Preparation is the key to success in any interview. In this post, we’ll explore crucial Survey Equipment Handling interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Survey Equipment Handling Interview

Q 1. Describe your experience with different types of total stations.

My experience with total stations spans over a decade, encompassing various models from leading manufacturers like Leica, Trimble, and Topcon. I’ve worked extensively with both robotic and conventional total stations, handling instruments ranging from basic models suitable for smaller-scale projects to high-precision instruments used in demanding applications like deformation monitoring and precise engineering surveys. This experience includes using different functionalities such as distance measurement, angle measurement, data logging, and various data processing techniques. For instance, I’ve used robotic total stations to significantly speed up data acquisition on large construction sites, while utilizing the high-accuracy capabilities of other models for precise cadastral surveys. I am also familiar with different interfaces and software associated with these instruments.

Q 2. Explain the process of setting up and leveling a total station.

Setting up and leveling a total station is crucial for accurate measurements. It’s a methodical process that begins with establishing a stable base. I typically use a tripod with sturdy legs, ensuring it’s firmly planted on the ground and centered over the survey point. Then, I carefully level the instrument using the built-in circular bubble level, adjusting the tripod legs until the bubble is centered. Once the instrument is roughly leveled, I use the finer adjustment screws on the instrument itself to precisely center the bubble, ensuring the instrument is perfectly plumb. This is crucial for avoiding vertical angle errors which will propagate through all subsequent measurements. After leveling, I orient the total station using known survey points or by setting up a control network which allows me to reference all future measurements to this known orientation.

Q 3. How do you ensure accurate data collection using a total station?

Accurate data collection with a total station hinges on several key steps. Firstly, proper instrument setup and leveling, as described previously, is paramount. Secondly, I always perform instrument calibration checks before and after surveys to minimize systematic errors. This includes checking the collimation and zenith angle. Then, accurate targeting is crucial. I use high-visibility prisms or reflectors and ensure they are correctly centered over the points being measured. Careful observation of the instrument display, monitoring the readings for stability and consistency, is also important. Multiple readings are taken and compared to ensure consistency, and any outliers are investigated. Proper data logging and management is also crucial, to prevent accidental data loss or errors in transcription. Finally, regular maintenance of the instrument, including cleaning of the lenses and checking for any damage, helps maintain accuracy.

Q 4. What are the common sources of error in total station surveying and how do you mitigate them?

Several factors can introduce errors into total station surveys. Instrument errors, such as collimation errors (misalignment of the telescope) and errors in the instrument constants, can be mitigated through calibration and regular maintenance. Atmospheric conditions, like temperature and pressure, can affect distance measurements, and these effects can be minimized using atmospheric correction models included in most modern total stations. Errors in prism centering or reflector placement lead to significant errors in measurements, which can be minimized through careful aiming and the use of properly centered prisms. Finally, human errors in reading the instrument, recording data, or setting up the instrument can also lead to mistakes; careful attention to detail and double-checking are important to reduce human error. I use quality assurance checks, such as comparing measurements from different setups, to identify and correct these errors.

Q 5. Describe your experience with GPS surveying equipment.

My experience with GPS surveying equipment encompasses both handheld and geodetic receivers, working with various satellite constellations including GPS, GLONASS, Galileo, and BeiDou. I’ve utilized GPS technology for a range of applications, from basic topographic surveys to precise geodetic control establishment and precise point positioning. I’m proficient in using both RTK (Real-Time Kinematic) and static GPS techniques, understanding the strengths and limitations of each method. For example, I’ve used RTK GPS for rapid mapping of large areas and static GPS for highly accurate baseline measurements in geodetic control networks. My experience extends to post-processing data using various software packages, ensuring the accuracy and reliability of the results.

Q 6. Explain the difference between RTK and static GPS surveying.

RTK and static GPS are both precise positioning techniques, but differ significantly in their methodology and applications. RTK GPS provides real-time centimeter-level accuracy by comparing data from a base station with a rover receiver. This makes it ideal for rapid surveys needing immediate results, such as construction layout or topographic mapping. However, it requires a continuous line of sight to the base station. Static GPS, on the other hand, involves collecting data over an extended period, typically several hours, to achieve millimeter-level accuracy. While significantly slower, it can operate across longer distances and does not require a constant line of sight. Post-processing of the collected data is required, using precise ephemeris and atmospheric models. Static GPS is often used for establishing control networks and high-precision geodetic surveys where the highest accuracy is needed.

Q 7. How do you handle GPS signal loss or interference during a survey?

GPS signal loss or interference is a common challenge in surveying. Strategies to mitigate this include choosing optimal survey times and locations to minimize obstructions, such as buildings or dense tree cover. The use of multiple receivers or antenna configurations can help improve signal reception and redundancy. When signal loss occurs, I immediately note the time and location of the interruption in my field notes. If the loss is short and intermittent, I can sometimes recover the signal and continue. In case of prolonged loss or severe interference, I will choose an alternate surveying method or revisit the site at a more favorable time. Careful planning, including site reconnaissance before the survey, helps to minimize the impact of signal loss or interference.

Q 8. What are the advantages and disadvantages of using GPS surveying compared to total station surveying?

GPS surveying and total station surveying both offer precise measurement capabilities, but they differ significantly in their methodologies and applications. GPS, or Global Positioning System, relies on satellite signals to determine coordinates, while total stations use a combination of electronic distance measurement (EDM) and angles to calculate distances and positions.

- GPS Advantages: GPS is incredibly efficient for large-scale projects covering extensive areas. Its speed and ability to work in challenging terrain make it ideal for tasks like topographic surveys or control network establishment. It requires fewer personnel compared to total stations, resulting in lower labor costs. Furthermore, GPS data can often be integrated directly into GIS systems.

- GPS Disadvantages: GPS accuracy can be affected by atmospheric conditions, satellite geometry (signal blockage from buildings or foliage), and multipath errors (signal reflections). Obtaining highly precise measurements requires post-processing techniques, which involve specialized software and time. GPS also struggles with precise measurements in areas with limited satellite visibility, like dense forests or urban canyons.

- Total Station Advantages: Total stations provide highly accurate measurements over shorter distances, making them excellent for detailed surveys like construction layout or cadastral surveys. They’re less susceptible to atmospheric and multipath errors than GPS. The immediate display of measurements reduces reliance on post-processing.

- Total Station Disadvantages: Total stations are more time-consuming and labor-intensive, particularly for large projects. Line of sight between the instrument and target is essential, limiting use in obstructed environments. They’re also more expensive to maintain than GPS systems.

In essence, the choice between GPS and total station surveying depends heavily on the project’s scale, required accuracy, budget, and environmental conditions. Often, a hybrid approach utilizing both technologies provides the best results.

Q 9. Describe your experience with leveling instruments.

My experience with leveling instruments spans over 15 years, encompassing various models from Leica, Sokkia, and Topcon. I’ve utilized these instruments extensively in construction layout, road surveys, and boundary establishment. My expertise includes not only the operation of the instruments but also their maintenance, calibration, and troubleshooting. I am proficient in identifying and mitigating systematic and random errors associated with leveling, ensuring the highest level of accuracy in all projects. I’ve trained numerous junior surveyors in proper leveling techniques, emphasizing the importance of meticulous procedures to achieve reliable results. I’m also familiar with the use of digital levels and their integration with data collectors for increased efficiency.

Q 10. Explain the process of setting up and leveling a level.

Setting up and leveling a level is a crucial first step in any leveling survey. The process involves these steps:

- Establish a suitable location: Choose a stable, level base for the instrument, ensuring it’s free from vibrations and obstructions. A tripod is typically used.

- Rough leveling: Extend the tripod legs to approximately the desired height. Use your eyesight to ensure the instrument is roughly level.

- Precise leveling: Using the leveling screws on the instrument’s base, carefully adjust until the circular bubble in the built-in level is perfectly centered. This is often done by systematically adjusting one screw at a time while observing the bubble’s movement.

- Fine adjustment: Once the circular bubble is centered, check the level’s accuracy using the built-in level’s adjustment screws. Repeat as needed to achieve perfect centering.

- Verification: Rotate the instrument 180 degrees to re-check the leveling. If the bubble drifts off-center, re-level using the leveling screws. This iterative process guarantees a precise level setup.

The process might sound simple, but precision is key; any misalignment introduces error into the survey data.

Q 11. How do you calculate elevations using a level?

Elevations are calculated using a level through a process called differential leveling. The height difference between two points is determined by measuring the difference in rod readings. This is done by:

- Backsight (BS): Taking a rod reading on a point of known elevation (a benchmark or previously established point).

- Foresight (FS): Taking a rod reading on the point whose elevation needs to be determined.

- Height of Instrument (HI): Calculating the HI by adding the BS reading to the known elevation of the benchmark:

HI = Benchmark Elevation + BS. - Elevation of the new point: Subtracting the FS reading from the HI to obtain the elevation of the new point:

Elevation = HI - FS.

For example, if a benchmark has an elevation of 100.00 meters, and the BS reading is 1.50 meters, then the HI is 101.50 meters. If the FS reading on the new point is 2.00 meters, then the elevation of the new point is 101.50 – 2.00 = 99.50 meters.

Q 12. What are the common sources of error in leveling and how do you correct them?

Several sources of error can affect leveling accuracy. These include:

- Instrument maladjustment: An improperly leveled instrument or a faulty level vial introduces significant errors. Regular calibration and careful leveling procedures are essential to mitigate this.

- Rod errors: Damage, wear, or improper graduation on the leveling rod can lead to inaccurate readings. Regular inspection and maintenance of leveling rods are crucial.

- Target misreading: Incorrect reading of the leveling rod by the surveyor introduces errors. Precise reading techniques and double-checking readings are essential.

- Refraction and curvature of the earth: These factors affect the path of light, causing small errors in long sights. These are usually negligible in short distances but need careful consideration on long lines.

- Settlement: Movement or settlement of the instrument or rod during measurement can result in errors. Choosing stable locations is crucial and observing for any shifting during measurement is important.

To correct these errors, meticulous procedures are essential. These include regular instrument calibration, careful rod handling, double-checking readings, using shorter sight distances where possible, and performing careful leveling checks. Furthermore, understanding the systematic errors introduced by refraction and curvature allows the surveyor to adjust for those effects in long lines using appropriate formulas.

Q 13. What is the difference between precise leveling and differential leveling?

Both precise leveling and differential leveling are used to determine elevations, but they differ in their accuracy and application:

- Differential Leveling: This is the most common leveling technique, used for establishing elevations across relatively short distances. It involves a series of backsights and foresights along a level line. The method is suitable for various applications, including construction layout and topographic surveys. Accuracy is typically within a few millimeters.

- Precise Leveling: Precise leveling is used to obtain highly accurate elevation differences over longer distances and is employed in high-precision engineering surveys, such as dam construction or deformation monitoring. It involves stringent procedures to minimize errors, including shorter sight distances, more frequent benchmarks, and careful temperature corrections. Accuracies in precise leveling are usually in the sub-millimeter range.

The key difference is the level of accuracy required and the implementation of strict procedures to minimize error sources in precise leveling. Differential leveling is adequate for many surveying tasks, but precise leveling is reserved for applications where extremely high accuracy is paramount.

Q 14. Explain your experience with data collectors and field software.

I possess extensive experience with various data collectors and field software, including Leica CS20, Topcon FC-5000, and Trimble TSC7. My experience includes data input, data processing, and report generation. I am proficient in using various software packages, including Trimble Business Center, Leica Geo Office, and Carlson Survey. I have experience using these systems for tasks such as:

- Data Acquisition: Recording survey measurements directly into data collectors, enhancing efficiency and minimizing errors during field work.

- Data Management: Organizing and managing survey data using field software, and transferring it to office software for further processing.

- Data Processing: Applying coordinate transformations, performing calculations, and creating detailed survey drawings.

- Report Generation: Preparing comprehensive reports and deliverables, including drawings, tables and summaries that integrate field data.

I’m also familiar with different file formats used in surveying (e.g., DXF, LandXML) and the best practices for data exchange between field and office software. Moreover, I am adept at troubleshooting software and hardware issues that can occur in the field, maximizing productivity.

Q 15. How do you ensure data integrity during a survey?

Ensuring data integrity in surveying is paramount; it’s like building a house on a solid foundation. A single flawed measurement can throw off the entire project. My approach is multifaceted and starts even before data collection begins.

- Pre-Survey Planning: This includes meticulously planning the survey’s scope, defining clear objectives, and selecting appropriate equipment and techniques. For example, if we’re dealing with a highly precise engineering survey, we’d use high-accuracy GPS equipment and implement rigorous quality control checks at every stage.

- Calibration and Maintenance: All equipment, from total stations to GPS receivers, is meticulously calibrated and regularly maintained according to manufacturer specifications. Imagine a carpenter using a warped ruler – the results wouldn’t be accurate! We maintain detailed logs of calibration and maintenance to ensure traceability.

- Field Procedures: During fieldwork, we adhere to strict protocols for data recording and handling. This involves double-checking measurements, using redundancy techniques (multiple measurements of the same point), and immediately flagging any anomalies. A simple example is having two surveyors independently measure a distance and comparing notes.

- Data Backup and Storage: Data is backed up regularly to multiple locations to prevent data loss. We use secure cloud storage and maintain local copies on encrypted hard drives.

By following these steps, I ensure the data collected is accurate, reliable, and trustworthy.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with data processing and quality control.

My experience in data processing and quality control spans over 10 years, encompassing various projects ranging from small-scale topographic surveys to large-scale engineering and construction projects. I am proficient in utilizing industry-standard software for data processing and manipulation.

My quality control process begins with a thorough review of the raw field data. This involves checking for outliers, inconsistencies, and gross errors. Next, I utilize software to perform various checks:

- Coordinate Geometry Checks: I verify the geometric relationships between points using coordinate geometry principles. For example, I check the closure of a traverse to ensure the measured distances and angles are consistent.

- Statistical Analysis: I use statistical methods to identify outliers and assess the precision of the measurements. This often involves calculating standard deviations and error ellipses.

- Graphical Review: Visual inspection of the data in various formats (e.g., maps, profiles) helps to identify inconsistencies or errors that might be missed by numerical checks.

If any errors are found, a rigorous investigation is carried out to determine the source of the error and correct it accordingly. This process ensures the final data is accurate, consistent, and reliable.

Q 17. How do you perform data checks and identify potential errors?

Data checks are crucial for identifying potential errors, ensuring accurate results and minimizing project risks. It’s like proofreading a critical document – you want to catch any mistakes before they become major issues.

- Initial Data Checks: As soon as data is downloaded from the instruments, I perform basic checks for missing values, unexpected values, and any obvious inconsistencies. For instance, a negative elevation reading in a topographic survey is an obvious error that needs immediate attention.

- Data Validation: I use software routines to check for range errors (e.g., elevations that are outside the expected range) and consistency checks (e.g., verifying that angles sum to 360 degrees in a closed traverse).

- Statistical Outlier Detection: Statistical techniques, such as standard deviation analysis, are used to identify data points that significantly deviate from the norm. This often highlights erroneous measurements.

- Graphical Analysis: Plotting the data as points, profiles, or contours allows for a visual examination of trends and potential anomalies. Imagine seeing a contour line suddenly jump—that’s a visual cue for potential errors.

By employing these checks, I ensure that potential errors are flagged early in the process, reducing the chance of them propagating through the final results.

Q 18. What software programs are you proficient in for survey data processing?

My proficiency in survey data processing software includes, but is not limited to:

- Trimble Business Center: Expert-level proficiency in processing GPS data, including RTK and PPK techniques.

- AutoCAD Civil 3D: Experienced in creating and managing digital terrain models (DTMs), and designing various civil engineering projects based on survey data.

- MicroStation: Proficient in data import, manipulation, and analysis, particularly useful for handling large datasets.

- ArcGIS: Experienced with spatial analysis and geodatabase management for geographic information systems (GIS) applications.

- LSSoft’s MAGNET: Experienced in processing data from total stations and other surveying instruments.

This software expertise allows me to handle diverse datasets efficiently and accurately.

Q 19. How do you handle conflicting data points or discrepancies?

Conflicting data points or discrepancies are inevitable in surveying, much like encountering unexpected challenges in any complex project. My approach to resolving such issues is systematic and data-driven:

- Review Field Notes and Procedures: I meticulously review field notes and procedures to determine the source of the conflict. This often involves revisiting the field location or contacting the field crew for clarification.

- Data Validation: Re-run calculations and checks on the potentially conflicting data to eliminate errors in data processing.

- Independent Verification: If the discrepancies persist, I perform independent measurements or leverage alternate data sources to validate or refute the conflicting data points.

- Statistical Analysis: Statistical analysis can help determine the weight and reliability of different data points. Data points with higher precision are usually given greater importance.

- Documentation: All steps taken to resolve the conflicts are thoroughly documented, along with the rationalization for the final decision.

The goal is to reach a resolution that maintains data integrity and ensures accurate representation of the surveyed area.

Q 20. Explain your knowledge of survey calculations and coordinate systems.

My knowledge of survey calculations and coordinate systems is comprehensive and firmly grounded in both theory and practice. I’m proficient in various coordinate systems, including:

- State Plane Coordinates: I understand the complexities of different state plane coordinate zones and can accurately transform coordinates between zones.

- Universal Transverse Mercator (UTM): I routinely use UTM coordinates for larger projects and understand the implications of using different UTM zones.

- Geographic Coordinates (Latitude and Longitude): I use these for referencing locations globally.

I am also skilled in performing numerous survey calculations such as:

- Traverse Computations: Precisely calculating coordinates of points within a traverse network, ensuring accurate closure.

- Triangulation and Trilateration: Utilizing these techniques for determining the positions of points based on angles and distances.

- Leveling Calculations: Calculating elevations accurately using leveling procedures and accounting for curvature and refraction.

- Volume Calculations: Computing volumes of earthwork, particularly crucial in construction projects.

My understanding extends to error propagation and the impact of measurement uncertainties on final results.

Q 21. Describe your experience with different types of survey markers and monuments.

My experience encompasses a wide range of survey markers and monuments. Understanding their types, uses, and limitations is vital for accurate and long-lasting survey results. This is like understanding the different types of foundations needed for a house to be built in different terrains.

- Iron Pipes and Rods: Commonly used for permanent benchmarks in various locations.

- Concrete Monuments: Durable and often used for critical control points in large-scale projects.

- Brass Caps: Typically placed on existing structures for referencing survey points.

- GPS Reference Stations: I have experience establishing and utilizing GPS reference stations for high-accuracy positioning.

- Survey Stakes: Used for temporary marking, usually during construction phases.

The selection of appropriate markers depends on the project’s requirements, the expected longevity of the survey, and the environmental conditions. For instance, I would use a more robust marker in a high-traffic area compared to a less accessible location.

Q 22. How do you maintain and care for survey equipment?

Maintaining survey equipment is crucial for accuracy and longevity. It’s like regularly servicing your car – preventative maintenance is far cheaper than emergency repairs. My approach involves a multi-step process:

- Daily Cleaning: After each use, I thoroughly clean the equipment, removing dust, dirt, and debris with a soft cloth and appropriate cleaning solutions. This prevents corrosion and ensures smooth operation.

- Regular Calibration: Total stations, levels, and GPS receivers require regular calibration to maintain accuracy. I follow manufacturer’s guidelines meticulously, often using certified calibration services for precision instruments. Think of it as getting your car’s alignment checked; it directly impacts the accuracy of your measurements.

- Storage: Proper storage is key. Equipment is stored in a dry, secure location, away from extreme temperatures and humidity. Cases and protective covers are used to prevent damage and corrosion. I also regularly check the batteries and ensure they’re stored properly to avoid damage.

- Routine Checks: I perform routine checks on all components before each use, verifying functionality and identifying any potential issues early. This includes checking batteries, levels, plumb bobs, and focusing mechanisms.

- Preventative Maintenance: This involves more in-depth servicing, often performed annually or as per manufacturer recommendations, which might involve professional servicing or internal cleaning.

Ignoring these steps can lead to inaccurate measurements, costly repairs, and even project delays. For instance, a misaligned total station can cause significant errors in large-scale surveys, resulting in wasted time and resources.

Q 23. What safety precautions do you take while using survey equipment?

Safety is paramount in surveying. We work in diverse environments, often involving challenging terrain and potentially hazardous situations. My safety protocols include:

- Site Assessment: Before starting work, I conduct a thorough site assessment, identifying potential hazards such as uneven terrain, overhead power lines, traffic, and wildlife. I create a safe work plan incorporating mitigation strategies.

- Personal Protective Equipment (PPE): I always use appropriate PPE, including safety boots, high-visibility clothing, safety glasses, and hard hats. The specific PPE will vary based on the site conditions and tasks involved.

- Safe Handling of Equipment: I always handle equipment carefully, following manufacturer’s instructions and best practices to avoid damage and accidents. For example, I use tripods to provide stability for total stations and levels, and never leave equipment unattended in hazardous areas.

- Awareness of Surroundings: Maintaining constant awareness of my surroundings and colleagues is crucial. I communicate clearly and actively collaborate to mitigate potential hazards.

- Emergency Procedures: I am familiar with emergency procedures and have access to communication tools in case of accidents or emergencies. Knowing the location of first aid kits and emergency contacts is vital.

Imagine working near a busy road – understanding traffic patterns and using warning signs prevents accidents. Similarly, working on uneven terrain needs extra caution with trip hazards and potential falls.

Q 24. Describe a time you had to troubleshoot a problem with survey equipment.

During a construction site survey, our total station suddenly stopped responding. The display showed an error message indicating a communication issue between the instrument and the data collector.

My troubleshooting steps were:

- Checked obvious things first: I started by checking the batteries in both the total station and the data collector. I replaced them with fresh ones, but the problem persisted.

- Verified connections: I carefully examined the cable connection between the total station and the data collector, ensuring a secure connection and tried using a different cable. This was a key step.

- Software reset: After multiple attempts at connecting, I performed a software reset on the total station following the manufacturer’s instructions.

- Internal settings: After the reset, the device powered up but I found the communication settings were somehow altered. I needed to re-establish connection parameters. Referencing the instruction manual was crucial here.

- Contacted Support: As the issue persisted, I contacted the equipment manufacturer’s technical support. Their expertise led to identifying a minor hardware fault, and I needed to send it back for repair.

The incident highlighted the importance of systematic troubleshooting, a good understanding of the equipment’s inner workings, and knowing when to escalate the issue to a professional. The delay caused minor schedule adjustments, but early detection saved us from larger scale problems.

Q 25. How do you deal with challenging fieldwork conditions?

Challenging fieldwork conditions are common – think extreme weather, difficult terrain, and remote locations. My approach focuses on preparation and adaptability:

- Weather preparedness: I always check weather forecasts and prepare accordingly. This might involve delaying work during extreme weather or using appropriate clothing and equipment for adverse conditions. Rain gear, appropriate footwear and sun protection are essentials.

- Terrain assessment: I meticulously assess the terrain before fieldwork. This might involve scouting the area and identifying potential hazards or difficulties. I adapt my equipment and methods based on the terrain conditions.

- Equipment selection: Choosing the right equipment for the job is crucial. For instance, ruggedized equipment is preferable in harsh environments.

- Safety planning: I always incorporate extra safety measures in challenging conditions. This might include working in pairs, using additional safety equipment, or establishing clear communication procedures.

- Adaptability: Flexibility is key. I am prepared to adjust my plans and approach as needed. For instance, adverse conditions might require adjustments to the survey techniques or a revised schedule.

For example, working in dense forest requires specialized equipment and careful attention to safety. Navigating steep slopes might involve extra precautions and using different survey techniques.

Q 26. Describe your experience with different types of surveying projects.

My experience encompasses a variety of surveying projects:

- Construction Surveys: I’ve extensively worked on construction surveys, including site surveys, setting out, and as-built surveys. These projects require precision and attention to detail to ensure the accurate construction of buildings and infrastructure.

- Topographic Surveys: I’ve created detailed topographic maps using various methods, including traditional and GPS-based techniques. This involves collecting and processing data to represent the terrain’s surface features accurately.

- Boundary Surveys: I’ve conducted boundary surveys to determine and demarcate property lines. This work requires a thorough understanding of legal frameworks and property regulations.

- Route Surveys: I have experience in surveying for road, railway, and pipeline projects. This involves setting out alignments, determining grades, and collecting data for design and construction purposes.

- Volume Calculations: I’ve utilized surveying data to accurately calculate earthworks volumes, vital in construction and engineering projects. This requires precise measurements and data processing.

Each project demands a specific approach, tailored to its unique requirements. My ability to adapt and efficiently apply appropriate techniques across different project types is a core strength.

Q 27. Explain your knowledge of relevant safety regulations and standards.

I am well-versed in relevant safety regulations and standards, including:

- Occupational Safety and Health Administration (OSHA) regulations: These regulations cover general safety guidelines for construction sites and other work environments.

- National Society of Professional Surveyors (NSPS) standards: These standards outline best practices for surveying operations, emphasizing accuracy, ethics, and professional conduct.

- American Society of Civil Engineers (ASCE) standards: Many surveying practices align with ASCE standards on design and construction, particularly in large-scale projects.

- Local regulations: I’m aware of and comply with all local regulations pertaining to land surveying and public safety.

My understanding of these regulations ensures our projects are conducted safely and ethically, adhering to industry best practices. This includes understanding site-specific safety rules and regulations as well as emergency procedures.

Q 28. How do you stay current with advances in surveying technology?

Staying current in surveying technology is essential for maintaining competitiveness and ensuring accuracy. My approach includes:

- Professional Development: I actively participate in professional development courses and workshops offered by organizations like the NSPS and other relevant bodies. This keeps me updated on the latest techniques and software.

- Industry Publications: I regularly read industry publications and journals to stay abreast of the latest advancements and research in the field. This includes online resources and industry newsletters.

- Conferences and Seminars: Attending conferences and seminars allows me to network with other professionals and learn about cutting-edge technologies and practices first hand.

- Manufacturer Training: I participate in manufacturer training programs to gain in-depth knowledge on specific equipment and software. This gives access to in-depth training and support.

- Online Resources: I leverage online resources and forums to explore and discuss new technologies and challenges with colleagues.

For instance, the adoption of UAV (Unmanned Aerial Vehicles) or drones has revolutionized data acquisition in surveying. Staying updated on these developments allows me to utilize the most efficient and effective methods.

Key Topics to Learn for Survey Equipment Handling Interview

- Equipment Calibration & Maintenance: Understanding the principles of calibrating various survey instruments (e.g., total stations, GPS receivers, levels) and performing routine maintenance checks to ensure accuracy and longevity. Practical application includes describing your experience with specific calibration procedures and troubleshooting malfunctions.

- Data Acquisition & Processing: Mastering techniques for accurate data collection using different survey equipment and proficiency in using relevant software for data processing and analysis. This includes understanding data quality control and error detection methods.

- Health & Safety Procedures: Demonstrating a thorough understanding of safe operating procedures for all survey equipment, including risk assessment, personal protective equipment (PPE) usage, and emergency response protocols. Practical application involves describing your experience adhering to safety regulations on various job sites.

- Survey Techniques & Methodologies: A solid grasp of different survey techniques (e.g., traversing, leveling, triangulation) and their appropriate application depending on project requirements and terrain conditions. Be prepared to discuss the advantages and limitations of each method.

- Understanding of Surveying Principles: A fundamental understanding of surveying principles, including coordinate systems, map projections, and error propagation. This foundational knowledge is crucial for explaining your decision-making processes in the field.

- Working with various terrains & conditions: Discuss your experience handling equipment in diverse environments – from challenging terrain to extreme weather conditions. This highlights adaptability and problem-solving abilities.

Next Steps

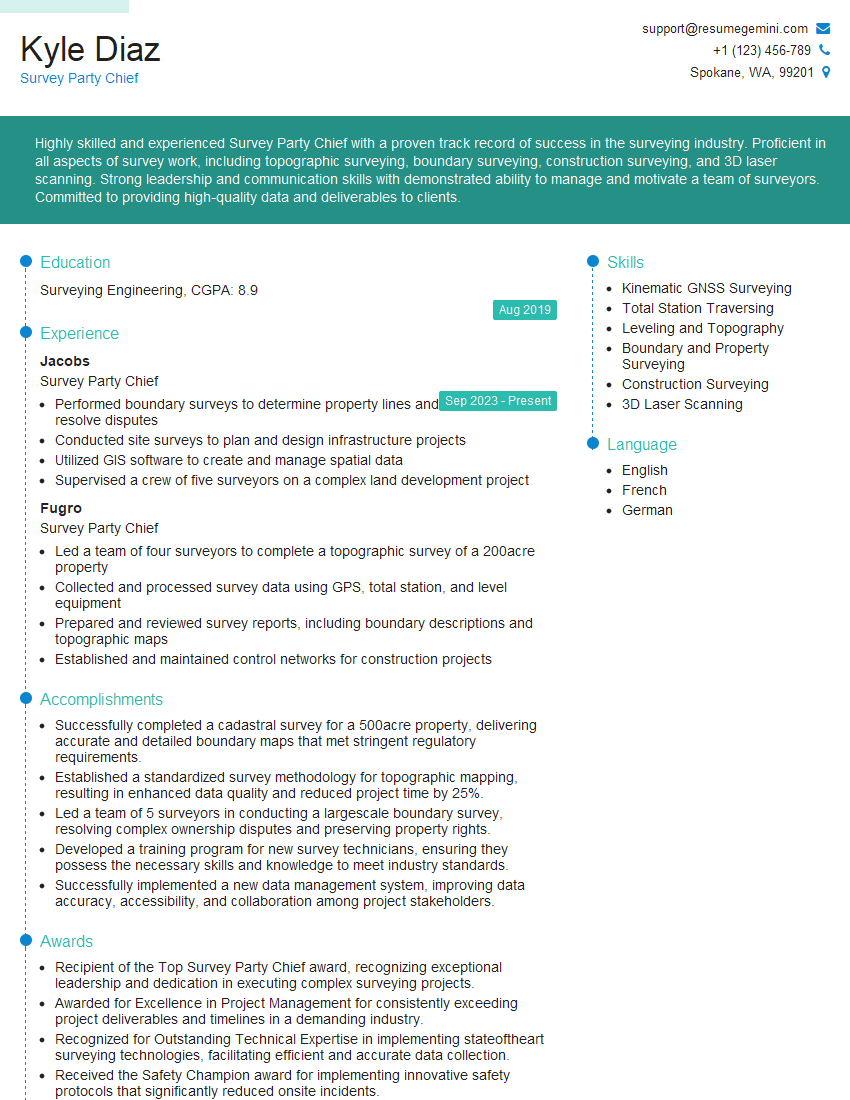

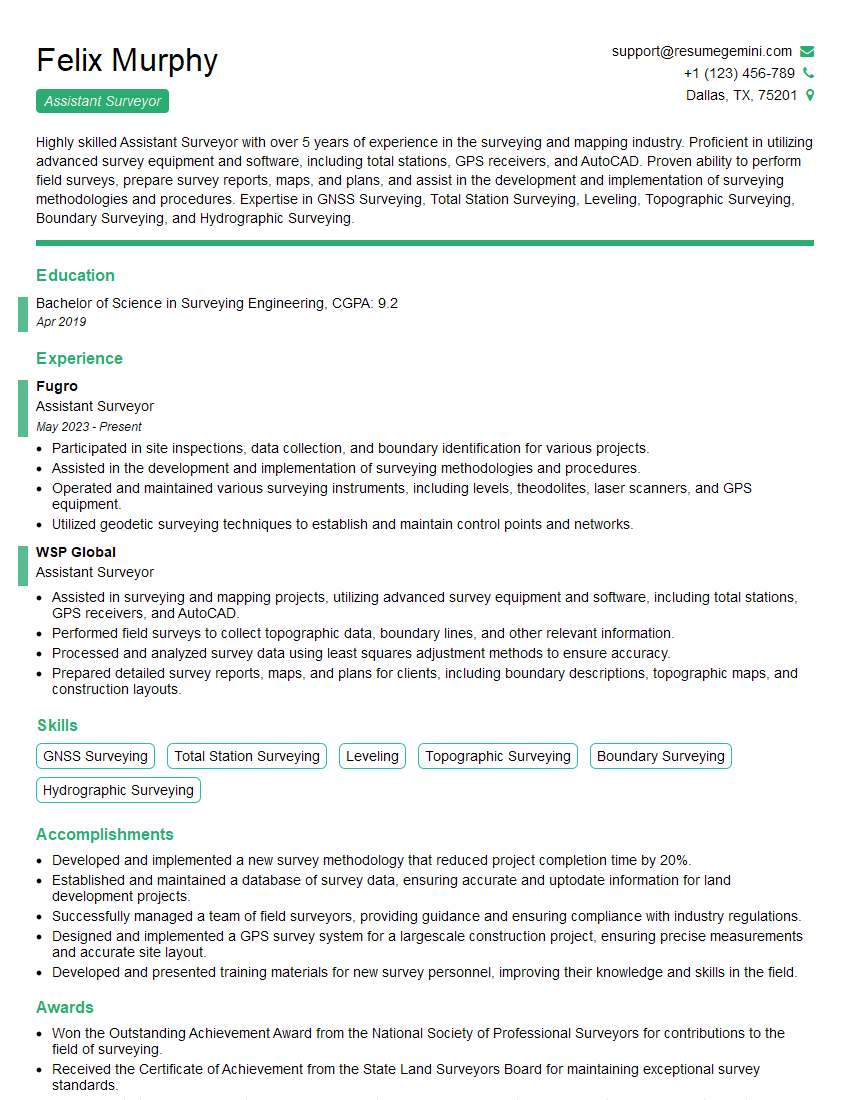

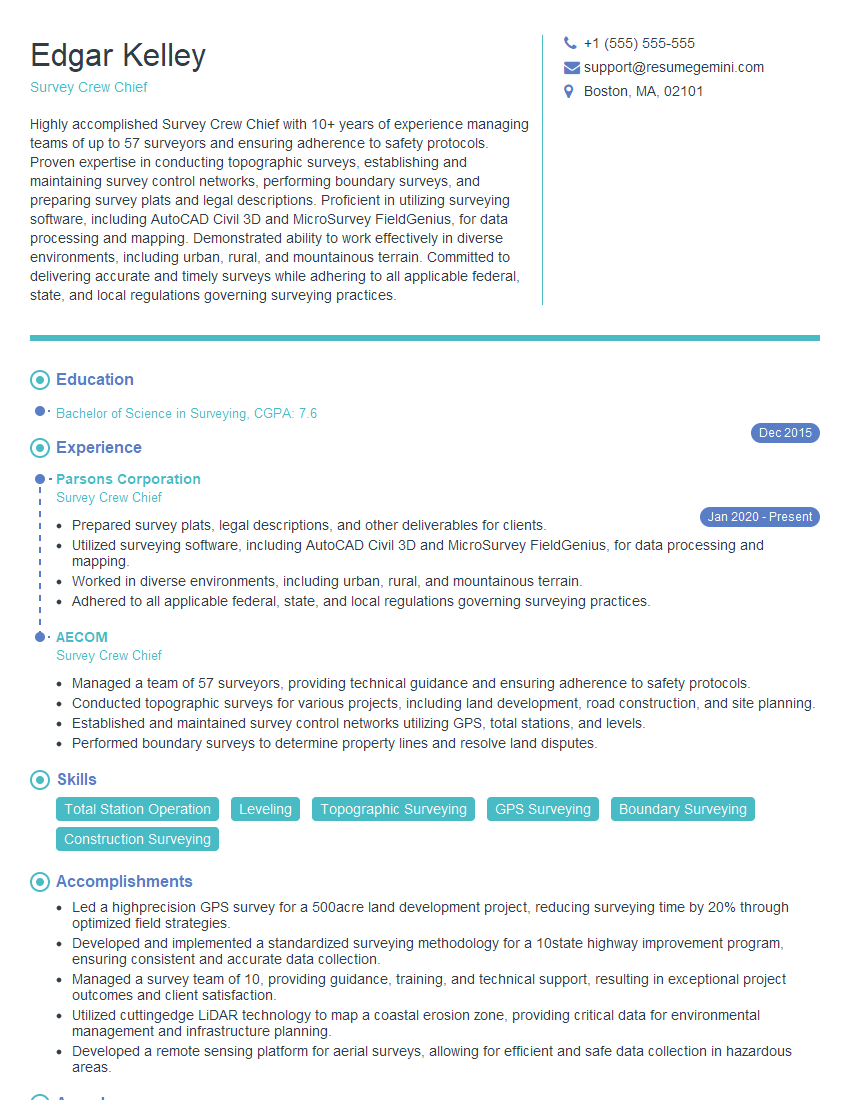

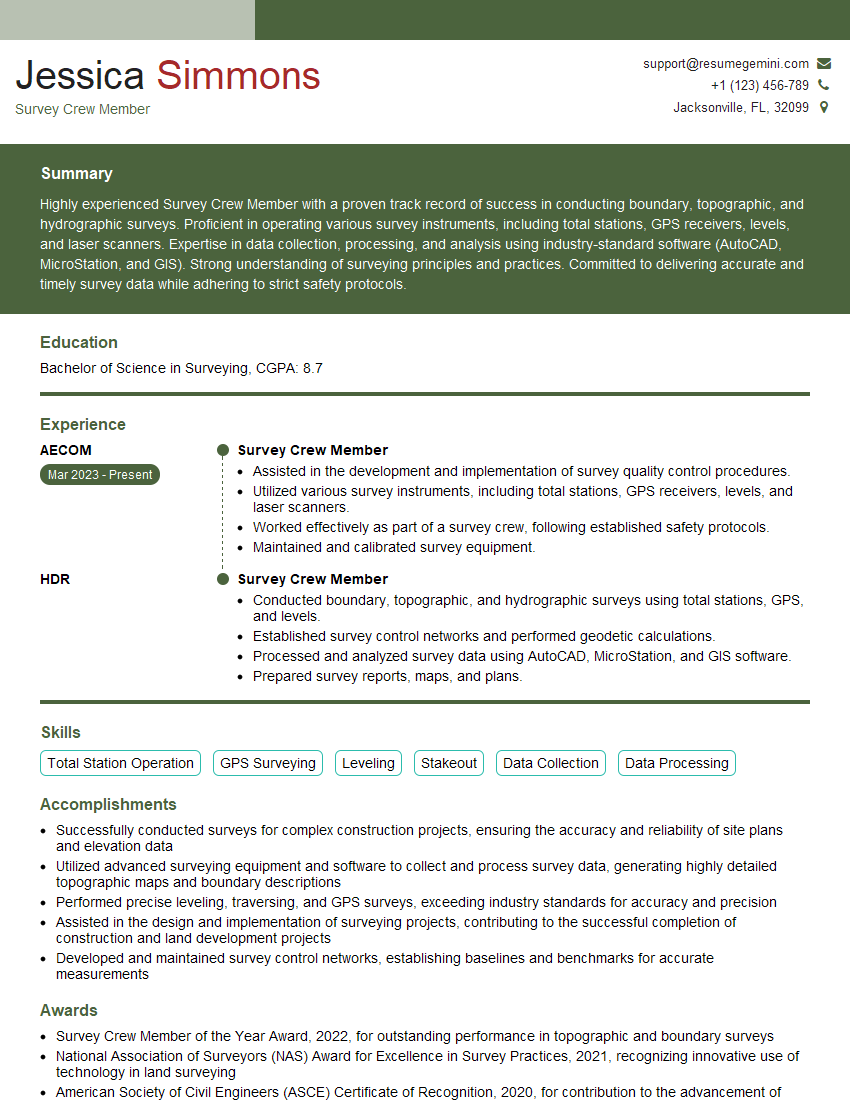

Mastering survey equipment handling is crucial for career advancement in the geospatial industry, opening doors to specialized roles and higher earning potential. A strong resume is your key to unlocking these opportunities. Creating an ATS-friendly resume is essential for getting your application noticed by recruiters. To help you build a compelling and effective resume, we recommend using ResumeGemini. ResumeGemini offers a streamlined process and provides examples of resumes tailored to Survey Equipment Handling, ensuring your qualifications shine.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).