Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Estimate concrete quantities interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Estimate concrete quantities Interview

Q 1. Explain the different methods for estimating concrete quantities.

Estimating concrete quantities involves accurately determining the volume of concrete needed for a project. There are several methods, each with its own advantages and disadvantages. The most common methods include:

- Direct Measurement Method: This involves directly measuring the dimensions (length, width, and depth) of each concrete element. It’s best suited for simple projects with clearly defined shapes. For example, calculating the volume of a rectangular footing is straightforward: Volume = Length x Width x Depth.

- Volume Calculation from Drawings: For complex projects, architectural and structural drawings are used. Detailed plans provide dimensions of walls, columns, slabs, and foundations. Each element’s volume is calculated individually and then summed up. This requires a strong understanding of construction drawings and ability to accurately extract the needed dimensions.

- Quantity Take-off from Bill of Quantities (BOQ): This method leverages a pre-prepared document listing the quantities of materials, including concrete. This is common in larger projects and allows for accurate estimation with readily available information.

The choice of method depends on the project’s complexity, the availability of drawings and specifications, and the level of detail required.

Q 2. How do you account for waste and spillage in your concrete quantity estimations?

Waste and spillage are inevitable during concrete placement and finishing. To account for this, we add a wastage factor to the calculated volume. The percentage added depends on several factors: the complexity of the formwork, the pouring method, the skill of the placement crew, and the weather conditions.

For example, a simple slab pour might only require a 3-5% wastage factor, while a complex structure with intricate formwork might need 7-10% or even higher. I usually start with industry standard percentages and adjust based on my experience with the specific project parameters. I’ve found that carefully documenting past projects is invaluable in refining these percentages for future estimations.

Furthermore, I’ll often build in contingency for unforeseen circumstances. It’s better to slightly overestimate and have leftover concrete than to run short and cause delays.

Q 3. Describe your experience with different types of concrete mixes and their impact on quantity calculations.

Different concrete mixes have varying densities, directly impacting quantity calculations. A higher cement content mix, for instance, will have a higher density compared to a leaner mix. This difference must be considered. The mix design, usually specified by the structural engineer, dictates the ratio of cement, aggregates (sand and gravel), and water. This ratio affects the final volume of the concrete produced from a given volume of materials.

I’ve worked with numerous mixes, from high-strength concrete used in columns and foundations to lower-strength mixes for pavements and slabs. For each type, I refer to the mix design to confirm the accurate density and calculate the exact volume needed. For example, if a project specifies a high-performance concrete with a higher density, I will adjust my calculations accordingly to ensure that enough concrete is ordered. I have also encountered situations where mix design was modified mid-project, requiring a recalculation of concrete quantities to avoid material shortages or excess.

Q 4. How do you handle changes in design during the concrete estimation process?

Design changes are a common occurrence in construction. When such changes happen during the concrete estimation process, a thorough reassessment is crucial. This involves reviewing the revised drawings and specifications, identifying the affected areas, recalculating the concrete volumes for those changes, and documenting the revisions clearly.

I utilize a version control system for my calculations and documentation. This allows me to easily track changes, revert to previous versions if needed, and maintain a clear audit trail. It also facilitates communication and collaboration with other project stakeholders in addressing the design changes and its impact on concrete quantities.

Q 5. What software or tools do you use for concrete quantity estimation?

I leverage several software and tools to enhance accuracy and efficiency in my concrete quantity estimations. These include:

- CAD Software (AutoCAD, Revit): For extracting dimensions directly from drawings and performing automated volume calculations.

- Spreadsheet Software (Microsoft Excel, Google Sheets): For organizing data, performing calculations, and generating reports. I often create templates for different project types to standardize my approach.

- Specialized Concrete Estimation Software: There are several software packages specifically designed for estimating concrete quantities, which often include features such as material take-off, waste factor adjustments, and cost estimation.

My choice of software depends on the project’s scale and complexity. For simple projects, spreadsheets are sufficient, while large-scale projects often benefit from the capabilities of CAD or specialized estimation software.

Q 6. How do you ensure accuracy in your concrete quantity estimations?

Ensuring accuracy in concrete quantity estimations is paramount to avoid cost overruns and material waste. I employ several strategies to achieve this:

- Double-checking Calculations: I always double-check my calculations manually, especially for complex geometries. Using different methods to cross-verify the results ensures that errors are minimized.

- Using Multiple Software and Tools: Employing multiple tools helps identify discrepancies and improves the reliability of the estimations.

- Regularly Reviewing and Updating Estimates: As the project progresses and design changes occur, I regularly update my estimations to reflect the latest information.

- On-site Verification: Whenever feasible, I make site visits to verify dimensions and account for any on-site adjustments not reflected in the drawings.

Thoroughness and attention to detail are critical aspects of my work process, ensuring accurate and reliable estimates.

Q 7. How do you estimate the concrete required for foundations?

Estimating concrete for foundations requires careful consideration of the foundation type (e.g., strip footings, spread footings, pile foundations) and their dimensions. I typically follow these steps:

- Identify Foundation Type and Dimensions: From the drawings, I determine the type of foundation and its dimensions (length, width, depth). This includes the dimensions of individual footings, walls, and any other components.

- Calculate Individual Volumes: I calculate the volume of each component separately using appropriate formulas (e.g., rectangular prism for simple footings, irregular shapes for complex footings). I pay close attention to units, ensuring consistency throughout the calculation.

- Sum Individual Volumes: After computing the volume of each foundation component, I sum them up to get the total volume of concrete required for the entire foundation system.

- Add Wastage Factor: Finally, I add a suitable wastage factor (depending on the complexity of the pour and site conditions) to account for spillage and waste.

For example, calculating the volume of a rectangular footing involves a simple multiplication of length, width, and depth. But for complex foundations like raft foundations, more intricate calculations may be needed, potentially involving 3D modeling or breaking down the structure into smaller, manageable sections.

Q 8. How do you estimate the concrete required for slabs?

Estimating concrete for slabs is straightforward. You essentially calculate the volume of the slab and add a waste factor. The volume is determined by multiplying the slab’s length, width, and thickness. Let’s break it down:

- Measure the dimensions: Accurately measure the length and width of the slab area in meters. For irregular shapes, break them down into smaller, regular shapes (rectangles, triangles) and calculate the area for each, then sum them.

- Determine the thickness: The thickness of the slab is usually specified in the design plans (typically in millimeters, convert to meters).

- Calculate the volume: Volume (m³) = Length (m) x Width (m) x Thickness (m)

- Account for waste: Always add a waste factor to account for spillage, imperfections, and additional concrete needed for finishing. A typical waste factor ranges from 2% to 10%, depending on the complexity of the pour and job site conditions. A higher waste factor is applied for complex shapes or difficult access.

- Example: A rectangular slab is 10m long, 5m wide, and 0.15m thick. The volume is 10m x 5m x 0.15m = 7.5m³. With a 5% waste factor, the total concrete required is 7.5m³ * 1.05 = 7.875m³.

Q 9. How do you estimate the concrete required for beams and columns?

Estimating concrete for beams and columns involves calculating the volume of each individual element. The process is similar to slab estimation but requires more attention to detail due to varying cross-sections.

- Define the shape and dimensions: Beams and columns come in various shapes (rectangular, T-shaped, L-shaped, circular). Carefully measure the length and cross-sectional dimensions of each. If the cross-section is irregular, break it into smaller, manageable shapes.

- Calculate the volume of each element: Use appropriate formulas for each shape. For rectangular sections: Volume (m³) = Length (m) x Width (m) x Height (m). For circular sections: Volume (m³) = π x (radius (m))² x Length (m).

- Sum the individual volumes: Once you’ve calculated the volume of each beam and column, add them together to get the total concrete volume.

- Include a waste factor: Apply a waste factor (typically between 5% and 10%) to account for losses during the pouring and finishing process. More complex shapes often require higher waste factors.

- Example: A rectangular column is 4m long, 0.3m wide, and 0.4m high. Its volume is 0.48m³. A beam with the same dimensions would also have a volume of 0.48m³. With a 7% waste factor, the total concrete required for both elements would be (0.48m³ + 0.48m³) * 1.07 ≈ 1.03m³.

Q 10. How do you estimate the concrete required for walls?

Estimating concrete for walls is much like estimating for slabs and beams, focusing on calculating the total volume. Walls, however, often have openings (doors and windows) that need to be subtracted from the total volume.

- Measure the wall dimensions: Calculate the total surface area of the wall by multiplying the length by the height. Convert all measurements to meters.

- Account for wall thickness: The thickness of the wall is usually given in the design specifications (e.g., 150mm, 200mm). Convert the thickness to meters.

- Calculate the gross volume: Gross volume (m³) = Length (m) x Height (m) x Thickness (m)

- Subtract openings: Measure the dimensions of all doors and windows and calculate their individual volumes. Subtract the volume of these openings from the gross volume to determine the net volume.

- Add a waste factor: Apply a waste factor (typically between 5% and 10%) to account for losses due to spillage and waste.

- Example: A wall is 10m long, 3m high, and 0.2m thick. The gross volume is 6m³. If there’s a 1m x 2m door opening (0.2m thick), the volume of the opening is 0.4m³. The net volume is 6m³ – 0.4m³ = 5.6m³. With a 7% waste factor, the total concrete required is 5.6m³ * 1.07 ≈ 5.99m³.

Q 11. Explain your understanding of concrete mix design and its relevance to quantity estimation.

Concrete mix design is the process of determining the proportions of cement, aggregates (sand and gravel), and water to achieve desired concrete properties like strength, workability, and durability. This is crucial for quantity estimation because the mix design dictates the volume yield of the concrete mix.

The mix design specifies the ratios of materials. For example, a 1:2:4 mix means one part cement, two parts sand, and four parts gravel. However, this doesn’t directly translate to volume for the field because the volume of mixed concrete is typically less than the sum of the individual volumes due to particle packing. Concrete producers provide information on the yield, which is the amount of hardened concrete produced per unit volume of mixed concrete. This yield is used to refine our volume estimates to account for this compaction effect. The mix design also impacts the overall cost as different materials have different prices. The stronger the required concrete, the higher the cement content (and usually the cost).

Q 12. How do you account for rebar volume within the concrete volume calculation?

Reinforcement bars (rebar) occupy space within the concrete volume. While the volume of rebar is relatively small compared to the total concrete volume, it’s essential to consider it for large projects or high rebar densities to prevent underestimating the concrete requirements. There are two common approaches to account for rebar volume:

- Neglecting rebar volume: For most projects, the rebar volume is negligible. This simplifies the calculation and is often acceptable, especially when the rebar percentage is low.

- Adding a volume adjustment: For projects with significant rebar density, you might add a small percentage (around 1-2%) to the concrete volume to account for the space occupied by the rebar. This approach adds a safety margin but might slightly overestimate.

Precise calculation of rebar volume is complex and typically done using specialized software. It involves calculating the volume of each rebar and summing them. For most practical estimations, however, neglecting the rebar volume or adding a small percentage is sufficient.

Q 13. How do you incorporate tolerances and allowances into your concrete estimates?

Incorporating tolerances and allowances is vital for accurate concrete estimation. Tolerances account for small variations in dimensions, while allowances add extra concrete to cover unexpected events.

- Dimensional tolerances: Building plans usually incorporate tolerances for dimensions to account for slight variations during construction. These tolerances should be considered during the volume calculations, leading to a slightly increased volume.

- Formwork imperfections: Formwork might not be perfectly aligned, leading to slight variations in the poured concrete’s dimensions. These imperfections justify an allowance of extra concrete.

- Settlement and shrinkage: Concrete might settle or shrink slightly after pouring. An allowance can compensate for this.

- Waste and spillage: As previously mentioned, a waste factor (typically 2-10%) accounts for spillage, mixing errors, and other losses.

The specific values for allowances depend on the project’s complexity and site conditions. Experienced estimators use their judgment and past experiences to determine appropriate allowances.

Q 14. What are the common sources of error in concrete quantity estimation and how do you mitigate them?

Several sources of error can affect concrete quantity estimations. Some common ones include:

- Inaccurate measurements: Errors in measuring the dimensions of the structure are the most common source of error. Using accurate measuring instruments and double-checking measurements are crucial.

- Ignoring openings: For walls, neglecting to account for doors and windows in the volume calculation is a frequent mistake.

- Insufficient waste factor: Using an insufficient waste factor can lead to running short of concrete. Choosing a realistic waste factor based on the project’s complexity and site conditions is essential.

- Incorrect assumptions about shape: For irregular shapes, making incorrect assumptions about the geometry can lead to inaccurate volume calculations. Breaking down irregular shapes into simpler shapes aids in preventing these errors.

- Not accounting for rebar volume (in specific cases): For projects with significant rebar, ignoring rebar volume can result in a shortage of concrete.

Mitigation Strategies: To mitigate these errors, utilize accurate measuring tools, double-check all measurements, use appropriate formulas for different shapes, account for all openings, and choose a suitable waste factor based on experience and job site conditions. Employing software tools for volume calculations can also improve accuracy and consistency.

Q 15. How do you determine the appropriate unit of measurement for concrete quantities?

The unit of measurement for concrete quantities is typically cubic yards (yd³) or cubic meters (m³), representing the volume of concrete needed. The choice depends on the project’s location and standard practices. In the US, cubic yards are more common, while cubic meters are the standard in many other parts of the world. For smaller projects, cubic feet (ft³) might be used for convenience, but it’s always crucial to convert to yd³ or m³ for larger orders to ensure accurate communication with suppliers. For example, a large commercial building would have its concrete needs specified in cubic yards, whereas a small patio might use cubic feet, which you would then convert to cubic yards for ordering from the concrete supplier.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your process for verifying the accuracy of your concrete quantity estimations.

Verifying the accuracy of concrete quantity estimations involves a multi-step process. First, I meticulously review the architectural and structural drawings to identify all concrete elements, including foundations, walls, columns, slabs, and beams. I then use appropriate calculation methods, often involving software like AutoCAD or specialized concrete estimation tools, to determine the volumes of each element. I perform multiple checks, ensuring consistent units, and accounting for waste factors (typically 5-10%, depending on the complexity and pour method). Finally, I compare my estimates against industry benchmarks, past project data, and even cross-check calculations with another estimator for extra validation. This cross-checking method helps to identify and resolve potential discrepancies early in the process, avoiding costly mistakes.

Q 17. How do you present your concrete quantity estimations to stakeholders?

Presenting concrete quantity estimations to stakeholders requires clear and concise communication. I typically prepare a well-structured report or presentation summarizing my findings. This document includes detailed breakdowns of concrete quantities by element type (e.g., foundation, slab), total volume, unit costs, and overall project costs. I use visual aids, such as drawings or 3D models, to illustrate my calculations and make the information more easily understandable. Importantly, I present the potential range of uncertainty due to unforeseen factors or changes in design and discuss potential cost implications associated with different levels of accuracy.

Q 18. How do you handle discrepancies between estimated and actual concrete quantities?

Discrepancies between estimated and actual concrete quantities are inevitable to some degree. When such discrepancies arise, I first investigate the reasons. This may involve reviewing the initial drawings for errors, checking the actual site conditions against the design assumptions, and investigating potential losses due to waste or unforeseen circumstances. Once the cause is identified, I document the findings and adjust subsequent estimates to reflect the actual usage. If significant overages occur, I analyze cost implications and discuss options with the project stakeholders, which may involve revising the project budget or implementing changes in the construction process to minimize future discrepancies. Transparency is paramount in addressing these situations.

Q 19. What are some common challenges you face when estimating concrete quantities?

Estimating concrete quantities presents several challenges. One common hurdle is incomplete or ambiguous drawings, leading to uncertain dimensions or element types. Another is accounting for complex shapes and irregular geometries, requiring precise calculations and potentially specialized software. Site conditions also play a significant role; unexpected obstacles or ground conditions can impact the actual concrete requirements. Furthermore, variations in concrete mix designs and required strengths can affect the overall volume needed and, importantly, the waste factor must be carefully considered, as it can significantly influence the final quantity estimate.

Q 20. How do you stay up-to-date on the latest techniques and technologies in concrete estimation?

Staying current in concrete estimation involves continuous professional development. I regularly attend industry conferences and workshops, keeping abreast of new estimation techniques and software. I also actively participate in online forums and professional organizations to engage with other experts and learn from their experiences. Subscribing to industry journals and leveraging online resources provides access to the latest research and best practices. For example, familiarizing oneself with BIM (Building Information Modeling) techniques can greatly improve the accuracy and efficiency of concrete quantity estimations.

Q 21. How do you collaborate with other team members during the concrete estimation process?

Collaboration is vital in concrete estimation. I work closely with architects, structural engineers, and other construction professionals to ensure the accuracy and completeness of my estimates. Regular meetings and open communication are crucial for clarifying design details, addressing potential issues, and incorporating feedback throughout the estimation process. Leveraging shared platforms for document management ensures that everyone has access to the most up-to-date information, preventing misunderstandings and facilitating efficient workflow. This collaborative approach minimizes errors and ensures that the concrete estimation accurately reflects the project’s requirements.

Q 22. Describe a situation where your concrete quantity estimation resulted in cost savings.

On a recent high-rise project, the initial architectural plans called for numerous, intricately designed concrete columns. My detailed quantity takeoff, however, revealed a potential for significant simplification. By subtly altering the design — using fewer, larger columns instead of many smaller ones — we maintained structural integrity while reducing the overall concrete volume by 15%. This resulted in considerable savings on material costs, labor, and transportation, ultimately saving the project approximately $75,000.

This was achieved through meticulous analysis of the structural calculations and exploring design alternatives. The key was not only to accurately estimate the initial plan, but to proactively look for cost-saving opportunities within the design constraints.

Q 23. How do you manage multiple concrete estimation projects simultaneously?

Managing multiple concrete estimation projects simultaneously requires a structured approach. I utilize project management software to track deadlines, assign tasks, and maintain clear communication. For each project, I create a detailed plan, breaking down the tasks into smaller, manageable components. This allows for efficient allocation of resources and ensures that each project remains on schedule.

Prioritization is key. I focus on urgent tasks with impending deadlines first, leveraging the project management software’s scheduling and reporting capabilities. Regular check-ins with my team and clients help in addressing any potential bottlenecks and ensure everyone is on the same page.

For example, I might use a Kanban board to visually track the progress of multiple estimations, moving tasks through stages from ‘To Do’ to ‘In Progress’ to ‘Completed’. This approach ensures transparency and allows for easy identification of any delays or issues.

Q 24. How do you use takeoff software to estimate concrete quantities?

Takeoff software is invaluable for accurate and efficient concrete quantity estimations. I primarily use software like Autodesk Quantity Takeoff or similar programs. These tools allow me to import digital drawings (DWG, PDF) and then use various tools to trace elements such as walls, slabs, and columns, automatically calculating volumes and areas.

For example, to estimate the volume of a concrete foundation, I would trace the outline of the foundation on the drawing using the software’s tools. The software then automatically calculates the area, and by inputting the required thickness, the volume is determined. The software also helps create detailed reports summarizing the quantities, which are crucial for accurate budgeting.

Beyond simple volume calculations, the software also allows for adjustments based on factors such as waste, tolerances and concrete mix design requirements. This leads to a far more accurate estimate compared to manual calculation.

Q 25. Explain the importance of accurate concrete quantity estimation in project budgeting.

Accurate concrete quantity estimation is paramount for effective project budgeting. Underestimating concrete quantities can lead to significant cost overruns, delays, and potential project failure. Overestimation, on the other hand, ties up unnecessary capital.

Concrete is a major component of most construction projects, often representing a substantial portion of the overall budget. An inaccurate estimation translates directly into inaccurate cost projections, impacting profitability and potentially leading to disputes with clients. Accurate estimations allow for precise material procurement, scheduling of concrete pours, and effective management of labor costs.

Think of it like baking a cake: if you don’t accurately measure the ingredients, the final product won’t turn out as planned. Similarly, in construction, precise concrete quantity estimation ensures the project is completed within budget and on time.

Q 26. Describe your experience working with different types of construction drawings.

Throughout my career, I’ve worked with various construction drawings, including architectural plans, structural drawings, and shop drawings. Architectural plans provide the overall layout and design of the concrete elements, while structural drawings offer detailed information on dimensions, reinforcement, and structural requirements. Shop drawings, on the other hand, provide detailed information for construction specifics such as formwork details.

I am proficient in interpreting different drawing formats and scales, understanding symbols and notations specific to concrete structures. My experience encompasses both 2D and 3D models, which aids in accurate visualization and estimation. Experience with various drawing software such as AutoCAD, Revit and Bluebeam is essential for interpreting information efficiently.

Q 27. How familiar are you with different concrete finishing techniques and their impact on quantities?

Different concrete finishing techniques significantly impact the quantities needed. For instance, a smooth, brushed finish requires less material compared to a textured, exposed aggregate finish which may require additional concrete to account for the texturing process. Also, the time required for each finish will differ, thus affecting the labor costs.

My knowledge of various finishes includes stamped concrete, exposed aggregate, broom finished, and power troweled surfaces. I understand how these choices impact not just the final aesthetic, but also the labor hours, and material quantity. This understanding allows me to produce a comprehensive estimate that factors in these variations.

Q 28. How do you account for formwork in your concrete quantity estimations?

Formwork is a crucial element in concrete quantity estimations. While formwork itself isn’t concrete, its volume significantly influences the overall concrete quantity. The formwork creates the shape and dimensions for the concrete pour, and any inaccuracies in the formwork design will directly impact the final concrete volume.

I account for formwork by carefully reviewing the structural drawings and shop drawings, identifying all formwork elements like walls, columns, and slabs. The formwork’s dimensions and geometry are then carefully measured and entered into the takeoff software, so that the accurate concrete volume can be calculated. Waste factors are also considered, especially around complex shapes to ensure enough concrete is accounted for.

Key Topics to Learn for Estimate Concrete Quantities Interview

- Understanding Project Drawings: Learn to accurately interpret architectural and engineering drawings to extract relevant dimensions for concrete volume calculations.

- Calculating Concrete Volume: Master the formulas and techniques for calculating volumes of various concrete elements like slabs, beams, columns, and foundations. Practice with different shapes and complexities.

- Material Waste Factor: Understand the concept of material waste and how to incorporate a realistic waste factor into your quantity estimations to account for spillage, breakage, and other losses.

- Concrete Mix Design & Properties: Familiarize yourself with different concrete mix designs and their properties (strength, slump, etc.) and how this relates to quantity calculations and project specifications.

- Practical Application: Practice estimating concrete quantities for different types of projects, from small residential foundations to large commercial structures. Consider varying complexities in design.

- Software & Tools: Explore common software and tools used for quantity takeoff and estimation in the construction industry. Familiarity with relevant software demonstrates valuable skills.

- Unit Conversions & Dimensional Analysis: Ensure proficiency in converting units of measurement (cubic yards, cubic meters, etc.) and applying dimensional analysis to verify the accuracy of calculations.

- Cost Estimation: Understand how estimated concrete quantities translate into cost estimations, including material, labor, and equipment costs.

Next Steps

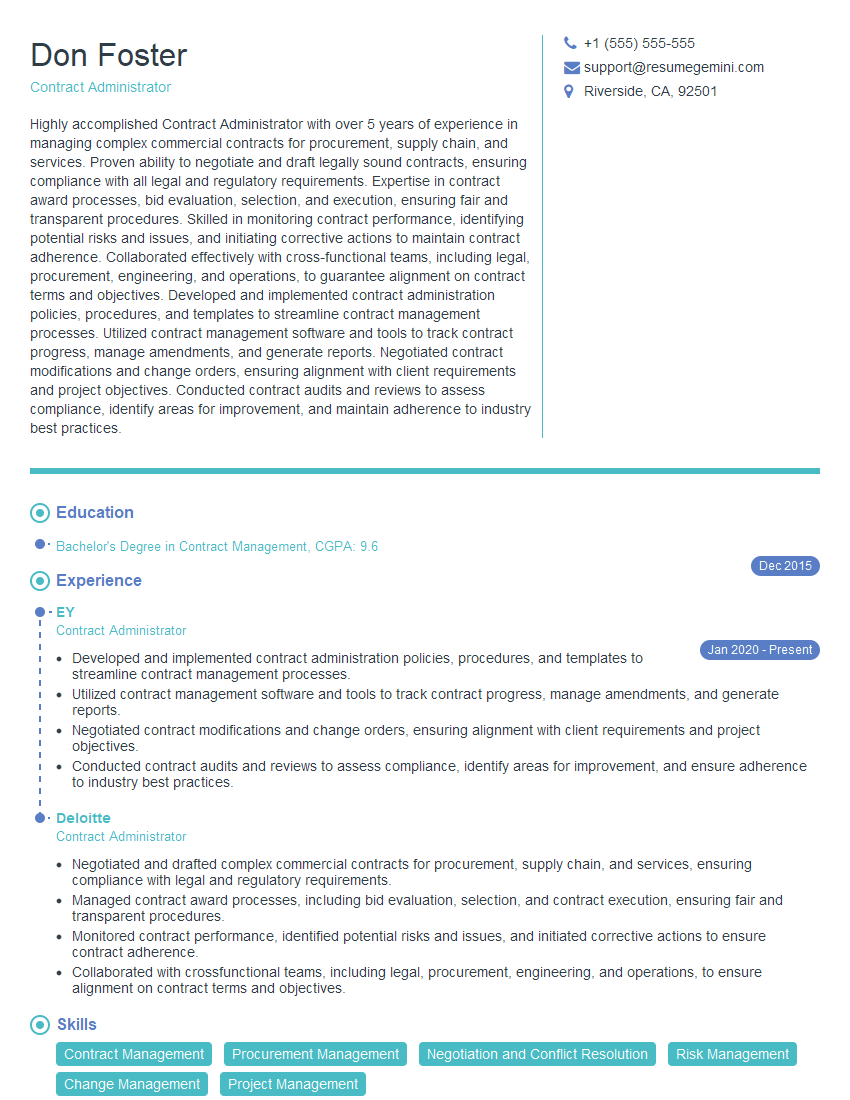

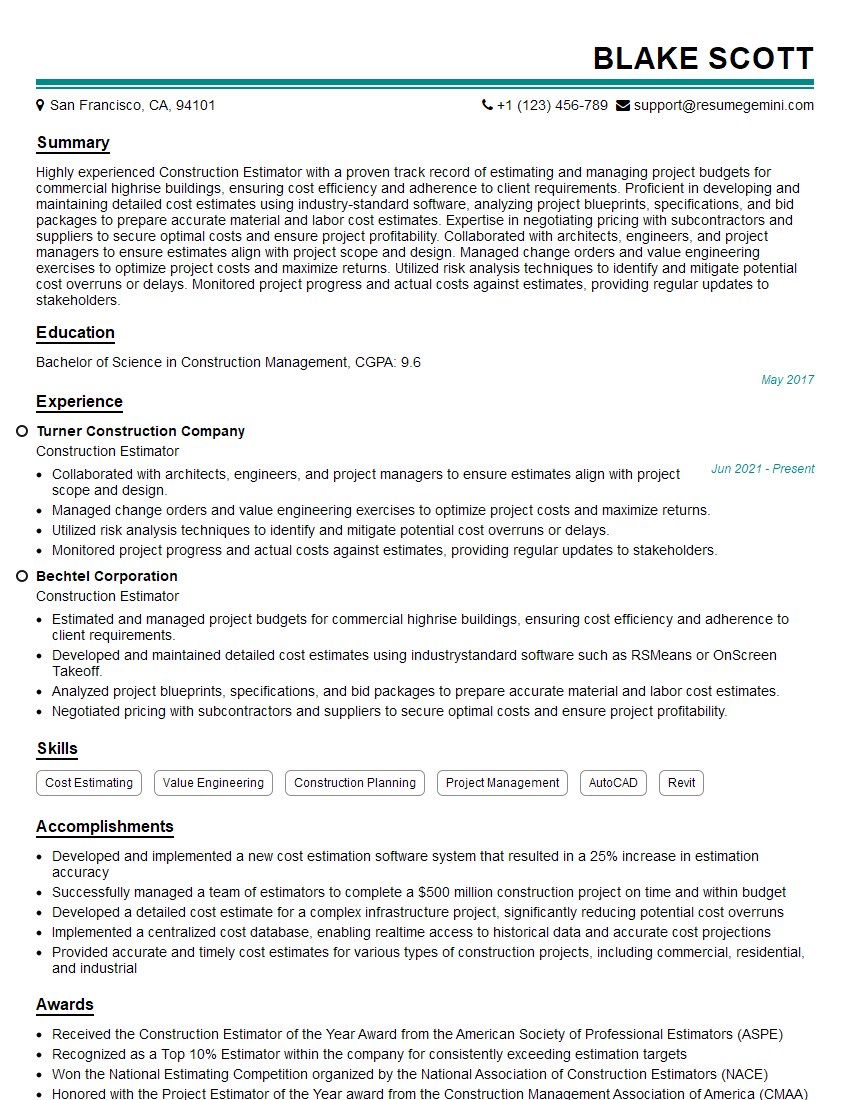

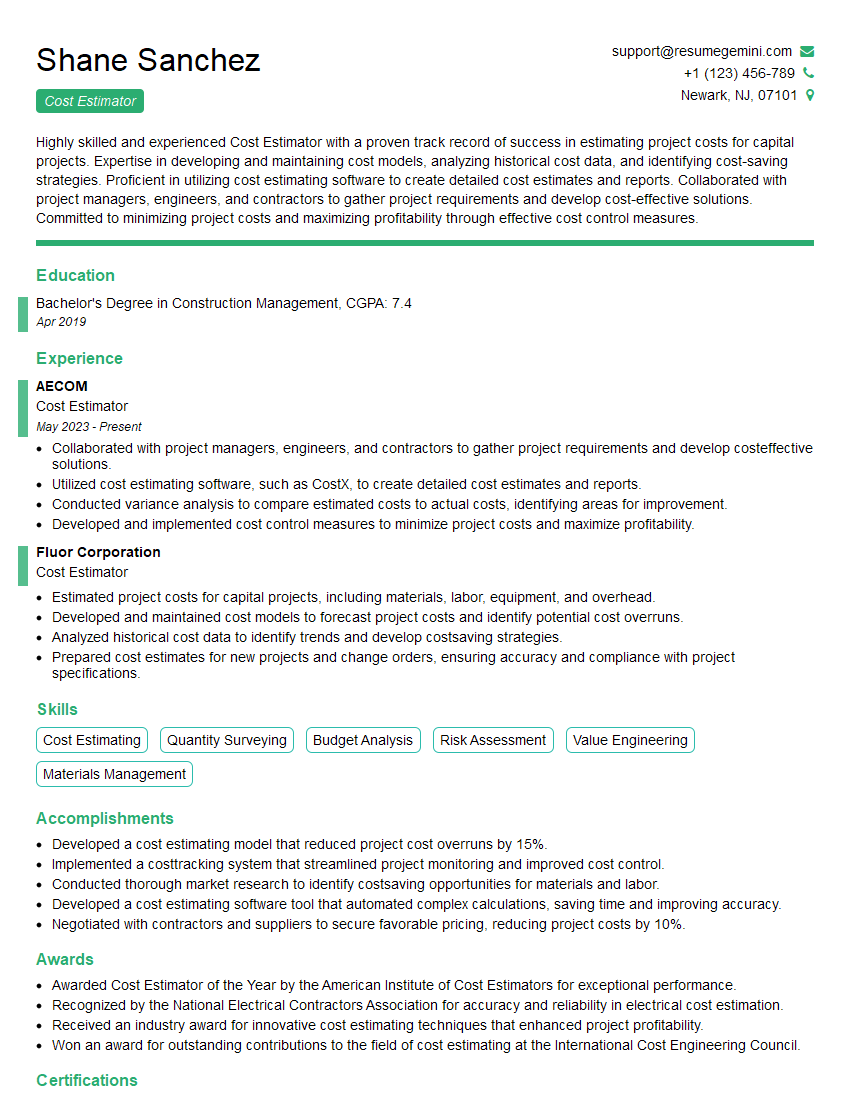

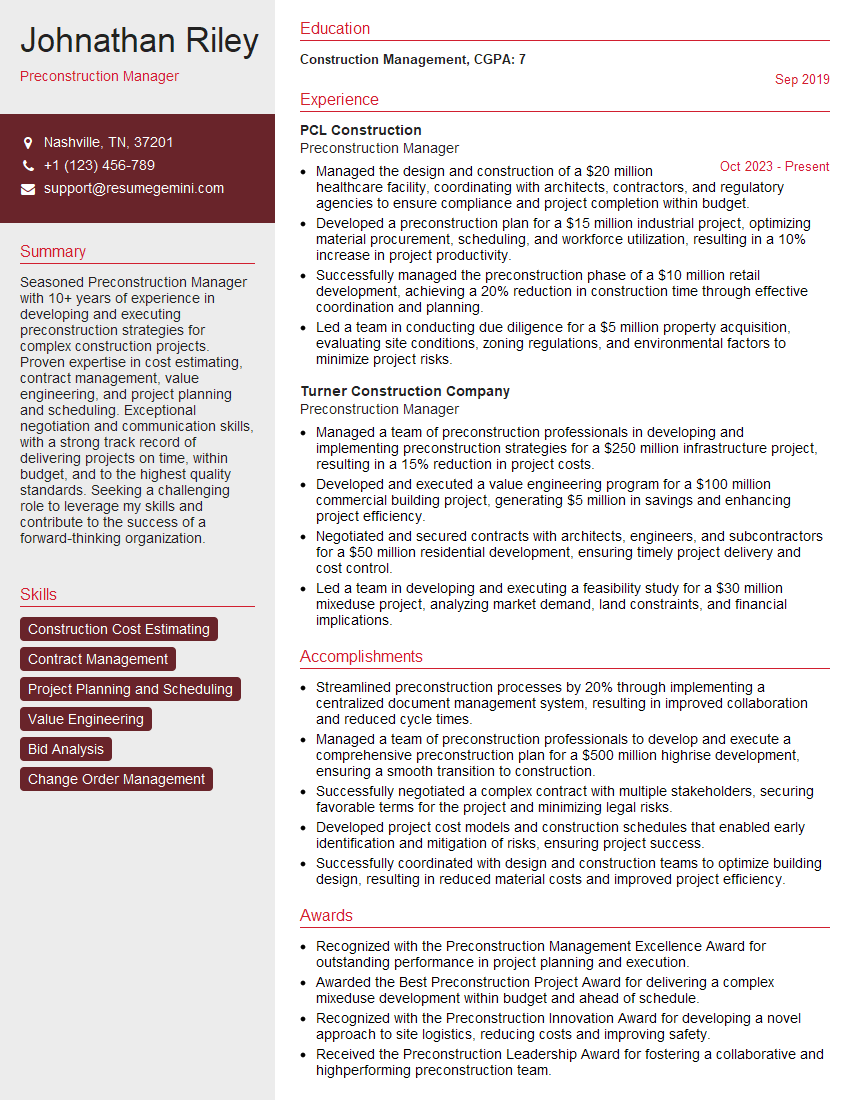

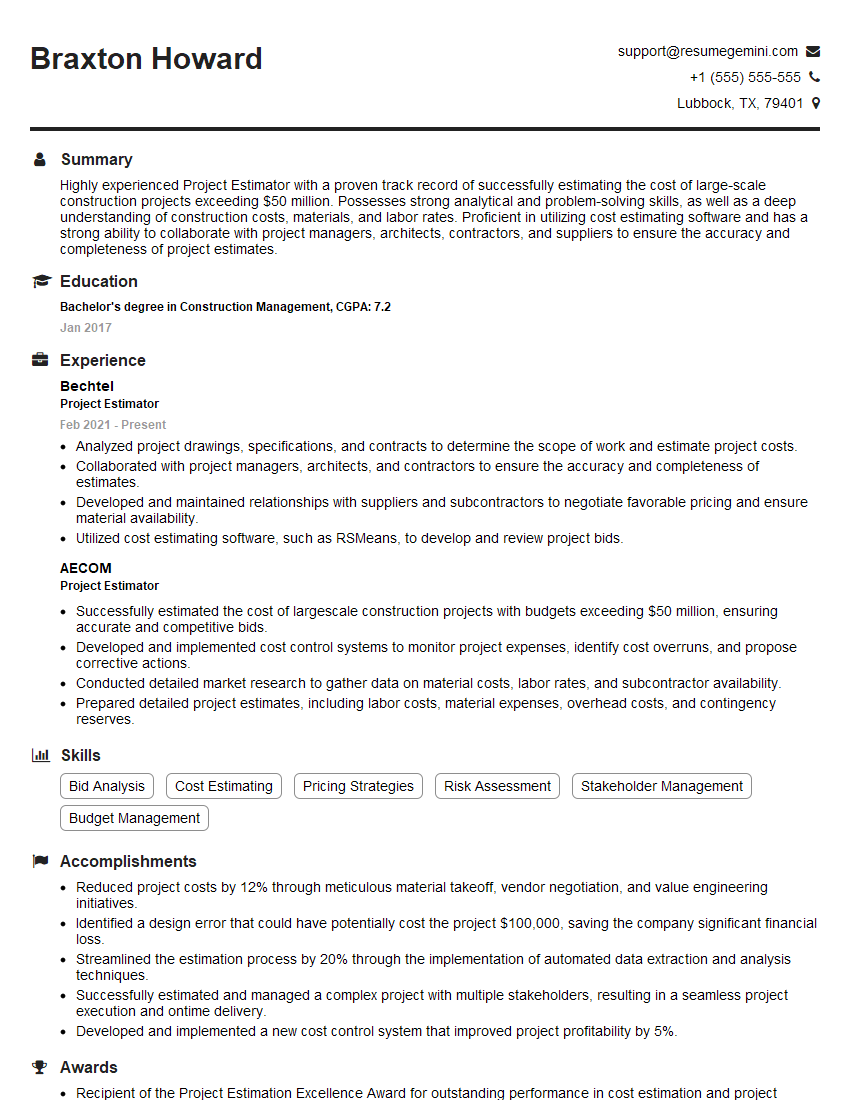

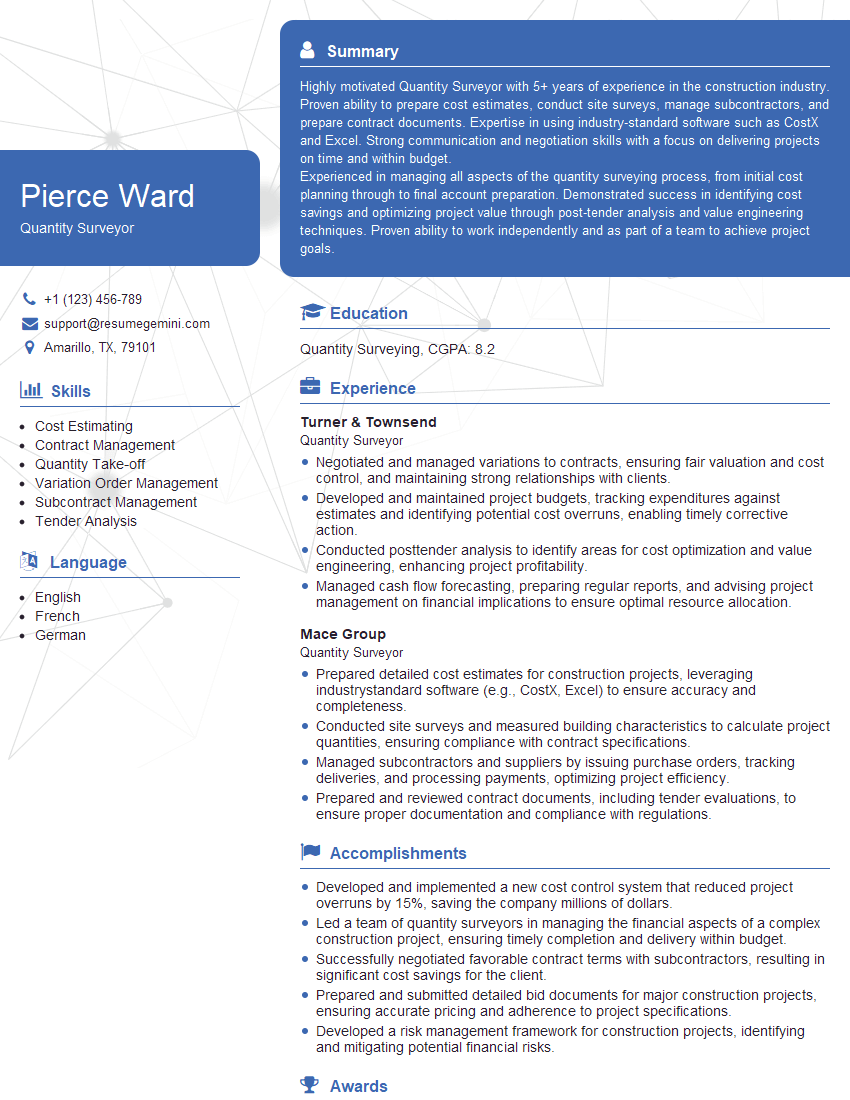

Mastering the art of estimating concrete quantities is crucial for success in the construction industry, opening doors to more senior roles and higher earning potential. A well-crafted resume is your key to unlocking these opportunities. Make sure your resume is ATS-friendly to ensure it gets noticed by recruiters. ResumeGemini is a trusted resource to help you build a professional and impactful resume that highlights your skills and experience. Examples of resumes tailored to estimating concrete quantities are available to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good