Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Lean Principles and Continuous Improvement interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Lean Principles and Continuous Improvement Interview

Q 1. Define Lean Principles and their application in a manufacturing environment.

Lean principles are a systematic approach to identifying and eliminating waste in any process, ultimately maximizing value for the customer. In a manufacturing environment, this translates to producing high-quality products efficiently, minimizing costs, and delivering them on time. The core is focused on understanding and optimizing the flow of materials and information.

Key Lean principles include:

- Value: Defining value strictly from the customer’s perspective.

- Value Stream: Mapping out all steps involved in delivering that value, identifying both value-added and non-value-added activities.

- Flow: Creating a smooth, uninterrupted flow of materials and information through the value stream, minimizing bottlenecks and delays.

- Pull: Producing only what is needed, when it is needed, based on customer demand (think Just-in-Time manufacturing).

- Perfection: Continuously striving to improve processes and eliminate waste.

For example, a manufacturing plant might use Lean to reduce inventory holding costs by implementing a Just-in-Time delivery system for raw materials, directly reducing the waste of storage and associated expenses. Another example would be streamlining the production line to eliminate unnecessary movements and steps, thus improving efficiency and throughput.

Q 2. Explain the 5S methodology and its benefits.

5S is a workplace organization method that uses five Japanese words starting with ‘S’ to create a more efficient and safer work environment. It’s a foundational Lean tool. The five S’s are:

- Seiri (Sort): Eliminate unnecessary items from the workspace. This involves identifying and removing anything that isn’t needed for the current process.

- Seiton (Set in Order): Arrange necessary items in a way that’s easy to find and use. This often includes clear labeling and logical placement.

- Seiso (Shine): Clean and maintain the workspace. This includes regular cleaning and ensuring equipment is well-maintained.

- Seiketsu (Standardize): Establish standards for maintaining the 5S practices. This ensures consistency and prevents backsliding.

- Shitsuke (Sustain): Maintain the standards through continuous improvement and discipline. This is the crucial ongoing aspect of 5S.

Benefits include: improved safety, increased efficiency, reduced waste, better quality control, and a more organized and productive work environment. Imagine a cluttered workshop versus a clean, organized one—the efficiency difference is immediately apparent.

Q 3. Describe the Value Stream Mapping process and its purpose.

Value Stream Mapping (VSM) is a lean manufacturing technique used to visually represent the flow of materials and information required to bring a product or service to the customer. It’s a powerful tool for identifying and eliminating waste in a process.

The process involves:

- Defining the scope: Identifying the beginning and end points of the value stream.

- Mapping the current state: Documenting all steps involved in the process, including both value-added and non-value-added activities.

- Data collection: Gathering data on lead times, inventory levels, and other key metrics.

- Identifying waste: Pinpointing areas where waste is occurring (e.g., transportation, inventory, motion, waiting).

- Developing a future state map: Designing an improved process that eliminates waste and optimizes flow.

- Implementation: Putting the improved process into action.

The purpose is to visualize the entire process, allowing for systematic improvements and waste reduction. A VSM acts like a roadmap showing where improvements will have the biggest impact.

Q 4. How would you identify and eliminate waste in a given process?

Identifying and eliminating waste requires a systematic approach. I would use a combination of methods, including:

- Value Stream Mapping: As previously discussed, this provides a visual representation of the process and helps pinpoint areas of waste.

- Gemba Walks: Going to the actual place where the work is done to observe the process firsthand and identify bottlenecks or inefficiencies.

- 5 Whys Analysis: Repeatedly asking ‘Why?’ to uncover the root cause of a problem. This helps to avoid simply addressing symptoms.

- Data Analysis: Using data to identify trends and patterns that indicate areas for improvement.

- Kaizen Events: Organizing focused workshops to brainstorm and implement improvements.

For example, if a process is experiencing long lead times, I would use VSM to visualize the flow, identify bottlenecks (e.g., waiting time at a particular machine), and then implement solutions such as improving equipment maintenance or adjusting work schedules.

Q 5. What are the seven types of waste (muda) in Lean?

The seven types of waste (muda) in Lean are often remembered by the acronym TIMWOOD:

- Transportation: Unnecessary movement of materials or information.

- Inventory: Excess materials or work-in-progress.

- Motion: Unnecessary movement of people or equipment.

- Waiting: Idle time waiting for materials, information, or equipment.

- Overproduction: Producing more than is needed.

- Over-processing: Performing more work than is necessary.

- Defects: Errors that require rework or scrap.

Understanding and addressing these wastes is crucial for improving efficiency and reducing costs. For instance, eliminating unnecessary movements of workers by optimizing their workspace layout significantly reduces motion waste.

Q 6. Explain the concept of Kaizen and its role in continuous improvement.

Kaizen, meaning ‘change for the better’ in Japanese, is a philosophy of continuous improvement. It emphasizes making small, incremental changes regularly rather than relying on large-scale, infrequent improvements. This approach fosters a culture of continuous improvement and employee engagement.

Its role is to create a mindset where everyone is empowered and responsible for identifying and implementing improvements in their work area. It’s not about grand overhauls, but consistent, incremental progress. Examples include: streamlining a small part of a process, improving a workstation layout, or identifying a simpler way to complete a task. The cumulative effect of many small Kaizen events can dramatically improve overall efficiency and productivity.

Q 7. Describe your experience with implementing Lean methodologies in a previous role.

In my previous role at [Previous Company Name], we implemented Lean methodologies across our manufacturing processes. We started with a Value Stream Mapping exercise to visualize the production of our flagship product. This revealed significant bottlenecks in the assembly process, primarily due to long waiting times for specific components.

Through Kaizen events, we identified and addressed several issues. We redesigned the assembly line layout to reduce the distance components needed to travel, reducing motion waste. We also implemented a Kanban system for managing inventory, reducing waiting times significantly. Furthermore, by implementing 5S methodologies, we cleaned and organized the workspace, improving worker efficiency and reducing the risk of errors.

These improvements resulted in a 15% reduction in lead time and a 10% decrease in production costs within six months. This successful implementation showcased the power of Lean principles and demonstrated the positive impact of employee involvement and continuous improvement on efficiency, productivity, and profitability. We also saw an improvement in employee morale and job satisfaction due to their direct contributions to process improvement.

Q 8. How would you measure the success of a Lean initiative?

Measuring the success of a Lean initiative requires a multi-faceted approach, going beyond simple cost reduction. We need to assess improvements across various dimensions, focusing on both quantitative and qualitative gains.

- Reduced Lead Times: Did we shorten the time it takes to deliver a product or service? This is a critical measure of efficiency improvement. For example, if we reduced order fulfillment from 10 days to 5, that’s a 50% improvement, readily quantifiable.

- Improved Quality: Did the number of defects or errors decrease? This demonstrates better process control. We can track this using metrics like defect rate, customer returns, or customer satisfaction scores.

- Increased Throughput: Did we increase the volume of goods or services produced or delivered? This speaks to efficiency and capacity utilization. For instance, increasing production from 100 units per day to 120 represents a 20% gain.

- Reduced Inventory: Did we minimize the amount of work in progress or finished goods inventory? Lower inventory signifies improved flow and less capital tied up in stock. We can measure this by comparing inventory turnover rates before and after the initiative.

- Enhanced Employee Engagement: Did the Lean initiative boost employee morale and participation? Engaged employees are more likely to contribute to continuous improvement. This can be measured via surveys, feedback sessions, or observation of increased problem-solving activities.

- Improved Safety: Did the initiative lead to a safer working environment? Reducing accidents and near-misses is a crucial success factor often overlooked. This is quantifiable through safety incident rates.

Ultimately, success is defined by achieving significant improvements across several of these areas. It’s not enough to improve one metric at the expense of another. A holistic view is essential for evaluating the overall impact.

Q 9. What are the key performance indicators (KPIs) you would use to track Lean progress?

Key Performance Indicators (KPIs) for tracking Lean progress should be carefully selected to reflect the specific goals of the initiative. Here are some examples, categorized for clarity:

- Process Efficiency: Lead time, cycle time, throughput, takt time, value-added ratio, overall equipment effectiveness (OEE), inventory turnover rate.

- Quality: Defect rate, customer returns, customer satisfaction, First Pass Yield (FPY), process capability indices (Cp, Cpk).

- Cost: Unit cost, total cost of ownership, cost of poor quality, inventory carrying costs.

- Employee Engagement: Employee satisfaction scores, safety incident rate, suggestion implementation rate, employee turnover rate.

- Waste Reduction: Reduction in transportation, inventory, motion, waiting, overproduction, over-processing, defects.

The chosen KPIs should be readily measurable, easily tracked, and directly linked to the goals of the Lean transformation. It’s crucial to establish baseline metrics before the initiative starts to accurately measure the progress and impact of the implemented changes.

Q 10. Explain the difference between Lean and Six Sigma methodologies.

While both Lean and Six Sigma aim to improve processes, they approach it differently:

- Lean focuses on eliminating waste (Muda) in all forms, aiming for maximum value with minimum effort. It emphasizes flow, continuous improvement (Kaizen), and empowering employees. Think of it as streamlining the process to make it faster and more efficient.

- Six Sigma focuses on reducing variation and defects in processes, aiming for near-perfection (six standard deviations from the mean). It utilizes statistical tools and methodologies to identify and eliminate sources of variation. It’s about improving consistency and precision.

Analogy: Imagine a car assembly line. Lean would focus on optimizing the flow of materials and workers to build cars faster and with less wasted motion. Six Sigma would focus on minimizing variations in car components to ensure consistent quality and reduce defects.

In practice, Lean and Six Sigma are often complementary. Lean provides the framework for streamlining and improving the overall flow, while Six Sigma offers the tools for eliminating defects and variations within that streamlined flow.

Q 11. How would you handle resistance to change during a Lean transformation?

Resistance to change is common during Lean transformations. Addressing it effectively requires a thoughtful and empathetic approach:

- Communication and Education: Clearly communicate the ‘why’ behind the Lean initiative, its benefits for the organization and individuals, and how it will impact different roles. Transparency builds trust and reduces anxieties.

- Involvement and Participation: Actively involve employees in the Lean transformation process. Solicit their input, ideas, and feedback. This fosters ownership and reduces resistance.

- Addressing Concerns: Identify and address employees’ specific concerns and anxieties openly and honestly. Provide training and support to help them adapt to new processes and skills.

- Celebrate Successes: Regularly celebrate small wins and acknowledge the contributions of employees. Positive reinforcement encourages further participation and strengthens buy-in.

- Leadership Commitment: Strong and visible leadership commitment is critical. Leaders need to champion the change and actively demonstrate their support for the initiative.

- Pilot Projects: Start with small pilot projects to demonstrate the effectiveness of Lean principles and build confidence before a full-scale implementation.

Remember, resistance isn’t necessarily negative; it often reflects valid concerns that need to be addressed. Handling resistance effectively requires active listening, empathy, and a commitment to collaboration.

Q 12. Describe your understanding of Poka-Yoke (error-proofing).

Poka-Yoke, also known as error-proofing, is a Lean manufacturing method designed to prevent defects from occurring in the first place. It focuses on designing processes and tools that make it difficult or impossible to make mistakes.

Examples:

- Shape-coding: Designing components with different shapes that only fit together in the correct orientation, preventing misassembly.

- Color-coding: Using different colors to indicate different sizes or types of components, reducing the risk of incorrect selection.

- Limit switches: Employing limit switches to prevent machines from operating outside their safe parameters, avoiding damage or injury.

- Checklists: Using checklists to guide workers through critical steps, reducing the probability of omission errors.

- Interlocks: Creating mechanical interlocks that prevent a machine from starting unless a previous step has been completed correctly.

Effective Poka-Yoke requires a deep understanding of the process and the potential points of failure. It’s a proactive approach to quality, moving from reactive defect detection to preventative defect prevention.

Q 13. What is the role of visual management in a Lean environment?

Visual management is a critical element of a Lean environment. It makes information readily available and easily understandable, allowing everyone to quickly grasp the current state of the process and identify potential problems.

Examples:

- Kanban boards: Visual representation of work flow, highlighting bottlenecks and progress.

- Andon lights: Visual signals indicating process problems that need immediate attention.

- Floor markings: Clearly defined pathways, work areas, and storage locations.

- Production charts: Visual displays of production targets, actual output, and key metrics.

- 5S implementation: Visual organization of the workplace, making it clean, orderly, and efficient.

Visual management improves communication, promotes teamwork, enhances problem-solving, and speeds up decision-making. By making information visible, it empowers all employees to contribute to continuous improvement.

Q 14. How do you prioritize improvement projects using Lean principles?

Prioritizing improvement projects within a Lean framework requires a systematic approach that considers both urgency and impact.

Commonly used methods include:

- Value Stream Mapping (VSM): This technique helps visualize the entire process, identifying bottlenecks and areas of waste that should be addressed first. This provides a data-driven approach to prioritization.

- Pareto Analysis (80/20 rule): This focuses on identifying the vital few problems that contribute to the majority of the issues (80% of problems stem from 20% of causes). This helps pinpoint the highest-impact areas for improvement.

- Prioritization Matrix (Urgency/Impact): This simple matrix allows for classifying improvement projects based on their urgency and potential impact. High-impact, high-urgency projects are tackled first.

- A3 problem-solving: A structured problem-solving approach that includes problem definition, root cause analysis, solution development, implementation planning, and outcome evaluation. Prioritization happens within the problem definition phase.

In addition to these methodologies, consider factors like resource availability, cost-benefit analysis, and alignment with strategic organizational goals when prioritizing projects. The goal is to focus efforts on those improvements that will yield the greatest impact with available resources.

Q 15. Explain your experience with root cause analysis techniques.

Root cause analysis (RCA) is crucial in Lean for identifying the underlying reasons behind problems, not just the symptoms. I’ve extensively used several techniques, including the 5 Whys, Fishbone diagrams (Ishikawa diagrams), and Fault Tree Analysis.

The 5 Whys is a simple yet effective method where you repeatedly ask ‘Why?’ to drill down to the root cause. For example, if a machine keeps malfunctioning, the 5 Whys might reveal a lack of preventative maintenance as the ultimate root cause.

Fishbone diagrams help visually organize potential causes categorized by factors like people, methods, machines, materials, environment, and measurement. This brainstorming approach encourages team participation and helps identify multiple contributing factors.

Fault Tree Analysis is more complex and suited for critical issues, mapping out potential failure points and their contributing causes. It’s especially helpful in identifying systemic issues that might be missed with simpler methods.

My experience shows that combining different RCA techniques often yields the most comprehensive results. I tailor my approach to the specific problem, considering the complexity and available data.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your experience with using A3 reports for problem-solving?

A3 reports are a powerful tool for structured problem-solving within Lean. They provide a concise, one-page summary of a problem, its analysis, proposed solutions, and implementation plan. I’ve used A3 reports extensively to document improvement projects, from initial problem definition to final results and ongoing monitoring.

The structure of an A3 report helps ensure clarity and focus. It typically includes sections for: Problem Statement, Current State, Target State, Root Cause Analysis, Proposed Solution, Implementation Plan, and Results. I find the visual nature of the A3 report, often incorporating charts and graphs, makes complex information easily digestible for stakeholders at all levels.

For example, in a previous project involving reducing production lead times, the A3 report clearly documented the bottleneck identified through value stream mapping, the proposed solution involving process re-engineering, the implementation timeline, and the quantifiable improvements achieved – a 20% reduction in lead time.

Q 17. How do you use data analysis to support Lean initiatives?

Data analysis is the backbone of effective Lean initiatives. It allows us to move beyond gut feelings and anecdotal evidence to make informed decisions based on facts. I leverage various statistical tools and techniques, including:

- Process capability analysis: To assess the consistency and predictability of processes.

- Statistical Process Control (SPC): To monitor processes, identify variations, and prevent defects.

- Value stream mapping data: To analyze lead times, cycle times, and inventory levels, pinpointing areas for improvement.

- Regression analysis: To identify correlations between variables and understand the impact of changes.

For instance, in a project aimed at reducing defect rates, we used control charts to track defect counts over time. This data revealed patterns and allowed us to identify specific process steps contributing to the defects. This data-driven approach ensured that improvement efforts were focused on the most impactful areas, leading to a significant reduction in defects and associated costs.

Q 18. Describe a time you successfully implemented a Lean improvement project.

In a previous role, we faced significant delays in order fulfillment. This impacted customer satisfaction and increased operational costs. Using Lean principles, I led a project to improve the order fulfillment process.

We started by mapping the current state value stream, revealing significant bottlenecks in the picking and packing stages. Using data analysis, we identified inefficiencies such as poorly organized storage, inadequate picking lists, and unnecessary movement of materials. We implemented several Kaizen events with the warehouse team to improve layout, optimize picking routes, and implement better labeling systems.

The results were impressive: order fulfillment times were reduced by 35%, and picking errors decreased by 40%. The project demonstrated the power of collaborative problem-solving, data-driven decision-making, and iterative improvement using Lean methodologies. This success was documented in an A3 report and shared across the organization to encourage similar improvement initiatives.

Q 19. What are your strengths and weaknesses in implementing Lean principles?

My strengths lie in my ability to facilitate collaborative problem-solving, analyze data effectively, and communicate complex concepts clearly. I’m adept at leading Kaizen events, implementing visual management systems, and driving continuous improvement across diverse teams.

My area for improvement is further developing my expertise in advanced statistical process control techniques and predictive modeling. While I have a solid understanding of these areas, I am actively seeking opportunities to enhance my skills and expand my knowledge base in these advanced statistical methods.

Q 20. How would you facilitate a Kaizen event?

Facilitating a Kaizen event involves structured planning and execution. I begin by clearly defining the scope and objectives, involving key stakeholders from the relevant areas. We then use value stream mapping to visualize the current state and identify areas for improvement.

The event itself is a collaborative workshop. I guide the team through brainstorming sessions, using techniques like 5 Whys and Fishbone diagrams to identify root causes. We then develop and prioritize solutions, focusing on quick wins and low-hanging fruit. Implementation plans are developed with clear responsibilities and timelines.

Throughout the event, I emphasize data collection and analysis to track progress and measure results. Post-Kaizen, I ensure the implemented changes are standardized and monitored to maintain the gains and prevent backsliding. The entire process is documented to share learnings and best practices.

Q 21. Explain your understanding of the Toyota Production System (TPS).

The Toyota Production System (TPS) is a lean manufacturing methodology that focuses on eliminating waste and maximizing value for the customer. It’s built on two core pillars:

- Just-in-time (JIT) production: Producing goods only when needed, minimizing inventory and waste.

- Jidoka (automation with a human touch): Building quality into the process through automation and empowering workers to stop the line when problems occur.

TPS employs several key tools and techniques, including Kanban, Poka-Yoke (error-proofing), and Kaizen. It emphasizes continuous improvement, respect for people, and a culture of problem-solving. I see TPS not just as a manufacturing system but as a philosophy that can be applied across various industries to improve efficiency, quality, and customer satisfaction.

Understanding TPS helps in identifying waste (muda) in all its forms: transportation, inventory, motion, waiting, overproduction, over-processing, and defects. By systematically eliminating waste, organizations can streamline their operations and achieve significant improvements in productivity and profitability.

Q 22. What is your experience with implementing Kanban systems?

Kanban is a visual system for managing workflow. It focuses on visualizing work, limiting work in progress (WIP), and improving flow. My experience involves implementing Kanban in several different contexts, from software development teams to manufacturing processes. In one instance, a software development team was struggling with late deliveries and inconsistent quality. We implemented a Kanban board, visually displaying tasks in various stages (To Do, In Progress, Testing, Done). We limited the WIP per stage, forcing the team to focus on completing tasks before starting new ones. This improved their focus, reduced context switching, and ultimately led to more on-time deliveries and higher quality code. We also used swimlanes to represent different features or types of work, providing a clearer picture of overall progress and potential bottlenecks.

Another example involved a manufacturing plant where Kanban was used to optimize the flow of materials. By visually representing the inventory levels of critical components and setting up a pull system, we were able to reduce waste in inventory, reduce lead times and improve the overall efficiency of the production line. Key to success in both cases was working closely with the teams to understand their specific challenges and tailoring the Kanban system to their needs. Regular reviews and adjustments were critical to adapt to changes and maintain the system’s effectiveness.

Q 23. Describe your understanding of Gemba walks.

Gemba walks are structured observations done on the actual work location or ‘Gemba’. They involve going to where the work is happening to understand the process firsthand. Instead of relying on reports or second-hand information, Gemba walks provide direct observation and interaction with the people performing the work. This allows for identification of bottlenecks, waste, and areas for improvement that might not be apparent through data alone.

For example, during a Gemba walk at a packaging facility, we observed that a significant amount of time was spent searching for specific tools. By simply reorganizing the tool storage area and implementing a 5S system (Sort, Set in Order, Shine, Standardize, Sustain), we dramatically reduced the time wasted searching, improved overall efficiency, and enhanced the morale of the packaging team by creating a safer, more organized workspace.

Effective Gemba walks involve asking targeted questions, actively listening to the team’s insights, and taking detailed notes. It’s crucial to approach the walk with a mindset of learning and collaboration, not as an inspection or audit. The insights gathered during Gemba walks directly inform improvements in processes and workflows.

Q 24. How do you ensure sustainability of Lean improvements after project completion?

Sustaining Lean improvements requires more than just implementing changes; it necessitates integrating Lean principles into the organizational culture. This involves several key strategies:

- Embedding Lean into daily routines: Regular Gemba walks, daily stand-ups, and visual management systems should be continued post-project. This ensures constant monitoring and improvement.

- Training and development: Teams need to be trained on Lean principles and empowered to identify and solve problems. Ongoing training helps maintain the knowledge and skills required for continuous improvement.

- Leadership support and commitment: Sustained success requires consistent commitment from leadership. Leaders must champion Lean and ensure its integration into performance management and incentive systems.

- Building a culture of continuous improvement: Establishing a culture where improvement is valued, encouraged, and rewarded is essential. This includes regular feedback loops, recognition of successful improvements, and creating a safe space for suggesting changes.

- Documentation and standardization: Clearly documenting improved processes and standardizing best practices prevents backsliding and ensures that knowledge is retained.

Without these elements, improvements may be temporary and ultimately unsustainable. For example, a successful Lean project focused on reducing cycle time is rendered useless if the supporting processes, such as training and visual management systems, are not maintained.

Q 25. What challenges have you faced in implementing Lean principles, and how did you overcome them?

One of the biggest challenges I’ve encountered was resistance to change. People are often comfortable with their existing ways of working, even if those ways are inefficient. To overcome this, I focused on building consensus and demonstrating the value of Lean through small, quick wins. By showing tangible improvements early on, I built trust and momentum, making subsequent changes easier to accept. I also involved the team throughout the process, ensuring their voices were heard and their concerns addressed. This participatory approach helped build ownership and commitment to the changes.

Another challenge was dealing with conflicting priorities. Lean projects often require significant time and resources, and competing demands can derail progress. To address this, I prioritized projects based on their potential impact and aligned them with overall business goals. Clear communication and effective project management were critical to managing expectations and ensuring resources were allocated effectively.

Q 26. Describe your experience with different Lean tools and techniques.

My experience encompasses a wide range of Lean tools and techniques. I’ve successfully utilized:

- Value Stream Mapping: To visualize and analyze the flow of materials and information, identify bottlenecks, and develop improvement plans.

- 5S: To organize workspaces, reduce waste, and improve efficiency.

- Kaizen Events: To conduct focused improvement projects involving teams working collaboratively to solve specific problems.

- Poka-Yoke (Mistake-Proofing): To design processes that prevent errors from occurring in the first place.

- Six Sigma: To reduce variation and improve quality in processes.

- Kanban (as discussed previously): To manage workflow and optimize throughput.

The selection of specific tools depends on the context and the specific challenges being addressed. Often, a combination of tools is most effective in achieving desired results.

Q 27. How do you stay current with the latest trends in Lean and continuous improvement?

Staying current in Lean requires a multi-faceted approach:

- Professional development: I regularly attend conferences, workshops, and seminars on Lean and continuous improvement. This allows me to learn about the latest trends and best practices from leading experts.

- Industry publications and journals: I actively follow industry publications and journals to stay updated on new research and innovations.

- Networking with peers: I participate in professional networks and communities to share knowledge and learn from other practitioners.

- Online resources: I leverage online resources such as reputable websites, blogs, and online courses to broaden my understanding of emerging topics.

- Case studies and real-world examples: I actively seek out and study case studies and real-world examples of successful Lean implementations to gain practical insights.

Continuous learning is essential to remain proficient in this ever-evolving field.

Key Topics to Learn for Lean Principles and Continuous Improvement Interviews

- Value Stream Mapping: Understand how to identify and analyze the flow of materials and information in a process, pinpoint bottlenecks, and propose improvements. Practical application: Analyze a real-world process (manufacturing, service, etc.) to identify waste and optimize efficiency.

- Waste Elimination (Muda): Master the seven (or eight) types of waste (Transportation, Inventory, Motion, Waiting, Overproduction, Over-processing, Defects, and potentially Underutilized Talent). Develop strategies for identifying and eliminating each type in diverse contexts.

- Kaizen & Continuous Improvement Methodology: Learn the principles of continuous improvement through small, incremental changes. Understand the PDCA cycle (Plan-Do-Check-Act) and its practical application in problem-solving.

- 5S Methodology: Explain the principles of 5S (Sort, Set in Order, Shine, Standardize, Sustain) and how it creates a more efficient and organized workplace. Be prepared to discuss practical implementation strategies and the benefits achieved.

- Lean Six Sigma: Understand the integration of Lean principles with Six Sigma methodologies for process improvement and defect reduction. This includes understanding DMAIC (Define, Measure, Analyze, Improve, Control).

- Problem-Solving Techniques: Be familiar with various problem-solving tools and techniques such as root cause analysis (e.g., Fishbone diagrams), Pareto charts, and A3 reporting. Practice applying these techniques to hypothetical scenarios.

- Kanban & Agile Principles: Understand the principles of visual workflow management and its applications within Lean environments. Discuss how Kanban and Agile principles support continuous improvement.

Next Steps

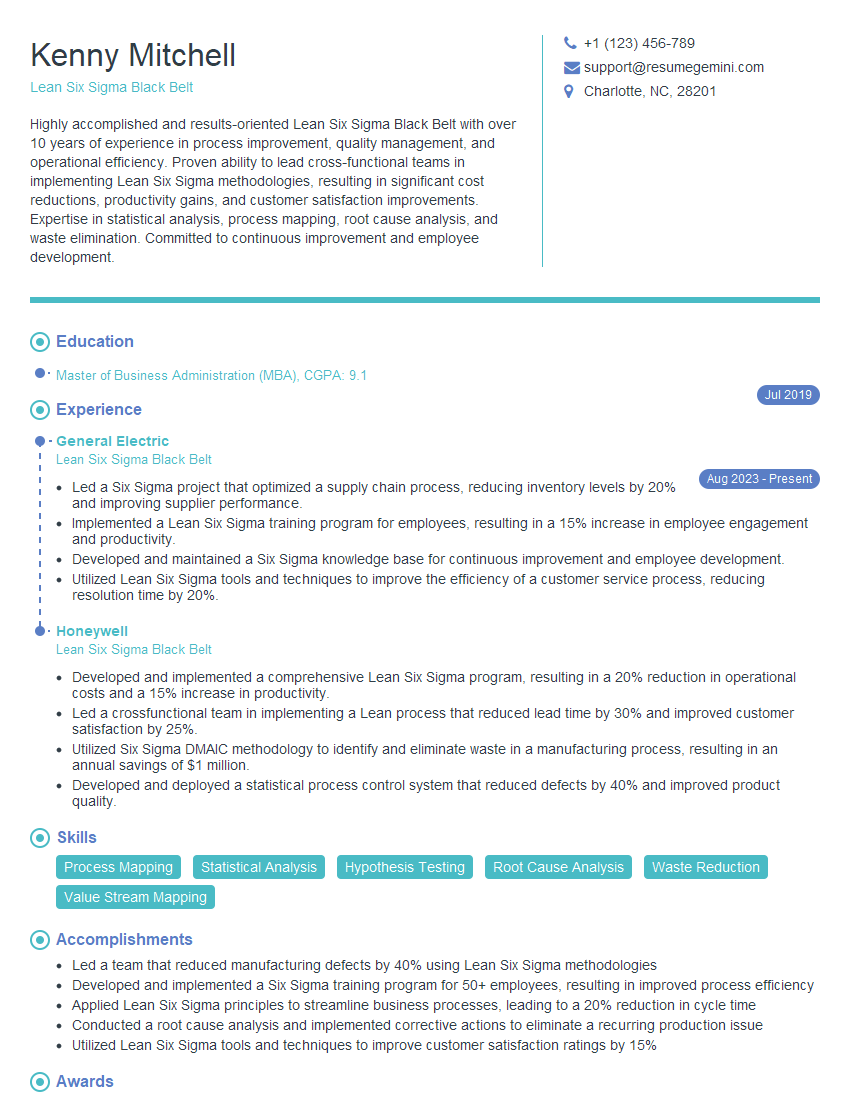

Mastering Lean Principles and Continuous Improvement significantly enhances your career prospects across various industries. It demonstrates your commitment to efficiency, problem-solving, and process optimization – highly valued skills in today’s competitive market. To maximize your job search success, it’s crucial to have an ATS-friendly resume that highlights these skills effectively. ResumeGemini is a trusted resource to help you build a powerful, professional resume that captures your experience and expertise in Lean and Continuous Improvement. Examples of resumes tailored to these principles are available to guide you. Take the next step and create a resume that showcases your qualifications to potential employers!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good