cause accidents. I strictly adhere to lockout/tagout procedures whenever performing maintenance or repairs, ensuring the machine is completely de-energized before any work commences. Finally, I’m vigilant in observing my surroundings and fellow operators, ensuring a safe working environment for everyone.

Q 24. What is your understanding of different machine safety features?

Machine safety features are critical for preventing accidents. I’m familiar with a wide range of these, including:

- Emergency Stop Buttons (E-Stops): Strategically placed buttons that instantly halt machine operation in case of emergencies.

- Light Curtains and Safety Sensors: These detect the presence of objects or personnel in hazardous zones, automatically stopping the machine to prevent collisions.

- Interlocks: Mechanisms that prevent operation until safety guards are properly in place.

- Two-Hand Controls: Requiring the operator to use both hands to operate the machine, preventing accidental activation.

- Guardrails and Enclosures: Physical barriers to protect operators from moving parts.

- Automatic Shut-off Systems: Systems that automatically shut down the machine if it detects anomalies, such as overheating or power surges.

Understanding these features, and how they work together to ensure safe operation, is a cornerstone of my approach to machinery operation. For example, I’ve worked with machines equipped with light curtains that automatically halt operations if a hand enters the work area. This prevented numerous potential injuries during high-speed operations. Regular inspection and maintenance of these safety features are crucial for their effective function.

Q 25. Describe your experience working within a team environment operating machinery.

Teamwork is essential in a machinery operation environment. I have extensive experience collaborating with teams of varying sizes, including technicians, engineers, and other operators. My approach emphasizes clear communication, mutual respect, and shared responsibility for safety and productivity. I’m comfortable sharing my expertise while also readily accepting input from others. For instance, in a previous project involving a complex assembly line, we faced a production bottleneck. By collaborating with the engineering team and other operators, we identified the root cause – a poorly calibrated component. Through teamwork and open communication, we quickly resolved the issue, minimizing downtime and restoring productivity. I believe in a collaborative approach where everyone’s contributions are valued, resulting in a more efficient and safer work environment.

Q 26. How familiar are you with different types of lubricants and their applications?

Lubricants play a vital role in maintaining machinery functionality and extending its lifespan. I’m familiar with various types, including:

- Grease: Used for lubricating bearings and other components requiring a thick, adhesive lubricant. Different greases are suited for different operating temperatures and loads.

- Oil: Used for lubricating moving parts, reducing friction and wear. Various oil viscosities are available, each tailored to specific applications and operating conditions.

- Synthetic Lubricants: Offer superior performance compared to traditional lubricants, particularly in extreme temperatures or high-pressure applications.

Selecting the appropriate lubricant is crucial. The choice depends on factors like the type of machine, the operating temperature, the load on the components, and the material compatibility. Improper lubrication can lead to premature wear, increased friction, and ultimately, machine failure. For example, using the wrong viscosity oil in a hydraulic system could cause overheating and damage to the system components. In my experience, I’ve always consulted manufacturer specifications to ensure the correct lubricant is used in each application.

Q 27. How do you handle unexpected situations or equipment failures?

Handling unexpected situations and equipment failures requires a calm and methodical approach. My first step is always to ensure the safety of myself and others, immediately shutting down the machine if necessary and clearing the area. Next, I assess the situation, identifying the nature of the problem. This might involve visual inspection, checking gauges and readouts, or consulting maintenance logs. Based on my assessment, I determine the appropriate course of action: simple repairs I can handle myself, escalating the issue to a more experienced technician, or contacting the manufacturer for support. Documentation is vital – I always record details of the failure, the steps taken to resolve it, and any preventative measures implemented to avoid future occurrences. For example, during an unexpected motor failure on a conveyor belt, I followed safety protocols, documented the event, contacted maintenance, and temporarily redirected the production flow to minimize disruption. A proactive, systematic approach is key to minimizing downtime and ensuring continuous operations.

Q 28. What are your strengths and weaknesses related to machinery operation?

My strengths lie in my methodical approach to problem-solving, my strong attention to detail, and my commitment to safety. I’m adept at troubleshooting mechanical issues, efficiently using diagnostic tools and referencing manuals to identify and resolve problems. My proactive maintenance practices help prevent equipment failures. However, I recognize that my weakness is sometimes being overly cautious, which can occasionally slow down the process. I am actively working to improve my efficiency while maintaining my high safety standards. I’m confident in my abilities, and I’m always eager to learn and improve my skills to better serve the team and the company.

Key Topics to Learn for Basic Machinery Operation Interview

- Safety Procedures and Regulations: Understanding and applying safety protocols for various machinery, including lockout/tagout procedures and personal protective equipment (PPE) usage. This includes knowing relevant industry standards and regulations.

- Machine Operation Principles: Grasping the fundamental mechanics of different machinery types (e.g., hydraulics, pneumatics, electric motors). This involves understanding how power is transmitted and controlled within the machine.

- Troubleshooting and Maintenance: Identifying common malfunctions, performing basic preventative maintenance tasks, and understanding the process for reporting equipment issues. This also includes knowing the importance of regular inspections.

- Blueprint Reading and Technical Drawings: Interpreting technical documentation to understand machine components, assembly, and operating procedures. This skill is crucial for understanding machine functionality and maintenance.

- Quality Control and Measurement: Understanding quality control processes related to machine operation, including using measuring tools and ensuring consistent output. This involves understanding tolerances and specifications.

- Practical Application and Use Cases: Being able to discuss real-world scenarios where you’ve applied your knowledge of machinery operation, emphasizing problem-solving skills and quick thinking under pressure.

- Advanced Concepts (Depending on the Role): Depending on the specific job, you might want to explore concepts such as Programmable Logic Controllers (PLCs), Computer Numerical Control (CNC) machining, or specific software used for machine control.

Next Steps

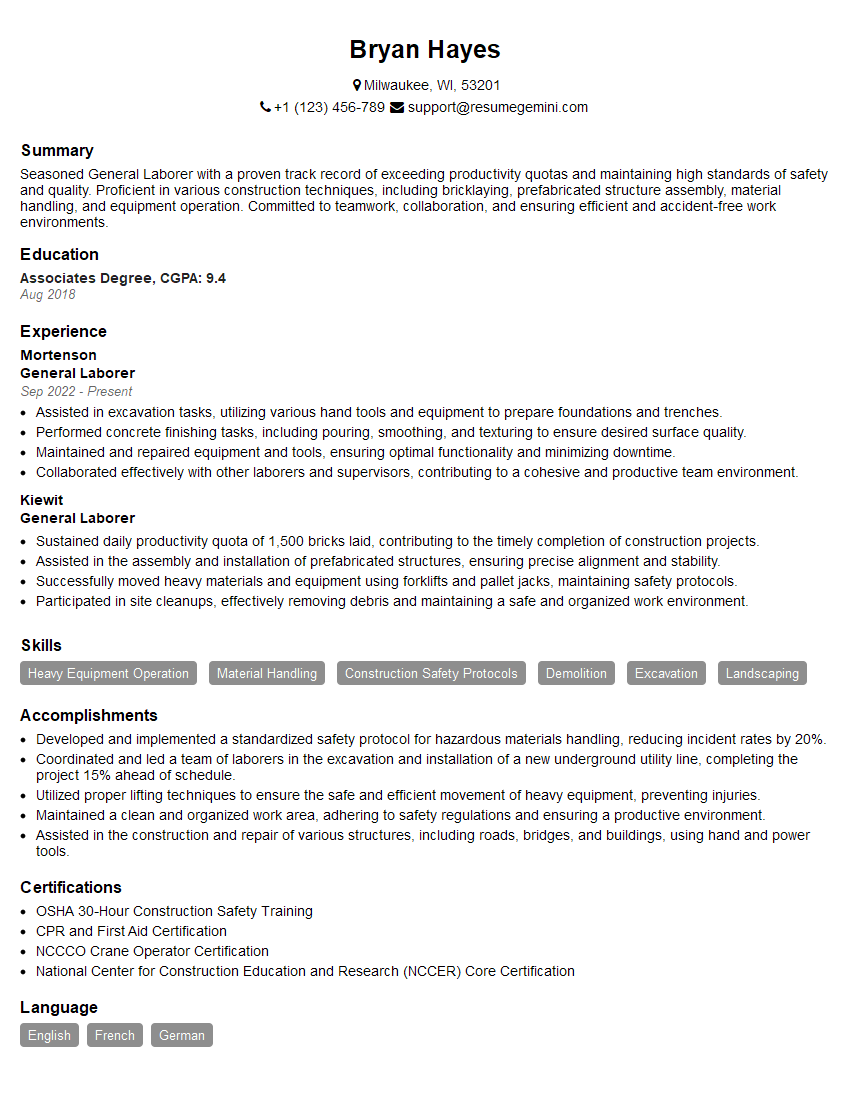

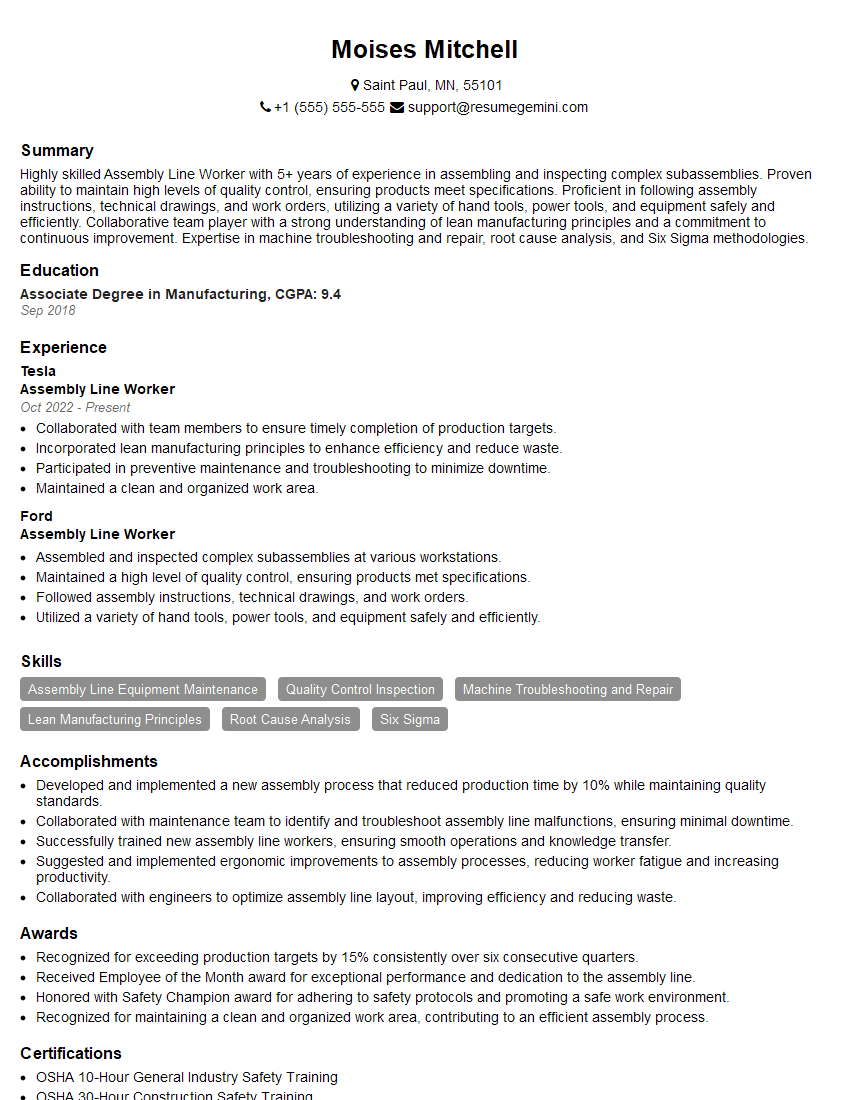

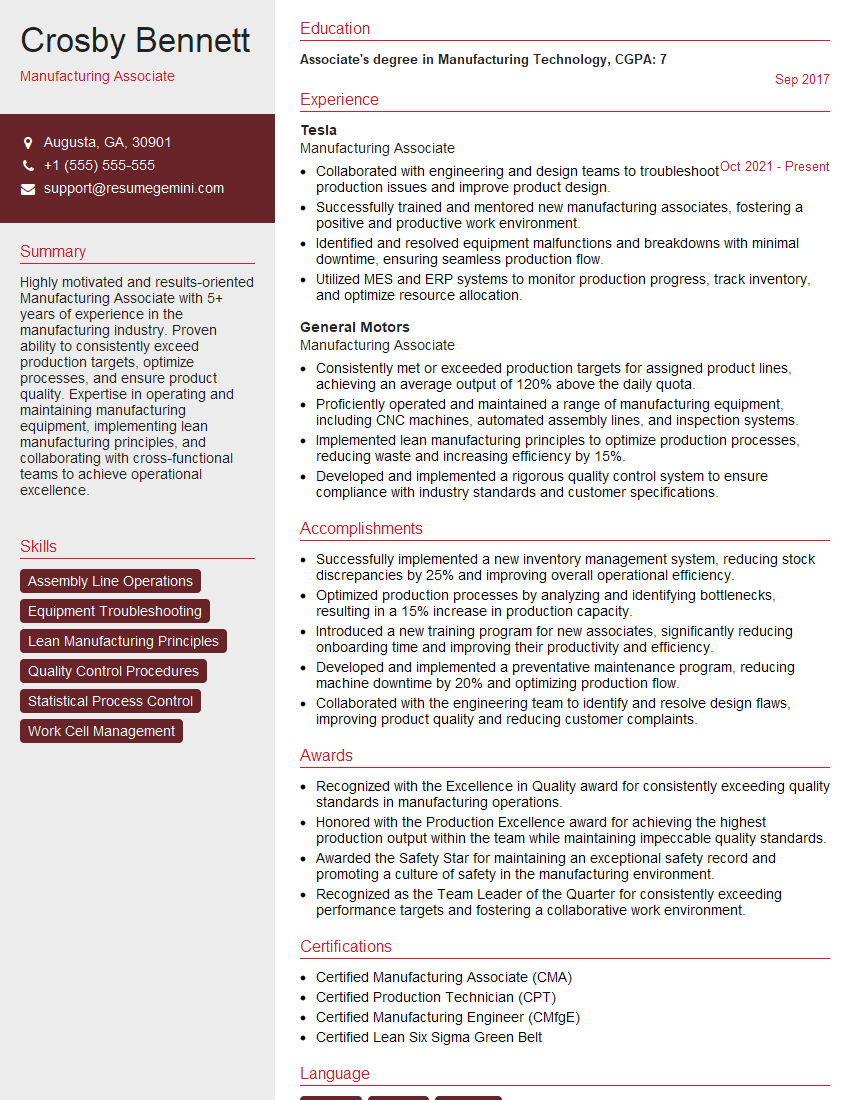

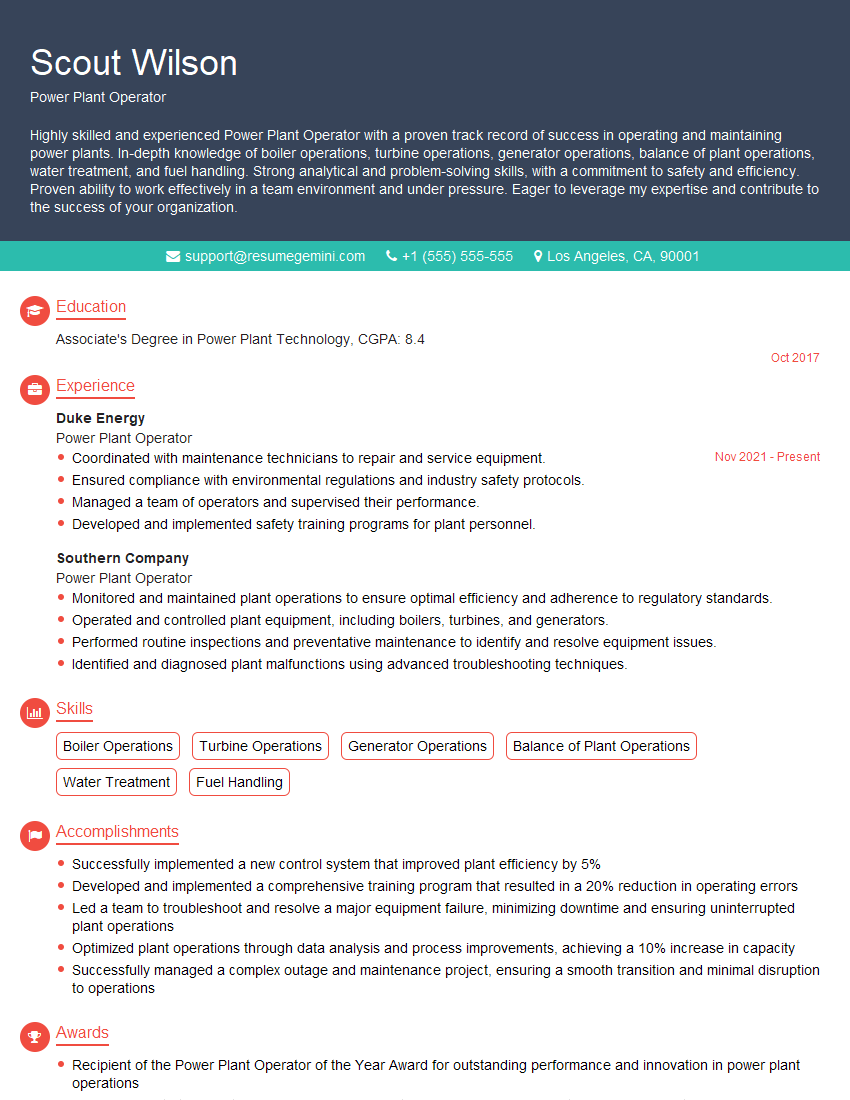

Mastering Basic Machinery Operation opens doors to a rewarding and diverse range of career opportunities, offering excellent prospects for growth and advancement within manufacturing and related industries. To maximize your job prospects, it’s crucial to present your skills effectively. Creating an ATS-friendly resume is key to getting your application noticed by potential employers. ResumeGemini is a trusted resource to help you build a professional and impactful resume that highlights your abilities and experience. We offer examples of resumes tailored to Basic Machinery Operation to guide you in crafting your own compelling application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good