Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Experience in Prepress Cost Optimization interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Experience in Prepress Cost Optimization Interview

Q 1. Explain your experience optimizing prepress workflows for cost reduction.

Optimizing prepress workflows for cost reduction involves a multifaceted approach focusing on efficiency, automation, and strategic resource allocation. It’s about streamlining the entire process from file preparation to platemaking, minimizing waste and maximizing output. This includes analyzing current processes to pinpoint bottlenecks and inefficiencies, then implementing targeted improvements using technology, process re-engineering and vendor management strategies.

- Automation: Implementing automated workflows for tasks like trapping, imposition, and color management significantly reduces manual effort and human error, leading to faster turnaround times and lower labor costs. For instance, automating the imposition process using software can eliminate hours of manual work per job.

- File Standardization: Establishing clear guidelines for file submission, ensuring consistent file formats and resolutions, eliminates costly rework due to incorrect file specifications. This ensures everyone uses the best practices, which speeds up the process.

- Waste Reduction: Implementing strategies to minimize plate waste, such as using more efficient imposition techniques or optimizing the size of printed sheets to reduce material usage.

- Technology Upgrades: Investing in newer, faster, and more efficient prepress equipment and software can lead to significant long-term cost savings. For example, switching to a more advanced RIP (Raster Image Processor) can significantly reduce processing times.

Q 2. Describe a time you identified and solved a prepress cost inefficiency.

At a previous company, we were experiencing significant delays and increased costs due to inconsistent file submissions from our clients. Many files lacked proper color profiles, resulting in time-consuming color corrections and reprint costs. To solve this, I implemented a comprehensive file preparation guideline document with detailed specifications for resolution, color profiles, and file formats. We also created a client-facing online portal with tutorials and examples, making it easier for them to submit compliant files. This significantly reduced rework, decreased our turnaround time and lowered prepress costs by approximately 25% within three months.

Q 3. What software and technologies are you proficient in for prepress cost management?

My proficiency spans a wide range of prepress software and technologies. I’m highly skilled in Adobe Creative Suite (Photoshop, Illustrator, InDesign), Esko Suite (Artwork, Studio, Automation Engine), and various RIP software such as Creo and Kodak Prinergy. I’m also familiar with MIS (Management Information System) software for job tracking and cost analysis, and have experience with cloud-based collaboration platforms like ShareFile and Dropbox for secure file transfer and project management. My understanding extends to color management software and workflow automation tools like Enfocus PitStop.

Q 4. How do you manage vendor relationships to optimize prepress costs?

Managing vendor relationships effectively is crucial for prepress cost optimization. I approach this by fostering open communication, negotiating favorable contracts based on volume and performance, and regularly reviewing vendor performance against pre-agreed KPIs (Key Performance Indicators). This includes:

- Building strong relationships: Developing trust and mutual understanding with vendors allows for more effective problem-solving and collaborative cost-saving initiatives.

- Competitive bidding: Regularly soliciting quotes from different vendors ensures we are securing the most competitive pricing for services.

- Performance monitoring: Tracking key metrics like turnaround time, error rates, and customer satisfaction helps identify areas for improvement and hold vendors accountable.

For example, by negotiating a volume discount with our plate supplier, we were able to reduce our plate costs by 10% annually.

Q 5. What metrics do you use to track and measure prepress cost effectiveness?

Tracking and measuring prepress cost effectiveness requires a robust system of key performance indicators (KPIs). These include:

- Cost per job: Tracks the total cost of prepress operations for each job, enabling identification of costly projects and areas for improvement.

- Turnaround time: Measures the time taken from file receipt to plate output, highlighting bottlenecks and inefficiencies.

- Error rate: Tracks the number of errors requiring rework, indicating areas where processes can be improved for quality control.

- Plate waste: Monitors the amount of plate material wasted, enabling identification of areas for improvement in imposition and workflow.

- Vendor performance: Tracks adherence to agreed-upon service level agreements (SLAs).

Regular monitoring of these KPIs allows for data-driven decision-making to optimize resource allocation and enhance prepress efficiency.

Q 6. Explain your understanding of different prepress file formats and their impact on cost.

Different prepress file formats significantly impact cost. Choosing the right format is critical for efficiency and quality. For instance, using a high-resolution TIFF file when a lower-resolution JPEG would suffice unnecessarily increases file size and processing time, leading to increased costs.

- PDF/X: A widely used format specifically designed for print production, minimizing compatibility issues and ensuring color consistency. This is often the preferred format due to its reliability.

- TIFF: A versatile raster image format suitable for high-resolution images, but can be large in file size.

- JPEG: A compressed raster format suitable for images with less detail, but can lead to quality loss with compression. Generally not suitable for high-quality printing.

- EPS: A vector format offering scalability without loss of quality, suitable for logo and text-based graphics. However, proper embedding of fonts is crucial.

Understanding these formats and their impact on file size and processing time is essential for choosing the most cost-effective option while maintaining print quality.

Q 7. How do you balance quality and cost in prepress operations?

Balancing quality and cost in prepress operations requires a strategic approach focusing on efficiency and process optimization without compromising the quality of the final product. It’s about finding the sweet spot where we maximize efficiency without sacrificing print quality. This involves:

- Targeted Quality Control: Implementing focused quality checks at crucial stages of the prepress workflow, minimizing costly rework while ensuring the final product meets the required standards.

- Process Optimization: Streamlining workflows, automating tasks, and using the right technology and software to increase throughput while reducing waste.

- Strategic Outsourcing: Leveraging the expertise of external vendors for specialized tasks like color separation or high-end image retouching, maximizing efficiency and controlling costs.

- Technology Adoption: Investing in newer technologies that balance cost-effectiveness with improved speed and quality.

For example, we might choose a slightly less expensive paper stock that still meets the quality requirements of the project, thus saving on material costs without significantly affecting the final print quality.

Q 8. Describe your experience with color management and its impact on prepress costs.

Color management is crucial in prepress for ensuring consistent color reproduction across different devices and media. Poor color management leads to costly reprints, client dissatisfaction, and wasted materials. My experience involves establishing and maintaining ICC profiles for various printing processes, ensuring accurate color conversion from design software to printing plates. This includes working with Pantone colors, CMYK, and RGB color spaces to achieve the desired color accuracy. For instance, in one project, implementing a robust color management system reduced our reprint rate by 15%, saving the company thousands of dollars.

I’ve successfully streamlined our color workflows by implementing standardized processes and training staff on best practices. This included the use of color proofing software to verify accuracy before proceeding to printing. By proactively addressing potential color discrepancies, we minimize costly mistakes and ensure client satisfaction.

Q 9. How do you handle unexpected prepress issues that impact costs?

Unexpected prepress issues, like file corruption or missing fonts, are inevitable. My approach focuses on rapid problem-solving and proactive mitigation. This begins with a thorough pre-flight check of all incoming files. I utilize automation tools to identify and flag potential problems early on, reducing downtime and preventing costly errors. If an unexpected issue arises, I follow a systematic process: 1) Assess the problem, 2) Identify the root cause, 3) Determine the best solution while prioritizing speed and minimizing impact on deadlines, 4) Communicate clearly with the client and internal team, 5) Implement corrective measures, 6) Document the issue and its resolution to prevent recurrence. For example, once a critical client file was severely corrupted. Using data recovery techniques and collaboration with the client, we salvaged 95% of the data, avoiding a complete reprint and maintaining the deadline.

Q 10. What are your strategies for implementing and maintaining a lean prepress workflow?

Implementing a lean prepress workflow requires a focus on efficiency and waste reduction. This includes automating repetitive tasks, streamlining communication, and optimizing file handling. My strategies involve: 1) Automation: Utilizing automation tools for tasks like pre-flight checks, color conversions, and imposition. 2) Standardization: Creating clear, documented processes for file handling, color management, and proofing. 3) Workflow optimization: Analyzing each step of the prepress process to identify bottlenecks and inefficiencies, then implementing solutions like improved software or better team collaboration. 4) Training & Communication: Ensuring the entire team understands and adheres to the standardized workflows. 5) Regular review and improvement: Continuously monitoring the workflow for areas of improvement and implementing changes based on data analysis. For example, implementing automated imposition saved us an estimated 2 hours per job, significantly boosting our overall efficiency.

Q 11. What is your experience with prepress automation tools and software?

I possess extensive experience with a variety of prepress automation tools and software, including Esko Suite, Adobe Creative Suite, PitStop Pro, and various imposition and workflow management systems. My proficiency extends to using these tools to automate tasks such as pre-flighting, color management, trapping, imposition, and file preparation for different printing methods. I’m also comfortable working with different file formats and integrating software solutions to optimize our prepress workflow. For example, I successfully integrated Esko Automation Engine to our workflow to automate job ticket creation and improve the accuracy of color separations, thereby reducing manual errors.

Q 12. How familiar are you with different printing methods and their cost implications?

Understanding different printing methods and their cost implications is fundamental for prepress cost optimization. My experience encompasses offset printing, digital printing, large format printing, and flexographic printing. Each method has unique cost structures influenced by factors such as plate making, ink usage, substrate costs, and machine setup time. For example, offset printing might be cost-effective for large print runs, while digital printing is more suitable for shorter runs and personalized materials. I consider the print run length, desired quality, turnaround time, and budget constraints when recommending the appropriate printing method to the client, ensuring cost-effectiveness without compromising quality.

Q 13. How do you assess and manage the risks associated with prepress cost optimization?

Managing risks in prepress cost optimization requires a proactive approach. Potential risks include client-side errors, unforeseen technical issues, and unexpected delays. My strategies include: 1) Thorough file checks and proofing: Identifying and resolving potential problems before they escalate. 2) Redundancy planning: Having backup systems and procedures in place to handle unexpected issues. 3) Clear communication with clients: Establishing realistic expectations and maintaining open communication throughout the process. 4) Continuous monitoring and improvement: Regularly analyzing the prepress workflow to identify and mitigate potential risks. 5) Risk assessment matrix: Identifying and prioritizing potential risks based on their likelihood and potential impact. This allows me to allocate resources appropriately to mitigate the most significant risks. By implementing these strategies, we significantly reduce the risk of costly delays and errors.

Q 14. Explain your understanding of different pricing models for prepress services.

Different pricing models exist for prepress services. These typically include: 1) Per-project pricing: A fixed fee for a specific project based on scope and complexity. 2) Hourly rates: Charging based on the time spent on the project. 3) Value-based pricing: Charging based on the value delivered to the client, reflecting the impact of the prepress services on their overall profitability. 4) Subscription models: Offering access to prepress services on a recurring subscription basis. The choice of pricing model depends on various factors such as project scope, client needs, and business goals. My expertise allows me to select the most appropriate pricing model to ensure fair compensation while maintaining client satisfaction and maximizing profitability. For instance, for high-volume clients, a value-based model might be more beneficial, while smaller projects might be priced on a per-project basis.

Q 15. How do you prioritize tasks to ensure timely and cost-effective prepress completion?

Prioritizing prepress tasks for timely and cost-effective completion requires a strategic approach. I use a combination of techniques, starting with a clear understanding of project deadlines and client priorities. This involves analyzing each job’s complexity, required turnaround time, and potential cost implications.

- Prioritization Matrix: I often employ a matrix prioritizing tasks based on urgency (deadline proximity) and importance (impact on overall project success). High-urgency, high-importance tasks take precedence. This ensures critical projects aren’t delayed.

- Workflow Optimization: I analyze the current workflow to identify bottlenecks. This could involve streamlining processes, automating repetitive tasks, or optimizing file handling. For example, implementing automated imposition software significantly reduces manual work and potential errors.

- Resource Allocation: Effective resource allocation is crucial. This means assigning tasks to the most appropriate team members based on their skill sets and availability. It also involves managing equipment usage efficiently to avoid downtime and unnecessary costs.

- Regular Monitoring and Adjustment: Throughout the process, I monitor progress against the schedule and make adjustments as needed. This might involve re-prioritizing tasks based on unforeseen issues or changing client requirements.

For instance, in a recent project involving multiple books with tight deadlines, I used a Kanban board to visualize the workflow. This allowed for quick identification and resolution of bottlenecks, ensuring all projects were delivered on time and within budget.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you effectively communicate cost-saving solutions to clients or management?

Communicating cost-saving solutions effectively requires a clear, concise, and data-driven approach. I tailor my communication to the audience – whether it’s a client or management – focusing on the value proposition of each solution.

- Quantifiable Results: I always present cost savings in concrete terms. Instead of saying ‘we can reduce costs,’ I’ll say ‘by implementing automated trapping, we can reduce prepress time by 15%, saving approximately $X per project.’

- Visual Aids: Charts and graphs can effectively illustrate cost comparisons and savings potentials. Visual representations make complex data more accessible and easier to understand.

- Client-Focused Language: When communicating with clients, I highlight the benefits of cost savings in terms of their overall project budget and timeline. This shows that I’m invested in their success.

- Transparency and Collaboration: I foster open communication and collaboration, involving clients in the decision-making process where appropriate. This builds trust and ensures they understand the rationale behind the proposed changes.

For example, when presenting a proposal for implementing a new color management system to a client, I showed a comparison of past color correction costs versus the projected costs with the new system, highlighting the significant long-term savings and improved color accuracy.

Q 17. Describe your experience with prepress budgeting and forecasting.

Prepress budgeting and forecasting is a critical aspect of my role. I use historical data, projected workload, and anticipated costs to create accurate and realistic budgets. My process typically involves:

- Historical Data Analysis: Reviewing past prepress expenses to identify trends and patterns. This includes labor costs, material costs, and equipment maintenance.

- Workload Projection: Estimating the volume of work expected in a given period. This requires analyzing sales forecasts, project pipelines, and client expectations.

- Cost Estimation: Determining the cost of each project based on complexity, required resources, and anticipated time investment.

- Contingency Planning: Building in a contingency buffer to account for unforeseen expenses or delays. This helps prevent budget overruns.

- Regular Monitoring and Adjustment: Tracking actual expenses against the budget and making adjustments as needed. This requires regular review and analysis of performance data.

I’ve successfully managed prepress budgets in environments with varying project volumes and complexities. For example, during a period of increased demand, I accurately forecasted the need for additional staff and equipment, preventing potential budget overruns and ensuring on-time delivery of projects.

Q 18. How do you ensure the accuracy and consistency of prepress data?

Ensuring accuracy and consistency of prepress data is paramount. My approach relies on a combination of robust processes and technological tools.

- Standardized File Formats: Implementing consistent file formats (e.g., PDF/X) across all projects helps minimize errors caused by incompatible file types.

- Color Management System (CMS): Utilizing a CMS ensures accurate color reproduction across different devices and workflows, reducing inconsistencies and potential reprints.

- Automated Checks and Validation: Employing automated preflight tools to check for potential issues such as missing fonts, low-resolution images, and incorrect color profiles. This catches errors early, preventing costly reprints.

- Version Control: Implementing version control systems to track changes made to files. This helps prevent accidental overwrites and ensures that the correct versions are used for printing.

- Data Backup and Recovery: Regularly backing up all prepress data to prevent data loss due to hardware failures or other unforeseen circumstances.

In a past project, the implementation of a standardized PDF/X workflow significantly reduced the number of errors related to missing fonts and incorrect color spaces, saving both time and money.

Q 19. What is your experience with implementing and managing a prepress quality control system?

My experience with implementing and managing prepress quality control systems involves a multi-faceted approach focusing on prevention and detection of errors.

- Process Documentation: Creating clear and concise documentation outlining each step of the prepress workflow. This ensures consistency and makes it easier to train new team members.

- Checklists and Forms: Utilizing checklists and forms to standardize quality checks at various stages of the prepress process. This ensures that all necessary steps are performed consistently.

- Proofing Procedures: Implementing rigorous proofing procedures, including soft proofs and hard proofs, to identify potential errors before printing. This reduces the risk of costly reprints.

- Defect Tracking System: Establishing a system for tracking and analyzing defects. This helps identify trends and patterns, enabling proactive measures to improve the quality of the prepress process.

- Regular Audits and Reviews: Conducting regular audits and reviews of the quality control system to ensure its effectiveness and identify areas for improvement.

In one instance, I implemented a color-managed workflow with standardized proofing procedures. This resulted in a significant decrease in color-related errors, reducing the need for costly reprints and boosting client satisfaction.

Q 20. How do you measure the ROI of prepress cost optimization initiatives?

Measuring the ROI of prepress cost optimization initiatives requires a systematic approach. I typically track key performance indicators (KPIs) related to cost savings, efficiency improvements, and quality enhancements.

- Cost Savings: Calculating the reduction in prepress expenses achieved through the implementation of optimization strategies. This might include savings in labor costs, material costs, or equipment costs.

- Efficiency Gains: Measuring improvements in turnaround time, throughput, or productivity. This could be quantified by tracking the time saved per project or the increase in the number of projects completed in a given period.

- Quality Improvements: Evaluating the reduction in errors, defects, or reprints. This can be measured by tracking the number of errors detected at different stages of the prepress process.

- Client Satisfaction: Assessing client satisfaction levels following the implementation of cost optimization measures. This can be achieved through feedback surveys or reviews.

For example, after implementing an automated imposition system, I calculated the ROI by comparing the cost savings from reduced labor time and the cost of the system’s implementation. The data clearly demonstrated significant cost savings and increased efficiency within a short timeframe.

Q 21. How familiar are you with different types of prepress equipment and their maintenance costs?

My familiarity with prepress equipment is extensive. I’m well-versed in various types of equipment, including:

- Digital Proofing Systems: I have experience with various digital proofing solutions, understanding their strengths, weaknesses, and associated costs, including software licenses, calibration, and maintenance.

- Imposition Software: I’m proficient in various imposition software packages, understanding their functionalities, cost implications, and impact on efficiency.

- Color Management Software: I have a strong understanding of various color management solutions and their cost-effectiveness in terms of accuracy and efficiency.

- RIPs (Raster Image Processors): I’m familiar with different RIP technologies and their associated costs, including software licenses and maintenance contracts.

- Prepress Servers and Workstations: I understand the hardware requirements for optimal prepress workflows and their associated acquisition and maintenance costs.

My knowledge extends to the maintenance costs associated with these machines. I understand the importance of regular maintenance to prevent costly breakdowns and ensure optimal performance. I’ve successfully managed equipment maintenance budgets, scheduling preventative maintenance to minimize downtime and extend the lifespan of equipment.

Q 22. What are your strategies for training and developing prepress team members on cost optimization?

Training a prepress team on cost optimization isn’t just about teaching software; it’s about fostering a culture of efficiency. My strategy involves a multi-pronged approach combining classroom learning, hands-on workshops, and ongoing mentorship.

Classroom Training: We cover topics such as file preparation best practices (avoiding unnecessary edits, using appropriate color spaces), efficient workflow design, and understanding the cost implications of different printing techniques.

Hands-on Workshops: Practical exercises using real-world projects are crucial. Teams work collaboratively to optimize files, troubleshoot common issues, and compare the cost implications of various solutions. For example, we might analyze the cost difference between using high-resolution images versus optimized versions, or the impact of choosing a different paper stock.

Mentorship and Ongoing Support: Regular one-on-one sessions provide personalized guidance and address specific challenges. I encourage team members to share their findings and learn from each other’s successes and failures. This creates a continuous learning environment where optimization strategies evolve organically.

Finally, success is measured by tracking key metrics like file preparation time, turnaround time, and overall prepress costs. This data drives further training and refinement of our strategies.

Q 23. How do you stay up-to-date with the latest technologies and trends in prepress cost optimization?

Staying current in the rapidly evolving world of prepress cost optimization is paramount. My approach involves a combination of active learning and networking:

Industry Publications and Conferences: I regularly read trade journals, attend industry conferences, and participate in webinars to stay abreast of the latest technologies and trends. This includes advancements in software, automation tools, and sustainable printing practices.

Vendor Relationships: Maintaining close relationships with prepress vendors allows me to learn about new product releases and cost-saving solutions firsthand. I often participate in beta testing programs to gain early access to innovative tools.

Online Communities and Forums: Active participation in online communities dedicated to prepress professionals provides exposure to best practices and valuable insights from peers around the globe.

Continuous Learning Platforms: Online courses and certifications from reputable institutions provide in-depth knowledge on specific aspects of prepress technology and cost management.

By actively engaging in these activities, I ensure my expertise remains relevant and allows me to proactively implement cost-saving solutions.

Q 24. Describe your experience with negotiating contracts with prepress vendors.

Negotiating contracts with prepress vendors requires a strategic and data-driven approach. I begin by thoroughly understanding the scope of the project, including file specifications, turnaround time, and quantity. Then, I gather quotes from multiple vendors to compare pricing and services.

Detailed Specifications: Clearly defined project specifications eliminate ambiguity and potential misunderstandings, leading to more accurate and competitive quotes.

Value-Based Negotiation: I don’t focus solely on price; I emphasize value. This includes factors like vendor reliability, quality of service, technical expertise, and the use of eco-friendly practices. For example, I might negotiate a slightly higher price for a vendor with a proven track record of on-time delivery and high-quality output, recognizing this minimizes risks and potential cost overruns.

Contractual Clauses: I carefully review contracts, paying attention to clauses related to payment terms, liability, and dispute resolution. Protecting the interests of my organization is crucial.

Building Relationships: Developing strong relationships with vendors can lead to more favorable terms and a greater willingness to collaborate on cost-saving initiatives.

My approach ensures I secure the best value for my organization while building long-term partnerships with reliable vendors.

Q 25. How do you handle conflicts between quality, turnaround time, and cost in prepress?

Balancing quality, turnaround time, and cost in prepress is a constant challenge. It’s not about compromising one for another; it’s about finding the optimal balance. My approach uses a prioritization matrix and involves collaborative decision-making.

Prioritization Matrix: We use a matrix to weigh the relative importance of each factor based on the specific project requirements. A high-priority project might prioritize turnaround time even if it slightly increases cost. A less urgent project with a larger print run may allow for more cost optimization, even if it slightly extends the timeline.

Open Communication: Transparent communication with clients and the prepress team is essential to manage expectations and make informed decisions. We discuss the trade-offs of each option and collaboratively choose the best approach.

Process Optimization: Identifying and eliminating bottlenecks in the prepress workflow can significantly improve turnaround time without compromising quality or drastically increasing costs. This might involve streamlining file preparation processes, automating repetitive tasks, or investing in more efficient software.

Cost-Effective Solutions: We explore cost-effective alternatives without sacrificing quality. For example, using alternative paper stocks or adjusting the finishing techniques can impact costs positively.

Through a structured approach, open communication, and process optimization, we consistently deliver high-quality results within budget and on schedule.

Q 26. How do you use data analytics to identify opportunities for prepress cost optimization?

Data analytics is a crucial tool for identifying opportunities for prepress cost optimization. I use data from various sources to gain insights into our processes and identify areas for improvement.

File Size Analysis: Tracking average file sizes helps pinpoint areas where file optimization strategies need to be implemented. Large files can significantly increase processing time and costs.

Turnaround Time Tracking: Monitoring turnaround times helps identify bottlenecks in the workflow. This allows us to target specific areas for improvement, such as automating tasks or improving communication.

Cost Analysis: Analyzing costs associated with different prepress processes (proofing, color correction, etc.) helps identify areas where cost reduction is most effective. We can then prioritize investment in automation, new technologies, or training in these specific areas.

Vendor Performance Data: We track vendor performance data, including turnaround times, error rates, and costs. This allows us to select vendors offering the optimal combination of quality, efficiency, and cost-effectiveness.

By using data-driven insights, we can identify specific opportunities for prepress cost optimization, leading to tangible and sustainable improvements.

Q 27. Explain your understanding of the impact of different paper types and stocks on prepress costs.

Different paper types and stocks significantly impact prepress costs. Heavier stocks require more power to process on the press and can lead to increased wear and tear on printing equipment. The paper’s surface finish also affects ink absorption and drying times, potentially impacting ink costs and production time.

Paper Weight: Heavier paper stocks (e.g., card stock) increase costs due to higher material costs and increased press run time. Lighter stocks, like 20lb bond paper, reduce the cost but might not be suitable for all applications.

Paper Type: Coated papers generally produce brighter, sharper images but are more expensive than uncoated papers. Uncoated papers might necessitate different ink formulations and potentially increase ink costs.

Paper Finish: Different paper finishes (matte, gloss, textured) affect ink absorption and drying, which can influence both ink costs and production time. Gloss finishes might require special inks to maintain quality and brightness.

Understanding the cost implications of paper selection is crucial for effective prepress cost management. We usually collaborate closely with clients to make informed choices about paper specifications that balance quality and cost.

Q 28. Describe your experience with implementing sustainable practices in prepress to reduce costs.

Implementing sustainable practices in prepress isn’t just environmentally responsible; it often translates to cost savings. My experience includes focusing on several key areas:

Reducing Paper Waste: Implementing robust proofing processes, such as soft proofing, minimizes the need for physical proofs. We also optimize file layouts to reduce paper usage during the printing process.

Sustainable Printing Methods: Choosing environmentally friendly inks and papers can significantly reduce environmental impact and sometimes lead to lower material costs. Negotiating with vendors who prioritize sustainable practices can also yield cost-effective solutions.

Energy Efficiency: Optimizing our workflow to reduce energy consumption is essential. This includes using energy-efficient equipment and software, and implementing strategies for reducing paper waste, as described above.

Waste Management: Proper waste management practices, including recycling and proper disposal of chemicals, minimize environmental impact and potentially reduce disposal costs.

By embracing sustainable practices, we create a win-win situation; reducing our environmental footprint while also saving money and enhancing our corporate social responsibility.

Key Topics to Learn for Prepress Cost Optimization Interviews

- File Preparation & Workflow Optimization: Understanding different file formats, color spaces, and their impact on printing costs. Optimizing workflows to minimize manual intervention and errors.

- Print Production Technologies: Knowledge of various printing technologies (offset, digital, large format) and their associated costs. Understanding the trade-offs between speed, quality, and price.

- Color Management & Proofing: Mastering color profiles and proofing techniques to reduce costly reprints due to color discrepancies. Implementing strategies for accurate color representation across different devices.

- Supplier Negotiation & Contract Management: Developing strong relationships with vendors and negotiating favorable pricing. Understanding contract terms and conditions to ensure cost-effectiveness.

- Waste Reduction Strategies: Identifying and minimizing waste in materials, time, and resources throughout the prepress process. Implementing lean principles to streamline workflows and reduce inefficiencies.

- Data Analysis & Reporting: Tracking key metrics (e.g., cost per job, turnaround time) to identify areas for improvement. Using data-driven insights to inform decision-making and optimize processes.

- Software & Technology: Familiarity with relevant prepress software (e.g., Adobe Creative Suite, imposition software, color management systems) and their capabilities in cost optimization.

- Problem-Solving & Decision-Making: Demonstrating the ability to analyze complex problems, identify cost-saving opportunities, and implement effective solutions. Applying critical thinking skills to optimize prepress operations.

Next Steps

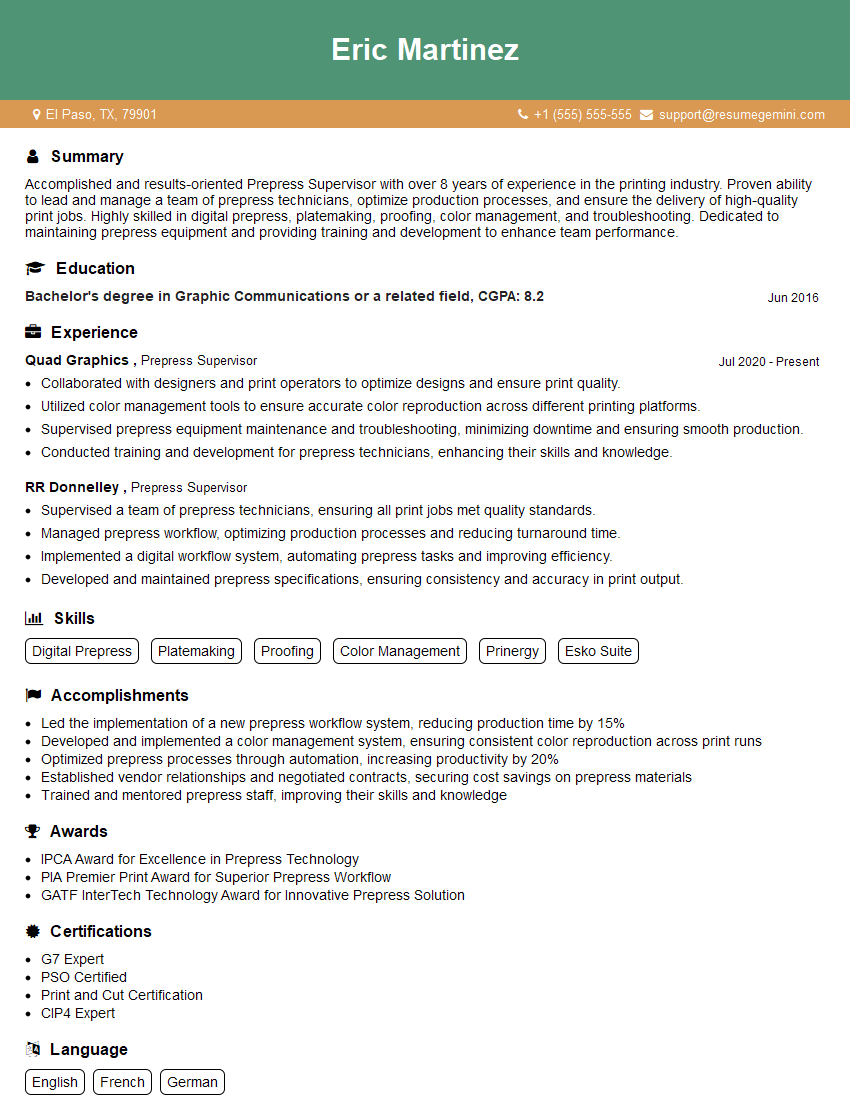

Mastering prepress cost optimization is crucial for career advancement in the printing and publishing industries. It showcases your ability to contribute significantly to a company’s bottom line and demonstrates valuable skills in efficiency, problem-solving, and strategic thinking. To maximize your job prospects, crafting an ATS-friendly resume is vital. ResumeGemini can help you create a powerful and effective resume that highlights your expertise in prepress cost optimization. We provide examples of resumes tailored to this specific area to guide you. Invest in your future – build a compelling resume that showcases your value.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good