The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to HACCP and ISO Standards interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in HACCP and ISO Standards Interview

Q 1. Describe the seven HACCP principles.

The seven HACCP principles provide a systematic approach to food safety. Think of them as building blocks for a robust food safety management system. They are:

- Conduct a hazard analysis: Identify potential biological, chemical, and physical hazards that could occur at each step of the food production process. For example, Salmonella contamination in poultry processing or Listeria in ready-to-eat meals.

- Determine critical control points (CCPs): These are steps in the process where control can prevent or eliminate a hazard or reduce it to an acceptable level. For instance, cooking temperature is a CCP for eliminating Salmonella.

- Establish critical limits: Set specific measurable criteria for each CCP. For the cooking example, this could be a minimum internal temperature of 74°C (165°F).

- Establish monitoring procedures: Define how you will regularly check that the CCPs are being controlled. This might involve using temperature probes, checking pH levels, or visually inspecting products.

- Establish corrective actions: Outline what actions to take if monitoring shows that a CCP is not under control. If the cooking temperature drops below 74°C, for example, you might reheat the product.

- Establish verification procedures: Verify that the HACCP system is working as intended. This involves regularly reviewing records, conducting audits, and performing other checks.

- Establish record-keeping and documentation procedures: Maintain detailed records of all HACCP activities, including hazard analysis, CCP monitoring, corrective actions, and verification procedures. This documentation is crucial for traceability and demonstrating compliance.

Q 2. Explain the difference between preventive and corrective actions in HACCP.

Preventive and corrective actions are distinct but interconnected elements within a HACCP plan. Think of prevention as avoiding problems, and correction as fixing them after they occur.

Preventive actions are proactive measures taken before a hazard occurs to prevent it from happening in the first place. Examples include proper sanitation procedures, employee training on hygiene practices, and implementing strict supplier controls for raw materials.

Corrective actions are reactive measures taken after a hazard or deviation has occurred to minimize its impact. This could involve discarding contaminated products, implementing a deeper cleaning procedure after a contamination event, or retraining employees if a hygiene protocol is not followed correctly.

Consider a scenario where a thermometer malfunction leads to undercooked chicken. Preventive action would involve regular calibration and maintenance of thermometers. Corrective action would be discarding the undercooked chicken and retraining the staff on proper temperature monitoring.

Q 3. How do you identify and assess hazards in a food production environment?

Identifying and assessing hazards involves a systematic approach. We use a hazard analysis and critical control point (HACCP) plan to identify and evaluate hazards. This usually includes a team with diverse expertise in food safety, microbiology, and production processes. The process involves:

- Flow Diagram: Create a detailed flow diagram of the entire food production process, from receiving raw materials to the final product. This visual representation allows us to systematically examine each step.

- Hazard Identification: Identify potential hazards at each step. This may involve brainstorming sessions, reviewing past incidents, consulting scientific literature, and using relevant checklists.

- Hazard Characterization: Assess the likelihood and severity of each identified hazard. This might involve considering factors like the probability of the hazard occurring, the potential consequences (e.g., illness, death), and the vulnerable population (e.g., young children, elderly).

- Risk Assessment: Combine likelihood and severity to determine the overall risk associated with each hazard. A risk matrix can be very useful here.

For example, in a bakery, potential hazards include flour contamination with E. coli (biological), presence of allergens (allergens), or broken glass (physical).

Q 4. What are critical control points (CCPs) and how are they determined?

Critical Control Points (CCPs) are steps in the food production process where control is essential to prevent or eliminate a food safety hazard or reduce it to an acceptable level. They are not every step in the process, but the crucial ones.

Determining CCPs involves analyzing each step in the process identified through the hazard analysis. We ask a series of questions for each step to determine if it’s a CCP. These questions might include:

- Can a biological, chemical, or physical hazard occur at this step?

- Can this hazard be prevented or reduced to an acceptable level at this step?

- Is control at this step essential to prevent or eliminate the hazard or reduce it to an acceptable level?

For example, in a canning process, the heat treatment step would be a CCP for eliminating Clostridium botulinum spores. A failure to control the heat treatment would lead to a potentially fatal hazard.

Q 5. Describe your experience with developing and implementing HACCP plans.

I have extensive experience developing and implementing HACCP plans across various food production environments. In my previous role at a large-scale meat processing plant, I led the development of a comprehensive HACCP plan that addressed risks associated with Salmonella and E. coli contamination. This involved working with a multidisciplinary team to conduct a thorough hazard analysis, identify CCPs (such as cooking and chilling temperatures), establish critical limits and monitoring procedures, and develop corrective action plans. We implemented a robust training program for all employees to ensure compliance and understanding of the plan.

In another project, I assisted a small-scale bakery in developing a simpler HACCP plan focused on allergen control. Here, the approach was more tailored to the specific hazards and resources of the business. We focused on preventing cross-contamination and implementing clear labeling procedures.

My approach always involves close collaboration with the food production team to ensure the plan is practical, effective, and integrated into their daily operations. I believe that a successful HACCP plan isn’t just a document; it’s a living system that requires constant monitoring, review, and adjustment as needed.

Q 6. What are the key elements of an effective HACCP monitoring system?

An effective HACCP monitoring system is the backbone of a successful food safety program. It ensures that the critical control points (CCPs) are under control at all times. Key elements include:

- Frequency: Monitoring must occur with sufficient frequency to ensure timely detection of deviations. This depends on the hazard and the process. Some CCPs may need continuous monitoring, while others may only require monitoring at set intervals.

- Methods: The monitoring methods must be appropriate for each CCP and capable of accurately measuring the critical limits. This could involve using thermometers, pH meters, visual inspections, or other relevant tools.

- Personnel: Trained and competent personnel are essential for accurate and consistent monitoring. They must understand the CCPs, critical limits, and corrective actions.

- Records: All monitoring data must be meticulously recorded and retained for future reference. This documentation provides evidence of compliance and aids in identifying trends or potential problems.

- Responsiveness: The system must be responsive enough to detect and address deviations promptly. This involves having clear corrective actions in place and a process for escalating issues when necessary.

Q 7. Explain the importance of record-keeping in HACCP.

Record-keeping in HACCP is paramount for demonstrating compliance, tracing the source of contamination (if any), and continually improving the food safety system. Accurate and complete records provide crucial evidence that the HACCP plan is effectively implemented and maintained. These records are often subject to audits by regulatory bodies. The type of records kept should include:

- Hazard Analysis: Documentation of the hazard analysis process, including the identified hazards and their evaluation.

- CCP determination: Records showing how CCPs were identified and justified.

- Monitoring data: Detailed records of all monitoring activities, including dates, times, measurements, and the person who performed the monitoring.

- Corrective actions: Documentation of any deviations, the corrective actions taken, and the effectiveness of these actions.

- Verification records: Records of verification activities, such as calibration of monitoring equipment, audits, and management reviews.

- Training records: Documentation of employee training on HACCP principles and procedures.

Maintaining these records not only ensures compliance but also allows for continuous improvement by analyzing data and identifying areas for improvement in the food safety system.

Q 8. How do you verify the effectiveness of a HACCP plan?

Verifying the effectiveness of a HACCP (Hazard Analysis and Critical Control Points) plan is crucial for ensuring food safety. It’s not a one-time activity but an ongoing process of monitoring, verification, and validation. We achieve this through several key methods:

- Monitoring CCPs: Regularly monitoring critical control points (CCPs) – points in the food production process where hazards can be prevented, eliminated, or reduced to acceptable levels – using pre-determined critical limits. For example, monitoring the temperature of cooked chicken to ensure it reaches a safe internal temperature. Deviations from these limits trigger corrective actions.

- Record Keeping: Maintaining detailed and accurate records of all monitoring activities, corrective actions, and verification procedures is essential. These records provide evidence of the effectiveness of the HACCP plan and allow for continuous improvement.

- Internal Audits: Conducting regular internal audits to assess the effectiveness of the HACCP plan’s implementation. This involves reviewing documentation, observing processes, and interviewing staff to identify gaps and areas for improvement. A checklist is essential for consistency and completeness.

- Management Review: Regular management reviews of the HACCP plan help to ensure its ongoing suitability, adequacy, and effectiveness. This includes evaluating performance data, identifying trends, and making necessary adjustments.

- Verification Activities: This can include microbiological testing of finished products, environmental monitoring (e.g., checking for pathogens in the production area), and validation of cleaning and sanitation procedures. These activities provide independent verification that the HACCP plan is working as intended.

- External Audits: Regular audits by external certification bodies (for example, for ISO 22000 certification) further verify compliance and effectiveness. These audits provide an independent assessment of the system’s performance.

Imagine a restaurant failing to consistently monitor the temperature of its refrigerator. Without proper monitoring and record keeping, there’s a risk of food spoilage and potential foodborne illness. A robust verification process prevents such scenarios.

Q 9. Describe the ISO 9001 quality management system.

ISO 9001 is a globally recognized standard for Quality Management Systems (QMS). It provides a framework for organizations to consistently meet customer and regulatory requirements, improve customer satisfaction, and enhance operational efficiency. At its core, it’s about establishing and maintaining a structured approach to managing processes. Key elements include:

- Leadership Commitment: Top management must demonstrate commitment to the QMS and its continual improvement.

- Customer Focus: Understanding and meeting customer requirements is paramount.

- Process Approach: Managing resources and processes effectively to achieve planned outcomes.

- Risk-based Thinking: Identifying and mitigating potential risks and opportunities that can affect the ability to achieve objectives.

- Improvement: Continuously improving the effectiveness of the QMS. This relies heavily on data analysis and feedback loops.

- Documentation: Maintaining documented information necessary to maintain the effectiveness of the QMS.

- Internal Audits: Regular internal audits verify compliance and identify areas for improvement.

- Management Review: Top management reviews the performance of the QMS and plans for improvements.

Think of it like building a house. ISO 9001 provides the blueprint, ensuring all processes are well-defined, documented, and consistently followed to deliver a quality product (the house) that meets customer expectations (the homeowner’s requirements).

Q 10. Explain the PDCA cycle (Plan-Do-Check-Act).

The PDCA cycle (Plan-Do-Check-Act) is a simple yet powerful iterative four-step management method for continuous improvement. It’s a cycle, meaning that the ‘Act’ stage leads back to the ‘Plan’ stage, ensuring ongoing refinement.

- Plan: Define objectives, processes, and resources required. This stage involves setting goals, identifying potential problems, and developing solutions. For example, if a manufacturing process is producing too many defects, you’d plan how to reduce them.

- Do: Implement the plan and collect data on the results. This is the execution phase, where the planned actions are carried out. You might implement a new quality control procedure.

- Check: Analyze the results from the ‘Do’ phase and compare them against the planned objectives. This involves reviewing data, identifying deviations, and understanding what worked and what didn’t. Did the new quality control procedure reduce defects?

- Act: Take action based on the analysis in the ‘Check’ phase. This could involve standardizing the successful changes, modifying the process, or abandoning the approach entirely and trying something new. You might implement changes to the process based on the data.

Imagine baking a cake. You plan the recipe (Plan), bake the cake (Do), taste and evaluate the result (Check), and adjust the recipe for next time (Act). The PDCA cycle is about making incremental improvements each time.

Q 11. What is internal auditing and why is it important?

Internal auditing is a systematic, independent, and documented process for obtaining audit evidence and evaluating it objectively to determine the extent to which the audit criteria are fulfilled. It’s a critical component of any effective management system, including ISO 9001 and HACCP. Essentially, it’s a self-assessment.

Why is it important?

- Identify Nonconformities: Early detection of nonconformities (areas where the system doesn’t meet requirements) allows for timely corrective action, preventing larger problems later.

- Verify Effectiveness: Internal audits verify that the management system is operating effectively and achieving its intended objectives.

- Continuous Improvement: By identifying weaknesses, internal audits drive continuous improvement and help to enhance the overall effectiveness of the management system.

- Compliance: Internal audits demonstrate to regulatory bodies and customers that the organization is committed to compliance.

- Employee Training: Internal audits offer valuable training opportunities for audit team members and operational staff.

Think of it like a health check-up. Regular internal audits ensure the ‘health’ of your management system, identifying potential issues before they escalate into major problems.

Q 12. How do you conduct a root cause analysis?

Root cause analysis (RCA) is a systematic approach to identifying the underlying causes of a problem, not just the symptoms. The goal is to prevent recurrence by addressing the root cause rather than just treating the symptoms. Several techniques can be used, including:

- 5 Whys: Repeatedly asking ‘why’ to drill down to the root cause. For example, if a machine breaks down (problem), you’d ask why (lack of maintenance), why (inadequate training), why (poor management oversight), and so on, until you reach the root cause.

- Fishbone Diagram (Ishikawa Diagram): A visual tool that helps to brainstorm potential causes categorized into different groups (e.g., materials, methods, manpower, machinery, measurement, environment). This is great for collaborative problem-solving.

- Fault Tree Analysis (FTA): A top-down approach that starts with the undesired event and works backward to identify contributing factors.

The key is to be thorough and systematic, involving relevant personnel in the process. Avoid jumping to conclusions and focusing on the immediate symptom. A well-conducted RCA leads to effective corrective actions that prevent recurrence.

For example, if customers are complaining about late deliveries (symptom), a root cause analysis might reveal that the problem stems from a lack of effective inventory management (root cause).

Q 13. Describe your experience with conducting internal audits of ISO 9001 or other management systems.

I have extensive experience conducting internal audits for ISO 9001 and HACCP systems, spanning over [Number] years in various industries including [List Industries]. My audit approach is always systematic and objective. I typically follow these steps:

- Planning: Defining the scope, audit criteria, and team members. Establishing a detailed audit plan including specific areas to be reviewed.

- Data Gathering: Collecting evidence through interviews, document review, observations, and sampling. Utilizing checklists for consistency.

- Analysis: Evaluating the collected data against the audit criteria to identify nonconformities and areas for improvement. This involves careful interpretation and analysis to ensure objectivity.

- Reporting: Preparing a comprehensive audit report documenting the findings, nonconformities, and recommendations for corrective actions. The report should be clear, concise, and well-documented.

- Follow-up: Verifying that corrective actions are implemented and effective. This is often done via follow-up audits to ensure the issues are resolved and prevent recurrence.

In one instance, during an internal audit of an ISO 9001 certified manufacturing facility, I identified a gap in their calibration process. My audit report detailed this issue, and corrective actions were implemented, resulting in improved accuracy and product quality.

Q 14. What are the key differences between ISO 9001 and ISO 22000?

While both ISO 9001 and ISO 22000 are management system standards focused on ensuring conformity to requirements, they address different aspects. ISO 9001 focuses on the overall quality management system, aiming for consistent product quality and customer satisfaction. ISO 22000, on the other hand, specifically addresses food safety management systems.

Here’s a comparison:

- Scope: ISO 9001 is applicable to any organization, regardless of its industry. ISO 22000 is specifically designed for the food industry, addressing food safety hazards throughout the supply chain.

- Focus: ISO 9001 focuses on achieving consistent product quality, meeting customer requirements, and improving operational efficiency. ISO 22000 focuses on preventing food safety hazards and ensuring that food is safe for consumption.

- Requirements: While both standards include requirements for risk management, internal audits, and management review, ISO 22000 includes specific requirements for HACCP principles, prerequisite programs (PRP), and traceability.

- Certification: Both standards can be independently certified, providing external validation of the management system’s effectiveness.

Think of it this way: ISO 9001 is like a general framework for building a robust system, while ISO 22000 is a specialized set of instructions for building a food safety system incorporating the specific principles of HACCP.

Q 15. How do you ensure compliance with relevant food safety regulations?

Ensuring compliance with food safety regulations requires a multi-faceted approach. It begins with a thorough understanding of all applicable laws and standards, including national and international regulations like FDA regulations in the US or the EU’s food safety regulations. This understanding forms the bedrock of our food safety management system.

We achieve compliance through a robust HACCP (Hazard Analysis and Critical Control Points) plan. This plan systematically identifies potential biological, chemical, and physical hazards in our production process. For each hazard, we establish critical control points (CCPs) – points in the process where control can be applied and monitored to prevent or eliminate the hazard. These CCPs are meticulously monitored using critical limits, and deviations trigger corrective actions.

Furthermore, regular internal audits are conducted to ensure our systems are working effectively. These audits assess our adherence to the HACCP plan, GMPs (Good Manufacturing Practices), and all relevant legal requirements. We also participate in external audits, such as those conducted by certification bodies for ISO 22000, to validate our compliance and maintain certification.

Finally, continuous training for all staff is crucial. Everyone from production line workers to management needs to understand their role in maintaining food safety. Regular refresher courses and updated standard operating procedures (SOPs) ensure everyone stays informed and maintains best practices.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the concept of traceability in food production.

Traceability in food production is the ability to track a product’s journey from its origin (farm, supplier, etc.) through every stage of processing and distribution to the final consumer. Think of it as a detailed food ‘passport’. This is vital for identifying the source of contamination in case of a food safety incident and for managing recalls effectively.

We achieve traceability through a combination of robust record-keeping systems and unique identification methods. This might involve batch numbers, lot codes, timestamps, and even RFID (Radio-Frequency Identification) tags, depending on the complexity of the production process. Each step in the supply chain – from raw material sourcing to packaging and distribution – is meticulously documented. This allows us to trace a product’s entire history quickly and efficiently.

For example, if a contamination issue is discovered, we can swiftly identify the affected batch, pinpoint the source of the contamination, and initiate the necessary recall procedures, minimizing the impact on public health and our reputation. This not only addresses immediate crises but also strengthens consumer confidence and enhances our brand’s credibility.

Q 17. Describe your experience with implementing corrective and preventive actions (CAPA).

Implementing Corrective and Preventive Actions (CAPA) is a cornerstone of our quality management system. It’s a systematic approach to addressing nonconformances – instances where our processes or products fail to meet specified requirements. It’s not just about fixing the immediate problem; it’s about preventing it from recurring.

My experience involves leading root cause analyses to identify the underlying reasons for nonconformances. We use various tools like fishbone diagrams (Ishikawa diagrams) and 5 Whys to delve deeper than surface-level issues. Once the root cause is identified, we develop effective corrective actions to address the immediate problem. For example, if a machine malfunction resulted in contaminated product, the corrective action would be to repair the machine and dispose of the contaminated product.

However, the true power of CAPA lies in preventive actions. This is where we implement changes to our processes or systems to prevent the nonconformity from happening again. This might involve upgrading equipment, revising SOPs, improving employee training, or enhancing our monitoring systems. We meticulously document all CAPA actions and track their effectiveness to ensure they are sustainable and prevent future problems.

For instance, following a repeated issue with incorrect packaging weights, we implemented a new automated weighing system and improved operator training to minimize errors. This resulted in a significant reduction in nonconformances and improved efficiency.

Q 18. How do you handle nonconformances in a quality management system?

Handling nonconformances within a quality management system is a critical aspect of maintaining compliance and continuous improvement. It’s about more than just identifying the problem; it’s about learning from it and preventing its recurrence. We follow a structured approach:

- Identification and Documentation: Every nonconformity is meticulously documented, including details such as date, time, location, nature of the nonconformity, and the severity.

- Investigation and Root Cause Analysis: A thorough investigation is conducted to understand the underlying causes of the nonconformity. Tools such as Pareto charts, fishbone diagrams, and the 5 Whys are used to pinpoint the root cause(s).

- Corrective Actions: Immediate corrective actions are implemented to address the immediate problem and prevent its propagation. This might involve disposing of non-conforming products, recalibrating equipment, or implementing temporary workarounds.

- Preventive Actions: Preventive actions are implemented to prevent similar nonconformances from happening in the future. This involves making system-wide changes to processes, training, or equipment.

- Verification and Validation: The effectiveness of corrective and preventive actions is verified and validated to ensure they have resolved the root cause and prevented recurrence.

- Record Keeping: The entire process, including investigation findings, corrective actions, preventive actions, and verification results, is meticulously documented and stored for future reference and audit trail purposes.

By diligently following this process, we not only address immediate problems but also foster a culture of continuous improvement, reducing the likelihood of future nonconformances.

Q 19. What are the key performance indicators (KPIs) you use to measure the effectiveness of a HACCP plan?

Key Performance Indicators (KPIs) are crucial for measuring the effectiveness of our HACCP plan. They provide objective data to assess our food safety performance and identify areas for improvement. Some key KPIs we utilize include:

- Number of nonconformances: Tracking the number of deviations from critical limits and other nonconformances helps assess the effectiveness of CCP monitoring and control.

- Number of corrective actions: Monitoring the frequency of corrective actions highlights areas needing improvement in our processes.

- Effectiveness of corrective and preventive actions: This KPI helps gauge the long-term impact of our CAPA program in reducing nonconformances.

- Customer complaints related to food safety: Tracking customer complaints provides valuable insights into potential food safety issues.

- Audit findings: Internal and external audit results reveal areas needing attention and the overall effectiveness of our food safety system.

- Product recall rate: A low product recall rate indicates a robust food safety management system.

- Microbiological testing results: Regular monitoring of microbiological parameters (e.g., bacterial counts) at CCPs indicates the effectiveness of our control measures.

These KPIs are regularly reviewed and analyzed to identify trends and make data-driven improvements to our HACCP plan and overall food safety management system. The data informs strategic decisions and provides evidence of our commitment to producing safe and high-quality food.

Q 20. Describe your experience with documenting and maintaining quality management system records.

Documenting and maintaining quality management system records is paramount for demonstrating compliance, facilitating continuous improvement, and ensuring traceability. Our system incorporates both paper-based and electronic records, chosen based on the specific needs of each process.

We utilize a combination of standard operating procedures (SOPs), quality records, training records, audit reports, and CAPA documentation. These are all meticulously organized and stored according to a structured filing system, allowing for easy retrieval and access. Our electronic records system provides additional features such as version control, audit trails, and secure access control, ensuring data integrity and preventing unauthorized modifications.

Regular reviews of records are conducted to ensure their accuracy, completeness, and relevance. Obsolete records are archived securely according to established retention policies, complying with both internal and external regulatory requirements. The use of a digital document management system ensures easy access, search capability, and secure backup and recovery, minimizing the risk of data loss or damage. This system enhances efficiency and allows for improved data analysis to support continuous improvement initiatives.

Q 21. How do you manage change within a quality management system?

Managing change within a quality management system requires a structured and controlled approach to minimize disruption and ensure the continued effectiveness of the system. We utilize a change management process that includes:

- Identifying the need for change: Changes might be triggered by new regulations, technological advancements, process improvements, or customer feedback.

- Assessing the impact: A thorough risk assessment is conducted to evaluate the potential impact of the proposed change on the quality management system.

- Planning the change: A detailed change plan is developed, including timelines, responsibilities, and resource allocation. This may include revising SOPs, updating training materials, and implementing new procedures.

- Implementing the change: The change is implemented in a controlled manner, often using a phased rollout to minimize disruption and allow for adjustments based on feedback.

- Verifying the change: After implementation, the effectiveness of the change is verified to ensure it has achieved the desired outcome and hasn’t introduced new issues.

- Documenting the change: All changes are meticulously documented, including the rationale for the change, the implementation process, and verification results.

This structured approach helps to ensure that any changes made are carefully considered, implemented effectively, and ultimately improve the quality management system. This proactive approach to change minimizes unexpected problems and ensures continuous improvement and compliance.

Q 22. What is the role of management in maintaining a food safety management system?

Management plays a pivotal role in a successful food safety management system (FSMS). It’s not just about compliance; it’s about fostering a culture of food safety throughout the organization. This starts with a strong commitment from top leadership, who must demonstrate visible support for the FSMS and allocate the necessary resources – financial, human, and technological – to make it effective.

Specifically, management’s responsibilities include:

- Defining the scope and objectives of the FSMS: This involves identifying potential hazards and setting measurable goals for food safety performance.

- Establishing and maintaining the FSMS: This includes developing and implementing procedures, providing training, conducting audits, and ensuring the system’s ongoing effectiveness.

- Ensuring resource allocation: Providing the necessary equipment, personnel, and budget to effectively implement and maintain the FSMS.

- Promoting a culture of food safety: This involves communicating the importance of food safety to all employees, encouraging proactive hazard identification and reporting, and rewarding safe food handling practices.

- Reviewing and improving the FSMS: Regularly assessing the system’s performance, identifying areas for improvement, and making necessary changes to enhance its effectiveness.

Think of it like building a house – management provides the blueprints, materials, and skilled workers (employees). Without their active involvement, the structure (FSMS) won’t be sound and won’t protect against the elements (food safety hazards).

Q 23. Describe your experience with training employees on food safety and quality management practices.

I have extensive experience in designing and delivering training programs on food safety and quality management practices. My approach is always tailored to the specific needs of the audience and incorporates a blend of interactive learning methods, including classroom instruction, hands-on workshops, and online modules. I focus not just on conveying information but on fostering a deep understanding of the ‘why’ behind the procedures.

For example, in a recent training session for a large food processing facility, I utilized a scenario-based approach. We simulated a real-life contamination incident and walked employees through the steps required to identify, contain, investigate, and correct the issue, emphasizing the importance of proper documentation at every stage. This hands-on experience proved far more effective than simply lecturing on the theoretical aspects of HACCP and ISO 22000. I also incorporate regular quizzes, assessments, and feedback sessions to monitor employee comprehension and ensure consistent application of food safety principles in their daily work.

Furthermore, I use various training materials, including visual aids, case studies, and interactive simulations, making the learning experience more engaging and effective. I also ensure that training is documented and that employees receive certifications upon successful completion. Following the training, I consistently monitor performance and provide ongoing support and coaching to ensure the efficacy of the training.

Q 24. How do you ensure effective communication within a quality management system?

Effective communication is the backbone of any successful quality management system. It ensures everyone is on the same page, understands their roles, and can quickly address any issues that arise. In my experience, a multi-faceted approach is essential.

- Clearly defined communication channels: Establish specific methods for reporting incidents, sharing information, and requesting assistance. This could involve regular meetings, email updates, internal communication platforms, or a dedicated food safety hotline.

- Regular training and updates: Keep employees informed about changes in regulations, procedures, and best practices. This ensures everyone is using the same information and language.

- Open-door policy and feedback mechanisms: Encourage employees to freely share their concerns and suggestions without fear of retribution. This helps to identify potential problems early on.

- Documentation and record-keeping: Maintain comprehensive records of all communication, training, and incident reports. This provides a valuable audit trail and facilitates continuous improvement.

- Use of visual aids and simplified language: Avoid technical jargon wherever possible and use visual aids, such as flowcharts and diagrams, to improve understanding.

For instance, in a previous role, we implemented a daily huddle system where team leads briefly discussed any issues or concerns related to food safety, and all findings were logged and promptly addressed. This simple communication method drastically improved our responsiveness to potential problems.

Q 25. How do you handle customer complaints related to food safety or quality?

Handling customer complaints related to food safety or quality is crucial for maintaining trust and reputation. My approach involves a structured process:

- Acknowledge and empathize: Respond promptly and professionally, showing understanding for the customer’s concerns.

- Gather information: Obtain detailed information about the complaint, including the product details, the nature of the issue, and any supporting evidence (photos, receipts).

- Investigate the complaint: Thoroughly investigate the root cause of the problem. This may involve reviewing production records, conducting laboratory testing, or interviewing employees.

- Take corrective action: Implement appropriate corrective actions to prevent similar incidents from occurring in the future. This might include recalling a batch of products, retraining staff, or improving sanitation procedures.

- Communicate the outcome: Keep the customer informed about the progress of the investigation and the steps being taken to resolve the issue. A sincere apology is often essential, even if the company isn’t directly at fault.

- Document the entire process: Maintain comprehensive records of all complaints, investigations, and corrective actions. This data can be invaluable for identifying trends and improving the FSMS.

For example, I once dealt with a complaint about foreign material found in a batch of cookies. Through a detailed investigation, we traced the source to a faulty sieve, implemented corrective actions, and provided the customer with a full refund and replacement products.

Q 26. Describe a time you had to solve a food safety problem.

In a previous role, we experienced a significant temperature fluctuation in our cold storage facility during a power outage. This immediately raised concerns about potential food spoilage and safety. My team and I sprang into action, following our established emergency procedures.

Our response involved:

- Immediate Assessment: We quickly assessed the extent of the temperature fluctuation and identified the affected products.

- Product Segregation: We immediately segregated the potentially affected products from the unaffected ones to prevent cross-contamination.

- Temperature Monitoring: We continued monitoring the temperature in the cold storage area to ensure stability.

- Investigation: We initiated a thorough investigation to identify the cause of the power outage and the duration of the temperature fluctuation.

- Product Evaluation: We conducted a detailed evaluation of the affected products, utilizing various tests to assess their safety and quality. Products deemed unsafe were discarded.

- Documentation: All procedures, tests, and results were documented thoroughly, ensuring traceability and compliance with regulations.

- Corrective Actions: Based on the investigation, we implemented a backup power system and improved our emergency response plan to mitigate the risk of future incidents.

This experience highlighted the importance of having a well-defined emergency plan, robust monitoring systems, and a team trained to effectively respond to unforeseen challenges. The swift and decisive action taken prevented potential health risks and minimized financial losses.

Q 27. How familiar are you with different food safety regulations (e.g., FDA, USDA, etc.)?

I possess a comprehensive understanding of various food safety regulations, including those enforced by the FDA (Food and Drug Administration) and the USDA (United States Department of Agriculture) in the US, as well as equivalent regulations internationally (e.g., EFSA in Europe). My knowledge extends to specific regulations governing different food categories (meat, poultry, seafood, produce), as well as regulations related to labeling, allergen control, and traceability. I understand the nuances of GMP (Good Manufacturing Practices), HACCP (Hazard Analysis and Critical Control Points), and other industry-specific standards.

I’m adept at interpreting and applying these regulations in practical settings to ensure compliance and develop effective food safety programs. Staying current with regulatory updates is a crucial aspect of my professional development, and I regularly engage in professional development activities and access resources to maintain this up-to-date knowledge. I can interpret regulations and help organizations create compliant systems.

Q 28. Describe your experience with implementing and maintaining a food safety management system.

I have extensive experience implementing and maintaining FSMS, drawing on my expertise in HACCP and ISO 22000 standards. My approach is systematic and holistic, encompassing all stages from initial assessment and hazard identification to ongoing monitoring and improvement. I begin with a thorough gap analysis to identify areas where existing processes need to be improved to meet the requirements of the chosen standard.

My process typically involves:

- Hazard Analysis: Identifying and assessing potential biological, chemical, and physical hazards throughout the entire food production chain.

- Critical Control Point (CCP) identification: Determining the critical control points where control is essential to prevent or eliminate hazards.

- Establishing Critical Limits: Setting measurable parameters for each CCP to ensure safety.

- Monitoring Procedures: Defining methods for monitoring CCPs and recording results.

- Corrective Actions: Implementing procedures for addressing deviations from critical limits.

- Verification and Validation: Regularly verifying the effectiveness of the HACCP plan and validating the overall FSMS through audits and inspections.

- Documentation and Record-Keeping: Maintaining accurate and comprehensive records of all procedures, monitoring results, and corrective actions. This ensures traceability and facilitates continuous improvement.

I’ve successfully implemented FSMS across diverse settings, from small-scale food processing plants to large multinational corporations. In each case, my focus is on building a system that’s not just compliant but also practical, efficient, and contributes to continuous improvement in food safety and quality.

Key Topics to Learn for HACCP and ISO Standards Interview

- HACCP Principles: Understand the seven principles of HACCP and their practical application in various food safety scenarios. Consider how to identify and control hazards at each stage of the food production process.

- ISO 22000: Familiarize yourself with the requirements of ISO 22000, including food safety management systems (FSMS) implementation and maintenance. Explore the interplay between HACCP and ISO 22000.

- Hazard Analysis: Master the techniques for identifying, evaluating, and controlling potential hazards. Practice analyzing different types of hazards (biological, chemical, physical) and their potential impact.

- Critical Control Points (CCPs): Learn how to effectively determine CCPs and establish critical limits for monitoring and control. Practice developing effective monitoring procedures and corrective actions.

- Documentation and Record Keeping: Understand the importance of thorough and accurate documentation in HACCP and ISO 22000 systems. Be prepared to discuss record-keeping best practices and the legal implications of incomplete documentation.

- Internal Audits and Corrective Actions: Know how to conduct internal audits to verify compliance with HACCP and ISO 22000 standards. Be ready to discuss corrective actions and preventative measures for identified non-conformities.

- Verification and Validation: Grasp the difference between verification and validation activities within a food safety management system. Understand how to demonstrate the effectiveness of your HACCP plan.

- Implementation and Practical Applications: Be prepared to discuss practical examples of how you’ve applied HACCP and ISO 22000 principles in real-world scenarios, highlighting your problem-solving skills and experience.

- Food Safety Legislation and Regulations: Familiarize yourself with relevant food safety regulations and how they impact the implementation and maintenance of HACCP and ISO 22000 systems. This demonstrates a broader understanding of the regulatory landscape.

Next Steps

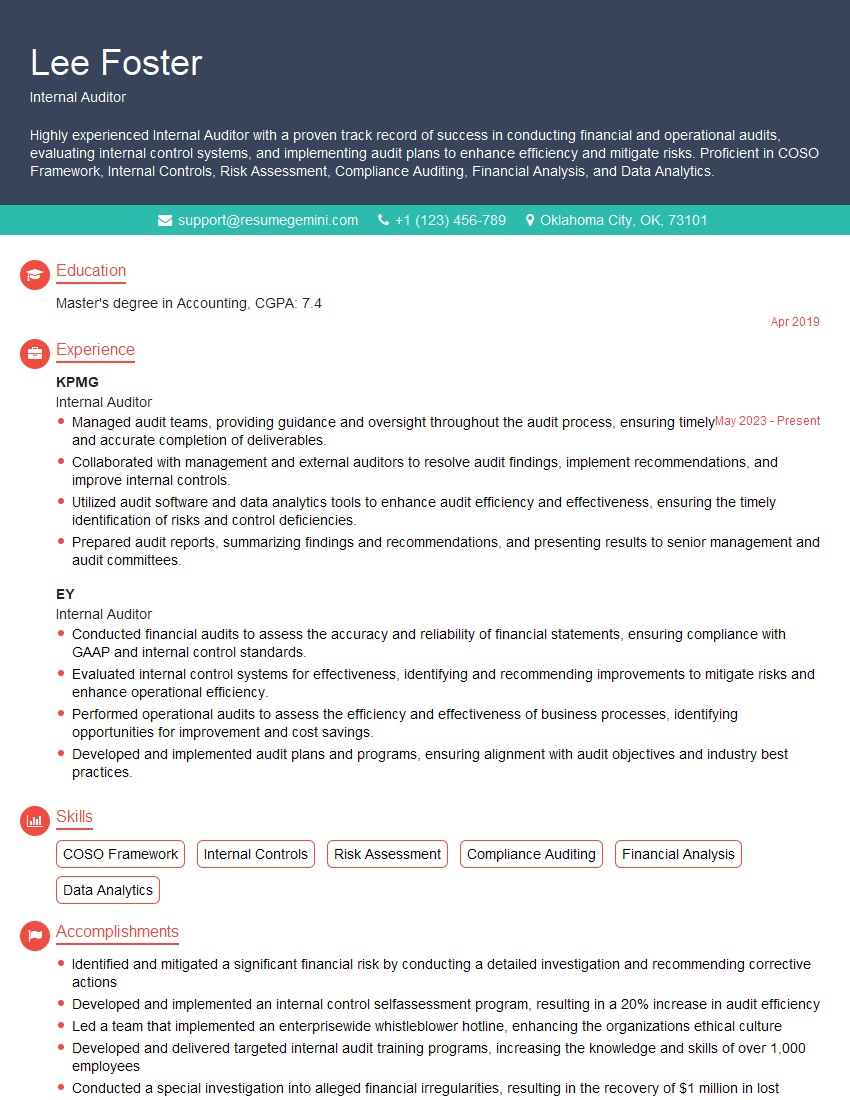

Mastering HACCP and ISO Standards significantly enhances your career prospects in the food industry and related sectors, opening doors to leadership roles and higher earning potential. To maximize your job search success, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource to help you build a professional and impactful resume that stands out from the competition. Examples of resumes tailored to HACCP and ISO Standards are available to guide you through the process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good