The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Knowledge of press operations and equipment interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Knowledge of press operations and equipment Interview

Q 1. Describe your experience with different types of printing presses (offset, flexographic, digital).

My experience encompasses a wide range of printing press technologies, including offset, flexographic, and digital printing. Offset lithography, which I’ve extensively used, is ideal for high-volume, high-quality printing, particularly for projects requiring fine details and consistent color reproduction, like brochures or magazines. The process involves transferring an image from a plate to a rubber blanket and then to the substrate. I’m proficient in operating both sheetfed and web offset presses, understanding the nuances of each. Flexography, on the other hand, is perfect for flexible packaging materials. It utilizes flexible photopolymer plates and works well with various substrates like plastic films and corrugated board. My experience includes working with both narrow and wide-web flexographic presses, adjusting for different printing speeds and ink viscosities. Finally, I have significant experience with digital printing, particularly toner-based and inkjet systems. These are best suited for short-run, personalized printing, where quick turnaround times and variable data are crucial. I’m familiar with various digital press models and their capabilities, including their strengths in handling smaller print jobs efficiently.

Q 2. Explain the setup process for a sheetfed press.

Setting up a sheetfed press is a meticulous process requiring precision and attention to detail. It begins with the makeready process, where we prepare the press for printing. This includes:

- Plate mounting: Carefully mounting the printing plates onto the press cylinders, ensuring they are securely fastened and correctly aligned.

- Ink and water balance: Achieving the optimal balance of ink and dampening solution on the plate is crucial for image quality. This involves adjusting the ink keys, fountain rollers, and dampening system to produce the desired ink density and sharpness. Think of it like fine-tuning a recipe—too much ink, and it’s muddy; too little, and the image is faint.

- Blanket cylinder setup: Ensuring the blanket cylinder is properly aligned with the plate cylinder is key to proper image transfer. Misalignment can lead to blurred or skewed images.

- Paper feed adjustments: Setting the paper feed system to handle the specific paper stock accurately. This includes adjusting the grippers, feeders, and delivery systems to prevent paper jams or misfeeds.

- Registration: Precisely aligning the colors or image elements for multi-color printing. This requires careful adjustment of the impression cylinders to ensure perfect overlay.

Q 3. How do you troubleshoot common printing press malfunctions?

Troubleshooting printing press malfunctions requires a systematic approach. I start by identifying the problem—is it a quality issue, a mechanical failure, or a material problem? For example, if I see streaks or blotches in the print, I’d first check the ink and water balance. If there are issues with registration, I’d look at the cylinder alignment and gripper settings. A systematic approach includes:

- Visual inspection: Carefully examine the entire press for any obvious problems.

- Check error logs: Modern presses have diagnostic systems; review error messages for clues.

- Test prints: Running test prints at various stages helps identify the source of the problem.

- Check consumables: Examine inks, plates, and blankets for quality and proper installation.

Q 4. What are the key safety procedures you follow when operating printing equipment?

Safety is paramount in a print shop environment. I strictly adhere to all safety regulations and company protocols, which include:

- Lockout/Tagout procedures: Always locking out and tagging out power sources before performing maintenance or repairs.

- Personal Protective Equipment (PPE): Wearing appropriate PPE such as safety glasses, gloves, and hearing protection at all times.

- Safe handling of materials: Following proper procedures for handling inks, chemicals, and paper stock.

- Machine guards: Ensuring all machine guards are in place and functioning correctly before operation.

- Regular inspections: Conducting routine inspections of the equipment to identify potential hazards.

Q 5. Describe your experience with color matching and registration.

Color matching and registration are critical to producing high-quality printed materials. Color matching involves achieving the exact colors specified by the client or design. This requires a deep understanding of color theory, the use of color management software, and the ability to adjust ink densities and other settings precisely. I use colorimetric devices to ensure accuracy throughout the process. Registration, on the other hand, involves accurately aligning multiple color prints to create a seamless, high-resolution image. This requires attention to detail, precise adjustments to the press settings, and an understanding of the mechanics of the printing press itself. A slight misalignment can significantly impact the quality of the final product. For example, I once worked on a project involving a complex, four-color logo where perfect registration was paramount. I used a combination of test strips, densitometer readings, and visual checks to fine-tune the registration marks. Through this iterative process, I managed to achieve perfect alignment, resulting in a flawless final product that met the client’s exacting standards.

Q 6. How do you maintain the quality of printed materials throughout the production process?

Maintaining print quality throughout production involves a multifaceted approach. First, it starts with careful pre-press preparation, which includes accurate proofing and color management. During the press run, continuous monitoring is key. Regular checks of ink density, moisture levels, and registration help keep everything consistent. This often includes using densitometers and colorimeters to measure and maintain color accuracy. Maintaining the press itself is also important. Regular maintenance, including cleaning, lubricating, and replacing worn parts, ensures the press operates at its peak performance. Finally, careful handling and storage of the printed materials protect against damage after printing. For example, if we’re printing on delicate paper stock, extra care is taken in handling to prevent scratches or tears. I work closely with the prepress team to ensure that the files are well-prepared and the press conditions are optimized for the specific job, making the quality control process much easier throughout the production run. It’s about vigilance and attention to detail in every step.

Q 7. Explain your understanding of different types of inks and their applications.

Different inks cater to specific needs and substrates. I’m familiar with several types:

- UV (Ultraviolet) cured inks: These are quickly cured using UV light, ideal for fast turnaround and applications needing instant drying, like packaging or signage.

- Water-based inks: Environmentally friendly, but require longer drying times and may not be suitable for all substrates.

- Solvent-based inks: Often used in flexographic printing, they offer good adhesion to various substrates but have strong odors and require proper ventilation.

- Vegetable-based inks: A sustainable option, environmentally conscious clients often prefer this type.

Q 8. What is your experience with pre-press and post-press operations?

My experience encompasses the entire print production workflow, from pre-press to post-press. Pre-press involves preparing the files for printing – this includes tasks like designing, trapping, color separation, and creating printing plates (often using Computer-to-Plate or CTP technology). I have extensive experience with software like Adobe Illustrator, InDesign, and Photoshop, ensuring files are print-ready. Post-press, on the other hand, covers all processes after the printing is complete. This includes finishing operations such as cutting, folding, binding (perfect binding, saddle stitch, wire-o), lamination, and packaging. I’ve managed teams and overseen projects involving various finishing techniques, optimizing for speed and quality.

For example, I once managed a project printing a large-scale marketing campaign. The pre-press stage involved meticulous color management to ensure brand consistency across thousands of brochures. Post-press included high-speed automated folding and a specialized UV coating for durability.

Q 9. How do you manage press downtime and optimize production efficiency?

Press downtime is the enemy of efficiency and profitability. My approach to minimizing it is proactive and multi-faceted. It begins with preventative maintenance – regular cleaning, lubrication, and inspections of the press to identify potential issues *before* they cause downtime. I also focus on operator training; skilled operators are less likely to make mistakes that lead to stops.

When downtime does occur (and it inevitably will), I implement a structured troubleshooting process. This involves quickly identifying the root cause – whether it’s a mechanical malfunction, a paper jam, or a software glitch – and resolving it efficiently. I maintain a well-stocked inventory of spare parts to minimize repair time. Data analysis is crucial here; tracking downtime causes helps identify patterns and implement preventative measures. For instance, frequent paper jams might indicate a problem with the feeder settings or paper quality. By consistently analyzing these metrics, I can significantly reduce downtime and maximize production output.

Q 10. Describe your experience with different paper types and their suitability for various printing techniques.

Different paper types drastically affect the outcome of a print job. My experience includes working with a wide range of papers, including coated (gloss, matte, dull), uncoated (offset, text), and specialty papers (textured, recycled, etc.). Coated papers are ideal for high-resolution images and vibrant colors, often used for magazines or brochures. Uncoated papers offer a more natural, rustic feel, suitable for books or letterheads. Specialty papers add unique tactile and visual elements.

The choice of paper is directly linked to the printing technique. For instance, heavier stocks are better suited for letterpress, which requires more robust paper to withstand the pressure. Thinner papers work well with offset lithography, offering good ink absorption. Understanding these relationships is essential for achieving the desired print quality. I’ve worked with clients to select the optimal paper based on their project’s needs and budget, ensuring the final product meets their expectations.

Q 11. What is your experience with using different types of plates (e.g., CTP plates)?

I have extensive experience with Computer-to-Plate (CTP) technology, which has revolutionized platemaking. CTP eliminates the need for film, offering greater precision and efficiency. I’m proficient in working with various CTP plates, including thermal, violet, and UV plates, each with its own strengths and weaknesses. Thermal plates, for example, are known for their ease of use and cost-effectiveness, while violet and UV plates offer greater durability and longevity. The selection of a specific plate depends on factors like the press type, ink, and desired print quality. My role also includes maintaining the CTP system and ensuring it is consistently calibrated to guarantee high-quality plate production.

Beyond CTP, I also possess familiarity with traditional platemaking methods, providing a broader understanding of the entire print production process. This knowledge helps me troubleshoot and address issues more effectively, regardless of the platemaking method employed.

Q 12. Explain your understanding of different printing techniques (e.g., screen printing, letterpress).

My understanding of printing techniques spans various methods. Offset lithography is the workhorse of the commercial printing industry, utilizing a plate-based system to transfer ink to paper indirectly. Screen printing is a stencil-based technique, excellent for high-viscosity inks and printing on unusual substrates like t-shirts or wood. Letterpress uses raised type or plates to create an impression on the paper, resulting in a unique tactile quality. Other techniques include flexography (ideal for packaging) and digital printing (suited for shorter runs and personalized materials).

I’ve personally worked with all of these techniques on numerous projects, allowing me to effectively advise clients on the best method for their specific requirements. Choosing the right technique impacts cost, speed, and the final product’s aesthetic and feel.

Q 13. How do you ensure consistent print quality across large production runs?

Maintaining consistent print quality across large production runs requires a meticulous approach. It starts with proper pre-press preparation, ensuring accurate color profiles and consistent file preparation across all elements. During the printing process, regular color checks using a densitometer are vital to monitor ink density and registration. Proper calibration of the printing press and consistent monitoring of variables such as ink viscosity and paper moisture are critical.

Regular cleaning and maintenance of the press prevent issues like ink build-up or roller wear, which can affect print quality. Implementing quality control checks at various stages throughout the run, and employing a robust process for dealing with discrepancies, are key to identifying and addressing problems early. Using color management software to control and maintain color accuracy from design to print is also crucial to ensuring consistent results.

Q 14. What are the key performance indicators (KPIs) you monitor in a pressroom?

In a pressroom, I closely monitor several key performance indicators (KPIs) to evaluate efficiency and quality. These include:

- Press speed (impressions per hour): Measures the overall productivity of the press.

- Uptime percentage: Indicates the percentage of time the press is actively printing, versus downtime.

- Waste percentage: Tracks the amount of paper wasted due to spoilage or errors.

- Color accuracy (delta E): Measures the difference between the target color and the actual printed color.

- Registration accuracy: Measures how accurately the colors and images align on the printed piece.

- Cost per impression: Calculates the cost of producing each printed piece.

By tracking these KPIs, I can identify areas for improvement, optimize processes, and ultimately enhance overall pressroom performance. Regular analysis of these metrics helps to make data-driven decisions, leading to a more efficient and profitable operation.

Q 15. Describe your experience with maintaining and troubleshooting printing press components (e.g., rollers, blankets, dampening system).

Maintaining and troubleshooting a printing press requires a deep understanding of its mechanical and chemical components. My experience spans various press types, including Heidelberg Speedmaster and Komori Lithrone, encompassing preventative maintenance and reactive troubleshooting.

Rollers: I regularly inspect rollers for wear, cleaning them using appropriate solvents and ensuring proper compression. Issues like roller flattening or gumming are addressed by cleaning, re-covering (if necessary), or replacing faulty rollers. I’ve even tackled situations where roller misalignment caused uneven ink distribution, resolving it by adjusting the roller settings and utilizing precision measuring tools.

Blankets: Blanket maintenance involves careful cleaning to remove debris and ink build-up, using appropriate cleaning solutions to prevent damage. I monitor blanket wear and tear, identifying potential defects early to prevent print quality issues. Replacing blankets is a precise process, requiring careful alignment and tension adjustment to ensure optimal performance. I’ve had to troubleshoot instances of blanket slippage by adjusting the blanket clamps and ensuring correct cylinder pressure.

Dampening System: This is crucial for offset printing. My experience includes maintaining the proper balance of water and ink, and troubleshooting issues like water streaks or mottle. I regularly check and adjust the fountain solution pH and conductivity, addressing problems like clogged nozzles or leaks promptly. For example, I once resolved a consistent water streak issue by identifying a hairline crack in a dampening roller and implementing timely replacement.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you handle paper jams and other common printing press issues?

Paper jams are a common occurrence, but their causes can vary widely. My approach is systematic: I first identify the location of the jam, carefully removing the jammed sheets, paying close attention not to damage the paper path components. I then check for the root cause: are the paper guides misaligned? Is the paper feed too aggressive? Is the paper itself the issue (e.g., too damp or wrinkled)?

Beyond paper jams, I’ve dealt with various issues: inconsistent ink density, which might indicate issues with the ink supply, fountain solution levels, or even the press’s roller settings; misregistration, tackled by adjusting the press’s registration controls; and print defects like streaks or smears, investigated by inspecting the rollers, dampening system, or blankets.

My problem-solving approach always begins with a visual inspection followed by a targeted investigation of the implicated system. I document all interventions and regularly consult maintenance manuals and the press’s error codes for more complex problems. I also prioritize preventative maintenance to reduce the frequency of such issues.

Q 17. Describe your experience with press automation and control systems.

I have extensive experience with press automation and control systems, including Heidelberg Prinect and other similar systems. This involves proficiency in setting up and operating pre-programmed jobs, adjusting parameters like speed, ink flow, and dampening, using the control console.

My work also involves troubleshooting automated functions. For instance, I’ve resolved issues with automatic blanket washing systems by identifying and fixing sensor malfunctions or software glitches. I am also familiar with the preventative maintenance needed for these systems to guarantee smooth, uninterrupted production. Understanding the software and its interaction with the mechanical aspects of the press is crucial to effectively managing automated processes.

Furthermore, I’m comfortable working with different automation levels, from partially automated presses to fully automated ones, adapting my approach depending on the specific press’s capabilities and control systems.

Q 18. What is your understanding of the relationship between pre-press, press, and post-press operations?

Pre-press, press, and post-press operations are interdependent stages in the printing process. Think of it as a relay race: each stage’s success relies on the previous one’s accuracy and efficiency.

Pre-press involves preparing the files for printing. This includes design, image editing, color correction, and creating printing plates. Errors at this stage directly impact print quality and can lead to costly reprints. For example, a poorly prepared file might result in misregistration or color inconsistencies.

Press is the actual printing phase where the prepared plates are used to transfer ink onto the substrate. This involves careful monitoring of print quality, ink density, and paper feed to ensure consistent output.

Post-press includes finishing operations like cutting, folding, binding, and other enhancements. Issues like incorrect cutting dimensions or binding problems can render even a well-printed product flawed. Effective communication and coordination between these stages are crucial for a flawless final product.

Q 19. How do you manage waste and ensure sustainable printing practices?

Waste management and sustainable printing practices are paramount. My strategies focus on minimizing waste at every stage. This starts with pre-press planning; optimizing file preparation to reduce material usage, and accurate imposition layout to minimize paper spoilage during printing.

On the press, I minimize paper waste by carefully monitoring the paper feed and promptly addressing jams. I also ensure that ink and cleaning chemicals are used efficiently and disposed of properly, in compliance with all relevant environmental regulations. I meticulously track waste quantities for ongoing improvement and identify areas where optimization is possible. We also use recycled paper whenever feasible and explore alternative sustainable printing methods when possible.

Q 20. What are your strategies for improving press efficiency and reducing costs?

Improving press efficiency and reducing costs requires a multifaceted approach. First, preventative maintenance is key; regular inspections and timely repairs minimize downtime and costly emergency repairs. Secondly, optimizing press settings—such as perfecting ink-water balance, fine-tuning paper feed, and adjusting printing speeds—can significantly enhance productivity.

Employee training and efficient workflow optimization are also important. A well-trained team can identify and fix problems quickly, reducing wasted materials and time. Finally, data analysis is crucial. Tracking key metrics such as production rates, waste levels, and material costs helps identify bottlenecks and areas for improvement. I also actively seek out opportunities to leverage automation technologies to enhance speed and reduce human error.

Q 21. Describe your experience with quality control and inspection procedures.

Quality control and inspection procedures are integral to my workflow. My approach begins with establishing clear quality standards for each project. This involves evaluating color accuracy, registration, ink density, and overall print quality using appropriate tools like densitometers, colorimeters, and magnifying glasses.

I regularly conduct inspections during and after the printing process, taking samples and analyzing them against the established standards. Any deviations are promptly addressed, with appropriate corrective actions taken and documented. This proactive approach ensures consistent high-quality output, minimizing reprints and customer dissatisfaction. Furthermore, I utilize statistical process control (SPC) charts to monitor key quality parameters over time, allowing for the identification of emerging trends and the implementation of preventative measures.

Q 22. How familiar are you with different file formats used in the printing process (e.g., PDF, TIFF)?

File formats are crucial for ensuring print quality and compatibility. PDF (Portable Document Format) is the industry standard for final print-ready files because it preserves fonts, images, and layout regardless of the operating system or software used. It’s essentially a snapshot of the document, ensuring what you see on screen is what you get printed. TIFF (Tagged Image File Format) is primarily used for high-resolution images, especially those requiring precise color reproduction, like photographs. Unlike PDFs, TIFFs can be losslessly compressed, maintaining image quality without data loss. Other formats like EPS (Encapsulated PostScript) are used less frequently now but might still appear in older projects. My experience covers all these, and I am proficient in identifying potential issues that might arise from using incorrect or poorly formatted files, such as missing fonts, low-resolution images, or incorrect color spaces.

- PDF: Ideal for final prepress files, ensuring consistent results across different print devices.

- TIFF: Best for high-resolution images that require exceptional detail and color accuracy. Often used for spot color images.

Q 23. Explain your understanding of color management and color profiles.

Color management is the process of controlling the appearance of color from the digital design stage to the printed output. It ensures consistent color reproduction across various devices and materials. This involves using color profiles, which are essentially mathematical descriptions of a device’s color capabilities. Each device – a monitor, printer, scanner – has a unique profile. A color profile maps the colors a device can reproduce to a standardized color space, like sRGB or Adobe RGB. When a file containing a color profile is sent to a printer, the printer’s profile is used to translate the colors accurately for output. Without proper color management, you’ll encounter unexpected color shifts, resulting in inaccurate final prints. Imagine trying to match a paint color without understanding the different pigments and their interactions – it’s chaos! Color management provides that crucial bridge for consistent color reproduction. In my experience, I use industry-standard software like Adobe Acrobat Pro and GMG ColorServer to manage color profiles and optimize output.

Q 24. How do you ensure accurate color reproduction on different substrates?

Accurate color reproduction across different substrates (the material being printed on, like paper, cardstock, or vinyl) requires careful calibration and profiling. Each substrate absorbs and reflects light differently, affecting how colors appear. For example, a color that looks vibrant on glossy paper might appear dull on uncoated stock. To ensure accuracy, we create specific color profiles for each substrate. This involves printing color swatches on the target substrate, measuring them with a spectrophotometer, and using that data to create a custom profile. This profile is then used in the RIP (Raster Image Processor) to translate the digital color data into the correct ink quantities for that specific substrate. We also account for variations in paper properties like brightness, opacity, and texture, and conduct test prints before large-scale production to verify the accuracy and consistency. Think of it like cooking – the same recipe can produce different results depending on the oven and ingredients used. Similarly, careful calibration and profiling is key to consistent color across substrates.

Q 25. What is your experience with troubleshooting and resolving problems related to ink consistency and density?

Troubleshooting ink consistency and density issues requires a systematic approach. Problems like streaks, banding, or poor color saturation can result from various factors including improper ink mixing, worn-out rollers, clogged print heads, incorrect ink viscosity, or even environmental factors like temperature and humidity. My approach starts with visually inspecting the printed output to pinpoint the issue’s location and pattern. Then, I systematically check:

- Ink viscosity: Using a viscometer to ensure the ink is within the recommended range.

- Roller condition: Checking rollers for wear and tear, cleaning or replacing them as needed.

- Print head condition: Inspecting the print heads for clogs, cleaning or replacing them if necessary.

- Ink mixing: Verifying proper mixing ratios and ensuring no contamination.

- Environmental factors: Checking temperature and humidity levels within the pressroom.

By systematically eliminating possibilities, I can quickly identify the root cause and implement a solution. I’ve successfully resolved numerous ink-related issues using this method, minimizing downtime and ensuring the quality of the final product.

Q 26. Describe your experience with maintaining a clean and organized pressroom environment.

Maintaining a clean and organized pressroom is paramount for safety, efficiency, and print quality. A cluttered environment increases the risk of accidents, delays production, and can even compromise print quality. My approach involves a structured cleaning schedule, regular equipment maintenance, and a system for storing inks, papers, and other supplies. We use designated areas for different materials, regularly clean and maintain the presses, rollers, and other equipment, and promptly dispose of waste materials. We use color-coded bins for different waste types for easier recycling and disposal. A well-organized pressroom fosters a safe and efficient work environment, boosts morale, and contributes to the overall quality of the print output. Think of a chef’s kitchen – the cleanliness and organization are as critical to the final product as the skill of the chef itself.

Q 27. How do you prioritize tasks and manage your workload in a fast-paced printing environment?

In a fast-paced printing environment, efficient task prioritization and workload management are crucial. I utilize a combination of methods, including:

- Job scheduling software: Employing software to manage deadlines, track progress, and assign tasks effectively.

- Prioritization matrix: Utilizing methods like the Eisenhower Matrix (urgent/important) to identify and tackle critical tasks first.

- Teamwork and communication: Effective communication with the team to ensure everyone is aware of priorities and can assist when needed.

- Regular check-ins: Conducting regular check-ins to monitor progress, address challenges, and adjust plans as needed.

I’m adept at adjusting to unexpected changes, prioritizing urgent tasks without compromising quality, and ensuring timely delivery of all projects. This involved experience in working with multiple deadlines and adapting to shifting priorities seamlessly.

Key Topics to Learn for Knowledge of Press Operations and Equipment Interview

- Press Types and Functionality: Understanding the differences between various press types (e.g., offset, digital, flexographic) and their operational capabilities. This includes knowledge of their strengths, weaknesses, and appropriate applications.

- Press Setup and Operation: Practical knowledge of the steps involved in setting up a printing press, including ink and paper adjustments, plate mounting, and pre-press checks. Be prepared to discuss troubleshooting common setup issues.

- Safety Procedures and Maintenance: Demonstrate awareness of safety regulations and procedures related to press operation. Include knowledge of preventative maintenance practices and troubleshooting mechanical problems.

- Quality Control and Monitoring: Discuss methods for ensuring consistent print quality, including color management, ink density control, and identifying and resolving print defects. Understanding the use of quality control instruments is crucial.

- Workflow and Production: Explain your understanding of the overall printing workflow, from pre-press to post-press, and your role within it. Be able to discuss production scheduling and efficiency optimization.

- Digital Press Technology: If applicable to the role, familiarize yourself with the specifics of digital printing technologies, including their advantages and limitations compared to traditional methods.

- Problem-Solving and Troubleshooting: Be prepared to discuss how you approach problem-solving in a press operation environment. Provide examples of situations where you identified and resolved issues efficiently.

Next Steps

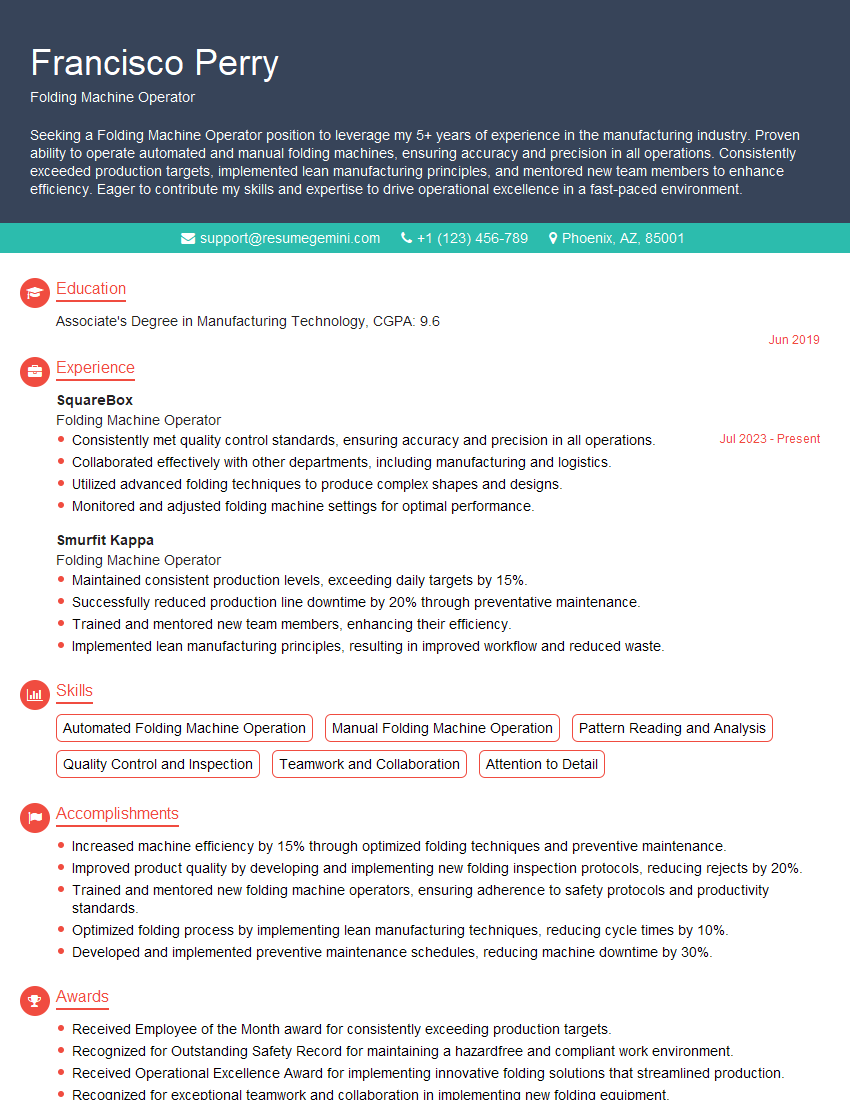

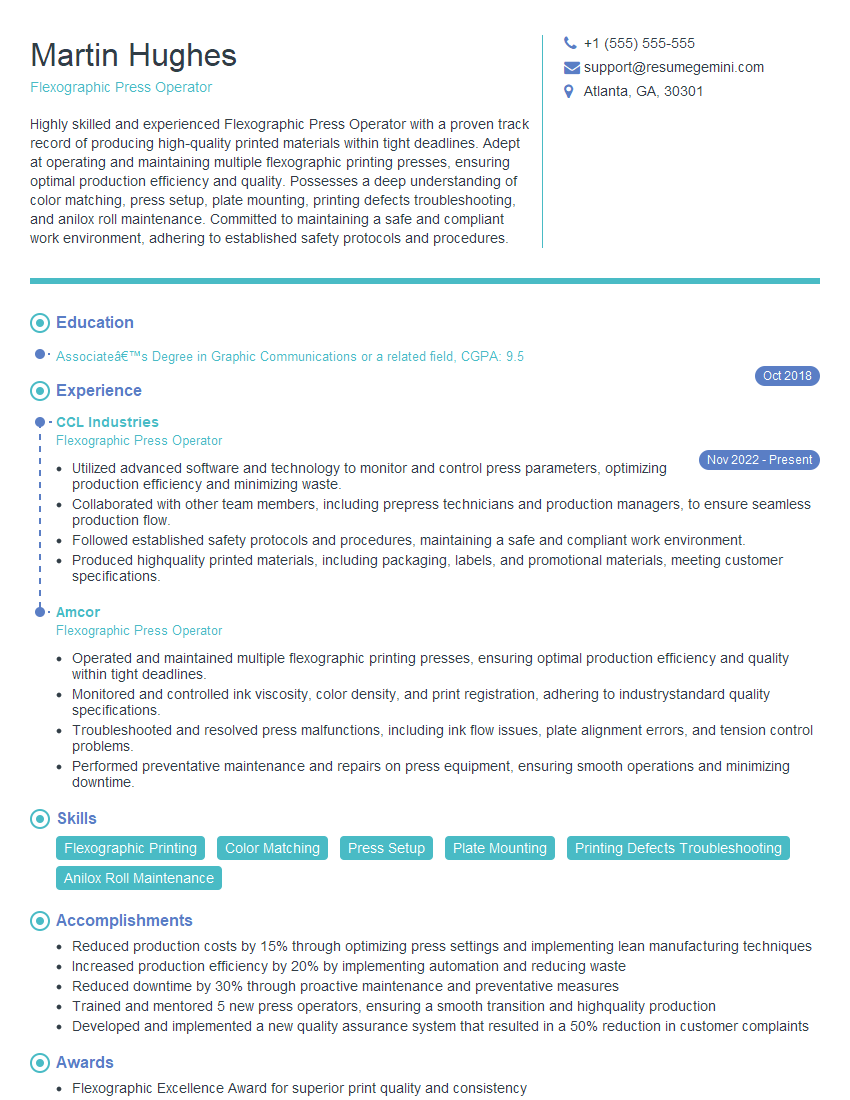

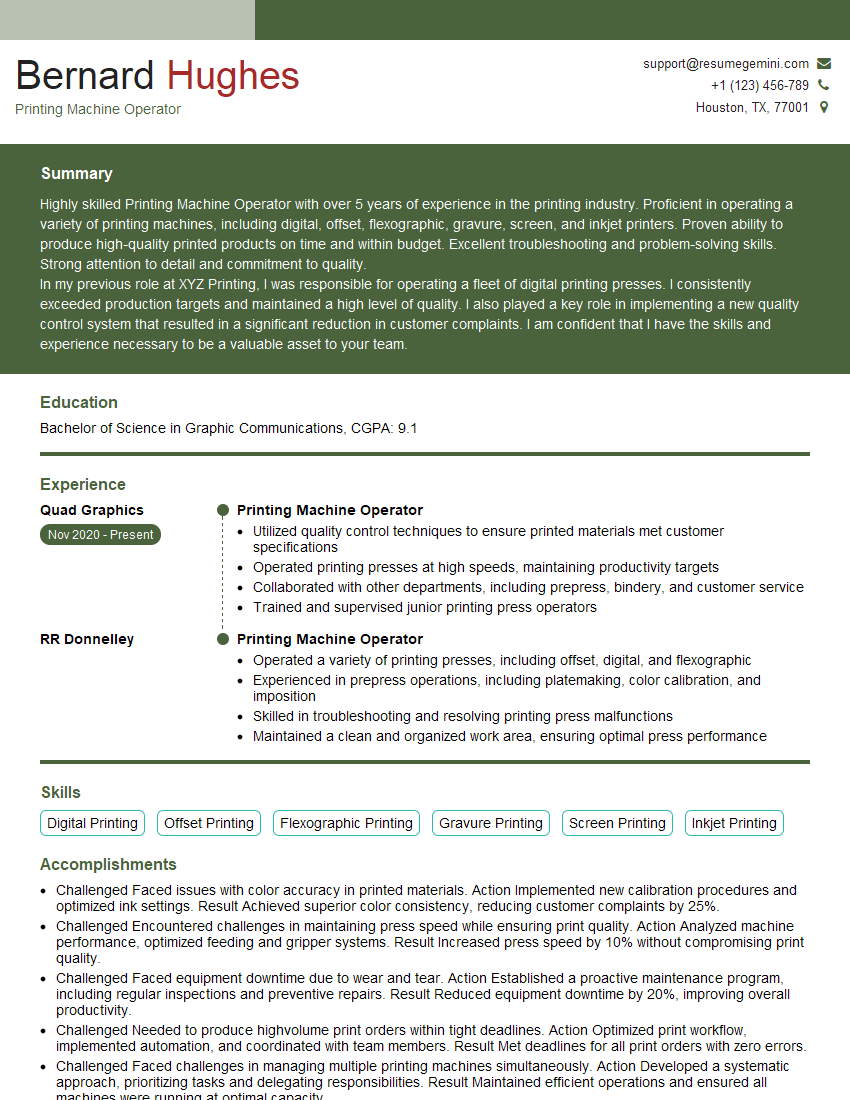

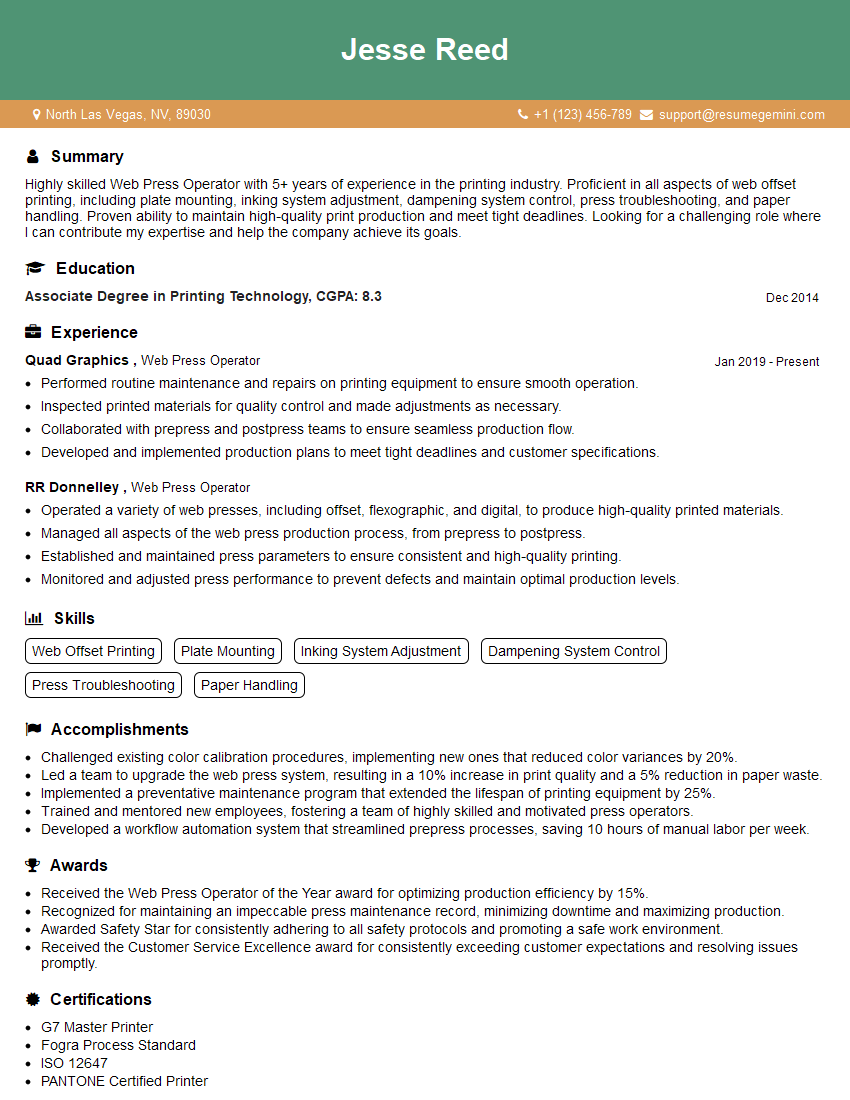

Mastering knowledge of press operations and equipment is essential for career advancement in the printing industry. It demonstrates practical skills and a strong understanding of the production process, leading to increased responsibility and earning potential. To enhance your job prospects, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource for building professional resumes that stand out to recruiters. Examples of resumes tailored to showcasing expertise in Knowledge of press operations and equipment are available to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good