Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Knowledge of Prepress Industry Best Practices interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Knowledge of Prepress Industry Best Practices Interview

Q 1. Explain the importance of color profiles in prepress.

Color profiles are crucial in prepress because they act as a translator between different devices and software. Think of them as dictionaries for colors. Each device – your monitor, your printer, your scanner – interprets colors differently. A color profile ensures that the color you see on your screen will be as close as possible to the color printed on paper. Without color profiles, you risk significant color discrepancies between your digital design and the final printed piece.

For instance, a vibrant red you see on your screen might print out as a dull pink without a proper profile. Different profiles exist for different color spaces, such as sRGB (for web) and CMYK (for print). Choosing the right profile (like embedding an ICC profile in your file) is essential for achieving accurate color reproduction. We typically use profiles like ISO Coated v2 (C) for standard print work, but specific projects might call for other profiles depending on the paper stock and printing process.

Q 2. Describe the different types of printing plates used in the prepress workflow.

The prepress workflow utilizes various printing plates, each with its strengths and weaknesses. The choice depends heavily on the print job’s specifications, budget, and run length. Here are some common types:

- Conventional Plates (PS Plates): These are the workhorses of offset printing. They are relatively inexpensive and offer good quality, making them suitable for large-volume jobs. They are photopolymer plates exposed using a photosensitive layer.

- Computer-to-Plate (CTP) Plates: These plates are imaged directly from a digital file, eliminating the need for an intermediary film. CTP plates save time and resources, reduce waste, and often yield superior print quality. Variations exist like thermal CTP and violet laser CTP.

- Flexographic Plates: Used mainly for flexible packaging and labels, these plates are typically made from photopolymer and are very durable, suitable for high-volume printing on various substrates.

- Screen Printing Screens: These aren’t technically plates, but rather screens made of mesh stretched over a frame, creating stencils. They’re used for screen printing, a technique that allows for printing on a variety of unusual surfaces.

The selection of plate type directly impacts the overall print quality, efficiency, and cost-effectiveness of the job. A careful consideration of these factors is crucial when planning the prepress stage.

Q 3. What are the key steps involved in preparing a file for offset printing?

Preparing a file for offset printing is a meticulous process that requires precision and attention to detail. The key steps are:

- File Format: Ensure your files are in the correct format, typically high-resolution PDF/X-1a or PDF/X-4. This ensures compatibility with the print workflow.

- Color Mode: Convert your file to CMYK color mode from RGB. RGB is designed for screen display, while CMYK is used for printing.

- Image Resolution: Check and ensure the images have a resolution of at least 300 DPI (dots per inch) for optimal print quality. Lower resolutions can lead to pixelation in the final print.

- Fonts: Outline or embed all fonts to prevent font substitution issues during printing.

- Bleeds and Margins: Add bleeds (extra image area beyond the trim size) to avoid unsightly white edges after trimming. Define proper margins to prevent important elements from being cut off.

- Color Management: Embed the appropriate color profile (e.g., ISO Coated v2 (C)) to ensure accurate color reproduction.

- Imposition: Arrange the pages according to the printer’s specifications for efficient printing and folding. This step is often automated using specialized software.

- Preflight Check: Perform a preflight check using software like Acrobat Pro to identify and resolve any potential printing problems before sending the file to the printer.

Omitting any of these steps can lead to costly reprints and delays.

Q 4. How do you ensure color consistency across different printing processes?

Color consistency across various printing processes is a significant challenge, often requiring a multi-pronged approach. The most effective strategy involves:

- Standardized Color Profiles: Using consistent color profiles (like ISO Coated v2 (C)) throughout the workflow ensures that all devices interpret colors similarly.

- Color Management Software: Employing sophisticated color management software (such as those found in Adobe Creative Suite) allows you to control and adjust colors across different devices and stages of production.

- Proofing: Utilizing soft proofing and hard proofing (printed proofs) enables visual verification of color accuracy before committing to large-scale printing.

- Collaboration with Printer: Close collaboration with the printer is paramount. This involves discussing the project specifications, the printing equipment they will use, and their preferred color management methods.

- Color Calibration: Regular calibration of monitors and other color-related equipment maintains consistency over time.

Imagine trying to paint a mural with different types of paints, each having slightly different shades of the same color! Color management is your palette that helps ensure a consistent and harmonious result.

Q 5. What is the significance of trapping in prepress?

Trapping in prepress refers to the intentional overlapping of colors to prevent tiny gaps or misregistration between colors in the final print. Misregistration happens when the different inks don’t align perfectly during the printing process, leading to thin white lines between colors. This is particularly noticeable with small text or thin lines.

Think of it like filling in the gaps between two pieces of a puzzle. Trapping ensures the colors blend seamlessly, preventing these unwanted gaps. There are different trapping methods, including choke (overprinting the darker color onto the lighter color) and spread (extending the lighter color into the darker color). The choice of trapping method depends on the specific design and printing process. Software tools automate this process, but careful consideration of the trapping strategy is necessary to avoid unwanted color shifts or thickening of lines.

Q 6. Explain your experience with different RIP software.

Throughout my career, I’ve worked extensively with various RIP (Raster Image Processor) software solutions. My experience includes:

- EFI Fiery: A highly versatile and powerful RIP, often found in high-end digital printing environments. I am proficient in setting up Fiery job properties, optimizing print quality settings, and troubleshooting any color-related issues.

- Agfa Apogee: Known for its excellent color management and workflow integration, Apogee offers advanced features for managing and processing large-volume print jobs. I am familiar with its color profiling capabilities and its integration with prepress workflows.

- Kodak Prinergy: A robust RIP solution well-suited for high-volume, large-format printing. My experience with Prinergy includes job submission, color calibration, and print-quality optimization.

My experience across different RIP systems allows me to adapt quickly to new workflows and effectively address diverse prepress challenges. I understand the nuances of each software and how to leverage their capabilities for optimal print production.

Q 7. Describe your workflow for preparing high-resolution images for print.

Preparing high-resolution images for print is a critical aspect of my workflow. It begins with ensuring the source image is of high quality. Here’s my approach:

- Source Image Quality: I always begin by assessing the source image’s resolution and sharpness. Low-resolution images will simply not print well, and resampling can introduce artifacts.

- Resolution Adjustment: If necessary, I carefully upscale or downscale images using professional image editing software, such as Adobe Photoshop. I avoid aggressive upscaling which can degrade image quality.

- Color Space Conversion: I convert RGB images to CMYK, selecting the appropriate color profile based on the printing method and paper stock, making sure to preserve the color integrity during this transition.

- Sharpening: I apply careful sharpening to enhance the image details without introducing noise or halo effects. The sharpening techniques are customized based on the image content and intended print size.

- Compression: I save the images using lossless compression (like TIFF or PSD) to prevent data loss which can be detrimental to the final print quality. Lossy compression (like JPEG) is generally avoided for print work.

- File Organization: I meticulously organize my files to ensure efficient workflow and prevent any confusion. Clear file naming conventions help maintain consistency.

This meticulous process guarantees that the final print accurately reflects the quality of the original image, minimizing any compromise in the print output.

Q 8. How do you handle image resolution issues during prepress?

Image resolution is paramount in prepress. Insufficient resolution leads to blurry, pixelated prints. We handle this by meticulously checking the resolution of all images against the intended output size. Think of it like building a LEGO castle: small bricks (low resolution) make a blurry castle, while larger bricks (high resolution) allow for finer detail.

Our process involves:

- Assessing the intended print size: We determine the final dimensions of the printed piece.

- Checking image resolution: We verify that the image resolution is at least 300 DPI (dots per inch) for high-quality printing at its final size. For smaller print sizes, a slightly lower resolution might suffice, but always strive for 300 DPI if possible. For web use, that’s unnecessary; 72 dpi is fine.

- Upscaling/downscaling images: If the resolution is too low, we might try to upscale it using professional image editing software like Adobe Photoshop. However, upscaling often reduces image quality, so it’s crucial to start with high-resolution images whenever possible. Downscaling is generally safer and often improves print quality by eliminating unnecessary detail.

- Replacing low-resolution images: If upscaling isn’t feasible, we’ll request a higher-resolution version from the client. In some situations, using a different image may be a better solution.

For example, a client providing a small online image for a large billboard will necessitate finding a higher resolution alternative. Ignoring this could result in a pixelated, unprofessional final product.

Q 9. What are your preferred methods for proofing?

Proofing is critical to ensure the final print matches the client’s expectations. My preferred methods combine digital and physical proofing:

- Soft Proofing: I use industry-standard software like Adobe Acrobat Pro to create soft proofs. This allows for on-screen review of color accuracy, text clarity, and image quality. We can easily make adjustments at this stage.

- Hard Proofing: For critical jobs or client demands, we create hard proofs. This involves printing a sample on the same press and paper stock as the final job. This provides the most accurate representation of the final product and lets clients touch and feel the print, giving them true confidence in the final result.

- Client-Approved Proofs: All proofs – both soft and hard – are always meticulously approved by the client before we proceed. This document serves as a legal agreement for the project’s specifications.

By combining both soft and hard proofing, we minimize the risk of costly reprints and ensure customer satisfaction. We strive for a combination of efficient digital workflows and the accuracy of physical proofing to meet client expectations.

Q 10. Explain your experience with color management systems like Pantone.

Pantone Matching System (PMS) is fundamental to ensuring consistent color reproduction across different print runs. My experience involves using Pantone color libraries in design software like Adobe Illustrator and InDesign. Think of Pantone as a universal language for colors, ensuring that a specific ‘Pantone 185 C’ will reproduce the same shade of red regardless of printer or location.

My workflow includes:

- Specifying Pantone colors: During the design phase, we ensure that specific Pantone colors are used, and the client is made aware of any potential color variations, especially when transitioning between different color spaces such as RGB and CMYK.

- Color separation and proofing: We use color management software to create accurate color separations for each Pantone color. These separations are then used to create the printing plates.

- Verification against the Pantone color bridge: We use Pantone’s color bridge guides to verify the accuracy of the colors achieved. This physical reference offers an absolute match for specific pantone colors to ensure consistency and eliminates any ambiguity.

- Communicating with printers: Effective communication with printers about the specified Pantone colors is crucial to ensuring accurate reproduction. A miscommunication could lead to a final print not quite meeting client expectations.

I’ve encountered situations where clients wanted a specific shade, a very delicate pale blue for example. Using Pantone ensured that shade was faithfully reproduced in various samples and the final product, reinforcing our commitment to precision.

Q 11. How do you identify and correct prepress errors?

Identifying and correcting prepress errors requires a systematic approach. We employ several techniques:

- Pre-flight checks: Before proceeding, we perform comprehensive pre-flight checks using software like PitStop Pro. This automatically identifies potential issues such as missing fonts, low-resolution images, and color profile mismatches.

- Proofreading: Meticulous proofreading of text and images is crucial. We use a checklist to help us thoroughly review each job.

- Color management review: We assess the color profiles to ensure consistency between the design software and the output device.

- Trap checking: We meticulously check for proper trapping (overlapping colors to prevent gaps between printed colors) to ensure clean, sharp results.

- Imposition check: Ensuring proper imposition, where pages are arranged for efficient printing, helps prevent errors later in the printing process.

For example, a missing font might cause the wrong font to be substituted during printing. Our pre-flight checks catch such issues, enabling us to replace the missing fonts with the correct ones before proceeding, preventing costly mistakes later. Our systematic approach ensures high-quality output.

Q 12. What are the common file formats used in prepress and their characteristics?

Several file formats are commonly used in prepress, each with its own strengths and weaknesses:

- PDF (Portable Document Format): The industry standard. It’s versatile, supports various color spaces (CMYK, RGB), and preserves fonts and images faithfully. However, it’s not always ideal for complex edits after creation.

- TIFF (Tagged Image File Format): Excellent for high-resolution images, preserving image data without compression artifacts. Often used for images that require superior color accuracy.

- JPEG (Joint Photographic Experts Group): Suitable for photographs and images where some loss of quality during compression is acceptable. However, it’s not the best choice for line art or text-heavy documents.

- EPS (Encapsulated PostScript): Used for vector graphics, making it suitable for logos and illustrations where scalability is important without losing quality. However, it’s less commonly used now compared to PDF.

- AI (Adobe Illustrator): A native vector format for Adobe Illustrator, allowing for easy editing and modification before final conversion to a print-ready format.

Choosing the right format depends on the specific needs of the project. We guide clients on the optimal format to ensure a smooth prepress process and the best quality possible.

Q 13. What is your experience with imposition software?

Imposition software is essential for efficiently arranging pages for printing. My experience includes working with software like Imposition Pro and other similar applications. These programs automate the complex process of arranging pages on a sheet to minimize paper waste and maximize printing efficiency. Think of it like arranging puzzle pieces to create a larger, complete image.

My expertise encompasses:

- Creating imposition schemes: We design imposition schemes that consider the type of printing press, paper size, and the number of pages to be printed. The goal is to minimize waste.

- Generating imposition proofs: Before sending files to the printer, we generate imposition proofs to verify the accuracy of the page arrangement.

- Troubleshooting imposition issues: We troubleshoot any imposition problems encountered during the process, ensuring that the final arrangement is correct and ready for printing.

For instance, a 24-page booklet requires careful imposition to ensure a smooth flow through the printer. Using imposition software drastically reduces manual work and mistakes, while ensuring the most efficient use of materials.

Q 14. Explain the process of creating a printing plate.

Creating a printing plate involves transferring the image from a digital file onto a physical plate used for printing. The process varies depending on the printing method (offset lithography, flexography, etc.), but the general principles remain the same.

For offset lithography (common for high-volume printing), a typical process involves:

- RIPping (Raster Image Processing): The digital file is processed by a RIP, which converts the data into a format the plate-making device understands.

- Plate imaging: The image data is then transferred to a printing plate using different technologies. Common methods include Computer-to-Plate (CTP) technology, where a laser exposes photosensitive material on the plate, or older methods using film and chemical processing.

- Plate processing: After imaging, the plate might need further processing, such as developing and baking (in CTP) to enhance its durability and image quality.

- Plate mounting: The completed plate is then mounted onto the printing press.

Each step is crucial. A flaw in any stage, like an issue with the RIP settings or a problem during plate processing, could lead to print errors. Our attention to detail at every step ensures high-quality, consistent printing results.

Q 15. Describe your knowledge of different printing techniques (offset, digital, flexo).

The prepress industry utilizes several printing techniques, each with its strengths and weaknesses. Let’s explore three major ones: Offset, Digital, and Flexo.

- Offset Printing: This is a widely used method, particularly for large print runs. It involves transferring the image from a plate to a rubber blanket, and then to the printing substrate (paper, etc.). It’s known for its high-quality results, vibrant colors, and cost-effectiveness for large volumes. Think of magazines or newspapers – often offset printed. The process is quite complex, involving careful color management and plate making.

- Digital Printing: This method is ideal for short to medium print runs, personalized items, or quick turnaround times. Images are printed directly onto the substrate, eliminating the need for plates. It offers flexibility in design and is often used for on-demand printing or personalized marketing materials like brochures or business cards. Because of its speed and variable data capabilities, it is becoming increasingly popular.

- Flexographic Printing: Primarily used for packaging, this method uses flexible relief plates made from photopolymer. Ink is applied to the raised portions of the plate and transferred to the substrate. It’s incredibly fast and efficient for high-volume printing on materials like plastic, film, and cardboard. Think cereal boxes or product labels – likely flexo printed.

My experience encompasses all three, enabling me to select the best approach depending on the client’s project requirements and budget.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure the accuracy of bleed and margins in your prepress work?

Ensuring accurate bleeds and margins is crucial for a professional print outcome. Bleed, the area extending beyond the trim line, prevents white edges after trimming. Margins define the safe zone for text and important elements.

I use a multi-step approach:

- Design Software Setup: I meticulously set up bleed and margin settings in my design software (InDesign, Illustrator, etc.) right from the start. This usually involves creating a document with the correct dimensions, including bleed areas.

- Templates and Guides: I leverage pre-made templates or create custom ones with clear guidelines to maintain consistency and accuracy. This visual aid minimizes errors significantly.

- Preflighting: Before sending files to print, I always run a preflight check using dedicated software or features within the design program. This automatically identifies potential issues with bleed, margins, and other prepress aspects.

- Visual Inspection: A final visual inspection is always part of my workflow. Zooming in and carefully checking the bleed and margin areas ensures no important elements are too close to the edges.

For example, a client’s brochure might need 3mm bleed on all sides. I’ll ensure my design extends 3mm beyond the final trim size. This guarantees the finished product is perfectly aligned without any unintended white borders.

Q 17. What is your experience with PDF workflows (creation, editing, preflighting)?

PDF workflows are the backbone of modern prepress. My expertise covers the entire process:

- PDF Creation: I’m proficient in generating press-ready PDFs from various design software (InDesign, Illustrator, Photoshop). I understand the importance of selecting the appropriate PDF/X standard for optimal print results (e.g., PDF/X-1a, PDF/X-4). Choosing the right standard ensures color consistency and prevents issues during the print process.

- PDF Editing: While I advocate for creating perfect files from the outset, I can also make minor edits to PDFs, like correcting typos or adjusting images. However, extensive alterations are best addressed within the original design file to prevent quality degradation.

- Preflighting: I use dedicated preflight software (such as Acrobat Pro) to thoroughly check PDFs for potential printing problems. This includes verifying color profiles, font embedding, resolution, bleed, margins, and overall file integrity. A preflight report helps catch errors before they reach the printer, saving time and money.

In a recent project, preflighting identified a missing font in a client’s PDF. By catching this early, we avoided costly delays and reprintings.

Q 18. Describe your understanding of different paper stocks and their impact on printing.

Paper stock selection significantly influences the final print quality. Different paper types offer unique characteristics affecting color reproduction, texture, and durability.

- Coated Papers: These papers have a smooth, coated surface, resulting in sharp, vibrant images and excellent color reproduction. They are ideal for high-resolution images and glossy finishes. However, they might not be suitable for certain environmentally conscious projects.

- Uncoated Papers: These have a natural, porous surface, offering a more textured feel. They are better suited for environmentally friendly printing and are often preferred for text-heavy documents where a softer feel is desired. Color reproduction might be less vibrant compared to coated papers.

- Specialty Papers: This broad category includes textured, metallic, and recycled papers, each offering unique visual and tactile characteristics. These choices heavily influence design and often dictate the printing process (e.g., metallic papers may require specific inks and print techniques).

Understanding the interplay between paper and printing is vital. For instance, choosing a heavy-weight uncoated paper for a large-format poster might be necessary to achieve desired durability and impact. The wrong paper stock can lead to ink bleeding, poor image quality, or unexpected texture.

Q 19. How do you handle complex client requests and tight deadlines?

Handling complex client requests and tight deadlines is a daily challenge. My approach centers on effective communication, meticulous planning, and prioritizing tasks.

- Clear Communication: I start with detailed discussions with the client to fully understand their needs and expectations. This includes clarifying all specifications and potential ambiguities.

- Project Breakdown: I divide complex projects into smaller, manageable tasks with clearly defined timelines. This allows for better monitoring of progress and identification of potential bottlenecks.

- Prioritization: Using task management tools and prioritization techniques (e.g., Eisenhower Matrix), I focus on high-impact activities first to ensure on-time delivery.

- Contingency Planning: I always build in some buffer time to account for unforeseen delays or issues. This proactive approach minimizes stress and prevents missed deadlines.

For example, in a recent project involving several design revisions and a tight print deadline, I used a Kanban board to visually track the progress of each task and ensure everything remained on schedule. This transparent approach kept the client informed and helped build trust.

Q 20. What is your experience with prepress quality control procedures?

Prepress quality control (QC) is paramount to avoid costly printing errors. My QC procedures are rigorous and encompass several stages:

- File Inspection: I carefully review all files for correct dimensions, bleeds, margins, color profiles, resolution, and font embedding.

- Preflight Checks: I run automated preflight checks to identify potential issues overlooked during manual inspection.

- Proofing: I utilize both soft proofing (on-screen) and hard proofing (physical print) to assess color accuracy, image quality, and overall visual appeal.

- Client Approval: I ensure the client reviews and approves all proofs before proceeding to the final print stage.

For example, a recent QC check revealed a slight color shift in a client’s logo. By catching this early, we ensured the final prints accurately reflected the client’s branding.

Q 21. Explain your experience with different types of proofing (soft proof, hard proof).

Different proofing methods provide distinct advantages at various stages of the prepress process.

- Soft Proofing: This involves reviewing the digital file on a calibrated monitor. It’s quick, cost-effective, and convenient for initial assessment and client feedback. However, it can’t perfectly represent the final printed output due to differences between screen and print technologies. Soft proofing relies heavily on a properly calibrated monitor and color profile.

- Hard Proofing: This involves creating a physical print sample using a proofing system (e.g., inkjet proofer) that closely simulates the final print conditions. It offers a more accurate representation of the final product and allows for tactile evaluation of paper stock and ink quality. While more costly than soft proofing, it’s indispensable for critical projects requiring precise color accuracy and texture assessment. The more closely a hard proof simulates the final press, the more valuable it becomes.

A common practice is to combine both soft and hard proofing. Soft proofing helps catch minor inconsistencies during the early stages, while hard proofing ensures color accuracy and consistency in the final stages before proceeding to the full print run.

Q 22. How familiar are you with different prepress workflow automation tools?

My familiarity with prepress workflow automation tools is extensive. I’ve worked with a range of solutions, from basic automation scripts to sophisticated MIS (Management Information Systems) and workflow management systems. This includes experience with tools that automate tasks such as job submission, imposition, trapping, color management, and proofing. For example, I’ve used tools like Esko Automation Engine, EFI Fiery Impose, and Enfocus Switch to streamline prepress operations significantly. These systems allow for the creation of standardized processes, reducing human error and speeding up turnaround times. I understand the importance of integrating these tools within a broader prepress ecosystem, ensuring seamless communication between different software and hardware components.

My expertise goes beyond simply using these tools. I understand the underlying principles of workflow automation and can design and implement custom automated solutions to address specific needs, ensuring maximum efficiency and consistency. I’m also proficient in troubleshooting any bottlenecks or errors that may arise within these automated workflows.

Q 23. Describe your experience working with different types of printing presses.

My experience encompasses a variety of printing presses, including offset, digital, and large-format printers. Working with offset presses, I’ve gained a deep understanding of the complexities involved in color management, platemaking, and press setup. This includes experience with both sheet-fed and web offset presses, handling different paper stocks and print sizes. With digital presses, my focus has been on optimizing print settings, ensuring color accuracy and efficient workflow integration with prepress software.

Experience with large-format printers broadened my understanding of handling large-scale print jobs, and the unique challenges related to media types, resolution, and color profiling. This multifaceted experience allows me to effectively communicate and collaborate with printers, ensuring the successful execution of print jobs, regardless of the chosen printing technology. I can optimize prepress files for specific press capabilities, minimizing potential issues during the printing process.

Q 24. What software packages are you proficient with in a prepress environment?

In a prepress environment, I’m highly proficient in a range of software packages. My core competencies lie in Adobe Creative Suite (Photoshop, Illustrator, InDesign), which are essential for image manipulation, vector graphics, and page layout. I’m also experienced with color management software like X-Rite i1Profiler and GMI ColorProof, ensuring consistent and accurate color reproduction across different devices.

Beyond this, I have expertise in prepress workflow automation software like those mentioned previously (Esko Automation Engine, EFI Fiery Impose, Enfocus Switch) and PDF editing tools like Acrobat Pro for preflighting and quality control. My skills also extend to RIP software (Raster Image Processor) for managing the output to different printers. This broad software proficiency enables me to handle a wide array of prepress tasks efficiently and effectively.

Q 25. What is your experience with managing and archiving prepress files?

Managing and archiving prepress files is critical for maintaining data integrity and ensuring efficient retrieval. I employ a robust system involving a combination of centralized file servers, version control, and a well-defined file naming convention. This ensures that files are easily locatable and identifiable. I use metadata tagging to categorize and index files, facilitating quick searches and retrieval.

Archiving is performed in accordance with industry best practices, utilizing both local and cloud-based storage solutions for redundancy and disaster recovery. This includes regular backups and rigorous access control to maintain data security and confidentiality. The archiving strategy takes into account both short-term and long-term storage needs, ensuring easy access to files when needed, while adhering to retention policies. My experience guarantees the preservation of crucial prepress assets, protecting intellectual property and ensuring seamless workflow continuity.

Q 26. How do you stay updated with the latest technologies and trends in the prepress industry?

Staying updated in the rapidly evolving prepress industry requires a multi-pronged approach. I actively participate in industry conferences and webinars, attending events like drupa and other relevant trade shows to learn about new technologies and trends firsthand. I also subscribe to industry publications and online resources, staying abreast of the latest advancements and best practices.

Furthermore, I actively engage with online communities and forums, participating in discussions and sharing knowledge with other professionals. Continuous learning is a cornerstone of my professional development, allowing me to adapt to changes and remain at the forefront of the prepress landscape. I regularly review and update my skillset through online courses and certifications to maintain peak proficiency.

Q 27. Describe a situation where you had to troubleshoot a prepress problem. What was the solution?

In one instance, a client’s high-resolution image files were causing significant delays during the imposition process. The large file sizes resulted in software crashes and extended processing times. The problem was that the images were not appropriately optimized for print. The solution involved a multi-step process.

First, we analyzed the image files to identify the cause of the large file sizes. This revealed that the images were unnecessarily high in resolution for the intended print output. Then, we used Adobe Photoshop to optimize the images for print, reducing the resolution to the appropriate level without compromising print quality. This significantly decreased file sizes. Finally, we implemented a preflight check within our workflow to automatically detect and flag any future excessively large files, preventing similar issues from arising. The result was a significant improvement in workflow efficiency and a smoother, faster production process.

Key Topics to Learn for a Knowledge of Prepress Industry Best Practices Interview

- Color Management: Understanding color spaces (CMYK, RGB, Pantone), color profiles, and color separations. Practical application: Troubleshooting color inconsistencies between digital and print outputs.

- File Preparation & Formats: Proficiency in handling various file formats (PDF, TIFF, JPEG, etc.), image resolution, and preflighting techniques. Practical application: Ensuring print-ready files meet specific client and printer requirements.

- Imposition & Finishing: Knowledge of different imposition techniques for various printing methods and understanding common finishing processes (folding, binding, die-cutting). Practical application: Optimizing print workflows for efficiency and cost-effectiveness.

- Proofing & Quality Control: Understanding different proofing methods (soft proof, contract proof, hard proof) and implementing quality control measures to minimize errors. Practical application: Identifying and correcting potential print issues before production.

- Digital Asset Management (DAM): Understanding the importance of organizing and managing digital assets efficiently. Practical application: Streamlining workflows and improving collaboration within a team.

- Print Production Workflow: A comprehensive understanding of the entire prepress workflow, from initial file submission to plate making. Practical application: Identifying and resolving bottlenecks in the production process.

- Industry-Specific Software: Familiarity with relevant software such as Adobe Acrobat, Photoshop, InDesign, and prepress workflow automation tools. Practical application: Demonstrating proficiency in handling and manipulating files for optimal print results.

- Troubleshooting & Problem-Solving: Ability to identify and resolve common prepress issues, such as trapping, image resolution problems, and color inconsistencies. Practical application: Demonstrating a proactive approach to quality control.

Next Steps

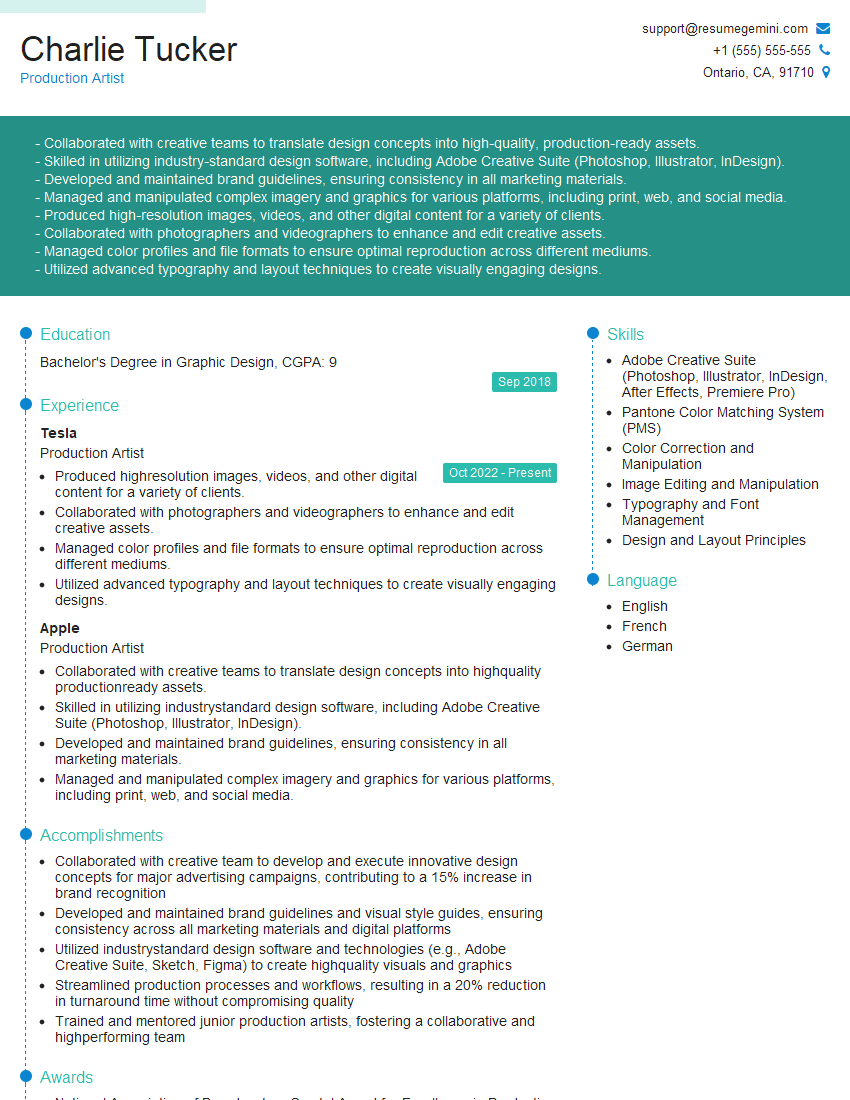

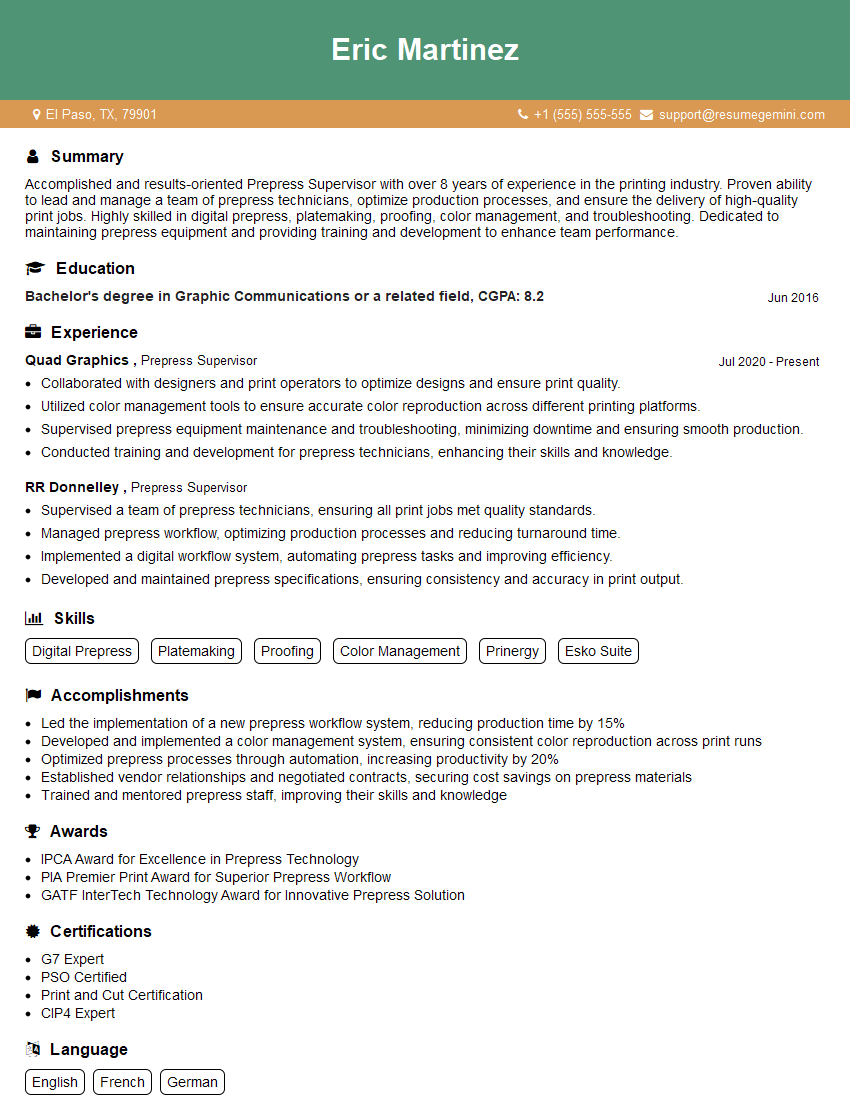

Mastering Knowledge of Prepress Industry Best Practices is crucial for career advancement and opens doors to exciting opportunities within the printing and publishing industries. A strong understanding of these concepts showcases your expertise and professionalism, making you a highly desirable candidate. To maximize your job prospects, invest time in creating an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource that can significantly enhance your resume-building experience. They offer examples of resumes tailored specifically to the Knowledge of Prepress Industry Best Practices, allowing you to craft a compelling document that stands out from the competition. Take the next step in your career journey and elevate your resume today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good