The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Press Operator Training interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Press Operator Training Interview

Q 1. Explain the setup and operation of a [specific type of press, e.g., Heidelberg Speedmaster] printing press.

Setting up and operating a Heidelberg Speedmaster, or any sheetfed offset press, is a multi-step process demanding precision and expertise. It begins with the pre-press stage, where the plates are made and checked for accuracy. Once the plates are ready, they are carefully mounted onto the press, ensuring correct orientation and registration. This involves using plate clamps and ensuring there’s no damage to the delicate plates. The next step is to prepare the paper stock. The paper needs to be correctly fed into the feeder, adjusting the side guides for the correct size and ensuring a smooth and consistent flow. The ink system needs careful attention; this includes adjusting the ink keys to achieve the desired color density and properly mixing the inks to achieve the target color profile. After this, we run a test print sheet to check for registration, color accuracy, and any mechanical issues. Adjustments to the dampening system, pressure, and ink feed are made until the test sheet perfectly matches the pre-press proof. Finally, once the test run meets the required standards, we begin the main print production run, maintaining close monitoring throughout the process to ensure print quality remains consistent.

For example, during one job, I encountered significant problems with paper jamming in the feeder. Through systematic troubleshooting, I identified the issue as being caused by static electricity build-up from the paper itself. To solve this, I adjusted the feeder settings, including the use of an anti-static device, to significantly reduce the jamming and keep the press running efficiently.

Q 2. Describe your experience with color matching and calibration on a printing press.

Color matching and calibration is crucial for achieving consistent and accurate print results. My experience involves using color measurement devices like spectrophotometers to measure the color of printed samples and compare them to the target color values specified in the job’s color profile. I use this data to make adjustments to the ink density, dot gain compensation, and color balance on the press, iteratively refining until the difference between the measured and target colors is minimal, usually within a specified Delta E tolerance. Calibration is an ongoing process, involving regular checks throughout a long run to account for fluctuations in paper, ink, and environmental conditions. For example, ink viscosity changes due to temperature variations necessitate fine-tuning ink keys to maintain consistent color.

In one particular instance, we were printing a high-end brochure with very specific Pantone colors. Slight variations in color occurred early in the run. Using a spectrophotometer, we precisely measured the color deviations and adjusted the ink keys accordingly, ensuring the final product met the client’s exacting standards.

Q 3. How do you identify and troubleshoot common printing press malfunctions?

Troubleshooting printing press malfunctions requires a systematic approach. I begin by identifying the symptom – such as blurry print, misregistration, or paper jams. Then, I systematically check different components, starting with the most likely causes. For example, blurry print might indicate issues with the dampening system, ink viscosity, or incorrect blanket cylinder pressure. Misregistration might stem from incorrect plate mounting or feeder issues. Paper jams can have various causes, from incorrect paper feed settings to damaged rollers or sensors. I utilize the press’s diagnostic tools and manuals to assist in the process. Using a logical troubleshooting process, I isolate the problem, and implement the necessary corrections—whether it’s cleaning a roller, adjusting settings, or replacing a worn part.

I once experienced a situation where the printed image exhibited a consistent horizontal streak. After checking various components, I found that a small piece of debris had become lodged in the inking system, which caused a localized lack of ink. By carefully removing the debris and cleaning the system, I restored perfect print quality.

Q 4. What safety procedures do you follow while operating a printing press?

Safety is paramount when operating a printing press. I always begin by conducting a thorough machine inspection before starting any work, checking for any loose parts or potential hazards. I never operate the press without proper personal protective equipment (PPE), including safety glasses, hearing protection, and closed-toe shoes. I follow the lock-out tag-out (LOTO) procedure diligently when performing maintenance or repairs, ensuring the machine is completely powered down and secured before accessing any moving parts. I am always aware of my surroundings and take precautions to prevent injury to myself and others. This includes maintaining a clean and organized workspace and promptly addressing any potential hazards.

I also adhere to all company safety regulations and participate regularly in safety training to stay updated on best practices and emergency procedures.

Q 5. What is your experience with different types of inks and their application?

My experience encompasses a wide range of inks, including conventional offset inks, UV inks, and vegetable-based inks. Each ink type has different properties and requires specific handling and application techniques. Conventional inks require careful adjustment of the dampening system to achieve the proper balance between ink and water, while UV inks require specialized curing systems. Vegetable-based inks are environmentally friendly but can sometimes present challenges in terms of drying and adhesion. I understand the importance of selecting the appropriate ink type based on the substrate (e.g., paper type, board, plastics), print quality requirements, and environmental considerations. I am also trained to handle and store inks safely, following all manufacturer’s recommendations and adhering to environmental regulations.

I recall a job that required using a specialized metallic ink. To ensure consistent and flawless results, I meticulously tested various ink dilutions to optimize its flow and achieve the desired print effect.

Q 6. How do you ensure consistent print quality throughout a long production run?

Maintaining consistent print quality during a long production run demands meticulous attention to detail and proactive problem-solving. Regular monitoring of the press is crucial—this includes continuously checking color accuracy using color measurement tools, verifying registration, and assessing the ink and dampening system’s performance. I also make adjustments as needed, based on my observations and data analysis. Regular maintenance of the press, including cleaning rollers and replacing worn parts, prevents issues that could impact print quality. By maintaining a consistent press speed and paper feed rate, I avoid irregularities in ink distribution and paper wrinkles or jams that can affect print consistency.

For instance, in a project involving a thousand-copy run, I implemented regular ink viscosity checks every 200 prints using a simple ink viscosity measurement tool. This allowed for preemptive adjustments preventing inconsistencies and maintaining uniform color throughout the whole run. This kind of proactive measure is key to quality control for longer print jobs.

Q 7. Describe your experience with pre-press processes and their impact on printing.

Pre-press processes, such as file preparation, color management, and plate making, significantly impact the final print quality. My understanding of these processes allows me to effectively diagnose print problems and collaborate with pre-press teams to optimize the workflow. Issues such as low resolution images, incorrect color profiles, and improper trapping can significantly affect the final print. By working closely with pre-press professionals, we ensure that the files are prepared correctly, color profiles are accurately matched, and plates are made to the highest standards. This collaborative approach avoids costly errors and ensures the final product meets the required specifications.

In one situation, poor image quality in the final print stemmed from a low-resolution image supplied by the client. Working with the pre-press team, we identified and addressed the issue early, re-supplying a higher resolution image, saving time and avoiding rework.

Q 8. Explain your understanding of different paper types and their suitability for various printing techniques.

Understanding paper types is crucial for a press operator. Different papers have varying weights, finishes, and compositions, impacting printability and final product quality. For example, coated papers, like glossy magazine stock, offer vibrant color reproduction ideal for high-impact images, but might not be suitable for offset printing requiring high ink absorption. Uncoated papers, such as newsprint, absorb ink readily, making them cost-effective for large-scale publications but less visually striking.

Choosing the right paper for a specific printing technique is key. Offset lithography thrives with coated papers due to their smooth surface, while screen printing can handle a broader range of papers, including thicker cardstock and textured materials. Digital printing often uses lighter-weight coated or uncoated papers, depending on the desired finish and print quality. The weight of the paper (measured in gsm – grams per square meter) directly influences the press settings; heavier paper requires adjustments to avoid paper jams or damage to the press.

- Coated Paper: Glossy, matte, or silk finish; excellent for color reproduction; used in magazines, brochures, and high-quality printing.

- Uncoated Paper: Absorbent; ideal for newsprint, books, and stationery; less vibrant color reproduction.

- Specialty Papers: Includes textured, metallic, or recycled papers, each requiring specific press adjustments.

Q 9. How do you maintain and clean a printing press to ensure optimal performance?

Maintaining a printing press is paramount for consistent performance and extends its lifespan. My routine involves daily cleaning, weekly thorough inspections, and regular scheduled maintenance. Daily cleaning focuses on removing ink and paper dust from rollers, blankets, and the feeding system. This prevents ink build-up, which can lead to smudging or color inconsistencies. Weekly inspections involve checking all moving parts for wear and tear, lubrication, and ensuring proper alignment. We check for any signs of damage to rollers, gears, or the printing plates themselves. Regular scheduled maintenance, often performed by qualified technicians, might include replacing worn rollers, calibrating the press, and adjusting precision settings for optimal registration and color accuracy.

Cleaning involves using appropriate solvents and cleaning agents specified by the manufacturer. Improper cleaning can damage the press components. For example, using abrasive cleaners on delicate rollers can cause scratches and affect printing quality. Detailed documentation of all maintenance activities is crucial for tracking performance and identifying potential problems before they significantly impact production.

Q 10. What is your experience with different printing plates and their preparation?

My experience encompasses various printing plates, including offset lithographic plates, flexographic plates, and digital plates. Each type requires specific preparation techniques. Offset lithographic plates, typically aluminum, need to be imaged using a plate-making machine. This process involves exposing the plate to ultraviolet (UV) light through a film negative, hardening the exposed areas and making them receptive to ink. The non-image areas are then treated to repel ink. This needs careful attention to ensure proper image reproduction and prevent defects like pinholes or scumming.

Flexographic plates, often polymer-based, are prepared through different processes, such as laser engraving or digital imaging, depending on the quality and complexity of the design. Digital plates, used in digital printing presses, require specific software and processes to prepare high-resolution print files. Preparing these plates correctly minimizes waste and ensures efficient and high-quality printing. A thorough understanding of each plate type and its preparation is vital for achieving optimal print results.

Q 11. How do you handle paper jams and other production stoppages?

Handling paper jams and production stoppages efficiently is a crucial skill for a press operator. The first step is to identify the cause of the stoppage. This often involves carefully observing the press’s behavior and reviewing any error messages displayed. Paper jams, for instance, can stem from humidity affecting the paper’s characteristics, incorrect paper feed settings, or misaligned rollers. A systematic approach is needed to address the problem.

For paper jams, I always follow safety procedures, turning off the press before accessing any jammed paper. Once the press is safely stopped, I carefully remove the jammed paper, ensuring no damage is caused to the press components. I then re-check the paper feed settings and the condition of the paper to prevent recurrence. Other stoppages, like ink flow issues or mechanical malfunctions, require more specialized troubleshooting, sometimes involving contacting maintenance personnel for assistance. Detailed records of each stoppage, including the cause, resolution, and time taken, are crucial for identifying trends and making improvements to press operation.

Q 12. Describe your experience with quality control checks during and after printing.

Quality control checks are integrated throughout the printing process, both during and after printing. During printing, regular checks ensure proper color registration, ink density, and image sharpness. This is accomplished by taking test prints at regular intervals and comparing them to color proofs or specified standards. I check for any inconsistencies, such as misaligned colors, light or dark areas, or blurring. The use of color measuring devices like densitometers helps provide objective and precise measurements for color accuracy. After printing, a final quality inspection is done to verify the overall print quality and detect any defects not previously identified. This typically includes checking for any printing errors such as smudging, scratches, or missing print elements.

Any discrepancies found are documented, and corrective actions are taken to ensure the consistent quality of the final product. These records are important for tracking the efficiency of quality control processes, and identifying any recurring problems. This commitment to quality control leads to efficient use of resources and ultimately minimizes waste and rework.

Q 13. What is your understanding of makeready and its importance in efficient press operation?

Makeready is the process of setting up the printing press for a particular job, including adjusting the press to accommodate the specific paper stock and printing requirements. This is a critical step that impacts efficiency and print quality. It involves several key steps: checking the printing plates for defects and ensuring correct alignment, setting up the ink fountain, adjusting the dampening system, and calibrating the press’s rollers and other mechanisms for optimum ink transfer. The proper makeready significantly minimizes waste and ensures the press runs smoothly and efficiently, reducing downtime.

For example, if the makeready process misses critical steps like precise plate alignment, it may lead to incorrect image registration, requiring the re-run of a considerable amount of printed sheets. A well-executed makeready not only saves time but also ensures a consistent print quality throughout the production run, reducing the chances of errors and costly waste.

Q 14. How do you interpret and follow production schedules and instructions?

Interpreting and following production schedules and instructions is essential for efficient press operation. I’m proficient in reading and understanding production schedules, including job specifications, deadlines, and quantities. This allows me to prioritize tasks, plan my workflow accordingly, and ensure timely completion of all printing jobs. The instructions often include detailed information on paper type, ink colors, printing speed, and quality control parameters. This information is crucial for setting up the press correctly and efficiently. Understanding these instructions is crucial to minimize errors and ensure the final product meets the client’s specifications.

I consistently communicate with the production team regarding any potential delays or issues that might arise during the printing process. Any deviation from the schedule is documented and communicated promptly to keep everyone informed. This proactive approach to managing schedules and instructions keeps the production process efficient and minimizes potential disruptions.

Q 15. What is your experience with different types of printing finishes (e.g., lamination, coating)?

My experience encompasses a wide range of printing finishes, crucial for enhancing the final product’s visual appeal and durability. I’m proficient in both aqueous and UV coatings, understanding their distinct properties and applications. Aqueous coatings offer a softer, less glossy finish, ideal for brochures or books where a subtle sheen is desired. UV coatings, on the other hand, provide a much harder, glossier finish, offering superior protection against scratches and scuffs, perfect for packaging or high-end marketing materials.

Lamination is another key finishing technique I’ve mastered. I’m experienced with both gloss and matte lamination films, selecting the appropriate film based on the substrate and desired aesthetic. For instance, a matte lamination might be chosen for a business card to avoid glare, while gloss lamination might enhance the vibrancy of a product catalog. Beyond gloss and matte, I also have experience with specialty laminates, including those with textured surfaces or enhanced tactile properties.

My expertise extends to understanding the interplay between different finishes. For example, I know when combining a UV coating with lamination could improve scratch resistance, or when a simple aqueous coating is sufficient to meet the client’s needs. This careful consideration ensures the optimal balance between visual appeal, durability, and cost-effectiveness.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your experience with waste reduction strategies in a printing environment.

Waste reduction is paramount in a printing environment, both for environmental and economic reasons. My approach is multifaceted, starting with meticulous pre-press planning. This involves careful job estimation, ensuring accurate calculations of materials needed to minimize overruns. I also leverage digital proofing to catch errors before they reach the press, drastically reducing material waste from print mishaps.

On the press itself, I maintain vigilant monitoring of paper feed, ink consumption, and waste output. I regularly inspect the press for any mechanical issues that might contribute to waste. For example, a slightly misaligned roller can cause significant paper waste, so regular preventative maintenance is crucial. Furthermore, I actively participate in implementing and improving our company’s waste management procedures, including the proper sorting and recycling of waste materials.

Beyond the technical aspects, I foster a culture of waste awareness among colleagues. This involves encouraging everyone to carefully review print jobs, adhere to best practices, and report any potential sources of waste immediately. This collective responsibility significantly contributes to our overall waste reduction goals. For example, I’ve successfully led initiatives to reduce paper waste by 15% through a combination of improved job planning and operator training.

Q 17. How do you perform basic press maintenance tasks (e.g., changing rollers, cleaning blankets)?

Basic press maintenance is a critical part of my daily routine and ensures smooth, efficient operation. Changing rollers is a standard procedure I perform regularly, ensuring the proper alignment and tension for optimal print quality. This involves carefully removing the old roller, inspecting its condition for wear, and securely installing the new roller. I always adhere to the manufacturer’s specifications and safety guidelines during this process.

Cleaning blankets is equally important. I use specialized cleaning solutions and tools to remove ink, debris, and dust from the blankets, maintaining their integrity and ensuring consistent print quality. The process involves gentle scrubbing to avoid damage and thorough rinsing to prevent residue build-up. I carefully inspect the blankets for any signs of wear or damage and replace them as necessary. I also maintain detailed logs of all maintenance activities, assisting in preventative maintenance and identifying potential problems early on.

Beyond rollers and blankets, I’m also capable of performing other basic maintenance tasks, such as lubricating moving parts, checking ink supply levels, and cleaning the press components regularly. Regular preventative maintenance helps prevent major breakdowns and downtime, ensuring the press runs efficiently and effectively.

Q 18. Describe your experience with troubleshooting and repairing minor press malfunctions.

Troubleshooting and repairing minor press malfunctions is a key skill I’ve honed over years of experience. I approach these situations systematically, starting with a thorough assessment of the problem. This often involves checking error messages, inspecting the press for visible issues, and listening carefully for unusual sounds. I use a combination of my experience and the press’s manual to identify the source of the problem.

For example, if the print is blurry, I would first check the rollers for proper alignment, then the ink supply, and finally the blanket condition. If there’s a paper jam, I carefully assess the cause, remove the jammed paper, and check the paper path for any obstructions. I’ve resolved many issues ranging from simple paper jams to minor mechanical adjustments. However, for more complex malfunctions, I know when to escalate the issue to experienced technicians to avoid further damage to the equipment.

My methodical approach to troubleshooting minimizes downtime and keeps the press running effectively. I maintain detailed records of all malfunctions and their resolutions, facilitating knowledge sharing and preventative maintenance within the team. This problem-solving approach is not only efficient but also essential for cost savings and operational effectiveness.

Q 19. What is your experience with different types of printing substrates (e.g., paper, cardstock, film)?

I have extensive experience working with a variety of printing substrates, each requiring a slightly different approach for optimal results. Paper substrates range from lightweight newsprint to heavy cardstock, each with unique properties affecting ink absorption and printing quality. I understand the characteristics of various paper finishes, such as coated, uncoated, and textured papers, and select the appropriate settings for each.

Cardstock, with its higher thickness and density, demands different settings to prevent jams and ensure proper feeding. I’m experienced in working with various weights and finishes of cardstock, adjusting press settings to avoid damage and achieve optimal print quality. Film substrates, such as vinyl or polyester, require specialized handling and press configurations to ensure accurate and consistent printing.

My understanding extends to the characteristics of various substrates, and I adapt my procedures accordingly. For instance, I know that coated papers require less ink than uncoated papers to achieve the same color intensity. I also account for the potential for stretching or curling in certain substrates, adjusting the press settings to compensate and ensure accurate registration.

Q 20. How do you ensure accurate registration and alignment of printed images?

Accurate registration and alignment are crucial for high-quality printing. I achieve this through a combination of careful pre-press preparation, precise press setup, and ongoing monitoring during the printing process. Pre-press includes ensuring accurate imposition of the artwork, checking for correct color profiles, and verifying the overall layout.

On the press, I meticulously align the plates or cylinders using the press’s registration marks. I continuously monitor print output, making small adjustments as needed to maintain accurate registration throughout the run. The process involves subtle adjustments to the feed rollers and plate positioning to ensure all colors align perfectly. I use a variety of tools, including magnifying glasses and registration gauges, to ensure accuracy down to the smallest detail.

My experience also includes understanding the factors that can affect registration, such as paper stretch, temperature fluctuations, and press wear. I’m adept at adjusting settings and taking preventative steps to mitigate these factors and ensure consistent, accurate registration throughout a printing job, resulting in a professional and high-quality final product.

Q 21. Describe your experience with using different types of printing software (e.g., RIP software).

My experience includes working with various RIP (Raster Image Processor) software packages, essential for converting digital files into a format suitable for printing. I’m familiar with the functions of a RIP, such as color management, halftoning, and image scaling. I understand how to adjust settings to optimize image quality for different substrates and printing techniques. For example, I know how to adjust color profiles to compensate for variations in paper absorption, ensuring consistent color reproduction across the entire print job.

I can effectively manage color profiles, ensuring accurate color reproduction across different substrates and printing methods. I understand the importance of correctly setting halftone screens and dot gain compensation to achieve optimal results. I also have experience troubleshooting RIP software issues, diagnosing problems related to color accuracy, image resolution, and file handling.

My proficiency in RIP software allows me to efficiently prepare jobs for printing, ensuring optimal output and minimizing errors. This includes optimizing the settings based on the specific requirements of the printing job, ensuring that the final product matches the client’s expectations, and troubleshooting any issues that may arise during the process. This is crucial for efficient workflow and top-quality results.

Q 22. How do you manage and prioritize multiple tasks simultaneously in a fast-paced printing environment?

In a fast-paced printing environment, effective task prioritization is crucial. I use a combination of techniques, including time management matrices (like Eisenhower’s Urgent/Important matrix) and visual aids like Kanban boards to manage multiple tasks. This helps me categorize tasks by urgency and importance, allowing me to focus on high-priority jobs first. For example, if a rush order for a client’s important marketing materials comes in, that takes precedence over a routine job. I break down larger tasks into smaller, manageable steps and use checklists to ensure nothing is overlooked. Regular communication with team members is essential; I proactively inform them of my workload and any potential delays, enabling us to collaborate effectively and ensure smooth workflow.

Imagine a scenario where we have three jobs: a large magazine print run, a small business card order, and a rush order of brochures. Using a matrix, the brochure order (urgent and important) is tackled immediately, the magazine run (important but less urgent) is scheduled efficiently, and the business cards (less urgent) are slotted in during downtime. This allows for maximum efficiency and minimal disruption.

Q 23. Explain your understanding of the importance of following safety regulations in a printing press operation.

Safety regulations in a printing press operation are paramount. Ignoring them can lead to serious injuries or even fatalities. My understanding encompasses a wide range of regulations, from proper machine guarding and lockout/tagout procedures to the use of personal protective equipment (PPE) such as safety glasses, gloves, and hearing protection. I’m familiar with the importance of regular machine inspections, understanding warning signs, and knowing emergency shutdown procedures. I consistently lead by example, reinforcing safety rules with my colleagues and reporting any hazards immediately. For instance, I would never bypass a safety guard on a machine, even if it seems like a minor inconvenience; the potential consequences far outweigh any time saved. I’ve participated in safety training and regularly review safety protocols to ensure my knowledge remains current.

Q 24. Describe your experience with documenting press operations and maintaining accurate records.

Accurate record-keeping is integral to efficient press operations. I’m experienced in documenting all aspects of a printing job, from initial setup and material usage to printing parameters (like ink density, speed, and pressure), and final quality checks. This usually involves maintaining detailed logs in both physical and digital formats – I’m proficient with various software for this purpose. These records are vital for tracking productivity, identifying potential problems, maintaining quality control, and resolving discrepancies. For example, meticulously recording the ink used for a particular run helps us reproduce the same color accurately for future orders, avoiding costly reprints. I also use this documentation to prepare reports on job performance, providing valuable insights into efficiency and areas for improvement. Clear and concise record keeping ensures accountability and traceability.

Q 25. What is your experience with using measuring tools and instruments to ensure printing accuracy?

Precise measuring is essential to ensure printing accuracy. I’m highly proficient in using various tools including micrometers, calipers, and colorimeters to measure dimensions, ink density, and color consistency. I understand how to interpret these measurements and make adjustments to the press settings accordingly to meet the required specifications. For instance, using a micrometer to accurately measure the thickness of paper ensures proper feeding and registration, and preventing paper jams. Colorimeters are crucial for maintaining color consistency throughout the print run, ensuring the final product matches the client’s expectations. I am also familiar with various software and digital measurement tools, further enhancing my accuracy and efficiency.

Q 26. How do you handle difficult situations or conflicts with colleagues in a pressroom environment?

Conflicts are inevitable in any team environment. My approach involves open and honest communication. I strive to understand the other person’s perspective before expressing my own, focusing on the issue, not the person. If a conflict arises, I attempt to resolve it through calm and respectful discussion. If a resolution can’t be reached through direct communication, I seek the help of a supervisor or team leader to mediate. For instance, if a disagreement occurs about the best way to complete a task, I’d first listen to the other person’s reasoning, explain my perspective, and work collaboratively towards a solution that benefits the team. The goal is always to maintain a positive and productive working relationship.

Q 27. Describe your problem-solving approach when faced with unexpected issues during press operation.

My problem-solving approach is systematic. When faced with unexpected issues, I follow a structured process. First, I identify and define the problem clearly. Next, I gather information – inspecting the machine, reviewing logs, and consulting with colleagues. Then, I generate potential solutions, considering their feasibility and potential consequences. I then test and implement the chosen solution, carefully monitoring the results. Finally, I document the problem, the solution, and the outcome for future reference. For example, if a print job is producing misaligned images, I systematically check factors like paper feed, registration, and plate alignment, eliminating possibilities one by one until I find the root cause. This method ensures effective troubleshooting and prevents similar issues from recurring.

Key Topics to Learn for Press Operator Training Interview

- Understanding Press Operation Principles: Grasp the fundamental mechanics of various printing presses, including setup, operation, and maintenance procedures. This includes understanding different printing techniques and their applications.

- Practical Application: Be prepared to discuss your experience (if any) with specific press types, such as offset, digital, or flexographic presses. Highlight your ability to troubleshoot common printing issues and perform routine maintenance tasks.

- Safety Procedures and Regulations: Demonstrate a thorough understanding of safety protocols within a printing press environment. This includes proper handling of materials, machinery operation, and emergency procedures.

- Quality Control and Inspection: Explain your knowledge of quality control measures, including color matching, ink consistency, and identifying defects in printed materials. Discuss your ability to ensure consistent output and meet production deadlines.

- Production Processes and Workflow: Showcase your understanding of the entire printing process, from job setup and pre-press preparation to final product inspection and delivery. Discuss optimizing workflow efficiency and minimizing downtime.

- Troubleshooting and Problem-Solving: Be ready to describe your approach to identifying and resolving technical issues encountered during press operation. This includes utilizing troubleshooting guides and collaborating with team members.

- Material Handling and Inventory Management: Demonstrate your understanding of proper material handling techniques, including paper stock management, ink storage, and waste disposal procedures.

Next Steps

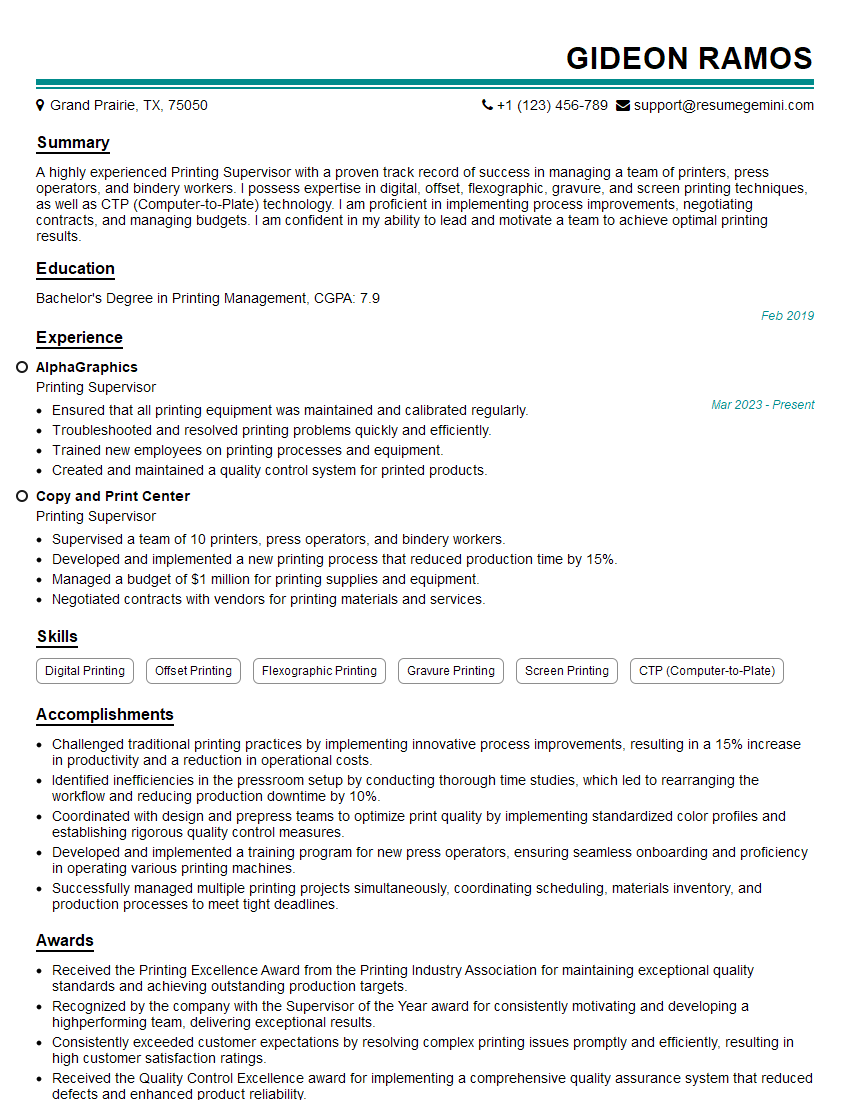

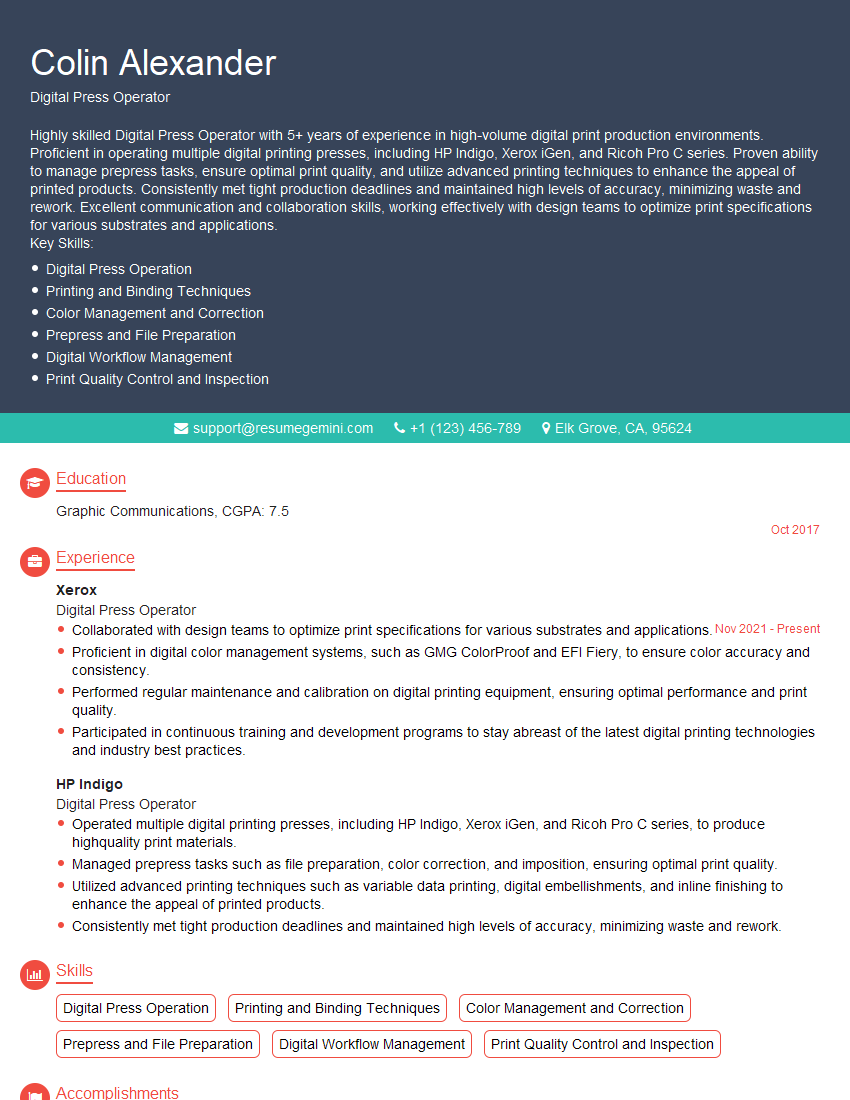

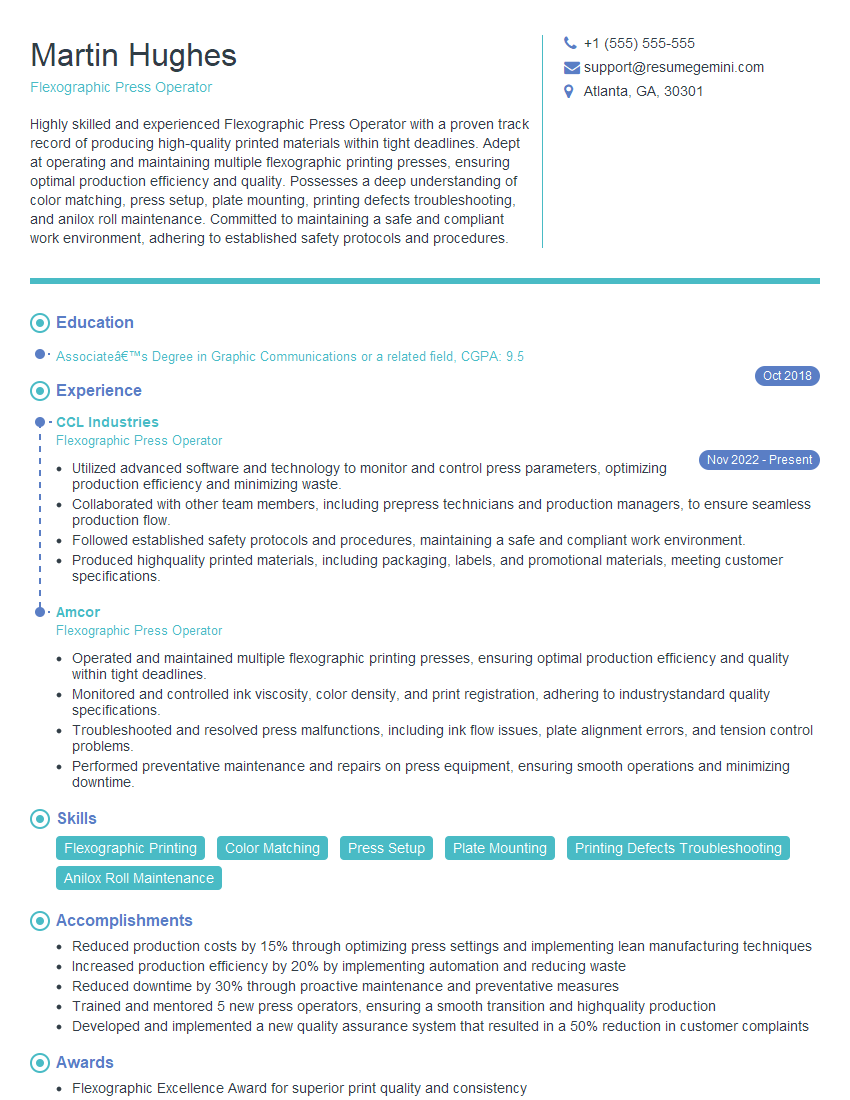

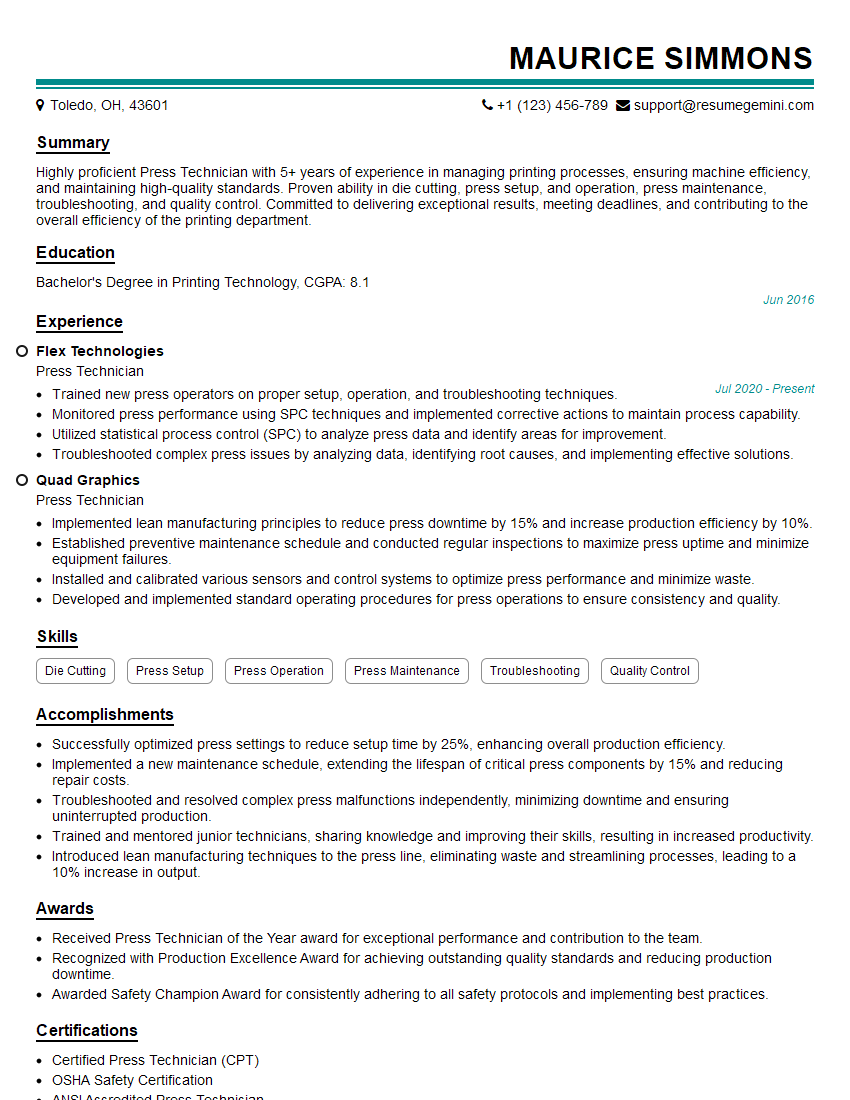

Mastering Press Operator Training opens doors to a rewarding career with excellent growth potential in a dynamic industry. To maximize your job prospects, it’s crucial to create a compelling and ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional resume that stands out. We provide examples of resumes tailored to Press Operator Training to guide you. Take the next step towards your dream job by crafting a strong resume that showcases your capabilities and secures your interview!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good